Euro-pro 412N User Manual

5 YEAR LIMITED WARRANTY

EURO-PRO Operating LLC warrants this sewing machine for a period of 5 years from date of the

original purchase, to be free of defective parts due to imperfections in the workmanship and materials,

subject to the following conditions, exclusions and exceptions.

EURO-PRO Operating LLC will, at its option, repair or replace this sewing machine free of charge if it

fails to operate according to specifications due to factory defects in materials or workmanship within one

year of purchase date. For 5 years from date of purchase, EURO-PRO Operating LLC will repair or

replace defective sewing machine head parts; owner pays for labor charges. The sewing machine must

be shipped freight and insurance prepaid to:

US: EURO-PRO Operating LLC, 94 Main Mill Street, Door 16, Plattsburgh, NY 12901

Canada: EURO-PRO Operating LLC, 4400 Bois Franc, St. Laurent, Qc, H4S 1A7

A copy of your sales receipt and $15.95 for handling and return packaging/shipping charges must be

included.*

The electrical equipment (motor, rheostat, control, light, electronic parts, etc.) are warranted from defects

in material and workmanship for a period of two years from the date of original purchase. Non-durable

parts including, without limitation, needles, belts, bobbins, bulbs, bobbin cases, shuttles, springs and

parts which normally require replacement are specifically excluded from this warranty.

This warranty is in effect provided the sewing machine is used only for normal household use by the

original purchaser when new, and is given reasonable good care and proper maintenance in accordance

with the accompanying instruction manual. The manufacturer is not held responsible for damage,

normal wear, accident, abuse, neglect, negligence or if the machine has been repaired by unqualified

personnel.

This warranty is extended to the original purchaser of the unit and excludes all other legal and/or

conventional warranties. The responsibility of EURO-PRO Operating LLC if any, is limited to the specific

obligations expressly assumed by it under the terms of the limited warranty. In no event is EURO-PRO

Operating LLC liable for any indirect, incidental or consequential damages of any nature whatsoever.

Some states do not permit the exclusion or limitation of incidental or consequential damages, so the

above may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to

state or province to province.

*Important: Carefully pack the item to avoid damage during shipping. We recommend you insure the

package (as damage in shipping is not covered by your warranty). Be sure to include a copy of your

sales receipt and attach a tag to the machine with your name, address and telephone number. Please

include $15.95 to cover return shipping and handling.

Instruction Manual

-----------------------------------------------------------------------------------------------------------------------------------

OWNERSHIP REGISTRATION CARD

Please fill out and mail the product registration card within ten (10) days of purchase. The registration will

enable us to contact you in the unlikely event of a product safety notification. By returning this card, you

acknowledge to have read and understood the instructions for use, and warnings set forth in the

accompanying instructions.

Return to:

US: EURO-PRO Operating LLC, 94 Main Mill Street, Door 16, Plattsburgh, NY, 12901

Canada: EURO-PRO Operating LLC, 4400 Bois Franc, St. Laurent, Qc, H4S 1A7

___________________________________________________________________________________

Appliance Model

___________________________________________________________________________________

Date Purchased Name of Store

___________________________________________________________________________________

Owner’s Name

___________________________________________________________________________________

Address City State/Prov. Zip/Postal Code

Please read the instructions carefully before operating

the machine.

Model

EURO-PRO Operating LLC, 94 Main Mill Street, Door 16, Plattsburgh, NY 12901 Tel.: 1 (800) 361-4639

412N

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety instructions should always be

followed, including the following:

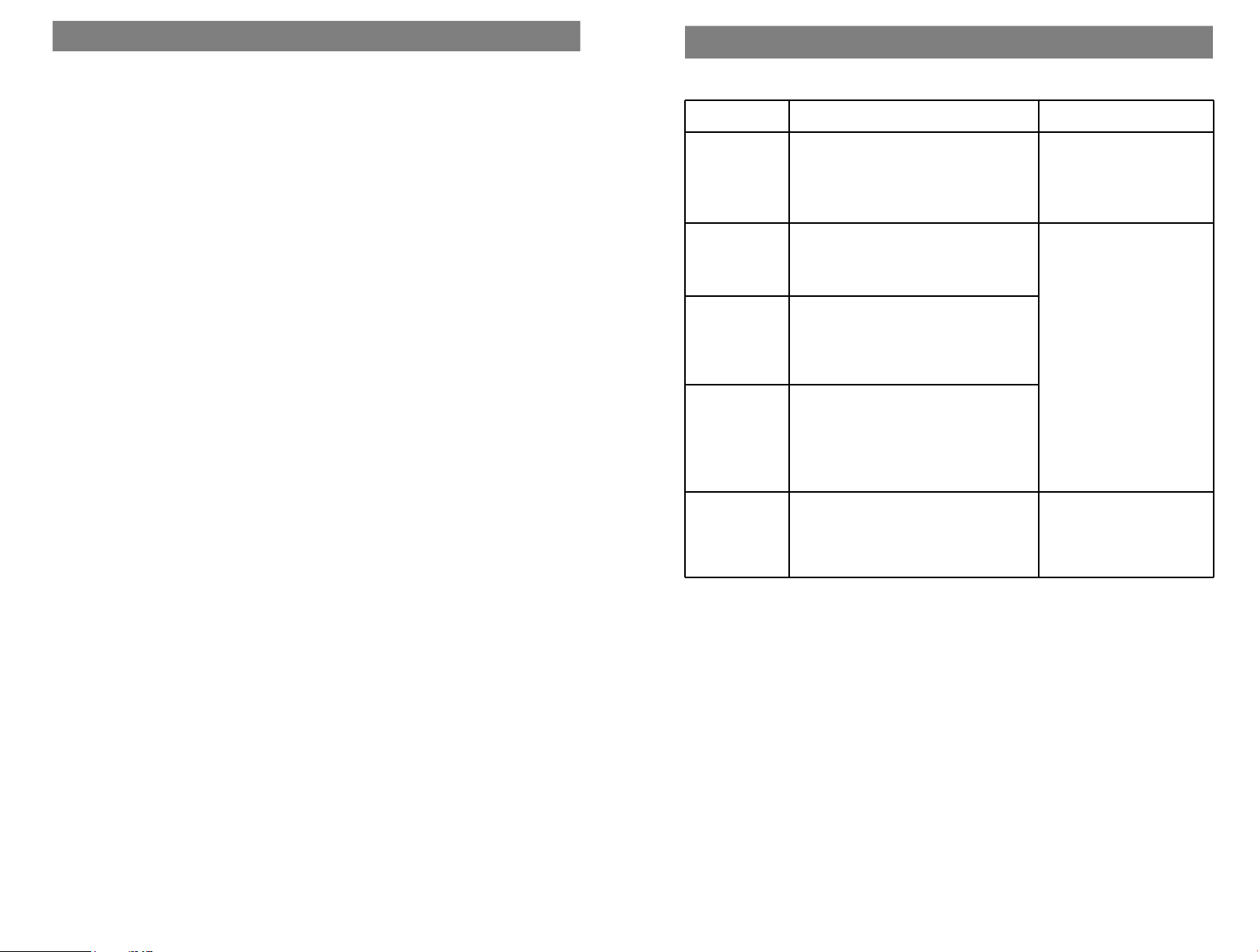

Matching needle / fabric / thread

NEEDLE,FABRIC,THREAD SELECTION GUIDE

“Read all instructions before using this sewing machine.”

“DANGER - To prevent the risk of electric shock:” A sewing machine should

never be left unattended when plugged in. Always unplug this appliance from

the electric outlet immediately after using and before cleaning.

“WARNING - To reduce the risk of burns, fire, electric shock, or injury to

persons:”

1. Do not allow to be used as a toy. Close attention is necessary when this

sewing machine is used by or near children.

2. Use this appliance only for its intended use as described in this manual.

Use only attachments recommended by the manufacturer as contained in

this manual.

3. Never operate this appliance if it has a damaged cord or plug, if it is not

working properly, if it has been dropped or damaged or dropped into water.

Return the appliance to EURO-PRO Operating LLC for examination, repair,

electrical or mechanical adjustment.

4. Never operate this appliance with any air openings blocked. Keep

ventilation openings of the sewing machine and foot controller free from the

accumulation of lint, dust and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where

oxygen is being administered.

8. To disconnect, turn all controls to the “Off” position, then remove the plug

from the electrical outlet.

9. Do not unplug by pulling on the power cord. To unplug, grasp the plug not

the cord.

10. Keep fingers away from all moving parts. Special care is required around

the sewing machine needle.

11. Always use the proper needle plate. The wrong plate can cause the

needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle causing

it to break.

14. Switch the sewing machine “Off” when making any adjustment in the

needle area, such as threading the needle, changing the needle, threading

the bobbin or changing the presser foot., etc.

15. Always unplug the sewing machine from the electrical outlet when

removing the cover, lubricating or when making any other user servicing

adjustments mentioned in the instruction manual.

16. This appliance has a polarized plug (one blade wider than the other). To

reduce the risk of electric shock, this plug is intended to fit into a polarized

outlet only one way. If the plug does not fit fully in the outlet, reverse the

plug. If it still does not fit, contact a qualified electrician to install the porper

outlet. Do not modify the plug in any way.

NEEDLE SIZE

11(65-75)

9-

12(80)

14(90)

16(100)

18(

110)

FABRICS

Lightweight fabrics-thin cottons.voile,

serge,lilk,muslin,Qiana,interlocks,cotton

knits,tricots,jerseys,crepes,woven

polyeste

Medium weight fabrics-cotton,satin,

kettlecloth,sailcloth,double knits,

lightweight woollens.

Medium weight fabrics-cotton duck,

woolen,heavier knits,terrycloth,

denims.

Heavyweight

outdoor tent and quilted fabrics,

denims,upholstery material (light to

medium).

Heavy woollens,overcoat fabrics,

upholstery

vinyls.

r,shirt& blouse fabrics.

fabrics-canvas,woolens,

fabrics,some leathers and

Light-duty

nylon or polyeste

Heavy duty thread,carpet

thread,(Use heavy foot

pressure-large numbers.)

THREAD

thread in cotton,

Most threads old are

medium size and

suitable

and needle sizes.Use

pollyester threads on

synthetic materials and

cotton

fabrics for best results.

Always use the same

thread on top and

bottom.

for these fabrics

on natural woven

IMPROTANT: Match needle size to thread size and weight of fabric.

r.

SAVE THESE INSTRUCTIONS

1

14

Trouble shooting guide

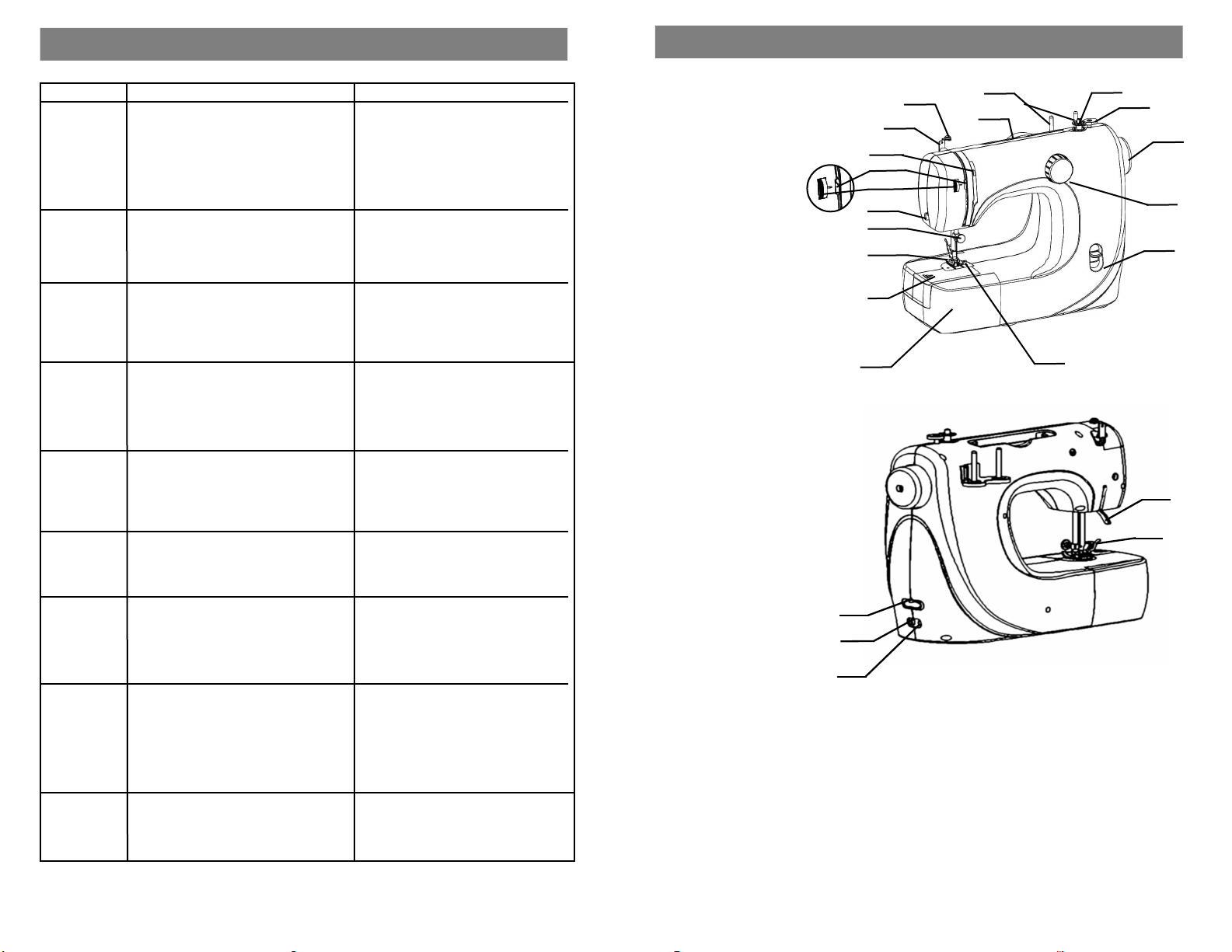

Details of the machine

Problem Cause

1.The machine is not threaded correctly

2.The thread tension is too tight

Upper thread

breaks

Lower thread

breaks

Skippe

stitches

Needle

breaks

Loose

stitches

Seams

pucking

Uneven stitches,

uneven feed

3.The thread is too thick for the needle

4.The needle is not inserted correctly

thread is round wound the spool

5.The

pin

6.The needle is damaged.

lower thread is not threaded correctly

1.The

2.The upper thread tension is too loose

1.The needle is not inserted correctly

d

2.The needle is damaged

3.The wrong size needle has been used.

4.The foot is not attached correctly

1.The needle is damaged

2.The needle is not correctly inserted

Wrong needle size for the fabric

3.

4.The wrong foot is attached.

1.The machine is not correctly threaded

2.The bobbin case is not correctly threaded

3.Needle/fabric/thread combination is wrong

4.Thread tension wrong

1.The needle size is too large for fabric

2.The stitch length is wrong

3.The thread tension is too tight

1.Poor quality thread

2.The bobbin is wrongly threaded

3.Fabric has been pulled

ly adjusted

Correction

1.Rethread the machine

2.Redu ce

number)

3.Select a larger needle

4.Remove and reinsert the needle (flat

side towards the back)

5.Remove the reel and wind thread onto

reel

6.Replace the needle

1.Check the threading carefully

2.Adjust the upper thread tension

1.

towards the back)

2.Insert a new needle

3.Choose a needle to suit the thread and

fabric

4.Check and attach correctly

1.Insert a new needle

2.Insert

towards the back)

3.Choose a needle to suit the thread and

fabric

4.Correct the thread tension

1.Check the threading

2.Thread the bobbin case as illustrated

3.The

thread

4.Correct the thread tension

1.Select a finer needle

2.Readjust the stitch length

3.Loosen the thread tension

1.Select a finer needle

2.Remove

insert correctly

3.Do not pull on the fabric while sewing,

let it be taken up by the machine.

the thr ead tens ion (lower

Remove and reinsert needle (flat side

the needle correctly (flat side

needle size must suit the fabric and

bobbin case and rethread and

1.Reverse sewing lever

2.Pattern selector dial

3.Hand wheel

4.Bobbin stopper

5.Bobbin winder

6.Spool pin

7.Handle

8.Winding thread guide

9.Upper thread guide

10.Thread take-up lever

11.Thread tension

release bar

12.Thread tension dial

13.Thread cutter

14.Needle clamp screw

15.Presser foot

16.Needle plate

17.Sewing table

18.Feed dogs

21

23

22

13

14

15

16

17

10

11

12

8

9

6

7

5

4

3

2

1

18

19

20

The machine

is noisy

The machine

jams

1.The machine must be lubricated

2.Flu

ff or iil have collected on the hook or

needle bar

3.Poor quality oil has been used

4.Fabric has been pulled

1.Thread is caught in the bobbin case

13

1.Lubricate as described

the hoo k an d feed dog as

2.Clea n

described

3.Only use good quality sewing machine

oil

4.Replace the needle

1.Cut the tip of the thread, remove the

bobbin, tidy up the caught thread

19.Presser foot lever

20.Presser foot holder

21.ON/OFF Switch

22.Foot control receptacle

23.AC/DC adaptor

2

Loading...

Loading...