Another quality product from

INSTRUCTION MANUAL

MANUAL DE INSTRUCCIONES

GUIDE DE DIRECTIVES

English

Spanish

French

Model

EURP-PRO Operating LLC: Boston, MA, 02465

4400 Bois Franc, St. Laurent, Quebec, H4S 1A7

Tel.: 1 (800) 361-4639, www.euro-pro.com

473 / 377B / 374/ 373 / 372 / 372H

¡°¡±

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical sewing machine, basic safety precautions should always be followed, including

the following.

Read all instructions before using this sewing machine.

This sewing machine is designed for household use.

English

DANGER-

A sewing machine should never be left unattended when plugged in. Always unplug this sewing machine

from the electrical outlet immediately after using and before cleaning.

Warning

Do not allow to be used as a toy. Attention is necessary when this sewing machine is used by

1.

or near children.

Use this sewing machine only for its intended use as described in this manual. Use only attachments

2.

recommended by the manufacturer as contained in this manual.

Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly,

3.

if it has been dropped or damaged, or dropped into water. Return the sewing machine to the nearest

authorized dealer or service center for examination, repair,electrical or mechanical adjustment.

4. Never operate the sewing machine with any air openings blocked. Keep ventilation openings from

the sewing machine and foot control free from the accumulation of lint, dust, and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol spray products are being used or where oxygen is being administered.

8. To disconnect, turn all controls to the off O position, then remove plug from outlet.

-To reduce the risk of burns, fire, electric shock or injury to persons...

TO REDUCE RISK OF ELECTRIC SHOCK:

¡±

¡±

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

11. Always use the proper needle plate. The wrong plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle, causing it to break.

14. Switch the sewing machine off O when making any adjustments in the needle area, such as

threading needle, changing needle, threading bobbin, or changing presser foot and the like.

15. Always unplug sewing machine from the electrical outlet when removing covers, lubricating,

o

r when making any other user servicing adjustments mentioned in the instruction manual.

16. Always unplug before replacing lamp. Replace bulb with the same rated 15 watts.

¡±

¡±

SAVE THESE INSTRUCTIONS

Rev. 05/04E

1

Contents

Principal parts

How to connect the machine to the power supply

How to use the foot control

How to replace the sewing lamp

Changing the needle

Thread and needle chart

To select a suitable needle

Removing and attaching the presser foot

Regulating the thread tension

Reverse stitch

The pattern selector

Removing the bobbin case and bobbin

Winding the bobbin

Threading the bobbin case

Threading the needle

Drawing up the bobbin thread

Straight stitch and zigzag stitch

Changing sewing direction

Fastening seams

Triple stretch stitch

Tricot zigzag stitch

3-4

4

4

4

5

5

5

6

6

7

7-8

8

9

9

10

11

11

12

12

12

13

Smocking stitch

Overlock stitch

Double action stitch

Double overlock stitch

Sewing buttonholes

Sewing zippers

Hemming

Sewing blind hems

Sewing embroidery

Darning plate

Buttons

Cleaning the feed dog

Cleaning the shuttle race

Free arm sewing

Trouble shooting: causes and remedies

13

13

14

15

14-15

15

16

16

17

17

17

18

18

19

20

2

15

14

4

1

2

17

3

5

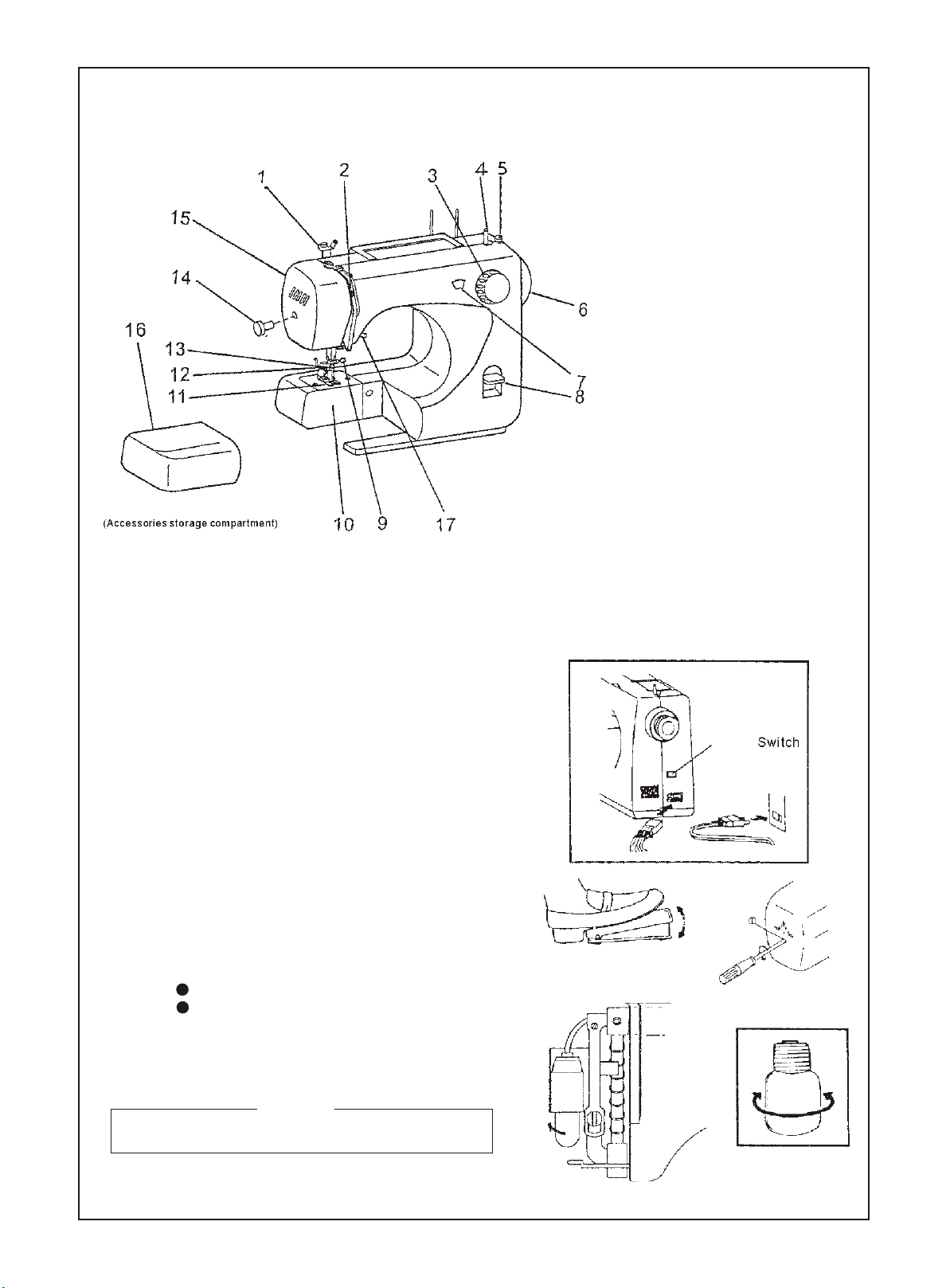

PRINCIPAL PARTS

1.Bobbin winder thread guide

2.Thread tension dial

3.Pattern selector dial

4.Bobbin winder spindle

6

5.Bobbin winder stopper

6.Balance wheel

7.Stitch length dial

8.Reverse button

7

8

9.Needle clamp and screw

( Mo

del 377B)

English

16

13

12

11

(Accessories storage compartment)

10

10.Shuttle cover

11.Presser foot

12.Presser foot thumb screw

13.Needle

14.Screw for face plate

15.Face plate

16.Extension table

17.Stitch display

18.Presser foot lifter

9

18

PRINCIPAL PARTS

1.Bobbin winder thread guide

2.Thread tension dial

3.Pattern selector dial

4.Bobbin winder spindle

5.Bobbin winder stopper

6.Balance wheel

7.Stitch length dial

8.Reverse button

9.Needle clamp and screw

(Model 374)

(Accessories storage compartment)

10.Shuttle cover

11.Presser foot

12.Presser foot thumb screw

13.Needle

14.Screw for face plate

15.Face plate

16.Extension table

17.Stitch display

18.Presser foot lifter

3

(Accessories storage compartment)

PRINCIPAL PARTS

1.Bobbin winder thread guide

2.Thread tension dial

3.Pattern selector dial

4.Bobbin winder spindle

5.Bobbin winder stopper

6.Balance wheel

7.Stitch display

8.Reverse button

9.Needle clamp and screw

10.Shuttle cover

11.Presser foot

12.Presser foot thumb screw

13.Needle

14.Screw for face plate

15.Face plate

16.Extension table

17.Presser foot lifter

(

473/373/372/372H

)

HOW TO CONNECT THE MACHINE TO THE POWER SUPPLY

1.Fit the machine plug into the machine.

2.Plug the power cord to the power supply.

Note:*Before plugging in the machine, ensure the voltage and

number of cycles indicated, conforms to your electrical

power supply.

HOW TO USE THE FOOT CONTROL

Sewing speed can be varied by the foot control. The harder you press

on the controller, the faster the machine runs.

Note:*By releasing the controller, the machine stops running auto matically.

*Before using the machine, practice controlling the speed

without threading.

HOW TO REPLACE THE SEWING LAMP

The sewing lamp is located behind the face plate.

Remove the face plate by loosing the screw of the face plate.

Bulb type:

To remove...Unscrew

To replace...Screw

Note:*Before replacing a bulb, disconnect the machine from the

power supply.

*Bulbs are available from sewing machine retailers.(Use a

15-Watt bulb)

Caution!

Before leaving the machine, changing parts or doing any other

work on it, always disconnect the plug from the wall socket.

Switch

4

THREAD AND NEEDLE CHART

FABRICS

LIGHT

WEIGHT

MEDIUM

WEIGHT

HEAVY

WEIGHT

Note: *In general, fine threads and needles are used for sewing thin fabrics, and thicker threads and needles are

used for sewing heavy fabrics, Always test thread and needle size on a small piece of fabric which will

be used for actual sewing.

Sheer cottons, Silk,

Synthetics, Georgette

Medium Weight Cottons, Synthetics,

Poplin, Velvet, Light Weight Woollens

Heavy Weight Cottons, Denim

Tweed, Gaberdine, Drapery

*Use the same thread for needle and bobbin.

*When sewing stretch, very fine fabrics and synthetics, use a STRETCH needle. The STRETCH

needle effectively prevents skipped stitches.

*When sewing very fine fabrics, sew over a piece of paper to prevent yarn distortion.

Fine Silk

Fine Cotton

Fine Synthetic

Fine Cotton Covered Polyester

50 silk

50 to 80 Cotton

50 to 60 Synthetic

Cotton Covered Polyester

50 Silk

40 to 50 Cotton

40 to 50 Synthetic

Cotton Covered Polyester

THREADS

NEEDLE SIZE

9 or 11

11 or 14

14 or 16

English

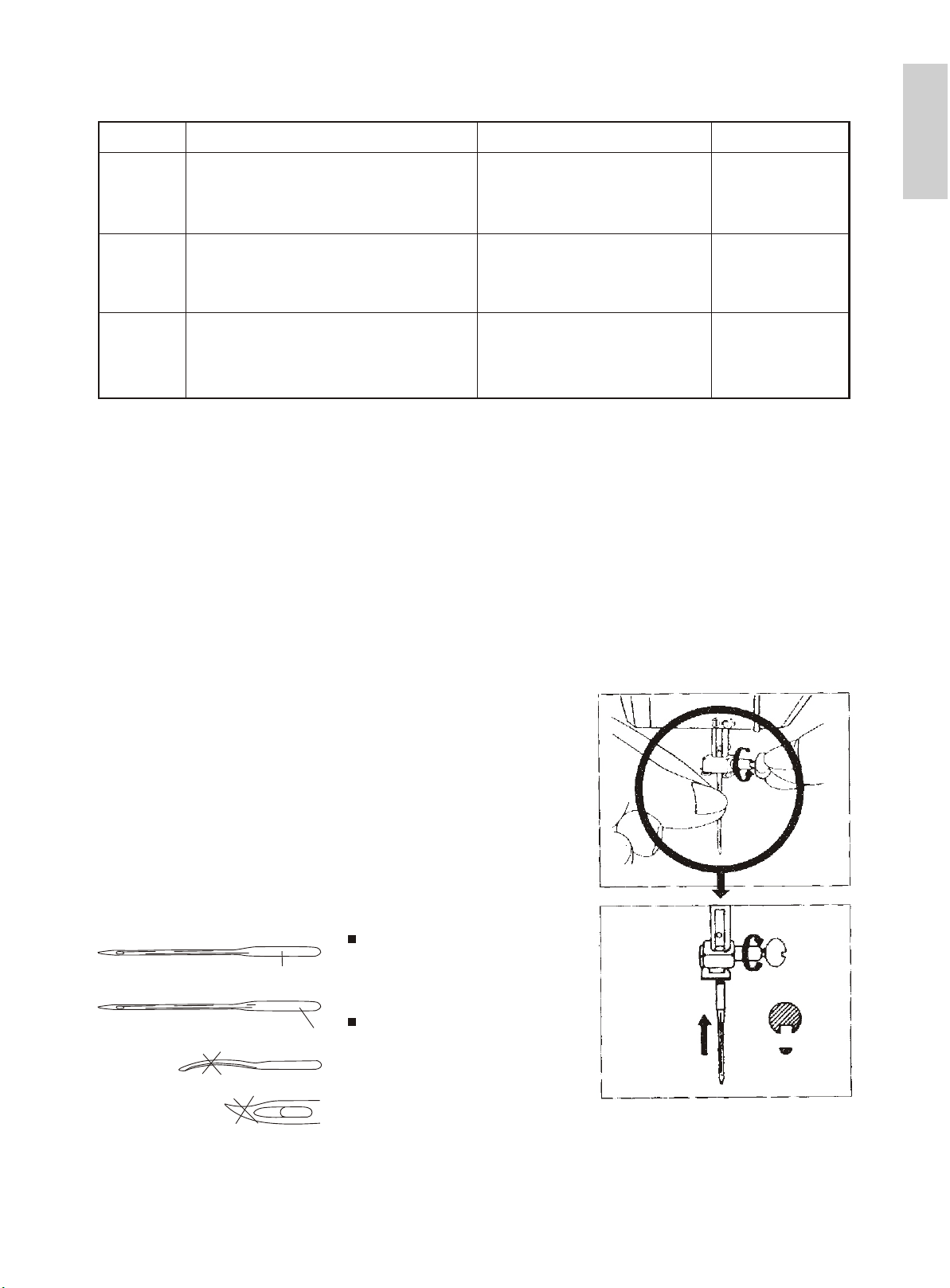

CHANGING THE NEEDLE

1. Turn the balance wheel towards you until the needle is in

its highest position.

2. Loosen the needle clamp screw by turning its top edge

towards you. Remove the needle from the clamp.

3. Place the new needle into the needle clamp with it s flat

side facing away from you. Push the needle up into needle

clamp as far as possible.

4. Tighten the needle clamp screw firmly.

TO SELECT A SUITABLE NEEDLE

A number indicating the size

of needle is marked on the

Stem

stem. The higher the number,

the thicker the needle.

,

A STRETCH needle is

stretch needle

recommended for stretch fabrics.

*

Do not use any needle which

is bent or blunted.

(4)

(3)

5

REMOVING AND ATTACHING THE PRESSER FOOT

To Remove:

1. Turn the balance wheel towards you until the needle is at its highest position.

2. By lifting the lever on the back of the foot holder, the presser foot will drop off.

Note: *Do not force the presser foot to remove it.

To Attach:

1. Place the presser foot so that the pin on the foot lies just under the groove of the

foot holder. Lower the foot holder.

presser

foot

1

lifter

2

2. When the presser foot lifter is raised youll fin d the presser foot is locked in place.

,

lever

groove

1

2

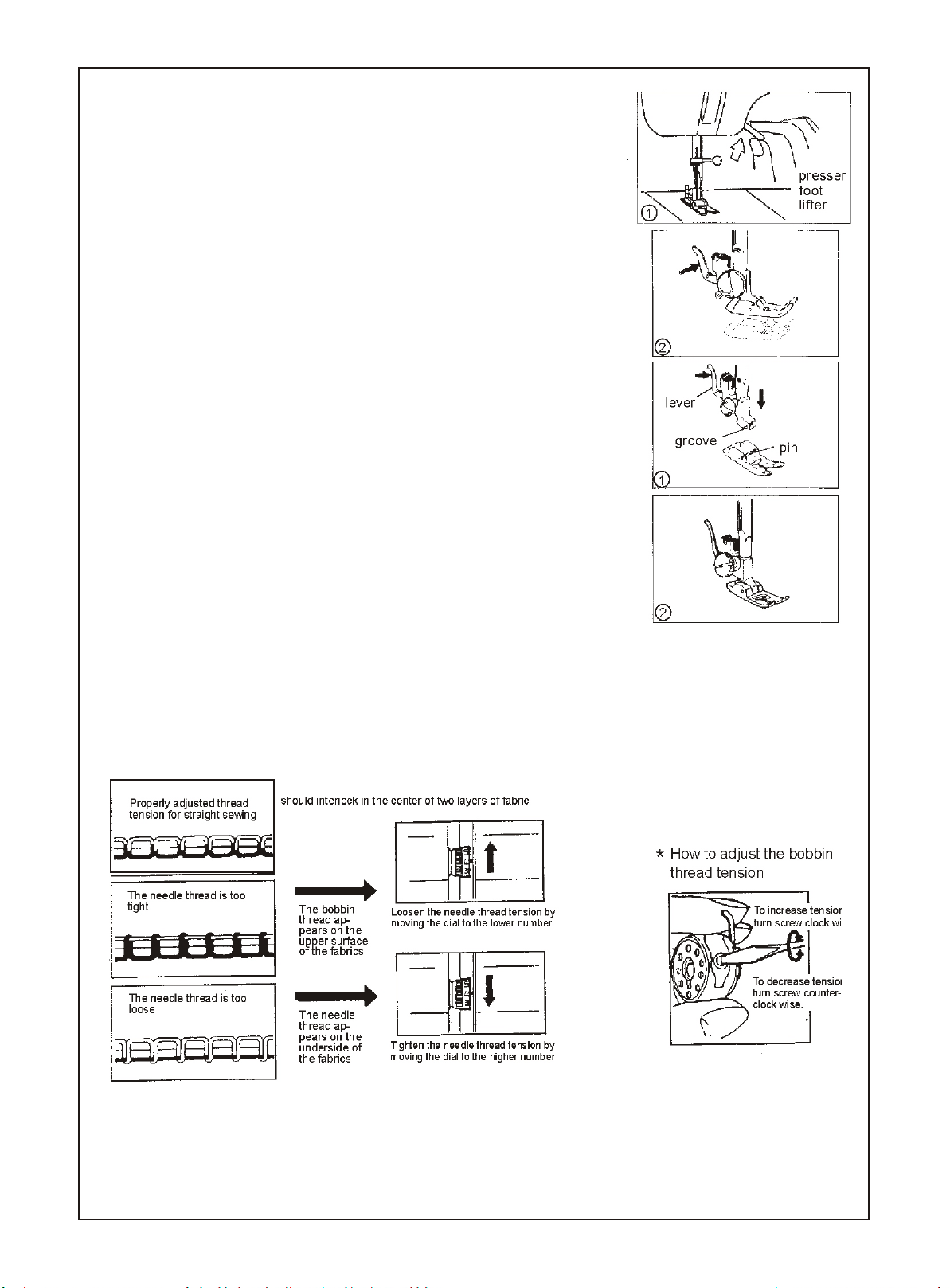

REGULATING THE THREAD TENSION

Generally, should any tension adjustment be necessary, the adjustment can normally be made by regulating

the upper thread tension dial only. Bobbin thread tension has been adjusted at the factory and readjustment

is seldom required except for special instances, thread and fabric.

Bobbin thread tension is just right when you can pull the thread from bobbin case easily with a little resistance.

Thread tension may be adjusted by tightening or loosening the thread tension dial.

The needle thread and the bobbin thread

Properly adjusted thread

tension for straight sewing

The needle thread is too

tight

should interiock in the center of two layers of fabric

The bobbin

thread ap-

pears on the

upper surface

of the fabrics

Loosen the needle thread tension by

moving the dial to the lower number

How to adjust the bobbin

*

thread tension

pin

To increase tension,

turn screw clock wise.

The needle thread is too

loose

The needle

thread ap-

pears on the

underside of

the fabrics

Tighten the needle thread tension by

moving the dial to the higher number

Remember the higher the number, the tighter the tension. Correctly balanced tensions for one fabric may not

be suitable for another. The required tension depends upon the stiffness of fabric, thickness of the fabric,

numbers of layers of fabric being sewn, as well as the type of stitch you are making. It is better to test the stitching on a scrap of the fabric you are using before starting to make a garment. The general range for many fabrics is 3-5.

6

To decrease tension.

turn screw counter-

clock wise.

STITCH LENGTH DIAL (Model 377B and 374 only)

To change the length of the stitches proceed as follows:

Turn the dial so that the number for the required stitch length is at setting mark. The numbers indicate the approximate

stitch length in mm. The smaller the numbers, the shorter the stitch.

English

3 74

stitch lengths

473/377B/374/373/372/372H)

REVERSE

377

setting

mark

STITCH:

(Model

Press center of the stitch length dial (reversing button) and hold for reverse stitching. Fabric will immediately start feeding

backwards. Release button and machine will resume normal forward sewing. Very useful for fastening ends of seams and

darts without having to tie threads, and for strengthening seams.

377 3 74 473/3 73/372/372H

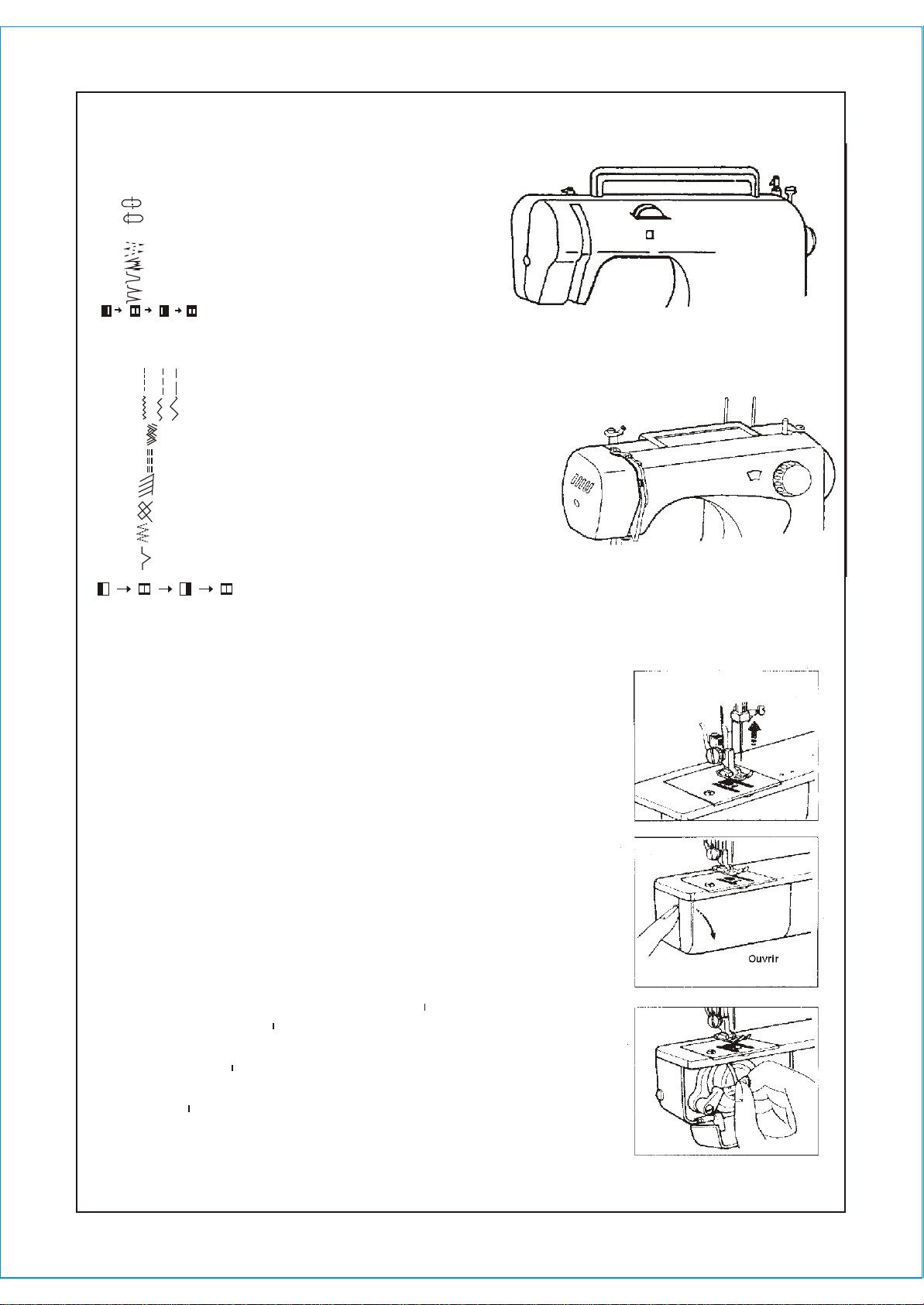

THE PATTERN SELECTOR (Model 377B)

The desired pattern can be selected by turning the pattern selector dial. The marks on the dial correspond to the

patterns shown on the panel respectively, as follows;

M( ) straight stitch, middle needle position

O( ) straight stitch, left needle position

1-5( 54321) zigzag stitch with variable width

A( ) tricot stitch

B( ) stretch blind stitch

C( ) double action stitch

D( ) reverse blind stitch

automatic buttonhole sewing

Selecting Stretch Stitch:

SS

When sewing stretch stitch, set the stitch length dial at

S.S. .

When you release the

stretch stitch mechanism will be off automatically.

M( ) triple straight stretch stitch, middle needle

position.

O( ) triple straight stretch stitch, left needle

position.

1-5( 54321) triple zigzag stretch stitch or ric-rac stitch

A( ) smocking stitch

B( ) fancy stretch stitch or blanket stitch

C( ) double overlock stitch

D( ) overlock stitch

engagement on the dial, the

Standard djustment

Turn the stitch length dial so that

the SS mark is uppermost.

This is a standard adjustment for most types of fabric.

For different types of fabric, adjustment may be necessary.

To shorten the stretch stitches, turn the dial slightly towards To lengthen, turn the dial towards .

¡°¡± ¡°¡±

On most fabrics, these adjustments allow for various

pattern possibilities.

When making stretch stitches, the mark must always

be within the SS range - (see drawing).

¡°¡±

SS

7

THE PATTERN SELECTOR

The desired pattern can be selected by turning the pattern selector dial. The marks in the stitch display correspond

to the patterns shown on the panel respectively, as follows:

A ( ) straight stitch, middle needle position

B ( ) straight stitch, left needle position

C ( ) zigzag stitch with variable width

D ( ) tricot stitch

E ( ) stretch blind stitch

F ( ) double action stitch

G ( ) reverse blind stitch

( Model 374)

automatic buttonhole sewing

THE PATTE

( )

1 - 3

( )

4-6

7

( )

8

( )

( )

9

10

( )

( )

11

12

( )

( )

RN SELECTOR

straight stitch

zigzag stitch

triple zigzag stretch stitch

triple straight stretch stitch

overlock stitch

smocking stitch

tricot stitch

shell stitch

automatic buttonhole sewing

( Mode

l 473/373/372/372H)

RE MOVING THE BOBBIN CASE AND BOBBIN

1. Raise the presser foot and turn the balance wheel towards

you until the thread takd-up lever is at its highest position.

2. Open the shuttle cover.

3. Open hinged latch of bobbin case and pull bobbin case out of

machine.

Release the latch and the bobbin will fall out. As long as you

hold the bobbin case latch open, the bobbin cannot drop

out.

8

Open

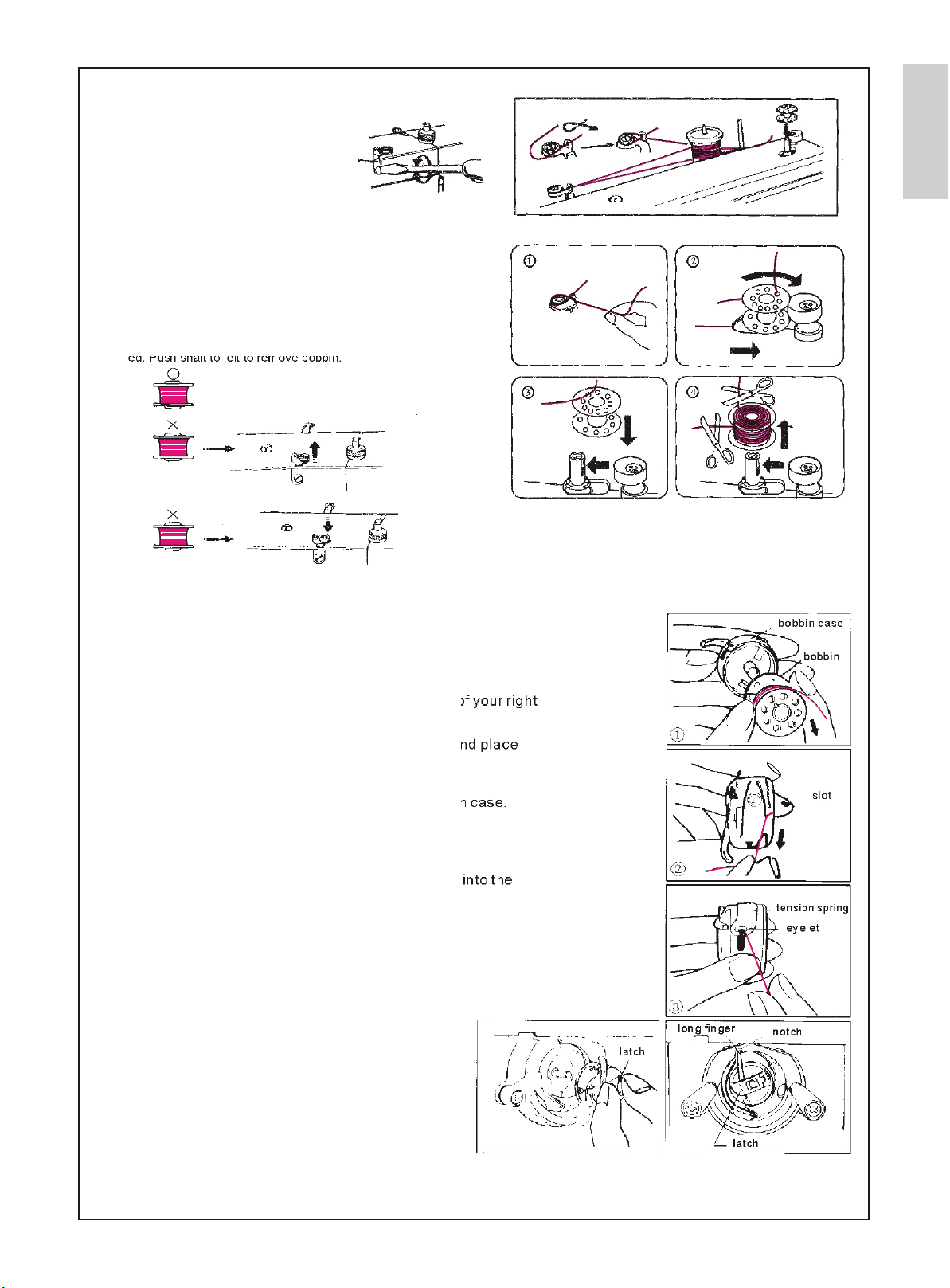

WINDING THE BOBBIN

1. Draw thread from spool through

bobbin winder tension disc as shown.

2. Pull end of thread through hole in bobbin

as shown.

3. Push bobbin winder shaft to far left position,

if it is not already there. Place bobbin onto

shaft with end of thread coming from top of

bobbin. Push bobbin winder shaft to right

until it clicks. Hold onto end of thread.

4. Start machine. The thread that is held will

snap or may be trimmed with a scissors,

Bobbin will cease turning when completely

filled. Push shaft to left to remove bobbin.

When the bobbin winding is incorrect, release

the screw of the upper thread guide and adjust

the thread guide up or down until the winding

of the bobbin is balanced.

THREADING THE BOBBIN CASE

Hold the bobbin between the thumb and forefinger of your right

hand and pull off about 15cm (6 inches) of thread.

1. Hold the bobbin case in your left hand as shown and place

the filled bobbin inside.

English

1

3

2

4

bobbin case

bobbin

2. Pull the thread into the slot in the edge of the bobbin case.

3. Now pull the thread under the tension spring and into the

thread eyelet.

To insert the bobbin case and bobbin......

Ensure that about 15 cm (6 inches) of thread extends

out of bobbin. Hold the bobbin case so that long

finger on case points up. Open the latch of bobbin

case. Slip the bobbin case over the center pin of

hook and press in place until the long finger of the

bobbin case enters the notch entirely to lock the

bobbin in place. Release latch and press it down.

9

latch

long finger

slot

tension spring

eyelet

notch

latch

THREADING THE NEEDLE

Install the spool pin behind the machine

(as sho

Place spool on spool pin, with thread

coming from the back of the spool. Place

the take - up lever 5 in the highest

position.

wn in fig A).

fig A

6, 7, 8

3

1

2

5

A

B

4

1. Raise the presser foot using the foot lever

marked B .

aw the thread through the thread

2. Dr

guides on the top cover as shown in Fig. 1 & 2. .¢Ù¢Ú

3. Hold the spool still with right hand, pull

the end of the thread between the

ension disk as shown in Fig. 3 .¢Û

t

4. Following the slotted threading path,

pull th

spring (inside) and lead it across from

left to right.

5. Pull the thread upward and slip into

the slotted hole of thread take-up level

from left to fight

6. Draw the thread through guides and

and thread the needle from front to

rear , leave the thread about 15cm(6

inches) long underneath the presser

foot.

e thread down to the thread check

5

.

7

,

8

6

B

1

2

5

3

6

7

4

8

10

DRAWING UP THE BOBBIN THREAD

1.Hold the end of the needle thread with your left hand.

2.Turn the balance wheel slowly towards you with your right

hand until the needle goes down and comes up. Then stop

the balance wheel when the take-up lever is at its highest

position.

Lightly draw up the needle thread forming a loop with the

bobbin thread.

3.Puil about 15cm (6 inches) of both threads away from you

under the presser foot.

English

needle thread

1

2

needle

thread

bobbin

thread

STRAIGHT STITCH AND ZIGZAG STITCH

377B 374

Presser foot

Pattern selector

Stitch length dial

zigzag foot

M ( )

(for straight gtitch)

1 - 5 (54321) (for zigzag stitch)

O ( )

or

0.3-4

A ( ) B ( )

(for straight stitch)

zigzag foot

or

C ( ) (for zigzag stitch)

0.3-4

Starting Sewing

1. Be sure both the threads are drawn back under the presser foot.

2. While holding the threads with your left hand, turn the balance

wheel toward you to bring the needle into the fabric where you

wish to start sewing.

3. Lower the presser foot, and press the speed controller gently,

then start sewing slowly.

*Sew a few reverse stitches by pushing reverse button for

reinforcing the end of seams.

*Raise the needle to its highest position before turning the

pattern selector dial and stitch width dial.

3

3

73/372/372H

473/

( ) (for straight stitch)

( ) (for zigzag stitch)

-

zigzag foot

11

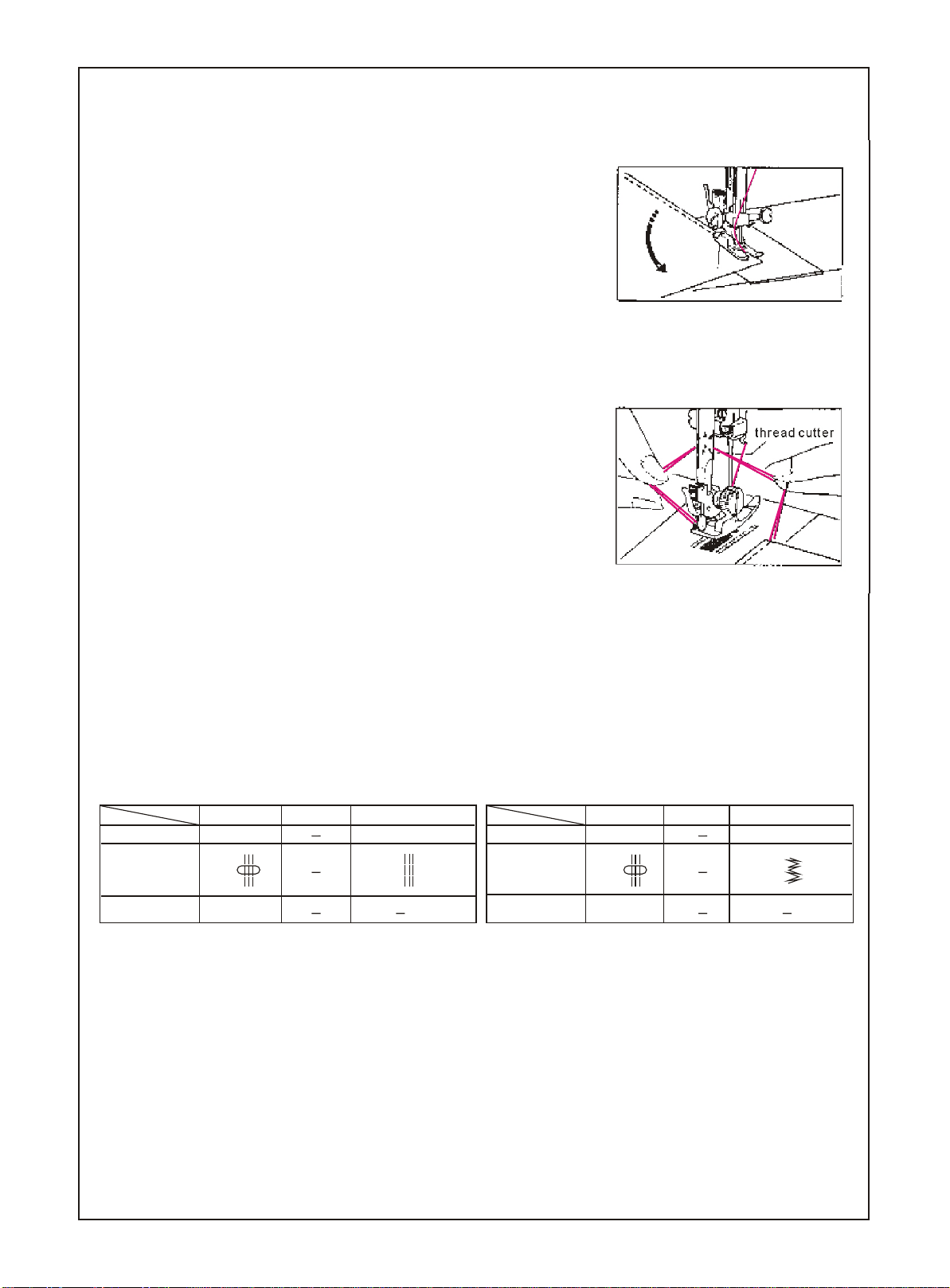

C hanging S ewing Dire c tions

1. Stop the ma chine, and turn the ba lance wheel toward you to

bring the ne edle down into the fabric. Ra is e the presser foot.

2. P ivot the fabric a round the nee dle to change direction a s

des ired.

3. Lower the pres ser foot and c ontinue sewing.

F as tening S eams

1. For fas tening the ends of seams, pres s in the revers ing

button and s ew seve ral reve rs e s titches .

2. To remove the fabric, rais e the pres ser foot and dra w the

fabric awa y from you.

3. C ut threa ds on thread c utter a t the rear of pres s er bar or

with a pair of s ciss ors.

Le ave a bout 15 cm (6 inches ) of hread ha nging from the

needle eye.

thread c utter

TR IP L E S TR E TC H S TITC H

If you wish to sew s tretch fabrics , this is the right stitch to avoid thread bre aking. T his is a ls o ve ry s uitalbe

for sea ms that nee d great s trength,e.g.crutch s eams or pocke t sea ms.

TR IP LE S T R A IG HT S TR E T CH S T ITC H

377B 374 473/373/372/372H

Presser foot

Pattern selector

Stitch length dial

zigzag foot

M( ) 8( )

S.S.

(Model 473/374/373/372/372H)

zigzag foot

Presser foot

Pattern selector

Stitch length dial

TR IP LE ZIG ZA G S T R E TC H S TIT C H

377B 374 473/373/372/372H

zigzag foot

zigzag foot

O( ) 7( )

S.S.

Note: * Us e a S TR E TC H needle.

The blue tipped s hank needle effectively prevents

skipped s titches .

12

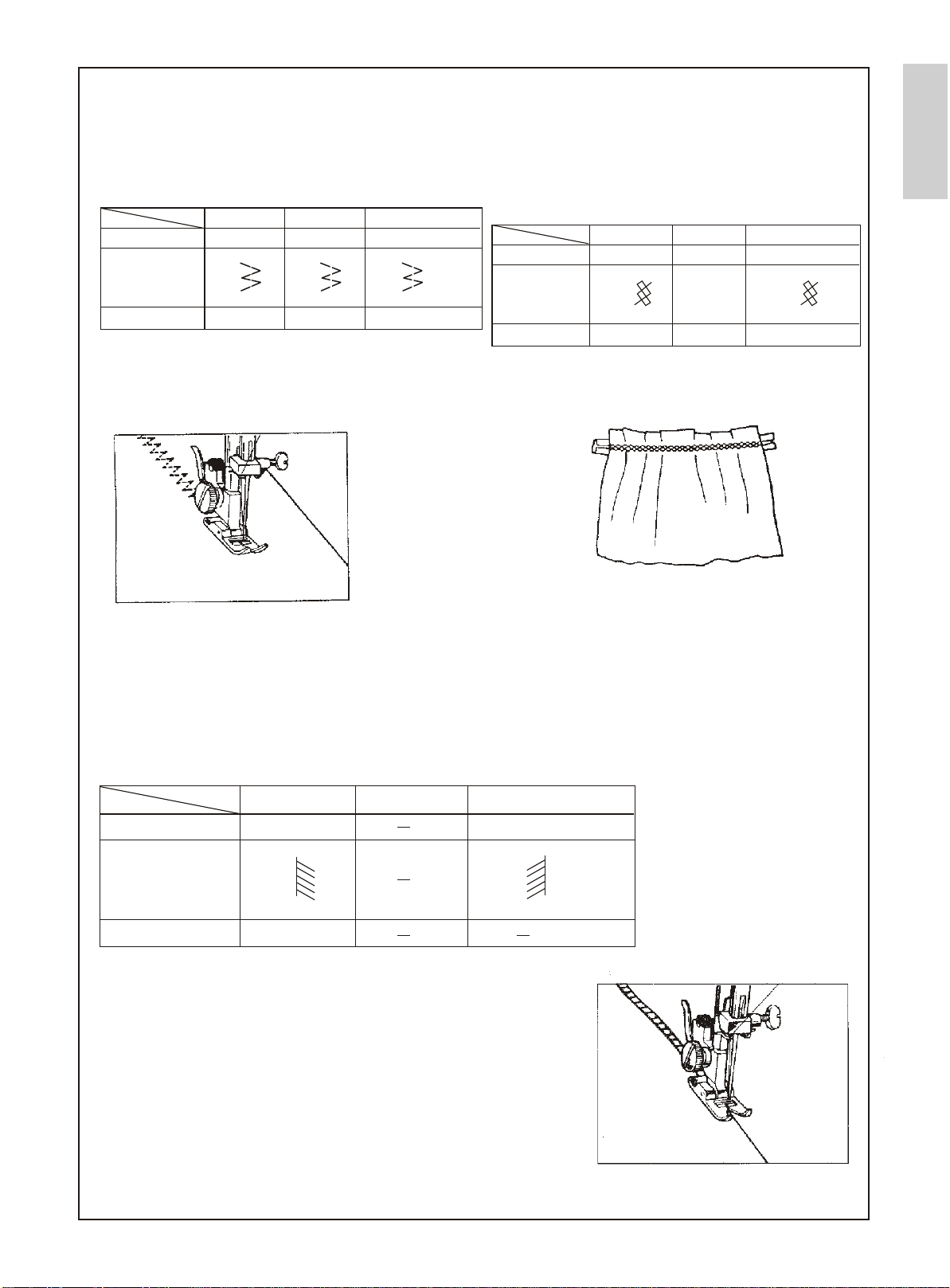

TR IC OT ZIG ZAG S TIT CH

This s titch is very suitable for darning tears. It c an

als o be us ed for reinforcing stretch materials a nd

sewing on fa bric parts.

377B 374 473/373/372/372H

Presser foot

Pattern selector

Stitch length dial

Note: *Us e a S T R E T C H nee dle.

The s tretch ne edle effectively prevents

skipped s titches .

zigzag foot

A ( )

0.3 to 4

zigzag foot

D ( )

0.5 to 4

zigzag foot

11( )

-

S MOC K ING S TIT CH

With a na rrow strip of fa bric directly under the line

of gathering, s titch over the ga thers . T he des ign will

be a s eries of small diamonds.

When s mocking a ga rment, the s titching should be

done before the piece is sewn into the garment.

377B 374 473/373/372/372H

Presser foot

Pattern selector

Stitch length dial

zigzag foot

A ( )

S.S.

zigzag foot

10( )

-

English

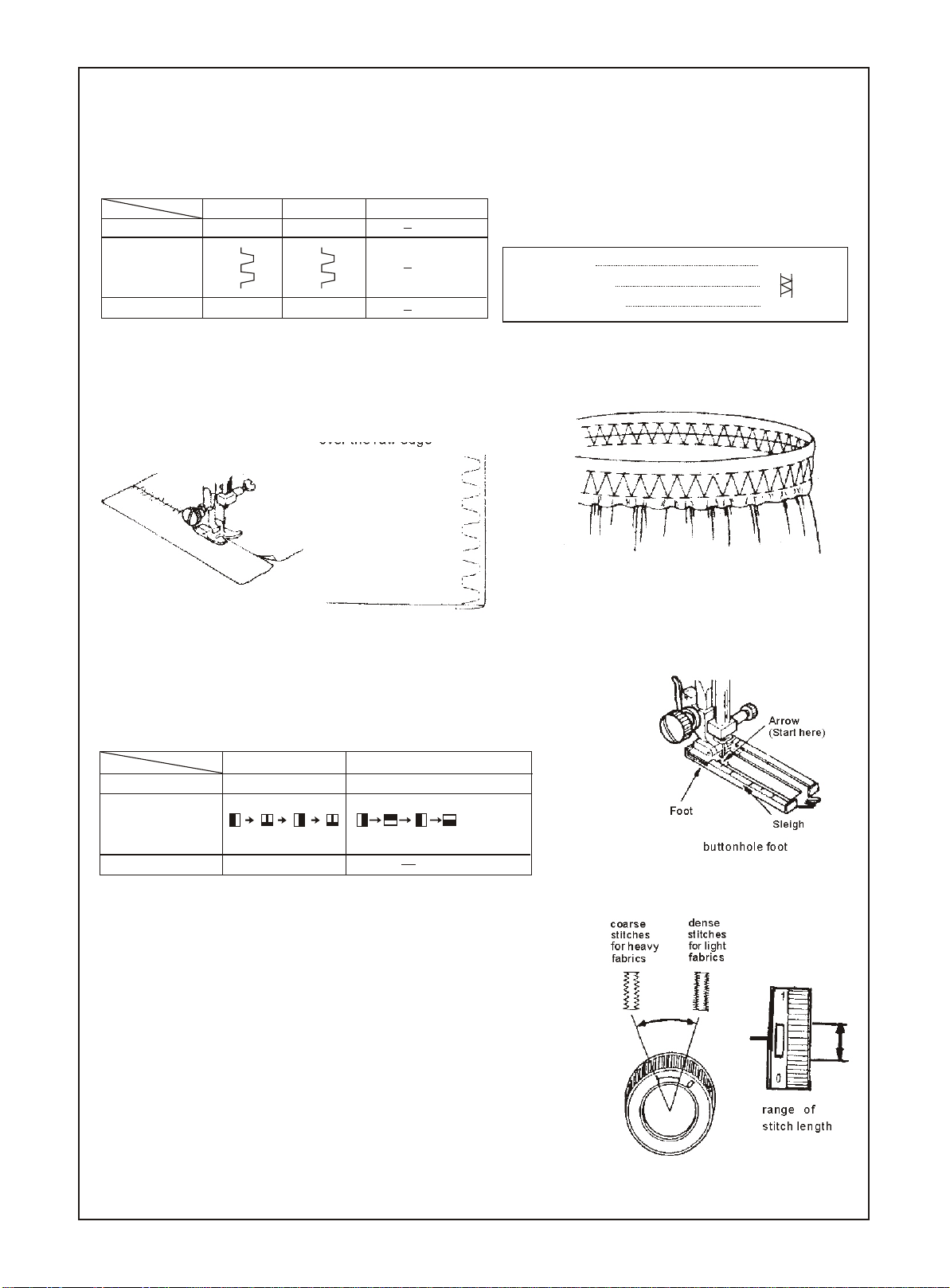

OVE R LOC K S TIT CH

With this s eam it is poss ible to prevent raw edges, es pecially on easilyfraying fabrics,with a good-locking and

las ting edge finish.

377B 374 473/373/372/372H

Presser foot

Pattern selector

Stitch length dial

P lace the fabric under the pres s er foot s o that the stitches are ma de

over the edge.

Lower the press er foot a nd s tart sewing.

G uide the material lightly as s hown.

S ew on a piece of waste fabric to check the ma chine s etting.

The overlock s titches a re formed correctly when the needle sews

to the right and just misses the fa bric edge.

Note: *Us e a needle.

D ( ) 9( )

S.S.

S T R E T C H

The stretch nee dle e ffectively prevents skipped s titches .

zigzag footzigzag foot

13

DO UB L E A CT IO N S TIT C H

DOUB L E OVE R L OC K S TITC H

(Model EP 377B only)

This is a good stilch to use in attaching or binding

elas tic fabrics and stretch lac e, lingerie s tretch knit.

The s titch is decorative as well as us eful.

377B 374 473/373/372/372H

Presser foot

Pattern selector

Stitch length dial

zigzag foot

C ( )

1 to 2.5

zigzag foot

F( )

1 to 2.5

DE C OR AT IVE E DG ING

Turn the raw e dgeunde r 2c m and pres s. P lace the

fabric right s ide up with the middle of the turnover

under the center of the presser foot, so that the

stitch sews on to the fold and just over the raw edge.

underne ath.

Us e this vers atile stitch to insert ela stic in garments.

S imply s titch elas tic into place, making sure it is

eve nly s paced. To do this, mark the corre ct length

piece into qua rters , then ma tch thes e markings with

center front and s ide sea ms .

P resser foot zigza g foot

P attern selector

S titch length dial

C ( )

S . S .

S E WIN G B UT TO NHO LE S

The built -in buttonhole mec hanism of this machine makes it possible to sew

button holes in a s hort time without turning the materia l.

Presser foot

377B/374

473/

373/372/372H

buttonhole footbuttonhole foot

Pattem selector

Stitch length dial

R ais e the foot and the needle to its highes t position. R eplac e the foot with

the trans parent buttonhole foot for sewing buttonholes.

Mark the loc ation a nd the des ired length of buttonhole on the fabric us ing a

pencil or tailor s cha lk.

Note:

(Model 377B and 374 only)

,

*To find the mos t suitable

s titch length, it is better

to s ew a sample buttonhole

on a piece of was te fabric.

* W hen sewing very fine

fabrics and s ynthetics , de cre as e the pres sure of foot

0.5 to 1

* The mark on the stitch

length dial s hows a range of

buttonhole sewing. An

adjus tment can be ma de

by s etting the mark, as

shown.

* Buttonhole stitch length is

adjus table only on one side.

and sew over a piece of

paper to prevent yarn dis tortion.

coa rse

s titche s

hea vy

for

fabrics

F oot

buttonhole foot

dens e

stitche s

for light

fabrics

Arrow

(S tart here)

S le igh

range of

stitch le ngth

14

SEWING BUTTONHOLES (Model 377B and 374)

1. Set the pattern selector at

throughthe opening in the buttonhole foot and draw both needle

and bobbin threa

towards you until the needle comes to the point

2.Lower the foot and sew slowly until the desired length is sewn,

then stop the machine at

3. Raise the needle and s

several stitches of bar tack until the needle is at point

4. Rais

e the needle and set the selector at

ds to the left side. Turn the balance w

right side of buttonhole the same length as the left side of

bu

ttonhole. Stop t

5. Raise needle and set the selector at then sew several

stitches of final ba

point . To lock threads, set the pattern selecto

point of zigz

6. Cut thebuttonhole open carefully using a seam ripper, taking care

not to damage the bar tacks.

(5).

he machine at

r tack. Stop the machine with the needle at

ag width). And sew a few stitches.

. Then pass the needle thread

¡°¡±

(1).

(2).

et the selector at . Th

(4).

¡°¡±

then sewthe

¡°¡±

¡°¡±

r at B (zero

heel

en sew

(3).

¡° §

SEWING BUTTONHOLES (Model 473/373/372/372H)

1. Set the pattern selector at Then pass the needle thread

through the open

needle and bobbin threads to the right side. Turn the balance

wheel towards yo

2. Lower the foot and sew slowly until a desired length is sewn,

then stop th

3. Raise the needle and s

several stitches of bar tack until the n

4. Raise the needle and set the selector at then sew the

left side of buttonhole just as the same length as the right side of

buttonhole. Stop the m

5. Raise the needle and set the selector at then se

stitches of final bar tack. Stop the machine with the needle at

point

6. Cut the buttonhole open carefully using a seam ripper, taking

care not to damage the bar tacks.

Note

same procedure.

(5).

: To make a heavier buttonhole, sew twice by repeating the

ing in the buttonhole foot and draw both of

u until the needle comes to the point

e machine at

¡°¡±

(2).

et the selector a

achine at

(4).

t then sew

¡°¡±

eedle is at point

¡°¡±

¡°¡±

(1).

(3).

w several

( 377B and 374 only)

E nglish

(473/373/372/372H)

S E WIN G ZIP PE R S

377B 374 473/373/372/372H

Presser foot

Pattern selector

Stitch l ength dial

R ais e the foot a nd the ne edle to its highes t position by turning

the bala nce whee l towards you. Re place the foot with the z ipper

foot.

zipper foot

M( )

1 to 4

1. Pin or ba ste the zipper tape to the fabric a nd place the work-

piece in position under the foot.

Attach s nap on z ipper foot s o that the needle pas ses on its

left hand side.

* Whe n starting s ewing, both ne edle a nd bobbin threads ends

should be put a wa y under the foot.

2. S ew on the right side of the zipper by guiding Zipper teeth

as close as pos sible to the nee dle drop. B efore the foot reaches

the s lider on the zipper tape, ra ise the foot and open the

zipper by keeping the needle in the fabric.

Lower the foot and s ew on the remaining of the s eam,

3. To se w the left side zipper change pos ition of foot to bring

the foot to the left s ide of the needle. Sew on in the s ame

way as you did on the right side of zipper.

zipper foot zipper foot

A( )

1-3( )

1 to 4

Zipper foot

E leme nts

Zipper foot

Tape

F a bric

S lider

Ne edle

F abric

E leme nt

tape

E leme nts

E le ment

S lider

F ia. 1

15

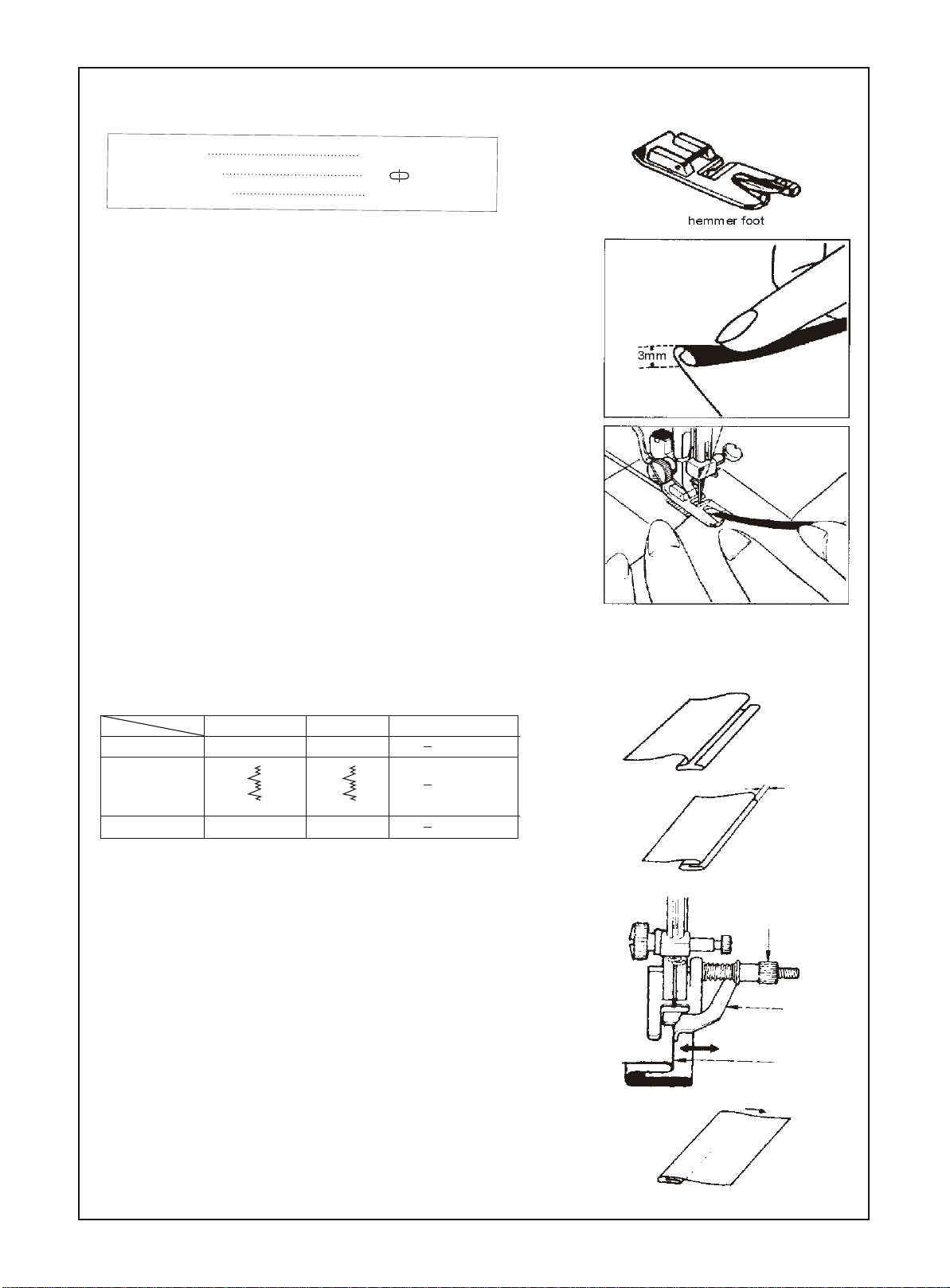

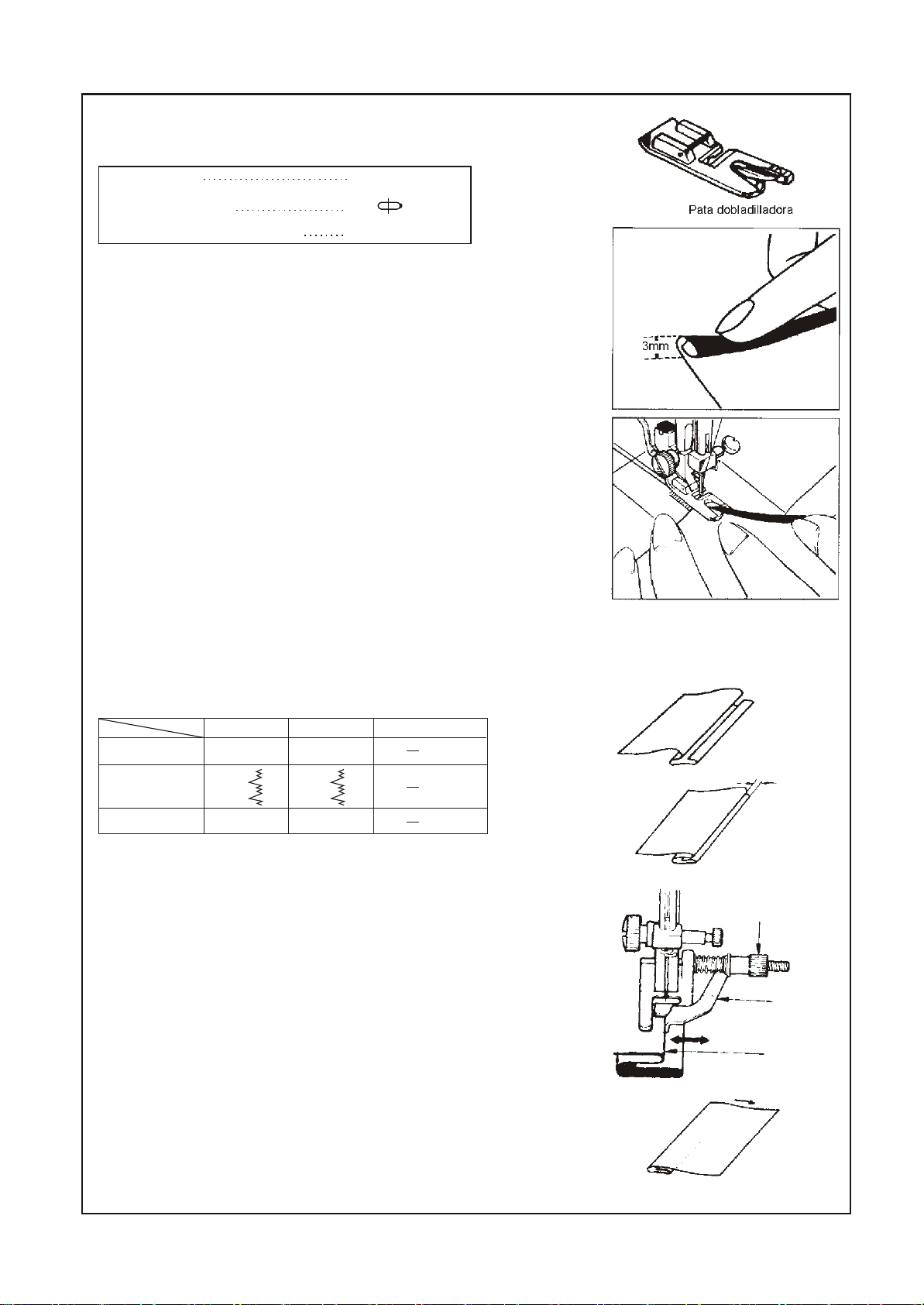

HE MMING

(Model 377B only)

P ress er foot

P attern selec tor

S titch length dial

hemmer foot

M( )

1 to 4

R ais e the foot and the needle to its highes t position. R epla ce the

foot with the hemmer foot.

F old over the fabric edge by a bout 3mm (1/8 inches ) and pla ce it

under the foot. Secure the folded edge with a few s titches . Take

out the workpiece and dra w the hem into the hemme r foot by

pulling on the threads.

Lower the foot a nd s we the hem.

During sewing, fold the fabric to the left a little a nd allow it to

run into the hemmer foot.

Make s ure that the fabric does not move under the right ha lf of

the foot. The fabric mus t be fed into the scroll of the hemmer

sufficiently s o that the workpiece edge runs freely through the

groove under the foot.

hemmer foot

3mm

S E WING B L IND HE MS

(Model 473/377/374/373/372/372H)

377B 374 473/373/372/372H

Presser foot

Pattern selector

Stitch length dial

blind hem foot

B ( )

1 to 3

blind hem foot

E ( )

1 to 3

1. T urn up the hem to the des ired width a nd pres s. ( F ig. 1)

2. Fold hem back a gainst the right s ide of the garment with

top edge of hem extending about 4 mm (1/6 inche s ) to the

right side of the ga rment folded. (F ig. 2)

3. Pla ce the garment under the foot so that double-folded edge

runs a long the hemlguide and lower the foot.

S ew s lowly for better control, ma king sure the na rrow

zigza g stitches are sewn on the hem edge and wide z igzag

s titche s will just c atch one thread of folded edge. (Fig. 3)

4. Unfold the fabric and you will have a bling s titch hem

(F ig. 4)

(F ig. 1)

4mm (1/6 )

,

(F ig. 2)

G uide

adjus ting

s c re w

(F ig. 3)

,

(F ig. 1)

G uide

F oided edge

16

(F ig. 4)

Rev. 12/04

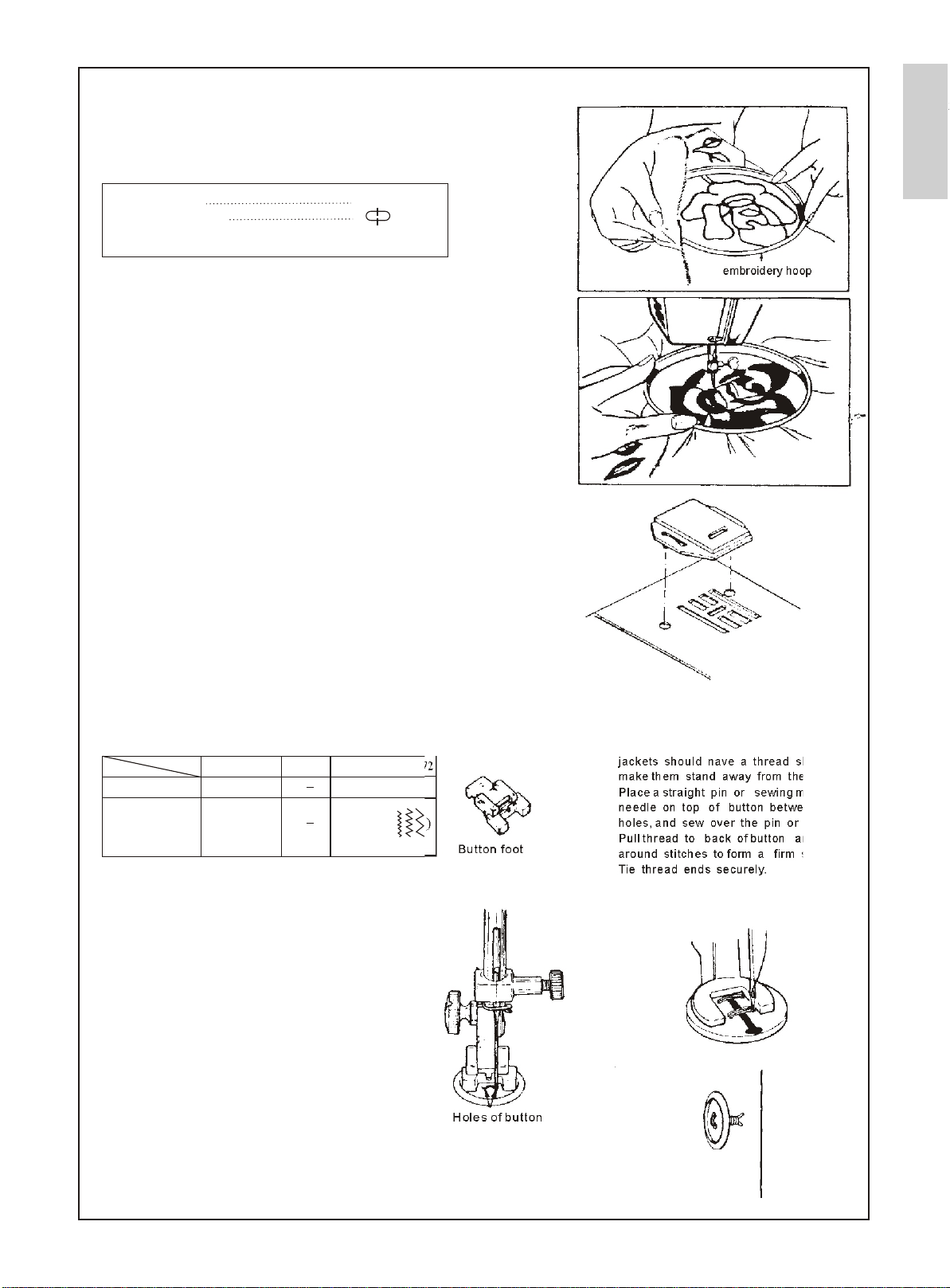

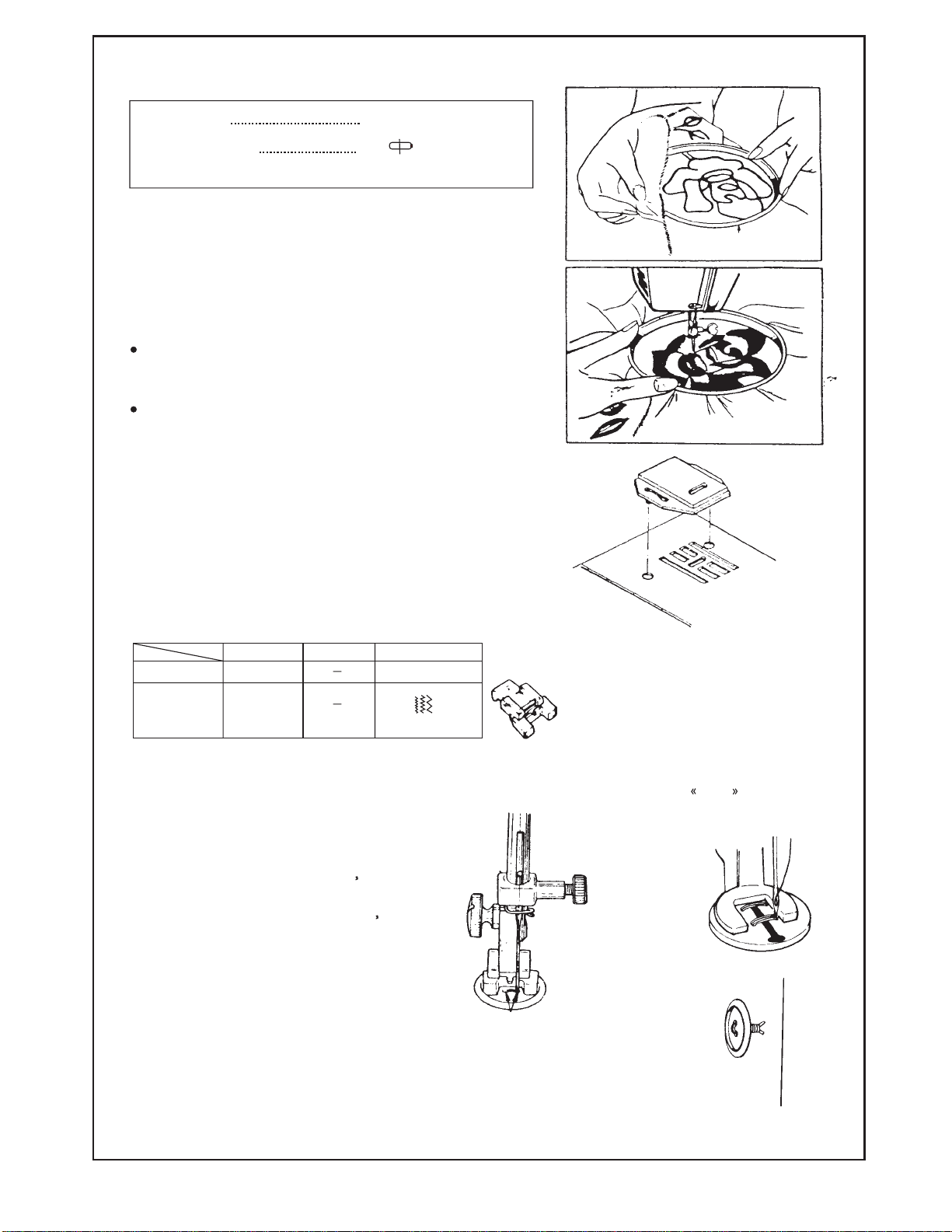

SEWING EMBROIDERY

Presser foot

Pattern selector

darning plate

( ) or

zig zag

Raise and take off the foot.

Place the fabric in embroidery hoop. Place darning plate

over needle plate (see below). Lower the presser foot lifter.

Hold the embroidery hoop firmly with your hand.

While sewing the desired pattern, move the embroidery hoop

slowly and do not allow your fingers to get near the needle.

*Set the needle thread tension a little looser so that the bobbin

thread is not pulled through to the right side of fabric.

(See page 13).

*It is recommended to mark the required embroidery pattern

on the right side of the fabric with a pencil or tailor s chalk.

,

DARNING PLATE

There are a few times when you want to control the feeding of

the fabric yourself. Raise needle to its highest position and

raise presser foot. Place darning plate over needle plate

aligning two pins of darning plate with holes of needle plate.

You may then determine the movement of the fabric yourself.

See above for embroidery.

English

embroidery hoop

BUTTONS

377B 374 473/373/372/372H

Presser foot

Pattern selector

1. Align two holes of button with slot

of presser foot and lower foot to

hold the button securely.

2. Turn hand wheel manually until

needle point is just above button.

3. Adjust stitch selector so needle enters

right hole of button.

4. Turn hand wheel by hand so needle

enters second hole. The stitch selector

may need to be adjusted again. Stitch

a number of times.

NOTE:

You may find it helpful to use transparent tape to position your button

and to keep it in place during sewing.

Tear away after stitching.

5. Finish sewing with an extra two

inches of thread remaining. Draw

these threads to reverse side of gar ment and tie.

button foot

1-5(54321)

button foot

4-6( )

Button foot

Holes of button

Thread Shank

Sew-through buttons on coats and

jackets should nave a thread shank to

make them stand away from the fabric.

Place a straight pin or sewing machine

needle on top of button between the

holes, and sew over the pin or needle.

Pull thread to back of button and wind

around stitches to form a firm shank.

Tie thread ends securely.

17

CLEANING THE FEED DOG

It is necessary to keep the feed dog teeth always cleaned in order

to ensure smooth sewing.

1. Remove the needle and the presser foot.

2. Unscrew the needle plate set screws with a screw driver to take

off the needle plate from the machine.

3. With a brush, clean out dust and lint clogged on the feed dog

teeth.

4. Refit the needle plate.

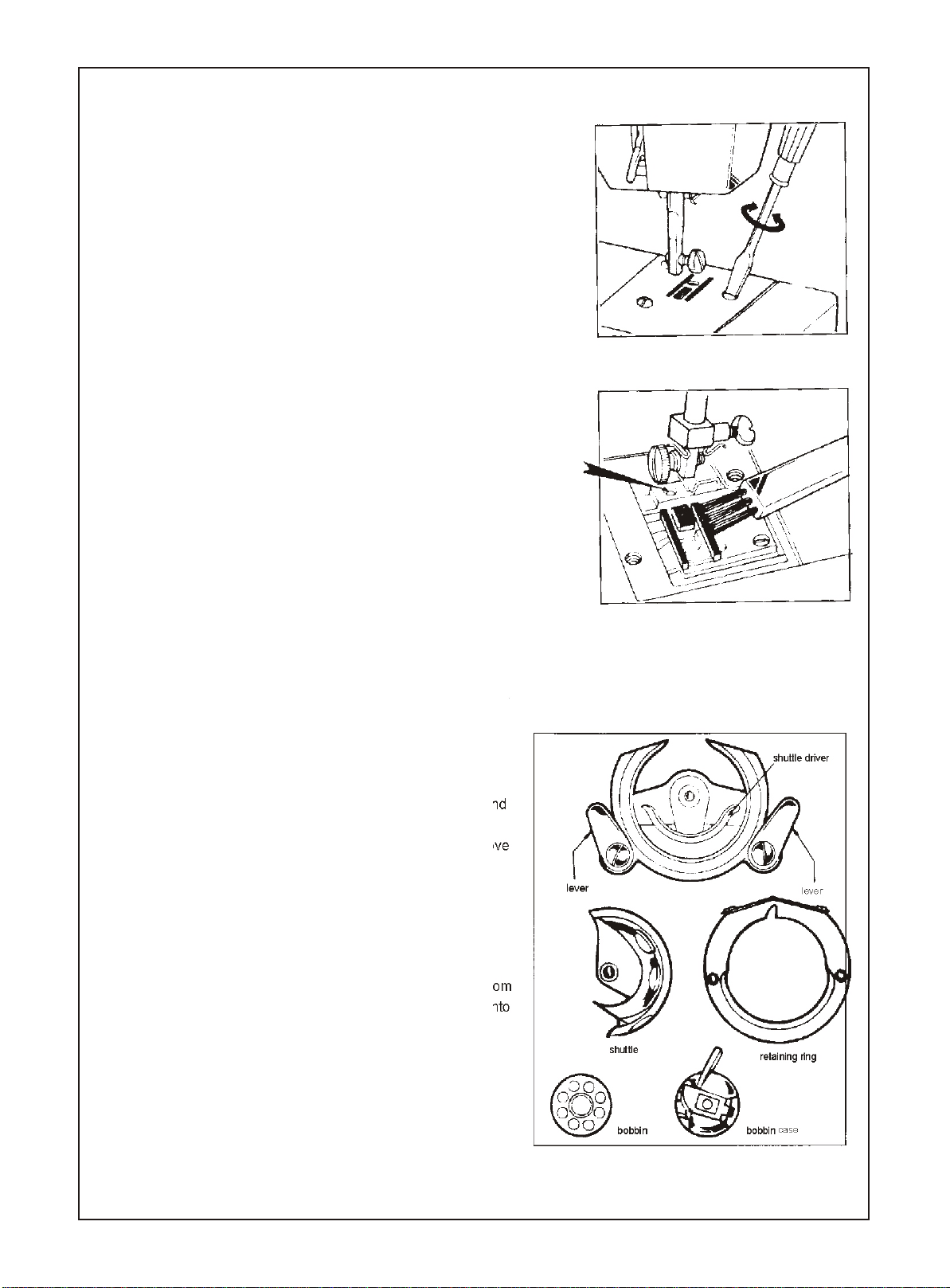

CLEANING THE SHUTTLE RACE

Unplug the machine from the power supply.

To remove shuttle:

Raise needle to its highest position and remove bobbin case.

Turn levers away from shuttle and lift out retaining ring and

shuttle, by grasping center pin.

Clean the reverse side of feed dog with a small brush. Remove

lint and thread from all parts of shuttle and wipe with a lightly

oiled cloth.

To reassemble:

Hold shuttle by center pin and fit carefully back into shuttle

race, forming perfect circle with shuttle driver..

Replace retaining ring polished side out, making sure the bottom

pin fits into notch. Lock retaining ring by turning levers back into

position, Refit bobbin case with bobbin.

lever

shuttle

bobbin

shuttle driver

retaining ring

case

bobbin

lever

18

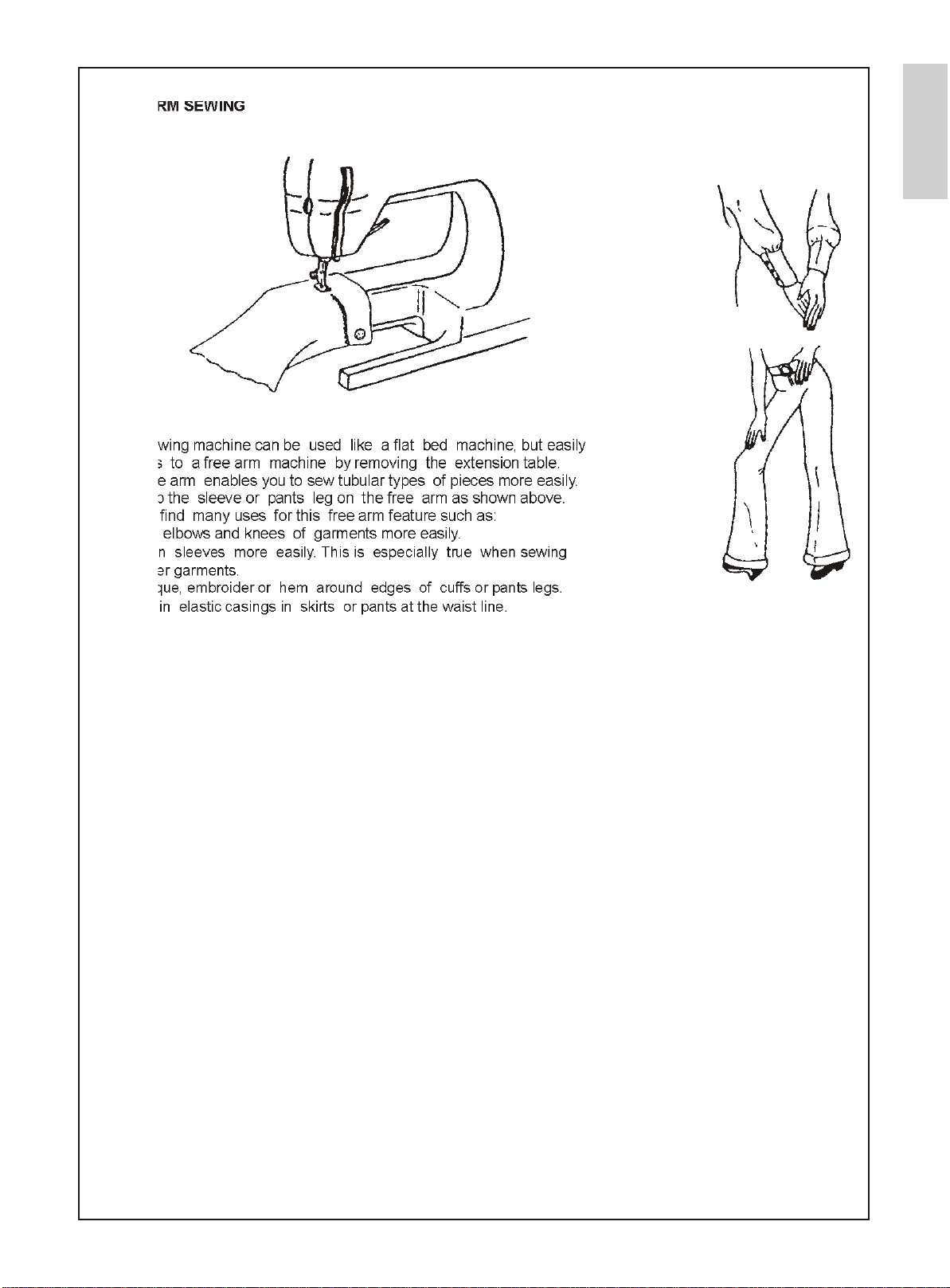

FREE ARM SEWING

This sewing machine can be used like a flat bed machine, but easily

converts to a free arm machine by removing the extension table.

The free arm enables you to sew tubular types of pieces more easily.

Just slip the sleeve or pants leg on the free arm as shown above.

You will find many uses for this free arm feature such as:

1. Mend elbows and knees of garments more easily.

2. Sew in sleeves more easily. This is especially true when sewing

smaller garments.

3. Applique, embroider or hem around edges of cuffs or pants legs.

4. Sew in elastic casings in skirts or pants at the waist line.

English

19

TROUBLE SHOOTING: CAUSES AND REMEDIES

THREAD FORMS LOOPS

CAUSE

Thread tension not properly regulated

Needle thread properly threaded and/or bobbin thread

not properly wound

Thread size not suited to fabric

Thread check spring not working properly

SHRINKING OR PUCKERING OF THE SEAM

Tension too tight

Sewing foot pressure too strong

Needle and bobbin threads of poor quality

Bobbin thread unevenly wound

MACHINE DOES NOT RUN FREELY AND MAKES A NOLSE

Machine needs oiling

Dust and thread in shuttle

Wrong oil used, has now clogged machine

Drive belt tension too tight

REMEDY

Read instructions for regulating needle-and bobbin thread tension

Thread machine properly and/or wing bobbin thread correctly

See Size of needle and thread

Have spring replaced

Read instructions for regulating needle-and bobbin thread tensions

Read instructions for regulating sewing foot pressure

IRREGULAR STITCHES

Use top quality threads

Re-wind bobbin

Read instructions on how to oil

Read instructions on how to clean shuttle race

Clean machine carefully and re-oil with top quality oil

Loosen tension of drive belt

TROUBLE SHOOTING: CAUSES AND REMEDIES

NEEDLE THREAD BREAKS

CAUSE

Needle not properly threaded

Thread tension too tight

Something wrong with the needle

Thread is too heavy for needle

Thread check spring is broken

Needle not properly inserted

Needle plate, shuttle or sewing foot damaged

BOBBIN THREAD BREAKS

Bobbin thread entangled because of incorrectly wound bobbin

Bobbin thread not under tension spring on bobbin case

STITCHES ARE LEFT OUT

Needle not properly fitted on needle bar

Needle bent or blunt

Needle worn

NEEDLE BREAKS

Needle bent

Needle not properly fitted

Fabric too heavy or too hard

You are pulling on the fabric

REMEDY

Thread properly

loosen tension

Replace needle

Change

Have a new spring fitted

Insert needle properly

Replace

Wind bobbin correctly

Thread bobbin correctly

Fit needle properly

Replace

Replace

Replace

Fit needle properly

Use needle of correct size

Do not pull

20

25 YEAR LIMITED WARRANTY

EURO-PRO Operating LLC warrants the sewing machine head and any of its parts other than those covered by the 2year warranty below or those subject to normal wear and tear for a period of 25 years from date of the original purchase,

to be free of defective parts due to imperfections in the workmanship and materials, subject to the following conditions,

exclusions and exceptions.

The electrical equipment (motor, foot control, light, etc.) are warranted free from defects in material and workmanship for

a period of two years from the date of original purchase.

Non-durable parts including, without limitation, needles, belts, bobbins, bulbs, bobbin cases, shuttles, springs, and parts

which normally require replacement are specifically excluded from this warranty.

This warranty is void if: (a) This product has been cleaned, serviced, modified or tampered with by anyone other than an

authorized service representative of EURO-PRO; (b) The serial number has been modified, defaced or removed from

this sewing machine; (c) This product has been abused or damaged; (d) Non EURO-PRO branded parts, supplies,

power supplies or other accessories have been used with this product.

This warranty is in effect provided the sewing machine is used only for normal household use

when new, and is given reasonable good care and proper maintenance in accordance with the accompanying instruction

book. The manufacturer is not held responsible for damage, normal wear, accident, abuse, neglect, negligence or if the

machine has been repaired by unqualified personnel.

This warranty is extended to the original purchaser of the unit and excludes all other legal and/or conventional

warranties. The responsibility of EURO-PRO Operating LLC if any, is limited to the specific obligations expressly

assumed by it under the terms of the limited warranty. In no event is EURO-PRO Operating LLC liable for any indirect,

incidental or consequential damages of any nature whatsoever. Some state/provinces do not permit the exclusion or

limitation of incidental or consequential damages, so the above may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state or

province to province.

EURO-PRO Operating LLC will, at its option, repair or replace this sewing machine free of charge if it fails to operate

according to specifications due to factory defects in materials or workmanship within one year from date of purchase. For

25 years from date of purchase, EURO-PRO Operating LLC will repair or replace defective sewing machine head parts;

owner pays for labor charges. The sewing machine must be shipped freight and insurance prepaid. For instructions

please call customer service a t 1 (80 0) 3 6 1-4 6 3 9 or visit o ur web site www. e ur o-pr o.c om.

A copy of your sales receipt and a check or money order made out to EURO-PRO Operating LLC in the amount of

$19.95 for handling and return packing/shipping charges must be included.*

*Important: Carefully pack item to avoid damage in shipping. We recommend you insure the package (as

damage in shipping is not covered by your warranty). Be sure to include a copy of your sales receipt and attach

a tag to the machine with your name, address and telephone number. Please include a check or money order

made out to EURO-PRO Operating LLC in the amount of $19.95 to cover return shipping and handling.

by the original purchaser

-------------------------------------------------------------------------------------------------------------------------------------------------------

OWNERSHIP REGISTRATION CARD

FOR CANADIAN CONSUMERS ONLY

Please fill out and mail the product registration card within ten (10) days of purchase. The registration will enable us to contact you in the unlikely

event of a product safety notification. By returning this card you acknowledge to have read and understood the instructions for use, and warnings set

forth in the accompanying instructions.

RETURN TO: EURO-PRO Operating LLC, 4400 Bois Franc, St. Laurent, QC H4S 1A7 Tel.: 1 (800) 361-4639

________________________________________

Appliance model

______________________________________________________________________________________________________________________

Date purchased Name of store

______________________________________________________________________________________________________________________

Owner’s name E-mail address

______________________________________________________________________________________________________________________

Address City State/Province Zip code/Postal Code

Rev. 07/08 21

Would you like to receive information on

updates, new products, etc. from EURO-PRO?

Yes No (fill one)

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

Al use artefactos electricos siempre se deben tomar precauciones basicas de seguridad, incluyendo las

siguientes :

`

Spanish

Leer todas las instrucciones antes de use la maquina de coser.

~~

Esta maquina de coser esta disenada solo para uso domestico.

`

`

``

PELIGRO:

No dejar la maquina de coser desatendida cuando este enchufada. Sieppre desenchufarla del tomacorriente

inmediatamente despues de usarla o antes de limpiarla

``

`

ADVERTENCIA:

PARA REDUCIR EL RIESGO DE CHOQUE ELESTRICO :

1. No permitir que se use como juguete. Se debe supervisar estrechamente a los ninos cuando usen la

maquina de coser o se use cerca de ellos.

2. Use la maquina de coser solo para lo que esta disenada y para lo que esta descrito en este manual. Solo

`

`

`

`

Para reducir el riesgo de choque electrico :

~

`

`

`

~

`

use los accesorios recomendados por el fabricante en este manual.

3. Nunca operar la maquina de coser si tiene el cordon o el enchufe danado, despues que hubiese funcionado

mal, que se hubiese caido, danado de cualquier forma o caido en agua. Devolverla al distribuidor o crntro

de servicio autorizado para su revision, reparacion o ajuste electrico o mecanico.

4. Nunca operar la maquina de coser si alguna de sus aberturas para aire esta obstruida. Mantener las

aberturas de ventilacion y el control de pie sin acumulaciones de pelusa, polvo y sin telas sueltas.

`

~

`

````

`

`

`

`

~

`

`

5. Nunca insertar o dejar caer objeto alguno en las aberturas.

6. No use en exteriores .

7. No operar en ambientes donde se esten usando aerosoles o donde se este administrando oxigeno.

8. Para desconectat, primero apagar la maquina poniendo el control en la posicion O y despues desenchufar

`

`

``

¡°

`

`

del tomacorriente.

9. No desconectar del tomacorriente jalando del cordon, hacerlo jalando del enchufe.

A Maquinas de Coser

`

10. Mantener los dedos alejados de las piezas moviles. Tener cuidado especial alrededor de la aguja de coser.

`

`

11. Siempre use la placa adecuada para la aguja. La placa equivocada puede hacer que la aguja se rompa.

12. No use agujas dobladas.

13. No empujar ni jalar la tela mientras la maquina este dando puntadas porque la aguja puede doblarse y

`

`

romperse.

14. Apagar la maquina de coser poniendo el control en posicion O antes de hacer cualquier ajuste alrededor

`

`

de la aguja, como enhebrar o cambiar la aguja, cambiar el carrete, enrollar la bobina o cambiar la pata

prensora, etc.

15. Siempre desenchufar la maquina de coser del tomacorriente antes de quitarle las cubiertas, se lubrique o se

`

le haga cualquier otro servicio o ajuste mencionado en este manual.

16. Siempre desenchufar antes de cambiarle el foco de luz por otro igual de 15 wats.

CONSERVE ESTAS INSTRUCCIONES

22

FAMILIARIZANDOSE CON MAQUINA DE COSER

``

Piezas principales

Como enchufar la maquina al tomacorriente

``

Como use el control de pie

Como cambiar el foco de luz

Cartilla de guia para hilos y agujas

Cambio de la aguja

``

Seleccion de la aguja adecuada

Desmontaje e instalacion de la pata prensora

`

Regulacion de la tension del hilo

``

Dial regulador de la longitud de la puntada.

Boton para puntada inversa

Desactivacion del mecanismo alimentador de tela

Desmontaje de la bobina y de su casquillo

Enrollado del hilo en la bobina

Enhebrado del casquillo de la bobina

Ensartado del hilo en la aguja

Jalado del hilo de la bobina hacia arriba

Puntada recta y puntada zigzag

24-25

24

25

25

25

26

26

26

27

27

28

28

28

29

30

30

31

32

32

Cambio de la direccion de la costura

``

Remate de costuras

Puntada triple para telas estirables

Puntada zigzag tricot

Puntada recogida

Puntada ribeteadora simple

Costura de ojalillos para botones

Costura de cremalleras

Costura de dobladillos o bastas

Costura de dobladillos o bastillas invisibles

Pata para botones

Bordados

Limpieza del mecanismo alimentador

Limpieza de la pista de la lanzadera

Costirra con el brazo libre de la maquina

Diagnostico y solucion de problemas

``

33

33

33

34

34

35

36

36

37

37

38

38

39

39

40

41

23

PIEZAS PRINCIPALES (Modelo 377B)

1. Guia para enrollar el hilo en la bobina

2. Dial tensionador del hilo

3. Dial selector del patron de costura

4. Eje enrollador de hilo en la bobina

5. Freno del enrollador de la bobina

6. Manivela equilibradora

7. Dial de selector de longitud de puntada

8. Boton reversador

9. Sujetador de aguja y tornillo fijador

10. Tapa de la lanzadera

11. Pata prensora

12. Tornillo fijador de la pata prensora

13. Aguja

14. Tornillo fijador de la placa frontal

15. Placa frontal

16. Mesa de extension

17. Indicador de puntada

18. Palanca accionadora de la pata prensora

`

`

(Compartimento para guardar accesorios)

`

16

15

14

13

12

11

4

5

17

1

2

3

6

7

8

18

9

10

Spanish

PIEZAS PRINCIPALES (Modelo 374)

1. Guia para enrollar el hilo en la bobina

2. Dial tensionador del hilo

3. Dial selector del patron de costura

4. Eje enrollador de hilo en la bobina

5. Freno del enrollador de la bobina

6. Manivela equilibradora

Perilla de longitud de puntada

7.

8. Boton reversador

9. Sujetador de aguja y tornillo fijador

10. Tapa de la lanzadera

11. Pata prensora

12. Tornillo fijador de la pata prensora

13. Aguja

14. Tornillo fijador de la placa frontal

15. Placa frontal

16. Mesa de extension

18. Palanca accionadora de la pata prensora

`

`

`

(Compartimento para guardar accesorios)

24

PIEZAS PRINCIPALES (Modelo 473/373/372/372H)

1. Guia para enrollar el hilo en la bobina

2. Dial tensionador del hilo

3. Dial selector del patron de costura

4. Eje enrollador de hilo en la bobina

5. Freno del enrollador de la bobina

6. Manivela equilibradora

7. Dial de selector de longitud de puntada

8. Boton reversador

9. Sujetador de aguja y tornillo fijador

10. Tapa de la lanzadera

11. Pata prensora

12. Tornillo fijador de la pata prensora

13. Aguja

14. Tornillo fijador de la placa frontal

15. Placa frontal

16. Mesa de extension

17. Indicador de puntada

18. Palanca accionadora de la pata prensora

`

`

(Compartimento para guardar accesorios)

`

COMO CONECTAR LA MAQUINA DE COSER AL TOMACORRIENTE

1. Inserte el enchufe hembra del cordon en la maquina de coser

2. Inserte el enchufe macho del cordon en el tomacorriente.

Nota:

COMO USAR EL CONTROL DE PIE

Antes de conectar la maquina, asegurese que el

voltaje y el numero de ciclos indicados en la maquina

coincidan con los del tomacorriente.

`

``

`

`

`

`

`

El control de pie sirve para graduar la velocidad de la costura.

Cuanto mas se presione el control, mas rapido cosera la

`

maquina.

Cuando se suelta el control de pie, la maquina se detiene

automaticamente.

Antes de usar la maquian, practique con el control de

velocidad sin enhebrar la maquina.

COMO CAMBIAR EL FOCO DE LUZ

El foco de luz se encuentra detras de la placa frontal.

Saque la placa frontal aflojando el tornillo que dsta en el frente.

Tipo de Foco: Para sacar el foco, desenroscarlo

Para instalar un foco, enroscarlo

Notas:

Siempre desenchufe la maquina del tomacorriente antes de dejarla

desatendida,cambiarle piezas o hacerle cualquier otro trabajo.

`

`

`

`

`

Antes de cambiar el foco, desenchufe la maquina del

tomacorriente.

Los focos de luz estan disponibles en las tiendas que

venden maquinas de coser. (Use un foco de 15 wats).

`

Cuidado!

`

``

`

`

`

Interruptor

Esta maquina esta equipada con un enchufe polarizado (una espiga es

`

mas ancha que la otra)y entra en un tomacorriente polarizado solo en una

forma. Si no entra completamente, inviertalo. Si aun asi no entra, llame a

`

`

`

``

un electricista calificado para que instale un tomacorriente adecuado. No

modificar el enchufe en forma alguna.

25

CARTILLA DE GUIA DE HILOS Y AGUJAS

`

TELA DEL GADA

TELA MEDIANA

TELA GRUESA

TELAS

Gasas de algodon, sedas,

sinteticas, georgettes

`

Telas we algodon, sinteticas,

popelinas, terciopelos y lanas

de peso mediano

Telas gruesas de algodon,

mezcilla, tweed, garbardina,

cortinas

`

``

`

HILOS

Seda fina

Algodon fino

`

Sintetico fino

`

Algodon fino recubierto en poliester

`

Seda 50

Algodon 50 a 80

`

Sintetico 50 a 60

`

Algodon recubierto de poliester

``

Seda 50

Algodon 40 a 50

`

Sisntetico 40 a 50

`

Algodon recubierto con poliester

``

`

TAMANO DE AGUJA

Notas:

En general, se usan hilos y agujas finas para coser telas delgadas o livianas, e hilos gruesos y

agujas gruesas para telas gruesas o pesadas. Siempre pruebe el hilo y el tamano de la aguja en

un retazo pequeno de la tela que se va a usar en la costura.

~

~

Use el mismo hilo en la aguja y en la bobina.

Al coser telas que se estiran, telas muy delgadas y sinteticas, use una aguja de

`

,, ,,

STRETCH

porque evita que la puntada se escape.

Cuando se cosan telas muy delgadas, cosalas sobre una pieza de papel para evitar que la trama

`

se distorsione.

9 o 11

`

11 o 14

`

14 o 16

`

Spanish

CAMBIO DE AGUJA

1. Gire la manivela equilibradora hacia usted hasta que la

aguja este en su posicion mas alta.

2. Afloje el tornillo sujetador de la aguja girandolo hacia

`

`

usted. Sacat ta aguja de su soporte.

3. Coloque la aguja nueva en el soporte con su parte

plana alejada de usted. Presione la aguja dentro del

sujetador tan adentro como sea posible.

4. Ajuste firmemente el tomillo fijador.

SELECCION DE LA AGUJA ADECUADA

`

El vastago de la aguja tiene

`

Vastago

`

marcado un numero que indica

su tamano. Cuanto mayor sea

el numero, mas gruesa sera la

```

`

~

aguja.

STRETCH

Aguja de

Se recomienda una aguja para

tela elástica al coser telas

elásticas.

`

,,

No use aguja alguna que este

doblada o con la punta sin filo.

2

(4)

(3)

`

26

DESMONTAJE EINSTALACION DE LA PATA PRENSORA

`

Para Desmontar:

1. Gire la manivela equilibradora hacia usted hasta que la aguja

este en la posicion mas elevada.

`

`

`

2. Para hacer que la pata caiga, levante la palanquita sujetadora

que esta en el talon de la pata.

`

`

Note: No fuerce la pata prensora para sacarla.

Para Instalar:

1. Coloque la pata prensora con la clavija en el frente de la pata

justo debajo de la ranura del sujetador de la pata. Baje el

sujetador de la pata.

2. Al subir la palanca accionadora de la pata podra observar que

la pata queda asegurada en posicion.

`

`

11

22

Palanquita

sujetadora

1

Ranura

Palanca para

levantar la

pata prensora

Clavija

2

REGULACION DELA TENSION DEL HILO

`

Generalmente, si se requiere regular la tension, solo se puede hacer con el dial superior tensionador del hilo. La tension del

hilo de la bobina viene regulada de fabrica y rara vez requiere vplverse a regular, excepto bajo circunstancias especiales

debidas al hilo o a la tela.

La tension del hilo de la bobina es la adecuada cuando se puede jalar del hilo del casquillo de la bobina facilmente con poca

resistencia. La tension del hilo puede regularse ajustando oel dial tensionador de hilo.

`

`

Hile con tension adecuada

para costura recta.

El hilo de la aguja esta

dema siado templado.

El hilo de la aguja esta

demasiado suelto.

`

`

`

El hilo de la aguja y el de la bobina deben entrelazarse

en el centro de las dos capas de tela.

Recuerde que cuanto mayor sea el numero, mayor sera la tension . Las tensiones correctas para un tipo de tela pueden no ser

adecuadas para otras. La tension requerida depende del grado de rigidez de la tela, su espesor y el numero de capas de tela que se

cose; asi como tambien del tipo de puntada que se este haciendo. Es preferible hacer puntadas de prueba en retazos desechables de

`

las telas que se van a usar antes de comenzar a coser la prenda. Generalmente el rango para muchas telas esta entre 3 y 5.

`

`

El hilo de

la bobina

aoarece en

la superticle

superior de

las telas.

El hilo de la

aguja aparece

en el lado

inferior de

las telas.

``

`

`

`

Afloje la tension del hilo de la

aguja moviendo el dial regulador

a un numero inferior.

Tempiar la tension del hilo de la

aguja moviendo el dial tensionador

a un numero mayor.

`

`

`

`

`

`

`

Como regular la tension

*

del hilo de la bobina.

Aumentar girando el

tomillo en el sentido

del reloj

Disminuir girando el

tomillo contra el

sentido del reloj

`

`

`

`

27

DIAL REGULADOR DE LONGITUD DE PUNTADA ( Modelo 377/374 )

El siguientees el procedimiento para cambiar la longitud de

las puntadas:

Gire el dial hasta la marca que indica la longitud de puntada

requerida. Los numeros indican los milimetros

`

aproximados del largo de la puntada. Cuanto menor es

el numero, mas corta es la puntada.

Modelo EP377B Modelo 374

Marac para

seleccionar

Spanish

`

BOTON PARA PUNTADA INVERSA:

Para hacer puntadas inversas, presione el boton en el

centro del dial de longitud de puntada y mantengalo

presionado. Inmediatamente la tela comenzara a

retroceder. Al soltar el boton, la maquina seguira cosiendo

`

`

`

` ` `

en forma normal hacia delante.

Este dispositivo es muy util para rematar los extremos de

`

las costuras, para hilvanar sin tener que amarrar los hilos y

para reforzar las costuras.

DESACTIVACION DEL MECANISMO ALIMENTADOR DE

`

Modelo EP377B Modelo 374 Modelo 373/372

TELA:

Los bordados y zurcidos se hacen mejor con el mecanismo

alimentador desenganchado. Esto se hace colocando el

dial de longitud de puntada en ,lo que permite que la tela

se mueva libremente bajo la aguja.

El mecanismo alimentador reinicia su funcion normal tan

pronto se regrese el dial a la posicion de 0 o mas alla.

SELECTOR DE PATRON DE PUNTADA DE COSTURA ( Modelo 377B )

El patron de puntada deseado se selecciona girando el

dial selector. Las marcas en el dial corresponden a los

patrones indicados en el panel, que son

respectivamente como sigue:

`

`

`

` `

Largo de la puntada

M( )

O( )

1-5(54321)

A( )

B( )

C( )

D( )

Seleccion de puntada estirable

Para coser telas que se estiran, coloque el selector de

longitud de puntada en S.S.

Cuando se desengancha el dial de la posicion S.S. ,

el mecanismo de puntada triple recta se desactiva

automaticamente.

M( )

O( )

1-5(54321)

A( )

B( )

C( )

D( )

puntada recta, aguja en del medio

puntada recta, aguja en la izquierda

puntada zigzag de diversos anchos

puntada zigzag tricot

puntada estirable invisible

puntada de doble accion

puntada inversa invisible

Costura automatlca de botones

`

`

,, ,,

`

puntada triple recta con aguja en el

medio.

puntada triple recta con aguja en la

izquierda.

puntada triple zigzag o ric-rac

puntada recogida

puntada estirable especial

puntada ribeteadora en zigzag

puntada ribeteadora simple

`

`

..

..

SS

`

Regulacion estandar

Gire el dial regulador de longitud de puntada hasta que

,,,,,,,,

la marca SS se encuentre en el punto mas alto.

Esta es la regulacion estandar para la mayoria de tipos

de telas. Algunos tipos de telas podrian requerir un

ajuste. Para acortar las puntadas, gire el dial

levemente hacia . Para alargarlas, gire el dial hacia

,,,,,,,,

+ .

En la mayoria de telas, estas graduaciones permitiran

varias posibilidades de patrones.

[Al hacer puntadas triples, la marca siempre debe

estar dentro del rango SS (Ver el dibujo)]

`

,,,,,,,,

``

,,,,,,,,

_

`

`

,,,,,,,,

,,,,,,,,

`

..

SS

`

..

`

28

SELECTOR DE PATRON DE PUNTADA DE COSTURA(Modelo 374)

`

Se puede elegir el diseño deseado girando la perilla de

selección de diseño. Las marcaciones de la perilla

corresponden a los respectivos diseños que se muestran

en el panel, de la siguiente forma:

A ( )

B ( )

C ( )

D ( )

E ( )

F ( )

G ( )

Costura recta, con la aguja el centro

Costura recta, con la aguja hacia la izquierda

Costura en zigzag con ancho variable

Costura simple

Costura invisible eláatica

Costura de doble acción

Costura invisible en reversa

Costura automática de botones

SELECTOR DE PATRON DE PUNTADA DE COSTURA(Modelo 473/373/372/372H)

( )

1 - 3

( )

4-6

7

( )

8

( )

( )

9

10

( )

( )

11

12

( )

( )

`

Costura recta

Costura en zigzag

Costura triple elástica en zigzag

Costura triple elástica recta

Costura de fijación

Costura nido de abeja

Costura simple

Costura caracol

Costura automática de botones

DESMONTAJE ED LA BOBINA Y DE SU CASOUILLO

1. Levante la pata prensora y gire la manivela

equilibradora hasta que la palanquita templadora

este en su posicion mas alta.

```

2. Abra la tapa de la lanzadera.

3. Abra el pestillo abisagrado del casquillo de la

bobina y jale el casquillo hacia afuera de la

`

maquina.

La bobina caera al soltar el pestillo. La bobina no

`

caera mientras se mantenga abierto el pestillo del

`

casquillo.

Abrir

29

ENROLLADO DEL HILO EN LA BOBINA

1. Jale el hilo del carrete y paselo por el disco

`

tensionador para el hilo de la bobina com

se muestra.

2. Jale del extremo del hilo pasandolo por un

`

orificio de la bobina como se muestra.

3. Mueva el eje del enrollador del hilo de la

bobina lo mas hacia la izquierda que sea

posible, si es que aun no esta ahi.

Coloque la bobina en el eje con el extremo

del hilo saliendo por encima de la bobina.

Mueva el eje hacia la derecha hasta que

enganche. Sostenga el extremo del hilo.

4. Ponga la maquina en marcha. El hilo que

se sostiene puede arrancarse o cortarse

con una tijera. La bobina cesara de girar

a

ndo e ste c ompletamente ll ena. P ara

cu

Sacar la bobina, mueva el eje a la

izquierda.

`

``

`

`

`

Spanish

`

1

3

2

4

Si la bobina se está devanado incorrectamente,

afloje el tornillo de arriba de la guía de devanado

y ajuste la guía de devanado hacia arriba o hacia

abajo hasta balancear el devanado de la bobina.

ENHEBRADO DEL CASQUILLO DE LA BOBINA

Sostenga la bobina entre el dedo pulgar y el indice de la

mano derecha y con la otra mano jale el hilo unos 15cm.

§

(6 ).

`

1. Sostenga el casquillo de la bobina en la mano

izquierda como se muestra e insertele la bobina

`

llena de hilo.

2. Jale el hilo haciendolo pasar por la ranura en el

`

extremo del casquillo de la bobina.

3. Ahora pasar el hilo bajo el resorte tensionador y

meterlo en el orificio para el hilo.

Para instalar el conjunto de la bobina con su

casquillo,haga lo siguiente:

`

Asegur

ese que unos 15cm. (6 ) del hilo

sobresalgan de la bobina. Sostenga el

casquillo de la bobina con su vastago largo

§

`

apuntando hacia arriba. Deslice el soporte del

la bobina sobre el eje central de la traba y

presiónela en su lugar hasta que la palanca

larga del porta bobina encaje en la muesca para

trabarlo en su lugar. Suelte la traba y presiónela

hacia abajo.

Pestillo

`

Vastago largo

Pestillo

Casquillo de

la bobina

Resorte

tensionador

Orificio

Ranura

Bobina

Ranuar

30

ENSARTADO DEL HILO EN LA AGUJA

Instale el eje para el carrete detras de la maquina

(como se muestra en la figura A ).

Coloque el carrete en el eje con el hilo saliendo por la

parte de atras del carrete. Coloque la palanquita

templadora (5) enla posicion mas alta.

`

``

`

Figura A

A

。ー 。 ア

`

6

,

7

1

2

5

A

3

B

8

,

4

1. Levante la pata prensora usando la palanca

de la pata indicada como “B”.

2. Pase el hilo por las guias para el hilo en la

tapa superior como se muestra en las figuras

1 y 2.

3. Sostenga el carrete con la mano derecha,

pase el extremo del hilo por el disco

tensionador como ese muestra en el numero

(3).

4. Siguiendo la ranura para el hilo, jale el hilo

hacia abajo, hacia el resorte verificador de hilo

(adentro) y llevelo de izquierda a derecha.

5. Jale el hilo hacia arriba y deslicelo de

izquierda a derecha en el orificio del anillo

ranurado del templador (5).

6. Pase el hilo por las guias 6 y 7 y ensartelo en

la aguja de adelante hacia atras (8), dejando

un tramo de hilo de 15cm.(6 ) de largo debajo

de la pata prensora.

`

`

`

`

GUIDE 1

3

4

GUIDE 2

B

5

6

7

8

31

JALADO DEL HILO DE LA BOBINA HACIA ARRIBA

1. Sujete el extremo del hilo de la aguja con la mano

izquierda.

2. Mueva la manivela niveladora lentamente nacia usted

con la mano derecha hacta que la aguja baje y suba.

Detenga la manivela equilibra cuando la palanquita

tensionadora este en su posicion mas alta.

```

Jale lebemente el hilo de la aguja hacia arriba formando

un nudo con el hilo de la bobina.

3. Jale unos 15cm. (6 ) de ambos hilos alejandolos de la

`

pata prensora.

1

2

Hilo de

la aguja

Hilo

de la

bobina

Hilo de

la aguja

Spanish

PUNTADA RECTA Y PUNTADA ZIGZAG

377B 374 473/373/372/372H

Pata prensora

Selector de patron

Selector de longitud

de puntada

`

Para comenzar a coser

1. Asegurese que ambos hilos esten jatados hacia atras

`

debajo de la pata prensora.

2. Mientras sostiene los hilos con la mano izquierda, con la

mano derecha mueva la manivela equilibradora hacia usted

para que la aguja penetre en la tela en el punto donde

desea comenzar a coser.

3. Baje la pata prensora y presione suavemente el control de

pie hasta lograr la velocidad de costura deseada.

Pata zigzag

M( )

O( )

u

(para puntada recta)

1-5(54321)

(para puntada zigzag)

0.3-0.4 0.3-0.4 0.4-5

Pata zigzag Pata zigzag

M( )

O( )

u

(para puntada recta)

1-5(54321)

``

(para puntada zigzag)

M( )

O( )

u

(para puntada recta)

1-5(54321)

(para puntada zigzag)

3

Pata para zigzag

Para rematar el extremo de las costuras, haga unas

cuantas puntadas a la inversa presionando el boton

`

reversador.

`

Suba la aguja a su posicion mas alta antes de girar el

dial selector del patron de costura y el dial selector del

`

`

ancho de la puntada.

32

C ambio de Direc c ion d e la C os tur a

1. Detenga la ma quina y gire la manivela equilibradora

`

`

ha cia us te d para que la aguja baje y e ntre en la tela.

S uba la pata prensora.

2. G ire la tela alrededor de la aguja para cambiar la

`

direccion segun s e des ee.

3. B aje la pata prens ora y continue cos iendo.

`

`

R emate de C os tura s

1. P ara reforz ar los e xtremos de las cos turas , pres ione e l

`

boton revers ador y cos a varias puntadas a la invers a.

2. P ara saca r la tela, s uba la pata prens ora y ja le la tela

hacia us ted.

3. C orte los hilos con el cortador que es ta en la parte

`

`

pos terior del va stago de la pata prensora o con un par

de tijeras .

Dejar como 15cm. ( 6 pulgades ) de hilo colga ndo fuera

del ojo de la a guja.

C ortador de hilo

P U NTADA T R IP L E PAR A T EL AS E S TIR A BL E S

S i s e des ea cos er telas que s e es tiran, es te es el tipo de puntada correcto para evitar que el hilo se rompa.

E sta puntada tambien es ade cuada para costuras que neces itan gran re sis te ncia; p. ej.: cos turas de fundillos

`

:

o de bolsillos.

P UNT ADA T R IP LE R E CTA PA R A T E LA E S TIR AB L E

377B 374 473/373/372/372H

P ata pre nsora

S elector de patron

S elector de largo

de puntada

Nota:

Use una a guja de

La aguja de - evita en forma efectiva que las puntadas fallen.

pata zigza g pata z igzag

`

M ( ) 8 ( )

S.S.

S TR E TC H

S TR E TC H

P UNT ADA T R IP LE ZOG ZAG [A R A T E LA E ATIR A BL E

377B 374 473/373/372/372H

P ata pre nsora

S elector de patron

S elector de largo

de puntada

pata zigza g pata z igzag

`

O ( )

7 ( )

S.S.

33

P U NTA DA ZIG ZA G T R IC O T

E sta puntada es muy adecuada para

zurcir. Tambien puede us ars e para

reforz ar tramos largos de telas y para unir

tramos de la tela

P ata pre nsora

S elector de patron

S elector de largo

de puntada

`

377B 374 473/373/372/372H

pata zigza g pata zigza g pata zigza g

`

A ( )

0.3 a 4

D ( )

0.5 a 4

Nota:

P U NTA DA R E C O G IDA

C on una tira angos ta de tela directamente debajo de la

linea de recogimiento, coser s obre los recogidos. E i

~~

diseno res ultara ser una serie de pequenos rombos .

`

~~

C uando se ha ce costura recogida en una predda, el

pes punteado debe hac erse a ntes de coser la prenda.

377B 374

P ata pre nsora

11( )

-

Use una aguja de

La a guja de evita e n forma efec tiva que la s puntadas fallen.

S TR E T CH

S elector de patron

S elector de largo

de puntada

S TR E T CH

.

pata zigza g pata zigza g pata zigza g

`

A ( ) A ( ) A ( )

S.S.

473/373/372/372H

-

S pa nis h

P U NTA DA R IB E TE A DOR A S IMP L E

C on es ta puntada es pos ible evitar que los bordes de fas telas s e des hilachen, ademas da una buena

pres entacion y un aca bado dura dero para dl borde.

`

`

377B 374 473/373/372/372H

P a ta prensora

S elector de patron

S elector de la rgo

de puntada

C oloque la tela debajo de la pata prens ora de modo que la cos tura se haga s obre el borde.

B aje la pata prensora y comiense a coser.

`

G uie la tela levemente como se mues tra.

P rimero coser un retazo de tela de des echo pa ra verificar las graduaciones de la maquina .

Las puntadas ribeteadorsa se forman correctamente cuando la aguja cose a la derecha del borde y justo

sobre el borde de la tela.

Nota:

Use una a guja de

La aguja de evita en forma efectiva que las puntadas fa llen.

pata z igzag pata z igzag

D ( )

`

S.S.

S T R E T C H.

S T R E T C H

9 ( )

`

34

P UNTADA DE DO BL E AC C IO N

E sta puntada e s buena para unir o para coser

telas ela s tic as o encaje y tejidos de lenceria

que s e estiren. E sta puntada es decorativa

ade mas de ser muy util.

P ata pre nsora

`

`

`

377B 374 473/373/372/372H

pata zigzag

`

pata zigzag

P UNTADA R IB E TE A DOR A E N ZIG ZAG

E sta es una puntada versatil para insertar cintas ela s ticas e n

`

prendas . Simplemente pespuntear la cinta ela s tica en posicion

as egurandose que los pes puntes es ten pare jos . P ara esto,

``

marque la piez a en cuartas partes y haga coincidir las ma rcas con

las costuras del centro, del frente y de loa cos tados .

P ata pre ns ora

`

`

` `

P ata z igzag

S elector de patron

S elector de largo

de puntada

R IB E TE S DE COR A T IVO S

C ( )

`

1 a 2.5 1 a 2.5

F( )

S elector de patron

S elector de la rgo de puntada

Voltee e l borde por rema tar ha cia a bajo unos

2 cm. y presione el doblez. . C oloque la tela

con la cara buena ha cia arriba con e l medio

del doblez debajo del centro de la pata

prens ora para que las puntadas cos an en e l

doblez y jus to s obre e l borde sin ribetear que

es ta de baio.

`

C OS TUR A DE OJ AL IL L OS PA R A B OTONE S

E sta ma quina tiene incorporado un mecanis mo para coser ojalillos de

`

botones que permite hace rlo en muy poco tiempo y s in darle vuelta a

la tela.

473/373/372/372H

pata para ojalillos

P ata prens ora

377B/374

pata para ojalillos

`

C ( )

S .S .

F lecha

(C omenzara qui)

S elector de patron

S elector de la rgo

de puntada

S uba la pata y la aguja a su posicion mas alta. C ambie la

`

0.3 a 1

`

`

pata prens ora por la pata trans parente para botones . Us ando

`

un lapiz o tiza de s a s tre , marque la ubicacion del boton y el

`

`

largo de puntada des eados en la tela.

Notas:(Modelo 377/374)

P a ra encontrar la longitud de la puntada mas adecuada es mejor

`

cos er un oja lillo de mues tra en un retaz o de tela.

C ua ndo cosa telas muy delga das o sinteticas , disminuya l pres ion

`

de la pata y c os a la tela s obre un papel para evitar que la trama

se dis torsione.

La marca en el dial selector de puntadas muestra un ra ngo para

cos tura de ojalillos. P uede gra duars e la puntada moviendo la

perilla c omo s e mues tra.

E l largo de la puntada para los ojalillos solo puede regulars e en

`

35

P untada s

abiertas

para telas

grues as

P ata

P ata pa ra ojalillos de botones

Marco

P untada s

apre tada s

para telas

delgadas

`

`

(C ontinua)

C OS TUR A DE OJ AL IL L OS P AR A B OTONE S (377B / 374)