Page 1

FIP-400

Fiber Inspection Probe and ConnectorMax

User Guide

Page 2

Copyright © 2008–2014 EXFO Inc. All rights reserved. No part of this

publication may be reproduced, stored in a retrieval system or transmitted

in any form, be it electronically, mechanically, or by any other means such

as photocopying, recording or otherwise, without the prior written

permission of EXFO Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

Version number: 6.0.0

ii FIP-400

Page 3

Contents

Certification Information ........................................................................................................v

1 Introducing the FIP-400 Fiber Inspection Probe and ConnectorMax ........ 1

Probe ......................................................................................................................................1

Probe Tips ...............................................................................................................................2

FIP Viewer (Optional) ..............................................................................................................3

USB Adapter (Optional) ..........................................................................................................5

ConnectorMax Software .........................................................................................................6

Conventions ............................................................................................................................7

2 Safety Information ....................................................................................... 9

Other Safety Symbols on Your Unit .......................................................................................11

Electrical Safety Information .................................................................................................11

3 Setting up Your Fiber Inspection Probe and ConnectorMax ................... 13

Changing the Fiber Inspection Probe Tip ..............................................................................13

Adjusting Brightness and Contrast .......................................................................................14

Selecting the Mode of Operation ..........................................................................................15

Setting up Autonaming ........................................................................................................16

Identifying Fibers ..................................................................................................................19

Managing and Selecting Test Configurations (Optional) .......................................................24

Reverting to Factory Settings ................................................................................................31

4 Inspecting Fiber Ends ................................................................................. 33

Inspecting Fiber Ends with the FIP Viewer ............................................................................34

Inspecting Fiber Ends with ConnectorMax ............................................................................35

Capturing Images .................................................................................................................36

Retesting a Fiber ...................................................................................................................38

Saving Files ...........................................................................................................................39

Opening and Closing Files ....................................................................................................41

Analyzing Captures (Optional, Single-Fiber Connector Mode Only) ......................................42

Creating Reports ...................................................................................................................48

5 Maintenance ............................................................................................... 51

General Maintenance ............................................................................................................51

Charging the Battery in The FIP Viewer .................................................................................52

Replacing Batteries ...............................................................................................................52

Recycling and Disposal (Applies to European Union Only) ....................................................53

Fiber Inspection Probe iii

Page 4

6 Troubleshooting ..........................................................................................55

Contacting the Technical Support Group ..............................................................................56

Viewing Information about ConnectorMax ..........................................................................57

Viewing Online Help .............................................................................................................57

Transportation ......................................................................................................................58

7 Warranty ......................................................................................................59

General Information .............................................................................................................59

Liability .................................................................................................................................60

Exclusions .............................................................................................................................60

Certification ..........................................................................................................................60

Service and Repairs ...............................................................................................................61

EXFO Service Centers Worldwide ..........................................................................................62

A Technical Specifications ..............................................................................63

Software ...............................................................................................................................63

Video Inspection Probe .........................................................................................................64

Fiber Probe Viewer ................................................................................................................64

USB Converter ......................................................................................................................64

B Fiber Inspection Probe Tip Compatibility Chart .......................................65

Index .................................................................................................................67

iv FIP-400

Page 5

Certification Information

Certification Information

North America Regulatory Statement

This unit was certified by an agency approved in both Canada and the

United States of America. It has been evaluated according to applicable

North American approved standards for product safety for use in Canada

and the United States.

Electronic test and measurement equipment is exempt from FCC part 15,

subpart B compliance in the United States of America and from ICES-003

compliance in Canada. However, EXFO Inc. makes reasonable efforts to

ensure compliance to the applicable standards.

The limits set by these standards are designed to provide reasonable

protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance

with the user guide, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

Modifications not expressly approved by the manufacturer could void the

user's authority to operate the equipment.

European Community Declaration of Conformity

An electronic version of the declaration of conformity for your product is

available on our website at www.exfo.com. Refer to the product’s page on

the Web site for details.

Fiber Inspection Probe v

Page 6

Page 7

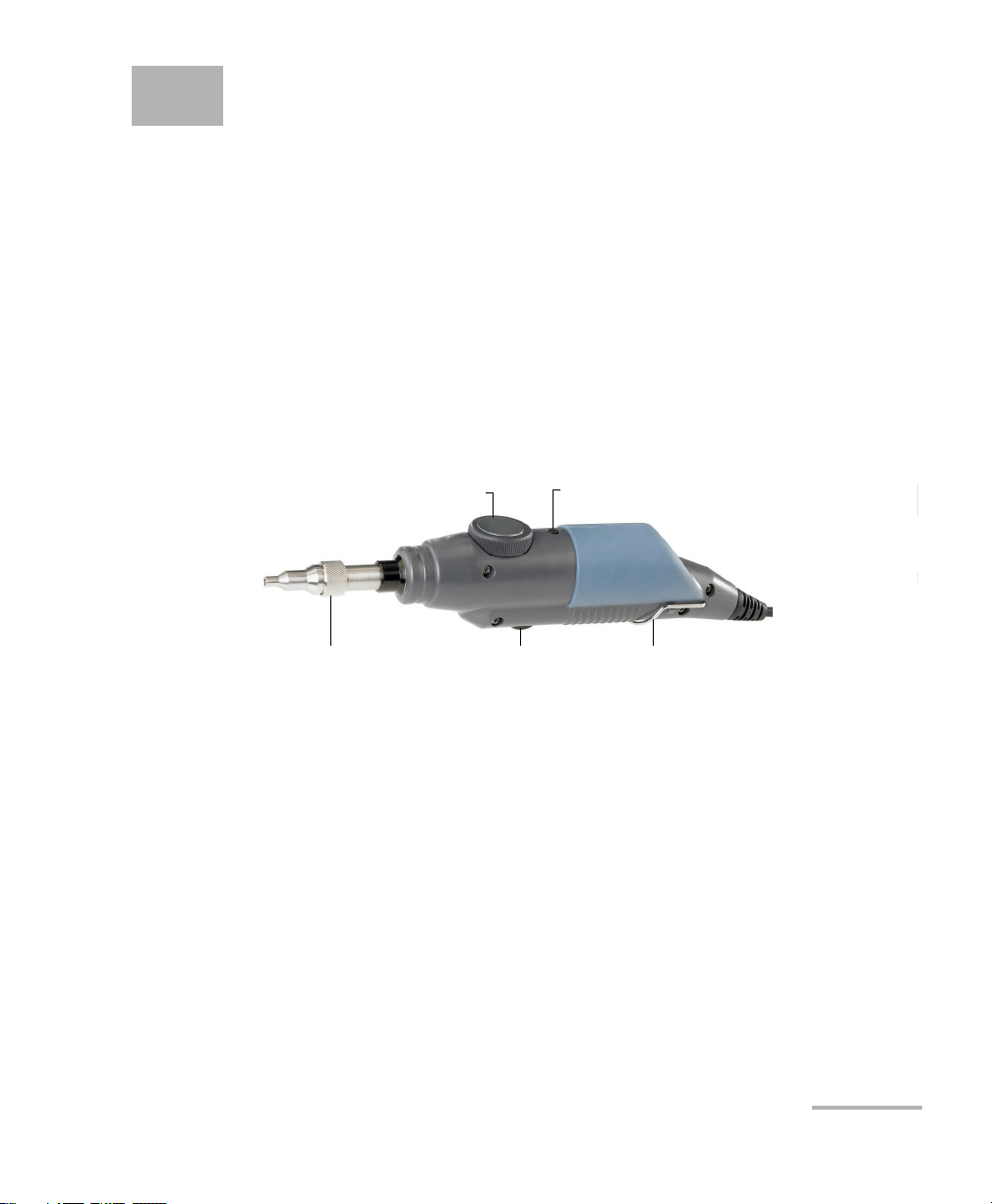

1 Introducing the FIP-400 Fiber

Focus knob

Retaining nut

Magnification button

(optional)

Fold out clip

Freeze/capture button

Inspection Probe and

ConnectorMax

The FIP-400 Fiber Inspection Probe is a portable video microscope used to

inspect fiber ends. Unlike traditional microscopes, the FIP-400 facilitates

the examination of patchcord connectors and also hard-to-reach

connectors on the back of patch panels and bulkhead adapters.

Probe

The FIP-400 is designed to be an intuitive, easy-to-use piece of equipment.

This video microscope is used for inspecting fiber ends.

The focus knob can be turned in either direction to focus the image.

The magnification button allows you to shift between two levels of

magnification.

The freeze/capture button is used together with the EXFO USB adapter

and your unit or computer. It allows you to capture an image, perform

an analysis, save a file or return to the Live video mode.

The retaining nut holds tips securely in place, ensuring they are always

fastened in the correct position.

The fold out clip at the back of the probe allows you to hang the probe

when you are not using it.

The probe comes equipped with a protective cap that fits over basic tips;

therefore, you do not need to remove the tip before putting the cap on.

Fiber Inspection Probe 1

Page 8

Introducing the FIP-400 Fiber Inspection Probe and ConnectorMax

Probe Tips

Probe Tips

The FIP-400 comes with two interchangeable tips but other models are

also available.

The tips included with the Fiber Inspection Probe are used to inspect flat

polish (PC) 2.5 mm connectors. One tip is for inspecting patchcords

(pigtails, male connectors) for SC, FC, and ST connectors. The other tip is

for examining SC and FC bulkhead adapters or patch panel adapters

(female).

Other tip models are available for various bulkhead adapters and

patchcord connectors including multifiber types. For more information

about tips and their use, see Fiber Inspection Probe Tip Compatibility Chart

on page 65, or visit the EXFO Web site.

2 FIP-400

Page 9

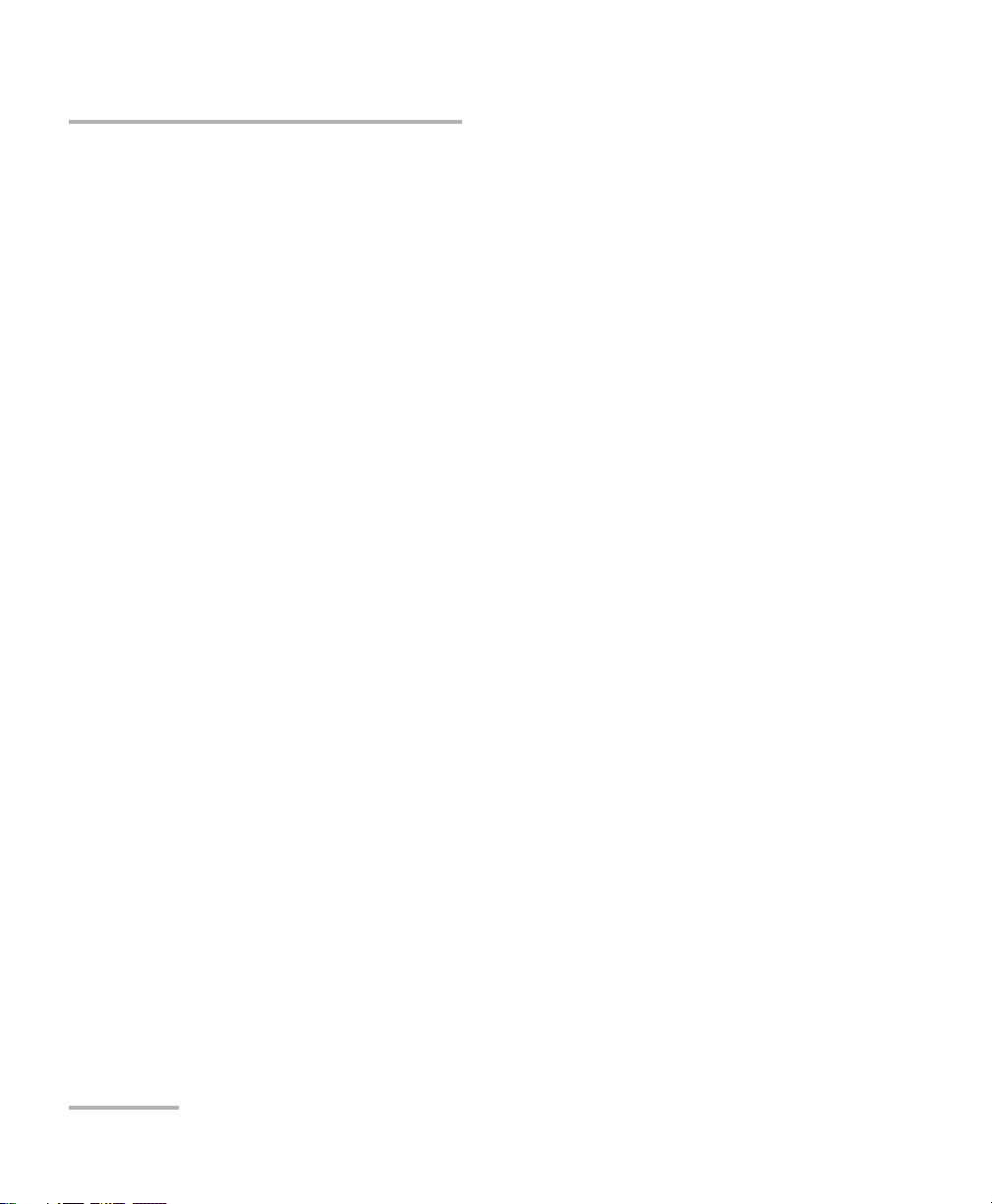

Introducing the FIP-400 Fiber Inspection Probe and ConnectorMax

On/Off button

AC charger/adapter connector

(indoor use only)

Probe connector

Contrast and

brightness keys

Battery status LED

Operation status LED

Stand

FIP Viewer (Optional)

FIP Viewer (Optional)

You can use the FIP Viewer with your Fiber Inspection Probe to inspect a

fiber end. The unit operates with an AC charger/adapter or a

lithium-ion battery.

IMPORTANT

The FIP Viewer is a standalone unit and does not work with

ConnectorMax.

Fiber Inspection Probe 3

Page 10

Introducing the FIP-400 Fiber Inspection Probe and ConnectorMax

FIP Viewer (Optional)

The two LEDs located on the front of the FIP Viewer provides you with the

status of your unit.

Operation status LED

LED Status

Green Probe connected

Flashing red Probe not connected

Battery status LED

LED Status

Green Full battery and AC

charger/adapter connected

Flashing green Charging battery

Yellow Low battery

Red Battery error

Note: If the battery is not full, the AC charger/adapter can support the operation

and charge the battery at the same time.

4 FIP-400

Page 11

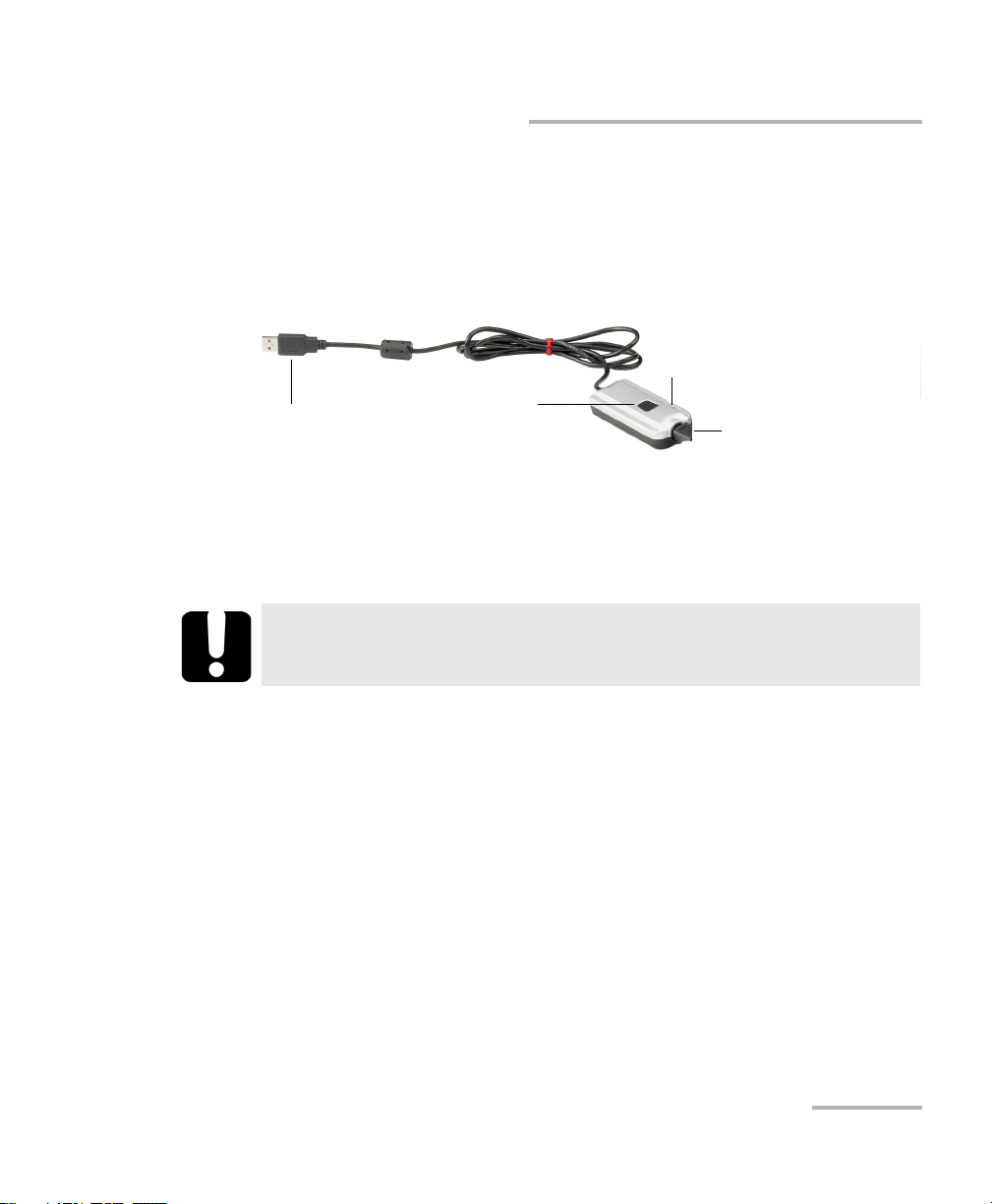

Introducing the FIP-400 Fiber Inspection Probe and ConnectorMax

Probe connector

USB connector

Capture button

Operation status LED

USB Adapter (Optional)

USB Adapter (Optional)

The USB adapter is used to connect the probe to a computer not equipped

with a 8-pin connector. It allows you to view probe images on your

computer screen. You can also capture and store these images on your

computer to document your work.

The Capture button on the USB adapter serves the same function as

the capture button on the probe.

The Status LED on the USB adapter will be green when the probe, USB

adapter, and computer are connected and the software is running.

IMPORTANT

The product supports USB 2.0 only. You cannot use it with USB 1.1.

Fiber Inspection Probe 5

Page 12

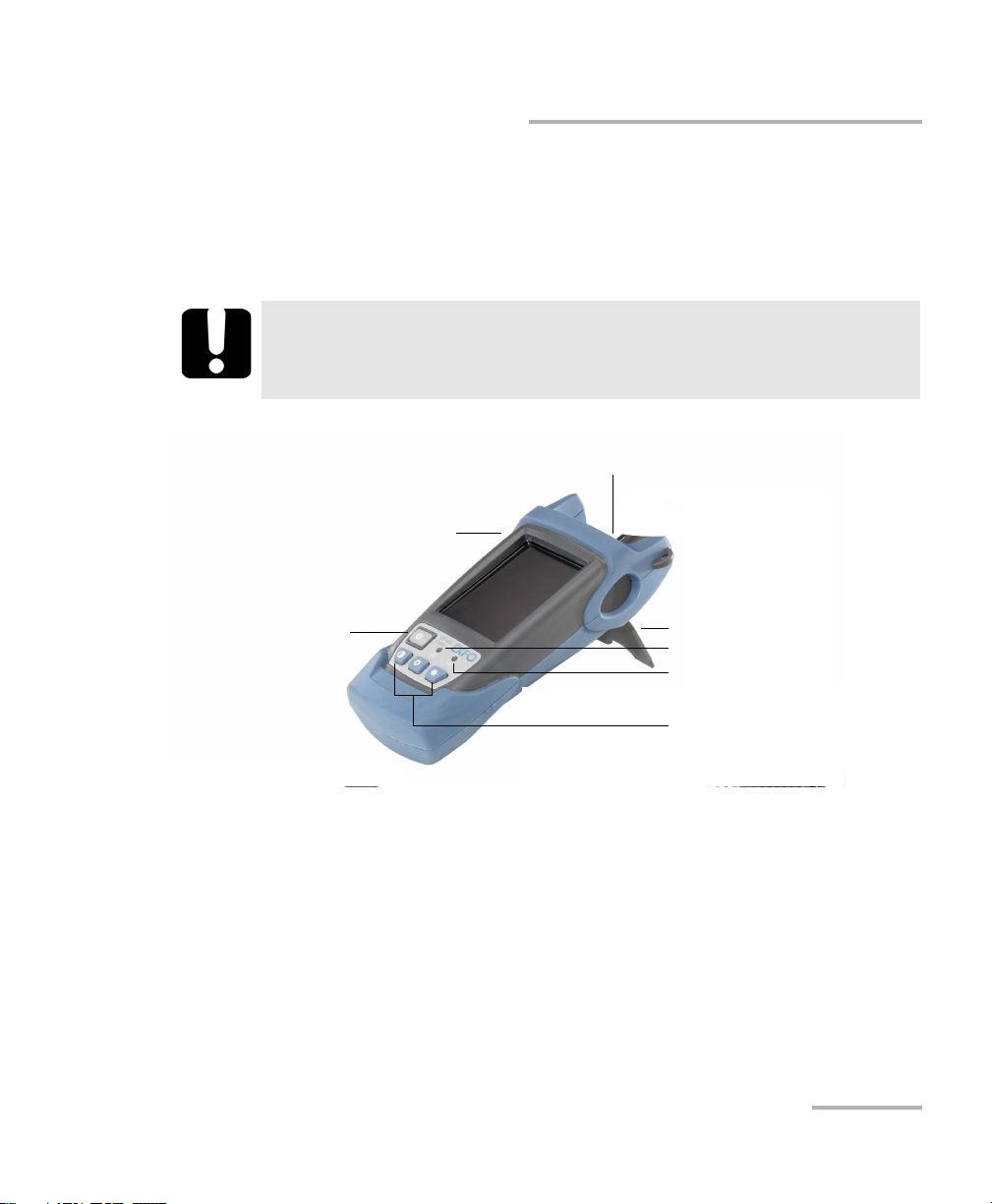

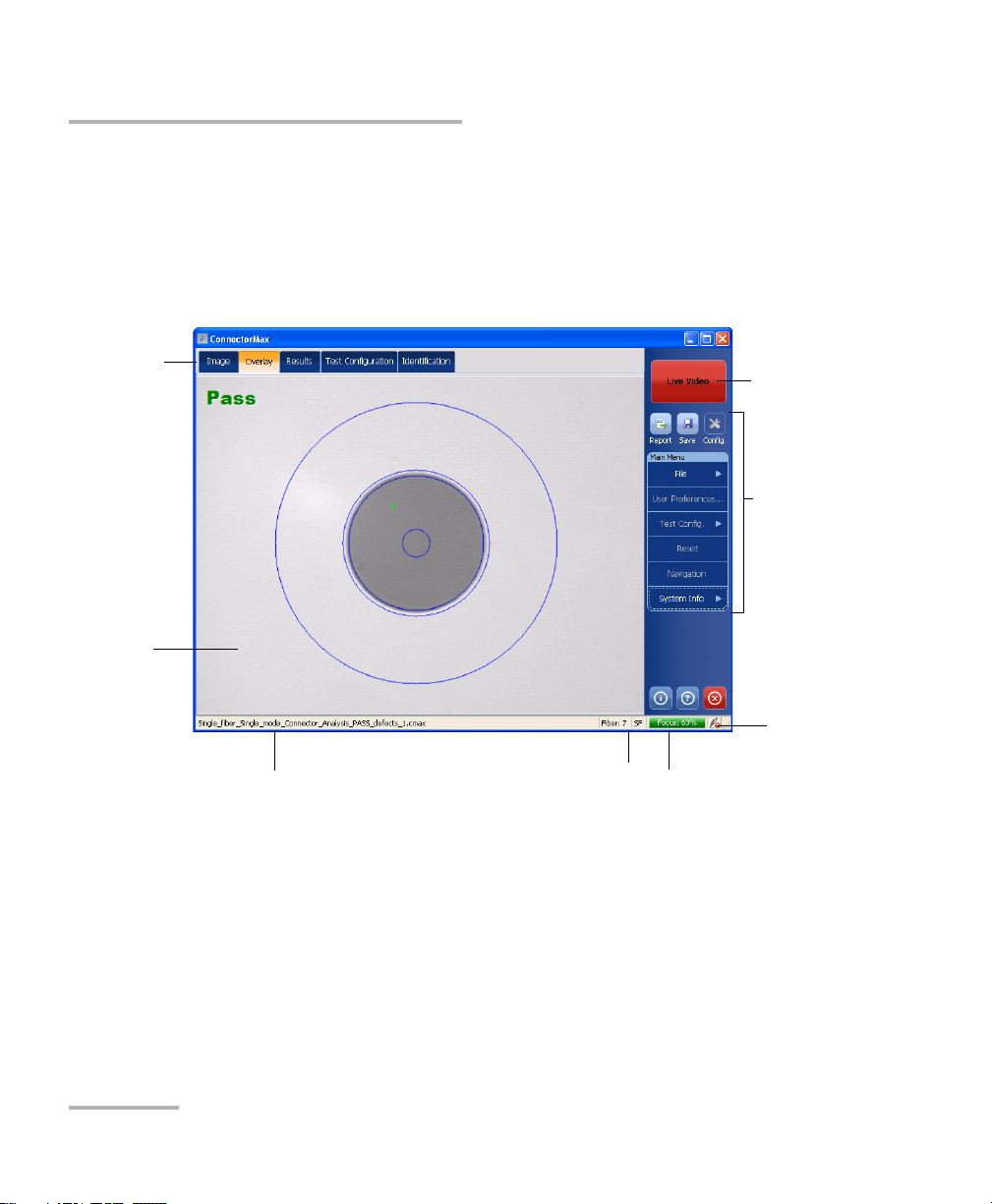

Introducing the FIP-400 Fiber Inspection Probe and ConnectorMax

Button bar

Viewing

area

File name preview (Capture

mode) or current test

configuration (Live mode)

Current (Capture

mode) or next (Live

mode) fiber index

Focus indicator

Probe

connection

status

Inspection

and analysis

tabs

Capture/Live

mode

button

ConnectorMax Software

ConnectorMax Software

ConnectorMax is the application used to view the fiber inspections. If you

have purchased the corresponding option, you can also use specific test

configurations and analyze the fibers automatically upon capturing a

picture.

6 FIP-400

Page 13

Introducing the FIP-400 Fiber Inspection Probe and ConnectorMax

Conventions

Conventions

Before using the product described in this guide, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

Note: The screen shots found in this user guide were made on a computer

running Microsoft Windows XP. The appearance of the application may

vary for other operating systems and platforms.

Fiber Inspection Probe 7

Page 14

Page 15

2 Safety Information

WARNING

Use only the listed and certified AC adapter/charger provided by

EXFO with your unit. It provides reinforced insulation between

primary and secondary, and is suitably rated for the country

where the unit is sold.

Use only accessories (such as the car outlet adapter, batteries,

and fiber inspection probe) designed for your unit and

approved by EXFO. For a complete list of accessories available

for your unit, refer to its technical specifications.

When you use the unit outdoors, ensure that it is protected

from liquids, dust, direct sunlight, precipitation, and full wind

pressure.

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

The use of controls, adjustments and procedures, namely for

operation and maintenance, other than those specified herein may

result in hazardous radiation exposure or impair the protection

provided by this unit.

IMPORTANT

When you see the following symbol on your unit , make sure

that you refer to the instructions provided in your user

documentation. Ensure that you understand and meet the required

conditions before using your product.

Fiber Inspection Probe 9

Page 16

Safety Information

Other safety instructions relevant for your product are located

throughout this documentation, depending on the action to

perform. Make sure to read them carefully when they apply to your

situation.

EXFO guarantees the specifications and viability of the products

ONLY if they are used with chargers and batteries provided by

EXFO.

IMPORTANT

CAUTION

10 FIP-400

Page 17

Safety Information

Other Safety Symbols on Your Unit

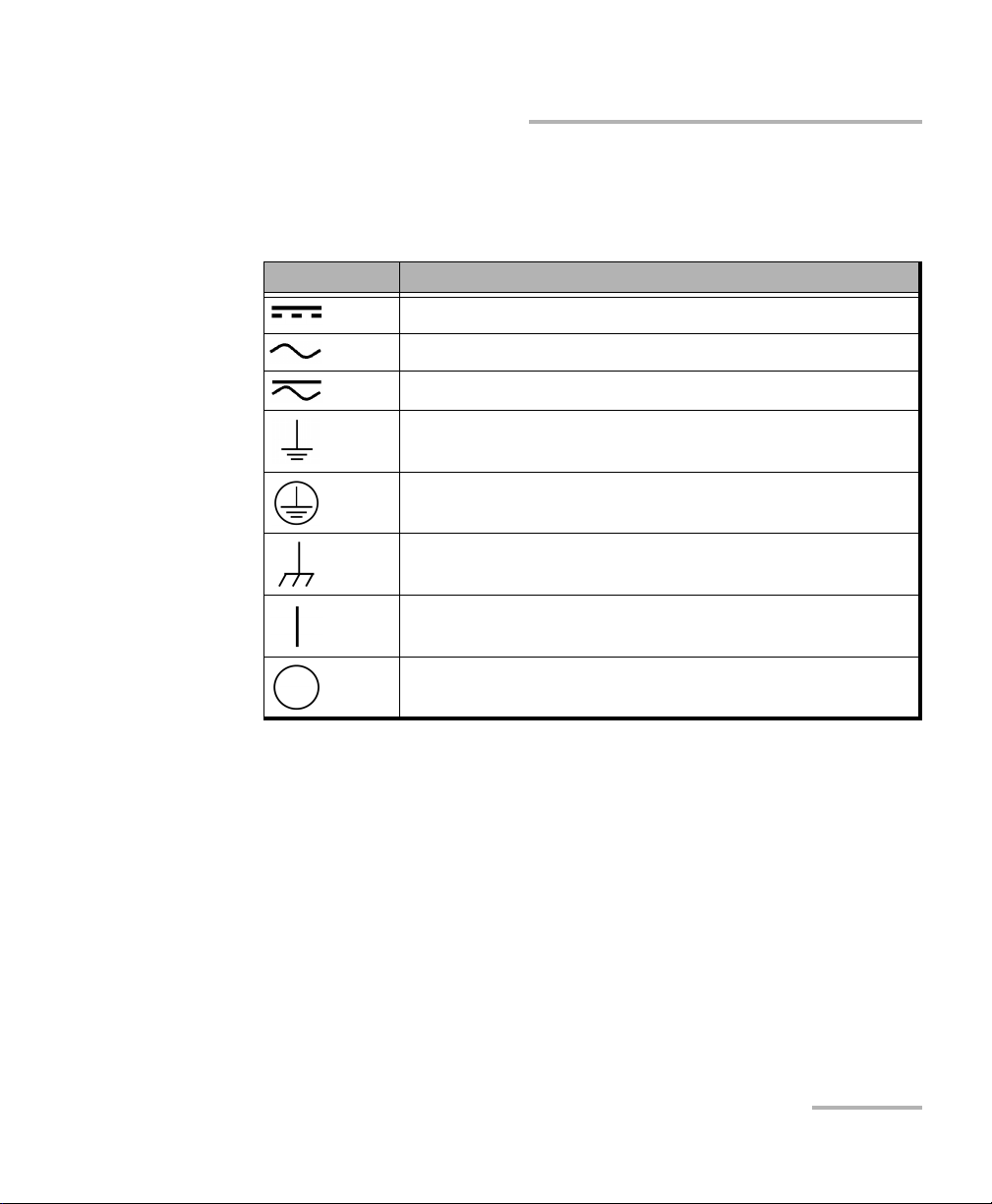

Other Safety Symbols on Your Unit

One or more of the following symbols may also appear on your unit.

Symbol Meaning

Direct current

Alternating current

Both direct and alternating current

The unit is equipped with an earth (ground) terminal.

The unit is equipped with a protective conductor terminal.

The unit is equipped with a frame or chassis terminal.

On (Power)

Off (Power)

Electrical Safety Information

If you need to ensure that the unit is completely turned off, disconnect the

power cable and remove the battery.

Fiber Inspection Probe 11

Page 18

Safety Information

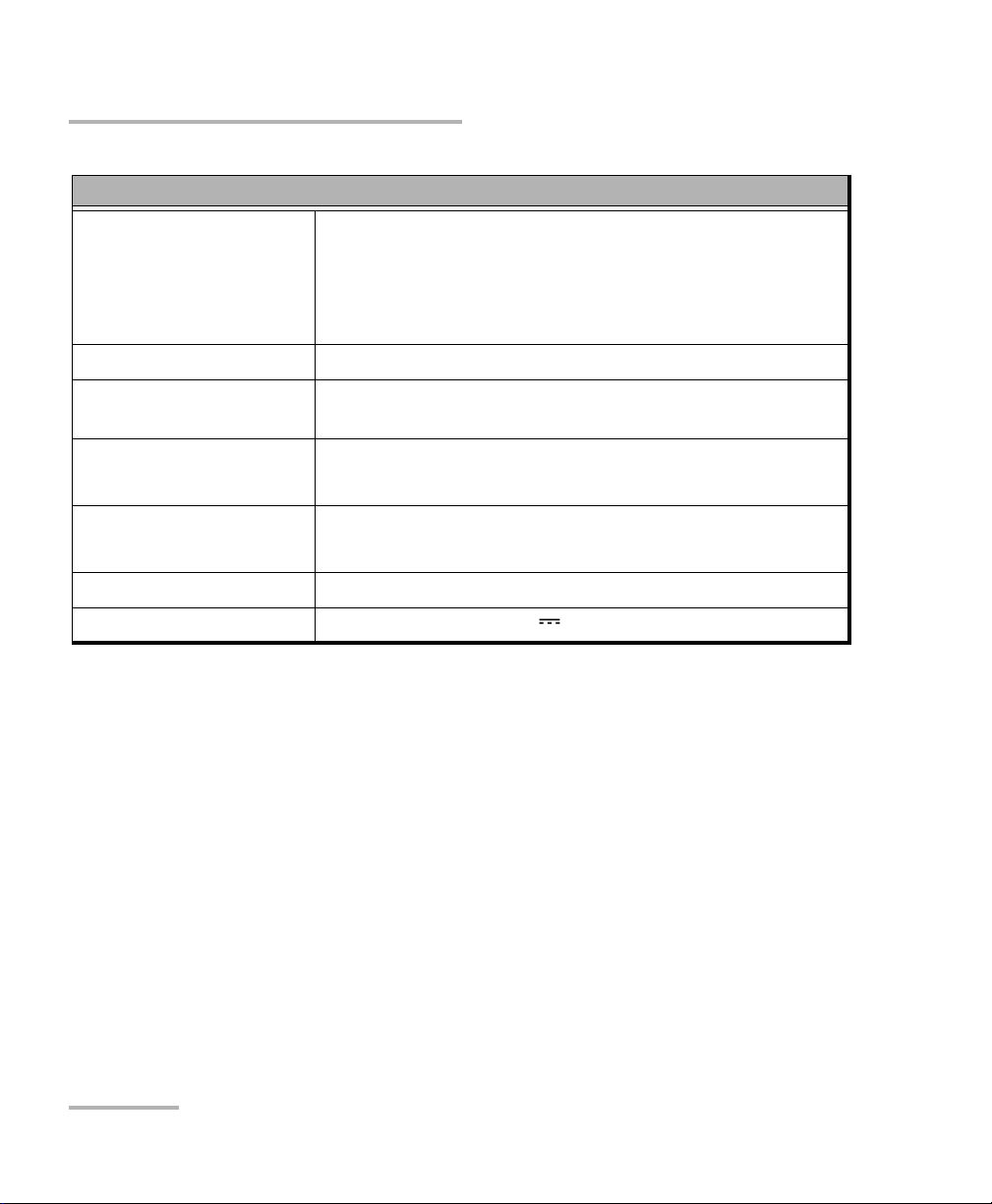

Electrical Safety Information

Equipment Ratings

Tem pe ra tu re

Operation

Storage

Battery operated: -10 °C to 50 °C (14 °F to 122 °F)

Charge mode: -10 °C to 40 °C (14 °F to 120 °F)

-40 °C to 70 °C (-40 °F to 158 °F)

Relative humidity unit: 95 % non-condensing

Maximum operation

2000 m (6562 ft)

altitude

Pollution degree

2 (unit connected to external power supply)

3 (unit operated from batteries)

b

a

Overvoltage category unit: I

AC adapter: II

Measurement category Not rated for measurement categories II, III or IV

Power supply rating 9V; 1A

a. Use the external power supply indoors only.

b. Equipment should be normally protected against exposure to direct sunlight, precipitations and full wind

pressure.

12 FIP-400

Page 19

3 Setting up Your Fiber

Inspection Probe and

ConnectorMax

You can change various settings in ConnectorMax such as the brightness

and contrast levels, default storage location, or automated file name. These

settings are stored for each user and kept for future work sessions.

Changing the Fiber Inspection Probe Tip

You can use various tips depending on the type of connector you are

inspecting. For more information about tips you can use, visit the EXFO

Web site at www.exfo.com.

To change a tip:

1. Untighten the tip’s retaining nut.

2. Remove the tip.

3. Insert a new tip.

4. Adjust the tip to the notch.

5. Retighten the retaining nut.

Fiber Inspection Probe 13

Page 20

Setting up Your Fiber Inspection Probe and ConnectorMax

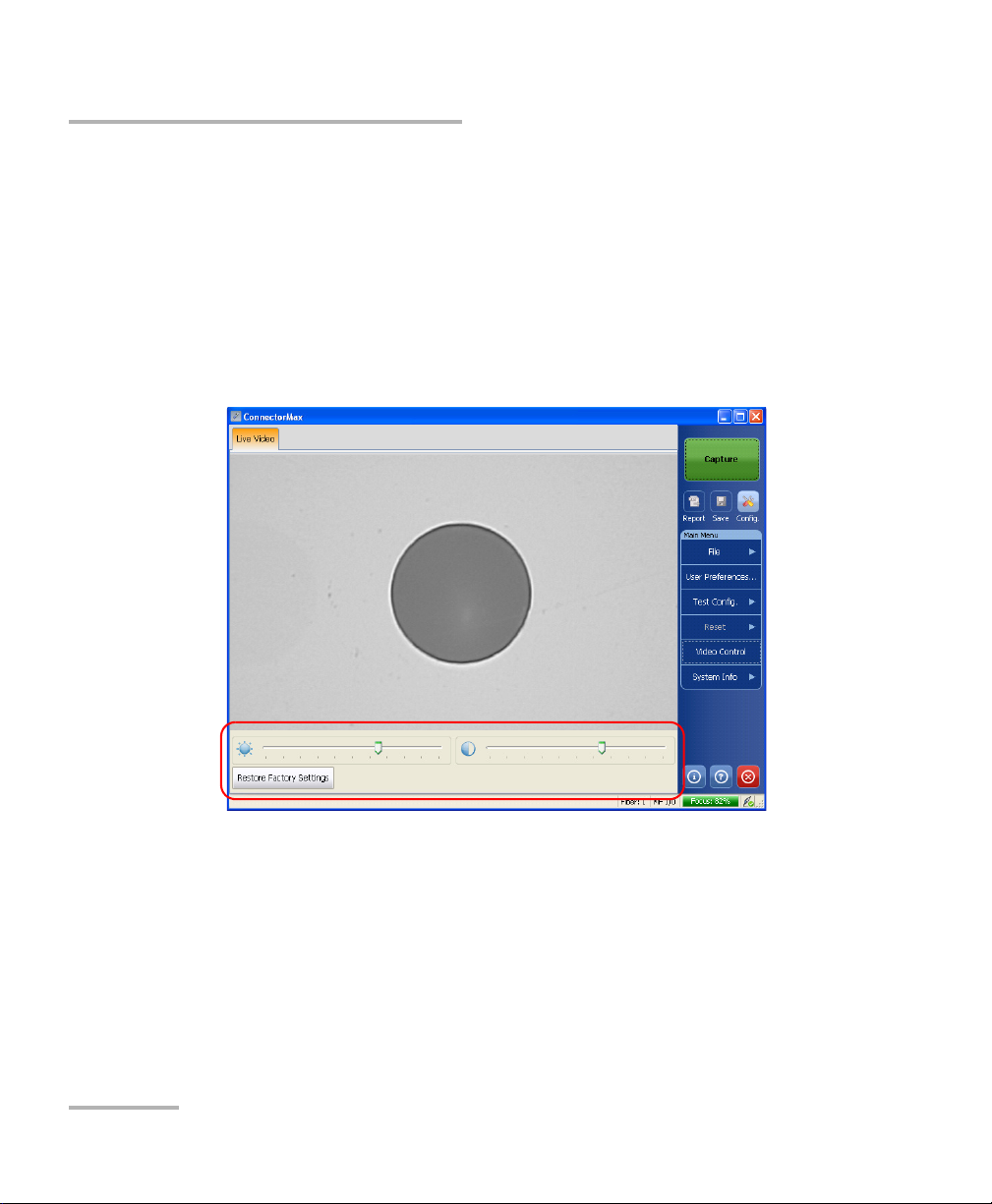

Adjusting Brightness and Contrast

Adjusting Brightness and Contrast

Once the probe is connected to a fiber, you can adjust brightness and

contrast in order to better view the fiber under inspection.

To adjust brightness or contrast:

1. From the main window, click Video Control.

2. Use the contrast and brightness sliders at the bottom of the viewing

area to set the levels to suit your needs.

3. Click Video Control again to exit the menu. The menu will close by

itself after 10 seconds of inactivity.

14 FIP-400

Page 21

Setting up Your Fiber Inspection Probe and ConnectorMax

Selecting the Mode of Operation

Selecting the Mode of Operation

ConnectorMax can be used to inspect single-fiber (SF) and multiple-fiber

(MF) connectors. Depending on which mode of operation you select,

different options will be available.

Note: The multiple-fiber connector option is only available if you have purchased

this option.

Note: The mode of operation is kept in memory when you exit the application.

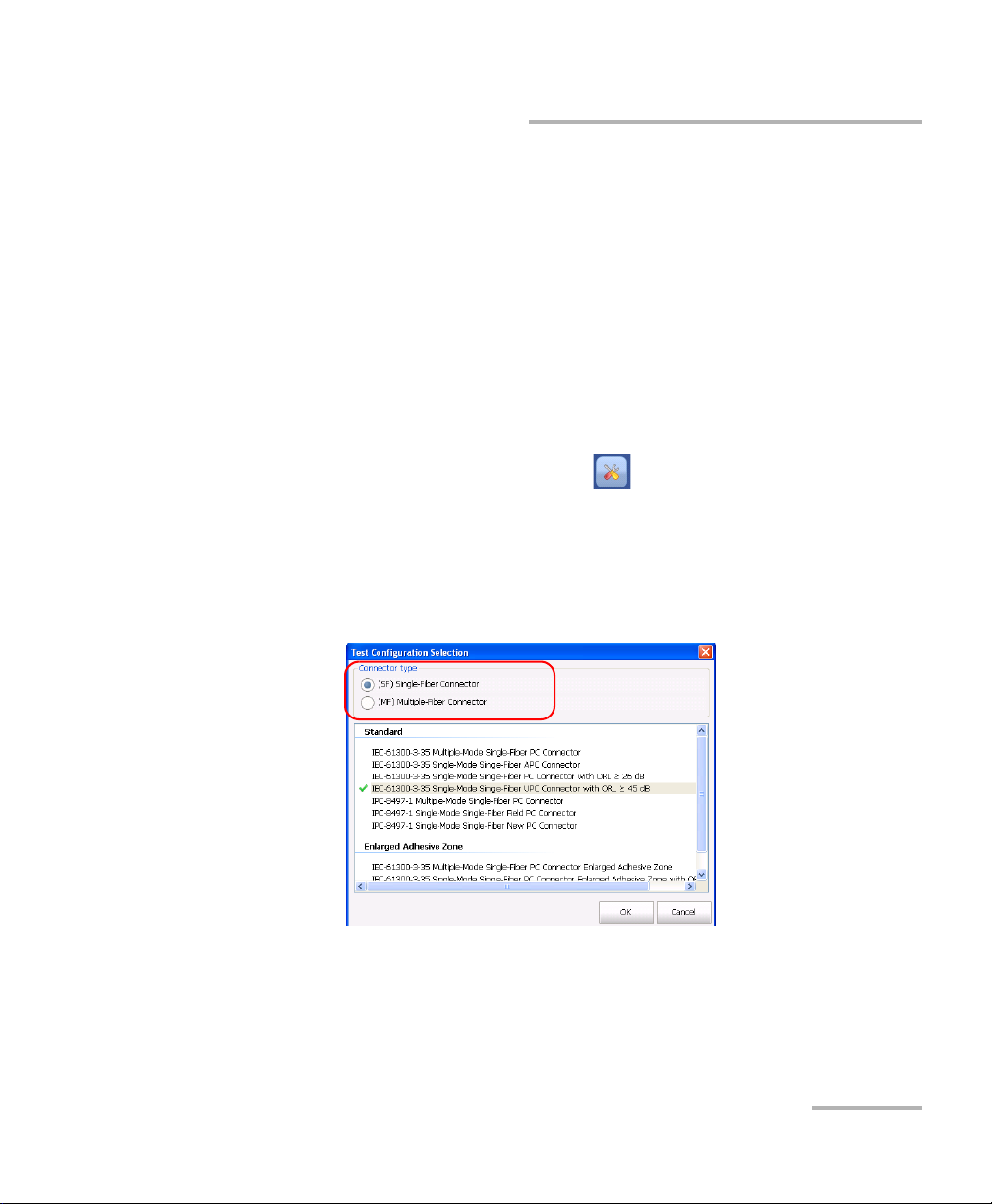

To select the mode of operation:

1. From the main window, click the button.

OR

Select the Test C onf i g . tab, then Select.

2. Select the connector type that suits your needs. The test configuration

selection window is automatically updated accordingly.

Fiber Inspection Probe 15

Page 22

Setting up Your Fiber Inspection Probe and ConnectorMax

Single-Fiber Connector

Current fiber in

connector

Multiple-Fiber Connector

Number of fiber results

presently included in

connector result

Setting up Autonaming

3. If you are testing single-fiber connectors and have purchased the

analysis option, you can also select a test configuration at this point.

4. Click OK to close the window.

At the bottom of the main window, you can see what mode is currently

active.

Setting up Autonaming

The autonaming feature is useful to make a relevant naming scheme for

your tests. This also ensures that you do not overwrite files by mistake. You

can select which item goes in the file name, as well as the type of separator

you want to use in between.

A preview is available to show you the final output of the file name.

Note: When in multiple-fiber mode, the scheme is only editable prior to the first

acquisition; afterwards, it is available as read-only until you have

completed the inspection for the set number of fibers. If the Fiber ID item is

selected for the autonaming scheme, the file name will display both the

start and end fiber number values.

16 FIP-400

Page 23

Setting up Your Fiber Inspection Probe and ConnectorMax

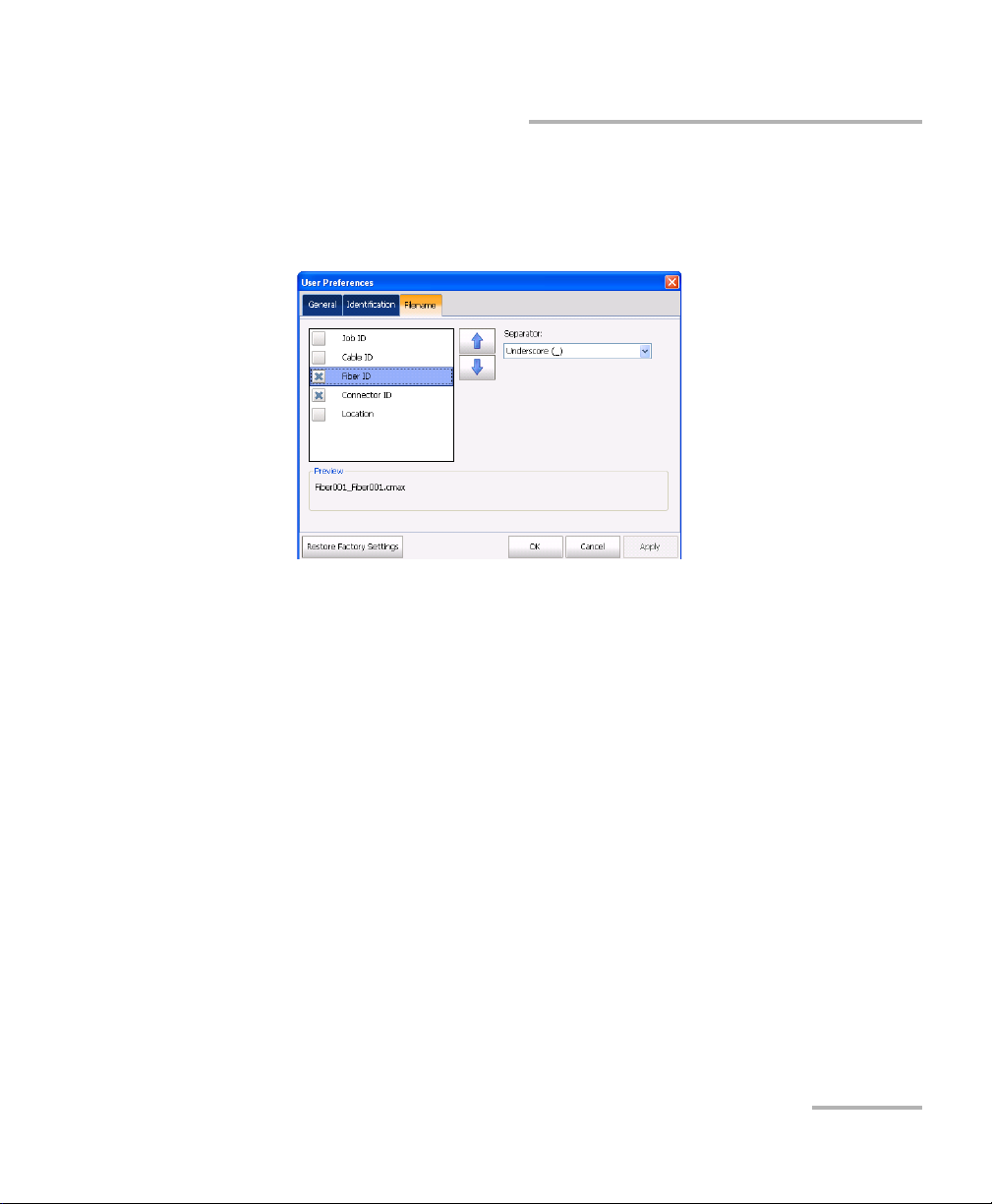

To set the autonaming scheme:

1. From the main window, select User Preferences.

2. Select the Filename tab.

Setting up Autonaming

Fiber Inspection Probe 17

Page 24

Setting up Your Fiber Inspection Probe and ConnectorMax

Setting up Autonaming

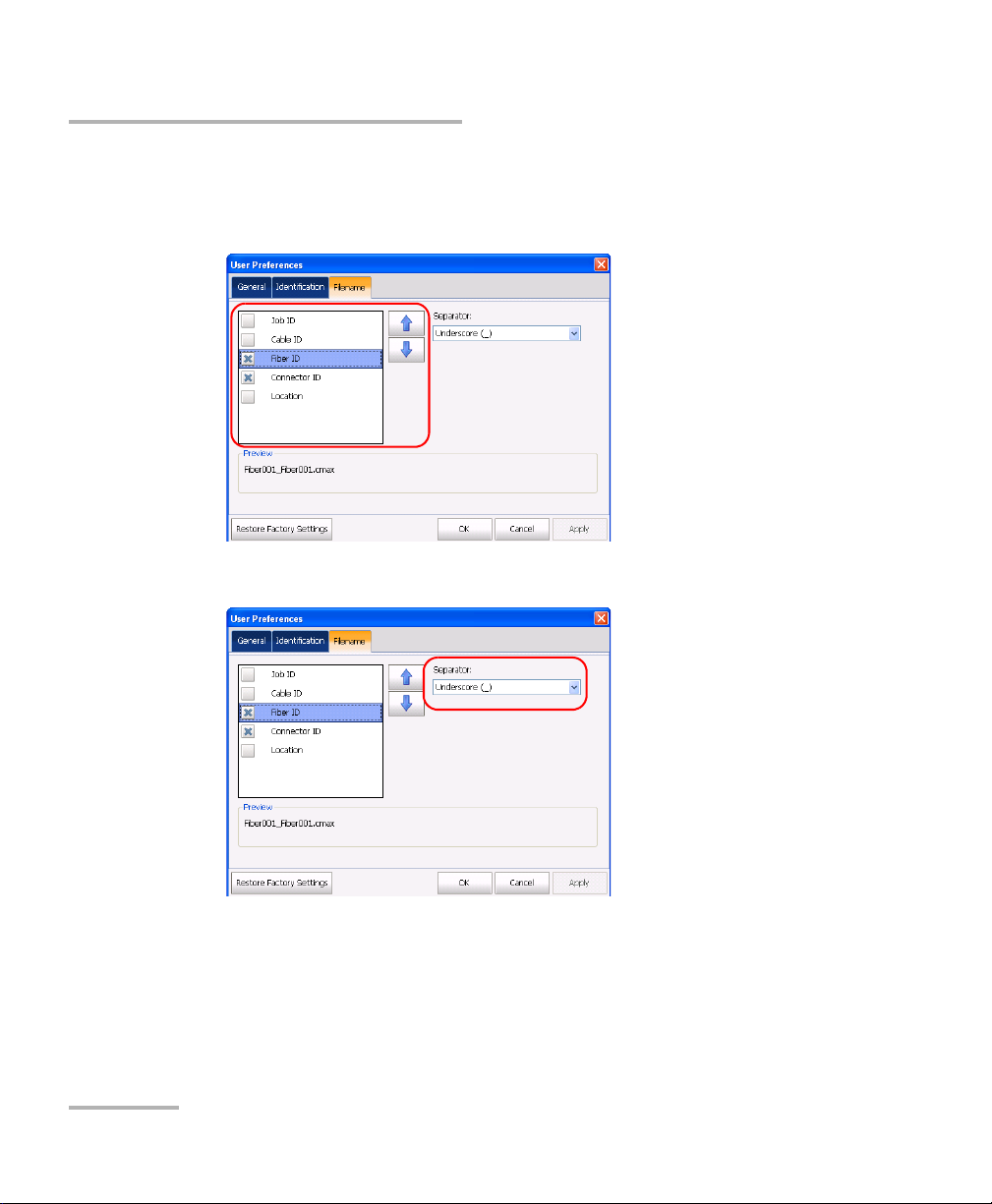

3. Select which items you want to include in the file name. The order of

the items in the name goes from top to bottom; use the up- and

down-arrow buttons to change the order.

4. Select a separator for the items in the list.

5. Click Apply to confirm your choice and continue working in the User

Preference window, or OK to confirm your choice and close the

window.

The new settings will apply the next time you perform a capture.

18 FIP-400

Page 25

Setting up Your Fiber Inspection Probe and ConnectorMax

Identifying Fibers

Identifying Fibers

ConnectorMax allows you to add information to your fiber inspection so

that your analysis is relevant and complete. Such information can be either

preset so that all of the analyses bear the same, or you can edit or add it

after the capture for a specific file.

Some of the items in the identification page can be customized to better

reflect your testing needs. However, as this is not directly part of the

application, you must change it manually. The items you can customize are

the following:

Cable ID.

Fiber ID.

Connector ID.

Location.

Note: Should you change the user interface language after modifying the items,

the latter will not be automatically translated; you will have to change the

items yourself into the new language.

Note: When in multiple-fiber mode, the information is only editable prior to the

first acquisition; afterwards, it is available as read-only until you have

completed the inspection for the set number of fibers. The information will

be the same for all of the fibers in the connector, except for the Fiber ID,

which will follow the connector currently tested.

Fiber Inspection Probe 19

Page 26

Setting up Your Fiber Inspection Probe and ConnectorMax

Identifying Fibers

To add information to the fibers:

1. From the main window, select User Preferences.

20 FIP-400

Page 27

Setting up Your Fiber Inspection Probe and ConnectorMax

Identifying Fibers

2. Select the Identification tab.

3. Fill out the boxes with the desired information. The identification will

increment the file name automatically using the step size you select.

In multiple-fiber connector mode, the start and stop values can be

used to indicate the number of fibers in the connector. The application

will prompt you to save the acquisition after you have reached the stop

number value.

4. Click Apply to confirm your choice and continue working in the User

Preference window, or OK to confirm your choice and close the

window.

Fiber Inspection Probe 21

Page 28

Setting up Your Fiber Inspection Probe and ConnectorMax

Identifying Fibers

To change fiber information once you have made a capture:

From the main window, select the Identification tab and enter the

information. The details that you have added from the User Preferences

window will already appear on-screen.

Note: In single-fiber connector mode, if you change items in the file name

identification, you will notice that the name at the bottom of the window is

automatically updated. This automated update is active until you save the

file and set the few file ID info.

Note: The analysis version and the capture platform are indicated at the bottom

of the tab.

22 FIP-400

Page 29

Setting up Your Fiber Inspection Probe and ConnectorMax

Identifying Fibers

To customize the identification items:

1. Depending on the unit onto which you are working, locate the

configuration file:

In Windows XP on a computer or on an FTB-500 platform:

C:\Documents and Settings\All Users\Application

Data\EXFO\ConnectorMax\Custom Fields.

On an FTB-1 or FTB-200 v2 unit: D:\Documents and Settings\All

Users\Application Data\EXFO\ConnectorMax\Custom Fields.

In Windows Vista and 7 on a computer:

C:\ProgramData\Exfo\ConnectorMax\Custom Fields

2. Open the file using a text editor that supports Unicode UTF-16

encoding.

3. Modify the four identifiers to reflect the desired changes. You can set

them to be visible or not as well.

The identifiers are limited to 15 characters. Special characters

(? / < > " : * | \) are not supported.

The identification item Fiber ID is set to have auto-increment attributes.

You can change the start, step and stop values as well. The start and

stop values must be a number between 1 and 999, and the step value

must be a number between -2 and 2.

Note: The text is case-sensitive and will appear as you write it on-screen.

4. Save and close the configuration file.

IMPORTANT

Make sure that the file is saved using a unicode UTF-16 encoding.

Otherwise, it will be considered as damaged or corrupt if it contains

accents or culture-specific characters.

The changes will be effective the next time you open ConnectorMax.

Fiber Inspection Probe 23

Page 30

Setting up Your Fiber Inspection Probe and ConnectorMax

Managing and Selecting Test Configurations (Optional)

To revert to the factory identification settings:

Delete the .xml configuration file.

Note: A new .xml file with the default settings will be created the next time you

start the application.

Managing and Selecting Test Configurations

(Optional)

If you have purchased the analysis portion of ConnectorMax, you can

create and select specific test configurations according to the type of fiber

you are analyzing, the connector type or the type of defect you are looking

for.

Note: If you have purchased the analysis option, some test configurations as per

IEC 61300-3-35 and IPC 8497-1 standards, and other configurations with an

enlarged C zone are available by default.

Creating custom test configurations is done through duplicating an existing

configuration, and then modifying the desired criteria.

If you create configurations on one unit or computer, and want to transfer

them to another unit or computer, you can do so. However, this feature is

not included directly in ConnectorMax, and you must proceed outside the

application.

24 FIP-400

Page 31

Setting up Your Fiber Inspection Probe and ConnectorMax

Managing and Selecting Test Configurations (Optional)

To select a test configuration:

1. From the main window, select Test C o nfi g , then Select.

OR

Click .

2. In the list of available test configurations, select the one you want to

use and click OK.

Fiber Inspection Probe 25

Page 32

Setting up Your Fiber Inspection Probe and ConnectorMax

Managing and Selecting Test Configurations (Optional)

To create a test configuration:

1. From the main window, select Test C o nfi g , then Manage.

2. Select the configuration that is the closest to the one you want to

create, then click Duplicate.

26 FIP-400

Page 33

Setting up Your Fiber Inspection Probe and ConnectorMax

Managing and Selecting Test Configurations (Optional)

3. In the General tab, modify the criteria as needed.

Configuration name: the application suggests a name for the

configuration. You can change it as needed (maximum 100

characters), but if you select a name that already exists, a suffix will

automatically be added so as not to overwrite files.

Connector type: select which type of connector you are using for

your inspection.

Fiber type: Select whether you are inspecting singlemode or

multimode fibers.

Pol i shing typ e: Select the type of polishing for the fibers between

APC, PC or UPC.

Analysis mode: Select the type of analysis between Outside plant

(selected by default) and Manufacturing. The manufacturing mode

is more sensitive for scratches and defects detection.

Cladding diameter: This value is set at 125 μm and cannot be

modified.

Fiber Inspection Probe 27

Page 34

Setting up Your Fiber Inspection Probe and ConnectorMax

Managing and Selecting Test Configurations (Optional)

4. Under the various layer tabs, indicate whether you want to be notified

of scratches, defects or both for each zone in the fiber, then set

thresholds for each item you select.

You can set up to 3 criteria per zone, and per anomaly type (scratches

or defects). The thresholds are divided into three categories:

Any: this enables the next criterion, which requires a specific

value.

1 to 10: the next criterion is automatically filled out to show the

infinity symbol ( ) and 0 as a threshold.

0: the criterion definition is complete.

Note: Zone C, as well as zone dimensions cannot be modified, as they are set as

per IEC and IPC recommendations.

5. Click Apply to confirm your choice and continue working in window,

or OK to confirm your choice and close the window.

28 FIP-400

Page 35

Setting up Your Fiber Inspection Probe and ConnectorMax

Managing and Selecting Test Configurations (Optional)

To edit a test configuration:

1. From the main window, select Test C o nfi g , then Manage.

2. Select the configuration you want to edit, then click Modify.

Note: You cannot edit standard or enlarged adhesive zone configurations.

3. Change the criteria as required. For details, see the section on creating

a test configuration.

Fiber Inspection Probe 29

Page 36

Setting up Your Fiber Inspection Probe and ConnectorMax

Managing and Selecting Test Configurations (Optional)

To delete a test configuration:

1. From the main window, select Test C o nfi g , then Manage.

2. Select the configuration you want to remove, then click Delete.

Note: You cannot delete standard or enlarged adhesive zone configurations.

30 FIP-400

Page 37

Setting up Your Fiber Inspection Probe and ConnectorMax

Reverting to Factory Settings

To transfer test configurations from one unit or computer to

another:

1. Using Windows Explorer, on the unit where the custom configurations

are located, select which files you want to transfer. The files are

located in different folders depending on the unit you are using.

In Windows XP on a computer, or on an FTB-500 platform:

C:\Documents and Settings\All Users\Application

Data\EXFO\ConnectorMax\Test configuration files\Custom.

In Windows Vista or 7 on a computer: C:\ProgramData\Exfo\

ConnectorMax\Test configuration files\Custom.

On an FTB-1 or FTB-200 v2 unit: D:\Documents and Settings\All

Users\Application Data\EXFO\ConnectorMax\Test configuration

files\Custom.

2. If the two units are linked through a network and that you have access,

you can paste the files directly into the corresponding folder of the

destination unit. Otherwise, copy the files onto a USB key, then paste

the files in the destination folder once you have.

Reverting to Factory Settings

At any time in the application, you can revert to factory settings in your

menus. However, the Restore Factory Settings button is valid only for the

window or tab where you use it.

Fiber Inspection Probe 31

Page 38

Page 39

4 Inspecting Fiber Ends

Viewing the fiber inspection is done using ConnectorMax. You can start the

application before or after connecting the probe, and the view on-screen

will be automatically updated.

To start the application:

On a computer, double-click the ConnectorMax icon on your desktop

or select Start > Programs > EXFO > ConnectorMax.

On an FTB-500, from the main window, select the Fiber Inspection

Probe function tab, or under the Applications tab, select

ConnectorMax. You can also use the direct Windows shortcut

Start > Programs > EXFO > Programs > ConnectorMax.

On an FTB-200 v2, select the Probe button in the Compact ToolBox

main window.

On an FTB-1, from the main window, select the Probe button, or under

the Utilities tab, select ConnectorMax. You can also use the direct

Windows shortcut

Start > Programs > EXFO > Programs > ConnectorMax.

The fiber under test appears on-screen.

Note: The screen size will adapt automatically to the unit you are using.

To exit the application:

1. Click .

OR

2. From the File menu, select Exit.

WARNING

Never look directly into a live fiber. It could cause serious eye

damage. Always use your FIP-400 Fiber Inspection Probe.

Fiber Inspection Probe 33

Page 40

Inspecting Fiber Ends

Inspecting Fiber Ends with the FIP Viewer

Inspecting Fiber Ends with the FIP Viewer

You can connect the Fiber Inspection Probe to the FIP Viewer to view and

inspect fiber ends.

Never look directly into a live fiber. It could cause serious eye

damage. Always use your FIP-400 Fiber Inspection Probe.

The battery in the FIP Viewer must be fully charged before the first

use. For more information, see Charging the Battery in The FIP

Viewer on page 52.

To inspect fiber ends:

1. Install a probe tip (see Changing the Fiber Inspection Probe Tip on

page 13).

WARNING

IMPORTANT

2. Insert the fiber into the probe tip.

3. Connect the probe to the FIP Viewer.

4. Press the On/Off button for approximately 2 seconds to turn on the FIP

Viewer.

5. Adjust the image to have the best view of the fiber end.

6. If the fiber end is dirty, remove it from the probe, clean it and

reinspect it.

7. Once you are satisfied with the inspection, go to the next fiber or turn

off the FIP Viewer.

34 FIP-400

Page 41

Inspecting Fiber Ends

Inspecting Fiber Ends with ConnectorMax

Inspecting Fiber Ends with ConnectorMax

When you connect the Fiber Inspection Probe to your unit (or computer via

a USB adapter) you can view and inspect fiber ends right away. This direct

viewing mode is known as the Live mode.

To inspect fiber ends in live mode:

1. Install a probe tip (see Changing the Fiber Inspection Probe Tip on

page 13).

2. Insert the fiber into the probe tip.

3. Connect your Fiber Inspection Probe to the USB video adapter, and

then connect the USB video adapter to your unit.

4. Start ConnectorMax if it is not already started.

5. Adjust the image focus to have the best view of the fiber end.

6. If the fiber end is dirty, remove it from the probe, clean it and

reinspect it.

7. Once you are satisfied with the inspection, go to the next fiber or turn

off the unit.

Fiber Inspection Probe 35

Page 42

Inspecting Fiber Ends

Capturing Images

Capturing Images

You can capture images of your inspections to include in reports, or save

them for future analyses. This is known as the Capture mode.

Note: Capturing an image with the dongle or the probe handset button

automatically brings ConnectorMax at the front of the screen if you have

more than one application running on your unit or computer.

The focus indicator in the status bar indicates whether the current view is

optimized for a capture. A green indicator shows a picture that can be

captured and analyzed. Analysis will be more difficult with a yellow

indicator, and impossible with a red indicator.

To capture an image of the fiber under inspection:

From the main window, when in high magnification level, press Capture.

OR

Press the Fiber Inspection Probe handset button

OR

If you are capturing the acquisition from a computer, press the button on

the dongle located between the probe and the computer.

In single-fiber connector mode, if the autosaving features are enabled, your

capture is stored in the default folder. If not, you will be prompted to save

the acquisition before you go to the next one.

36 FIP-400

Page 43

Inspecting Fiber Ends

Capturing Images

In multiple-fiber connector mode, continue capturing files until you have

reached the number set in the user preferences. At the end of the capture,

you will be prompted to save your file. You can also save the file at any

time, even if you have not reached the maximum incremental value set.

While capturing the files, you can browse through the acquisitions you

have made. You will notice that the Video Control button becomes a

Navigation button.

To browse through the multiple-fiber connector acquisitions:

1. From the main window, click the Navigation button.

2. Use the arrow buttons to browse through the acquired files, or use the

drop-down menu to go directly to a specific acquisition.

Fiber Inspection Probe 37

Page 44

Inspecting Fiber Ends

Retesting a Fiber

Retesting a Fiber

Sometimes, a capture will show a fail status, but it could only be because

the fiber is dirty and you want to clean it and test it again. However, if you

have saved the file, the next capture you take will be incremented instead

of replacing the current file.

In order to avoid this incrementation and end up with unwanted files, you

can test a fiber again.

In single-fiber connector mode, retesting a fiber is only possible on the

most recent capture. In multiple-fiber connector mode, you can reset a

specific fiber within the capture, or reset the whole connector.

To retest a fiber:

1. After the capture, return to the Live mode.

2. From the main window, click Reset.

3. If you are in multiple-fiber mode, select whether you want to reset a

specific fiber, or the whole connector. If you reset a specific fiber,

select it in the provided list.

4. Capture the file again.

Note: The reset function will only become available again in the main window

once you save your file (single-fiber test mode only).

38 FIP-400

Page 45

Inspecting Fiber Ends

Saving Files

Saving Files

In capture mode, you can save the acquisition files manually for future

reference.

If you have purchased the analysis option you can also set ConnectorMax

so that it saves the capture automatically regardless of the result, or

automatically when the result is Pass only.

Note: When you return to the live mode, your file name structure will be

automatically incremented so that you do not overwrite your work.

Note: In multiple-fiber connector mode, the option is set automatically to Manual

and you cannot change it.

To save files automatically or automatically when the status is set

to Pass:

1. From the main window, select User Preferences.

2. Select the General tab.

3. Select whether you want the capture to be automatically saved

regardless of the result, saved if the result of the analysis is pass, or

select the manual save option if you only want to save specific files.

4. If you want to change the default location where the files will be saved,

you can do so by using the button.

5. Click Apply to confirm your choice and continue working in the

window, or OK to confirm your choice and close the window.

Fiber Inspection Probe 39

Page 46

Inspecting Fiber Ends

Saving Files

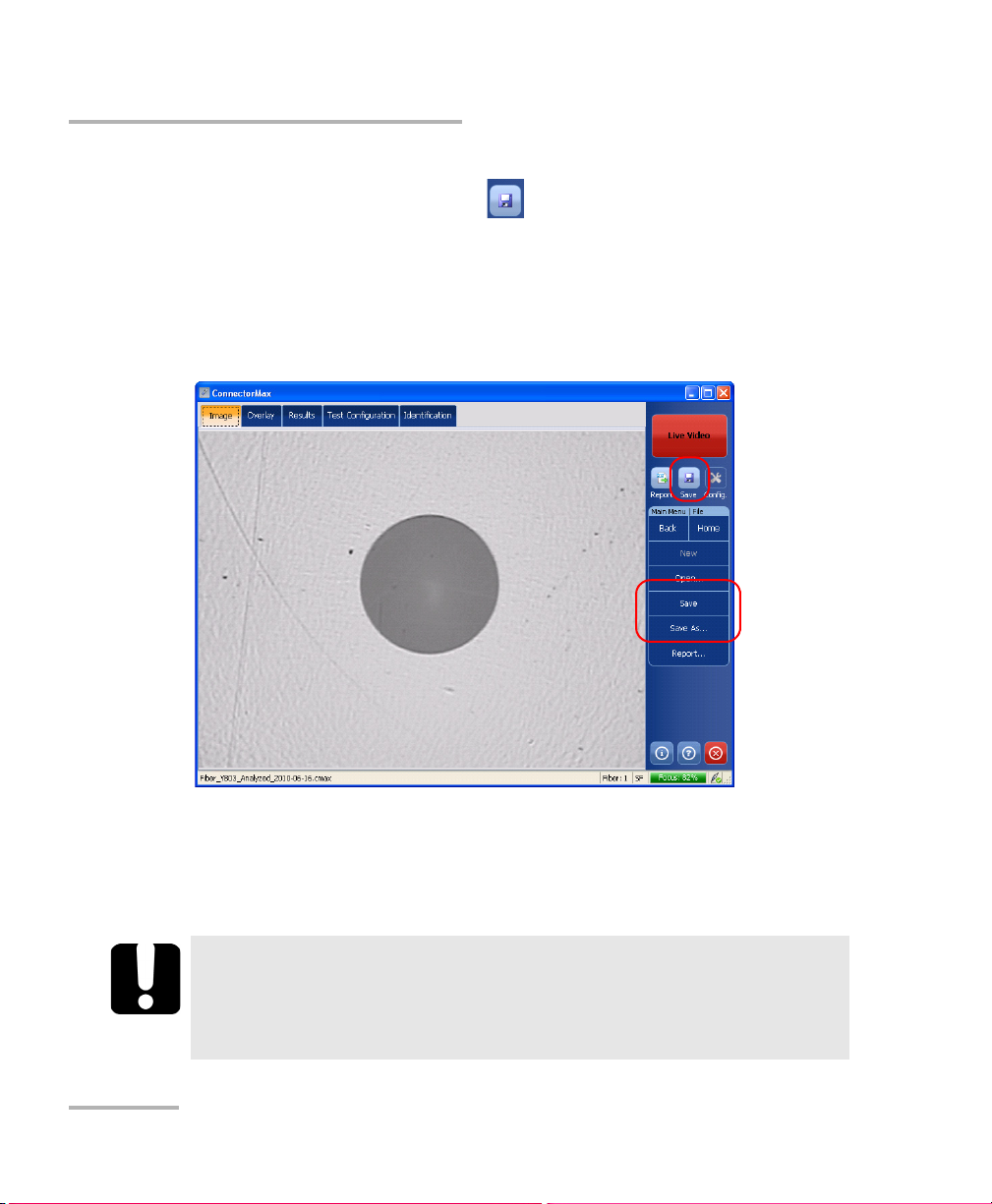

To s av e a f il e:

From the main window, click the button.

OR

Select the File menu, then Save to overwrite an existing file.

OR

Select the File menu, then Save As to change the file name or location.

Note: If you change the location for saving the files, this location will remain as

the default location for the remainder of the work session, or until you

change the location again.

IMPORTANT

If you have enabled the Generate report on save option, the new

report file will automatically overwrite the old one without

notifying you.

40 FIP-400

Page 47

Inspecting Fiber Ends

Opening and Closing Files

Opening and Closing Files

You can open captured files directly from the application to view them.

You can either open current .cmax files, or a legacy image file taken from a

previous fiber inspection.

Note: The accepted image formats for legacy files are .bmp, .jpg and .gif.

Note: Sample files for both single-fiber and multiple-fiber test modes are

available under the folder where ConnectorMax was installed, under a

folder named UserSamples.

To o pe n a f il e:

1. From the main window, select File, and then Open.

2. Select the desired file, and then click Open.

If you are opening a multiple-fiber connector file, you can browse through

the individual files using the Navigation button.

Note: If you are in a file browser, you can also double-click on the file to open it in

ConnectorMax. Double-clicking on a legacy file will open the application

currently associated with this file format.

Fiber Inspection Probe 41

Page 48

Inspecting Fiber Ends

Analyzing Captures (Optional, Single-Fiber Connector Mode Only)

Analyzing Captures (Optional, Single-Fiber

Connector Mode Only)

If you have acquired the capture analysis tool, it will be available in

ConnectorMax for you to perform automated pass/fail analyses according

to the criteria you have set.

The analysis option enables all of the tabs in the viewing area, whereas the

inspection-only option only enables the Image and Identification tabs.

Note: On units that allow it (FTB-500, FTB-200 v2), you will notice that the

Pass/Fail LED will indicate the analysis result as you capture files.

To enable the analysis tool:

1. From the main window, select User Preferences.

2. Under the General tab, select Analyze on capture.

42 FIP-400

Page 49

Inspecting Fiber Ends

Analyzing Captures (Optional, Single-Fiber Connector Mode Only)

3. Select whether you want the analysis to be automatically saved if the

result of the analysis is pass, or select the manual save option if you

only want to save specific analyses.

Note: The automated save option is only available if you have purchased the

analysis option. If you only have the inspection option, the save option is

automatically set to manual.

4. Click Apply to confirm your choice and continue working in the

window, or OK to confirm your choice and close the window.

Fiber Inspection Probe 43

Page 50

Inspecting Fiber Ends

Analyzing Captures (Optional, Single-Fiber Connector Mode Only)

Once the analysis option is activated, you will notice that when you capture

a fiber image, all of the tabs in the viewing area will be available with

information about the results. This information is read-only, except for the

Information tab, and shows you the details you would see in the

corresponding report, if you choose to make one.

The Image tab shows the snapshot of the fiber when you captured it.

You can see some anomalies right away, but no analysis is performed.

44 FIP-400

Page 51

Inspecting Fiber Ends

Analyzing Captures (Optional, Single-Fiber Connector Mode Only)

The Overlay tab shows the status of the analysis, the analysis zones,

and any anomalies (defects, scratches) found on the fiber endface.

Fiber Inspection Probe 45

Page 52

Inspecting Fiber Ends

Analyzing Captures (Optional, Single-Fiber Connector Mode Only)

The Results tab shows detailed information for scratches and defects

detected in each test zone and the corresponding test status.

46 FIP-400

Page 53

Inspecting Fiber Ends

Analyzing Captures (Optional, Single-Fiber Connector Mode Only)

The Test Configuration tab shows the detail of the test configuration

you had selected to perform this analysis.

Fiber Inspection Probe 47

Page 54

Inspecting Fiber Ends

Creating Reports

Creating Reports

You can create a report based on the current inspection and analysis

results (single fiber mode only). This report is saved as an html, or mhtml

file, depending on the format you select.

The html report separates the text from the graphical elements and

puts them in the folder separately.

The mhtml report gathers all of the graphical elements and report

text into one file.

Note: The mhtml format is automatically supported in Microsoft Internet Explorer

version 6 and later. You could need to install a plugin to view this format in

other types of browsers.

Note: The report creation is available only in Capture mode.

If you have selected the Generate report on save option, a report is

automatically created when you save your capture.

48 FIP-400

Page 55

Inspecting Fiber Ends

Creating Reports

To activate automated report creation:

1. From the main window, select User Preferences.

2. Under the General tab, select Generate report on save.

3. Select the type of report you want.

4. If you want to change the default location where the reports will be

saved, you can do so by using the button.

5. Click Apply to confirm your choice and continue working in the

window, or OK to confirm your choice and close the window.

Fiber Inspection Probe 49

Page 56

Inspecting Fiber Ends

Creating Reports

To create a report manually:

1. From the main window, click .

OR

Select the File menu, then Report.

2. Select the type of report you want to create, and the location for the

report.

3. Click Save to close the window.

You can now open the report in any Internet browser from the location

where the file was saved.

50 FIP-400

Page 57

5 Maintenance

General Maintenance

To help ensure long, trouble-free operation:

Keep the unit free of dust.

Clean the unit casing and front panel with a cloth slightly dampened

with water.

Store unit at room temperature in a clean and dry area. Keep the unit

out of direct sunlight.

Avoid high humidity or significant temperature fluctuations.

Avoid unnecessary shocks and vibrations.

If any liquids are spilled on or into the unit, turn off the power

immediately and let the unit dry completely.

The use of controls, adjustments and procedures other than those

specified herein may result in exposure to hazardous situations or

impair the protection provided by this unit.

WARNING

Fiber Inspection Probe 51

Page 58

Maintenance

Charging the Battery in The FIP Viewer

Charging the Battery in The FIP Viewer

The new battery in the FIP Viewer must be fully charged before first use.

To charge the battery:

Connect the AC charger/adapter to the FIP Viewer.

Normal charging time is about 4 hours.

Note: The FIP Viewer may be used on AC charger/adapter while the batteries are

charging.

Replacing Batteries

Your unit uses batteries with built-in protection that have been especially

designed for EXFO. For this reason, you can only replace the main battery

with a battery designed for your FIP-400.

You can purchase new batteries and empty battery compartments (also

known as “battery covers”) from EXFO.

WARNING

There is a risk of explosion if you do not use the appropriate

battery.

CAUTION

Use Li-Ion batteries of the same type and model only. Use of other

batteries may damage the unit and compromise your safety.

52 FIP-400

Page 59

Maintenance

Recycling and Disposal (Applies to European Union Only)

To replace the battery:

1. Acquire a new battery from EXFO.

2. Turn off the unit (if the AC adapter is plugged in, you may replace the

battery while unit is on).

3. Open the battery compartment door located at the back of the unit.

4. Replace the battery, respecting the polarity.

5. Close the battery compartment door.

WARNING

Do not throw batteries into fire or water and do not short-circuit

the batteries’ electrical contacts. Do not disassemble.

Recycling and Disposal

(Applies to European Union Only)

For complete recycling/disposal information as per European Directive

WEEE 2012/19/UE, visit the EXFO Web site at www.exfo.com/recycle.

Fiber Inspection Probe 53

Page 60

Page 61

6 Troubleshooting

Solving Common Problems

The table below presents common problems and their solutions.

Problem Solution

I cannot analyze an

image

The analysis was

interrupted before it

was complete

I cannot see the fiber

on-screen

The image is not focused properly; use the focus knob on

the probe until the focus indicator displays the best value

available. Yellow indicates an acceptable range, and green

shows the preferred range.

Ensure that the probe is connected properly.

Ensure that the connector is aligned properly.

Ensure that the focus value is sufficient to perform the

analysis.

Ensure that the contrast and brightness values are

appropriate in the capture.

Ensure that you are using a high magnitude level.

Turn the probe on

Verify the probe connection status to see if ConnectorMax

is detecting the probe properly. If the probe is connected

properly, close ConnectorMax and open it again.

If you are using a USB adapter and the probe status is

green, ensure that the probe is connected properly to the

adapter. ConnectorMax will only function with the USB 2.0

dongle.

Fiber Inspection Probe 55

Page 62

Troubleshooting

Contacting the Technical Support Group

Contacting the Technical Support Group

To obtain after-sales service or technical support for this product, contact

EXFO at one of the following numbers. The Technical Support Group is

available to take your calls from Monday to Friday, 8:00 a.m. to 7:00 p.m.

(Eastern Time in North America).

Technical Support Group

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

For detailed information about technical support, and for a list of other

worldwide locations, visit the EXFO Web site at www.exfo.com.

If you have comments or suggestions about this user documentation, you

can send them to customer.feedback.manual@exfo.com.

To accelerate the process, please have information such as the name and

the serial number (see the product identification label), as well as a

description of your problem, close at hand.

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

support@exfo.com

56 FIP-400

Page 63

Troubleshooting

Viewing Information about ConnectorMax

Viewing Information about ConnectorMax

You can view information about ConnectorMax such as the version

number and contact information for technical support in the About

window.

To view ConnectorMax information:

On a computer, an FTB-500 or an FTB-1, from the main window, click

.

On an FTB-200 v2 Compact Modular Platform, select the System Info,

then About.

Viewing Online Help

You can view the online help for ConnectorMax at any time.

To view the online help:

From the main window, click .

OR

From the main window, select System Info, then Help.

Fiber Inspection Probe 57

Page 64

Troubleshooting

Transportation

Transportation

Maintain a temperature range within specifications when transporting the

unit. Transportation damage can occur from improper handling. The

following steps are recommended to minimize the possibility of damage:

Pack the unit in its original packing material when shipping.

Avoid high humidity or large temperature fluctuations.

Keep the unit out of direct sunlight.

Avoid unnecessary shocks and vibrations.

58 FIP-400

Page 65

7 Warranty

General Information

EXFO Inc. (EXFO) warrants this equipment against defects in material and

workmanship for a period of one year from the date of original shipment.

EXFO also warrants that this equipment will meet applicable specifications

under normal use.

During the warranty period, EXFO will, at its discretion, repair, replace,

or issue credit for any defective product, as well as verify and adjust the

product free of charge should the equipment need to be repaired or if the

original calibration is erroneous. If the equipment is sent back for

verification of calibration during the warranty period and found to meet all

published specifications, EXFO will charge standard calibration fees.

The warranty can become null and void if:

unit has been tampered with, repaired, or worked upon by

unauthorized individuals or non-EXFO personnel.

warranty sticker has been removed.

IMPORTANT

case screws, other than those specified in this guide, have been

removed.

case has been opened, other than as explained in this guide.

unit serial number has been altered, erased, or removed.

unit has been misused, neglected, or damaged by accident.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED,

IMPLIED, OR STATUTORY, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL EXFO BE LIABLE FOR

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

Fiber Inspection Probe 59

Page 66

Warranty

Liability

Liability

EXFO shall not be liable for damages resulting from the use of the product,

nor shall be responsible for any failure in the performance of other items to

which the product is connected or the operation of any system of which

the product may be a part.

EXFO shall not be liable for damages resulting from improper usage or

unauthorized modification of the product, its accompanying accessories

and software.

Exclusions

EXFO reserves the right to make changes in the design or construction of

any of its products at any time without incurring obligation to make any

changes whatsoever on units purchased. Accessories, including but not

limited to fuses, pilot lamps, batteries and universal interfaces (EUI) used

with EXFO products are not covered by this warranty.

This warranty excludes failure resulting from: improper use or installation,

normal wear and tear, accident, abuse, neglect, fire, water, lightning or

other acts of nature, causes external to the product or other factors beyond

the control of EXFO.

IMPORTANT

In the case of products equipped with optical connectors, EXFO will

charge a fee for replacing connectors that were damaged due to

misuse or bad cleaning.

Certification

EXFO certifies that this equipment met its published specifications at the

time of shipment from the factory.

60 FIP-400

Page 67

Warranty

Service and Repairs

Service and Repairs

EXFO commits to providing product service and repair for five years

following the date of purchase.

To send any equipment for service or repair:

1. Call one of EXFO’s authorized service centers (see EXFO Service

Centers Worldwide on page 62). Support personnel will determine if

the equipment requires service, repair, or calibration.

2. If equipment must be returned to EXFO or an authorized service

center, support personnel will issue a Return Merchandise

Authorization (RMA) number and provide an address for return.

3. If possible, back up your data before sending the unit for repair.

4. Pack the equipment in its original shipping material. Be sure to include

a statement or report fully detailing the defect and the conditions under

which it was observed.

5. Return the equipment, prepaid, to the address given to you by support

personnel. Be sure to write the RMA number on the shipping slip. EXFO

will refuse and return any package that does not bear an RMA number.

Note: A test setup fee will apply to any returned unit that, after test, is found to

meet the applicable specifications.

After repair, the equipment will be returned with a repair report. If the

equipment is not under warranty, you will be invoiced for the cost

appearing on this report. EXFO will pay return-to-customer shipping costs

for equipment under warranty. Shipping insurance is at your expense.

Routine recalibration is not included in any of the warranty plans. Since

calibrations/verifications are not covered by the basic or extended

warranties, you may elect to purchase FlexCare Calibration/Verification

Packages for a definite period of time. Contact an authorized service center

(see EXFO Service Centers Worldwide on page 62).

Fiber Inspection Probe 61

Page 68

Warranty

EXFO Service Centers Worldwide

EXFO Service Centers Worldwide

If your product requires servicing, contact your nearest authorized service

center.

EXFO Headquarters Service Center

400 Godin Avenue

Quebec (Quebec) G1M 2K2

CANADA

EXFO Europe Service Center

Winchester House, School Lane

Chandlers Ford, Hampshire S053 4DG

ENGLAND

EXFO Telecom Equipment

(Shenzhen) Ltd.

3rd Floor, Building 10,

Yu Sheng Industrial Park (Gu Shu

Crossing), No. 467,

National Highway 107,

Xixiang, Bao An District,

Shenzhen, China, 518126

1 866 683-0155 (USA and Canada)

Tel.: 1 418 683-5498

Fax: 1 418 683-9224

support@exfo.com

Tel.: +44 2380 246800

Fax: +44 2380 246801

support.europe@exfo.com

Tel: +86 (755) 2955 3100

Fax: +86 (755) 2955 3101

support.asia@exfo.com

62 FIP-400

Page 69

A Technical Specifications

IMPORTANT

The following technical specifications can change without notice.

The information presented in this section is provided as a reference

only. To obtain this product’s most recent technical specifications,

visit the EXFO Web site at www.exfo.com.

Software

Fiber Inspection Probe 63

Page 70

Technical Specifications

Video Inspection Probe

Video Inspection Probe

Fiber Probe Viewer

USB Converter

64 FIP-400

Page 71

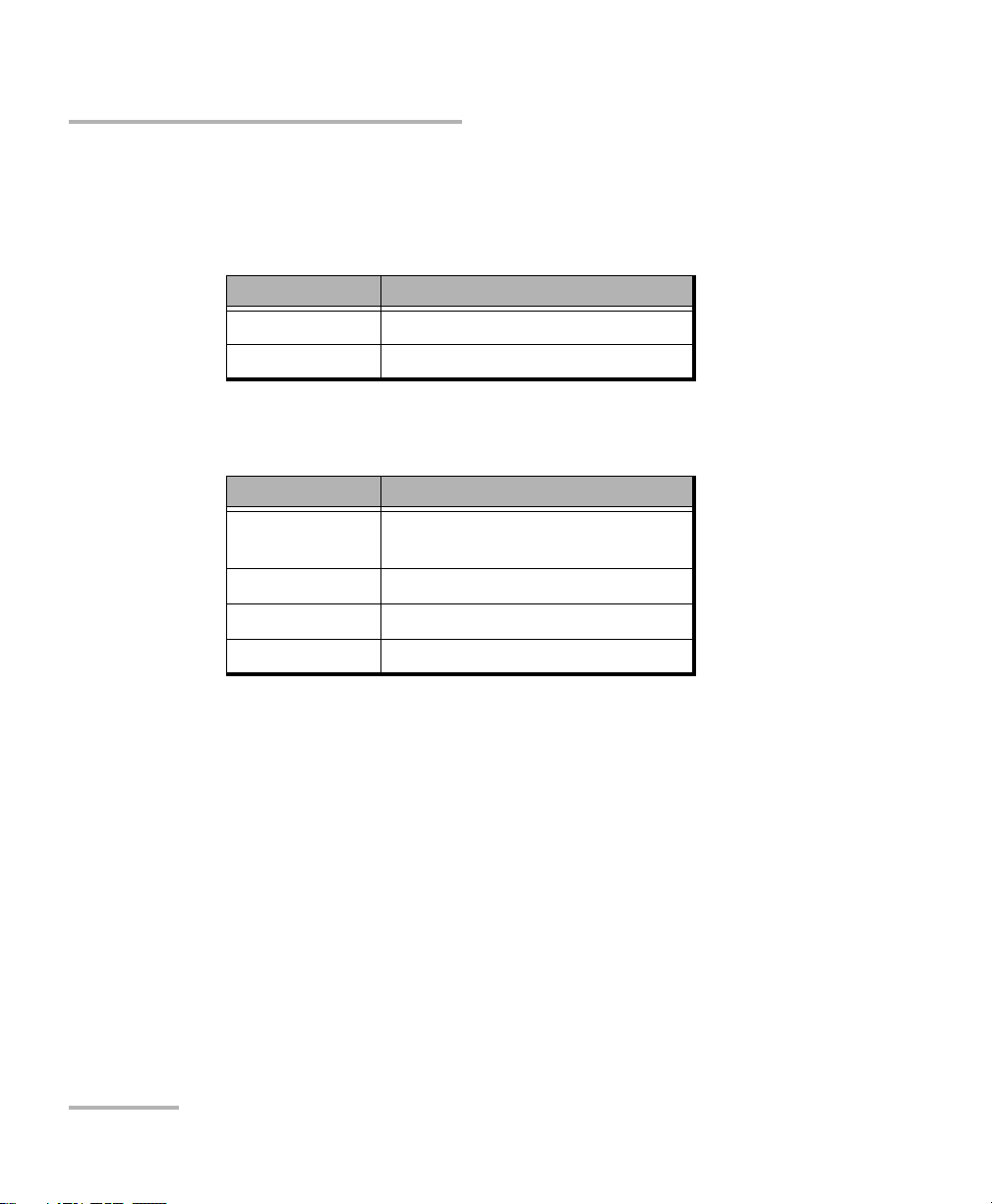

B Fiber Inspection Probe Tip

Compatibility Chart

The table below establishes the Fiber Inspection Probe tip compatibility

with the different fiber inspection and the analysis (option) modules

provided with the ConnectorMax application:

Tip Description Tip Code Inspection Analysis

Uni.1.25 mm tip for PC connector FIPT-400-U12M X X

LC tip for PC bulkhead adapter FIPT-400-LC X X

FC and SC APC tip for bulkhead adapter FIPT-400-FC-SC-APC X X

Uni.2.5 mm tip for APC connector FIPT-400-U25MA X X

Uni.1.25 mm tip for APC connector FIPT-400-U12MA X X

ST tip for UPC bulkhead adapter FIPT-400-ST X X

FC and SC tip for bulkhead adapter FIPT-400-FC-SC X X

Uni.2.5 mm tip for PC connector FIPT-400-U25M X X

Extended SC tip for PC bulkhead

adapter

MU tip for UPC bulkhead adapter FIPT-400-MU X X

E-2000 tip for PC bulkhead FIPT-400-E2000 X X

MU-L tip for UPC bulkhead adapter FIPT-400-MU-L X X

Tip for D4 bulkhead adapter FIPT-400-D4 X X

U20M2 tip for male ferule connector FIPT-400-U20M2 X X

LEMO tip for bulkhead adapter FIPT-400-LEMO X X

E-2000 tip for APC bulkhead adapter FIPT-400-E2000-APC X

OPTITAP tip for APC bulkhead adapter FIPT-400-OTAP-APC X

OPTITIP MT tip kit for APC bulkhead

adapter

Fiber Inspection Probe 65

FIPT-400-SC-L X X

FIPT-400-OTIP-MT-APC X

Page 72

Fiber Inspection Probe Tip Compatibility Chart

Tip Description Tip Code Inspection Analysis

OPTITIP MT tip for APC bulkhead

FIPT-400-OTIP-MT-APC/M X

adapter - male end

LC tip for APC bulkhead adapter TIP LC for APC bulkhead X

LC tip for bulkhead adapter 60 Degree

FIPT-400-LC-A6 X

Angled

LX5 tip for UPC bulkhead adapter FIPT-400-LX5 X

LX5 tip for APC bulkhead adapter FIPT-400-LX5-APC X

MTP/APC tip for bulkhead adapter -

FIPT-400-MTPA2 X

Extended & Improved

MTP2 tip for bulkhead adapter FIPT-400-MTP2 X

MTP2 component used with

FIPT-400-MTP2-TIP X

FIPT-400-MTP2 tip

MTPA component used with MTP2 tip FIPT-400-MTPA-TIP X

Bulkhead adapter FIPT-400-ADAPTER X

Tip for SMA bulkhead adapter FIPT-400-SMA X

Tip for SMA male connector FIPT-400-SMAM X

Tip for MTRJ bulkhead adapter FIPT-400-MTRJ X

Contact your vendor for additional information regarding the most recent

Fiber Inspection Probe tips that are not listed above.

66 FIP-400

Page 73

Index

Index

A

about window............................................. 57

after-sales service ........................................ 56

analysis tool ................................................ 42

application

exiting ................................................... 33

starting.................................................. 33

autonaming ................................................ 16

B

battery

charging ................................................ 52

status LED................................................ 4

brightness ................................................... 14

browsing, multiple-fiber acquisition............ 37

buttons, description ...................................... 6

C

capture mode.............................................. 36

caution

of personal hazard................................... 7

of product hazard.................................... 7

certification information ................................v

charging the battery ................................... 52

cleaning

front panel............................................. 51

closing application. ..................................... 33

configurations, test ..................................... 24

ConnectorMax

exiting ................................................... 33

introduction............................................. 6

starting.................................................. 33

contrast....................................................... 14

conventions, safety ....................................... 7

copying configuration to another unit ........ 31

creating reports........................................... 48

custom configurations, transferring ............ 31

customer service.......................................... 61

D

documentation............................................ 57

E

equipment returns....................................... 61

exiting application....................................... 33

F

factory settings............................................ 31

fiber to test.................................................. 15

fibers, identification .................................... 19

file naming .................................................. 16

files

legacy .................................................... 41

opening .................................................41

saving ....................................................39

FIP Viewer

buttons .................................................... 3

connector................................................. 3

LEDs ......................................................... 3

focus indicator............................................. 36

front panel, cleaning ................................... 51

H

help ............................................................. 57

html report.................................................. 48

I

identification label....................................... 56

identifying fibers .........................................19

image file

closing ...................................................41

opening .................................................41

Fiber Inspection Probe 67

Page 74

Index

information about ConnectorMax............... 57

inspecting fiber ends............................. 34, 35

inspection mode

capture .................................................. 36

live......................................................... 35

L

label, identification ..................................... 56

LED, battery status

flashing green.......................................... 3

flashing red ............................................. 3

green ....................................................... 3

yellow...................................................... 3

legacy picture files....................................... 41

live mode .................................................... 35

M

maintenance

front panel ............................................ 51

general information............................... 51

mhtml report .............................................. 48

mode of operation ...................................... 15

multifiber test ............................................. 15

N

naming files ................................................ 16

navigating, multiple-fiber acquisition.......... 37

O

online help .................................................. 57

opening files ............................................... 41

operation mode .......................................... 15

overlay tab .................................................. 45

P

probe

capture button ........................................ 1

focus knob............................................... 1

fold out clip ............................................. 1

magnification control button................... 1

protective cap .......................................... 1

retaining nut............................................ 1

product

identification label ................................. 56

specifications ......................................... 63

R

reports......................................................... 48

results tab ................................................... 46

return merchandise authorization (RMA) .... 61

S

safety

caution .................................................... 7

conventions .............................................7

warning ...................................................7

saving files................................................... 39

service and repairs....................................... 61

service centers ............................................. 62

setting

brightness.............................................. 14

contrast ................................................. 14

settings, factory........................................... 31

shipping to EXFO......................................... 61

single fiber test............................................ 15

specifications, product ................................63

starting application .....................................33

storage requirements ..................................51

storage, files................................................ 39

symbols, safety.............................................. 7

T

tabs

overlay ................................................... 45

results .................................................... 46

test configuration .................................. 47

technical specifications................................ 63

technical support......................................... 56

temperature for storage .............................. 51

68 FIP-400

Page 75

test configuration

tab......................................................... 47

transferring............................................ 31

test configurations, managing .................... 24

tips

changing ............................................... 13

types........................................................ 2

tool for analysis........................................... 42

transferring test configurations................... 31

transportation requirements ................. 51, 58

type of fiber ................................................ 15

U

USB

adapter.................................................... 5

connector ................................................ 5

V

video, image adjustment............................. 14

viewing fiber ends................................. 34, 35

Index

W

warranty

certification ........................................... 60

exclusions .............................................. 60

general .................................................. 59

liability................................................... 60

null and void.......................................... 59

Fiber Inspection Probe 69

Page 76

NOTICE

抩⛙

CHINESE REGULATION ON RESTRICTION OF HAZARDOUS SUBSTANCES

₼⦌␂ℝ☀⹂䓸德棟Ⓟ䤓屓⸩

NAMES AND CONTENTS OF THE TOXIC OR HAZARDOUS SUBSTANCES OR ELEMENTS

CONTAINED IN THIS EXFO PRODUCT

▔⚺⦷㦻 EXFO ℶ❐₼䤓㦘㹡㦘⹂䓸德㒥⏒侯䤓⚜䱿✛⚺摞

O

Indicates that this toxic or hazardous substance contained in all of the homogeneous

materials for this part is below the limit requirement in SJ/T11363-2006

嫷䯉年㦘㹡㦘⹂䓸德⦷年捷ↅ㓏㦘⧖德㧟㠨₼䤓⚺摞⧖⦷ SJ/T11363-2006 㪖屓⸩䤓

棟摞尐㻑ⅴₚᇭ

X

Indicates that this toxic or hazardous substance contained in at least one of the homogeneous

materials used for this part is above the limit requirement in SJ/T11363-2006

嫷䯉年㦘㹡㦘⹂䓸德咂⺠⦷年捷ↅ䤓㩟⧖德㧟㠨₼䤓⚺摞怔⒉ SJ/T11363-2006 㪖

屓⸩䤓棟摞尐㻑ᇭ

Part Name

捷ↅ⚜䱿

Toxic or hazardous Substances and Elements

㦘㹡㦘⹂䓸德✛⏒侯

Lead

杔

(Pb)

Mercury

㻭

(Hg)

Cadmium

椣

(Cd)

Hexavalent

Chromium

⏼ↆ杻

(Cr VI)

Pol yb ro mi na te d

biphenyls

⮩䅃勣啾

(PBB)

Polybrominated

diphenyl ethers

⮩䅃ℛ啾搩

(PBDE)

Enclosure

⮥⮂

OO O O O O

Electronic and

electrical

sub-assembly

䟄✛䟄兓ↅ

XO X O X X

Optical

sub-assembly

a

⏘ⷵ兓ↅ

a

a. If applicable.

Ⱁ㨫抑䞷ᇭ

XO O O O O

Mechanical

sub-assembly

a

㧉㬿兓ↅ

a

OO O O O O

Page 77

MARKING REQUIREMENTS

㪖㽷尐㻑

Product

ℶ❐

Environmental protection use period (years)

䘾⬒≬㔳∎䞷㦮棟 ( )

Logo

㪖㉦

This Exfo product

㦻 EXFO ℶ❐

10

Battery

a

䟄㻯

a

a. If applicable.

Ⱁ㨫抑䞷ᇭ

5

Page 78

P/N: 1065930

www.EXFO.com · info@exfo.com

CORPORATE HEADQUARTERS 400 Godin Avenue Quebec (Quebec) G1M 2K2 CANADA

Tel.: 1 418 683-0211 · Fax: 1 418 683-2170

EXFO AMERICA 3400 Waterview Parkway Suite 100 Richardson, TX 75080 USA

EXFO EUROPE Winchester House,

EXFO ASIA-PACIFIC 62 Ubi Road 1,

EXFO CHINA Beijing Global Trade Center, Tower C,

EXFO SERVICE ASSURANCE 270 Billerica Road Chelmsford MA, 01824 USA

EXFO FINLAND Elektroniikkatie 2 FI-90590 Oulu, FINLAND

TOLL-FREE (USA and Canada) 1 800 663-3936

© 2014 EXFO Inc. All rights reserved.

Printed in Canada (2014-01)

School Lane

#09-01/02 Oxley Bizhub 2

Room 1207, 36 North Third Ring Road

East, Dongcheng District

Tel.: 1 972-761-927 · Fax: 1 972-761-9067

Chandlers Ford, Hampshire S053 4DG ENGLAND

Tel.: +44 2380 246 800 · Fax: +44 2380 246 801

SINGAPORE 408734

Tel.: +6563338241 · Fax: +6563338242

Beijing 100013 P. R. CHINA

Tel.: +86 (10) 5825 7755 · Fax: +86 (10) 5825 7722

Tel.: 1 978 367-5600 · Fax: 1 978 367-5700

Tel.: +358 (0) 403 010 300 · Fax: +358 (0) 8 564 5203

Loading...

Loading...