Page 1

GE Fanuc Automation

Computer Numerical Control Products

Series 21i / 210i―MB

for Machining Center

Operator's Manual

GFZ-63614EN/01 July 2001

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or may

be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein which

are not present in all hardware and software systems. GE Fanuc Automation assumes no

obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 2001 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of CNC units. It is essential that these precautions

be observed by users to ensure the safe operation of machines equipped with a CNC unit (all descriptions in this

section assume this configuration). Note that some precautions are related only to specific functions, and thus

may not be applicable to certain CNC units.

Users must also observe the safety precautions related to the machine, as described in the relevant manual supplied

by the machine tool builder. Before attempting to operate the machine or create a program to control the operation

of the machine, the operator must become fully familiar with the contents of this manual and relevant manual

supplied by the machine tool builder.

Contents

1. DEFINITION OF WARNING, CAUTION, AND NOTE s–2. . . . . . . . . . . . . . . . . . . . . . .

2. GENERAL WARNINGS AND CAUTIONS s–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. WARNINGS AND CAUTIONS RELATED TO PROGRAMMING s–5. . . . . . . . . . . . .

4. WARNINGS AND CAUTIONS RELATED TO HANDLING s–7. . . . . . . . . . . . . . . . . . .

5. WARNINGS RELATED TO DAILY MAINTENANCE s–9. . . . . . . . . . . . . . . . . . . . . . . .

s–1

Page 4

1

SAFETY PRECAUTIONS

B–63614EN/01

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the

machine. Precautions are classified into W arning and Caution according to their bearing on safety.

Also, supplementary information is described as a Note. Read the Warning, Caution, and Note

thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a danger of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

` Read this manual carefully, and store it in a safe place.

s–2

Page 5

B–63614EN/01

2

SAFETY PRECAUTIONS

GENERAL W ARNINGS AND CAUTIONS

WARNING

1. Never attempt to machine a workpiece without first checking the operation of the machine.

Before starting a production run, ensure that the machine is operating correctly by performing

a trial run using, for example, the single block, feedrate override, or machine lock function or

by operating the machine with neither a tool nor workpiece mounted. Failure to confirm the

correct operation of the machine may result in the machine behaving unexpectedly, possibly

causing damage to the workpiece and/or machine itself, or injury to the user.

2. Before operating the machine, thoroughly check the entered data.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

3. Ensure that the specified feedrate is appropriate for the intended operation. Generally , for each

machine, there is a maximum allowable feedrate. The appropriate feedrate varies with the

intended operation. Refer to the manual provided with the machine to determine the maximum

allowable feedrate. If a machine is run at other than the correct speed, it may behave

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

4. When using a tool compensation function, thoroughly check the direction and amount of

compensation.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

5. The parameters for the CNC and PMC are factory–set. Usually , there is not need to change them.

When, however, there is not alternative other than to change a parameter, ensure that you fully

understand the function of the parameter before making any change.

Failure to set a parameter correctly may result in the machine behaving unexpectedly , possibly

causing damage to the workpiece and/or machine itself, or injury to the user.

6. Immediately after switching on the power , do not touch any of the keys on the MDI panel until

the position display or alarm screen appears on the CNC unit.

Some of the keys on the MDI panel are dedicated to maintenance or other special operations.

Pressing any of these keys may place the CNC unit in other than its normal state. Starting the

machine in this state may cause it to behave unexpectedly.

7. The operator’s manual and programming manual supplied with a CNC unit provide an overall

description of the machine’s functions, including any optional functions. Note that the optional

functions will vary from one machine model to another. Therefore, some functions described

in the manuals may not actually be available for a particular model. Check the specification of

the machine if in doubt.

s–3

Page 6

SAFETY PRECAUTIONS

B–63614EN/01

WARNING

8. Some functions may have been implemented at the request of the machine–tool builder . When

using such functions, refer to the manual supplied by the machine–tool builder for details of their

use and any related cautions.

NOTE

Programs, parameters, and macro variables are stored in nonvolatile memory in the CNC unit.

Usually, they are retained even if the power is turned of f. Such data may be deleted inadvertently,

however, or it may prove necessary to delete all data from nonvolatile memory as part of error

recovery.

T o guard against the occurrence of the above, and assure quick restoration of deleted data, backup

all vital data, and keep the backup copy in a safe place.

s–4

Page 7

B–63614EN/01

3

1. Coordinate system setting

SAFETY PRECAUTIONS

W ARNINGS AND CAUTIONS RELATED T O PROGRAMMING

This section covers the major safety precautions related to programming. Before attempting to

perform programming, read the supplied operator’s manual and programming manual carefully

such that you are fully familiar with their contents.

WARNING

If a coordinate system is established incorrectly, the machine may behave unexpectedly as a

result of the program issuing an otherwise valid move command.

Such an unexpected operation may damage the tool, the machine itself, the workpiece, or cause

injury to the user.

2. Positioning by nonlinear interpolation

When performing positioning by nonlinear interpolation (positioning by nonlinear movement

between the start and end points), the tool path must be carefully confirmed before performing

programming.

Positioning involves rapid traverse. If the tool collides with the workpiece, it may damage the

tool, the machine itself, the workpiece, or cause injury to the user.

3. Function involving a rotation axis

When programming polar coordinate interpolation or normal–direction (perpendicular) control,

pay careful attention to the speed of the rotation axis. Incorrect programming may result in the

rotation axis speed becoming excessively high, such that centrifugal force causes the chuck to

lose its grip on the workpiece if the latter is not mounted securely.

Such mishap is likely to damage the tool, the machine itself, the workpiece, or cause injury to

the user.

4. Inch/metric conversion

Switching between inch and metric inputs does not convert the measurement units of data such

as the workpiece origin offset, parameter, and current position. Before starting the machine,

therefore, determine which measurement units are being used. Attempting to perform an

operation with invalid data specified may damage the tool, the machine itself, the workpiece, or

cause injury to the user.

5. Constant surface speed control

When an axis subject to constant surface speed control approaches the origin of the workpiece

coordinate system, the spindle speed may become excessively high. Therefore, it is necessary

to specify a maximum allowable speed. Specifying the maximum allowable speed incorrectly

may damage the tool, the machine itself, the workpiece, or cause injury to the user.

s–5

Page 8

SAFETY PRECAUTIONS

WARNING

6. Stroke check

After switching on the power, perform a manual reference position return as required. Stroke

check is not possible before manual reference position return is performed. Note that when stroke

check is disabled, an alarm is not issued even if a stroke limit is exceeded, possibly damaging

the tool, the machine itself, the workpiece, or causing injury to the user.

7. Tool post interference check

A tool post interference check is performed based on the tool data specified during automatic

operation. If the tool specification does not match the tool actually being used, the interference

check cannot be made correctly, possibly damaging the tool or the machine itself, or causing

injury to the user.

After switching on the power, or after selecting a tool post manually, always start automatic

operation and specify the tool number of the tool to be used.

8. Absolute/incremental mode

B–63614EN/01

If a program created with absolute values is run in incremental mode, or vice versa, the machine

may behave unexpectedly.

9. Plane selection

If an incorrect plane is specified for circular interpolation, helical interpolation, or a canned cycle,

the machine may behave unexpectedly. Refer to the descriptions of the respective functions for

details.

10.Torque limit skip

Before attempting a torque limit skip, apply the torque limit. If a torque limit skip is specified

without the torque limit actually being applied, a move command will be executed without

performing a skip.

11. Programmable mirror image

Note that programmed operations vary considerably when a programmable mirror image is

enabled.

12.Compensation function

If a command based on the machine coordinate system or a reference position return command

is issued in compensation function mode, compensation is temporarily canceled, resulting in the

unexpected behavior of the machine.

Before issuing any of the above commands, therefore, always cancel compensation function

mode.

s–6

Page 9

B–63614EN/01

4

1. Manual operation

SAFETY PRECAUTIONS

W ARNINGS AND CAUTIONS RELATED T O HANDLING

This section presents safety precautions related to the handling of machine tools. Before attempting

to operate your machine, read the supplied operator’s manual and programming manual carefully,

such that you are fully familiar with their contents.

WARNING

When operating the machine manually , determine the current position of the tool and workpiece,

and ensure that the movement axis, direction, and feedrate have been specified correctly.

Incorrect operation of the machine may damage the tool, the machine itself, the workpiece, or

cause injury to the operator.

2. Manual reference position return

After switching on the power, perform manual reference position return as required. If the

machine is operated without first performing manual reference position return, it may behave

unexpectedly . Stroke check is not possible before manual reference position return is performed.

An unexpected operation of the machine may damage the tool, the machine itself, the workpiece,

or cause injury to the user.

3. Manual numeric command

When issuing a manual numeric command, determine the current position of the tool and

workpiece, and ensure that the movement axis, direction, and command have been specified

correctly, and that the entered values are valid.

Attempting to operate the machine with an invalid command specified may damage the tool, the

machine itself, the workpiece, or cause injury to the operator.

4. Manual handle feed

In manual handle feed, rotating the handle with a large scale factor, such as 100, applied causes

the tool and table to move rapidly. Careless handling may damage the tool and/or machine, or

cause injury to the user.

5. Disabled override

If override is disabled (according to the specification in a macro variable) during threading, rigid

tapping, or other tapping, the speed cannot be predicted, possibly damaging the tool, the machine

itself, the workpiece, or causing injury to the operator.

6. Origin/preset operation

Basically, never attempt an origin/preset operation when the machine is operating under the

control of a program. Otherwise, the machine may behave unexpectedly, possibly damaging the

tool, the machine itself, the tool, or causing injury to the user.

s–7

Page 10

SAFETY PRECAUTIONS

WARNING

7. Workpiece coordinate system shift

Manual intervention, machine lock, or mirror imaging may shift the workpiece coordinate

system. Before attempting to operate the machine under the control of a program, confirm the

coordinate system carefully.

If the machine is operated under the control of a program without making allowances for any shift

in the workpiece coordinate system, the machine may behave unexpectedly, possibly damaging

the tool, the machine itself, the workpiece, or causing injury to the operator.

8. Software operator ’s panel and menu switches

Using the software operator’s panel and menu switches, in combination with the MDI panel, it

is possible to specify operations not supported by the machine operator’s panel, such as mode

change, override value change, and jog feed commands.

Note, however, that if the MDI panel keys are operated inadvertently, the machine may behave

unexpectedly, possibly damaging the tool, the machine itself, the workpiece, or causing injury

to the user.

B–63614EN/01

9. Manual intervention

If manual intervention is performed during programmed operation of the machine, the tool path

may vary when the machine is restarted. Before restarting the machine after manual intervention,

therefore, confirm the settings of the manual absolute switches, parameters, and

absolute/incremental command mode.

10.Feed hold, override, and single block

The feed hold, feedrate override, and single block functions can be disabled using custom macro

system variable #3004. Be careful when operating the machine in this case.

11. Dry run

Usually, a dry run is used to confirm the operation of the machine. During a dry run, the machine

operates at dry run speed, which differs from the corresponding programmed feedrate. Note that

the dry run speed may sometimes be higher than the programmed feed rate.

12.Cutter and tool nose radius compensation in MDI mode

Pay careful attention to a tool path specified by a command in MDI mode, because cutter or tool

nose radius compensation is not applied. When a command is entered from the MDI to interrupt

in automatic operation in cutter or tool nose radius compensation mode, pay particular attention

to the tool path when automatic operation is subsequently resumed. Refer to the descriptions of

the corresponding functions for details.

13.Program editing

If the machine is stopped, after which the machining program is edited (modification, insertion,

or deletion), the machine may behave unexpectedly if machining is resumed under the control

of that program. Basically , do not modify, insert, or delete commands from a machining program

while it is in use.

s–8

Page 11

B–63614EN/01

5

1. Memory backup battery replacement

SAFETY PRECAUTIONS

W ARNINGS RELATED TO DAILY MAINTENANCE

WARNING

Only those personnel who have received approved safety and maintenance training may perform

this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

and

NOTE

The CNC uses batteries to preserve the contents of its memory, because it must retain data such as

programs, offsets, and parameters even while external power is not applied.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

contents of the CNC’s memory will be lost.

Refer to the maintenance section of the operator’s manual or programming manual for details of the

battery replacement procedure.

s–9

Page 12

SAFETY PRECAUTIONS

B–63614EN/01

WARNING

2. Absolute pulse coder battery replacement

Only those personnel who have received approved safety and maintenance training may perform

this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

NOTE

The absolute pulse coder uses batteries to preserve its absolute position.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

absolute position data held by the pulse coder will be lost.

Refer to the FANUC SERVO MOTOR α series for details of the battery replacement procedure.

and

s–10

Page 13

B–63614EN/01

3. Fuse replacement

SAFETY PRECAUTIONS

WARNING

Before replacing a blown fuse, however, it is necessary to locate and remove the cause of the

blown fuse.

For this reason, only those personnel who have received approved safety and maintenance

training may perform this work.

When replacing a fuse with the cabinet open, be careful not to touch the high–voltage circuits

(marked

Touching an uncovered high–voltage circuit presents an extremely dangerous electric shock

hazard.

and fitted with an insulating cover).

s–11

Page 14

B–63614EN/01

Table of Contents

SAFETY PRECAUTIONS s–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I. GENERAL

1. GENERAL 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 GENERAL FLOW OF OPERATION OF CNC MACHINE TOOL 6. . . . . . . . . . . . . . . . . . . . . . . . .

1.2 CAUTIONS ON READING THIS MANUAL 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 CAUTIONS ON VARIOUS KINDS OF DATA 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II. PROGRAMMING

1. GENERAL 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 TOOL MOVEMENT ALONG WORKPIECE PARTS FIGURE–INTERPOLATION 12. . . . . . . . . . .

1.2 FEED–FEED FUNCTION 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 PART DRAWING AND TOOL MOVEMENT 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Reference Position (Machine–Specific Position) 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Coordinate System on Part Drawing and Coordinate System Specified by

1.3.3 How to Indicate Command Dimensions for Moving the T ool – Absolute,

1.4 CUTTING SPEED – SPINDLE SPEED FUNCTION 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 SELECTION OF TOOL USED FOR VARIOUS MACHINING – TOOL FUNCTION 21. . . . . . . . . .

1.6 COMMAND FOR MACHINE OPERATIONS – MISCELLANEOUS FUNCTION 22. . . . . . . . . . . .

1.7 PROGRAM CONFIGURATION 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 TOOL FIGURE AND TOOL MOTION BY PROGRAM 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.9 TOOL MOVEMENT RANGE – STROKE 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CNC – Coordinate System 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Incremental Commands 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. CONTROLLED AXES 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 CONTROLLED AXES 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 AXIS NAME 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 INCREMENT SYSTEM 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 MAXIMUM STROKE 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. PREPARATORY FUNCTION (G FUNCTION) 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. INTERPOLATION FUNCTIONS 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 POSITIONING (G00) 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 SINGLE DIRECTION POSITIONING (G60) 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 LINEAR INTERPOLATION (G01) 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 CIRCULAR INTERPOLATION (G02,G03) 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 HELICAL INTERPOLATION (G02,G03) 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 CYLINDRICAL INTERPOLATION (G07.1) 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 THREAD CUTTING (G33) 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 SKIP FUNCTION (G31) 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 HIGH SPEED SKIP SIGNAL (G31) 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–1

Page 15

Table of Contents

B–63614EN/02

5. FEED FUNCTIONS 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 GENERAL 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 RAPID TRAVERSE 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 CUTTING FEED 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 CUTTING FEEDRATE CONTROL 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 Exact Stop (G09, G61) Cutting Mode (G64) Tapping Mode (G63) 64. . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Automatic Corner Override 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2.1 Automatic Override for Inner Corners (G62) 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2.2 Internal Circular Cutting Feedrate Change 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 DWELL (G04) 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. REFERENCE POSITION 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 REFERENCE POSITION RETURN 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. COORDINATE SYSTEM 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 MACHINE COORDINATE SYSTEM 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 WORKPIECE COORDINATE SYSTEM 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.1 Setting a Workpiece Coordinate System 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.2 Selecting a W orkpiece Coordinate System 79. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.3 Changing Workpiece Coordinate System 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.4 W orkpiece coordinate system preset (G92.1) 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2.5 Adding Workpiece Coordinate Systems (G54.1 or G54) 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 LOCAL COORDINATE SYSTEM 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 PLANE SELECTION 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. COORDINATE VALUE AND DIMENSION 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 ABSOLUTE AND INCREMENTAL PROGRAMMING (G90, G91) 91. . . . . . . . . . . . . . . . . . . . . . .

8.2 POLAR COORDINATE COMMAND (G15, G16) 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 INCH/METRIC CONVERSION (G20,G21) 95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 DECIMAL POINT PROGRAMMING 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. SPINDLE SPEED FUNCTION (S FUNCTION) 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 SPECIFYING THE SPINDLE SPEED WITH A CODE 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 SPECIFYING THE SPINDLE SPEED VALUE DIRECTLY (S5–DIGIT COMMAND) 98. . . . . . . . .

9.3 CONSTANT SURFACE SPEED CONTROL (G96, G97) 99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.TOOL FUNCTION (T FUNCTION) 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 TOOL SELECTION FUNCTION 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 TOOL LIFE MANAGEMENT FUNCTION 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.1 T ool Life Management Data 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.2 Register, Change and Delete of T ool Life Management Data 106. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.3 T ool Life Management Command in a Machining Program 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2.4 T ool Life 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.AUXILIARY FUNCTION 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 AUXILIARY FUNCTION (M FUNCTION) 114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 MULTIPLE M COMMANDS IN A SINGLE BLOCK 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–2

Page 16

B–63614EN/01

Table of Contents

11.3 THE SECOND AUXILIARY FUNCTIONS (B CODES) 116. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.PROGRAM CONFIGURATION 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 PROGRAM COMPONENTS OTHER THAN PROGRAM SECTIONS 119. . . . . . . . . . . . . . . . . . . . .

12.2 PROGRAM SECTION CONFIGURATION 122. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.3 SUBPROGRAM (M98, M99) 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.FUNCTIONS TO SIMPLIFY PROGRAMMING 132. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 CANNED CYCLE 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.1 High–speed Peck Drilling Cycle (G73) 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.2 Left–handed T apping Cycle (G74) 139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.3 Fine Boring Cycle (G76) 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.4 Drilling Cycle, Spot Drilling (G81) 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.5 Drilling Cycle Counter Boring Cycle (G82) 145. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.6 Peck Drilling Cycle (G83) 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.7 Small–hole peck drilling cycle (G83) 149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.8 T apping Cycle (G84) 153. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.9 Boring Cycle (G85) 155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.10 Boring Cycle (G86) 157. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.11 Back Boring Cycle (G87) 159. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.12 Boring Cycle (G88) 161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.13 Boring Cycle (G89) 163. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1.14 Canned Cycle Cancel (G80) 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2 RIGID TAPPING 168. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.1 Rigid Tapping (G84) 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.2 Left–handed Rigid T apping Cycle (G74) 172. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.3 Peck Rigid T apping Cycle (G84 or G74) 175. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.2.4 Canned Cycle Cancel (G80) 177. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.3 OPTIONAL ANGLE CHAMFERING AND CORNER ROUNDING 178. . . . . . . . . . . . . . . . . . . . . . .

13.4 EXTERNAL MOTION FUNCTION (G81) 181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.5 INDEX TABLE INDEXING FUNCTION 182. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.COMPENSATION FUNCTION 185. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1 TOOL LENGTH OFFSET (G43,G44,G49) 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1.1 General 186. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.1.2 G53, G28, G30, and G30.1 Commands in T ool Length Offset Mode 191. . . . . . . . . . . . . . . . . . . . . . . . . .

14.2 AUTOMATIC TOOL LENGTH MEASUREMENT (G37) 194. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.3 TOOL OFFSET (G45–G48) 198. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.4 OVERVIEW OF CUTTER COMPENSATION C (G40 – G42) 203. . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.5 DETAILS OF CUTTER COMPENSATION C 209. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.5.1 General 209. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.5.2 T ool Movement in Start–up 210. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.5.3 T ool Movement in Of fset Mode 214. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.5.4 T ool Movement in Of fset Mode Cancel 228. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.5.5 Interference Check 234. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.5.6 Overcutting by Cutter Compensation 239. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.5.7 Input Command from MDI 242. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.5.8 G53,G28,G30,G30.1 and G29 Commands in Cutter Compensation C Mode 243. . . . . . . . . . . . . . . . . . . .

14.5.9 Corner Circular Interpolation (G39) 262. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.6 TOOL COMPENSA–TION VALUES, NUMBER OF COMPENSATION VALUES,

AND ENTERING VALUES FROM THE PROGRAM (G10) 264. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–3

Page 17

Table of Contents

B–63614EN/02

14.7 SCALING (G50,G51) 266. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.8 COORDINATE SYSTEM ROTATION (G68, G69) 271. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.9 NORMAL DIRECTION CONTROL (G40.1, G41.1, G42.1 OR G150, G151, G152) 277. . . . . . . . . . .

14.10 PROGRAMMABLE MIRROR IMAGE (G50.1, G51.1) 282. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.CUSTOM MACRO 284. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.1 VARIABLES 285. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.2 SYSTEM VARIABLES 289. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.3 ARITHMETIC AND LOGIC OPERATION 298. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.4 MACRO STATEMENTS AND NC STATEMENTS 303. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.5 BRANCH AND REPETITION 304. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.5.1 Unconditional Branch (GOTO Statement) 304. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.5.2 Conditional Branch (IF Statement) 305. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.5.3 Repetition (While Statement) 306. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.6 MACRO CALL 309. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.6.1 Simple Call (G65) 310. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.6.2 Modal Call (G66) 314. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.6.3 Macro Call Using G Code 316. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.6.4 Macro Call Using an M Code 317. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.6.5 Subprogram Call Using an M Code 318. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.6.6 Subprogram Calls Using a T Code 319. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.6.7 Sample Program 320. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.7 PROCESSING MACRO STATEMENTS 322. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.7.1 Details of NC statements and macro statements execution 322. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.7.2 Caution for using system variables 324. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.8 REGISTERING CUSTOM MACRO PROGRAMS 327. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.9 LIMITATIONS 328. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.10 EXTERNAL OUTPUT COMMANDS 329. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.11 INTERRUPTION TYPE CUSTOM MACRO 333. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.11.1 Specification Method 334. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15.11.2 Details of Functions 335. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.PATTERN DATA INPUT FUNCTION 343. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.1 DISPLAYING THE PATTERN MENU 344. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2 PATTERN DATA DISPLAY 348. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.3 CHARACTERS AND CODES TO BE USED

FOR THE PATTERN DATA INPUT FUNCTION 352. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17.PROGRAMMABLE PARAMETER ENTRY (G10) 354. . . . . . . . . . . . . . . . . . . . . . . . . . .

18.MEMORY OPERATION USING FS10/11 TAPE FORMAT 356. . . . . . . . . . . . . . . . . . .

19.HIGH SPEED CUTTING FUNCTIONS 357. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.1 FEEDRATE CLAMPING BY ARC RADIUS 358. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.2 ADVANCED PREVIEW CONTROL (G08) 359. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.3 HIGH–SPEED REMOTE BUFFER 361. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.3.1 High–speed remote buffer A (G05) 361. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.3.2 High–speed remote buffer B (G05) 364. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–4

Page 18

B–63614EN/01

Table of Contents

19.4 AI ADVANCED PREVIEW CONTROL 365. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.AXIS CONTROL FUNCTIONS 381. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.1 SIMPLE SYNCHRONOUS CONTROL 382. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20.2 ROTARY AXIS ROLL–OVER 385. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

III. OPERATION

1. GENERAL 389. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 MANUAL OPERATION 390. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 TOOL MOVEMENT BY PROGRAMMING– AUTOMATIC OPERATION 392. . . . . . . . . . . . . . . . . .

1.3 AUTOMATIC OPERATION 393. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 TESTING A PROGRAM 395. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.1 Check by Running the Machine 395. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.2 How to View the Position Display Change without Running the Machine 396. . . . . . . . . . . . . . . . . . . . . .

1.5 EDITING A PART PROGRAM 397. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 DISPLAYING AND SETTING DATA 398. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 DISPLAY 401. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.1 Program Display 401. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.2 Current Position Display 402. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.3 Alarm Display 402. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.4 Parts Count Display, Run Time Display 403. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7.5 Graphic Display 403. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.8 DATA INPUT / OUTPUT 404. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. OPERATIONAL DEVICES 405. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 SETTING AND DISPLAY UNITS 406. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 7.2″/8.4″ LCD–Mounted T ype CNC Control Unit 407. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2 9.5″/10.4″ LCD–Mounted T ype CNC Control Unit 407. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3 Stand–Alone Type Small MDI Unit 408. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.4 Stand–Alone Type Standard MDI Unit 409. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.5 Stand–Alone T ype 61 Full–Key MDI Unit 410. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 EXPLANATION OF THE KEYBOARD 411. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 FUNCTION KEYS AND SOFT KEYS 413. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 General Screen Operations 413. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Function Keys 414. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.3 Soft Keys 415. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.4 Key Input and Input Buffer 431. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.5 W arning Messages 432. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.6 Soft Key Configuration 433. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 EXTERNAL I/O DEVICES 434. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 F ANUC Handy File 436. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 F ANUC Floppy Cassette 436. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.3 F ANUC FA Card 437. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.4 F ANUC PPR 437. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.5 Portable T ape Reader 438. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 POWER ON/OFF 439. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Turning on the Power 439. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.2 Screen Displayed at Power–on 440. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.3 Power Disconnection 441. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–5

Page 19

Table of Contents

B–63614EN/02

3. MANUAL OPERATION 442. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 MANUAL REFERENCE POSITION RETURN 443. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 JOG FEED 445. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 INCREMENTAL FEED 447. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 MANUAL HANDLE FEED 448. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 MANUAL ABSOLUTE ON AND OFF 451. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 MANUAL LINEAR/CIRCULAR INTERPOLATION 456. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. AUT OMATIC OPERA TION 461. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 MEMORY OPERATION 462. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 MDI OPERATION 465. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 DNC OPERATION 469. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 PROGRAM RESTART 472. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 SCHEDULING FUNCTION 479. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 SUBPROGRAM CALL FUNCTION (M198) 484. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 MANUAL HANDLE INTERRUPTION 486. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 MIRROR IMAGE 489. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 MANUAL INTERVENTION AND RETURN 491. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10 DNC OPERATION WITH MEMORY CARD 493. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10.1 Specification 493. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10.2 Operations 494. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10.2.1 DNC operation 494. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10.2.2 Subprogram call (M198) 495. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10.3 LIMITATION and NOTES 496. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10.4 PARAMETER 496. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10.5 Connecting PCMCIA Card Attachment 497. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10.5.1 Specification number 497. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10.5.2 Assembling 497. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10.6 Recommended Memory Card 499. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. TEST OPERATION 500. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 MACHINE LOCK AND AUXILIARY FUNCTION LOCK 501. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 FEEDRATE OVERRIDE 503. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 RAPID TRAVERSE OVERRIDE 504. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 DRY RUN 505. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.5 SINGLE BLOCK 506. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. SAFETY FUNCTIONS 508. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 EMERGENCY STOP 509. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 OVERTRAVEL 510. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 STORED STROKE CHECK 511. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. ALARM AND SELF–DIAGNOSIS FUNCTIONS 515. . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 ALARM DISPLAY 516. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 ALARM HISTORY DISPLAY 518. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 CHECKING BY SELF–DIAGNOSTIC SCREEN 519. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–6

Page 20

B–63614EN/01

Table of Contents

8. DATA INPUT/OUTPUT 522. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 FILES 523. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 FILE SEARCH 525. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 FILE DELETION 527. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4 PROGRAM INPUT/OUTPUT 528. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.1 Inputting a Program 528. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.4.2 Outputting a Program 531. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5 OFFSET DATA INPUT AND OUTPUT 533. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.1 Inputting Offset Data 533. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.5.2 Outputting Offset Data 534. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6 INPUTTING AND OUTPUTTING PARAMETERS AND

PITCH ERROR COMPENSATION DATA 535. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.1 Inputting Parameters 535. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.2 Outputting Parameters 536. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.3 Inputting Pitch Error Compensation Data 537. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.6.4 Outputting Pitch Error Compensation Data 538. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7 INPUTTING/OUTPUTTING CUSTOM MACRO COMMON VARIABLES 539. . . . . . . . . . . . . . . . .

8.7.1 Inputting Custom Macro Common Variables 539. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.7.2 Outputting Custom Macro Common Variable 540. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8 DISPLAYING DIRECTORY OF FLOPPY CASSETTE 541. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8.1 Displaying the Directory 542. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8.2 Reading Files 545. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8.3 Outputting Programs 546. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.8.4 Deleting Files 547. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.9 OUTPUTTING A PROGRAM LIST FOR A SPECIFIED GROUP 549. . . . . . . . . . . . . . . . . . . . . . . . .

8.10 DATA INPUT/OUTPUT ON THE ALL IO SCREEN 550. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10.1 Setting Input/Output–Related Parameters 551. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10.2 Inputting and Outputting Programs 552. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10.3 Inputting and Outputting Parameters 557. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10.4 Inputting and Outputting Offset Data 559. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10.5 Outputting Custom Macro Common Variables 561. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10.6 Inputting and Outputting Floppy Files 562. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.10.7 Memory Card Input/Output 567. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.11 DATA INPUT/OUTPUT USING A MEMORY CARD 576. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. EDITING PROGRAMS 588. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 INSERTING, ALTERING AND DELETING A WORD 589. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.1 W ord Search 590. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.2 Heading a Program 592. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.3 Inserting a W ord 593. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.4 Altering a W ord 594. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1.5 Deleting a W ord 595. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 DELETING BLOCKS 596. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.1 Deleting a Block 596. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2.2 Deleting Multiple Blocks 597. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 PROGRAM NUMBER SEARCH 598. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 SEQUENCE NUMBER SEARCH 599. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 DELETING PROGRAMS 601. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.1 Deleting One Program 601. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.2 Deleting All Programs 601. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5.3 Deleting More Than One Program by Specifying a Range 602. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–7

Page 21

Table of Contents

B–63614EN/02

9.6 EXTENDED PART PROGRAM EDITING FUNCTION 603. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.1 Copying an Entire Program 604. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.2 Copying Part of a Program 605. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.3 Moving Part of a Program 606. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.4 Merging a Program 607. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.5 Supplementary Explanation for Copying, Moving and Merging 608. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6.6 Replacement of W ords and Addresses 610. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7 EDITING OF CUSTOM MACROS 612. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.8 BACKGROUND EDITING 613. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.9 PASSWORD FUNCTION 614. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.CREATING PROGRAMS 616. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 CREATING PROGRAMS USING THE MDI PANEL 617. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 AUTOMATIC INSERTION OF SEQUENCE NUMBERS 618. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.3 CREATING PROGRAMS IN TEACH IN MODE (PLAYBACK) 620. . . . . . . . . . . . . . . . . . . . . . . . . .

1 1.SETTING AND DISPLA YING DATA 623. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 SCREENS DISPLAYED BY FUNCTION KEY

11.1.1 Position Display in the Work Coordinate System 631. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1.2 Position Display in the Relative Coordinate System 632. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1.3 Overall Position Display 634. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1.4 Presetting the W orkpiece Coordinate System 635. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1.5 Actual Feedrate Display 636. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1.6 Display of Run Time and Parts Count 638. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1.7 Operating Monitor Display 639. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2 SCREENS DISPLAYED BY FUNCTION KEY

POS

PROG

(IN MEMORY MODE OR MDI MODE) 641. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2.1 Program Contents Display 642. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2.2 Current Block Display Screen 643. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2.3 Next Block Display Screen 644. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2.4 Program Check Screen 645. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.2.5 Program Screen for MDI Operation 647. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3 SCREENS DISPLAYED BY FUNCTION KEY

11.3.1 Displaying Memory Used and a List of Programs 648. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.3.2 Displaying a Program List for a Specified Group 652. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4 SCREENS DISPLAYED BY FUNCTION KEY

11.4.1 Setting and Displaying the Tool Offset Value 656. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.2 T ool Length Measurement 659. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.3 Displaying and Entering Setting Data 661. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.4 Sequence Number Comparison and Stop 663. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.5 Displaying and Setting Run Time, Parts Count, and Time 665. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.6 Displaying and Setting the W orkpiece Origin Offset Value 667. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.7 Direct Input of Measured W orkpiece Origin Offsets 668. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.8 Displaying and Setting Custom Macro Common V ariables 670. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.9 Displaying Pattern Data and Pattern Menu 671. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.10 Displaying and Setting the Software Operator’s Panel 673. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.11 Displaying and Setting T ool Life Management Data 675. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.4.12 Displaying and Setting Extended T ool Life Management 678. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROG

(IN THE EDIT MODE) 648. . . . . . . . . . . . . . .

OFFSET

SETTING

630. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

655. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–8

Page 22

B–63614EN/01

Table of Contents

11.5 SCREENS DISPLAYED BY FUNCTION KEY

11.5.1 Displaying and Setting Parameters 684. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.5.2 Displaying and Setting Pitch Error Compensation Data 686. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.6 DISPLAYING THE PROGRAM NUMBER, SEQUENCE NUMBER, AND STATUS,

AND WARNING MESSAGES FOR DATA SETTING OR INPUT/OUTPUT OPERATION 689. . . . .

11.6.1 Displaying the Program Number and Sequence Number 689. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.6.2 Displaying the Status and W arning for Data Setting or Input/Output Operation 690. . . . . . . . . . . . . . . . . .

11.7 SCREENS DISPLAYED BY FUNCTION KEY

11.7.1 External Operator Message History Display 692. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.8 CLEARING THE SCREEN 694. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.8.1 Erase Screen Display 694. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.8.2 Automatic Erase Screen Display 695. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYSTEM

MESSAGE

12.GRAPHICS FUNCTION 696. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.1 GRAPHICS DISPLAY 697. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2 DYNAMIC GRAPHIC DISPLAY 703. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.2.1 Path Drawing 703. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.HELP FUNCTION 712. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14.SCREEN HARDCOPY 717. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

683. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

692. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV. MAINTENANCE

1. METHOD OF REPLACING BATTERY 723. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 REPLACING BATTERY FOR LCD–MOUNTED TYPE i SERIES 724. . . . . . . . . . . . . . . . . . . . . . . .

1.2 REPLACING THE BATTERY FOR STAND–ALONE TYPE i SERIES 727. . . . . . . . . . . . . . . . . . . . .

1.3 BATTERY IN THE PANEL i (3 VDC) 730. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 BATTERY FOR SEPARATE ABSOLUTE PULSE CODERS (6 VDC) 732. . . . . . . . . . . . . . . . . . . . . .

1.5 BATTERY FOR BUILT–IN ABSOLUTE PULSE CODERS (DC6V) 733. . . . . . . . . . . . . . . . . . . . . . .

APPENDIX

A. TAPE CODE LIST 741. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. LIST OF FUNCTIONS AND TAPE FORMAT 744. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. RANGE OF COMMAND VALUE 750. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. NOMOGRAPHS 753. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.1 INCORRECT THREADED LENGTH 754. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.2 SIMPLE CALCULATION OF INCORRECT THREAD LENGTH 756. . . . . . . . . . . . . . . . . . . . . . . . .

D.3 TOOL PATH AT CORNER 758. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.4 RADIUS DIRECTION ERROR AT CIRCLE CUTTING 761. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–9

Page 23

Table of Contents

B–63614EN/02

E. STATUS WHEN TURNING POWER ON,

WHEN CLEAR AND WHEN RESET 762. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F. CHARACTER–TO–CODES CORRESPONDENCE TABLE 764. . . . . . . . . . . . . . . . . .

G. ALARM LIST 765. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

c–10

Page 24

I. GENERAL

Page 25

B–63614EN/01

GENERAL

1

About this manual

GENERAL

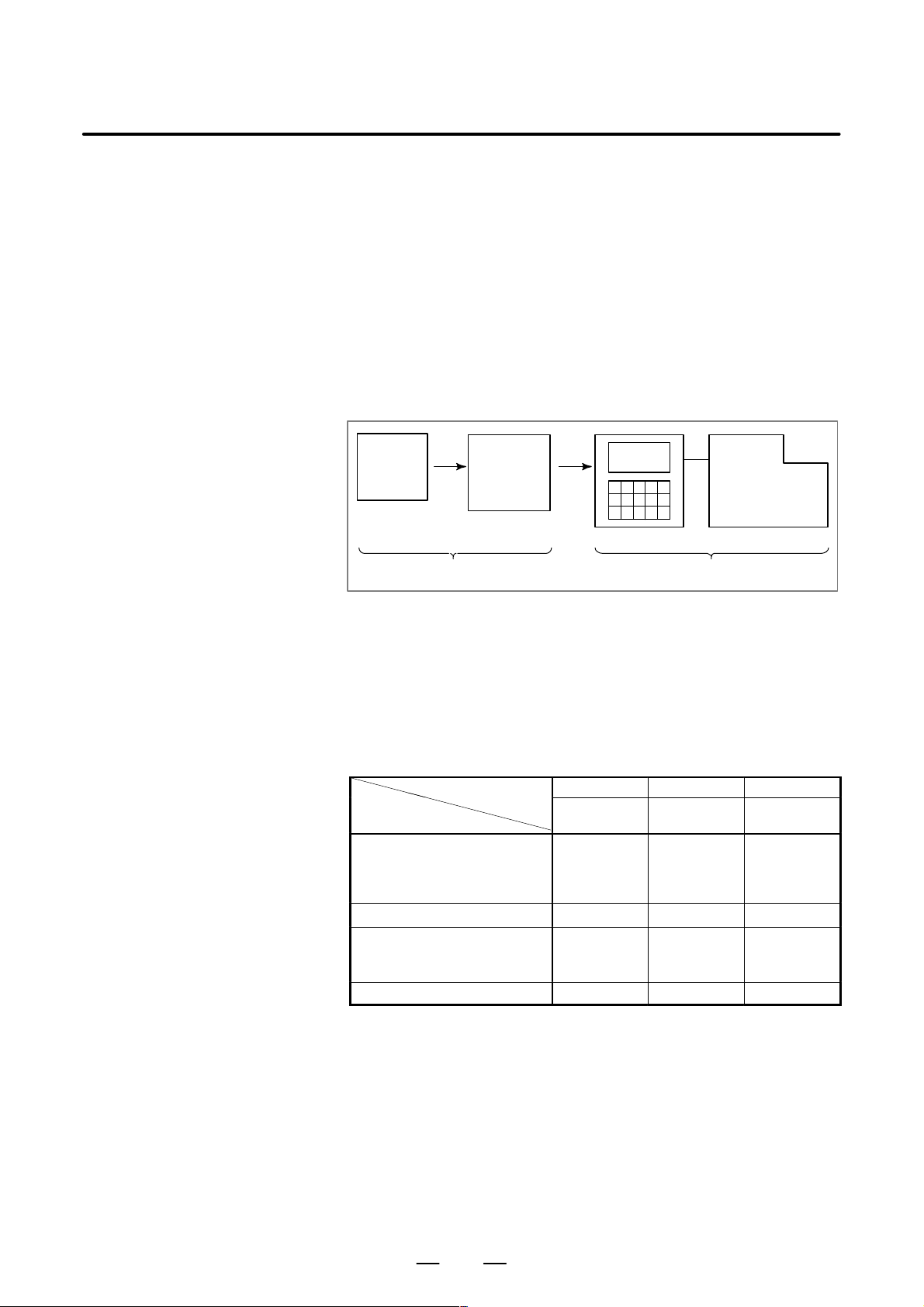

This manual consists of the following parts:

I. GENERAL

Describes chapter organization, applicable models, related manuals,

and notes for reading this manual.

II. PROGRAMMING

Describes each function: Format used to program functions in the NC

language, characteristics, and restrictions. When a program is created

through conversational automatic programming function, refer to the

manual for the conversational automatic programming function

(Table 1).

III. OPERATION

Describes the manual operation and automatic operation of a machine,

procedures for inputting and outputting data, and procedures for

editing a program.

IV. MAINTENANCE

Describes procedures for replacing batteries.

APPENDIX

Lists tape codes, valid data ranges, and error codes.

1. GENERAL

Some functions described in this manual may not be applied to some

products. For detail, refer to the DESCRIPTIONS manual(B–63522EN).

This manual does not describe parameters in detail. For details on

parameters mentioned in this manual, refer to the manual for parameters

(B–63610EN).

This manual describes all optional functions. Look up the options

incorporated into your system in the manual written by the machine tool

builder.

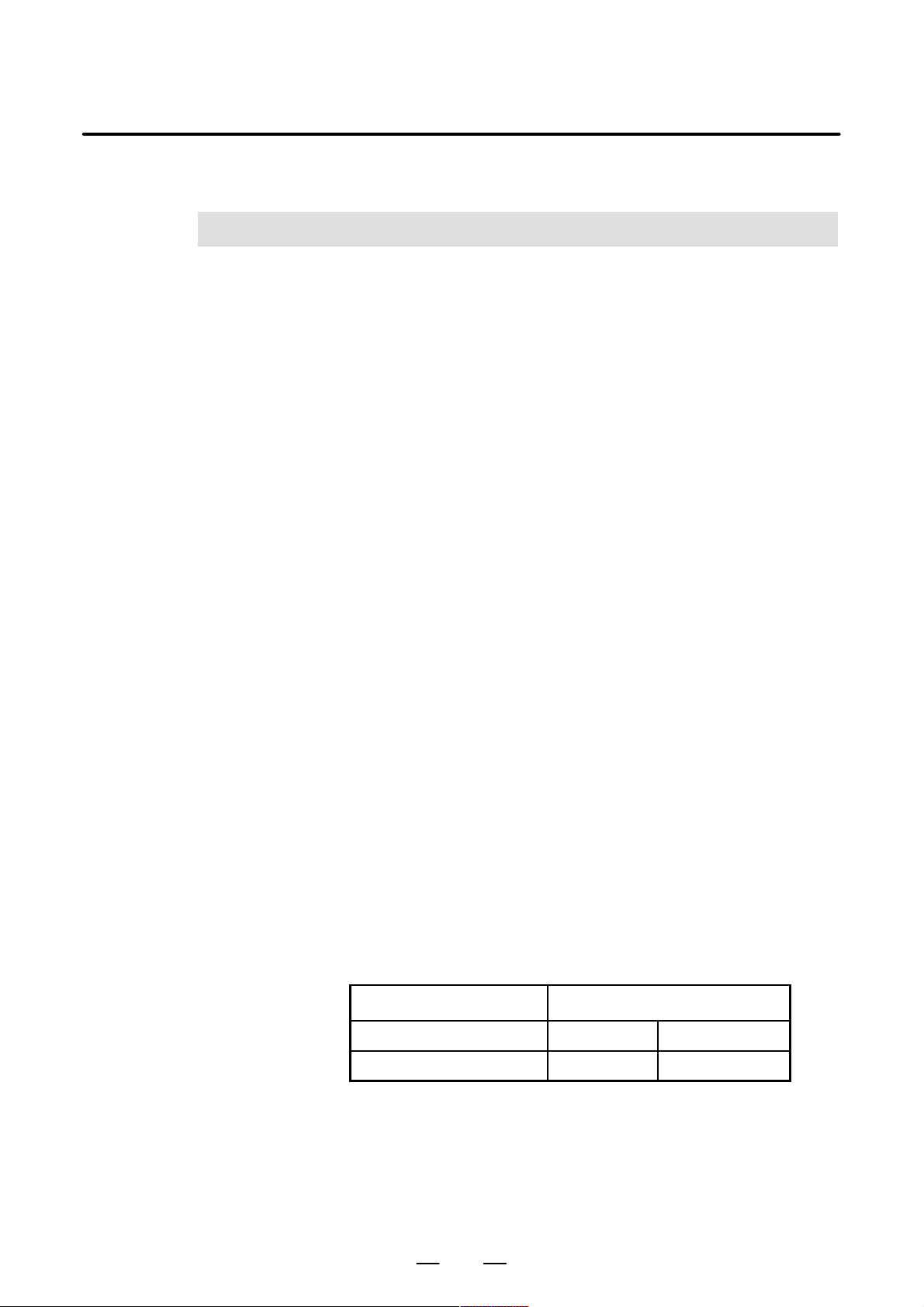

The models covered by this manual, and their abbreviations are:

Product name Abbreviations

FANUC Series 21i–MB 21i–MB Series 21i

FANUC Series 210i–MB 210i–MB Series 210i

3

Page 26

GENERAL1. GENERAL

B–63614EN/01

Special symbols

_

D P

I

D ;

Related manuals of

Series 16i/18i/21i/160i/

180i/210i–MODEL B

This manual uses the following symbols:

Indicates a combination of axes such as X__ Y__ Z (used in

PROGRAMMING.).

Indicates the end of a block. It actually corresponds to the ISO code LF

or EIA code CR.

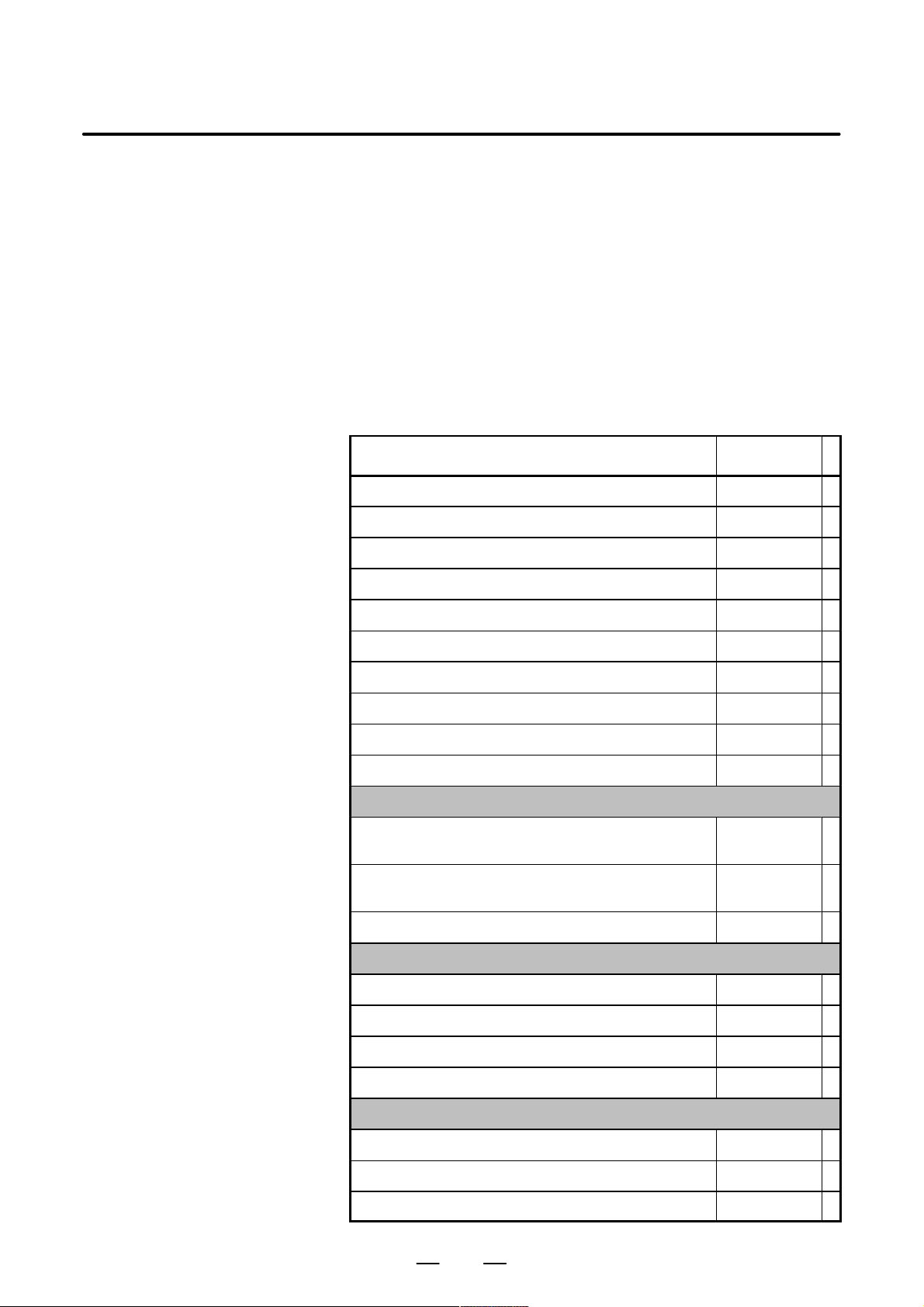

The following table lists the manuals related to Series 16i, Series 18i,

Series 21i, Series 160i, Series 180i, Series 210i–MODEL B. This manual

is indicated by an asterisk(*).

Manual name

DESCRIPTIONS B–63522EN

CONNECTION MANUAL (HARDWARE) B–63523EN

CONNECTION MANUAL (FUNCTION) B–63523EN–1

OPERA T ORS MANUAL (16i/18i/160i/180i–TB) B–63524EN

OPERATOR’S MANUAL (16i/18i/160i/180i–MB) B–63534EN

Specification

number

OPERATOR’S MANUAL (21i/210i–TB) B–63604EN

OPERATOR’S MANUAL (21i/210i–MB) B–63614EN *

MAINTENANCE MANUAL B–63525EN

P ARAMETER MANUAL (16i/18i/160i/180i–MODEL B) B–63530EN

P ARAMETER MANUAL (21i/210i–MODEL B) B–63610EN

PROGRAMMING MANUAL

Macro Compiler/Macro Executor

PROGRAMMING MANUAL

FAPT MACRO COMPILER (For Personal Computer)

PROGRAMMING MANUAL

C Language Executor PROGRAMMING MANUAL B–62443EN–3

CAP (T series)

FANUC Super CAPi T OPERATORS MANUAL B–63284EN

FANUC Symbol CAPi T OPERATOR’S MANUAL B–63304EN

MANUAL GUIDE For Lathe PROGRAMMING MANUAL B–63343EN

MANUAL GUIDE For Lathe OPERA T OR’S MANUAL B–63344EN

B–61803E–1

B–66102E

CAP (M series)

FANUC Super CAPi M OPERATOR’S MANUAL B–63294EN

MANUAL GUIDE For Milling PROGRAMMING MANUAL B–63423EN

MANUAL GUIDE For Milling OPERA T OR’S MANUAL B–63424EN

4

Page 27

B–63614EN/01

GENERAL

1. GENERAL

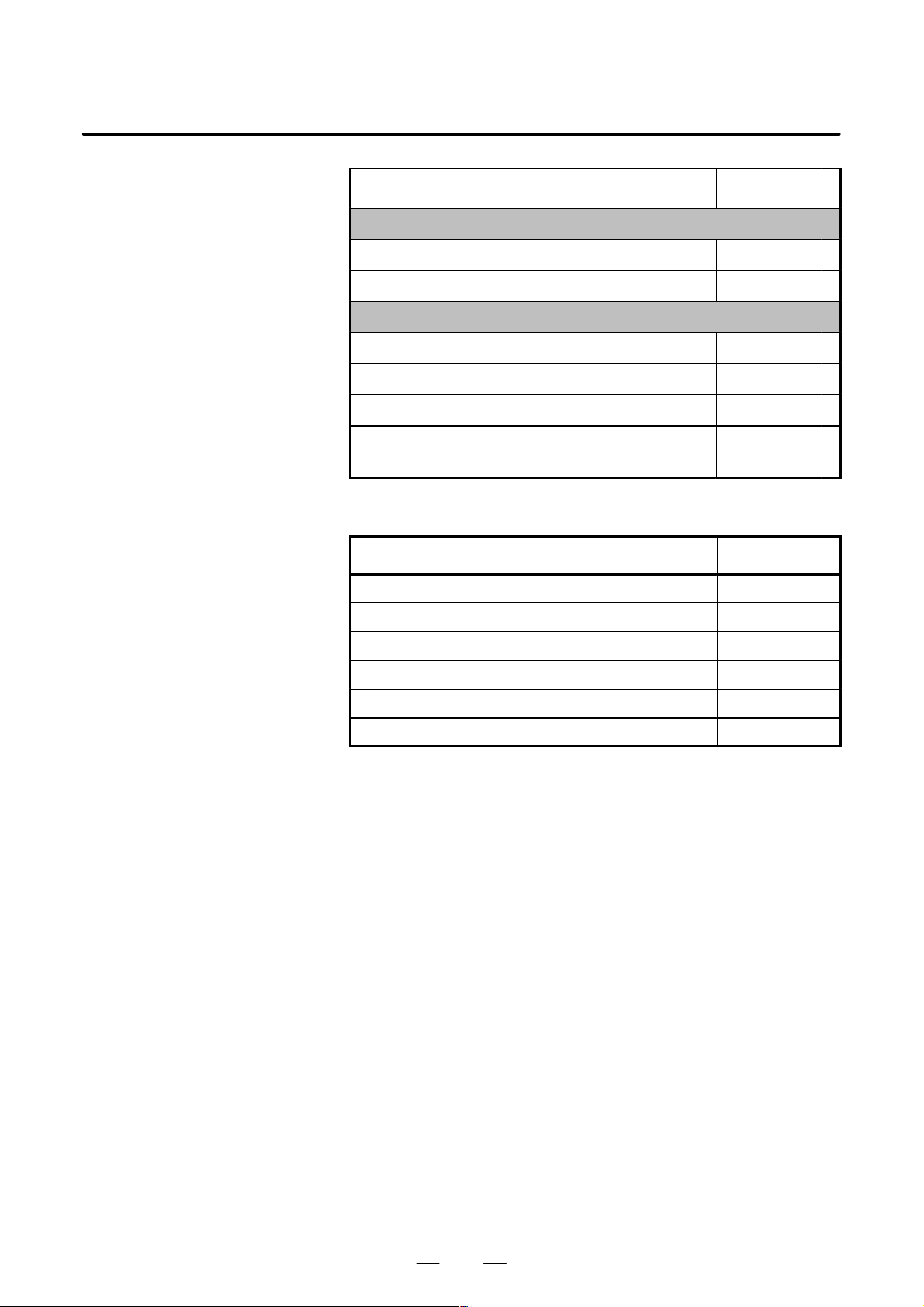

Related manuals of

SERVO MOTOR a series

Manual name

PMC

PMC Ladder Language PROGRAMMING MANUAL B–61863E

PMC C Language PROGRAMMING MANUAL B–61863E–1

Network

FANUC I/O Link–II CONNECTION MANUAL B–62714EN

Profibus–DP Board OPERA T OR’S MANUAL B–62924EN

DeviceNet Board OPERA T OR ’S MANUAL B–63404EN

Ethernet Board/DA T A SERVER Board

OPERATOR’S MANUAL

Specification

number

B–63354EN