Page 1

Confidential

Service manual

TM-U220 Series

(Type A)

Issued date , ,

Issued by

EPSON

English

404619501

Rev. B

Page 2

Confidential

TM-U220 Type A Service Manual

CONFIDENTIALITY AGREEMENT

BY USING THIS DOCUMENT, YOU AGREE TO ABIDE BY THE TERMS OF THIS AGREEMENT. PLEASE RETURN

THIS DOCUMENT IMMEDIATELY IF YOU DO NOT AGREE TO THESE TERMS.

❏ This document contains confidential, proprietary information of Seiko Epson Corporation or its affiliates. You

must keep such information confidential. If the user is a business entity or organization, you must limit disclosure

to those of your employees, agents, and contractors who have a need to know and who are also bound by

obligations of confidentiality.

❏ On the earlier of (a) termination of your relationship with Seiko Epson, or (b) Seiko Epson’s request, you must

stop using the confidential information. You must then return or destroy the information, as directed by Seiko

Epson.

❏ If a court, arbitrator, government agency, or the like orders you to disclose any confidential information, you must

immediately notify Seiko Epson. You agree to give Seiko Epson reasonable cooperation and assistance in the

negotiation.

❏ You may use confidential information only for the purpose of operating or servicing the products to which the

document relates, unless you obtain the prior written consent of Seiko Epson for some other use.

❏ Seiko Epson warrants that it has the right to disclose the confidential information. SEIKO EPSON MAKES NO

OTHER WARRANTIES CONCERNING THE CONFIDENTIAL INFORMATION OR ANY OTHER

INFORMATION IN THE DOCUMENT, INCLUDING (WITHOUT LIMITATION) ANY WARRANTY OF TITLE

OR NON-INFRINGEMENT. Seiko Epson has no liability for loss or damage arising from or relating to your use of

or reliance on the information in the document.

❏ You may not reproduce, store, or transmit the confidential information in any form or by any means (electronic,

mechanical, photocopying, recording, or otherwise) without the prior written permission of Seiko Epson.

❏ Your obligations under this Agreement are in addition to any other legal obligations. Seiko Epson does not waive

any right under this Agreement by failing to exercise it. The laws of Japan apply to this Agreement.

Cautions

❏ No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of

Seiko Epson Corporation.

❏ The contents of this document are subject to change without notice. Please contact us for the latest information.

❏ While every precaution has been taken in the preparation of this document, Seiko Epson Corporation assumes no

responsibility for errors or omissions.

❏ Neither is any liability assumed for damages resulting from the use of the information contained herein.

❏ Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third parties

for damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of: accident, misuse, or

abuse of this product or unauthorized modifications, repairs, or alterations to this product, or (excluding the U.S.)

failure to strictly comply with Seiko Epson Corporation’s operating and maintenance instructions.

❏ Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any options

or any consumable products other than those designated as Original EPSON Products or EPSON Approved

Products by Seiko Epson Corporation.

®

EPSON

and ESC/POS® are registered trademarks of Seiko Epson Corporation

Rev. B i

Page 3

Confidential

Contents

Revision Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

For Safe Repair and Maintenance Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Key to Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Safety Precautions on Maintenance/Repair/Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

Modular Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vi

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Aim of the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Manual Content . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Chapter 1 Product Overview

Notes on Connecting the Power Supply Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Part Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Control Panel (LEDs and Button) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Power Switch and Power Switch Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Power Switch Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Inserting Roll Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Installing or Replacing the Ribbon Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Differences between the TM-U300, TM-U200, and TM-U220 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

Chapter 2 Repair Guide

Repair Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Outline of Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Repair Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Confirming the User’s Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Confirming the Printer Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Self-test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Service Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Chapter 3 Troubleshooting

Preparations for Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Before Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Diagnosing Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Symptoms and Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Symptoms when Power is On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Symptoms when the All Function Test is Executed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Symptoms for other operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

Test Points on the Main Circuit Board Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Resistance Values of Printer Mechanism Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Chapter 4 Disassembly and Assembly

Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Standard Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Tool List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Notes for Assembly and Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

Shortest Route for Disassembly of Major Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Disassembling the TM-U220 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Exploded Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Disassembling the Mechanism Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Exploded Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

ii Rev. B

Page 4

Confidential

DIsassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Disassembling the Carriage Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Exploded Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

DIsassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Disassembling the Rotation Frame Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Exploded Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

DIsassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Disassembling the Roll Paper Guide / Roll Paper Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Exploded Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

DIsassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Disassembling the Autocutter Unit / Fixed Blade Holder Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Exploded Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

DIsassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Disassembly and Assembly Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Lubrication Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Chapter 5 Adjustment and Setting

Setting the Installation Position for the Roll Paper Near-End Detector . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Adjusting the Detection Point for the Roll Paper Near-End Detector . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Setting the Paper Roll Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Setting the Autocutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Platen Gap Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Carriage Belt Tension Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Adjust Various Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

How to Confirm the Current Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Adjusting the DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Memory Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Memory Switch Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

TM-U220 Type A Service Manual

Chapter 6 Preparation for Shipment

Inspection and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

How to Clean the Cases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Removing Dirt, Paper Chips, and Dust from Inside the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Appendix Parts List

Reference Number List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Rev. B iii

Page 5

Confidential

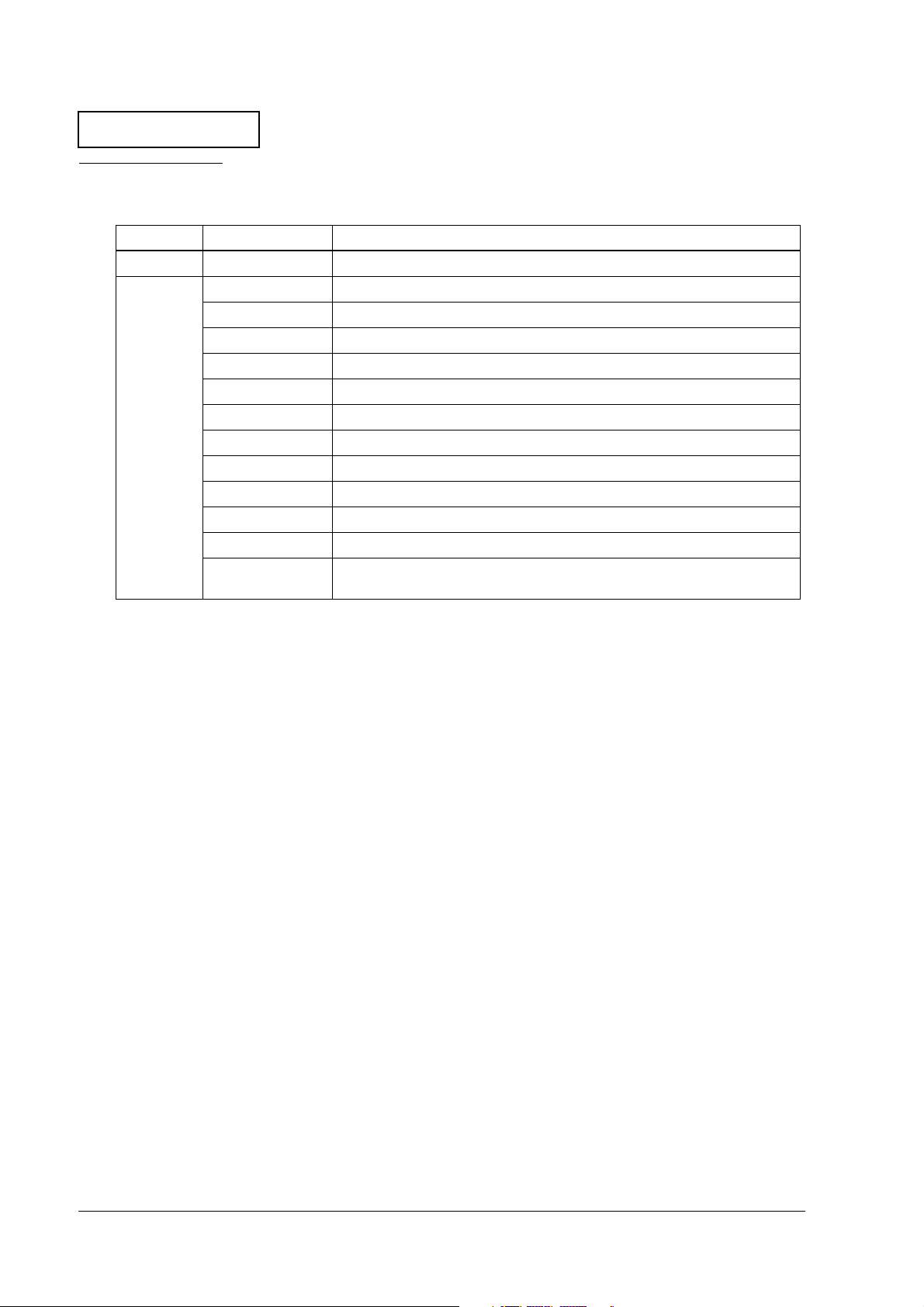

Revision Table

Revision Pages Description

Rev. A All pages Newly authorized.

Rev. B 1-2 Part names added.

1-3 Control panel (LEDs and buttons) added.

1-4 Inserting roll paper added.

1-8 Installing and replacing the ribbon cassette added.

4-3, 4-4 Illustration was changed.

4-5, 4-16, 4-17 An explanation of the roll paper cover assembly was added.

4-6, 4-7 Cutter rotation plate (1129) added.

4-7 Step 6 added to disassembly.

4-10, 4-11, 4-20 Paper feed roller plate B deleted.

4-11 An explanation of the platen assembly 1 was added.

4-30 An explanation of the lubrication reference was added.

Chapter 6 Inserting roll paper and installing or replacing the ribbon cassette was

moved to Chapter 1.

iv Rev. B

Page 6

Confidential

TM-U220 Type A Service Manual

For Safe Repair and Maintenance Work

Key to Symbols

The symbols in this manual are identified by their level of importance, as defined below. Read

the following carefully before handling the product.

WARNING:

You must follow warnings carefully to avoid serious bodily injury.

CAUTION:

Observe cautions to avoid minor injury to yourself, damage to your equipment, or loss of

data.

Note:

Notes have important information and useful tips on the operation of your equipment.

Rev. B v

Page 7

Confidential

Safety Precautions on Maintenance/Repair/Inspection

WARNING:

❏

Be sure to use the EPSON-supplied fuse on the circuit board. Use of another fuse may

result in fire.

❏

Remove the power cord and all other cables from this product before disassembly

or reassembly to prevent electrical shock.

❏

To prevent the possibility of electrical shock, do not perform maintenance, repair, or

inspection during a thunderstorm.

❏

Shut down your equipment immediately if it produces smoke, a strange odor, or

unusual noise. Continued use may lead to fire or electric shock. Immediately unplug

the equipment.

❏

Only disassemble this product as described in this manual. Do not make

modifications to the unit. Tampering with this product may result in injury, fire, or

electric shock.

❏

Be sure to use the specified power source. Connection to an improper power source

may cause fire or shock.

❏

Never insert or disconnect the power plug with wet hands. Doing so may result in

severe shock.

CAUTION:

❏

Parts on the circuit board may become hot during operation. Therefore, wait

approximately 10 minutes after turning the power off before touching them.

❏

To avoid injury, take care not to insert fingers or any part of the hand in the paper roll

opening where the manual cutter is installed.

❏

Do not open the paper roll cover without taking the necessary precautions, as this

can result in injury from the autocutter fixed blade.

Modular Connectors

Use the modular connectors specifically designed for the cash drawer and customer display for

this product. Do not connect these connectors to an ordinary telephone line.

vi Rev. B

Page 8

Confidential

TM-U220 Type A Service Manual

About this Manual

Aim of the Manual

This manual was created to provide the information on printer maintenance and repair required

by technicians who handle this work.

Manual Content

The manual is made up of the following sections

Chapter 1 Product Overview Provides an overview of the product.

Chapter 2 Repair Guide Describes the instructions to complete repair of

the product.

Chapter 3 Troubleshooting Provides information on troubleshooting.

Chapter 4 Disassembly and

Assembly

Chapter 5 Adjustments and Settings Describes adjusting and settings procedures.

Chapter 6 Preparation for shipment Describes preparation for transport. Also

Appendix Parts List Provides a parts list. Also describes screw types.

Describes disassembly and assembly procedures.

Also, shows exploded diagrams and lubrication

point diagrams for this product.

provides information on maintenance,

inspection, and cleaning.

Rev. B vii

Page 9

Confidential

TM-U220 Type A Service Manual

Chapter 1

Product Overview

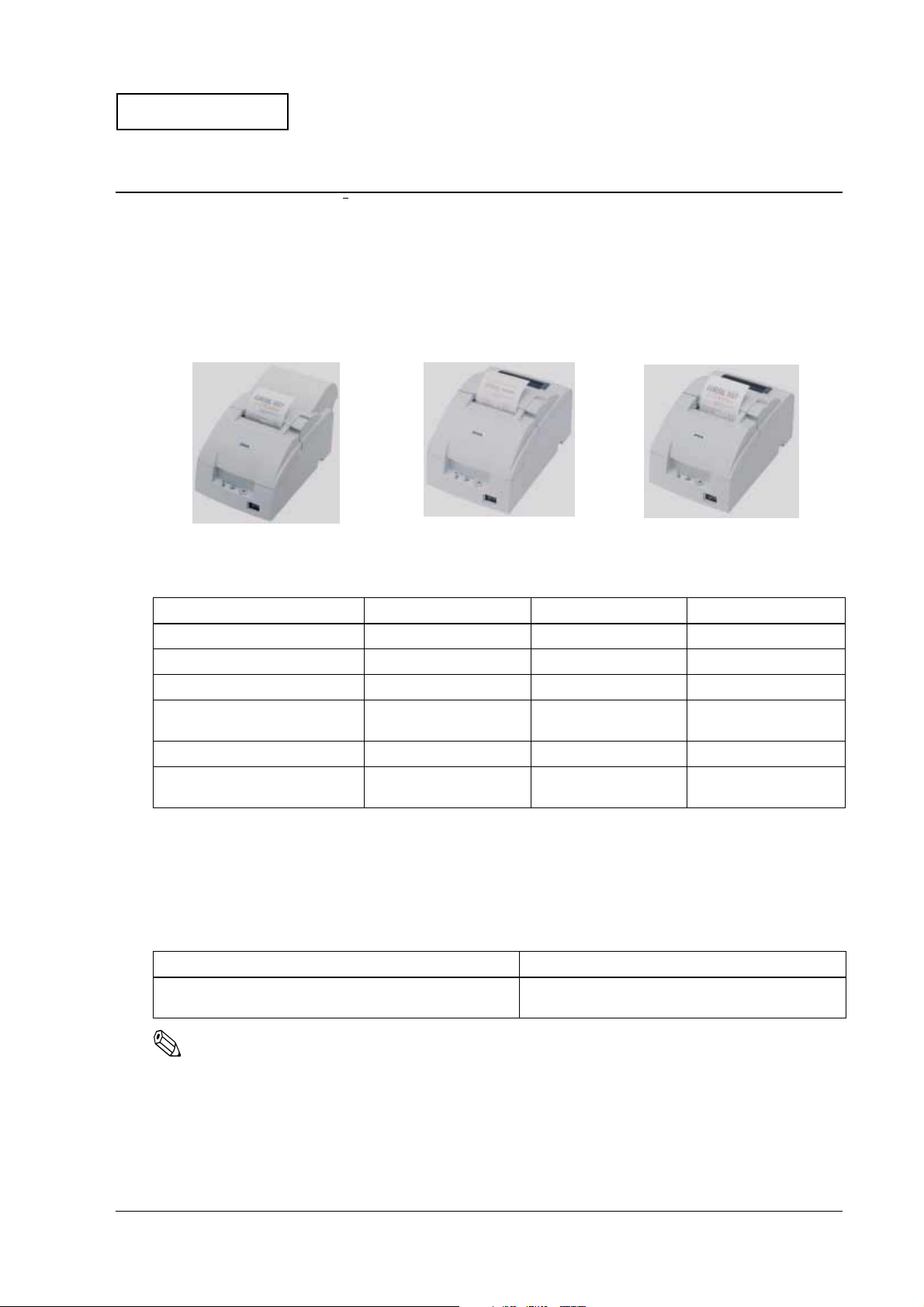

The TM-U220 is a serial impact dot-matrix printer for POS systems that can print on roll paper of

various widths. This manual describes the TM-U220 Type A, which has a take-up shaft for

journal paper. The following model types are available for the TM-U220.

Type A

Type B

TM-U220 external views

Type D

TM-U220 Model Comparison

Type A Type B Type D

Two-color printing Yes Yes Yes

Autocutter Yes Yes No

Take-up device Yes No No

Paper width

Interface (supplied with printer)* Serial or parallel Serial or parallel Serial or parallel

Characters supported

Note: * Other compatible interfaces, such as USB and Ethernet, are available from the dealer.

** Multilingual support means that the printer can print any one of the following: Japanese Kanji, Simplified

Chinese, Traditional Chinese, Thai characters, or Korean characters.

76 / 69.5 / 57.5 mm

{3" / 2.74" / 2.26"}

Alphanumeric (ANK) or

multilingual**

76 / 69.5 / 57.5 mm

{3" / 2.74" / 2.26"}

Alphanumeric (ANK) or

multilingual**

76 / 69.5 / 57.5 mm

{3" / 2.74" / 2.26"}

Alphanumeric (ANK) or

multilingual**

Notes on Connecting the Power Supply Unit

Be sure to use the correct power supply unit, as listed in the table below.

TM-U220 alphanumeric model TM-U220 multilingual model

1. AC adapter C (packed with the alphanumeric model)

2. PS-180 (option)

Note:

The AC adapter C, which is packed with the alphanumeric model, cannot be used with the multilingual

model. Be sure to use the PS-180 with the multilingual model. If the AC adapter C power supply is

connected to the multilingual model by mistake, the printer may not operate correctly. For example,

printing may stop before all lines are printed, or the printer might print the same line repeatedly.

Rev. B Product Overview 1-1

PS-180 (packed with the multilingual model)

Page 10

Confidential

Configurations

This TM-U220 is configured by combining features from the list below.

Table 1-1 Configurations

Features Selection Description

UB-S01 (RS-232)

Interface types

Paper width selections 76, 69.5, or 57.5 mm {3", 2.74", or 2.26"}

Power supply unit types

Installation positions

UB-P02II (IEEE 1284 (bidirectional parallel))

EPSON UB universal interface board

options

Exclusive external power supply for the

alphanumeric model:

AC Adapter C (North America only)

(pre-packaged).

External power supply unit for the

multilingual model:

PS-180

Horizontally (default)

Vertically by use of the optional WH-10

wall-hanging bracket

Use an EPSON-approved interface board

Be sure to change the paper guide

spacer if paper of a different width is used.

Then, set the customized value in printer

memory for the correct paper width. For

details about how to set the paper width,

see Chapter 6, “Installation.”

Do not use the AC Adapter C with the

multilingual model.

Selections in the table above may be added to or changed in the future.

Note:

dpi: dots per 25.4 mm (dots per inch)

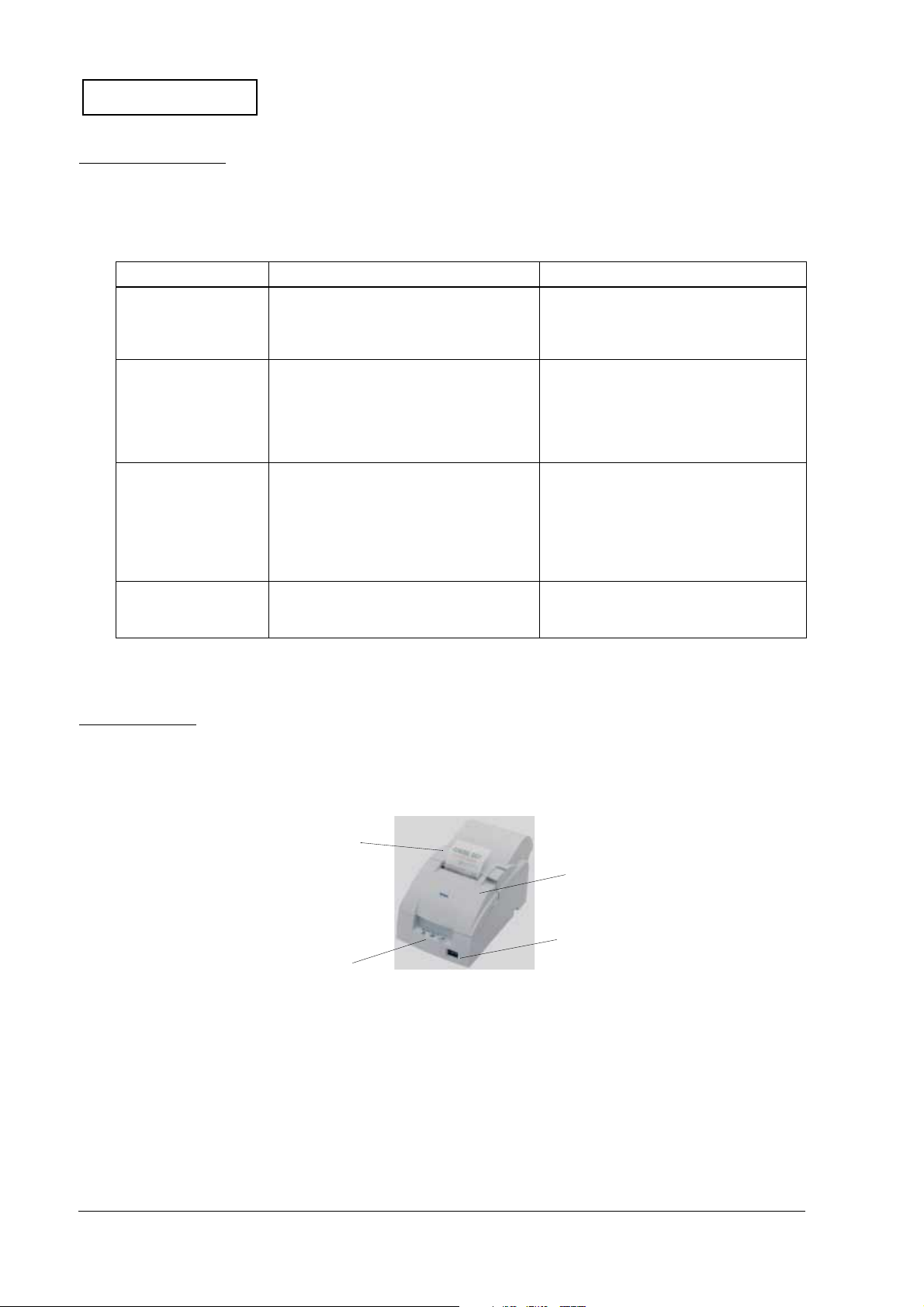

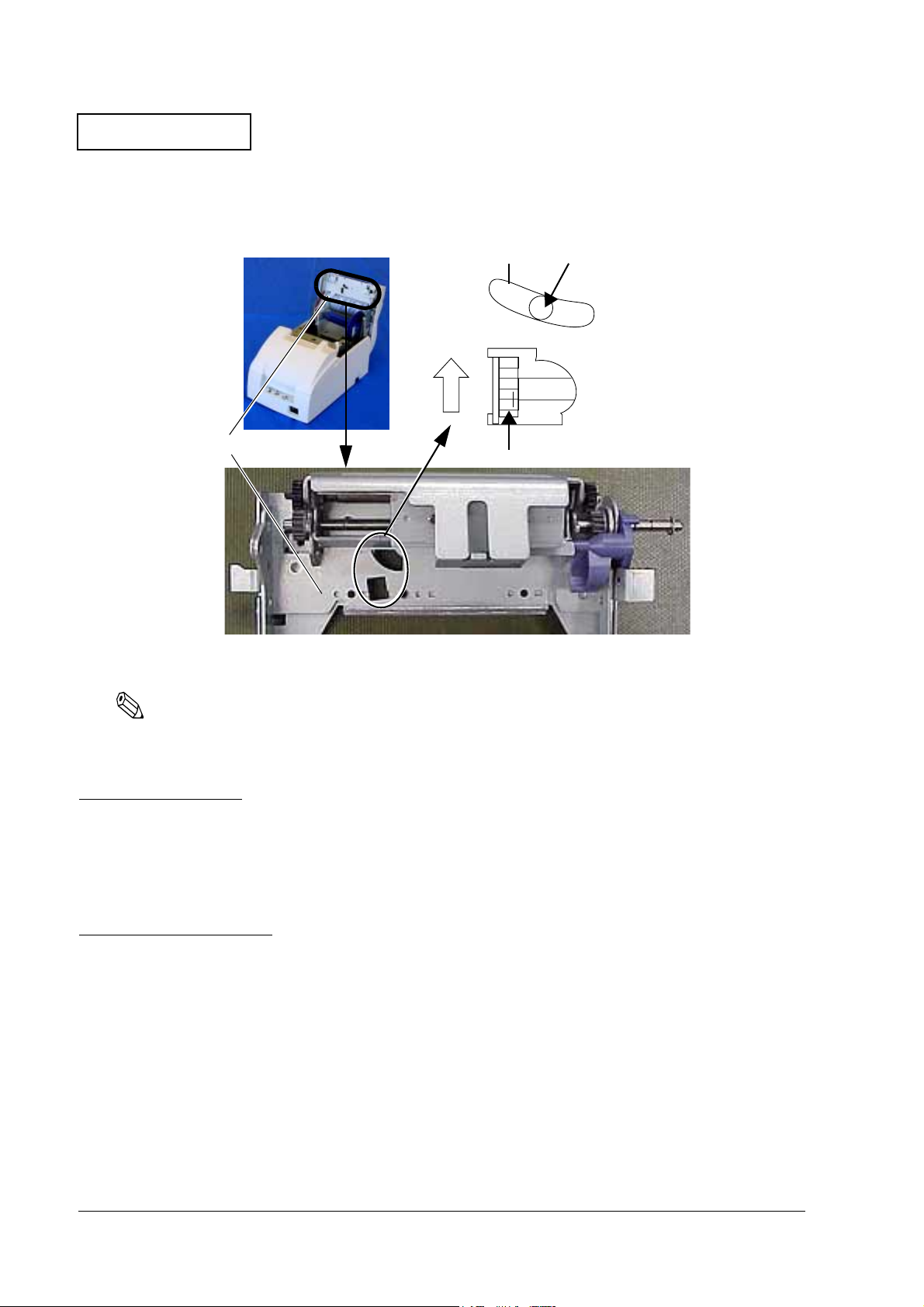

Part Names

The figure below shows part names for the TM-U220.

Roll paper cover

Control panel

Ribbon cassette cover

Power switch

1-2 Product Overview Rev. B

Page 11

Confidential

TM-U220 Type A Service Manual

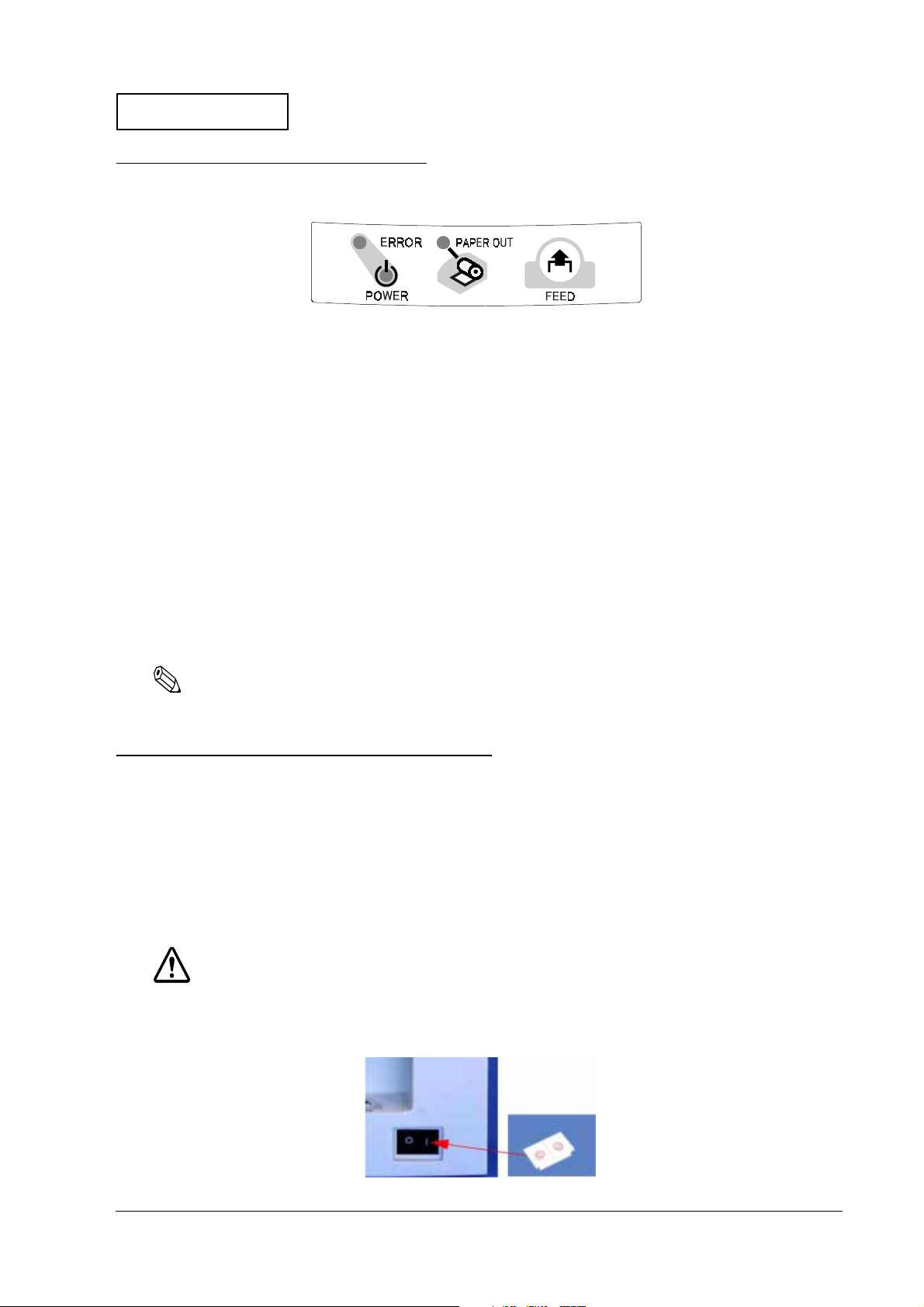

Control Panel (LEDs and Button)

LEDs

POWER

On when power is on.

ERROR

On when printer is offline. Off when printer is online. Flashes during an error.

PAPER OUT

On when paper is out or nearly out. Flashes during self-test

Button

FEED

This button feeds roll paper or starts a self-test.

Note:

Paper cannot be fed by using this button when a paper out is detected.

Power Switch and Power Switch Cover

The power switch is on the front of the printer. Press this switch to turn on the printer.

Power Switch Cover

This cover prevents the power from being turned off accidentally during printing. If you need to

turn the power on or off while the cover is attached, you can insert a small screwdriver or

similar tool into one of the holes in the cover to flip the switch.

WARNING:

If an accident occurs while the power switch cover is attached, immediately unplug the

power supply cable to avoid fire.

Rev. B Product Overview 1-3

Page 12

Confidential

Inserting Roll Paper

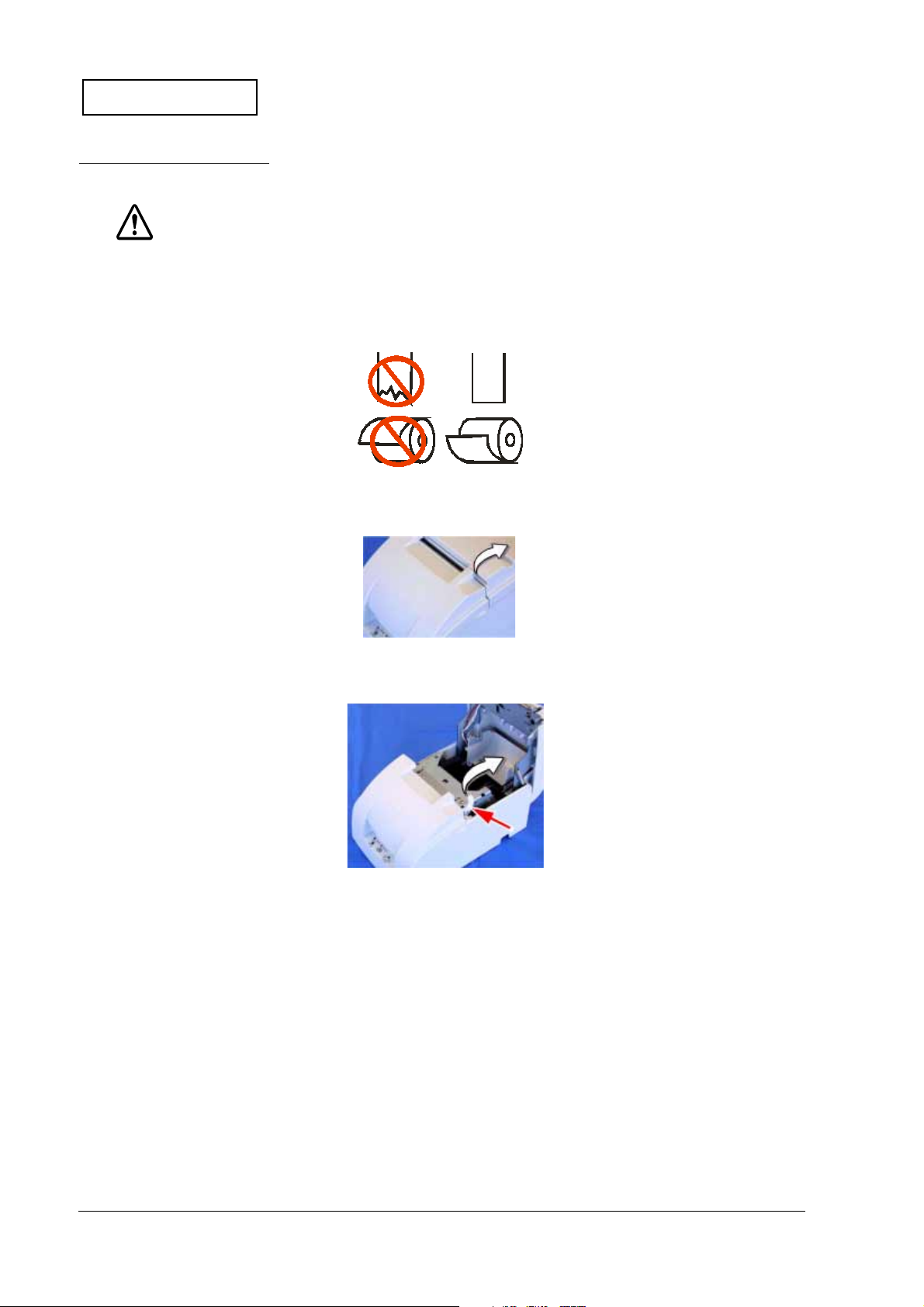

CAUTION:

Be sure to use only roll paper that meets the specifications.

Be sure not to touch the manual cutter. Otherwise, you may cut your fingers.

1. Using scissors, cut the leading edge of the roll paper.

2. Turn on the printer and open the roll paper cover by using the tab.

3. Open the unit by using the unit open lever, as shown below.

Unit open lever

1-4 Product Overview Rev. B

Page 13

Confidential

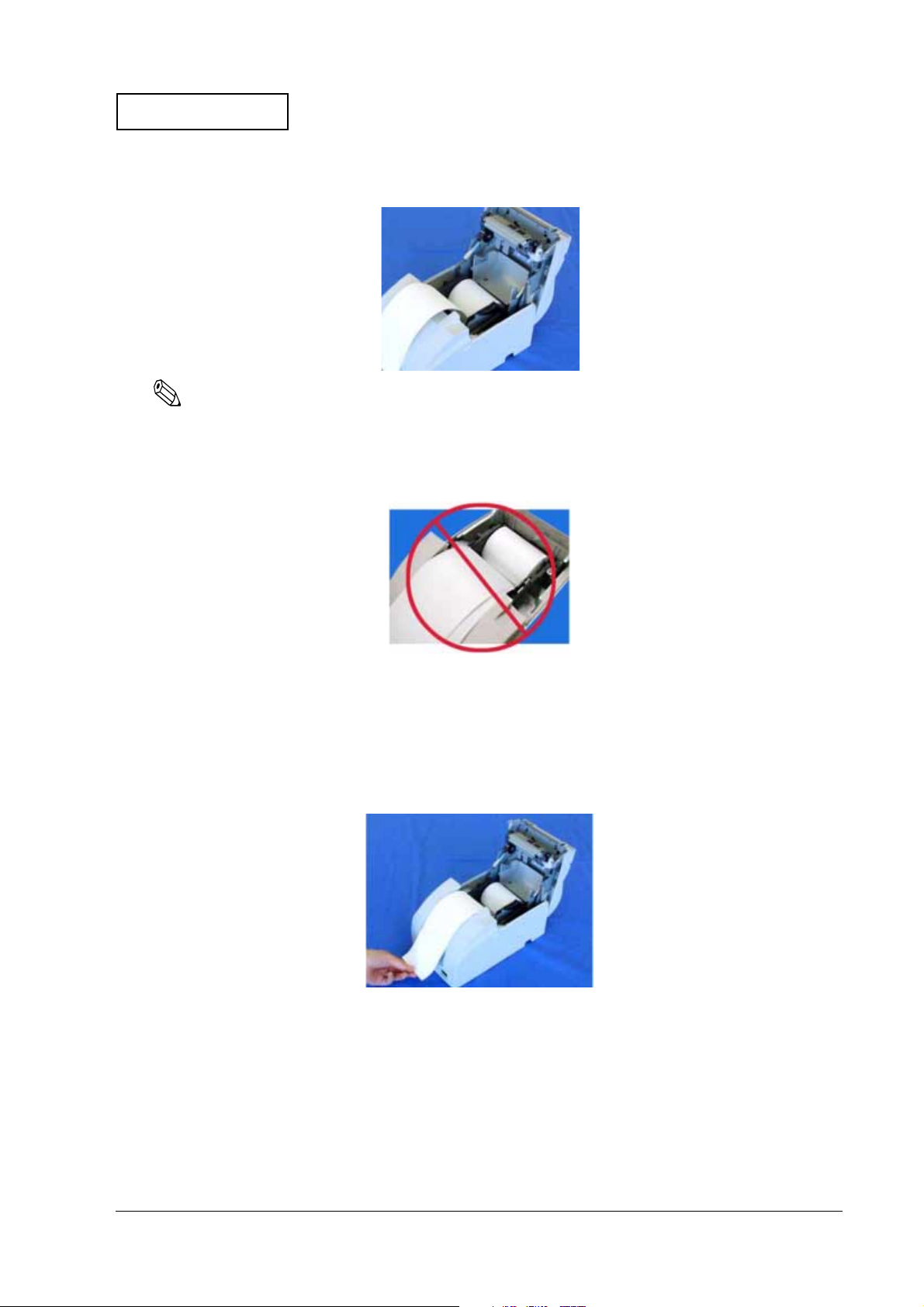

4. Insert the roll paper.

Note:

Note the direction that the paper comes off the roll, as shown above.

When using two-ply paper, be sure that the top and bottom sheets are aligned at the paper exit. Do not

allow paper to be loaded as shown below.

TM-U220 Type A Service Manual

5. If you are not using the take-up flange, pull out a small amount of roll paper and close the

roll paper cover. Then, tear off the paper with the manual cutter. You can skip steps 6

through 11.

6. When using 2-ply roll paper, pull out the roll paper to the bottom front of the printer, as

shown below.

Rev. B Product Overview 1-5

Page 14

Confidential

7. Close the unit, as shown below.

8. Insert the end of the bottom layer of paper (journal paper) into the paper take-up flange, as

shown below.

Take-up flange

9. Insert the paper take-up flange into the printer. Be sure that the paper is aligned with the

flange, as shown.

10. Feed the paper with the FEED button so that the paper is taken up by the flange.

11. Close the roll paper cover and tear off the roll paper with the manual cutter, as shown

below.

Note:

Do not open the roll paper cover during printing or paper feeding.

When using the printer, be sure to cut the roll paper with the manual cutter after paper feeding is

complete.

1-6 Product Overview Rev. B

Page 15

Confidential

TM-U220 Type A Service Manual

Installing or Replacing the Ribbon Cassette

CAUTION:

EPSON recommends the use of only genuine EPSON ribbon cassettes. Ribbon cassettes

not manufactured by EPSON may cause damage to your printer that is not covered by

EPSON’s warranties.

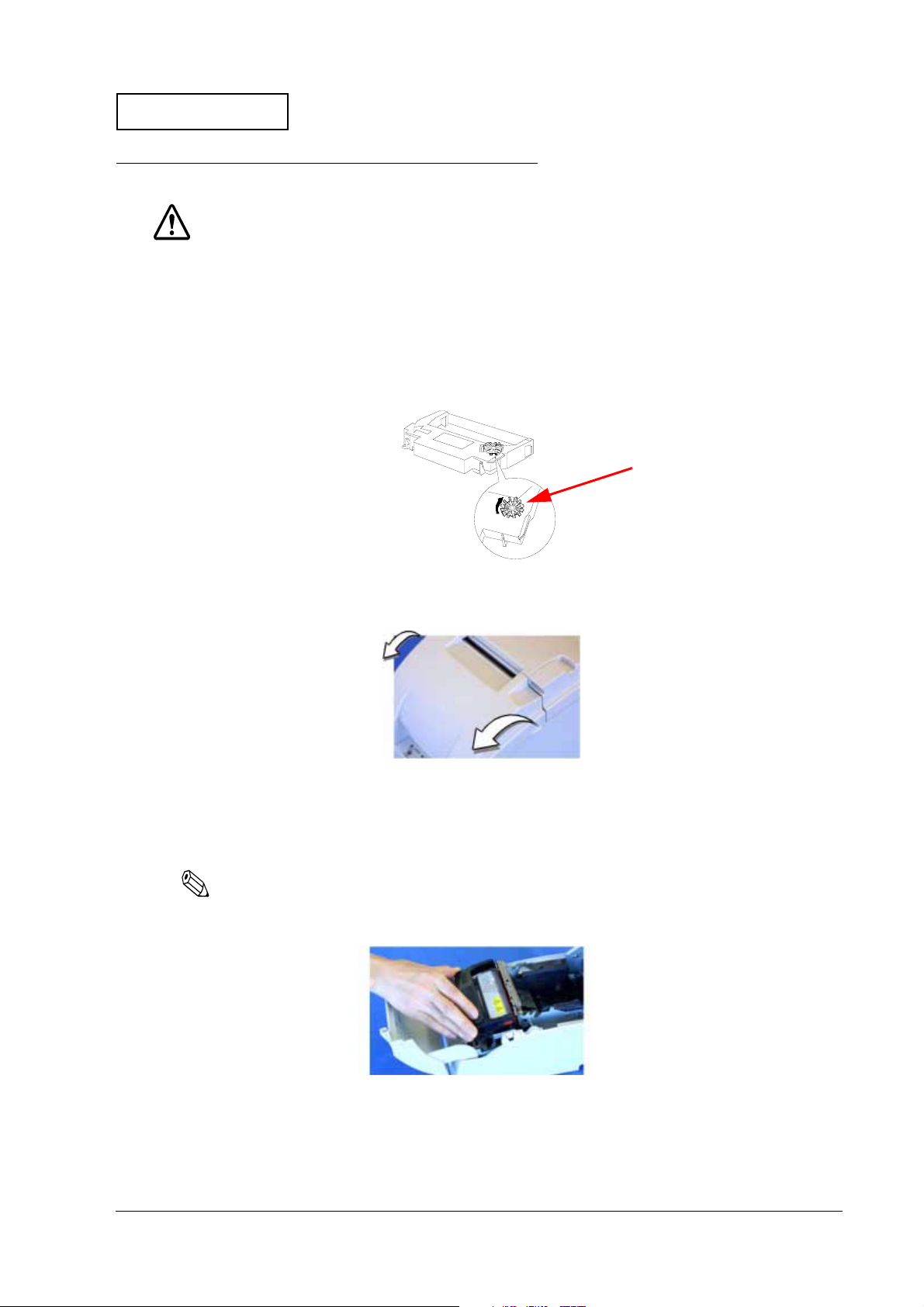

To install the ribbon cassette for the first time or to replace a used ribbon, follow the steps below.

1. Unpack the ribbon cassette and turn the knob in the direction shown to take up any slack.

Knob

2. Open the printer’s ribbon cassette cover using the tabs on each side of the cover.

3. Remove the old ribbon, if there is one.

4. Insert cassette as shown below. Put ribbon between print head and platen. Push cassette

down until it clicks.

Note:

Make sure the ribbon is installed between the print head and the platen without wrinkles or creases.

5. Again, turn the cassette knob 2 or 3 times to take up slack.

6. Close the printer’s ribbon cassette cover.

Rev. B Product Overview 1-7

Page 16

Confidential

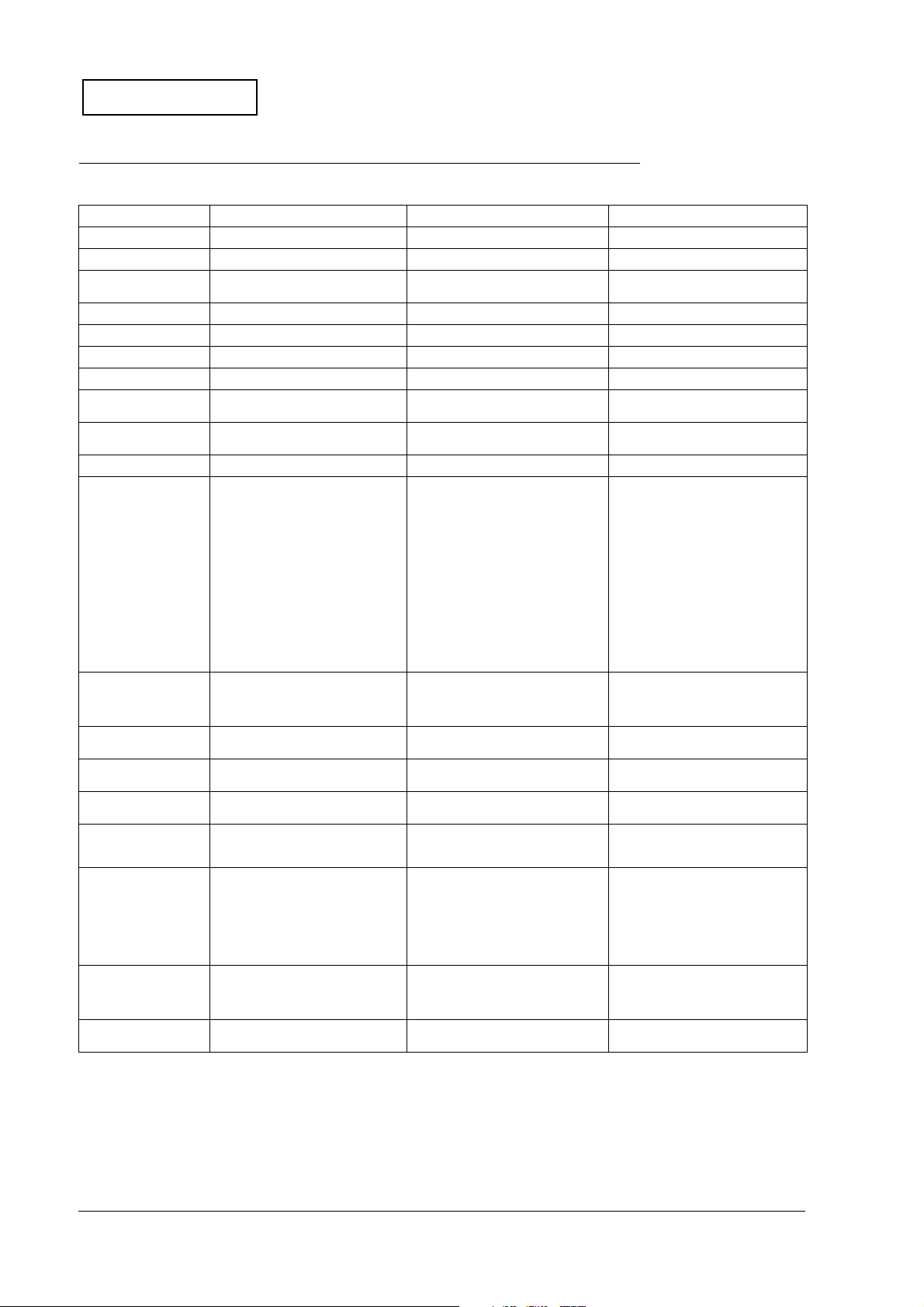

Differences between the TM-U300, TM-U200, and TM-U220

Specification TM-U300 (Type A, B, C, D) TM-U200 (Type A, B, D) TM-U220 (Type A, B, D)

Print speed 3.5 lines/second (at 40 columns, 16 cpi) 3.5 lines/second (at 40 columns, 16 cpi) 4.7 lines/second (at 40 columns, 16 cpi)

Paper feed speed 25 lines/second 25 lines/second 30 lines/ second

Character tables Alphanumeric 95, international 32,

Paper loading Paper roll holding shaft Semi automatic loading Drop in loading

Paper near-end sensor Yes Option Configured option

Cover open detector Yes No Yes

Paper width 76 mm 76 mm 76 mm, 69.5 mm, or 57.5 (B and D only)

Number of copies Original + 2 copies (at 77°F)

Autocutter

(Type A, B only)

Auto take-up unit Type A, C Type A Type A

Print area 76 mm paper:

Space from autocut to

print start:

Space from manual cut to

print start:

Receive buffer Alphanumeric: 1KB/40 bytes

NV bit image memory Alphanumeric: none

NV user memory Alphanumeric: none

Power supply PA-6509 or PB-6509 (North America) PB-6509 (North America) AC Adapter C — Low-cost universal

Dimensions (W x D x H) Type A: 170 x 288 x 183 mm

Installation Horizontally with a 15° slant, maximum.

Buzzer None None Printer also can be used with annunciator

extended 126 x 7

Original + 1 copy (at all temperatures)

Full cut or partial cut set by command Partial cut default;

Width: 63.34 mm (200 dots x

Left margin: 6 mm

Right margin: 6.5 mm (approx.)

36 mm

Type A, B: 26 mm; Type C, D: 28 mm

Multilingual: 512 bytes/40 bytes

Multilingual: none

Multilingual: none

Type B: 170 x 253 x 148 mm

Type C: 158 x 295 x 145 mm

Type D: 158 x 235 x 125 mm

Type B, D: Vertically on wall using WH-10

bracket.

400 positions)

{6.7 x 11.3 x 7.2"}

{6.7 x 10 x 5.8"}

{6.2 x 11.6 x 5.7"}

{6.2 x 9.3 x 4.9"}

Alphanumeric 95, international 32,

extended 128 x 8

A and B: original + 1 copy;

D: original + 2 copies

full cut set by command

76 mm paper:

Width: 63.34 mm (200 dots x

Left margin: 5.9 mm

Right margin: 6.76 mm

27 mm

20.2 mm

Alphanumeric: 1KB/40 bytes

Multilingual: 512 bytes/40 bytes

Alphanumeric: none

Multilingual: none

Alphanumeric: none

Multilingual: none

Type A: 160 x 295 x 160 mm

Type B: 160 x 248 x 150 mm

Type D: 160 x 248 x 133 mm

Horizontally with a 15° slant, maximum. Horizontally with a 15° slant, maximum.

400 positions)

{6.3 x 11.6 x 6.3"}

{6.3 x 9.8 x 5.9"}

{6.3 x 9.8 x 5.2"}

Alphanumeric 95, international 48,

extended 128 x 12

All models: original + 1 copy

Partial/full cut set by command

76 mm paper:

Width: 63.34 mm (200 dots x

Left margin: 6.8 mm

Right margin: 5.8 mm

69.5 mm paper:

Width: 57 mm (180 dots x

Left margin: 6.7 mm

Right margin: 5.8 mm

57.5 mm paper:

Width: 47.5 mm (150 dots x

Left margin: 4.2 mm

Right margin: 5.8 mm

27 mm

Type D: 22.1 mm; Type A, B: 34.9 mm

Alphanumeric: 4KB/40 bytes

Multilingual: 4KB/40 bytes

Alphanumeric: 128KB

Multilingual: 128KB

Alphanumeric: 8KB

Multilingual: 8KB

power supply for impact dot matrix

printer supplied in box.

Type A: 160 x 286 x 157.5 mm

Type B: 160 x 248 x 138.5 mm

Type D: 160 x 248 x 138.5 mm

Optional IR tray also can be used.

Type B, D: Vertically on wall using WH-10

bracket.

interface.

400 positions)

360 positions)

300 positions)

{6.3 x 11.3 x 6.2"}

{6.3 x 9.8 x 5.5"}

{6.3 x 9.8 x 5.5"}

1-8 Product Overview Rev. B

Page 17

Confidential

TM-U220 Type A Service Manual

Chapter 2

Repair Guide

This chapter gives instructions to complete repair of the product. Follow the process in this

section for repair.

Repair Process

Outline of Repair

Check each item before and after repair, as shown in the following flowchart. This chapter

explains the operations to confirm a “normal state” of operation of items in the flowchart. If an

item is in a state other than the “normal state,” follow the instructions in the chapter to

troubleshoot based on the symptom.

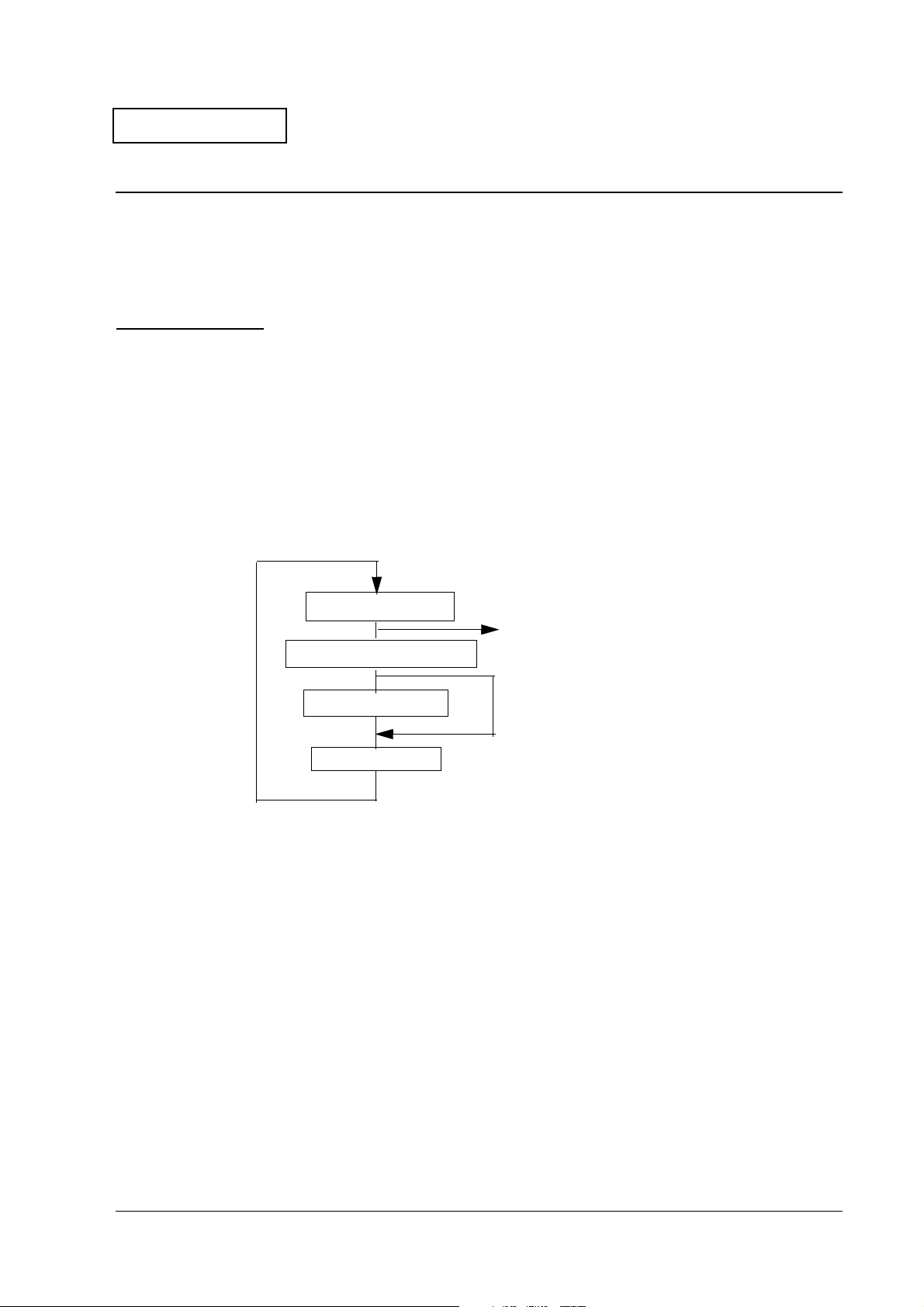

Repair Flow

Confirm the right status

If no problem is found, the product is considered to be

Troubleshooting

Assembly/disassembly

Adjustment/setting

normal, and can be sent to the user’s environment.

Confirming the User’s Environment

Confirm the printer’s settings by using the service utility.

Confirming the Printer Status

Confirm the status of the printer you are repairing. Confirm that the power turns on/off; run the

self-test; run all function tests with the service utility; and check other items, following the table

below. Perform the appropriate measures for the symptom.

Rev. B Repair Guide 2-1

Page 18

Confidential

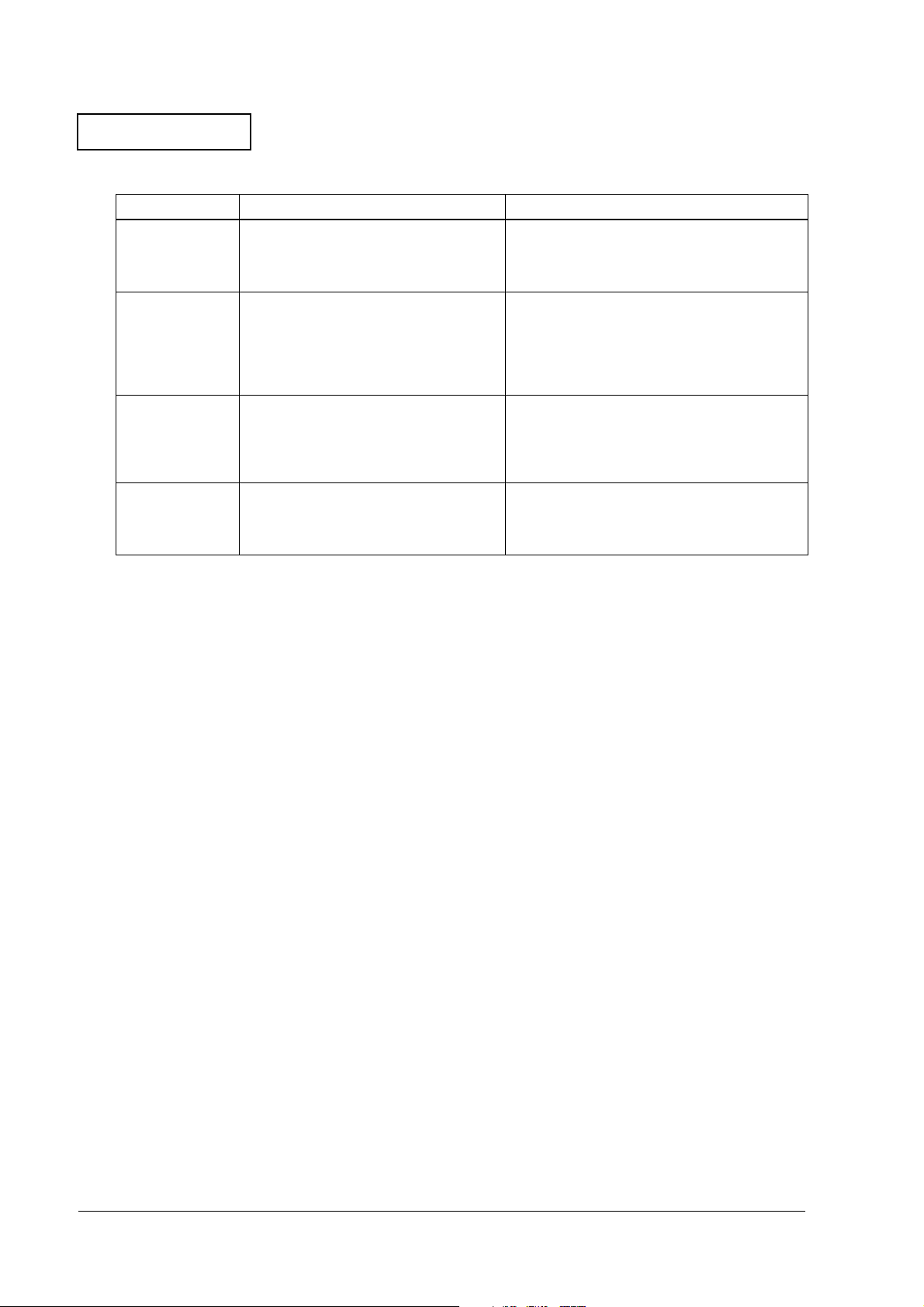

Printer Status Checks

Operation Normal printer operation When a problem occurs

Power LED light comes on.

Power on.

Run the self-test.

*Refer to page 2-2

for operation.

Run the “all

function test” with

the service utility.

*Refer to page 2-7

for operation.

Perform other

checks of

operation.

Mechanical initializing operation occurs.

ERROR LED light is off.

POWER LED light comes on.

Prints the printer status. (See page 2-3.)

Prints the roll pattern after the FEED button

is pressed. (See page 2-3.)

Mechanical initialization occurs.

ERROR LED light is off.

Reads printer status.

Prints the RECEIPT sheet. (See page 2-9.)

Prints the STATUS sheet after confirming the

sensor operation. (See page 2-10.)

Prints the REPORT sheet. (See page 2-12.)

Normal opening/closing of roll paper

cover.

Normal opening/closing of ribbon cover.

The case is dirty.

Once you have confirmed the printer status using the table above, you can perform the

necessary functions below.

POWER LED does not light. (See page 3-3.)

ERROR LED light. (See page 3-3.)

ERROR LED flashes. (See page 3-4.)

PAPER OUT LED lights. (See page 3-6.)

Self-test cannot be performed. (See page 3-6.)

Printing cannot be performed. (See page 3-7.)

The print result is not normal. (See page 3-12.)

A paper jam occurs. (See page 3-14.)

PAPER OUT LED lights. (See page 3-6.)

The communication test fails. (See page 3-16.)

The print result is not normal. (See page 3-12.)

Drawer kick is not performed. (See page 3-17.)

The sensor does not work. (See page 3-18.)

Parts do not move smoothly. (See page 3-20.)

The case is dirty. (See page 3-20.)

Identification of defective parts. (See Chapter 3.)

❏

❏ Preparation for replacing parts. (Read and follow the precautions and notes at the beginning

of Chapter 4.)

❏ Parts replacement, assembly, and disassembly. (See Chapter 4.)

Adjustment and setting. (See Chapter 5.)

❏

Preparation for shipment. (See the Chapter 6 before sending the printer back to the

❏

customer.)

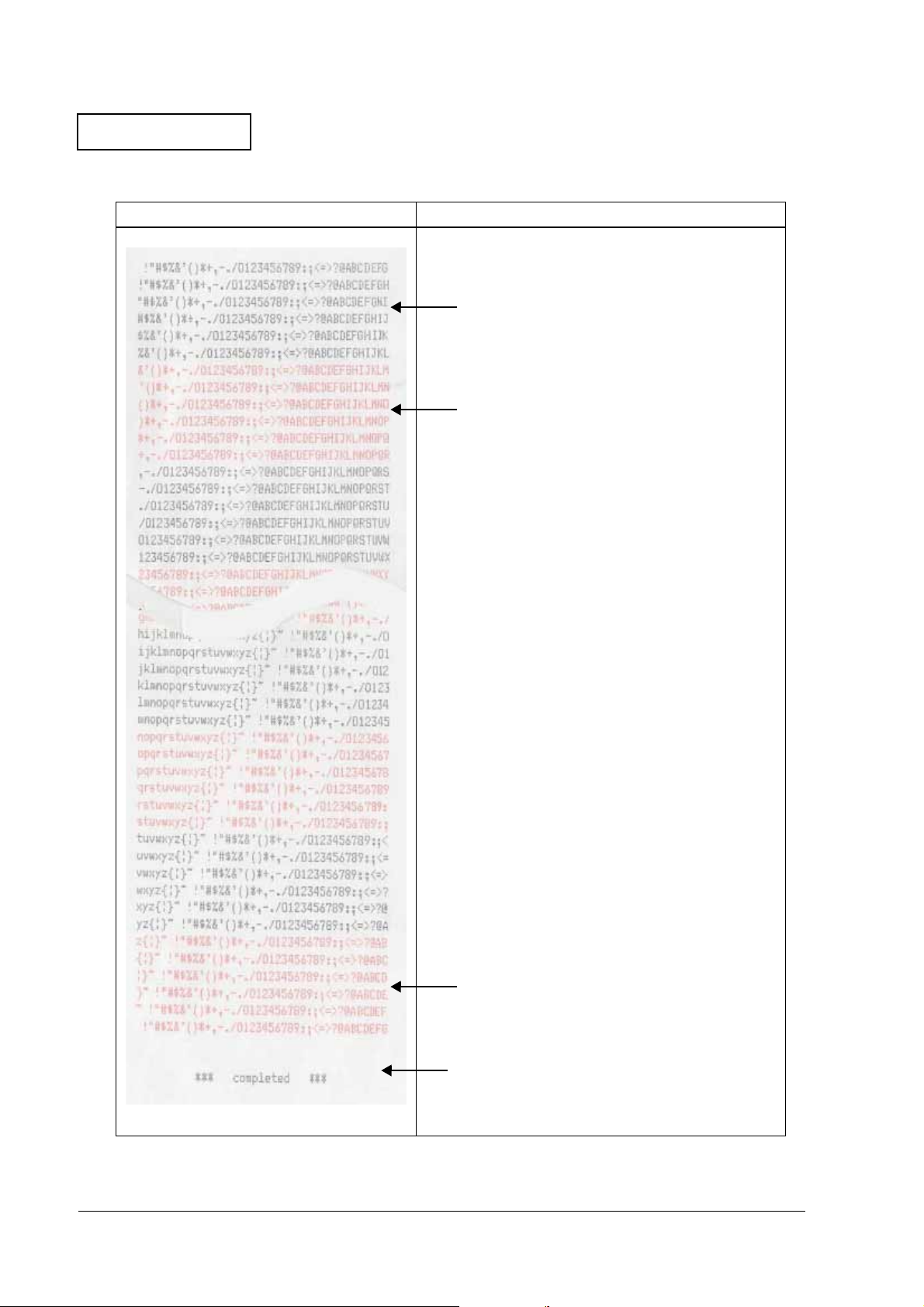

Self-test

Operation

The self-test can be run using the service utility or by operating the control panel. See page 2-12

for information about control panel operation.

Before running the self-test, make sure the roll paper and ribbon are installed correctly in the

printer. Then, turn power off. To run the self-test, turn the power back on while holding down

the FEED button.

The first page of the self-test printout should look like the example in the table below. To print

the second part of the self-test, press FEED again.

2-2 Repair Guide Rev. B

Page 19

Confidential

Printer Status Print

Normal printout result Explanation

TM-U220 Type A Service Manual

➀

➁

➂

➃

➀ Version information

Main program version

Boot program version

➁ Interface classification

Interface information

➂ Receive buffer capacity *1)

➃ Busy release conditions for receive buffer full *2)

➄ Busy condition *3)

➅ Resident character *4)

7 Paper roll width *5)

➇ Dot spacing between characters *6)

9 Characters per line *7)

Autocutter unit installed/not installed *8)

Note:

*1) Differs depending on DIP SW1-2.

➄

➅

7

➇

*2) Differs depending on MSW 8-7. Prints only when the

receive buffer capacity is 4KB. (Does not print when the

receive buffer capacity is 40 bytes.)

*3) Differs depending on DIP SW1-8.

*4) Performs a multilingual CG judgment when printing resident

characters.

*5) Differs depending on the paper roll width set with the

memory switch (customized value).

*6) Differs depending on DIP SW2-1.

*7) Differs depending on the paper roll width and dots

between characters.

*8) Differs depending on DIP SW2-2.

9

Rev. B Repair Guide 2-3

Page 20

Confidential

Roll Pattern

Normal print result Explanation

Black (6 lines)

Red (6 lines)

Red (6 lines)

Paper feeds 2 lines.

Paper is fed to a position where the user can see

the ending message at left

.

2-4 Repair Guide Rev. B

Page 21

Confidential

TM-U220 Type A Service Manual

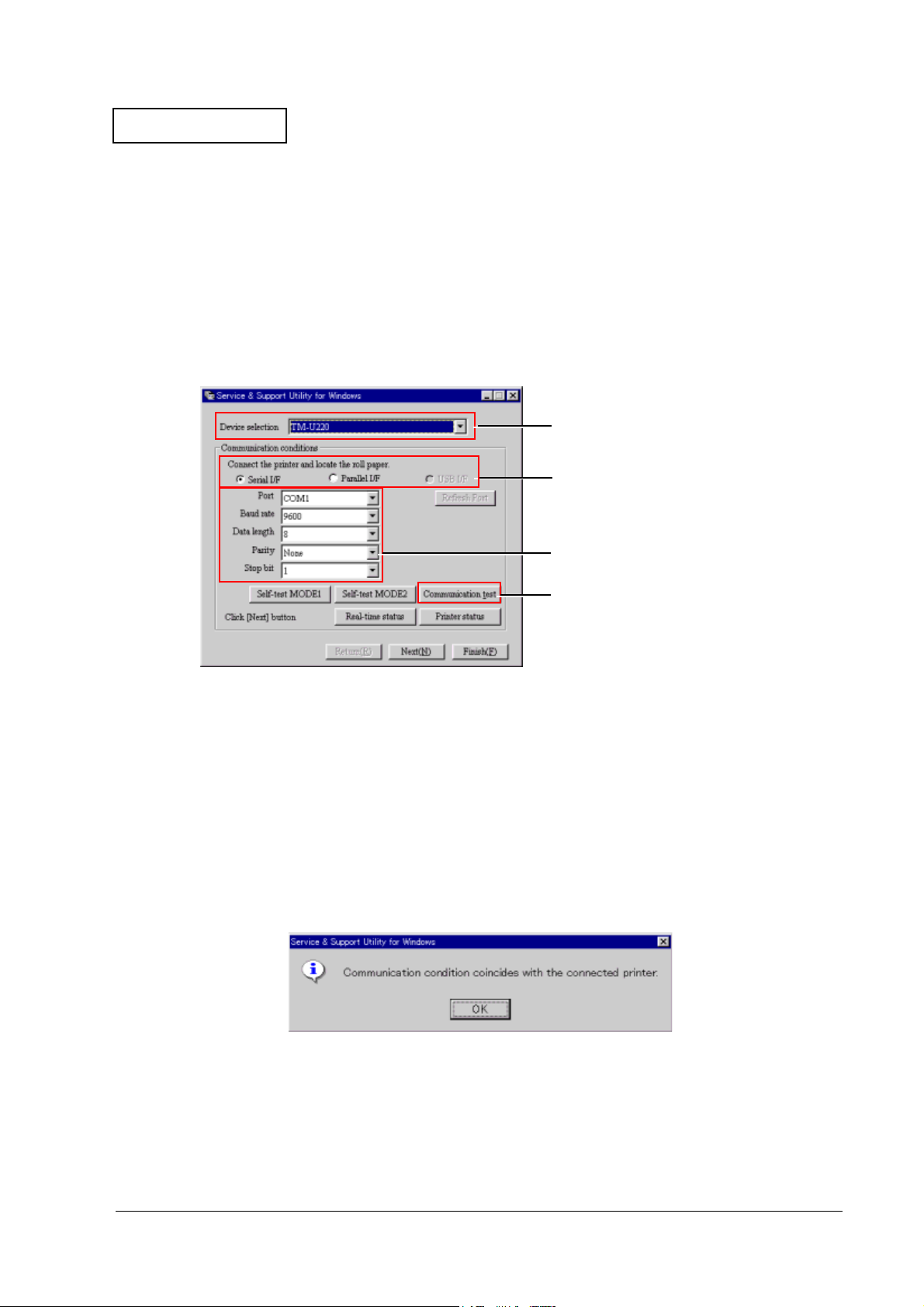

Service Utility

Using the service utility, you can confirm the printer status and change settings. The following

section explains the operation for confirming the printer status.

* To use the repair functions in the service utility, a password is required. Refer to the manual

supplied with the service utility for the password.

Start up of the service utility

When you start the service utility, the following communication conditions dialog box appears.

1. Select the model (TM-U220).

2. Select the type of I/F.

3. Select the parameters to

communicate with the printer.

4. Test the communication.

1. Model selection:

Select the TM-U220 (Type A model printer).

2. Communication condition selection:

Select the I/F used with the printer. You can confirm the communication conditions set for

the printer by running the self-test. Refer to the self-test section for details.

3. Communication test:

4. Confirm the communication status with the connected printer. Normally, the following

message appears.

.

When the communication conditions are set correctly, the following functions are available.

❏

Self-test mode 1: Outputs the same results as the self-test printout of status.

❏

Self-test mode 2: Outputs the same results as the self-test printout of the roll pattern.

Rev. B Repair Guide 2-5

Page 22

Confidential

❏

Real-time status: Lets you confirm sensor operations, such as cover open/close, in real

time.

❏

Printer status: Lets you read and set the printer values collectively. Also, you can save

the settings to a file, read the set values in the file, and the display the default state. Refer

to the chapter on adjustment settings.

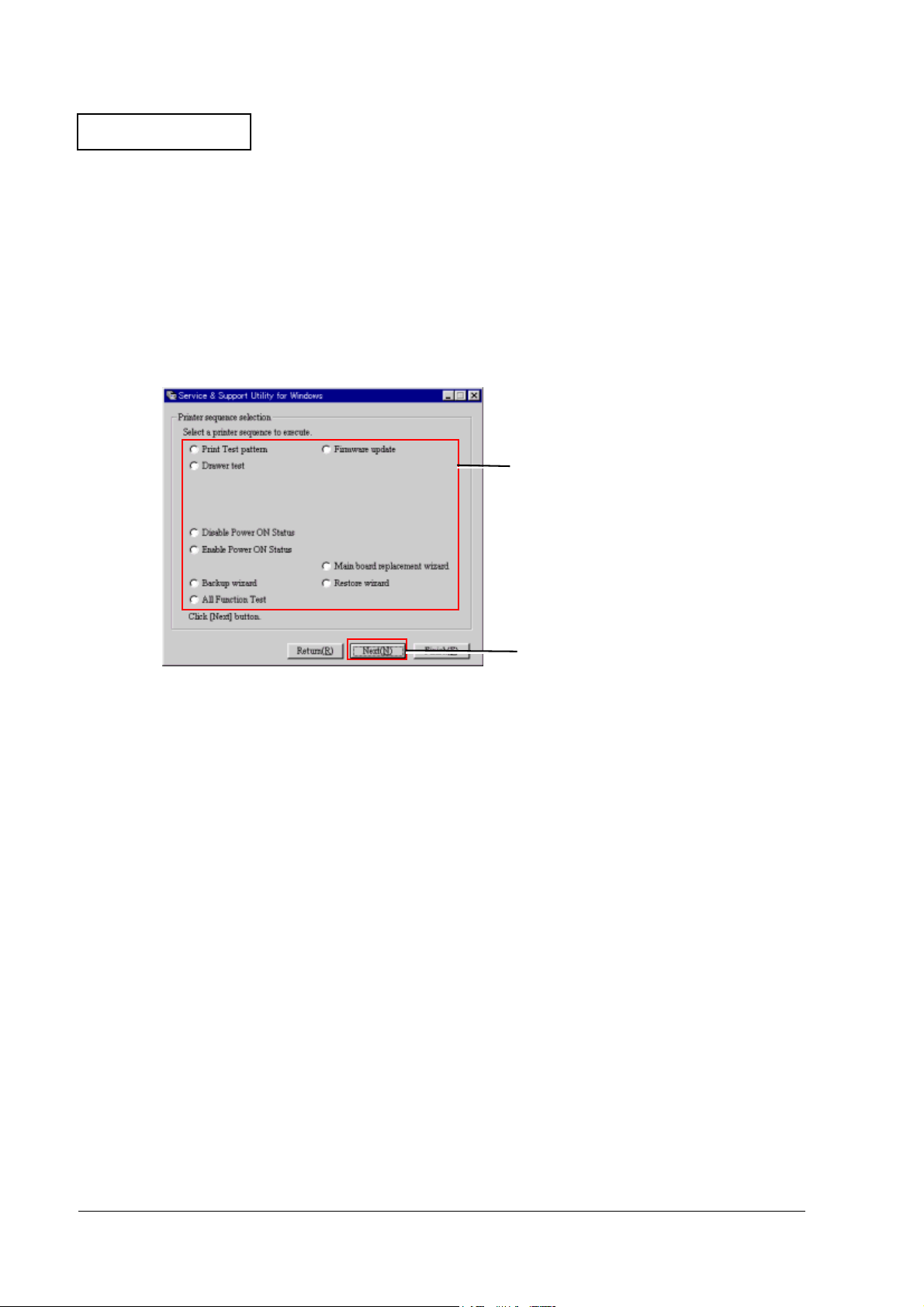

Printer sequence selection

When you click the Next button at the bottom of the communication conditions dialog box, the

printer sequence selection screen appears.

1. Select a printer sequence

to execute.

2. Click Next to proceed.

❏

Test printing:

This outputs a test pattern to confirm printer status. Follow the screen instructions to

operate.

❏

Confirmation of the drawer operation:

You can confirm the drawer open function and the change in the open/close status. Follow

the screen instructions to operate.

❏

Setting for notification of power on:

You can enable or disable the notification function for power on.

❏

Firmware update:

You can update the firmware. Follow the screen instructions to operate.

❏

Main circuit board replacement wizard/backup wizard/restore wizard:

You can back up the data in the main circuit board and restore it in the repaired product.

Follow the screen instructions to operate.

2-6 Repair Guide Rev. B

Page 23

Confidential

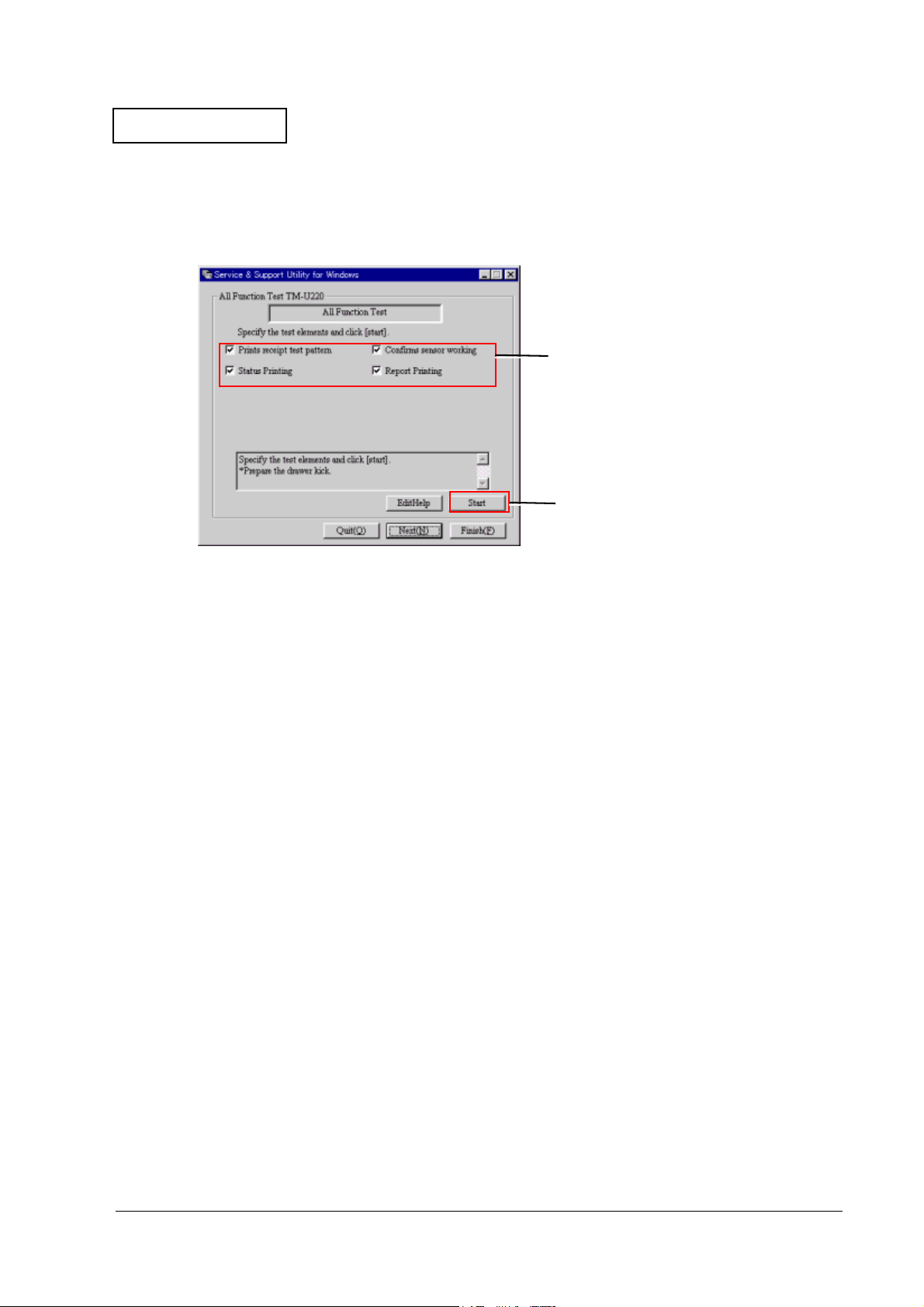

All Function Test

When you select the all function test in the printer sequence selection screen and click Next, the

all function test screen appears.

1. Select the test elements.

2. Click to start the All Function Test.

TM-U220 Type A Service Manual

Select the test elements and click the Start button to start the all function test.

Using this test, you can check the following functions for the printer.

❏ Communication function:

You can confirm that communication with the printer is enabled/disabled.

❏ Setting function:

Reads and prints on the status sheet the status settings for EPSON NV memory, memory

switches, communication conditions, and customized value.

Receipt print function:

❏

Prints patterns to confirm print operations and print quality.

Roll paper cut function:

❏

The Type A model autocutter cuts roll paper after each printing on the roll.

Drawer open/close function:

❏

Runs a test of drawer open/close operation while printing the receipt pattern. Be sure to

connect the drawer kick to the printer before executing the all function test.

❏ Sensor function:

Confirms the operation of sensors controlling and detecting printer operations. The checking

method for the sensor indicated with the arrow is displayed on the screen. Operate the

printer following the instructions on the screen.

Rev. B Repair Guide 2-7

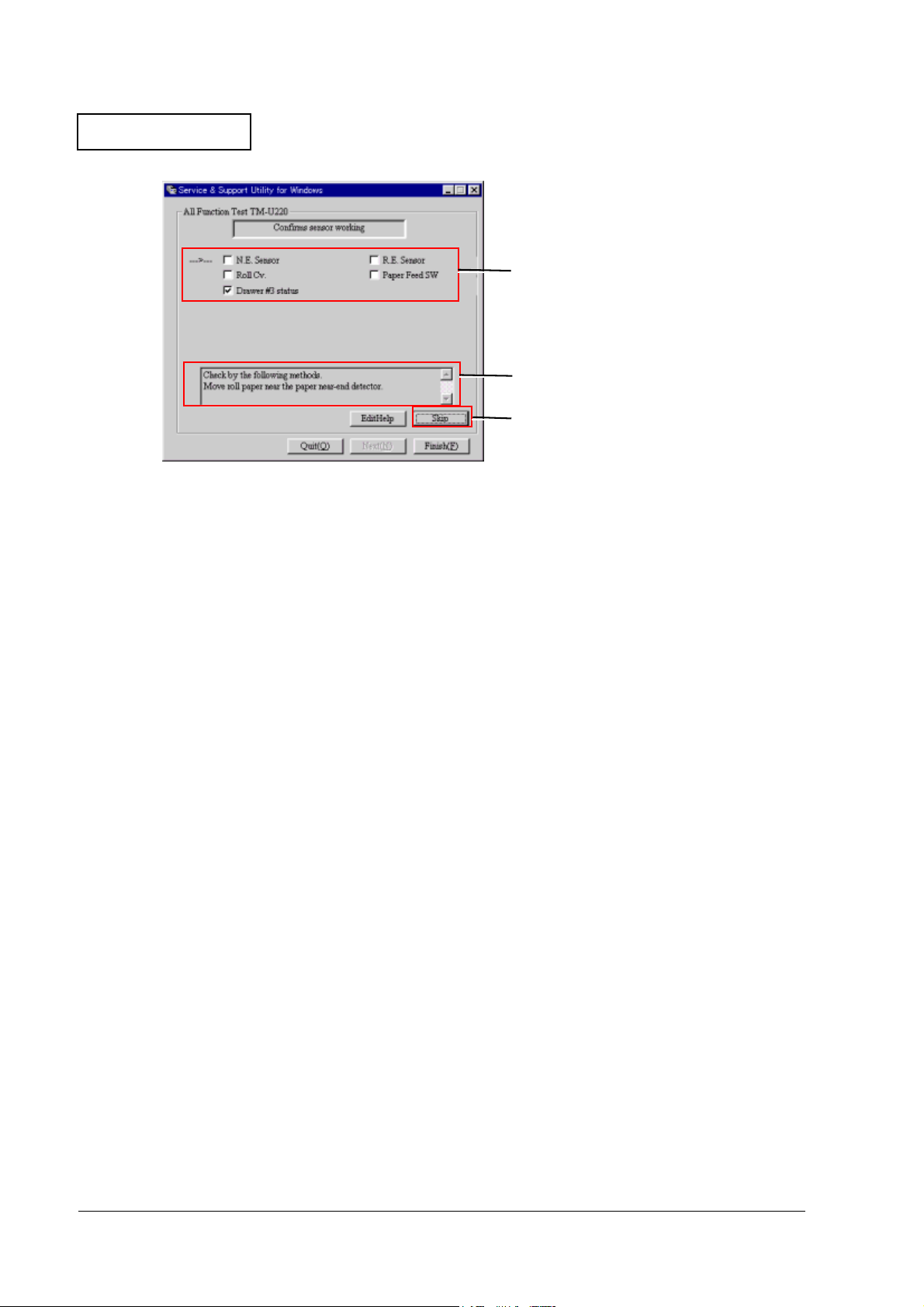

Page 24

Confidential

When the sensor detects the printer operation correctly, OK is displayed.

When the sensor is not installed (depending on the printer model), you can skip with

the Skip button.

Test results are OK when the tests confirm the normal operation of the sensors.

1. Indicate the sensor to test.

2. Follow the message to operate

the printer.

3. Click If you want to skip the test.

2-8 Repair Guide Rev. B

Page 25

Confidential

TM-U220 Type A Service Manual

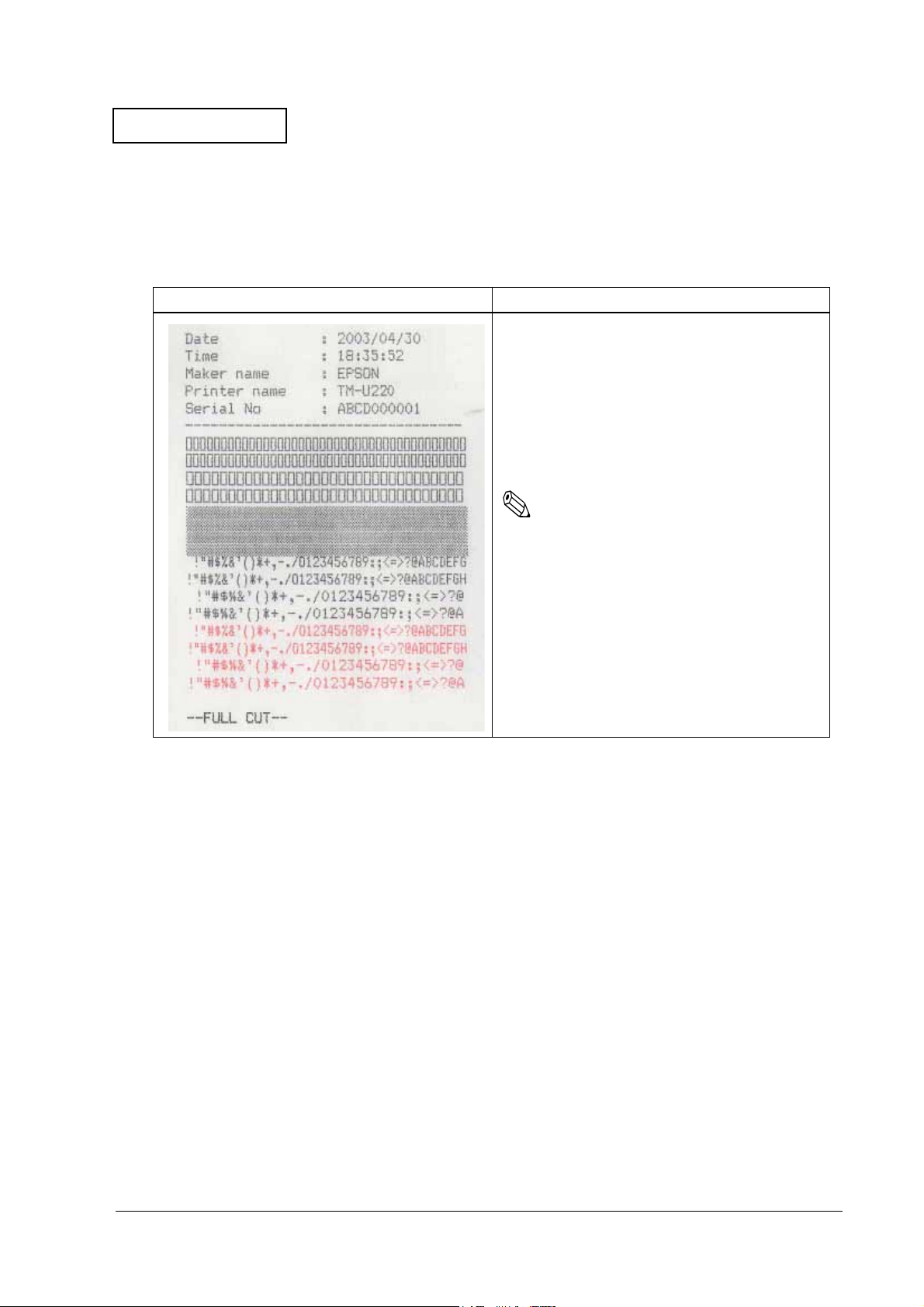

Output result

When the printer operates normally, the following sheet is printed. Refer to the chapters on

“Troubleshooting” and “Adjustment and Setting” when print results differ.

Receipt Print

Normal print result Explanation

➀

➁

➂

➃

➄

➅

➀ Prints execution date.

➁ Prints execution time.

➂ Prints “EPSON/”

➃ Prints “TM-U220.”

➄ Prints product serial number. *1)

➅ Prints graphic pattern. Checks for missing dots.

(See“Dots are missing continuously” on page 3-12.)

➆ Prints ANK characters. *2)

➇ Performs full cut. *3)

Note:

*1) When the serial number is not registered on the

product itself, “NG” is printed.

➆

➇

*2) When using the 2-color ribbon, prints in 2 colors.

*3) When autocutter setting is partial cut, full cut is

not performed.

Rev. B Repair Guide 2-9

Page 26

Confidential

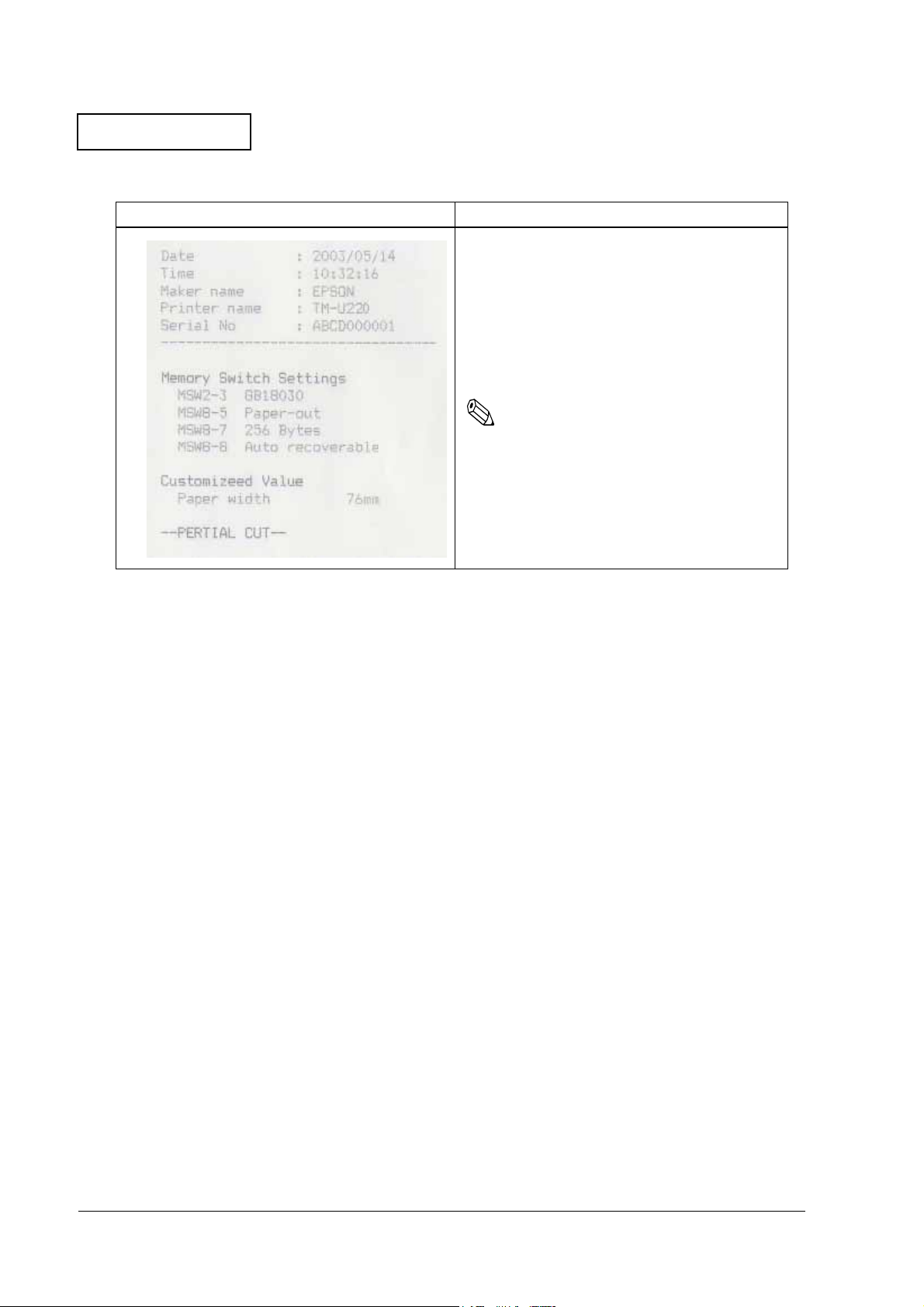

Status Print

Normal print result Explanation

➀

➁

➂

➃

➄

➅

➀ Prints execution date.

➁ Prints execution time.

➂ Prints “EPSON.”

➃ Prints “TM-U220.”

➄ Prints product serial number. *1)

➅ Prints setting status of memory switches. *2)

➆ Prints setting status of customize value. *3)

➇ Performs partial cut. *4)

Note:

*1) When the serial number is not registered on the

product itself, “NG” is printed.

*2, 3) When the default setting is changed, “

➆

➇

printed before the memory switch number.

*4) When autocutter setting is full cut, partial cut is

not performed.

*

” is

2-10 Repair Guide Rev. B

Page 27

Confidential

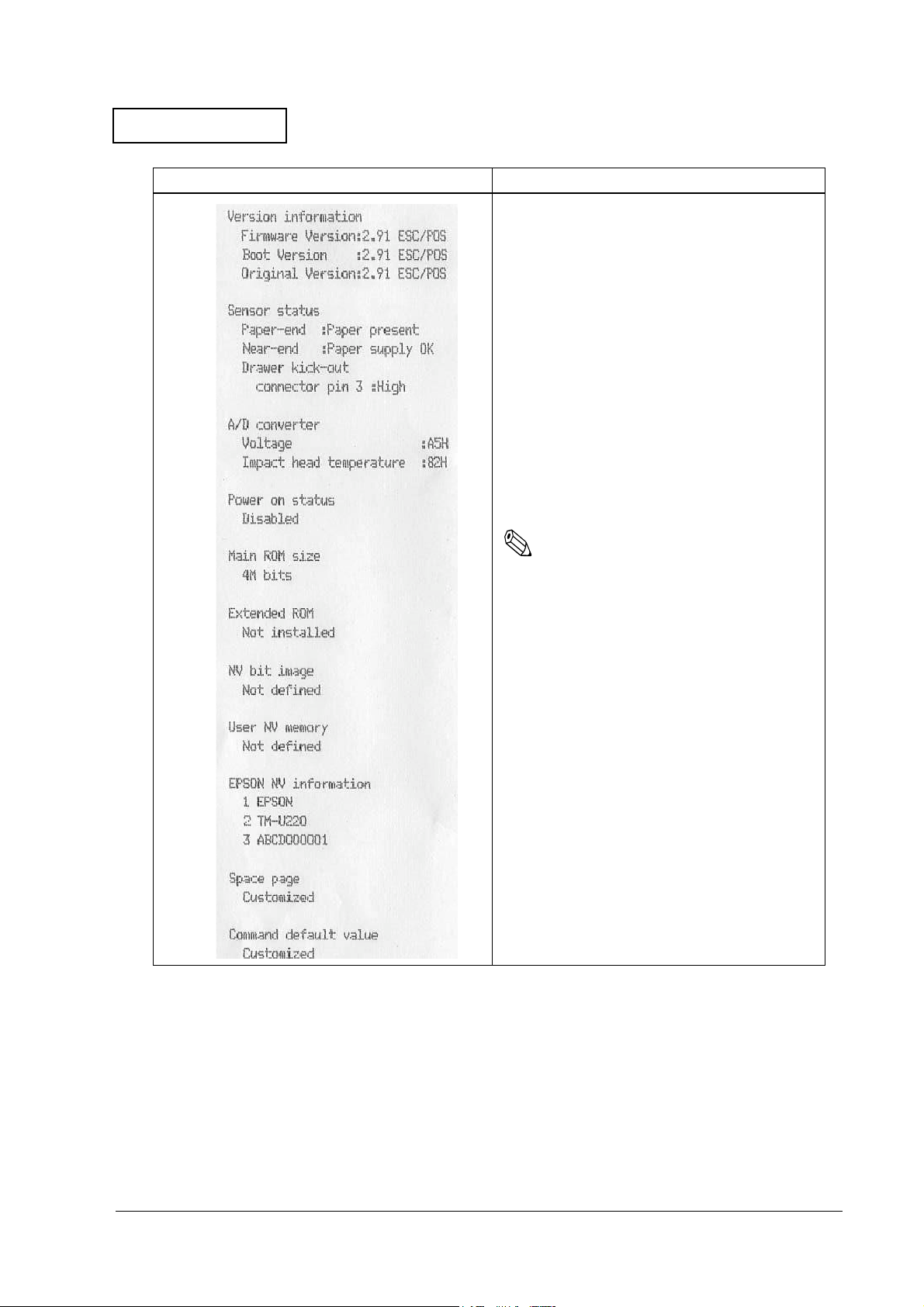

Normal print result Explanation

TM-U220 Type A Service Manual

➀

➁

➂

➃

➀ Prints program version.

Main program version is printed.

Boot program version is printed.

Original program version is printed.

➁ Prints ”power on status” set with printer sequence.

➂ Displays size of main ROM. (Differs depending on

specifications.)

➃ Displays size of extended ROM. (Differs depending

on specifications.)

➄ Prints defined bit image data in NV memory. *1)

➅ Prints defined data in NV user memory. *2)

➆ Prints information on EPSON NV memory. It is

changeable with the printer status. *3)

Manufacturer name

Model name

Product serial no.

➇ Prints defined data for the space page.

➈ Prints definition of command default values.

Note:

*1, 2) Data defined by a user must be backed up

and restored.

➄

➅

➆

➇

➈

Rev. B Repair Guide 2-11

Page 28

Confidential

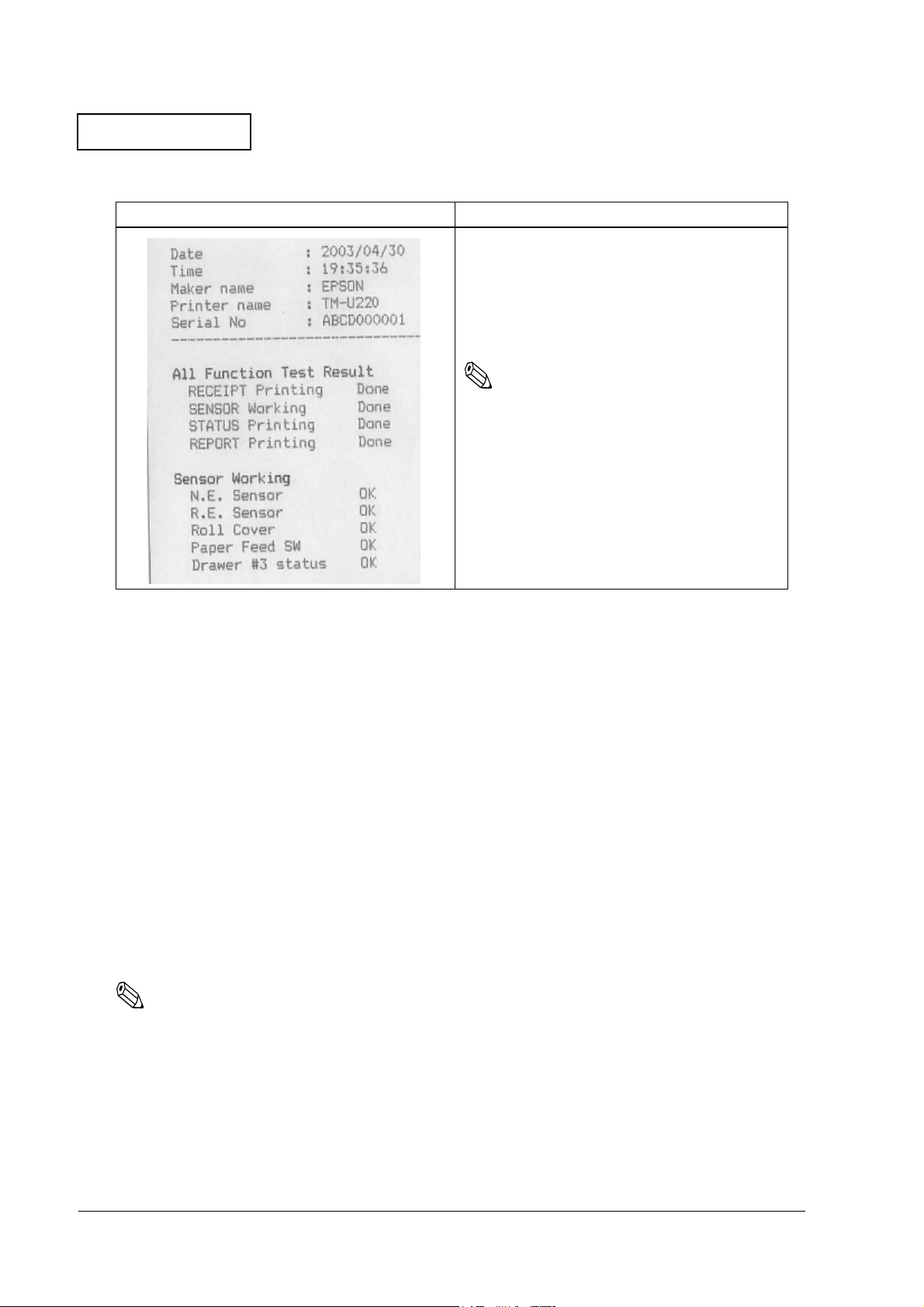

Report Print

Normal print result Explanation

➀

➁

➂

➃

➄

➅

➆

➀ Prints execution date.

➁ Prints execution time.

➂ Prints “EPSON.”

➃ Prints “TM-U220.”

➄ Prints the serial number for the product.

➅ Prints the execution status of all function test.

➆ Prints test results of sensor operation. *1)

Note:

*1) When an operation such as cover open sensor

check is skipped using the button on the screen,

the report shows a problem for that item. (Refer

to “Cannot pass one of the tests for a sensor” on

page 3-18.)

Running a Self-test

The steps below describe how to run a self-test by operating the control panel.

1. Make sure the printer is turned off and the roll paper cover is closed properly.

2. While holding down the FEED button, turn on the printer using the switch on the front of the

printer. The self-test prints the printer settings and then prints the following, cuts the paper,

and pauses. (The PAPER OUT light flashes.)

If you want to continue SELF-TEST printing, Please press the FEED button.

3. Press the FEED button to continue printing. The printer prints a pattern using the built-in

character set.

4. The self test automatically ends and cuts the paper after printing the following:

*** completed ***

5. The printer is ready to receive data as soon as it completes the self test.

Note:

If you want to pause the self-test manually, press the FEED button. Press the FEED button again to

continue the self-test.

2-12 Repair Guide Rev. B

Page 29

Confidential

TM-U220 Type A Service Manual

Chapter 3

Troubleshooting

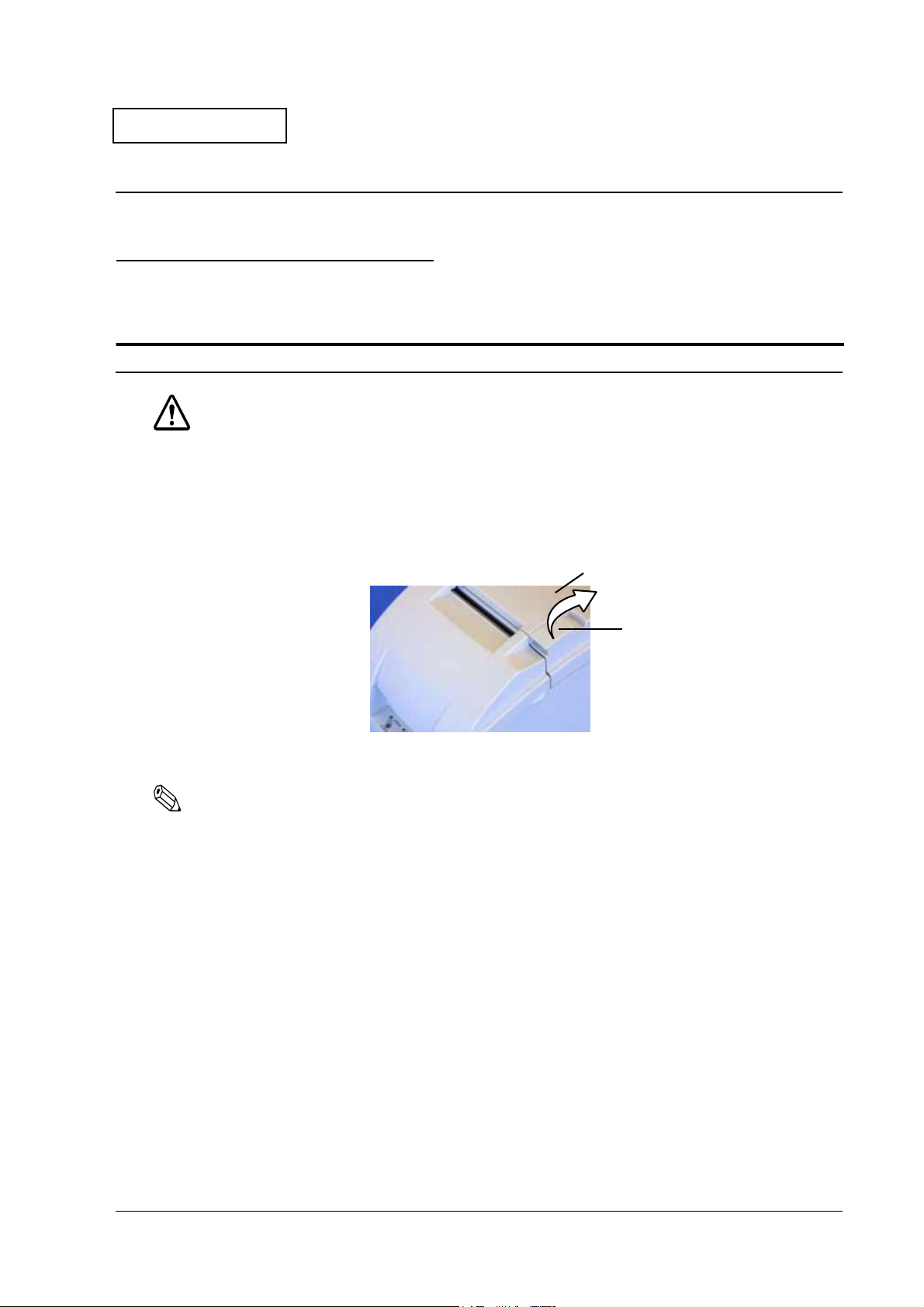

Preparations for Troubleshooting

Before troubleshooting, check and, if necessary, correct the following points.

Paper is jammed inside the printer

CAUTION:

Be sure not to touch the manual cutter. Otherwise, you may cut your fingers.

1. Turn the power off.

2. Open the roll paper cover using the tab, as shown in the below illustration.

Roll paper cover

Tab

3. Remove the jammed paper.

Note:

If you turn the power off accidentally during printing, the cutter blade may stop in the paper feed path. So,

paper may not be fed normally at first when you turn the power on again. If the cutter blade does not

return to the normal position, the autocutter unit may be jammed. If so, follow the procedure described

below to repair the autocutter unit.

1. Power off the unit and open the roll paper cover.

2. Remove the jammed paper.

Rev. B Troubleshooting 3-1

Page 30

Confidential

3. Return the cutter blade to the normal position by rotating the autocutter knob in the

direction of the arrow. When the blade is returned to the normal position, the lever moves to

the center of the hole in the autocutter frame.

Autocutter unit

4. Lift up the roll paper cover.

Hole

Knob

Lever

Note:

❏

Besides a paper jam, a foreign object, such as a push pin, can cause the autocutter to lock up. In

this case, follow the same procedure described above to return the cutter to its normal position.

Before Servicing

Pages iv to v at the beginning of this manual provide precautions you should observe to perform

work safely and supply the necessary information to service this product safely. Always read

that information before starting your work.

Diagnosing Failures

Use one of the following methods to identify the area where a failure occurred.

See the tables in the section "Symptoms and Solutions" for diagnosing failures by the

❏

symptom of the problem.

See "Test Points on the Main Circuit Board Unit" for failures on the main circuit board unit.

❏

3-2 Troubleshooting Rev. B

Page 31

Confidential

TM-U220 Type A Service Manual

Symptoms and Solutions

Symptoms when Power is On

POWER LED does not light

Table 3-1 POWER LED not Lit

Probable part/probable cause Checkpoints Action to correct the problem

External power unit

Cable connector (1098)

Sub circuit board unit (123)

Main circuit board unit (201)

(Refer to page 3-21.)

Check the connections. Make sure the

connector is plugged in.

Check the output voltage. Make sure

24 V is coming out.

Check the connectors. Make sure the

ones below are plugged in:

❑ Connector (CN10) on the main circuit

board unit (201)

❑ Connector (CNC3) on the sub circuit

board unit (123)

Check the sub circuit board unit for

damage. Make sure it looks normal.

Check the resistance value of fuses F1

and F4. Make sure neither fuse is blown.

Check the operation of SW1.

Check the power voltage. Make sure the

power voltage has proper voltage rating.

Plug in the connector. Completed if

the POWER LED lights.

Replace power unit. Completed if

the POWER LED lights.

Plug in the connectors. Completed if

the POWER LED lights.

Replace the sub circuit board unit

(123). Completed if the POWER LED

lights.

If the circuit board has no damage,

such as burns, replace fuse F1 or F4.

Completed if the POWER LED lights.

If the fuse blows when power is

turned on, unplug all connectors

from the mechanism assembly (120)

and check again.

If the POWER LED does not light and

the fuse is blown, replace the main

circuit board unit.

Replace the main circuit board unit

(201). Completed if operation is

normal.

ERROR LED lights

Table 3-2 ERROR LED On

Probable part/probable cause Checkpoints Action to correct the problem

Roll paper cover assembly (119)

Paper-end state Check the roll paper.

Check the roll paper cover assembly.

Make sure the roll paper cover is

closed.

Close the roll paper cover assembly.

Completed if the ERROR LED turns off.

Load the roll paper properly.

Completed if the ERROR LED turns off.

Rev. B Troubleshooting 3-3

Page 32

Confidential

ERROR LED flashes

Table 3-3 ERROR LED Flashes

Probable part/probable cause Checkpoints Action to correct the problem

Home position detection error Check for jammed paper

around the carriage. Make sure

there is no paper jam.

Check the tension of the

carriage belt (507). Make sure

the carriage belt has

appropriate tension.

Check operation of the parts

around the carriage by moving

the carriage from side to side.

Make sure the belt drive pulley

(505) rotates by moving the

carriage sub assembly (1025)

from side to side.

Check the resistance value of

the carriage motor sub assembly

(1034). Make sure it is 7.2 Ω or

less.

Check the operation of the HP

board assembly (518). Make sure

the signal changes when you

block the sensor.

Check the connection of main

circuit board unit (201)

connectors. Make sure they are

plugged in securely.

CN7: carriage motor sub

assembly (1034)

CN4: HP board assembly (518)

Check if the parts on the main

circuit board unit (201) have any

damage. Make sure connector

CN7 and U8 look normal.

R/W error in memory

Check for repeatability. Make

sure operation is normal by

rebooting.

Remove any jammed paper.

Completed if operation is normal.

Adjust carriage belt tension (Refer to

page 5-6). Completed if operation is

normal.

Reinstall the carriage belt (507) into

the carriage sub assembly (1025).

Completed if operation is normal.

Replace the carriage motor sub

assembly (1034). Completed if

operation is normal.

Replace the HP board assembly

(518). Completed if operation is

normal.

Plug in the connectors securely.

Completed if operation is normal.

Replace the main circuit board unit

(201). Completed if operation is

normal.

Replace the main circuit board unit

(201). Completed if operation is

normal.

High-voltage error Check the DC power voltage on

the main circuit board unit (201).

Make sure the power voltage

has the proper voltage rating.

(Refer to page 3-21.)

Low-voltage error Check the DC power voltage on

the main circuit board unit (201).

Make sure the power voltage

has proper voltage rating. (Refer

to page 3-21.)

Replace the main circuit board unit

(201). Completed if operation is

normal.

Replace the main circuit board unit

(201). Completed if operation is

normal.

3-4 Troubleshooting Rev. B

Page 33

Confidential

TM-U220 Type A Service Manual

Table 3-3 ERROR LED Flashes

Probable part/probable cause Checkpoints Action to correct the problem

CPU execution error Check the connection of the I/F

Connect the I/F circuit board unit

(122). Completed if operation is

normal.

Connect the I/F circuit board unit

(122). Completed if operation is

normal.

Replace the main circuit board unit

(201). Completed if operation is

normal.

Wait for the print head temperature

to drop. Completed if operation is

normal.

Connect the head FFC (521).

Completed if operation is normal.

Connect the print head unit (503).

Completed if operation is normal.

Replace the main circuit board unit

(201). Completed if operation is

normal.

Switch DIP SW2-6 on the main circuit

board unit (201) to OFF. Completed if

operation is normal.

If operation is not normal, rewrite the

firmware. Completed if operation is

normal.

Head high-temperature detection

circuit error

The ERROR LED flashes 3 or 6 times

and then does not operate all.

circuit board unit (122). Make

sure the connector is plugged

into the main circuit board unit

(201).

Check parts on the I/F circuit

board unit (122) for damage.

Make sure the I/F circuit board

unit appears normal.

Check main circuit board unit

(201) parts for damage. Make

sure the main circuit board unit

(201) looks normal.

Check the print head

temperature. Make sure it is not

too high.

Check connection of the head

FFC (521). Make sure it is plugged

into the print head unit (503) and

connector (CN9) on the main

circuit board unit (201).

Check the continuity of the print

head unit (503). Make sure wires

are not broken or shorted out.

Check if main circuit board unit

(201) parts have any damage.

Make sure the main circuit board

unit (201) looks normal.

Check the setting of DIP SW2-6.

OFF: Initial state

ON: Rewriting flash memory.

Rev. B Troubleshooting 3-5

Page 34

Confidential

PAPER OUT LED lights

Table 3-4 PAPER OUT LED is Lit

Probable part/probable cause Checkpoints Action to correct the problem

Check the roll paper. Make sure it is

Roll paper

Paper end assembly (514)

Near-end sensor

Main circuit board unit (201)

loaded correctly. Make sure enough

paper is left.

Check operation of the paper end

assembly (514). Make sure the continuity

changes when you operate the switch.

Check operation of the micro switch

(1039). Make sure the continuity

changes when you operate the switch.

Check the parts for damage. Make sure

the following parts look normal.

CN6:for lead wires of the near-end

sensor

CN4:on the HP board assembly

Symptoms when the self-test is run

Replace the roll paper. Completed if

the PAPER OUT LED turns off.

Replace the paper end assembly

(514). Completed if the PAPER OUT

LED turns off.

Replace the near-end sensor.

Completed if the PAPER OUT LED

turns off.

Replace the main circuit board unit

(201). Completed if operation is

normal.

Self-test is not printed

Before running the self-test, make sure the roll paper and ribbon are installed correctly in the

printer. Then turn power off. To run the self-test, turn the power on while holding down the

FEED button. If the test does not print, check the following:

❏ When the POWER LED does not light: Refer to page 3-3.

When the ERROR LED lights: Refer to page 3-3.

❏

When the ERROR LED flashes: Refer to page 3-4.

❏

3-6 Troubleshooting Rev. B

Page 35

Confidential

TM-U220 Type A Service Manual

When only the initializing operation is executed

Table 3-5 Only the Initializing Operation Occurs

Probable part/probable cause Checkpoints Action to correct the problem

For the serial I/F, check the reset function

DIP switch setting

Main circuit board unit (210)

setting for pins # 6 and # 25. If the I/F

cable is connected and the reset

function is available, the I/F may always

be resetting.

Check the operation of SE2. Make sure

pressing the FEED button feeds paper.

Make sure the continuity changes when

you operate the switch.

Disable the reset function with the DIP

switch setting. Completed if

operation is normal.

Replace the main circuit board unit

(201). Completed if operation is

normal.

The printer does not print

The print head operates, but paper is not fed

Table 3-6 The Printer Does not Print

Probable part/probable cause Checkpoints Action to correct the problem

Roll paper is inserted

incorrectly

Paper jam

Gear does not rotate

Paper hold spring (1014)

Paper hold roller (1015)

Paper guide roller (1045)

Check the roll paper. Make sure it meets

specifications. Make sure it is loaded

correctly.

Check the paper path. Make sure there

is no paper jam.

Check the gear operation. Make sure

the following gears rotate:

Paper feed gear (1063)

Paper feed middle gear B (510)

Paper feed middle gear (509)

Paper feed reduction gear 1 (1093)

Make sure the paper feed motor sub

assembly (1046) shaft rotates with

rotation of paper feed reduction gear 2

(1058).

Check the mounting state. Make sure it

is mounted correctly. (See page 4-18.)

Check operation. Make sure it rotates

smoothly.

Check the operation. Make sure the

roller rotates smoothly.

Check for damage. You should see no

damage, such as wear.

Load roll paper that meets

specifications. Completed if

operation is normal.

Open the roll paper cover assembly

and remove any jammed paper.

Completed if operation is normal.

Replace the defective gear.

Completed if operation is normal.

Insert the paper hold spring (1014)

correctly. Completed if operation is

normal.

Replace the paper hold roller (1015).

Completed if operation is normal.

Clean, so that the paper guide roller

(1045) rotates correctly. Completed if

operation is normal.

Replace the mechanism assembly

(120). Completed if operation is

normal.

Rev. B Troubleshooting 3-7

Page 36

Confidential

Table 3-6 The Printer Does not Print

Probable part/probable cause Checkpoints Action to correct the problem

Check the connectors. Make sure they

PF (paper feed) lead wire set

(1047)

Paper feed motor sub

assembly (1046)

Main circuit board unit (201)

are plugged in securely:

Paper feed motor sub assembly (1046)

Connector (CN8) on the main circuit

board unit (201)

Check the wires for breaks and shorts.

Make sure no wires are broken or

shorted out.

Check the resistance value. Make sure it

is 7.2 Ω or less.

Check if the parts have any damage.

Make sure the following parts look

normal.

Connector (CN8)

U8

Plug in the connectors. Completed if

operation is normal.

Replace the PF lead wire set (1047).

Completed if operation is normal.

Replace the paper feed motor sub

assembly (1046). Completed if

operation is normal.

Replace the main circuit board unit

(201). Completed if operation is

normal.

3-8 Troubleshooting Rev. B

Page 37

Confidential

TM-U220 Type A Service Manual

Paper is fed, but characters are not printed

Table 3-7 Paper is Fed, but Characters do not Print

Probable part/probable cause Checkpoints Action to correct the problem

Ribbon cassette

Head FFC (521)

Print head unit (503)

Main circuit board unit (201)

Check the ribbon mounting. Make sure

it is installed correctly.

Check the ribbon. Make sure it is not

wrinkled, kinked, or broken.

Check the continuity with a tester. Make

sure wires are not broken or shorted out.

Check the continuity with a tester. Make

sure wires are not broken or shorted out.

Check parts for damage. Make sure the

following parts look normal.

Connector (CN9)

QM22, QM23, QM24

Load the ribbon cassette correctly.

Completed if operation is normal.

Replace the ribbon cassette with a

new one. Completed if printing is

correct.

Replace the head FFC (521).

Completed if printing is correct.

Replace the print head unit (503).

Completed if printing is correct.

Replace the main circuit board unit

(201). Completed if the print is correct.

Error occurs during printing

Table 3-8 ERROR during Printing

Probable part/probable cause Checkpoints Action to correct the problem

Check the connection of the

main circuit board unit (201)

connector. Make sure the AC

lead wire set (1090) is

connected.

Check the operation of the drive

gear sub assembly (1072). Make

sure it rotates with rotation of the

cutter motor sub assembly (117).

Check the operation of the

cutter motor sub assembly (117).

Autocutter (AC) error

Check the operation of the

micro switch (121). Make sure

the continuity changes when

you operate the switch.

Check the AC lead wire set

(1090) for breaks and shorts.

Make sure wires are not broken

or shorted out.

Check fuse F3 on the main

circuit board unit (201). Make

sure it is not blown.

Plug in the connector. Completed if

operation is normal.

Replace the drive gear sub assembly

(1072). Completed if operation is

normal.

Replace the cutter motor sub

assembly (117). Completed if

operation is normal.

Replace the micro switch (121).

Completed if operation is normal.

Replace the AC lead wire set (1090).

Completed if operation is normal.

If the circuit board has no damage

such as burns, replace fuse F3.

Completed if operation is normal.

If the fuse blows again in operation of

the autocutter, replace the main

circuit board unit.

Rev. B Troubleshooting 3-9

Page 38

Confidential

Table 3-8 ERROR during Printing

Probable part/probable cause Checkpoints Action to correct the problem

Check the parts on the main

Head high-temperature detection

circuit error

Roll paper cover open error

circuit board unit (201) for

damage. Make sure the

following parts look normal.

Connector (CN2)

QM1

Check the print head

temperature. Make sure it is not

too high.

Check the error frequency.

Make sure it does not occur too

often.

Check the state of the cover

when the error occurs. Be sure

not to open the roll paper cover

during printing.

Check the error frequency.

Make sure it does not occur too

often.

Replace the main circuit board unit

(201). Completed if operation is

normal.

Wait for the print head temperature to

drop. Completed if operation is

normal.

Replace the print head unit (503). If

the symptom continues, replace the

main circuit board unit (201).

Completed if operation is normal.

If MSW 8-8 is OFF, close the roll paper

cover again. Completed if operation

is normal.

If the MSW 8-8 is ON, turn power on

again. Completed if operation is

normal.

If the error occurs when the roll paper

cover is not open, refer to “Cannot

pass one of the tests for a sensor” on

page 3-18.

Replace the print head unit (503).

Completed if operation is normal. If

the symptom continues, replace the

main circuit board unit (201).

Completed if operation is normal.

3-10 Troubleshooting Rev. B

Page 39

Confidential

TM-U220 Type A Service Manual

Paper is not cut correctly

Table 3-9 Cutter not Working Correctly

Probable part/probable cause Checkpoints Action to correct the problem

DIP switch setting

Full cut/partial cut setting

Fixed blade spring (1016)

Cutter blade

Check the setting of DSW 2-2.

OFF: Autocutter is disabled.

ON: Autocutter is enabled.

Check the full cut and partial cut

setting. Make sure the autocutter unit

(113) is mounted in the correct position.

Check the spring power. Make sure it

has enough power to push the fixed

blade (513) against the fixed blade

holder (1017).

Check the fixed blade (513). Make sure

it does not have any nicks.

Check the movable cutter blade on

the cutter frame assembly (114). Make

sure it does not have any nicks.

Switch DSW 2-2 to ON. Completed if

cutting is normal.

Mount the autocutter unit (113) in the

correct position. Completed if cutting

is normal.

Replace the fixed blade spring (1016).

Completed if cutting is normal.

Replace the fixed blade (513).

Completed if cutting is normal.

Replace the cutter frame assembly

(114). Completed if cutting is normal.

Ribbon feed mechanism does not operate

Table 3-10 Ribbon Feed Mechanism not Functioning Correctly

Probable part/probable cause Checkpoints Action to correct the problem

Ribbon cassette

Ribbon take-up function

Adjustment roller shaft holders

(506)

Check the mounting. Make sure it is

installed correctly.

Check the ribbon cassette itself. Make

sure the ribbon is fed by turning the

tab.

Check the take-up operation. Be sure

the following parts move with

operation of the carriage sub

assembly (1025):

❑ Belt drive pulley (505)

❑ Ribbon middle gear (512)

❑ Ribbon drive plate sub assembly

(517)

❑ Ribbon take-up gear sub assembly

(516)

Check the platen gap adjustment.

0.45 mm: falls with no weight applied

0.55 mm: does not fall

Install the ribbon cassette correctly.

Completed if printing is normal.

Replace the ribbon cassette with a

new one. Completed if printing is

normal.

Replace the defective gear.

Completed if the operation is normal.

Adjust the platen gap (refer to page

5-5). Completed if printing is normal.

Rev. B Troubleshooting 3-11

Page 40

Confidential

Print result is not normal

Print is light or irregular

Table 3-11 Light or Irregular Print

Probable part/probable cause Checkpoints Action to correct the problem

Ribbon cassette

Ribbon take-up function

Adjustment roller shaft holders

(506)

Check the ribbon mounting. Make

sure it is installed correctly.

Check the ribbon cassette. Make sure

the ribbon is fed by turning the tab.

Check the take-up operation. Be sure

the following parts operate with

operation of the carriage sub

assembly (1025)

❑ Belt drive pulley (505)

❑ Ribbon middle gear (512)

❑ Ribbon drive plate sub assembly

(517)

❑ Ribbon take-up gear sub assembly

(516)

Check the platen gap adjustment.

0.45 mm: falls with no weight applied

0.55 mm: does not fall

Install the ribbon cassette correctly.

Completed if printing is normal.

Replace the ribbon cassette with a

new one. Completed if printing is

normal.

Replace the defective gear.

Completed if the operation is normal.

Adjust the platen gap (refer to page

5-5). Completed if printing is normal.

Print is dark

Table 3-12 Dark Print

Probable part/probable cause Checkpoints Action to correct the problem

Adjustment roller shaft holders

(506)

Check the platen gap adjustment.

0.45 mm: falls with no weight applied

0.55 mm: does not fall

Adjust the platen gap (refer to

page 5-5). Completed if printing

is normal.

Dots are missing continuously

Table 3-13 Missing Dots

Probable part/probable cause Checkpoints Action to correct the problem

Head FFC (521)

Print head unit (503)

Check the continuity with a tester. Make

sure no wires are broken or shorted out.

Check the continuity with a tester. Make

sure no wires are broken or shorted out.

Check the state of the dot wires. Make sure

they are not broken.

Replace the head FFC (521).

Completed if printing is normal.

Replace the print head unit

(503). Completed if printing is

normal.

3-12 Troubleshooting Rev. B

Page 41

Confidential

TM-U220 Type A Service Manual

Line spacing is irregular

Table 3-14 Irregular Line Spacing

Probable part/probable cause Checkpoints Action to correct the problem

Roll paper is inserted

incorrectly

Paper jam

Gear does not rotate

Paper hold spring (1014)

Paper hold roller (1015)

Paper guide roller (1045)

Check the roll paper. Make sure it meets

specifications and is loaded correctly.

Check the paper path. Make sure there

is no paper jam.

Check gear operation. Make sure the

following gears rotate with each other.

Paper feed gear (1063)

Paper feed middle gear B (510)

Paper feed middle gear (509)

Paper feed reduction gear 1 (1093)

Make sure the shaft of platen assembly 3

(522) rotates with the rotation of paper

feed reduction gear 2 (1058).

Check the spring mounting. Make sure it

is mounted correctly. (Refer to page 4-

18)

Check operation. Make sure it rotates

smoothly.

Check operation. Make sure it rotates

smoothly.

Load roll paper that meets

specifications correctly. Completed if

operation is normal.

Open the roll paper cover and

remove the paper jam. Completed if

operation is normal.

Replace the defective gear.

Completed if operation is normal.

Insert the paper hold spring (1014)

correctly. Completed if operation is

normal.

Replace the paper hold roller (1015).

Completed if operation is normal.

Clean, so the paper guide roller

(1045) rotates correctly. Completed if

operation is normal.

Two-color printing is not performed, or colors are mixed

Table 3-15 Printing is not Two-color, or Colors are Mixed

Probable part/probable cause Checkpoints Action to correct the problem

Replace the ribbon cassette with one

for 2-color printing. Completed if

printing is normal.

Install the ribbon cassette correctly.

Completed if printing is normal.

Mount the springs correctly.

Completed if printing is normal.

Ribbon cassette

Two-color shift function

Check the ribbon type. Make sure it is for

2-color printing.

Check the mounting. Make sure the

ribbon is installed correctly.

Check the mounting of the spring. Make

sure the following springs are mounted

correctly.

Ribbon take-up spring (1088)

Ribbon frame spring (1022)

Rev. B Troubleshooting 3-13

Page 42

Confidential

Printed contents are not normal

Table 3-16 Abnormal Printing Content

Probable part/probable cause Checkpoints Action for the problem

Firmware version

Boot version

DIP switch settings

Resident character

Paper width

Check the version number. (See page 2-1.)

Make sure it is the same as the version used

by the customer, or the latest version.

Check the version number. (See page 2-1.)

Make sure it is the same as the version used

by the customer, or the latest version.

Check the DIP switch settings printed. Make

sure the following items are same as the DIP

switch settings. (See page 5-7.)

Serial Interface (when serial I/F is installed)

Receive buffer capacity

Receive buffer full release condition

Handshaking operation

Characters per line (CPL)

Autocutter unit

If they are not correct, check the continuity

of the DIP switch.

Check the resident character set. Make sure

it is same as the character set used by the

customer.

Check if this error message is printed:

If so, the multilingual font is not correct. Please

download the correct one. Make sure the

message above is not printed.

Check the print item corresponding to the

paper width. Make sure the entire area of

the paper width is printed.

### ERROR ###

Update the firmware. Completed

if printing is normal.

Update the firmware. Completed

if printing is normal.

Replace the main circuit board

unit (201). Completed if printing is

normal.

Update the firmware. Completed

if printing is normal.

Update the firmware.

Completed if printing is normal.

If printing is not normal, replace

the main circuit board unit (201).

Match the paper width setting to

the paper width. Completed if

printing is normal

Paper jam occurs

Table 3-17 Paper Jams

Probable part/probable cause Checkpoints Action to correct the problem

Roll paper is inserted

incorrectly

Fixed blade (513)

Paper hold rollers (1015)

Check the roll paper. Make sure it meets

specifications and is loaded correctly.

Check for defects. Make sure you see no

defects, such as deformation.

Check operation. Make sure the 2 rollers

rotate smoothly.

Load roll paper that meets

specifications correctly.

Completed if operation is normal.

Replace the fixed blade (513).

Completed if operation is normal.

Replace the paper hold roller(s)

(1015). Completed if operation is

normal.

3-14 Troubleshooting Rev. B

Page 43

Confidential

TM-U220 Type A Service Manual

Table 3-17 Paper Jams

Probable part/probable cause Checkpoints Action to correct the problem

Clean, so that both paper guide

rollers (1045) rotate correctly.

Completed if operation is normal.

Replace the mechanism

assembly (120). Completed if

operation is normal.

Replace the roll paper holder

plate (508). Completed if

operation is normal.

Paper guide rollers (1045)

Roll paper holder plate (508)

Check operation. Make sure the 2 rollers

rotate smoothly.

Check for defects. Make sure you see no

defects, such as wear.

Check for defects. Make sure you see no

defects, such as deformation.

Printing is loud