Page 1

TM-U300A/U300B/U300PA/U300PB

Operator’s Manual

Using this online operator’s guide

The words on the left side of this screen are bookmarks for all the

topics in this guide.

Use the scroll bar next to the bookmarks to find any topic you

want. Click a bookmark to instantly jump to its topic. (If you wish,

you can increase the size of the bookmark area by dragging the

dividing bar to the right.)

Use the scroll bar on the right side of this screen to move through

the text.

Use the zoom tools to magnify or reduce the page display.

Click the Find button if you want to search for a particular term.

(However, using the bookmarks is usually quicker.)

Complete online documentation for Acrobat Reader is located in the Help directory for Acrobat Reader.

Return to main menu

Page 2

1

station printer

TM-U300A/U300B

TM-U300PA/U300PB

Operator’s Manual

400137504

Page 3

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system, or transmitted in any form or by any means, mechanical, photocopying,

recording, or otherwise, without the prior written permission of Seiko Epson Corporation.

No patent liability is assumed with respect to the use of the information contained herein.

While every precaution has been taken in the preparation of this book, Seiko Epson

Corporation assumes no responsibility for errors or omissions. Neither is any liability

assumed for damages resulting from the use of the information contained herein.

Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this

product or third parties for damages, losses, costs, or expenses incurred by purchaser

or third parties as a result of: accident, misuse, or abuse of this product or unauthorized

modifications, repairs, or alterations to this product, or (excluding the U.S.) failure to

strictly comply with Seiko Epson Corporation’s operating and maintenance instructions.

Seiko Epson Corporation shall not be liable against any damages or problems arising

from the use of any options or any consumable products other than those designated as

Original Epson Products or Epson Approved Products by Seiko Epson Corporation.

Centronics is a trademark of Centronics Data Computer

Epson and ESC/POS are registered trademarks of Seiko Epson Corporation.

Corporation.

NOTICE:

The contents of this manual are subject to change without notice.

Copyright 0 1992, 1994, 1997 by Seiko Epson Corporation, Nagano, Japan

Page 4

EMC and Safety Standards Applied

Printer

Product Name: TM-U300A/B,

TM-U300PA/PB

Model Name: M51JA/B, M51PA/PB

The following standards are applied only

to the printers that are so labeled. (EMC is

tested using the packaged AC adapter.)

Europe: CE marking

North America: EMI: FCC/ICES-003

Class A

Japan: EMI: VCCI Class A

Oceania: EMC: AS/NZS 3548

Taiwan: EMI: Class B

AC Adapter

Product Name:PA-6511/6513,

Model Name: M34PA, M34PB

The following standards are applied only

to the AC adapters that are so labeled.

(The printer and the AC adapter together

are applied to the EMC standards.)

Europe: CE marking

North America: Safety:UL 1950/CSA

Japan: Safety: Electrical

Oceania: Safety: AS 3260

PB-6509/6510

Safety: EN60950

C22.2 No. 950

Appliance and Material

Control Law of Japan

WARNING

The connection of a non-shielded printer

interface cable to this printer will

invalidate the EMC standards of this

device.

You are cautioned that changes or

modifications not expressly approved by

SEIKO EPSON could void your authority

to operate the equipment.

CE Marking

The printer conforms to the following

Directives and Norms:

Directive 89/336/EEC

FCC Compliance Statement

For American Users

This equipment has been tested and found

to comply with the limits for a Class A

digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to

provide reasonable protection against

harmful interference when the equipment

is operated in a commercial environment.

This equipment generates, uses, and can

radiate radio frequency energy and, if not

installed and used in accordance with the

instruction manual, may cause harmful

interference to radio communications.

Operation of this equipment in a

residential area is likely to cause harmful

interference, in which case the user will be

required to correct the interference at his

own expense.

FOR CANADIAN USERS

This Class A digital apparatus complies

with Canadian ICES-003.

Cet appareil numérique de la classe A est

conforme

Canada.

EN 55022 Class B

EN 50082-1

IEC 801-2

IEC 801-3

IEC 801-4

la norme NMB-003 du

à

i

Page 5

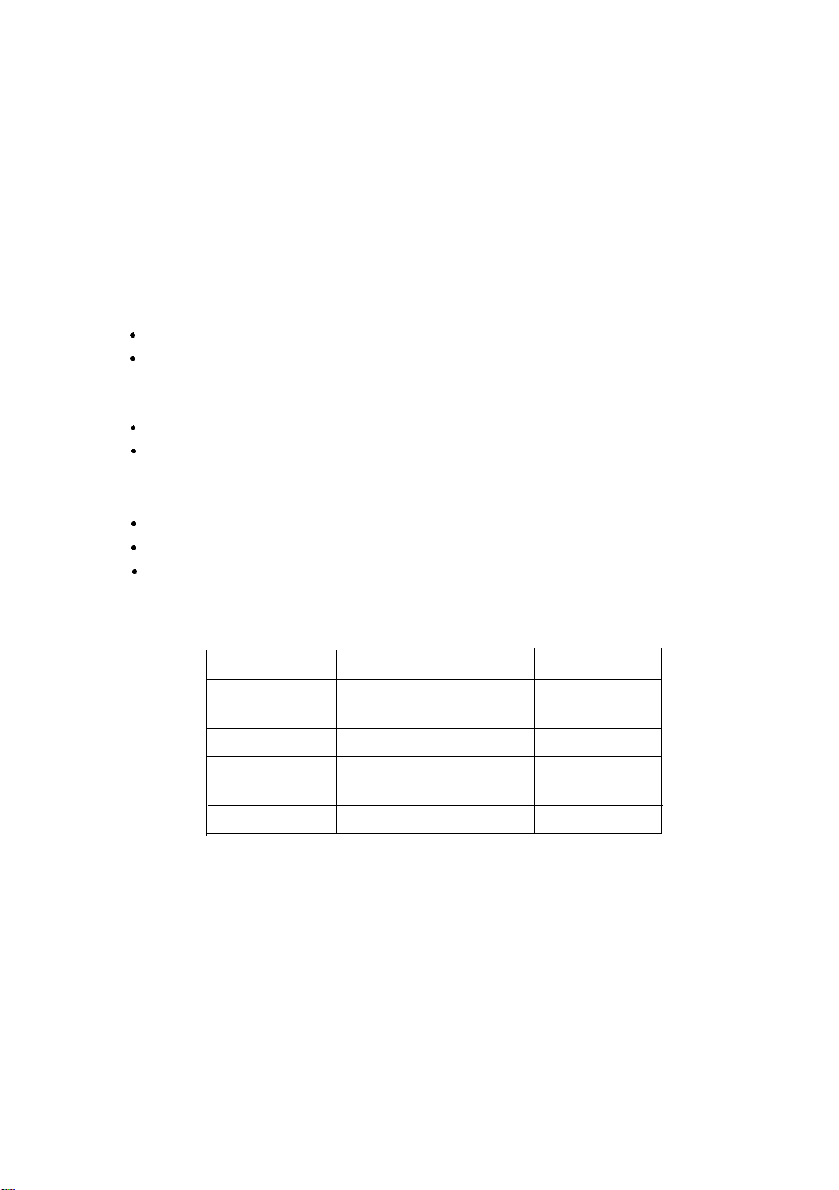

INTRODUCTION

The TM-U300A/U300B and TM-U300PA/U300PB printers are designed to provide a high

cost-performance ratio. They are compact, light-weight, and highly reliable one-station

printers using plastic mechanical frames. They have the following features and are applicable to the POS 1 station printer market.

l Compact and light-weight.

*

High speed printing using logic-seeking.

.

High reliability and long life due to the use of stepping motors for both carriage

return and paper feeding.

l Printing color switch (red/black) available.

*

Various formats are possible because the paper feeding pitch is selectable.

.

High general control utility based on the ESC/POS® standard.

l 2 drawers can be driven due to the internal drawer interface.

l Character font (7 X 9, 9 X 9) is selectable.

*

Semi-automatic paper loading.

*

Compact AC adapter power supply.

.

An auto-cutter unit is provided and full cut/partial cut is selectable by command.

l A take-up device is included.

(Standard only for the TM-U300A/U300PA)

Interface

Serial

Serial

Parallel

Parallel

TM-U300A

TM-U300B

TM-U300PA

TM-U300PB

Function Available

With auto-cutter

With take-up device

With auto-cutter

With auto-cutter

With take-up device

With auto-cutter

Please be sure to read the instructions in this manual carefully before using

your new Epson printer.

ii

Page 6

CONTENTS

1

Chapter

1-1 Checking the Contents of the Box

1-2

1-3

1-4

Chapter

2-1

2-2 Connecting theHost Computer to the

Chapter

3-1 Installing the Ribbon Cassette........................................................................

3-2

3-3

3-4 DIP Switches

Chapter

4-1

Chapter

5-1

APPENDIX

APPENDIX A

UnpackingthePrinter

Choosing a Place for the Printer..

Removing the Transportation Damper..

Names andFunctions ofParts

2

BeforeSettingUp..................................................................................

Connecting the AC

3

Installingthe

Installing

Adjusting thePaperNear-EndDetector

4

The Self Test................................................................................................

5

Removing Jammed Paper..

theRoll

TheSelfTest

RemovingJammedPaper

...............................................................................................................

General Specifications..

adapter to the

Parts.................................................................................

Paper...............................................................................

................................................................................................

........................................................................................

...........................................................................

..................................................................

...................................................................

.........................................................

......................................................................

Printer......................................................

Printer................................................

......................................................

...................................................................

..........................................................................

..............................................................

1

1

2

2

3

5

5

6

8

8

11

17

19

21

21

22

22

23

23

iii

Page 7

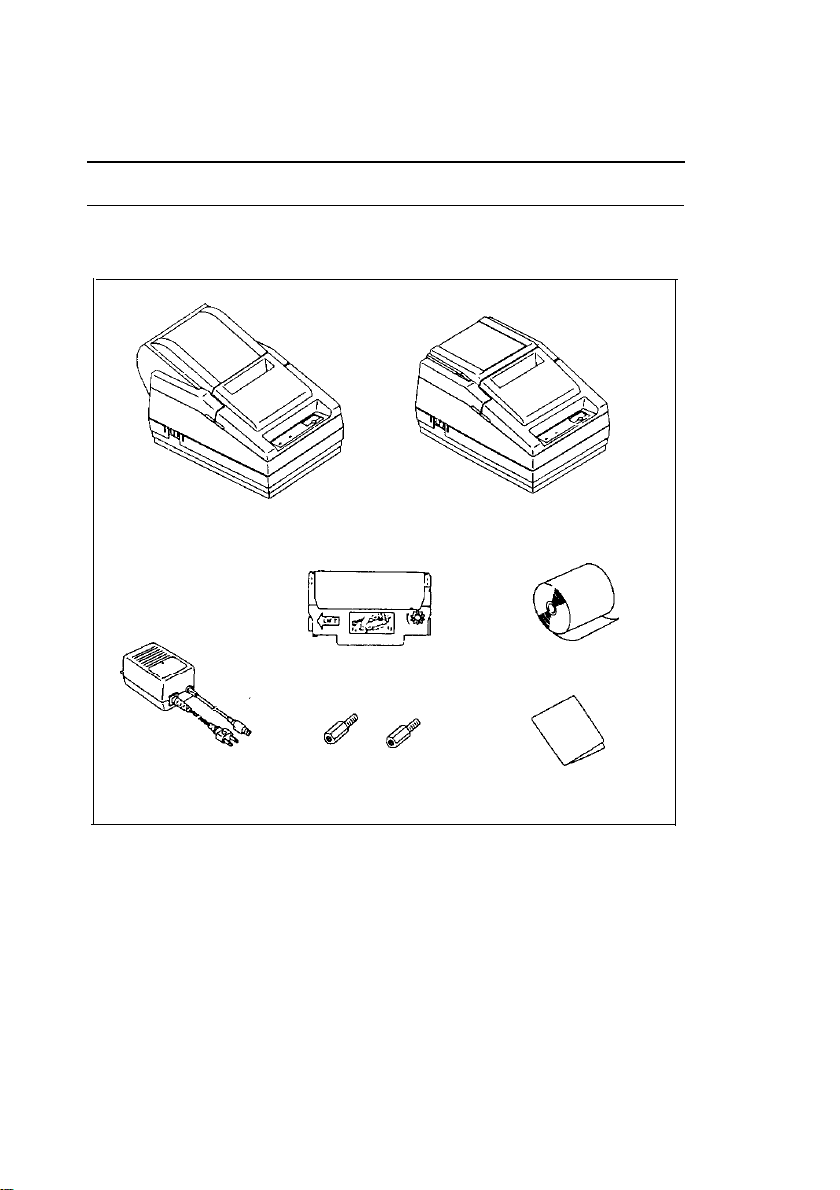

Chapter 1 Unpacking the Printer

1-1 Checking the Contents of the Box

n

Checking the parts

The illustration below shows the items included for the standard specification printer.

TM-U300A/U300PA

l

Ribbon cassette l Roll paper

l

AC adapter (*1)

l

Hexagonal lock

l

Printer

TM-U300B/U300PB

l

Operator’s Manual

screws (2 pcs) (*2)

(*1)

One of eight types of AC adapters may be included with your printer.

Refer to Appendix A, General Specifications for information on your AC

adapter’s input voltage, dimensions, and weight.

(*2)Hexagonal lock screws are provided only if the printer has a serial inter-

face. See note on page 7 for more information about these screws.

Make sure no parts are missing or damaged. If you find any damaged or missing

parts, please contact your dealer for assistance.

n

Maintenance

Keep the packing case in case you ever need to transport or store your printer.

1

Page 8

1-2

Choosing a Place for the Printer

n Avoid locations that are subject to direct sunlight or excessive heat (near

heaters).

n

Avoid using or storing the printer in places subject to excessive temperatures or

moisture.

n

Do not use or store the printer in a dusty or dirty location.

n

When setting up the printer, choose a stable, horizontal location.

Intense vibration or shock may damage the printer.

n

Ensure the printer has enough space to be used easily.

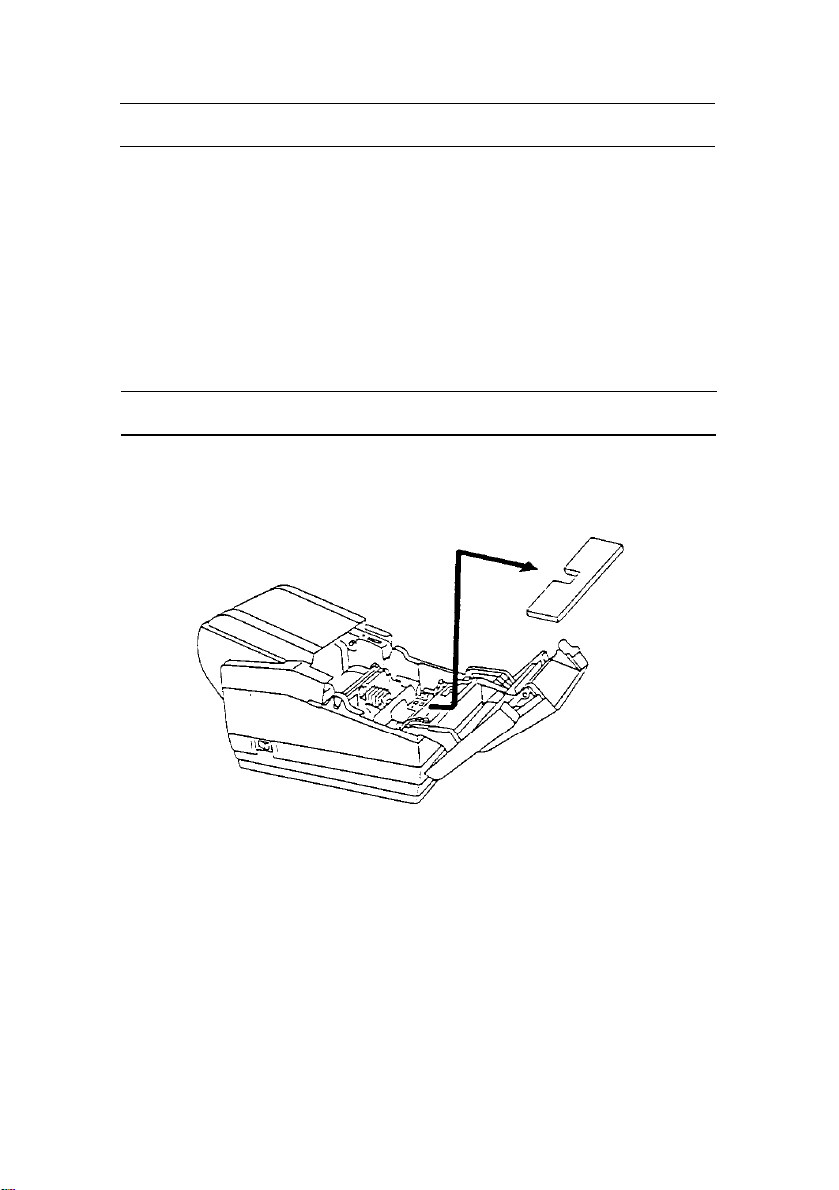

1-3 Removing the Transportation Damper

The transportation damper must be removed before turning on the printer.

Open the printer cover, and remove this material as follows:

2

Page 9

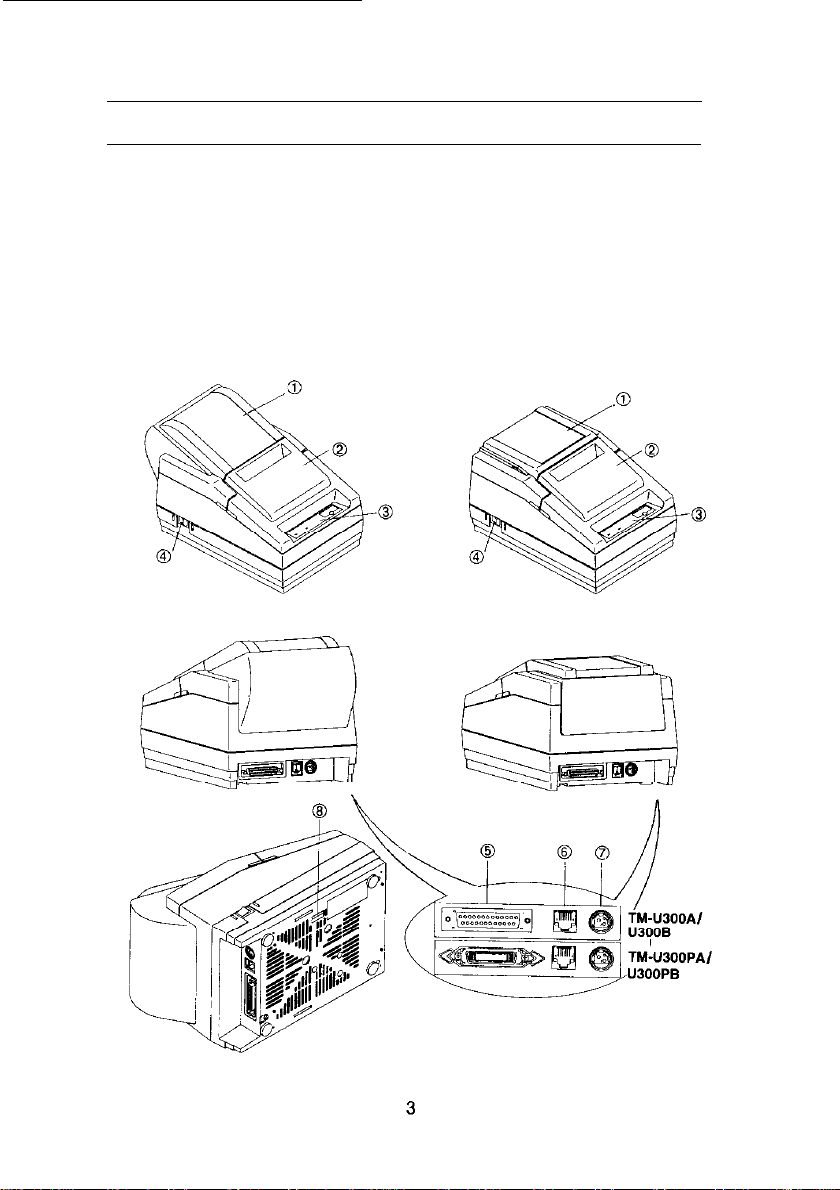

1-4

Names and Functions of Parts

n

Part names

➀

TM-U300A/U300PA:

TM-U300B/U300PB:

➁

Printer cover

➂

Operation panel

➃

Power switch

Take-up cover

Roll-paper cover

➄

Interface connector

➅

Drawer kick-out connector

➆

Power connector

➇

DIP switches

TM-U300A/U300PA

TM-U300B/U300PB

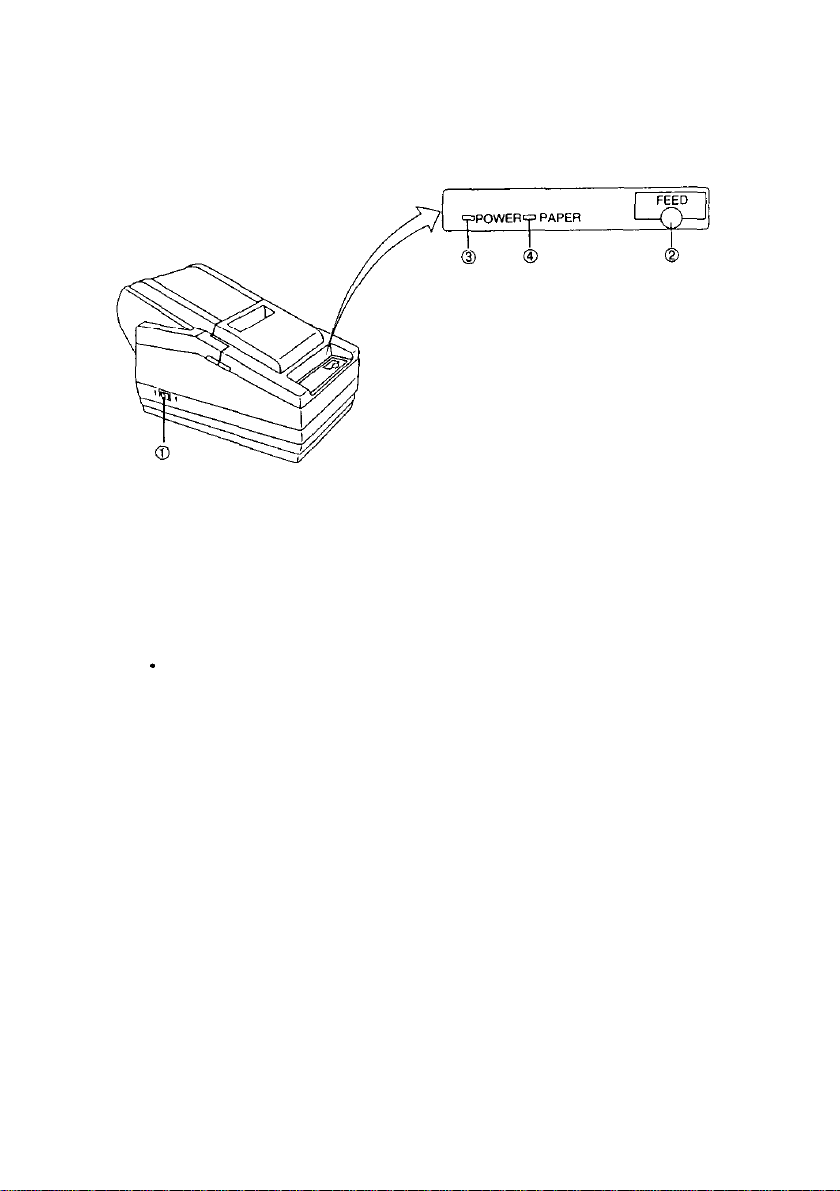

Page 10

n

Operation panel

Panel Switches

➀

POWER switch

Turn the printer ON and OFF.

➁ FEED switch

Feeds roll paper.

*

Feeds roll paper based on the line feed amount set by

ESC

2 and

ESC 3.

Panel Lights (LED)

➂

POWER LED (green)

On when power is turned on.

➃

PAPER LED (red)

On when the paper roll near the end.

Blinks when an error has been detected, when the printer is in the test printing

standby state, or when printing has stopped due to exceeding the allowable

print duty cycle.

4

Page 11

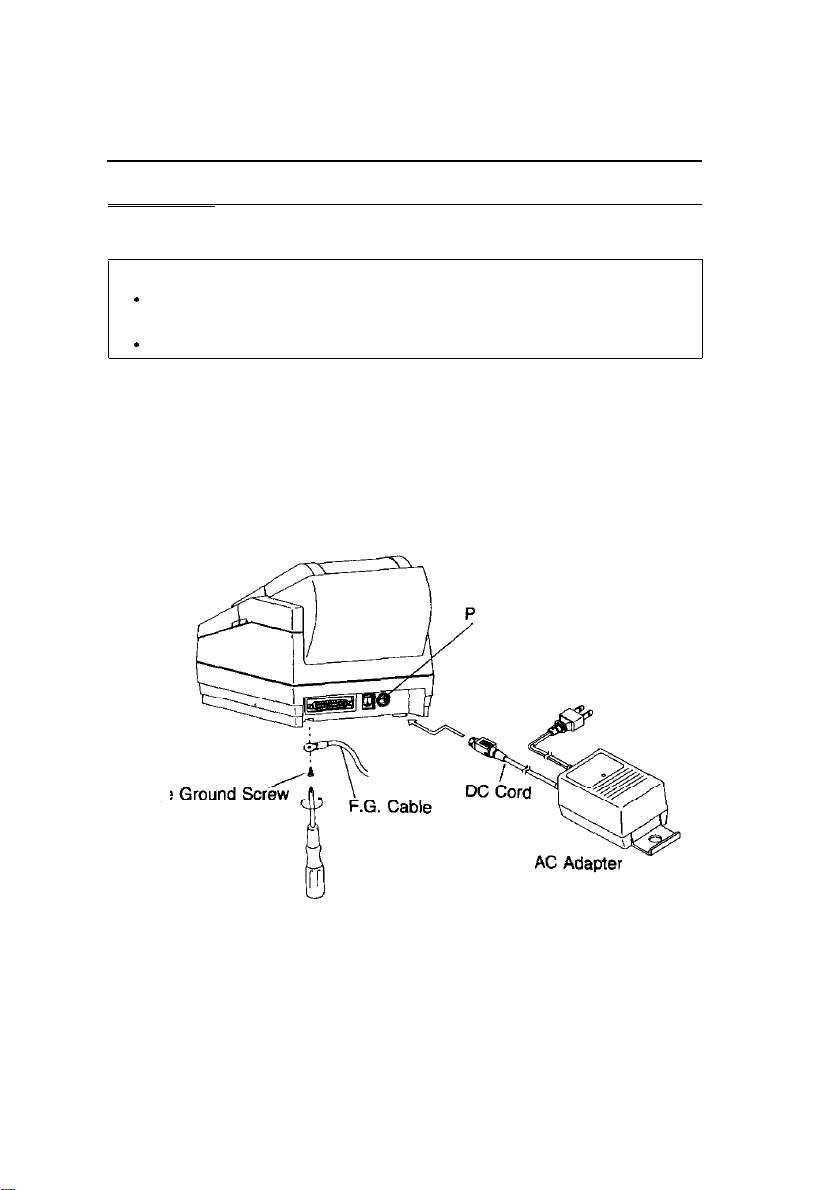

Chapter 2 Before Setting Up

2-1

Connecting the AC Adapter to the Printer

n

Plugging in AC adapter

CAUTIONS:

*

Before connecting the printer to the power supply, make sure that the

voltage and power specifications match the printer’s requirements.

-

Using an incorrect power supply can cause serious damage to the printer.

Connect the AC adapter according to the following procedure.

➀

Make sure the printer is turned off.

➁

Plug the power cable connector into the printer’s power connector with the ar-

row mark facing upward. (You can remove the power cable by grasping the

connector firmly at the arrow mark and pulling straight out.)

ower Connectorower Connector

Frame

➂

Plug the power cord into the outlet, and turn on the power.

➃

Be sure to ground the printer with the frame ground screw on the board at the

rear side of the unit via a F.G cable.

5

Page 12

2-2

Connecting the Host Computer to the Printer

n

Connecting the interface cable

Connect the printer with the host ECR (host computer) through an interface cable

matching the specifications of the printer and the host ECR (host computer).

Be sure to use a drawer that matches the printer’s specifications.

<TM-U300A/U300B>

Connect the interface cable according to the following procedure.

➀

Turn off the printer and the ECR (host computer).

➁

Plug the interface cable connector into the interface connector on the printer;

then fasten the screw on both sides of the connector.

➂

Plug the drawer kick-out cable connector into the drawer kick-out connector on

the printer. (When removing the drawer kick-out cable, press in on the

connector’s clip and pulling out.)

Drawer Kick-out Connector

,

Drawer Kick-out Cable

Serial Interface Cable Connector

r

I

NOTE:

l

Your printer

plan to use

comes with inch-type hexagonal lock screws installed. If you

an interface cable that requires millimeter-type lock screws,

replace the inch-type screws with the enclosed millimeter-type screws using

a hex screwdriver (5 mm). To distinguish the two types of screws, see the

figure below.

Notch (one or more line)

Inch-type

Millimeter-type

-

6

Page 13

<TM-U300PA/U300PB>

Connect the interface cable according to the following procedure.

➀

Turn off the printer, and the ECR (host computer).

➁

Plug the interface cable connector into the interface connector on the printer.

➂

Squeeze the wire clips together until they lock in place on both sides of the

connector.

➃

Attach the ground wire to the ground connector on the bottom of the printer.

➄

Plug the drawer kick-out cable connector into the drawer kick-out connector on

the printer. (When removing the drawer kick-out cable, press in on the

connectors clip and pulling out.)

Drawer Kick-out Connector

Interface Conne

Drawer Kick-out Cable

7

Page 14

Chapter 3 Installing the Parts

3-1

Installing the Ribbon Cassette

n

Installing the ribbon cassette

Be sure to use a ribbon cassette that matches the printer’s specifications.

➀

Open the printer cover.

➁

Turn the ribbon-tightening knob in the direction of the arrow to take up any slack

in the ribbon.

Page 15

➂ Fit the ribbon between the head unit and the ribbon mask. Then push the

cassette firmly into position.

➃

Turn the ribbon-tightening knob five or six times in the direction of the arrow to

feed the ribbon smoothly into place between the head unit and the ribbon mask.

-

Check that the ribbon is not twisted or creased.

CAUTION:

.

Do not turn the ribbon-tightening knob in the reverse direction.

➄

Close the printer cover.

Page 16

■

Exchanging the ribbon cassette

Be sure to use a ribbon cassette that matches the specifications.

➀ Open the printer cover.

➁ When removing the ribbon cassette, grasp the tab on the left side and lift

the left side out first.

➂ Install a new ribbon cassette.

See 3-1 Installing the Ribbon Cassette

➁ to ➄.

10

Page 17

3-2 Installing the Roll Paper

n

Installing the roll paper for TM-U300A/U300PA

Be sure to use roll paper that matches the printer’s specifications.

➀ Using scissors, cut the leading edge of the roll paper perpendicular to the paper

feed direction.

l-H.-Au.

Good

➁ Open the printer cover and the take-up cover.

l Check that the ribbon cassette is properly installed.

Bad

Bad

➂ Load the roll paper while lightly pressing the left roll-paper holder outward.

Release the holder after fitting the paper core onto the holder. Make sure the

roll paper turns freely. When loading roll paper, make sure to insert so that it

rotates in the correct direction.

Correct

Incorrect

Page 18

➃

Turn on the printer.

➄ While leaving some slack in the roll paper, insert the end of the roll paper

straight into the paper inlet. The printer automatically feeds the roll paper into

the printer.

➅

Press the FEED switch to continue feeding the paper until it extends about

20 cm beyond tear-off edge.

➆

Remove the take-up spool from the take-up frame.

Remove the side of the spool and insert the end of the paper roll (journal paper

when using 2-ply paper and 3-ply paper) into the groove on the spool and wrap

the roll paper around the spool two or three times.

shaft.

Install the flange to flange

12

Page 19

➇

Install the take-up spool to the take-up frame.

➈

Tear off the receipt paper by the cutter when

paper.

➉

Close the printer cover and the take-up cover.

using the 2-ply paper and 3-ply

Page 20

■

Installing the roll paper for TM-U300B/U300PB

Be sure to use roll paper that matches the printer's specifications.

➀

Using scissors, cut the leading edge of the roll paper perpendicular to the paper

feed direction.

Good

➁

Open the printer cover and the roll-paper cover.

l

Check that the ribbon cassette is properly installed.

Bad Bad

➂ Load the roll paper while lightly pressing the left roll-paper holder outward.

Release the holder after fitting the paper core onto the holder. Make sure the

roll paper turns freely. When loading roll paper, make sure to insert so that it

rotates in the correct direction.

Page 21

➃

Turn on the printer.

➄ While leaving some slack in the roll paper, insert the end of the roll paper

straight into the paper inlet. The printer automatically feeds the roll paper into

the printer.

Roll Paper

➅

Tear off any extra paper at the tear-off edge by pulling the paper toward yo

u.

➆

Close the printer cover and the roll-paper cover.

Page 22

n

Exchanging the paper roll

Be sure to use roll paper that matches the printer’s specifications.

<TM-U300A/U300PA>

➀

Open the printer cover and the take-up cover.

Remove the journal paper and the receipt paper. While pressing the FEED

switch, remove the remaining paper by pulling it out in the direction of the arrow

➁

Install a new roll paper.

See Installing the Roll Paper for TM-U300A/U300PA ➀ to ➉.

➀

Open the printer cover and the roll-paper cover.

Remove the roll paper. While pressing the FEED switch, remove the remaining paper by pulling it out in the direction of the arrow.

.

➁

Install a new roll paper.

See Installing the Roll Paper for TM-U300B/U300PB ➀ to ➆.

16

Page 23

3-3 Adjusting the Paper Near-End Detector

■

The paper near-end detector

The paper near-end detector senses when the paper is nearing its end and turns

on the PAPER LED.

The paper near-end detector can be adjusted according the thickness of the

paper core.

n

Adjusting the paper near-end detector

Roll paper differs in paper core size, so you may need to adjust the paper nearend detector.

➀

Make sure the paper core inside diameter (Ød) is 10.5 to 12.5 mm.

➁

Measure the paper core thickness A (Refer to Figure below) for the roll paper

to be used.

➂

Determine the corresponding adjustment value from the table below.

Table 3-1. Paper Core Thickness and its Graduation Degrees

Dimension A Adjustment value

4.5 mm I

#1

17

\

A

.

Page 24

➃ The adjusting screw which holds the roll paper near-end detector, may be

loosened and then set the top of “B” to the adjustment value found in

➂, and

tighten the adjusting screw. (The adjusting screw can be turned with a coin.)

Screw

➄ Be sure that the detecting lever operates smoothly after finishing the adjust-

ment.

NOTES:

l Since the adjustment values in Table 3-1 are calculated from standard

measurements, there may be some variations depending on the model.

*

If a roll paper with a red end mark at the paper end is used, this mark may

cause the paper to stick together.If this occurs, the dimension A differs from

the table.

-

Be surethat the detecting lever operates smoothly after finishing the

adjustment.

*

If the roll paper becomes loose due to poor paper quality, the detector may

operate incorrectly.

18

Page 25

3-4 DIP Switches

n

Locating DIP switches

On the bottom of your printer are DIP switches that allow the printer to be set or

perform a number of different functions.

.

The switches are numbered SW-1 to SW-10 (TM-U300A/U300B) or SW-1 to SW-8

(TM-U300PA/U300PB), from left to right as shown in figure below.

.

The lists on the following page describe each switch’s function.

■

Setting the DIP switches

Follow these steps when changing DIP switch settings.

➀

Turn the printer power switch off.

➁

Flip the DIP switches using tweezers or other narrow-ended tool.

Switches are on when up and off when down.

➂

The new setting takes effect when you turn on the printer.

NOTES:

*

Always change DIP-switch settings when printer is turned off.

.

Changes made with the power on have no effect until you turn the printer off

and then on again.

19

Page 26

n

TM-U300A/U300B DIP Switch Functions

Table 3-2. TM-U300A/U300B DIP Switch Functions

Switch Function

SW-1

SW-2

SW-3

SW-4

SW-5

SW-6

SW-7

SW-8

SW-9

SW-10

) Do not change the setting of DIP switches 9 and 10 in the TM-U300A/U300B.

*

■

TM-U300PA/U300PB DIP Switch Functions

Data receive error

Receive buffer capacity

Handshaking

/

Word length

Parity check

Parity selection

Baud rate selection (Refer to Table 3-3.)

(Internal use)

(Internal use)

Table 3-3. Baud Rate Selection

Transmission Speed (bps)

1200

2400

4600

9600

ON

Ignored

40 bytes

(

XON/XOFF ( DSR/DTR

7 bits

On Off

Even

*

SW-7

ON

OFF ON

ON OFF

OFF

OFF

Prints “?”

Approx. 1 Kbyte

8 bits

Odd

)

SW-8

ON

OFF

Table 3-4. TM-U300PA/U300PB DIP Switch Functions

Switch

SW-1

SW-2

SW-3

SW-4

SW-5 (Internal use)

SW-6

SW-7

SW-8 (Internal use)

)

Do not change the setting of DIP switches 3 to 8 in the TM-U300PA/U300PB.

*

Function

Auto-feed

Receive buffer capacity

(Internal use)

(Internal use)

(Internal use) *) Fixed to ON.

(Internal use)

Always enable

0 byte Approx. 1 Kbyte

) Fixed to ON.

*

) Fixed to OFF.

*

) Fixed to ON.

*

20

ON OFF

Depends on AUTO FEED XT

)

*

Page 27

Chapter 4 The Self Test

4-1 The Self Test

n

The purpose of the self test

The self test checks whether the printer has any problems. When the printer

does not function properly, contact the dealer.

The self test checks the following

-

Control circuit functions

-

Printer mechanism functions

*

Print quality

n

Running the self test

Run the self test only when roll

paper is loaded the printer.

➀

Make sure the ribbon cassette

and paper have been installed

properly.

➁

Turn on the power while hold-

ing down the FEED switch.

The self test begins.

➂ The following contents are

printed for printer current status printing first.

*

Control ROM version

-

DIP-switch settings

➃

After printing the printer cur-

rent status, the printer blinks

the PAPER LED and enters

the test printing standby state.

Press the FEED switch to restart test printing.

➄

After the printer completes a

certain number of lines, it prints

“* *

*completed * + w, and

stops printing automatically.

*

The printer goes off-line dur-

ing and after self-test printing.

Turn the power off and on again

to put the printer on-line before

transmitting data from the host

computer.

-

Control ROM version

-

DIP-switch settings

(TM-U300A/U300B)

Self-test Printing Samples

(TM-U300PA/U300PB)

21

Page 28

Chapter 5 Removing Jammed Paper

5-1 Removing Jammed Paper

■

Removing jammed paper

Remove jammed paper according to the following steps.

➀

Open the roll-paper take-up cover (TM-U300A/U300PA) or the roll-paper cover

(TM-U300B/U300PB).

➁

Then turn the paper-feed knob and remove any jammed paper.

➂

Reload roll paper, and close the roll-paper take-up cover (TM-U300A/U300PA) or the

roll-paper cover (TM-U300B/U300PB).

See 3-2, Installing the Roll Paper.

22

Page 29

APPENDIX

APPENDIX A General Specifications

1. Printing specifications

Printing method:

Head wire arrangement:

Printing directions:

Lines per second:

Characters per line:

Character per inch:

Print color switching mechanism:

Serial impact dot matrix

Serial-type 9 pin

Bi-directional (logic-seeking)

Approx. 3.5 LPS (40 columns, 16 CPI, Single

color continuous printing)

Approx. 5.6 LPS (20 columns, 16 CPI, Single

color continuous printing)

In the case of heavy use, printing stops to

*

protect the head.

In this case the actual lines per second may be

lower.

(LPS: Lines Per Second)

(CPI: Characters Per Inch)

Refer to Table A-1

Refer to Table A-1

Selectable black or red printing

2. Character specifications

Number of characters:

Character structure:

Character size:

Alphanumeric:

Graphics:

International characters: 32

7 x 9 (Total number of dots in the horizontal

direction: 400 half dots)

9 x 9 (Total number of dots in the horizontal

direction: 406 half dots)

Refer to Table A-1

23

95

126 X 7 tables

Page 30

Table A-1. Character Size, Characters Per Line, Characters Per Inch

(*1) 7 X 9 font is the default. (*2) ANK: Alphanumeric and Kana

Example) 7 X 9 font

1.24

3. Ribbon

Ribbon cassette type:

Color:

Ribbon life:

(In case of using 2-color type)

Ribbon cassette overall dimensions:

1.59

Exclusive ribbon cassette ERC-38 (

Black and Red, Black, Purple

Black: Approx. 1,500,000 characters

Red:

Approx. 750,000 characters

Refer to Figure A-1

[Units: mm]

*

Units: mm1

)

Figure A-1. ERC-38 Overall Dimensions

(*) Single-color ribbons [Part No.:ERC-34(P)(purple) or ERC-34(B)(black)] and

P-color ribbon [Part No.:ERC-34(B/R)(black and red)] are also available. In

case of using the single-color ribbon, the print color selection command,

ESC r

must not be used.

24

Page 31

[Condition]

*

Character font: 7 X 9 font

*

Printing pattern: ASCII 96-character rolling

-

Temperature:

4. Roll paper supply device

Supply method:

Near-end detector:

-

Detection method:

-

Roll paper core inside diameter:

-

Near-end adjustment:

5. Roll paper take-up device

The TM-U300A and TM-U300PA are equipped with a take-up device. The paper is automatically take-up by the paper feed motor.

6. Auto-cutter

Both the TM-U300A/U300B and TM-U300PA/U300PB are equipped with the auto-cutter.

Full-cut/partial-cut can be executed by commands.

Roll paper shaft-support loading

Micro switch

Ø 10.5

to 12.5 mm

Adjustable slider

(Refer to 3-3, Adjusting the Paper Near-End De-

tector)

(with descenders)

pattern continuous printing

25°C

7. Paper

Paper feed method:

Paper feed pitch:

Paper feed speed:

Paper size:

*

Roll paper

Paper width:

Friction feed

Default 1/6 inch

Can be set in 1/144 inch units by software command.

Approx. 4.17 IPS (25 LPS) (continuous feeding)

(IPS: Inches Per Second)

(LPS: Lines Per Second)

76

mm ± 0.5 mm

25

Page 32

Ø

83

Maximum diameter:

mm (When 2-ply or 3-ply paper is used.

When 1-ply paper is employed, the maximum diameter shall be Ø 60 mm.)

Paper core inside diameter:

Ø 10.5 to 12.5 mm

*

Normal paper

Paper thickness: 0.06 to 0.85 mm

Weight:

52.3 g/m2 to 64 g/m

2

(45 to 55 kg/1000 sheets/1091 X 788 mm)

*

Pressure sensitive paper

Maximum 1 original + 2 copies. Copy capability is considerably affected by

the ambient temperature.

Refer to table A-2. Relationship between Ambient Temperature and Number

of Copies.

Paper thickness:

Total thickness shall be a 0.2 mm or less combination of 0.05 to 0.08 mm sheets. Paper thickness to

be auto cut should be 0.06 mm + 0.06 mm, and the

total thickness shall be a 0.12 mm or less.

Table A-2. Relationship between Ambient Temperature

and Number of Copies

/

Number of Copies

1 original + 1

1

original + 2

copy

copies

1

Temperature

5 to 40 °C

1

Approx. 25°C

1

8. Receive buffer

Either 40 bytes or approx. 1 Kbyte is selectable using DIP switch. (TM-U300A/U300B)

Either 0 byte or approx. 1 Kbyte is selectable using DIP switch. (TM-U300PA/U300PB)

9. Electrical characteristics

Opening power supply:

Packaged AC adapter

One of the following 4 AC adapters is selected,

depending on the local power:

26

Page 33

Page 34

Storage:

-10 to 50°C (excluding paper and

ribbon cassette)

Humidity:

Operating: 20 to 80°C (non-condensing)

Storage:

20 to 90%

(non-condensing, excluding paper

and ribbon cassette)

Figure A-2. Operating Temperature and Humidity Range

28

Page 35

Loading...

Loading...