Page 1

TM-U200 Series (Type A)

Operator’s Manual

Using this onl ine operat or’s guid e

The words on the left side of this screen are book marks for all the

topics in this guide.

Use the scroll bar next to the bookmarks to find any topic you

want. Click a bookmark to instantly jump to its topic. (If you wish,

you can increase the size of the bookmark area by dragging the

dividing bar to the right.)

Use the scroll bar on the right side of this screen to move through

the text.

Use the zoom tools to magnify or reduce the page display.

Click the Find button i f you w an t to sea rch fo r a pa rti cula r te rm.

(However, using the bookmarks is usually quicker.)

Complete online documentation for Acrobat Reader is located in the Help directory for Acrobat Reader.

Retu rn to ma in m en u

Page 2

TM-U200 Series

(Type A)

Operator’s Manual

400898901

Page 3

Note:

Everything in this manual app lies to the TM-U210 printer.

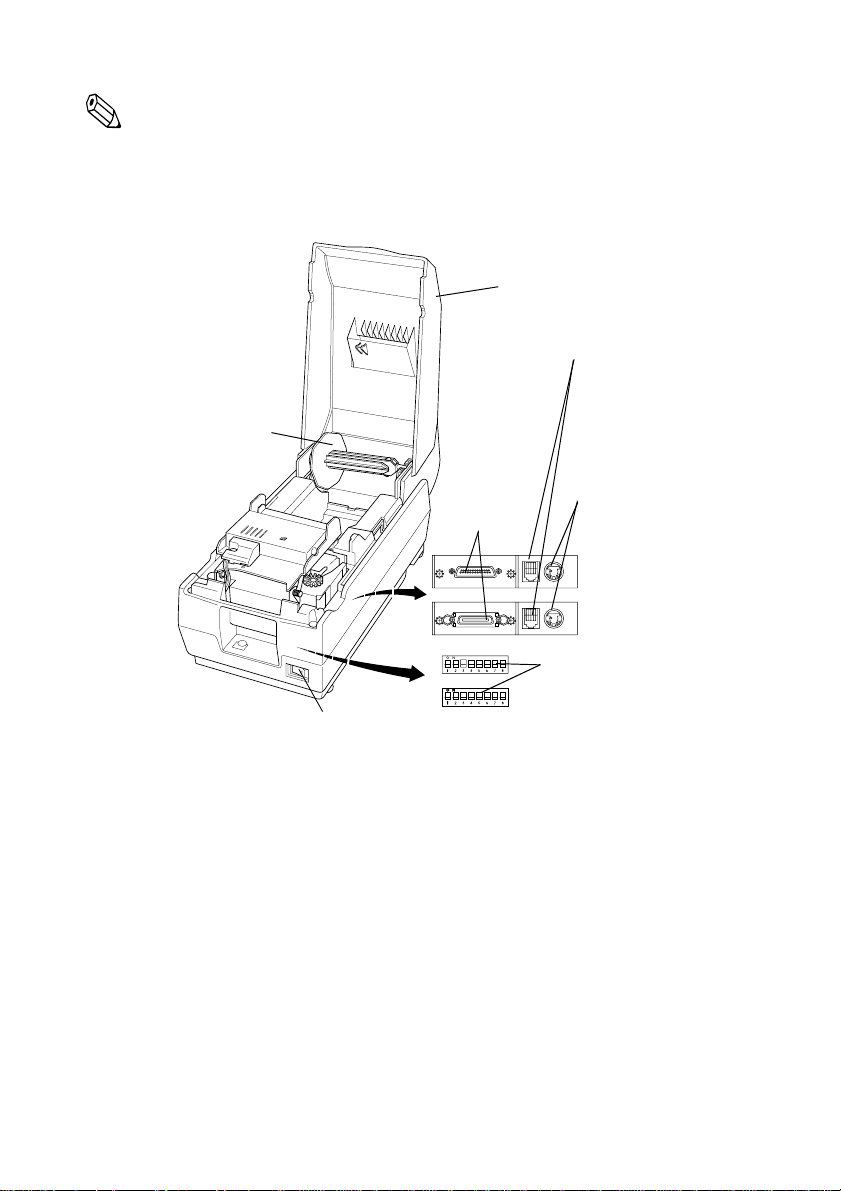

Printer parts and Labels

Printer cover

Drawer kick-out connectors

Journal take-up

spool

Power switch

Interface

Connector

Power connector

Model with Serial

Interface

Model with

Parallel Interface

DIP switches

Page 4

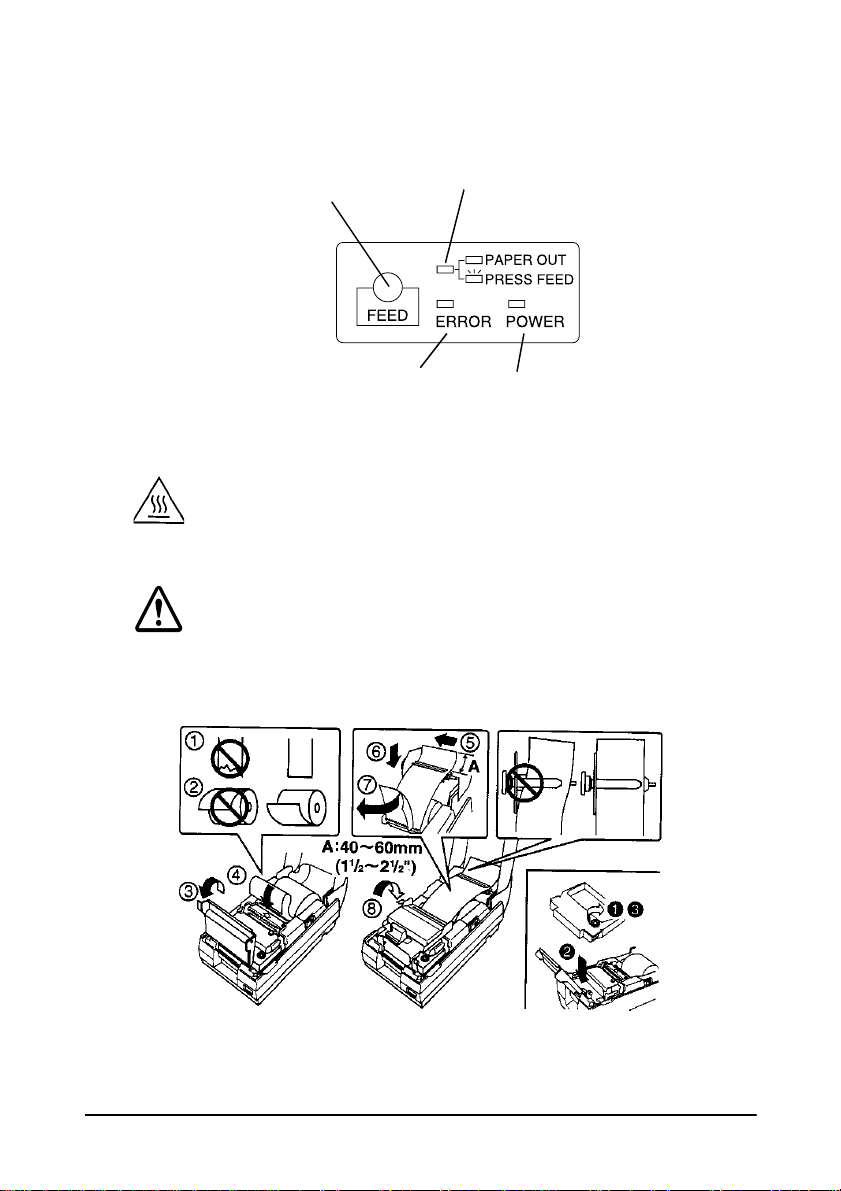

Control panel

PAPER FEED

button

ERROR light

Caution Labels

CAUTION:

Head cover and printer head are hot.

CAUTION:

Caution label for drawer kick-out.

Instruction Label

PAPER OUT light

POWER light

Page 5

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted in any form or by any means, mechanical,

photocopying, recording, or o therwise, without t he prior wri tten permission of Seiko

Epson Corporation. No patent liability is assumed with respect to the use of the

information contained herein. While every precaution has been taken in the

preparation of this book, Seiko Epson Corporation assumes no responsibility for

errors or omissions. Neither is any liability assumed for damages resulting from the

use of the information contained herein.

Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of

this product or third parties for damages, losses, costs, or expenses incurred by

purchaser or third parties as a result of: accident, misuse, or abuse of this product or

unauthorized modifications, repairs, or alterations to this product, or (excluding the

U.S.) failure to strictly comply with Seiko Epson Corporation’s operating and

maintenance instructions.

Seiko Epson Corporation shall not be liable again st any damage s or problems arising

from the use of any options or any cons umable pr oducts other than those desig nated

as Original Epson Products or Epson Approved Products by Seiko Epson

Corporation.

EPSON is a registered trademark of Seiko Epson Corporation.

ESC/POS is a registered trademark of Seiko Epson Corporation.

NOTICE: The contents of this manual are subject to change without notice.

Copyright © 1998 by Seiko Epson Corporation, Nagano, Japan.

i

Page 6

FCC CLASS A

FCC Compliance Statement

For American Users

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interferenc e, in wh ich case the user will be required to

correct the interference at his own expense.

WARNING

The connection of a non-s hielded printer i nterface cable to th is printer w ill invalidat e

the FCC Verification of this device and may cause interference levels which exceed

the limits established by the FCC for this equipment.

You are cautioned that changes or modifications not expressly approved by the

party responsible for compliance could void your authority to operate the

equipment.

FOR CANADIAN USERS

This Class [*] digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe [*] est conforme à la norme NMB-003 du

Canada.

GERÄUSCHPEGEL

Gemäß der Dritten Verordnung zum Gerätesicherheitsgesetz

(Maschinenlärminformations- Verordnung-3. GSGV) ist der arbeitsplatzbezogene

Geräusch-Emissi on swert kleiner als 70 dB(A) (basierend auf ISO 7779).

ii

Page 7

DECLARATION OF CONFORMITY

Product Name: Printer

Model Name: M119A

This printer conforms to the following Directives and Norms:

Directive 89/336/EEC

EN 55022 (1987 and 1994 2nd/1995) Class B

EN 50082-1 (1992)

IEC 801-2 (1991)

IEC 801-3 (1984)

IEC 801-4 (1988)

Directive 90/384/EEC

EN45501: (1992)

iii

Page 8

Introduction

Features

The TM-U200 Series Type A printer is one-station printer for ECR and POS use that

can print the results of weighing or measuring.

TM-U200 Series (Type A) has the following 2 types.

• Two-color with a serial interface

• Two-color with a parallel interface

The main features of the TM-U200 Series Type A printer are the following:

❏ High-speed printing through logic-seeking control

❏ Excellent reliability and long life due to use of two stepping motors, one for

moving the carriage and one for paper feeding

❏ Flexible paper feed s etting per mits printi ng in ac cordance with an y user-de fined

format

®

❏ Command protocol based on ESC/POS ,

❏ Built-in drawer kick-out interface provides capability to drive two drawers

❏ Selectable character fonts (7 x 9, 9 x 9)

a widely u sed standard

❏ Semi-automatic paper loading capability

❏ AC adapter provides compact power supply

❏ Compact and light in weight

❏ Automatic Status Back (ASB) function to automatically send printer status

changes

❏ Auto cutter is installed

❏ Journal take-up spool is installed

❏ Bidirectional parallel inte rfa ce in acco rda nce wit h th e IEEE 12 84 Nibble /By te

Modes

❏ Two-color printing (black an d red)

iv

Page 9

About This Manual

Setting Up and Using

❏ Chapter 1 contains information on unpacking the printer, setting it up, running

the self test, and setting the DIP switches.

❏ Chapter 2 contains information on using the printer.

❏ Chapter 3 contains troubleshooting information.

Reference

❏ Chapter 4 contains specifications.

Notes, Cautions, and Warnings

Note:

Notes have important information and useful tips on the operation of your

printer.

CAUTION:

Cautions must be observed to avoid minor injury to yourself or

damage to your equipment.

WARNING:

Warnings must be followed carefully to avoid serious bodily

injury.

v

Page 10

Contents Chapter 1 Setting Up the Printer

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Selecting the Place . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Attaching the Paper Roll Near-End Detector (Option) . . . . . . . . . . . . . . . . . . . . . . . 1-2

Connecting the Printer to the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Parallel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Connecting the Printer to the Drawer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Grounding the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Connecting the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Installing the Ribbon Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Installing the Paper Roll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Running the Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Setting the DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Using the Power Switch Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-25

Affixing the Fastening Tape (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Chapter 2 Using the Printer

Operating the Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Indicator lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Chapter 3 Troubleshooting

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

General Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Printing Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Removing Jammed Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Hexadecimal Dump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Chapter 4

Printing Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Character Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Safety and EMI Standards Applied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Interface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Drawer Kick-out Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Reference Information

vi

Page 11

Chapter 1

Setting Up the Printer

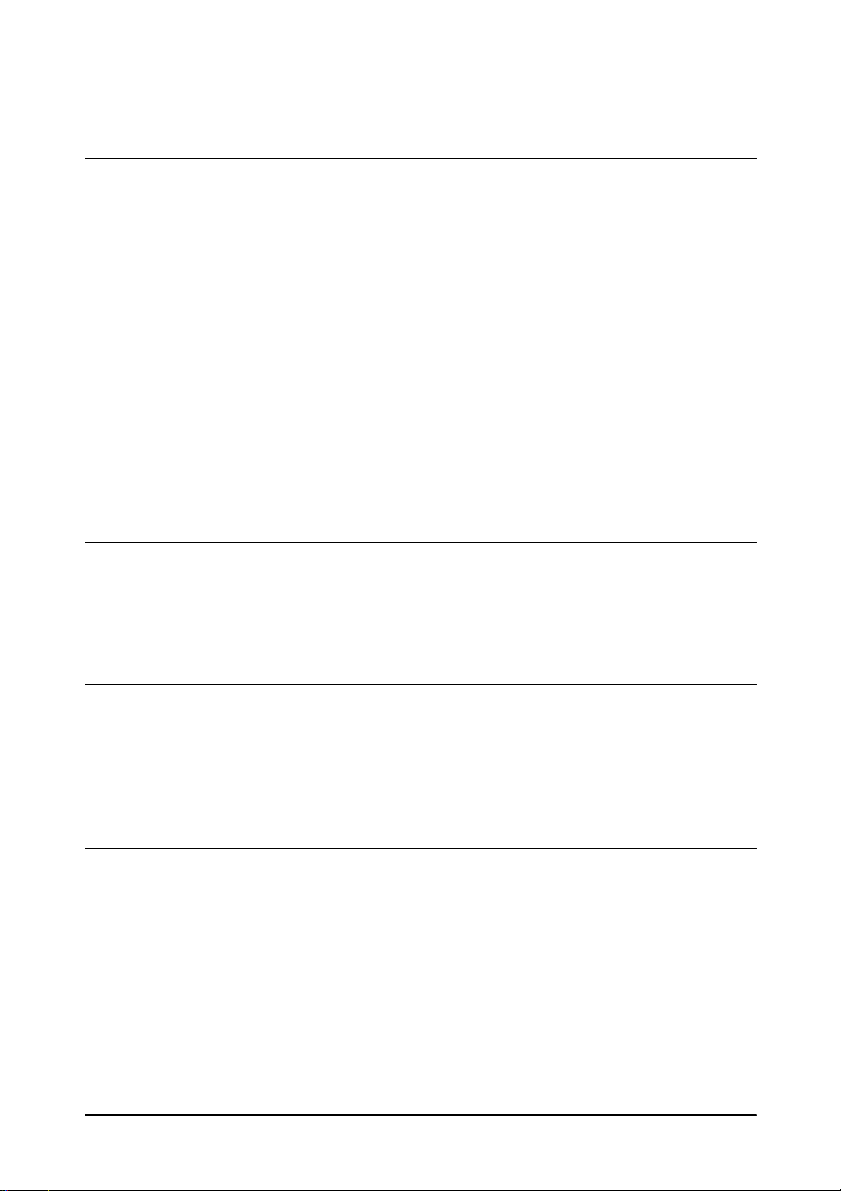

Unpacking

When you unpack the TM-U200 Series Type A printer, make sure

you have these items.

Ribbon cassette

Printer

Roll paper

Journal take-up

spool

Power supply

Power switch

cover

Hexagonal lock screw (2 pcs)

(only for the printer with the serial

interface. The hexagonal lock screw

is not included f or s ome models of this

printer.)

If any item is missing or damaged, please contact your dealer for

assistance.

Note:

See the Note on page 1-5 for information on the screws.

Selecting the Place

Place the printer on a surface that is as horizontal as possible.

Setting Up the Printer 1–1

Page 12

The printer should be installed so that it does not move or vibrate

during paper cutting or the drawer kick-out operation.

Fastening tape is available as an option.

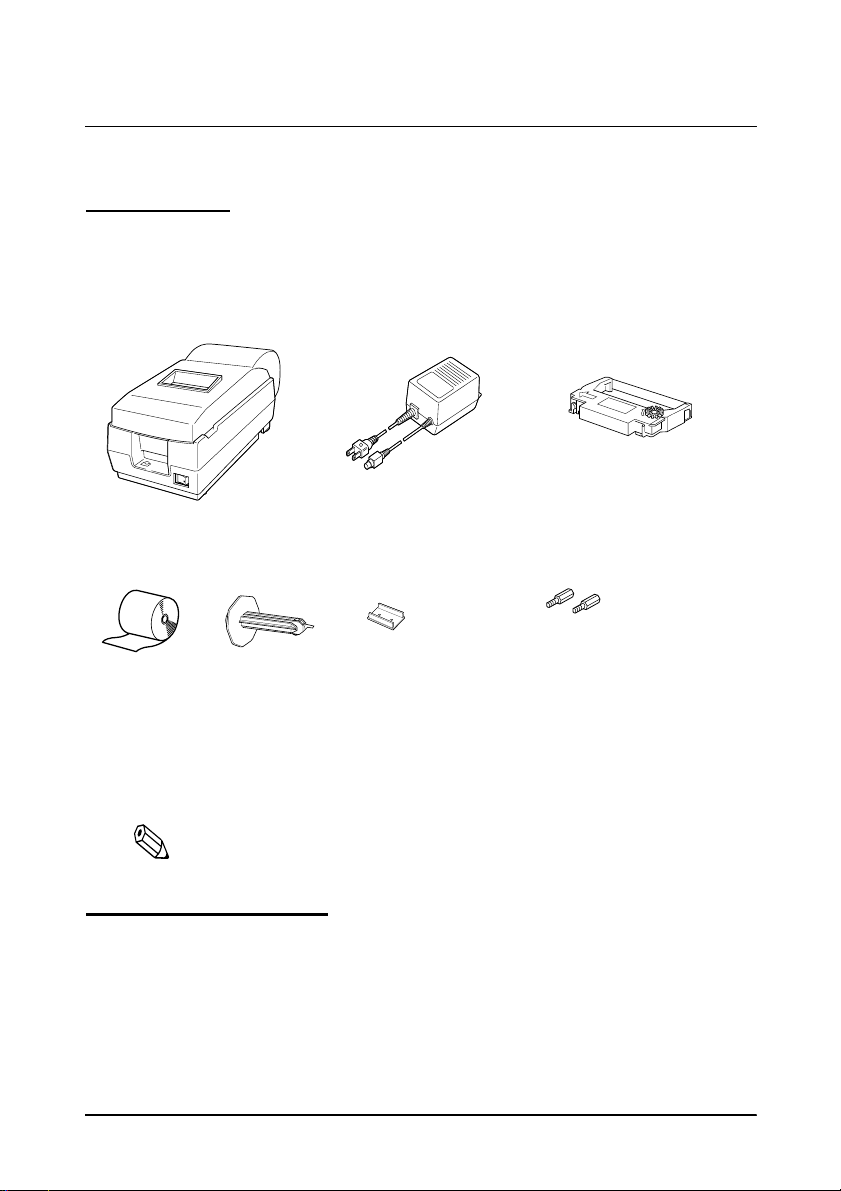

Attaching the Paper Roll Near-End Detector (Option)

If you do not have a paper roll near-end detector or do not want to

attach it, skip this section.

Note:

If you use this detector, use paper rolls with a core diameter 10.5

to 12.5 mm (0.41 to 0.47”) so that the detector senses the

remaining paper correctly.

1. Make sure the power supply is disconnected from the printer.

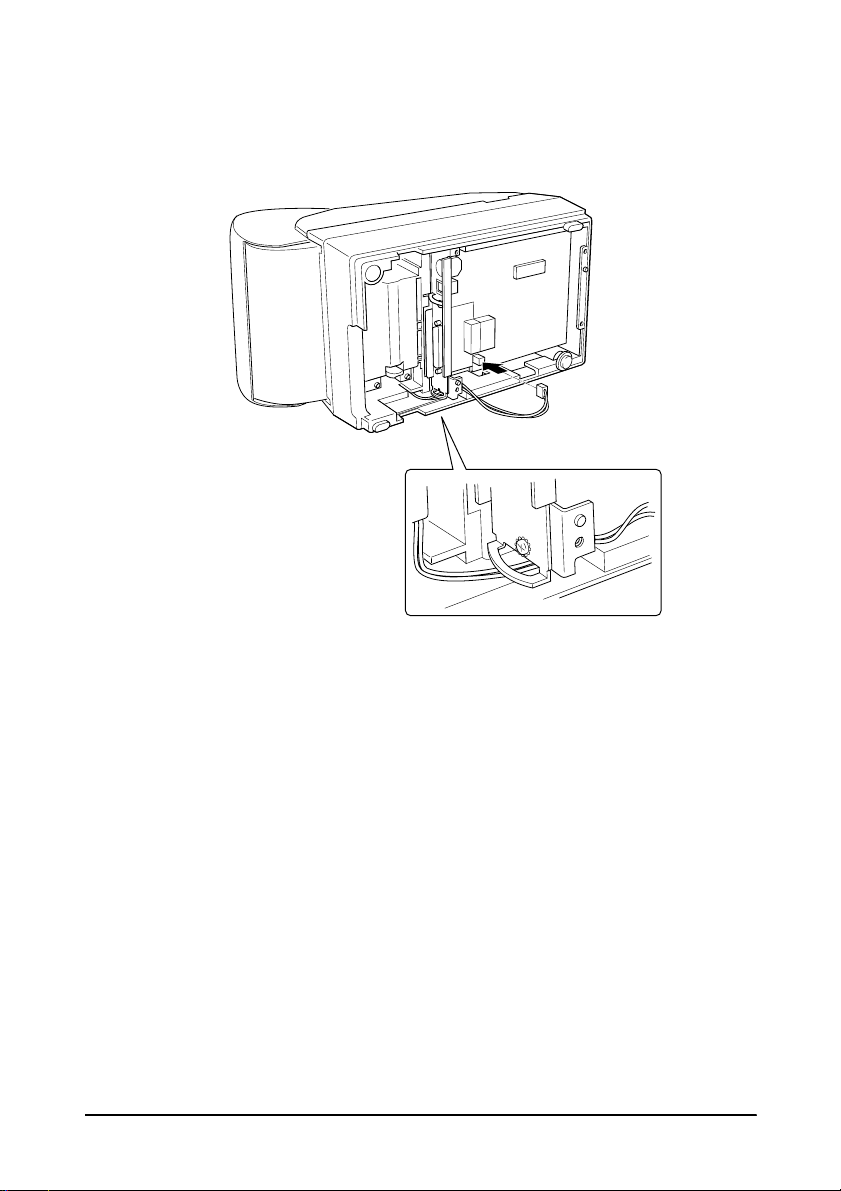

2. Remove four screws from the bottom of the printer; then

remove the cover.

1–2 Setting Up the Printer

Page 13

3. Two spacers are included with the near-end detector. See the

illustration below, and decide whether or not you want to use

them. Use them if you want the near-end detector to be

triggered when distance A is 3 to 4 mm (0.12 to 0.16”);

otherwise it will be trigger ed when distance A is appr oximately

6 mm (0.24”).

distance A

4. Secure the paper roll near-end detector (and spacers) with two

screws. When you insert the spacers, be sure you set the

spacers in the direction shown in the illustration.

Setting Up the Printer 1–3

Page 14

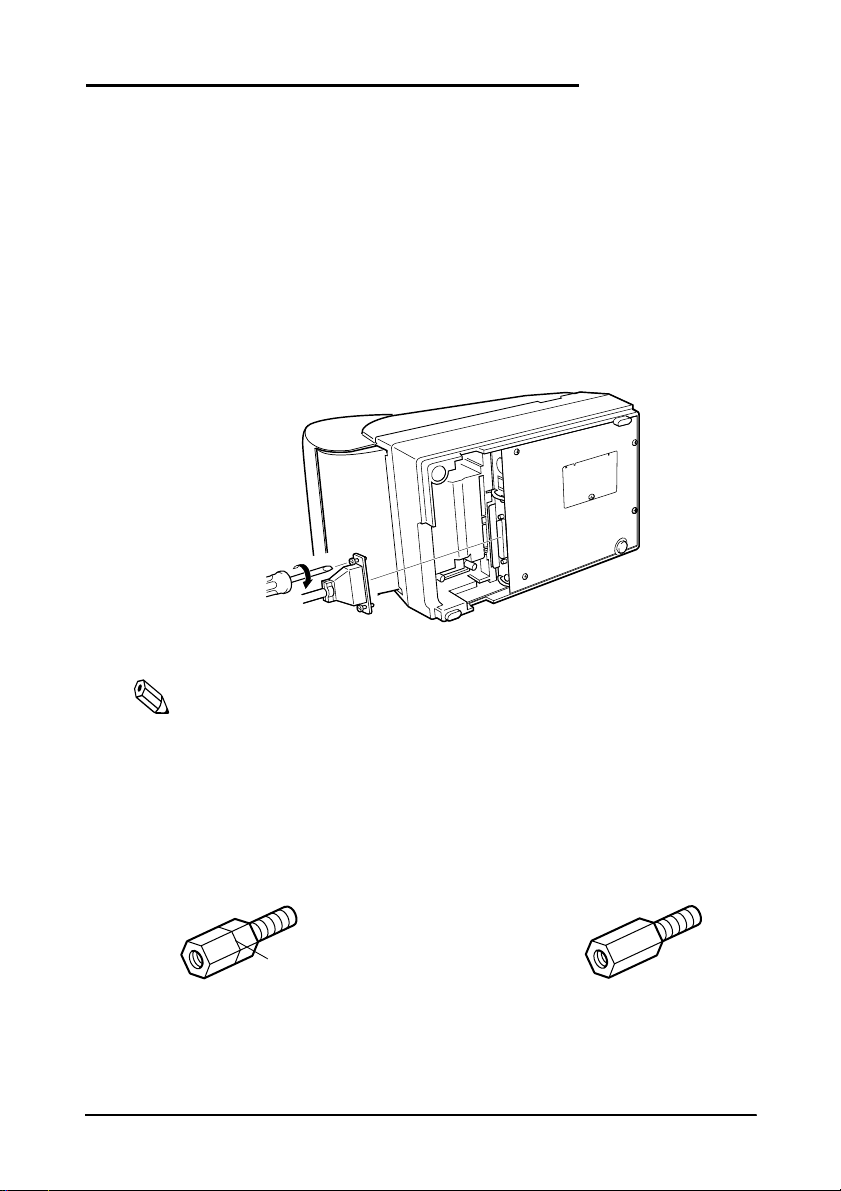

5. Connect the connector of the detector to CN11 on the printer.

Position the cable as shown in the illustration.

6. Replace the cover and fasten it with the four screws.

1–4 Setting Up the Printer

Page 15

Connecting the Printer to the Computer

You need an appropriate serial interface or parallel interface cable

to connect your computer to the p rinte r (null modem seri al or IEEE

1284 parallel).

The Model with Serial Interface

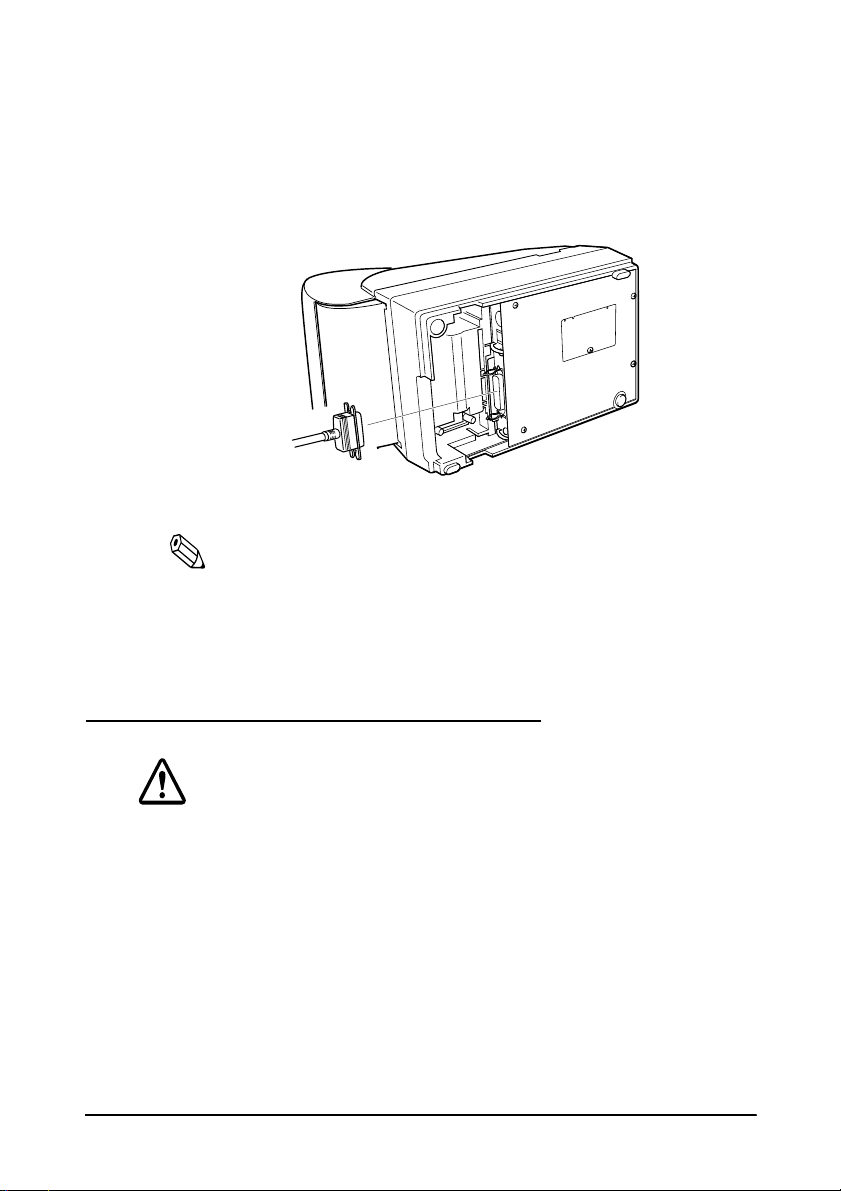

1. Make sure the printer and computer are turned off. Then plug

the cable into the connector on the printer, as shown.

Note:

Your printer comes with inch-type hexagonal lock screws installed.

If you plan to use an interface cable that requires millimeter-type

lock screws, replace the inch-type screws with the enclosed

millimeter-type screws by using a hex screwdriver (5 mm). To

distinguish between the two types of screws, see the illustration

below.

Notch (one or more lines)

Inch-type

Millimeter-type

2. Connect the other end of the cable to the connector on your

computer.

Setting Up the Printer 1–5

Page 16

The Model with Parallel Interface

1. Make sure the printer and computer are turned off. Then, plug

the cable into the connector on the printer, as shown.

Note:

Squeeze the wire clips on the printer together until they lock in

place on both sides of the connector.

2. Connect the other end of the cable to the connector on your

computer.

Connecting the Printe r to th e Dr aw er

WARNING:

Use a drawer that matches printer specifications. Using an

improper drawer may damage the drawer as well as the

printer. (See Chapter 4 “Reference Information” for

information on the drawer.

1–6 Setting Up the Printer

Page 17

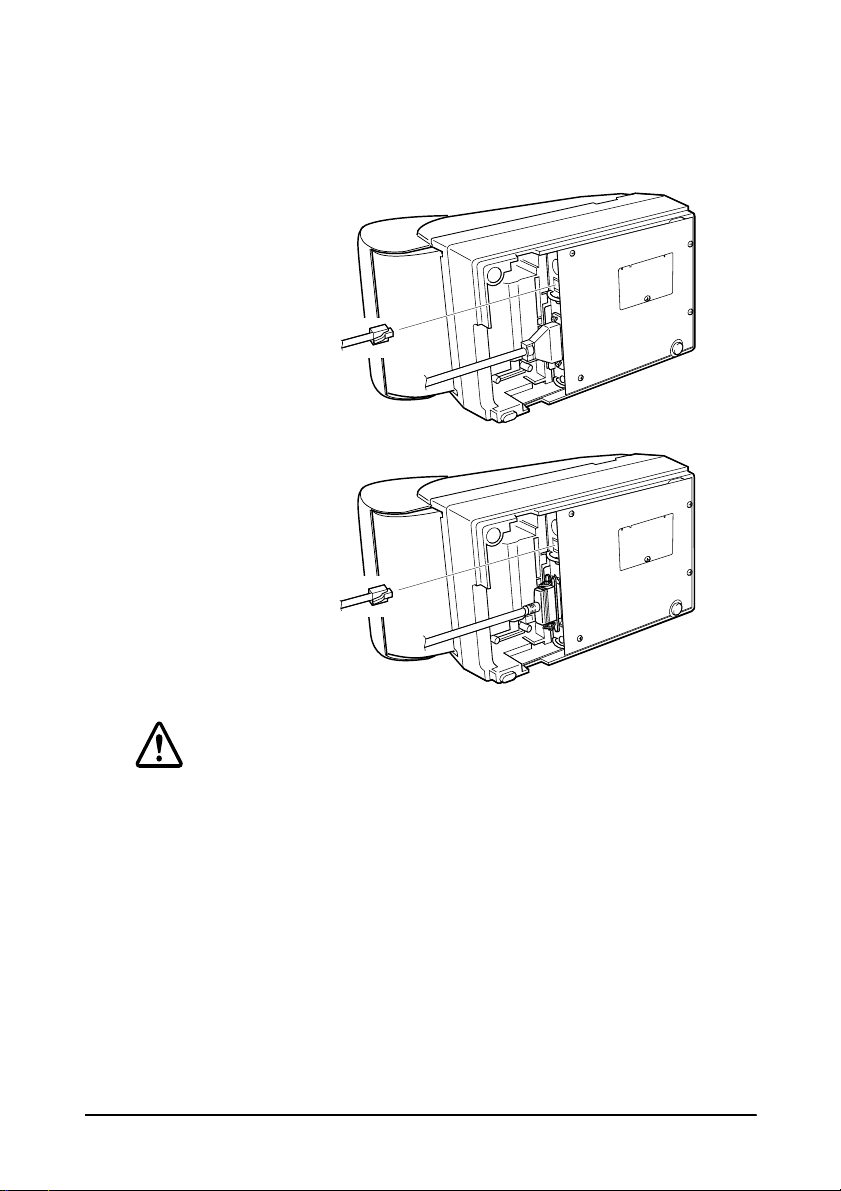

Plug the drawer cable into the drawer kick-out connector on the

bottom of the printer next to the computer interface connector.

Model with

Serial Interface

Model with

Parallel Interface

CAUTION:

Do not connect a telephone line to the drawer kick-out

connector; otherwise the printer and the te lephone line may

be damaged.

Setting Up the Printer 1–7

Page 18

Den Drucker an die Lade anschließen

Das Kabel der Lade an die Schnappsteckerbuchse (neben der

Schnittstellenbuchse) an der Unterseite des Druckers anschließen.

ACHTUNG:

Kein Telefonkabel an die Schnappsteckerbuchse

anschließen.

1–8 Setting Up the Printer

Page 19

Grounding the Printer

You need a ground wire to ground your printer. Make sure the

wire meets the specification below.

Thickness of wire: AWG 18 or equivalent

Diameter of terminal to be attached: 3.2

1. Make sure that the printer is turned off.

2. Connect the ground wire to the printer using the FG screw on

the bottom of the printer, as shown.

Setting Up the Printer 1–9

Page 20

Connecting the Power Supply

This printer requires an external power supply. Be sure to use a

power supply that matches the specifications listed under

“Electrical Specifications” in Chapter 4.

WARNING:

Using an incorrect power supply may cause fire or electrical

shock.

CAUTION:

When connecting or disconnecting the power supply from

the printer, make sure the power supply is not plugged into

an electrical outlet; otherwise you may damage the power

supply or the printer.

CAUTION:

Do not connect the enclosed power supply to the EPSON

customer display DM-D101 or DM-D202. This can damage the

customer display and the powe r supply. However, you can

connect this power supply to the EPSON customer display

DM-D101 II or DM-D202 II.

1–10 Setting Up the Printer

Page 21

1. Make sure the printer and power supply are turned off.

2. Plug the power supply’s cable into the printer’s connector as

shown below. Note that the flat side of the connector faces

down.

3. Plug the power supply’s cord into an outlet.

If you ever need to remove the cable, unplug the power

❏

supply’s cord from an outlet and then grasp the connector

firmly at the arrow mark and pull it straight out.

Setting Up the Printer 1–11

Page 22

Installing the Ribbon Cassette

CAUTION:

Never turn the ribbon casse tte’s feed knob in the opposite

direction of the arrow marked on the cassette; otherwise the

ribbon cassette may be damaged.

Do not replace the ribbon cassette while you are using the

printer. If the printer is receiving data when you replace the

ribbon cassette, data may be lost.

Note:

Use the EPSON ERC-38 ribbon cassette for your printer.

1. Open the printer cover.

2. Turn the ribbon cassette’s knob two or th ree times in the

direction of the arrow to take up any slack in the ribbon.

3. Open the auto cutter by pulling the tab up and toward you.

4. Insert the ribbon in the position shown in th e illustratio n on the

next page and push the ribbon cassette until it clicks.

1–12 Setting Up the Printer

Page 23

Note:

Make sure the ribbon is installed between the print head and the

platen without wrinkles or creases.

Setting Up the Printer 1–13

Page 24

5. Turn the ribbon cassette’s knob 2 or 3 times in the direction of

the arrow again to take up any slack in the ribbon.

6. Close the auto cutter by using the tab.

7. Close the printer cover.

To remove the ribbon cassette, follow the steps below.

1. Be sure the printer is not receiving data.

2. Open the auto cutter by using the tab.

3. Lift up the left side of the ribbon cassette to remove the ribbon

cassette.

1–14 Setting Up the Printer

Page 25

Installing the Paper Roll

CAUTION:

Be sure the printer is not receiving data when you replace a

paper roll. If ther e is data, printing will start.

Notes:

Be sure to use roll paper that meets the specifications. (See “Paper

Specifications” in Chapter 4.

If you use roll paper with the paper glued or taped to the core, the

core may be pulled into a paper feed path, which may cause a paper

jam or lock the paper feed mechanism.

When you use a paper roll with the end attached to the core, use the

optional paper roll near-end detector or replace the paper roll when

the mark that indicates you are near the end of the paper roll

appears.

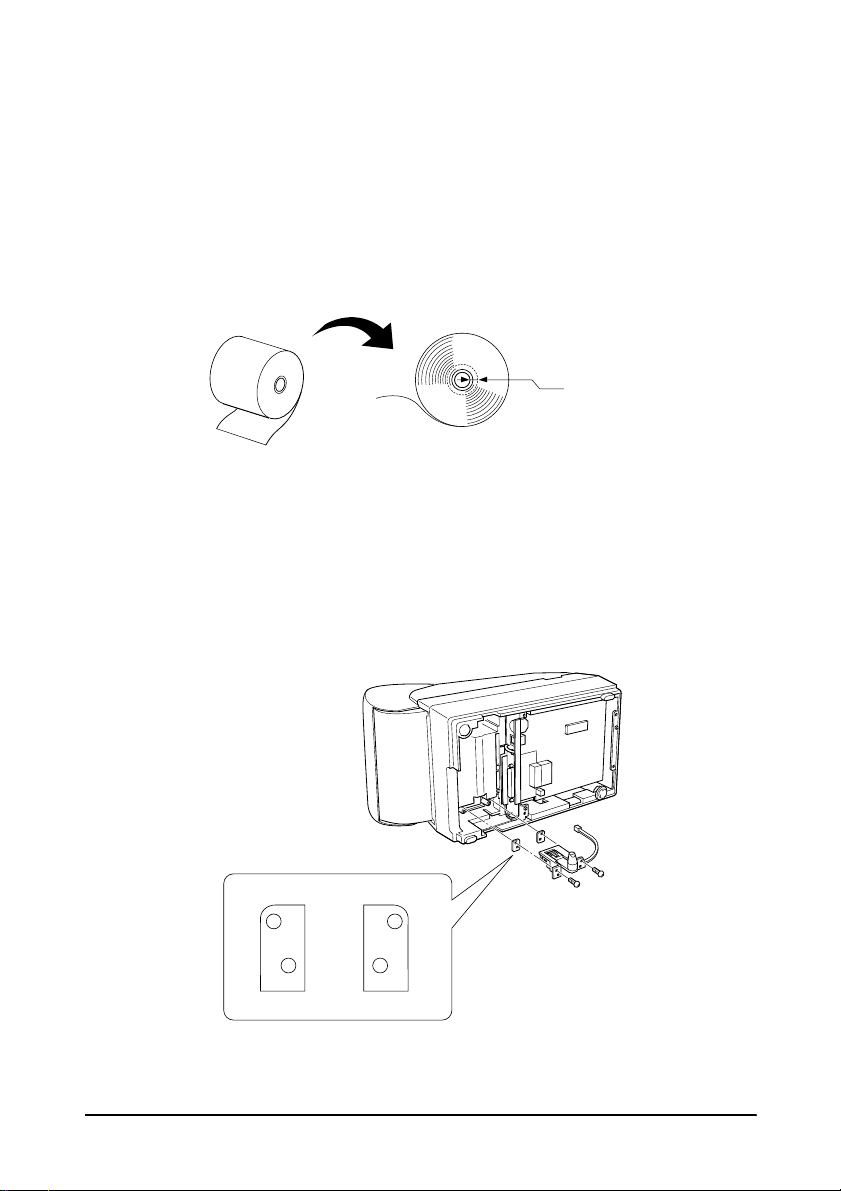

1. Using scissors, cut the leading edge of the paper roll as shown

below.

2. Turn on the printer and open the printer cover.

Setting Up the Printer 1–15

Page 26

3. Insert the paper roll.

Note:

Be sure to note the correct direction that the paper comes off the

roll, as shown below.

1–16 Setting Up the Printer

Page 27

4. Open the auto cutter by pulling the tab up and toward you.

Setting Up the Printer 1–17

Page 28

5. Hold both edges of the paper and insert it straight into the

paper slot. The printer feeds the paper automatically.

6. When using a 2-ply roll paper, remove the journal take-up

spool from the printer, and insert the end of the paper into the

spool as shown below. Be sure that length of A is between 40

and 60 mm (1.58 and 2.36”) and the left side of the paper is

aligned with the spool’s flange.

Flange

1–18 Setting Up the Printer

A

Journal take-up

spool

Journal paper

Page 29

7. Insert the journal take-up spool in the printer.

8. Cut the receipt paper (when using a 2-ply roll paper) on the

manual cutter.

Tab

Receipt paper

9. Close the auto cutter by using the tab. Be sure to check again

that the left side of the paper is aligned with the spool’s flange

as shown below.

10. Close the prin ter cover.

To remove the paper roll, follow the steps below.

1. Be sure the printer is not receiving data and open the printer

cover.

Setting Up the Printer 1–19

Page 30

2. Cut the journal and receipt paper as shown in the illustration

below.

Cut here

3. Remove the paper take-up spool from the printer.

4. Remove the paper roll from the printer.

5. Press the

FEED

button to remove the remaining paper.

Note:

Do not pull the remaining paper in the opposite direction of

paper feeding.

Running the Self Test

Any time you want to check the performance of your printer you

can run the self test described below. This shows whether your

printer is working correctly. It is independent of any other

equipment or software.

1–20 Setting Up the Printer

Page 31

Note:

Be sure to install the ribbon cassette and the paper roll before

you run the self test.

1. To perform th e self test, hold down the

turn on the printer with the power switch.

2. The printer prints the current printer settings, and then the

PAPER OUT

printing standby state.

3. Press the

which the printer prints a pattern using the built-in character

set.

4. After the printer completes a certain number of lines, it prints

the following:

Then it enters the normal mode.

Note:

If you want to pause the self test manually, press the FEED

button. Press the FEED button again to continue the self test.

light blinks to indicate that the printer is in the test

FEED

button to start the second part of the test, in

*** completed ***

FEED

button while you

Setting the DIP Switches

CAUTION:

Turn off the printer while removing the DIP switch cover to

prevent an electrical short, which can damage the printer.

You can change your serial interface and print column settings by

changing the DIP switch settings.

1. Make sure the printer is off.

Setting Up the Printer 1–21

Page 32

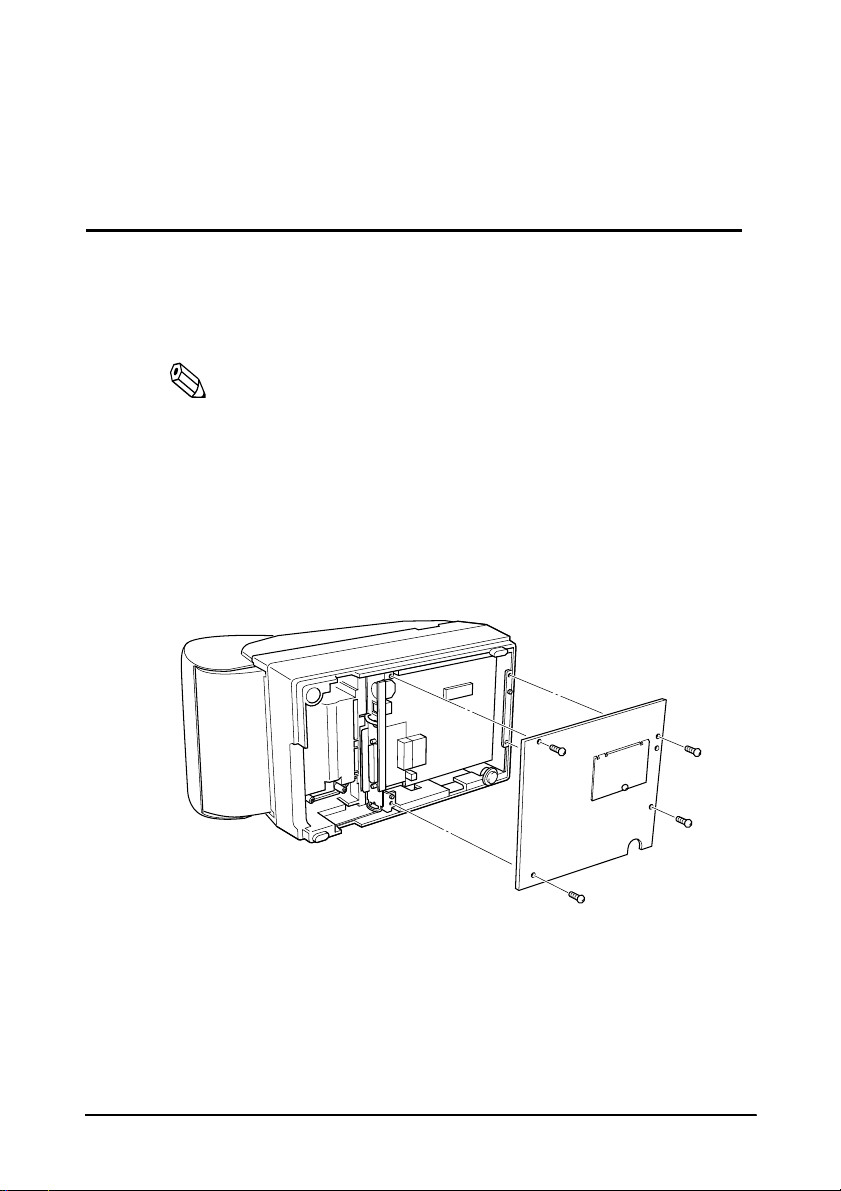

2. Turn the printer over and remove the DIP switch access cover,

as shown below.

3. There are two sets of switches. Use tweezers or another nar row

tool to move the switches.

4. Use the following tables to set the DIP switches. Numbers

starting with 1 are in the first set, and numbers starting wit h 2

are in the second.

Model with Serial Interface DIP-Switch Functions

DIP Switch Set 1

Switch Function ON OFF

1-1

1-2 Receive buffer

1-3 Handshaking XON/XOFF DTR/DSR

1-4 Word length 7 bits 8 bits

1-5 Parity check Yes No

Data reception

error

capacity

1–22 Setting Up the Printer

Ignored Prints”?”

40 bytes Approximately 1K

byte

Page 33

DIP Switch Set 1

Switch Function ON OFF

1-6 Parity selecti on E ven Odd

1-7 Baud rate 4800 BPS 9600 BPS

1-8 Busy condition Sets the printer to

go BUSY when the

receive buffer is full

Sets the printer to go

BUSY when it is off

line or the receive

buffer is full

DIP Switch Set 2

Switch Function ON OFF

2-1 Print column selection

7 × 9 font/9 × 9 font

2-2 Internal use. Setting must not be changed. (Fixed to ON)

2-3 Internal use. Setting must not be changed. (Fixed to OFF)

2-4 Undefined

2-5 Internal use. Setting must not be changed. (Fixed to ON)

2-6 Internal use. Setting must not be changed. (Fixed to OFF)

2-7 I/F pin 6 reset signa l Enabled Disabled

2-8 I/F pin 25 reset sig na l Enabled Disabled

42/35 40/33

CAUTION:

Do not change the settings of switches 2-2, 2-3, 2-5, and 2-6.

Changing these settings may cause inferior print quality.

Model with Parallel Interface DIP-Switch Functions

DIP Switch Set 1

Switch Function ON OFF

1-1 Auto-line feed Enabled Disabled

1-2 Receive buffer

capacity

1-3 Undefined

40 bytes Approximately 1K

byte

Setting Up the Printer 1–23

Page 34

DIP Switch Set 1

Switch Function ON OFF

1-4 Undefined

1-5 Undefined

1-6 Undefined

1-7 Undefined

1-8 Handshaking

(BUSY condit io n)

Sets the printer to go

BUSY when the

receive buffer is full or

when reading data

Sets the printer to

go BUSY when it is

off line, the receive

buffer is full, or when

reading data

DIP Switch Set 2

Switch Function ON OFF

2-1 Print column selection

7 × 9 font/9 × 9 font

2-2 Internal use. Setting must not be changed. (Fixed to ON)

2-3 Internal use. Setting must not be changed. (Fixed to OFF)

2-4 Undefined

2-5 Internal use. Setting must not be changed. (Fixed to ON)

2-6 Internal use. Setting must not be changed. (Fixed to OFF)

2-7 Undefined

2-8 Internal use. Setting must not be changed. (Fixed to ON)

42/35 40/33

CAUTION:

Do not change the settings of switches 2-2, 2-3, 2-5, 2-6, and

2-8. Changing these settings may cause inferior print quality.

5. Replace the DIP switch cover and secure it with the screw.

Note:

DIP switch settings are effective only when the power is turned on

or the printer is reset with the interface connector.

1–24 Setting Up the Printer

Page 35

Using the Power Switch Cover

You can use the provided power switch cover to protect the p ower

switch from accidental or improper operation. Attach the cover as

shown in the illustration below.

You can turn the power on or off with the switch cover attached by

inserting a pointed object (like a ball point pen) through either of

the two small holes on the switch cover.

WARNING:

If an accident occurs when the power switch cover is

attached, unplug th e power supply cord from th e outlet

immediately.

Setting Up the Printer 1–25

Page 36

Affixing the Fastening Tape (Option)

Two sets of tape are included as an option to fasten your printer to

a countertop or other surface. Follow the steps below:

1. Clean the countertop or other surface where the printer will be

installed.

2. Peel the green backing paper off of one side of each of the two

sets of tape and affix them to the bottom of the printer, as

shown below.

3. Peel the green backing paper off of the other side of the tape.

4. Press the printer onto the counte rtop; it will be held firmly in

place by the fastening tape.

1–26 Setting Up the Printer

Page 37

Chapter 2

Using the Printer

Operating the Control Panel

You can feed paper with the button on the control panel. The

indicator lig hts help you monitor the printer’s status.

Switch

The power switch on the front of the printer turns the printer on

and off.

Button

FEED

Press the

also hold down

FEED

button once to advance roll paper one line. You can

FEED

to feed the paper continuously.

Note:

This button can be disabled by the ESC c 5 command, but depending

on the setting of GS z 0 command, it can work while replacing the

paper roll even if it has been disabled.

Using the Printer 2-1

Page 38

Indicator lights

The control panel lights provide information on printer conditions.

POWER

(Green)

POWER

The

light is on wh en printer power is on.

PAPER OUT (Red)

This light is on when the paper roll is at the end or near the end.

This light blinks in the following cases. When it blinks, press the

FEED

button.

In the self-tes t standby mode

❏

Note:

The paper near-end detector is an option.

ERROR (Red)

This light is on when the printer is off line. It blinks to indicate an

error condition.

The blinking pattern shown below indicates that the temperature

of the print hea d is too high. The printer rec overs automatically

and resumes printing when the head cools.

Approximately 160 ms

If the printer sto ps working and the

the printer off, check for jammed paper, and remove it by following

the instructions on page 3-3, if necessary. Then turn the printer

back on. If the printer s till does no t work, unplug the p ower supply

cord from the outlet immediately; then contact a qualified service

person.

2-2 Using the Printer

ERROR

light is blinking, turn

Page 39

CAUTION:

The print head becomes very hot during printing. Allow it to

cool before you reach into the printer.

Note:

The power switch and FEED button can also be used to start the

self test.

Using the Printer 2-3

Page 40

Chapter 3

Troubleshooting

Troubleshooting

This chapter gives solutions to some of the more common printer

problems.

General problems

The lights on the control panel do not come on.

Make sure the power supply cables are correctly plugged into the

printer, the AC adapter, and to the po wer outlet.

Make sure power is supplied to the power outlet. If the outlet is

controlled by a switch or timer, use another outlet.

Printing problems

ERROR

The

light is blinking and the printer does not print.

First, turn off the printer and check for a paper jam. (See the paper

jam description on page 3-3.)

If there is no paper jam and the printer has been printing for quite a

while, the print head may be overheated. If the print head is

overheated, the printer will resume printing when the head has

cooled (usually within two or three m inutes).

If there is no paper jam and the print head is not overheated, turn

off the printer and turn it back on after about 10 seconds. If the

printer still does not wor k, unplug the power suppl y cord from the

outlet immediately. Then contact a qualified service person.

Troubleshooting 3-1

Page 41

ERROR

The

The printer sounds like it is printin g, but nothing is printed.

light is off, but nothing is printed .

Try to run the self test to check that the printer works pro perly . See

the self test instructions in Chapter 1 to run the self test. If the self

test does not work, contact your dealer or a qualified service

person.

If the self test works properly, check the following:

1. Check the connection at both ends of the interface cable

between the printer and the computer. Also make sure this

cable meets the specifications for both the printer and the

computer.

2. The data transmission settings may be different between the

printer and co mputer. Make sure the printe r’s DIP switch

settings for data transmission are the same as the computer’s.

You can print the printer’s interface settin gs using the self test.

If the printer still does not print, contact your dealer or a qualified

service person.

The ribbon cassette may not be installed properly. See the

instructions in Chapter 1.

The ribbon may be worn out. Replace the ribbon cassette as

described in Chapter 1.

If the printer still does not print, contact your dealer or a qualified

service person.

The printout is faint.

The ribbon may be worn out. Replace the ribbon cassette as

described in Chapter 1.

3-2 Troubleshooting

Page 42

A line of dots is missing in the printout.

The print head may be damaged. Stop printing and contact your

dealer or a qualified service person.

Removing jammed paper

Follow these steps to clear a paper jam:

CAUTION:

The print head becomes very hot during printing. Allow it to

cool before you reach into the printer.

1. Open the printer cover.

2. Cut the journal and receipt paper as shown in the illustration

below.

Cut here

Troubleshooting 3-3

Page 43

3. Remove the paper roll from the printer.

4. Open the auto cutter by pulling the tab up and toward you.

5. Remove the jammed paper by pulling it in the direction of

paper feeding.

Note:

Do not pull the jammed paper in the opposite direction of paper

feeding.

6. If paper sti ll remains in the printer, follow the steps below.

7. Remove the ribbon cassette.

3-4 Troubleshooting

Page 44

8. Loosen the screw securing the print head cover. Turn the screw

only until you can tilt it as shown in the illustration.

Note:

Do not remove the screw from the print head cover.

Troubleshooting 3-5

Page 45

9. Lift up the print head cover.

10. Remove all the jammed paper.

Note:

Do not pull the jammed paper in the opposite direction of paper

feeding.

11. Replace the print head cover and secure it with the screw.

12. Replace the ribbon cassette and close the auto cutter.

3-6 Troubleshooting

Page 46

13. If the auto cutter blade is not in its normal position (if you can

see the blade in the auto cutter slit, the blade is not in the

normal position), insert a screwdriver to the right side of the

auto cutter and turn the gear inside to move the blade to the

normal position.

Slit

14. Replace the paper roll and close the printer cover.

Hexadecimal Dump

This feature allows experienced users to see exactly what data is

coming to the printer. This can be useful in finding software

problems. When you turn on the hex dump function, the printer

prints all commands and other data in hexadecimal format along

with a guide section to help you find specific commands.

Troubleshooting 3-7

Page 47

To use the hex dump feature, follow these steps:

1. After you make sure that t he print er is off, set DI P switch 1- 2 to

ON

.

2. Turn on the printer while you hold down the

release and press the

Note:

Releasing and pressing the FEED button should be performed

before the printer finishes initializing; otherwise the printer

begins the self test.

3. When the printer enters the hex dump mode, it prints

“Hexadecimal Dump.”

4. Run any software program that sends data to the printer. The

printer prints all the codes it receives in a two-column format.

The first column contains the hexadecimal codes and the

second column gives the ASCII characters that correspond to

the codes.

Hexadecimal Dump

1B 21 00 1B 26 02 40 40 : . ! . . & . @ @

1B 25 01 1B 63 34 00 1B : . % . . c4 . .

41 42 43 44 45 46 47 48 : ABCDEFGH

A period (.) is printed for each code that has no ASCII

❏

equivalent.

FEED

button quick ly.

FEED

button; then

During the hex dump all commands except

❏

DLE ENQ

5. When the printing finishes, turn off the printer or reset it to

turn off the hex dump mode.

6. If you changed the DIP switch 1-2, set it back to

3-8 Troubleshooting

are disabled.

DLE EOT

OFF

.

and

Page 48

Chapter 4

Reference Info rm ation

Printing Specifications

Printing method:

Head wire

configuration:

Printing direction:

Characters/line

(default):

Character spacing

(default)

Fonts A and B:

Printing speed:

Note:

When printing exceeds the allowable print duty cycle, the printer

automatically stops printing. In this case, the printing speed

described above is not guaranteed.

Serial impact dot-matrix

9-pin serial configuration

Bi-directional, logic-seeking

See table on page 4-2.

See table on page 4-2.

Approximately 3.5 lines/second (40

columns, 16 characters/inch)

Approximately 6.4 lines/second (16

columns, 16 characters/inch)

(excluding data transmission time and

processing time)

When selecting red-color or 2-color (black/red) combination

printing, the printing speed goes down, compared to black-color

printing. It is caused by the switching operation in the printer.

Reference Information 4-1

Page 49

Character Specifications

Number of

characters:

Alphanumeric characters: 95

Extended graphics: 128 x 5 pages,

Internati onal characters: 32

Character structure:

7 x 9 (the total number of dots in

horizontal: 400 in half dot units)

9 x 9 (the total number of dots in

horizontal: 400 in half dot units)

Character size:

See table below.

Character Sizes, Character Spacing, Character Columns

Character structure

W x H

(mm)

7 x 9

9 x 9

7 x 9

9 x 9

Character

ANK 1.2 x 3.1 3 half dots 40 16

Graphics 1.7 x 3.1 0 40 16

ANK 1.6 x 3.1 3 half dots 33 13.3

Graphics 2.0 x 3.1 0 33 13.3

ANK 1.2 x 3.1 2 half dots 42 17.8

Graphics 1.6 x 3.1 0 42 17.8

ANK 1.6 x 3.1 2 half dots 35 14.5

Graphics 1.9 x 3.1 0 35 14.5

Character size

W x H (mm)

Character

spacing

Dot space

CPL

CPI

CPL = Characters per line

CPI = Characters per inch

LPS = Lines per second

ANK = Alphanumeric characters

Note:

• The default is

dot units and 2-dot spacing in half dot units depend on the DIP switch setting.

7 x 9 font. The dot spacing between characters for 3-dot spacing in half

4-2 Reference Information

Page 50

Paper Specifications

Paper feed method:

Paper feed pitch:

Friction feed

Default 4.233 mm (1/6 inch)

Can be set in units of 0.176 mm (1/144

inch) by the

ESC 2

and

ESC 3

commands.

Paper feed speed:

Approximately 25 lines/second (4.17

inches/second) (continuous feeding)

Paper size and weight: Normal paper (single-ply)

Size: Width 76 mm ± 0.5 mm

(3.0" ± 0.02")

Maximum

83 mm (3.27")

outside

diameter:

Core: Paper rolls that have the

paper glued or taped to

the core can cause a paper

jam. If you use a paper

roll with the pa per glued

or taped to the core, be

sure to use the optional

near end detector.

Thickness: 0.06 to 0.085 mm (.0024 to

.0033")

2

Weight: 52.3 to 64.0 g/m

(13.9 to

17 lbs) (45 to 55 Kg (20.41

to 24.94 lbs)/1000 sheets/

1091 mm ✕ 788mm

(43.00" ✕ 31.02")

Reference Information 4-3

Page 51

Pressure sensitive paper

Maximum 1 original + 1 copy

Size: Width 76 mm ± 0.5 mm

(3.0" ± 0.02")

Maximum

83 mm (3.27")

outside

diameter:

Thickness: 0.05 to 0.08 mm (.0020 to

.0031")

(Total thickness should

be a 0.2 mm or less

combination of 0.05 to

0.08 mm sheet.)

Recommend

-ed paper:

MITSUBISHI PAPER

MILLS, LTD.

Non-carbon paper

(blue color)

Top and middle sheets:

N40

(thickness: 0.06 mm,

2

weight: 47.2 g/m

)

Bottom sheet: N60

(thickness: 0.08 mm,

2

weight: 68.0 g/m

)

4-4 Reference Information

Page 52

Electrical Specifications

Packaged AC adapter: One of the followi ng 5 AC adapter s is

selected, depending on local power:

Factory setting Voltage Manufacturer’s Number

Japan 100 V ± 10 %, 50/60Hz PA-6508

North America 120 V ± 10 %, 60 Hz PB-6509

Europe (Germany) 230 V ± 10 %, 50 Hz PB-6510

Europe (England) 230 V ± 10 %, 50 Hz PA-6511

Australia 240 V ± 10 %, 50 Hz PA-6513

Note:

The power supply may not be included with the printer with

serial interface.

Voltage output range 24 - 30 V at 1.2 A

Current consumption Operating : Average 43 W

(excluding driving

drawer kickout) Standby: Average 6 W

Safety and EMI Standards Applied

(EMC is measured using Seiko Epson’s AC adapter provided with the

printer)

Europe: CE marking:

EN55022

EN50082-1

EN45501

Safety standard:

TÜV

North America: EMI:

FCC class A

Safety standard:

UL1950-2TH-D3

C-UL

Reference Information 4-5

Page 53

Reliability

Life: Mechanism 7,500,000 lines

Print head: 150 million characters

(at an average of 2 dots/wire per

character.)

Auto cutter: 800,000 cuts

End of life is defined as the point at

which the printer reaches the

beginning of the Wearout Period.

Recommended paper must be used.

MTBF: 180,000 hours

Failure is defined as Random failure

occurring at the time of the Random

Failure Period.

MCBF: 18 ,000,000 lines

This is an average failure interval

based on failures relating to wearout

and random failures up to the life of

7.5 million lines.

4-6 Reference Information

Page 54

Environmental Conditions

Temperature

Operating:

Storage:

Humidity

Operating:

Storage:

90

80

60

0 to 50° C (32 to 122° F)

(when the temperature is 34° C or more,

there is a limitation for the humidity.

Refer to the figure in the next page.)

–10 to 50° C (14 to 122° F)

(except for paper, and a ribbon)

10 to 90% RH

10 to 90% RH

(except for paper a nd a ribbon)

Operating environment range

34° C, 90%

40° C, 65%

40

Relative humidity

20

10

0

0

10

20

40

30

Environment temperature [° C]

50° C, 35%

50

Reference Information 4-7

Page 55

Interfa ce Specifications

Serial interface:

Parallel interface:

RS-232 compatible or RS-485 compatible

IEEE 1284 compatible (Nibble/Byte

Modes)

Note:

The interface is a factory-installed option. One of the following

interfaces is already installed: RS-232, RS-485, or parallel.

See the EPSON TM-U200 Series (Type A) Specification for details.

Drawer Kick-out Specifications

‚P

‚U

Pin No. Signal Name Direction

1Frame GND —

2 Drawer kick-out drive signal 1 Output

3 Drawer op en /clo se sig na l Input

4 +24 V —

5 Drawer kick-out drive signal 2 Output

6 Sig nal GND —

Output signal voltage:

Output current:

Solenoid resistance:

4-8 Reference Information

Approximately 24 V

1 A or less

24 Ω or more

Loading...

Loading...