Page 1

FTB-2200

Broadband Source for FTB-200 v2

User Guide

Page 2

Copyright © 2011–2014 EXFO Inc. All rights reserved. No part of this

publication may be reproduced, stored in a retrieval system or transmitted

in any form, be it electronically, mechanically, or by any other means such

as photocopying, recording or otherwise, without the prior written

permission of EXFO Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

Patents

Feature(s) of this product is/are protected by one or more of US patents

6,612,750 and 8,373,852.

Version number: 2.0.1

ii FTB-2200

Page 3

Contents

Certification Information ....................................................................................................... iv

1 Introducing the FTB-2200 Broadband Source ............................................ 1

Typical Applications ................................................................................................................1

Conventions ............................................................................................................................2

2 Safety Information ....................................................................................... 3

3 Setting Up and Operating the Broadband Source ..................................... 5

Inserting and Removing Test Modules ....................................................................................5

Starting Module Applications ...............................................................................................11

Cleaning and Connecting Optical Fibers ...............................................................................13

Installing the EXFO Universal Interface (EUI) .........................................................................15

Activating or Deactivating Light Emission .............................................................................16

4 Maintenance ............................................................................................... 17

Cleaning Fixed Connectors ....................................................................................................18

Cleaning EUI Connectors ......................................................................................................20

Recalibrating the Unit ...........................................................................................................22

Recycling and Disposal (Applies to European Union Only) ....................................................23

5 Troubleshooting ......................................................................................... 25

Solving Common Problems ...................................................................................................25

Obtaining Online Help ..........................................................................................................26

Contacting the Technical Support Group ..............................................................................27

Transportation ......................................................................................................................28

6 Warranty ..................................................................................................... 29

General Information .............................................................................................................29

Liability .................................................................................................................................30

Exclusions .............................................................................................................................30

Certification ..........................................................................................................................30

Service and Repairs ...............................................................................................................31

EXFO Service Centers Worldwide ..........................................................................................32

Index ................................................................................................................ 33

Broadband Source iii

Page 4

Certification Information

Certification Information

North America Regulatory Statement

This unit was certified by an agency approved in both Canada and the

United States of America. It has been evaluated according to applicable

North American approved standards for product safety for use in Canada

and the United States.

Electronic test and measurement equipment is exempt from FCC part 15,

subpart B compliance in the United States of America and from ICES-003

compliance in Canada. However, EXFO Inc. makes reasonable efforts to

ensure compliance to the applicable standards.

The limits set by these standards are designed to provide reasonable

protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance

with the user guide, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

Modifications not expressly approved by the manufacturer could void the

user's authority to operate the equipment.

iv FTB-2200

Page 5

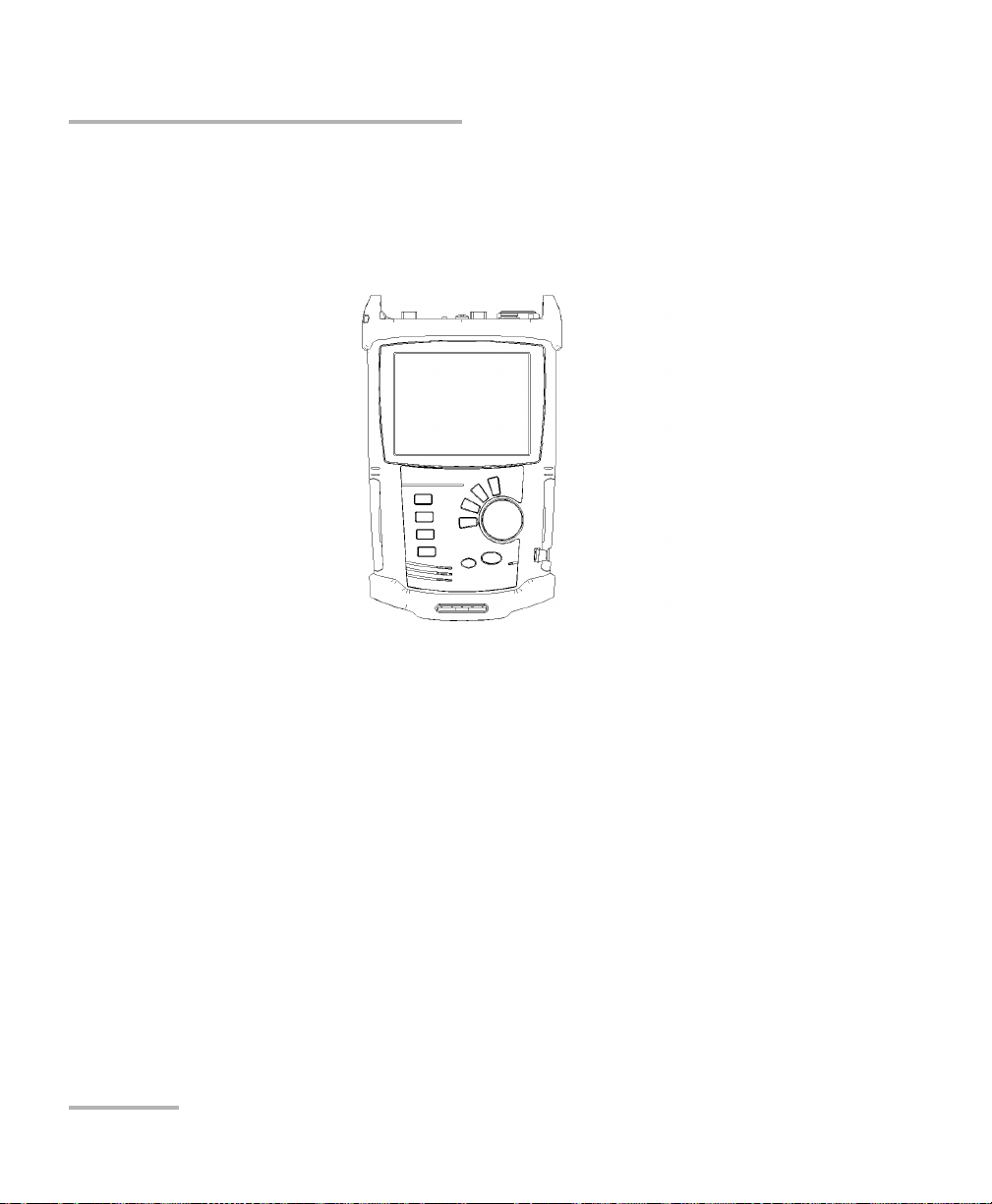

1 Introducing the FTB-2200

FTB-2200

BROADBAND SOURCE

OUT

ACTIVE

Broadband Source

The FTB-2200 Broadband Source is a polarization scrambled broadband

LED source covering the C + L bands. It is ideal for high-accuracy

polarization mode dispersion (PMD) measurement and has been

specifically designed to be used with EXFO’s FTB-5500B PMD Analyzer.

Typical Applications

This light source is suitable for high-accuracy PMD measurement, quality

control, calibration, acceptance testing and loss and return loss testing.

Broadband Source 1

Page 6

Introducing the FTB-2200 Broadband Source

Conventions

Conventions

Before using the product described in this guide, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

For more information on equipment ratings, refer to the FTB-200 v2

Compact Modular Platform user guide

2 FTB-2200

Page 7

2 Safety Information

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

The use of controls, adjustments and procedures, namely for

operation and maintenance, other than those specified herein may

result in hazardous radiation exposure or impair the protection

provided by this unit.

IMPORTANT

When you see the following symbol on your unit , make sure

that you refer to the instructions provided in your user

documentation. Ensure that you understand and meet the required

conditions before using your product.

IMPORTANT

Other safety instructions relevant for your product are located

throughout this documentation, depending on the action to

perform. Make sure to read them carefully when they apply to your

situation.

Broadband Source 3

Page 8

Safety Information

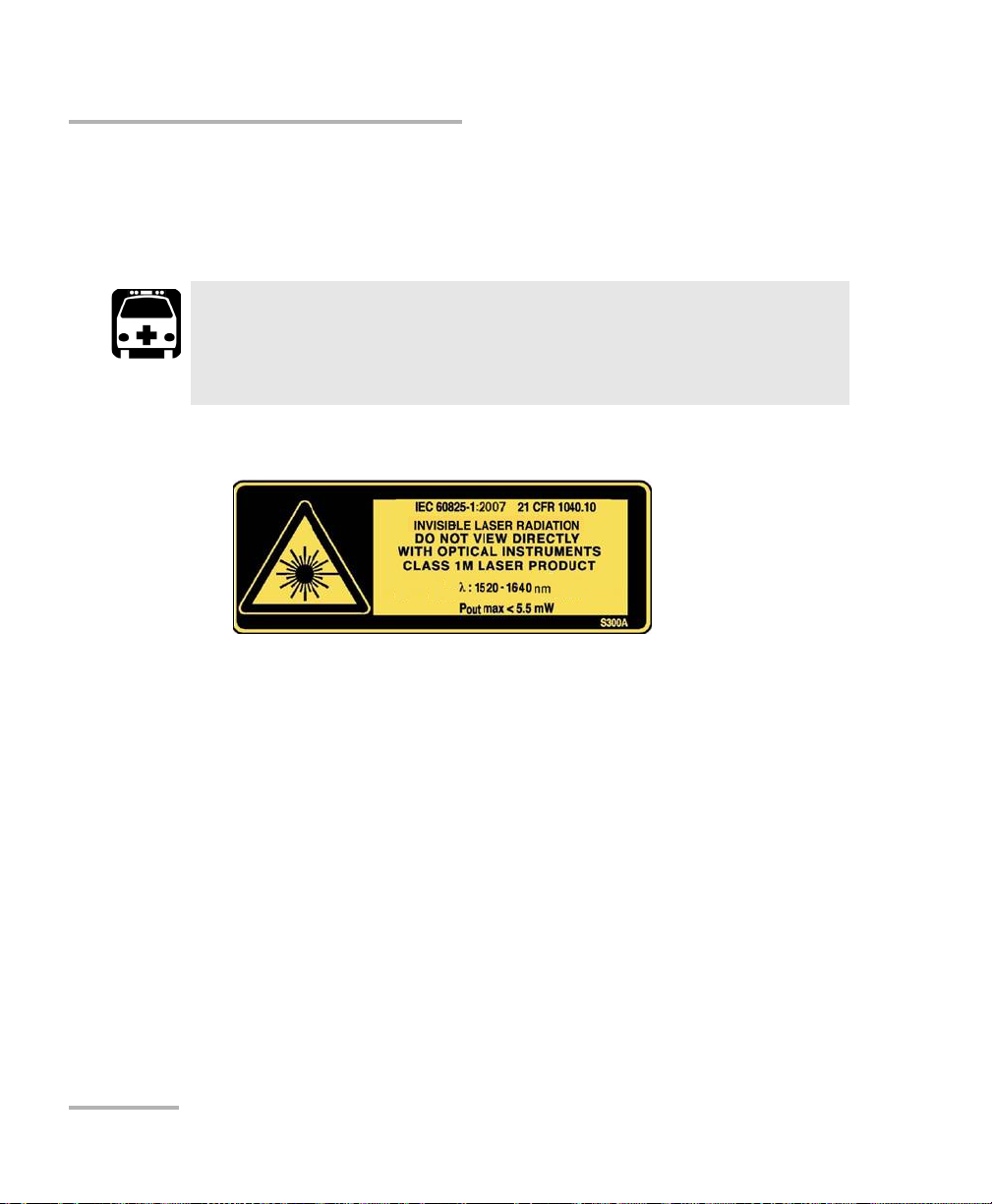

Your instrument is a Class 1M laser product in compliance with standards

IEC 60825-1: 2007 and 21 CFR 1040.10, except for deviations pursuant to

Laser Notice No. 50, dated June 24, 2007. Invisible laser radiation may be

encountered at the output port.

Viewing the laser output with certain optical instruments (for

example, eye loupes, magnifiers, and microscopes) within a

distance of 100 mm may pose an eye hazard.

The following label(s) indicate that the product contains a Class 1M source:

WARNING

4 FTB-2200

Page 9

3 Setting Up and Operating the

Broadband Source

Inserting and Removing Test Modules

CAUTION

Never insert or remove a module while the FTB-200 v2 Compact

Modular Platform is turned on. This will result in immediate and

irreparable damage to both the module and unit.

CAUTION

To avoid damaging your unit, use it only with modules approved by

EXFO.

WARNING

When the laser safety LED is flashing, at least one of your modules

is emitting an optical signal. Please check all modules, as it might

not be the one you are currently using.

Broadband Source 5

Page 10

Setting Up and Operating the Broadband Source

Inserting and Removing Test Modules

To insert a module into the FTB-200 v2 Compact Modular

Platform:

1. Turn off your unit.

2. Position the unit so that its front panel is facing you.

6 FTB-2200

Page 11

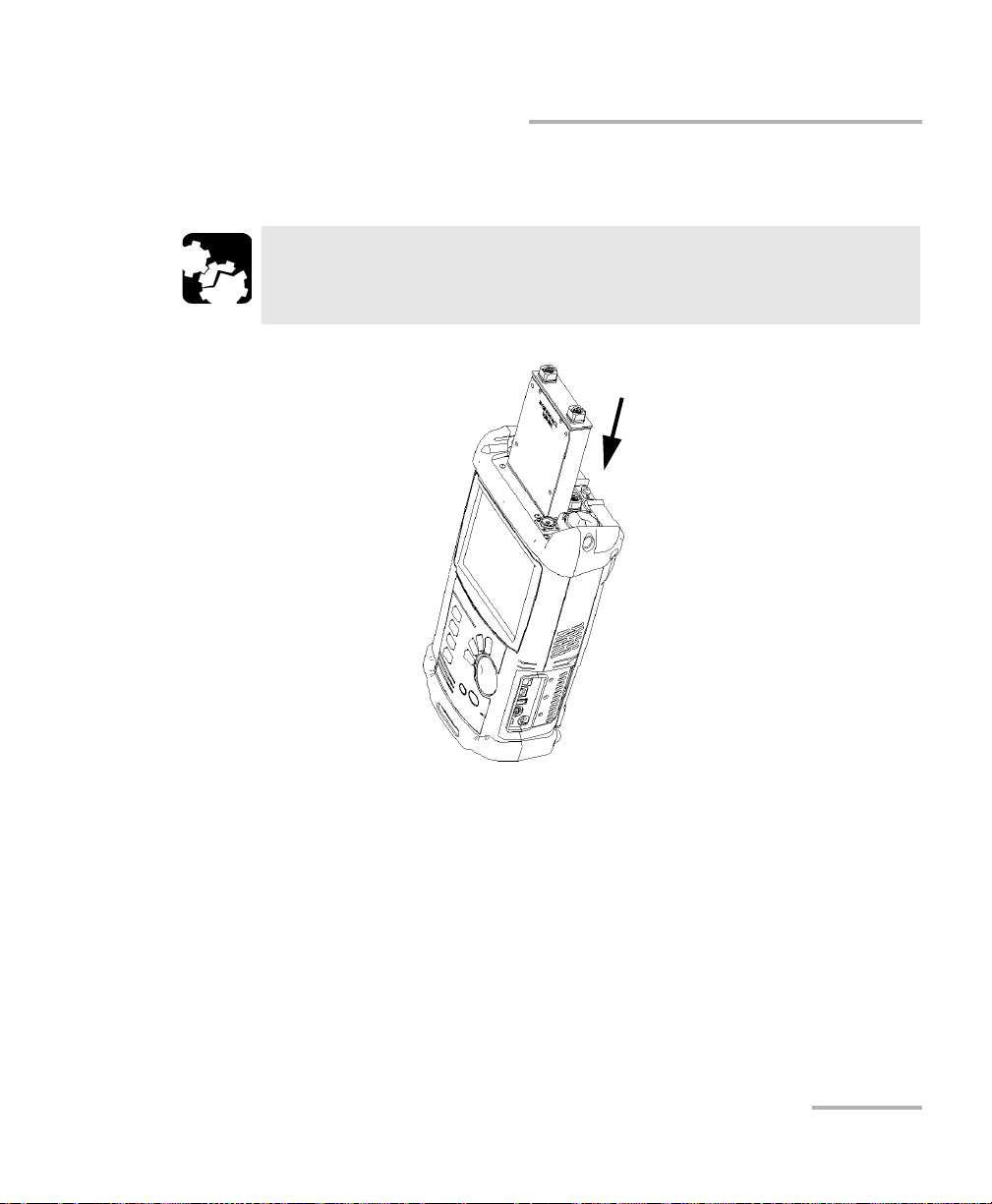

Setting Up and Operating the Broadband Source

Inserting and Removing Test Modules

3. Take the module and place it vertically so that the retaining screw hole

is at the left of the connector pins.

CAUTION

Inserting a module upside down could result in permanent damage

to the module, as the connector pins might be bent.

4. Insert the protruding edges of the module into the grooves of the unit’s

module slot.

5. Push the module all the way to the bottom of the slot, until the

retaining screw makes contact with the unit casing.

6. Place the unit so that its bottom panel is facing you.

Broadband Source 7

Page 12

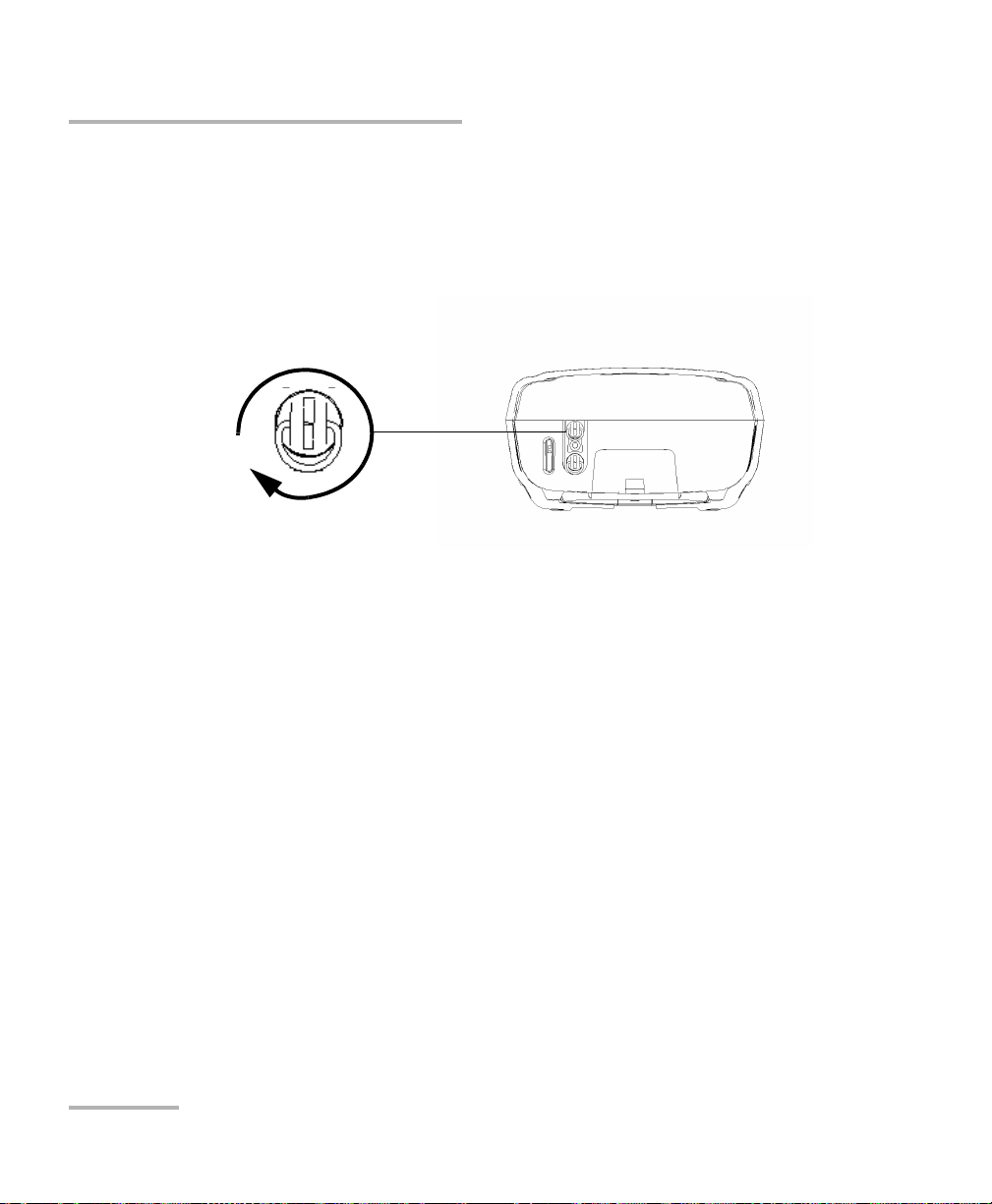

Setting Up and Operating the Broadband Source

Turn retaining screws

clockwise

Bottom panel

Inserting and Removing Test Modules

7. While applying slight pressure to the module, lift the mobile part of the

retaining screw and use it to turn the retaining screw clockwise until it

is tightened.

This will secure the module into its “seated” position.

When you turn on the unit, the startup sequence will automatically detect

the module.

8 FTB-2200

Page 13

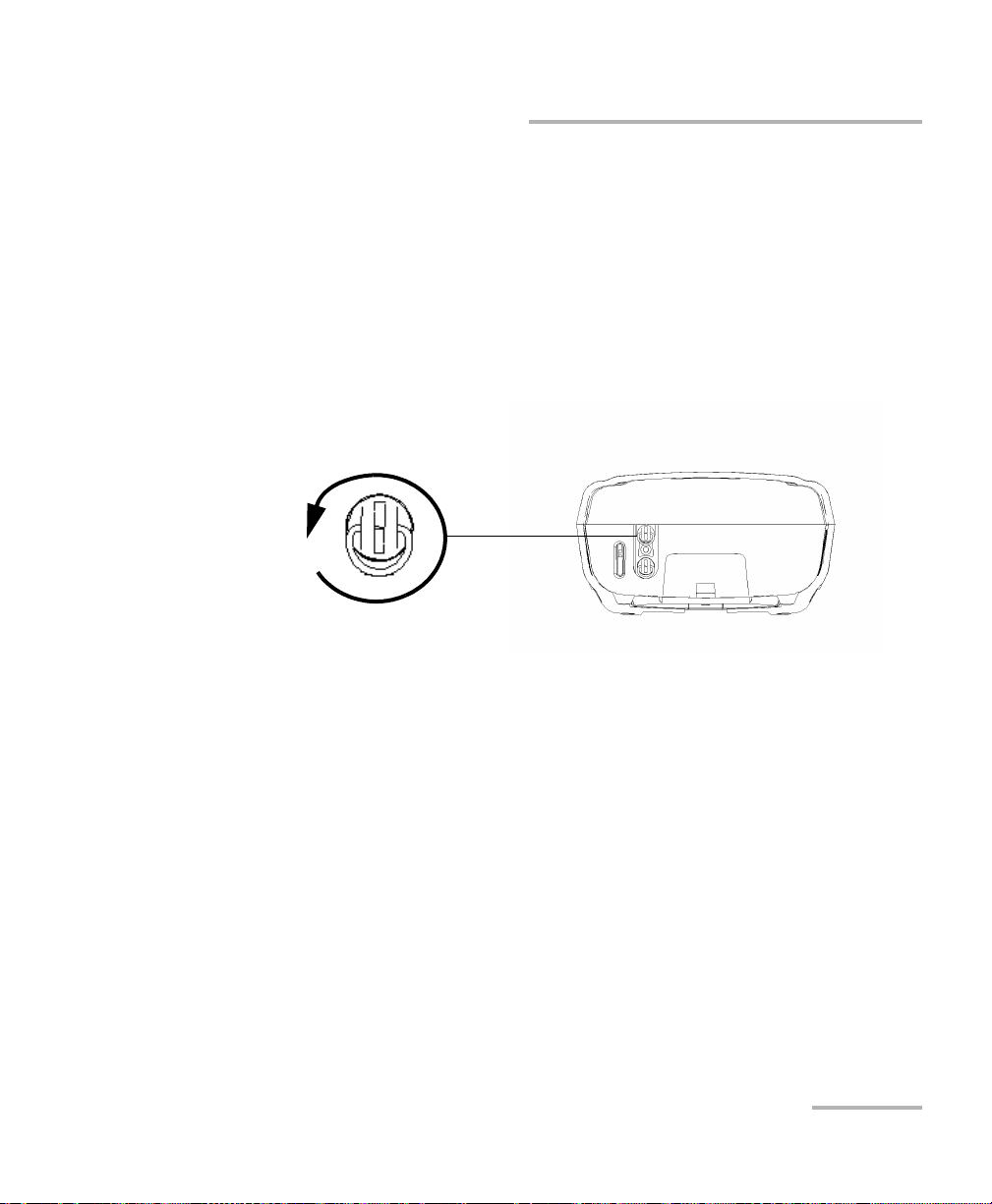

Setting Up and Operating the Broadband Source

Turn retaining screws

counterclockwise

Bottom panel

Inserting and Removing Test Modules

To remove a module from the FTB-200 v2 Compact Modular

Platform:

1. Turn off your unit.

2. Position the unit so that the bottom panel is facing you.

3. Lift the mobile part of the retaining screw and use it to turn the

retaining screw counterclockwise until it stops.

The module will be slowly released from the slot.

4. Place the unit so that the top panel is facing you.

Broadband Source 9

Page 14

Setting Up and Operating the Broadband Source

Inserting and Removing Test Modules

5. Hold the module by its sides or by the handle (NOT by the connector)

and pull it out.

CAUTION

Pulling out a module by a connector could seriously damage both

the module and connector. Always pull out a module by its casing.

6. Cover empty slots with the supplied protective covers.

10 FTB-2200

Page 15

Setting Up and Operating the Broadband Source

Starting Module Applications

Starting Module Applications

Your modules can be configured and controlled from their dedicated

applications in Compact ToolBox.

To start a module application:

1. From Compact ToolBox, select the module to use.

It will turn blue to indicate that it is highlighted.

2. Under Applications, select an application, then press Start.

To start the Power Meter or Probe application:

From Main Menu, press Power Meter or Probe.

Broadband Source 11

Page 16

Setting Up and Operating the Broadband Source

Display

pane

Control

Center

Function

Ta bs

Starting Module Applications

The main window (shown below) contains all the commands required to

control the Broadband Source:

12 FTB-2200

Page 17

Setting Up and Operating the Broadband Source

Cleaning and Connecting Optical Fibers

Cleaning and Connecting Optical Fibers

IMPORTANT

To ensure maximum power and to avoid erroneous readings:

Always inspect fiber ends and make sure that they are clean as

explained below before inserting them into the port. EXFO is

not responsible for damage or errors caused by bad fiber

cleaning or handling.

Ensure that your patchcord has appropriate connectors. Joining

mismatched connectors will damage the ferrules.

To connect the fiber-optic cable to the port:

1. Inspect the fiber using a fiber inspection microscope. If the fiber is

clean, proceed to connecting it to the port. If the fiber is dirty, clean it as

explained below.

2. Clean the fiber ends as follows:

2a. Gently wipe the fiber end with a lint-free swab dipped in isopropyl

alcohol.

2b. Use compressed air to dry completely.

2c. Visually inspect the fiber end to ensure its cleanliness.

Broadband Source 13

Page 18

Setting Up and Operating the Broadband Source

Cleaning and Connecting Optical Fibers

3. Carefully align the connector and port to prevent the fiber end from

touching the outside of the port or rubbing against other surfaces.

If your connector features a key, ensure that it is fully fitted into the

port’s corresponding notch.

4. Push the connector in so that the fiber-optic cable is firmly in place,

thus ensuring adequate contact.

If your connector features a screwsleeve, tighten the connector

enough to firmly maintain the fiber in place. Do not overtighten, as this

will damage the fiber and the port.

Note: If your fiber-optic cable is not properly aligned and/or connected, you will

notice heavy loss and reflection.

EXFO uses good quality connectors in compliance with EIA-455-21A

standards.

To keep connectors clean and in good condition, EXFO strongly

recommends inspecting them with a fiber inspection probe before

connecting them. Failure to do so will result in permanent damage to the

connectors and degradation in measurements.

14 FTB-2200

Page 19

Setting Up and Operating the Broadband Source

Bare metal

(or blue border)

indicates UPC

option

Green border

indicates APC

option

2 3 4

Installing the EXFO Universal Interface (EUI)

Installing the EXFO Universal Interface (EUI)

The EUI fixed baseplate is available for connectors with angled (APC) or

non-angled (UPC) polishing. A green border around the baseplate

indicates that it is for APC-type connectors.

To install an EUI connector adapter onto the EUI baseplate:

1. Hold the EUI connector adapter so the dust cap opens downwards.

2. Close the dust cap in order to hold the connector adapter more firmly.

3. Insert the connector adapter into the baseplate.

4. While pushing firmly, turn the connector adapter clockwise on the

baseplate to lock it in place.

Broadband Source 15

Page 20

Setting Up and Operating the Broadband Source

Activating or Deactivating Light Emission

Activating or Deactivating Light Emission

Before activating the source, read the Safety Information on page 3.

Note: You should let the source warm up for 30 minutes to obtain optimum

wavelength stability.

To activate or deactivate light emission:

Select ON to activate the light emission. The ACTIVE LED on the

module’s front panel lights up, indicating that the source is active. The

data display lights up and two red arrows appear beside the status

indicator on the data display, indicating that the source is on.

Select OFF to deactivate the light emission. The ACTIVE LED on the

module’s front panel turns off, indicating that the source is off. The

status indicator on the data display is dimmed and the two red arrows

disappear from the data display.

16 FTB-2200

Page 21

4 Maintenance

To help ensure long, trouble-free operation:

Always inspect fiber-optic connectors before using them and clean

them if necessary.

Keep the unit free of dust.

Clean the unit casing and front panel with a cloth slightly dampened

with water.

Store unit at room temperature in a clean and dry area. Keep the unit

out of direct sunlight.

Avoid high humidity or significant temperature fluctuations.

Avoid unnecessary shocks and vibrations.

If any liquids are spilled on or into the unit, turn off the power

immediately, disconnect from any external power source, remove the

batteries and let the unit dry completely.

The use of controls, adjustments and procedures, namely for

operation and maintenance, other than those specified herein may

result in hazardous radiation exposure or impair the protection

provided by this unit.

WARNING

Broadband Source 17

Page 22

Maintenance

Cleaning Fixed Connectors

Cleaning Fixed Connectors

Regular cleaning of connectors will help maintain optimum performance.

Do not try to disassemble the unit. Doing so would break the connector.

Looking into the optical connector while the light source is active

WILL result in permanent eye damage. EXFO strongly recommends

to TURN OFF the unit before proceeding with the cleaning

procedure.

To clean fixed connectors:

1. Fold a lint-free wiping cloth in four to form a square.

2. Moisten the center of the lint-free wiping cloth with only one drop of

isopropyl alcohol.

Alcohol may leave traces if used abundantly. Avoid contact between

the tip of the bottle and the wiping cloth, and do not use bottles

that distribute too much alcohol at a time.

WARNING

IMPORTANT

3. Gently wipe the connector threads three times with the folded and

moistened section of the wiping cloth.

IMPORTANT

Isopropyl alcohol takes approximately ten seconds to evaporate.

Since isopropyl alcohol is not absolutely pure, evaporation will

leave microscopic residue. Make sure you dry the surfaces before

evaporation occurs.

4. With a dry lint-free wiping cloth, gently wipe the same surfaces three

times with a rotating movement.

18 FTB-2200

Page 23

Maintenance

7

8

9

Cleaning Fixed Connectors

5. Throw out the wiping cloths after one use.

6. Moisten a cleaning tip (2.5 mm tip) with only one drop of isopropyl

alcohol.

IMPORTANT

Alcohol may leave traces if used abundantly. Avoid contact between

the tip of the bottle and the cleaning tip, and do not use bottles

that distribute too much alcohol at a time.

7. Slowly insert the cleaning tip into the connector until it reaches the

ferrule inside (a slow clockwise rotating movement may help).

8. Gently turn the cleaning tip one full turn.

9. Continue to turn as you withdraw the cleaning tip.

10. Repeat steps 7 to 9, but this time with a dry cleaning tip (2.5 mm tip

provided by EXFO).

Note: Make sure you don’t touch the soft end of the cleaning tip and verify the

cleanliness of the cotton tip.

11. Throw out the cleaning tips after one use.

Broadband Source 19

Page 24

Maintenance

Push

Tur n

Pull

Cleaning EUI Connectors

Cleaning EUI Connectors

Regular cleaning of EUI connectors will help maintain optimum

performance. There is no need to disassemble the unit.

If any damage occurs to internal connectors, the module casing will

have to be opened and a new calibration will be required.

Looking into the optical connector while the light source is active

WILL result in permanent eye damage. EXFO strongly recommends

to TURN OFF the unit before proceeding with the cleaning

procedure.

To clean EUI connectors:

1. Remove the EUI from the instrument to expose the connector

baseplate and ferrule.

IMPORTANT

WARNING

2. Moisten a 2.5 mm cleaning tip with one drop of isopropyl alcohol

(alcohol may leave traces if used abundantly).

3. Slowly insert the cleaning tip into the EUI adapter until it comes out on

the other side (a slow clockwise rotating movement may help).

20 FTB-2200

Page 25

Cleaning EUI Connectors

3

4

5

4. Gently turn the cleaning tip one full turn, then continue to turn as you

withdraw it.

5. Repeat steps 3 to 4 with a dry cleaning tip.

Note: Make sure you don’t touch the soft end of the cleaning tip.

6. Clean the ferrule in the connector port as follows:

6a. Deposit one drop of isopropyl alcohol on a lint-free wiping cloth.

IMPORTANT

Isopropyl alcohol may leave residues if used abundantly or left to

evaporate (about 10 seconds).

Maintenance

Avoid contact between the tip of the bottle and the wiping cloth,

and dry the surface quickly.

6b. Gently wipe the connector and ferrule.

6c. With a dry lint-free wiping cloth, gently wipe the same surfaces to

ensure that the connector and ferrule are perfectly dry.

6d. Verify connector surface with a portable fiber-optic microscope

(for example, EXFO’s FOMS) or fiber inspection probe (for

example, EXFO’s FIP).

7. Put the EUI back onto the instrument (push and turn clockwise).

8. Throw out cleaning tips and wiping cloths after one use.

Broadband Source 21

Page 26

Maintenance

Recalibrating the Unit

Recalibrating the Unit

EXFO manufacturing and service center calibrations are based on the

ISO/IEC 17025 standard (General Requirements for the Competence of

Testing and Calibration Laboratories). This standard states that calibration

documents must not contain a calibration interval and that the user is

responsible for determining the re-calibration date according to the actual

use of the instrument.

The validity of specifications depends on operating conditions. For

example, the calibration validity period can be longer or shorter depending

on the intensity of use, environmental conditions and unit maintenance, as

well as the specific requirements for your application. All of these elements

must be taken into consideration when determining the appropriate

calibration interval of this particular EXFO unit.

Under normal use, the recommended interval for your FTB-2200

Broadband Source is: one year.

For newly delivered units, EXFO has determined that the storage of this

product for up to six months between calibration and shipment does not

affect its performance (EXFO Policy PL-03).

22 FTB-2200

Page 27

Maintenance

Recycling and Disposal (Applies to European Union Only)

To help you with calibration follow-up, EXFO provides a special calibration

label that complies with the ISO/IEC 17025 standard and indicates the unit

calibration date and provides space to indicate the due date. Unless you

have already established a specific calibration interval based on your own

empirical data and requirements, EXFO would recommend that the next

calibration date be established according to the following equation:

Next calibration date = Date of first usage (if less than six months

after the calibration date) + Recommended calibration period (one

year)

To ensure that your unit conforms to the published specifications,

calibration may be carried out at an EXFO service center or, depending on

the product, at one of EXFO’s certified service centers. Calibrations at

EXFO are performed using standards traceable to national metrology

institutes.

Note: You may have purchased a FlexCare plan that covers calibrations. See the

Service and Repairs section of this user documentation for more

information on how to contact the service centers and to see if your plan

qualifies.

Recycling and Disposal

(Applies to European Union Only)

For complete recycling/disposal information as per European Directive

WEEE 2012/19/UE, visit the EXFO Web site at www.exfo.com/recycle.

Broadband Source 23

Page 28

Page 29

5 Troubleshooting

Solving Common Problems

Problem Possible Cause Solution

Source appears unstable. Insufficient

stabilization time.

Reflection

destabilizing the

source.

Ambient

temperature is

varying.

Wait a minimum

of 30 minutes for

optimum

stabilization.

Connect the

source using an

optical isolator.

Control ambient

temperature.

Broadband Source 25

Page 30

Troubleshooting

Obtaining Online Help

Obtaining Online Help

An online version of the FTB-2200 Broadband Source user guide is

conveniently available at all times from the application.

Note: You will also find a printable PDF version on your installation DVD.

To access online help:

Click the Help button on the function bar.

26 FTB-2200

Page 31

Troubleshooting

Contacting the Technical Support Group

Contacting the Technical Support Group

To obtain after-sales service or technical support for this product, contact

EXFO at one of the following numbers. The Technical Support Group is

available to take your calls from Monday to Friday, 8:00 a.m. to 7:00 p.m.

(Eastern Time in North America).

Technical Support Group

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

For detailed information about technical support, and for a list of other

worldwide locations, visit the EXFO Web site at www.exfo.com.

If you have comments or suggestions about this user documentation, you

can send them to customer.feedback.manual@exfo.com.

To accelerate the process, please have information such as the name and

the serial number (see the product identification label), as well as a

description of your problem, close at hand.

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

support@exfo.com

Broadband Source 27

Page 32

Troubleshooting

Transportation

You may also be requested to provide software and module version

numbers. This information, as well as technical support contact

information, can be found in the About function tab.

Select the Technical Support tab to view phone numbers and active

Select the Module Information tab to view the module identification,

Internet links to EXFO’s Technical Support Group. Use these links to

send an information request by e-mail or to access EXFO’s web site.

serial number and firmware version.

Transportation

Maintain a temperature range within specifications when transporting the

unit. Transportation damage can occur from improper handling. The

following steps are recommended to minimize the possibility of damage:

Pack the unit in its original packing material when shipping.

Avoid high humidity or large temperature fluctuations.

Keep the unit out of direct sunlight.

Avoid unnecessary shocks and vibrations.

28 FTB-2200

Page 33

6 Warranty

General Information

EXFO Inc. (EXFO) warrants this equipment against defects in material and

workmanship for a period of one year from the date of original shipment.

EXFO also warrants that this equipment will meet applicable specifications

under normal use.

During the warranty period, EXFO will, at its discretion, repair, replace,

or issue credit for any defective product, as well as verify and adjust the

product free of charge should the equipment need to be repaired or if the

original calibration is erroneous. If the equipment is sent back for

verification of calibration during the warranty period and found to meet all

published specifications, EXFO will charge standard calibration fees.

The warranty can become null and void if:

unit has been tampered with, repaired, or worked upon by

unauthorized individuals or non-EXFO personnel.

warranty sticker has been removed.

IMPORTANT

case screws, other than those specified in this guide, have been

removed.

case has been opened, other than as explained in this guide.

unit serial number has been altered, erased, or removed.

unit has been misused, neglected, or damaged by accident.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED,

IMPLIED, OR STATUTORY, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL EXFO BE LIABLE FOR

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

Broadband Source 29

Page 34

Warranty

Liability

Liability

EXFO shall not be liable for damages resulting from the use of the product,

nor shall be responsible for any failure in the performance of other items to

which the product is connected or the operation of any system of which

the product may be a part.

EXFO shall not be liable for damages resulting from improper usage or

unauthorized modification of the product, its accompanying accessories

and software.

Exclusions

EXFO reserves the right to make changes in the design or construction of

any of its products at any time without incurring obligation to make any

changes whatsoever on units purchased. Accessories, including but not

limited to fuses, pilot lamps, batteries and universal interfaces (EUI) used

with EXFO products are not covered by this warranty.

This warranty excludes failure resulting from: improper use or installation,

normal wear and tear, accident, abuse, neglect, fire, water, lightning or

other acts of nature, causes external to the product or other factors beyond

the control of EXFO.

IMPORTANT

In the case of products equipped with optical connectors, EXFO will

charge a fee for replacing connectors that were damaged due to

misuse or bad cleaning.

Certification

EXFO certifies that this equipment met its published specifications at the

time of shipment from the factory.

30 FTB-2200

Page 35

Warranty

Service and Repairs

Service and Repairs

EXFO commits to providing product service and repair for five years

following the date of purchase.

To send any equipment for service or repair:

1. Call one of EXFO’s authorized service centers (see EXFO Service

Centers Worldwide on page 32). Support personnel will determine if

the equipment requires service, repair, or calibration.

2. If equipment must be returned to EXFO or an authorized service

center, support personnel will issue a Return Merchandise

Authorization (RMA) number and provide an address for return.

3. If possible, back up your data before sending the unit for repair.

4. Pack the equipment in its original shipping material. Be sure to include

a statement or report fully detailing the defect and the conditions under

which it was observed.

5. Return the equipment, prepaid, to the address given to you by support

personnel. Be sure to write the RMA number on the shipping slip. EXFO

will refuse and return any package that does not bear an RMA number.

Note: A test setup fee will apply to any returned unit that, after test, is found to

meet the applicable specifications.

After repair, the equipment will be returned with a repair report. If the

equipment is not under warranty, you will be invoiced for the cost

appearing on this report. EXFO will pay return-to-customer shipping costs

for equipment under warranty. Shipping insurance is at your expense.

Routine recalibration is not included in any of the warranty plans. Since

calibrations/verifications are not covered by the basic or extended

warranties, you may elect to purchase FlexCare Calibration/Verification

Packages for a definite period of time. Contact an authorized service center

(see EXFO Service Centers Worldwide on page 32).

Broadband Source 31

Page 36

Warranty

EXFO Service Centers Worldwide

EXFO Service Centers Worldwide

If your product requires servicing, contact your nearest authorized service

center.

EXFO Headquarters Service Center

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

EXFO Europe Service Center

Winchester House, School Lane

Chandlers Ford, Hampshire S053 4DG

ENGLAND

EXFO Telecom Equipment

(Shenzhen) Ltd.

3rd Floor, Building 10,

Yu Sheng Industrial Park (Gu Shu

Crossing), No. 467,

National Highway 107,

Xixiang, Bao An District,

Shenzhen, China, 518126

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

support@exfo.com

Tel.: +44 2380 246800

Fax: +44 2380 246801

support.europe@exfo.com

Tel: +86 (755) 2955 3100

Fax: +86 (755) 2955 3101

support.asia@exfo.com

32 FTB-2200

Page 37

Index

Index

A

About function tab ..................................... 28

activating source ......................................... 16

after-sales service ........................................ 27

application

contacting EXFO support from .............. 28

application, starting .................................... 11

C

caution

of personal hazard................................... 2

of product hazard.................................... 2

certification information ...............................iv

cleaning

EUI connectors....................................... 20

fiber ends .............................................. 13

fixed connectors .................................... 18

front panel............................................. 17

connectors, cleaning ............................. 18, 20

contact information, EXFO .......................... 28

conventions, safety ....................................... 2

customer service.................................... 28, 31

D

deactivating source ..................................... 16

detecting module.......................................... 8

E

equipment returns ...................................... 31

EUI

baseplate ............................................... 15

connector adapter ................................. 15

dust cap................................................. 15

EUI connectors, cleaning ............................. 20

EXFO support e-mail ................................... 28

EXFO universal interface. see EUI

EXFO Web site............................................. 28

F

fiber ends, cleaning ..................................... 13

firmware version, module............................ 28

front panel, cleaning ................................... 17

H

help. see online user guide

I

identification label....................................... 27

inserting a module ........................................ 5

L

label, identification...................................... 27

M

maintenance

EUI connectors....................................... 20

fixed connectors .................................... 18

front panel............................................. 17

general information ............................... 17

module

detection ................................................. 8

insertion................................................... 5

removal.................................................... 5

module information

firmware version number....................... 28

module identification number ...............28

serial number......................................... 28

mounting EUI connector adapter ................ 15

O

online user guide......................................... 26

Broadband Source 33

Page 38

Index

P

PDF. see online user guide

product

identification label................................. 27

R

removing a module ....................................... 5

return merchandise authorization (RMA) .... 31

S

safety

caution .................................................... 2

conventions ............................................. 2

warning ................................................... 2

serial number, module ................................ 28

service and repairs....................................... 31

service centers............................................. 32

shipping to EXFO ........................................ 31

software. see application

source

turning off............................................. 16

turning on ............................................. 16

storage requirements .................................. 17

symbols, safety.............................................. 2

W

warranty

certification............................................ 30

exclusions .............................................. 30

general................................................... 29

liability ................................................... 30

null and void.......................................... 29

T

technical support .................................. 27, 28

temperature for storage.............................. 17

transportation requirements ................. 17, 28

turning off source ....................................... 16

turning on source........................................ 16

U

user guide. see online user guide

34 FTB-2200

Page 39

NOTICE

抩⛙

CHINESE REGULATION ON RESTRICTION OF HAZARDOUS SUBSTANCES

₼⦌␂ℝ☀⹂䓸德棟Ⓟ䤓屓⸩

NAMES AND CONTENTS OF THE TOXIC OR HAZARDOUS SUBSTANCES OR ELEMENTS

CONTAINED IN THIS EXFO PRODUCT

▔⚺⦷㦻 EXFO ℶ❐₼䤓㦘㹡㦘⹂䓸德㒥⏒侯䤓⚜䱿✛⚺摞

O

Indicates that this toxic or hazardous substance contained in all of the homogeneous

materials for this part is below the limit requirement in SJ/T11363-2006

嫷䯉年㦘㹡㦘⹂䓸德⦷年捷ↅ㓏㦘⧖德㧟㠨₼䤓⚺摞⧖⦷ SJ/T11363-2006 㪖屓⸩䤓

棟摞尐㻑ⅴₚᇭ

X

Indicates that this toxic or hazardous substance contained in at least one of the homogeneous

materials used for this part is above the limit requirement in SJ/T11363-2006

嫷䯉年㦘㹡㦘⹂䓸德咂⺠⦷年捷ↅ䤓㩟⧖德㧟㠨₼䤓⚺摞怔⒉ SJ/T11363-2006 㪖

屓⸩䤓棟摞尐㻑ᇭ

Part Name

捷ↅ⚜䱿

Toxic or hazardous Substances and Elements

㦘㹡㦘⹂䓸德✛⏒侯

Lead

杔

(Pb)

Mercury

㻭

(Hg)

Cadmium

椣

(Cd)

Hexavalent

Chromium

⏼ↆ杻

(Cr VI)

Pol yb ro mi na te d

biphenyls

⮩䅃勣啾

(PBB)

Polybrominated

diphenyl ethers

⮩䅃ℛ啾搩

(PBDE)

Enclosure

⮥⮂

OO O O O O

Electronic and

electrical

sub-assembly

䟄✛䟄兓ↅ

XO X O X X

Optical

sub-assembly

a

⏘ⷵ兓ↅ

a

a. If applicable.

Ⱁ㨫抑䞷ᇭ

XO O O O O

Mechanical

sub-assembly

a

㧉㬿兓ↅ

a

OO O O O O

Page 40

MARKING REQUIREMENTS

㪖㽷尐㻑

Product

ℶ❐

Environmental protection use period (years)

䘾⬒≬㔳∎䞷㦮棟 ( )

Logo

㪖㉦

This Exfo product

㦻 EXFO ℶ❐

10

Battery

a

䟄㻯

a

a. If applicable.

Ⱁ㨫抑䞷ᇭ

5

Page 41

P/N: 1064485

www.EXFO.com · info@exfo.com

CORPORATE HEADQUARTERS 400 Godin Avenue Quebec (Quebec) G1M 2K2 CANADA

Tel.: 1 418 683-0211 · Fax: 1 418 683-2170

EXFO AMERICA 3400 Waterview Parkway Suite 100 Richardson, TX 75080 USA

EXFO EUROPE Winchester House,

EXFO ASIA-PACIFIC 100 Beach Road,

EXFO CHINA Beijing Global Trade Center, Tower C,

EXFO SERVICE ASSURANCE 270 Billerica Road Chelmsford MA, 01824 USA

EXFO FINLAND Elektroniikkatie 2 FI-90590 Oulu, FINLAND

TOLL-FREE (USA and Canada) 1 800 663-3936

© 2014 EXFO Inc. All rights reserved.

Printed in Canada (2014-01)

School Lane

#25-01/03 Shaw Tower

Room 1207, 36 North Third Ring Road

East, Dongcheng District

Tel.: 1 972-761-927 · Fax: 1 972-761-9067

Chandlers Ford, Hampshire S053 4DG ENGLAND

Tel.: +44 2380 246 800 · Fax: +44 2380 246 801

SINGAPORE 189702

Tel.: +6563338241 · Fax: +6563338242

Beijing 100013 P. R. CHINA

Tel.: +86 (10) 5825 7755 · Fax: +86 (10) 5825 7722

Tel.: 1 978 367-5600 · Fax: 1 978 367-5700

Tel.: +358 (0) 403 010 300 · Fax: +358 (0) 8 564 5203

Loading...

Loading...