Technical Reference Guide

Describes features for this product.

Describes the printer functions and setting methods.

Describes the pre-installed Widows settings and specications.

Describes the requirements for system development

using TM-DT software.

Describes the PC-POS System interface, the control method

for devices, and system development using the Thin-Client

environment.

Describes this product's specications.

Product Overview

Printer Functions and Settings

Windows Settings

System Development Using TM-DT Software

PC-POS System Development

Product Specifications

M00060306

Rev. G

Cautions

No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form or by

any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Seiko Epson Corporation.

The contents of this document are subject to change without notice. Please contact us for the latest informa-

tion.

While every precaution has been taken in the preparation of this document, Seiko Epson Corporation

assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained herein.

Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third

parties for damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of:

accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this

product, or (excluding the U.S.) failure to strictly comply with Seiko Epson Corporation’s operating and

maintenance instructions.

Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of any

options or any consumable products other than those specified as Original Epson Products or Epson

Approved Products by Seiko Epson Corporation.

Trademarks

EPSON is a registered trademark of Seiko Epson Corporation.

Exceed Your Vision and ESC/POS are registered trademarks or trademarks of Seiko Epson Corporation.

Microsoft and Windows are registered trademarks of Microsoft Corporation.

®

Intel

, Intel® AtomTM are registered trademarks or trademarks of Intel Corporation in United States of America

and other countries/regions.

®

IOS

is a trademark or registered trademark of Cisco in the U.S. and other countries and is used under license.

Android

Wi-Fi

ica and other countries/regions.

All other trademarks are the property of their respective owners and used for identification purpose only.

TM

is trademark of Google Inc. in the United States and other countries.

®

, WPATM, WPA2TM are registered trademarks or trademarks of Wi-Fi Alliance in United States of Amer-

ESC/POS Proprietary Command System

Epson took the initiative by introducing ESC/POS, a proprietary POS printer command system, which includes

patented or patent pending commands and enables versatile POS system construction with high scalability.

Compatible with all types of Epson POS printers and displays, this proprietary control system also offers the

flexibility to easily make future upgrades. Its popularity is worldwide.

ESC/POS is designed to reduce the processing load on the host computer in POS environments. It comprises a

set of highly functional and efficient commands that enables the full realization of the potential of printers.

©Seiko Epson Corporation 2013-2017. All rights reserved.

2

For Safety

Key to Symbols

The symbols in this manual are identified by their level of importance, as defined below. Read the following

carefully before handling the product.

You must follow warnings carefully to avoid serious bodily injury.

WARNING

Provides information that must be observed to prevent damage to the equipment or loss of data.

Possibility of sustaining physical injuries.

CAUTION

Possibility of causing physical damage.

Possibility of causing information loss.

Provides information that must be observed to avoid damage to your equipment or a

malfunction.

Provides important information and useful tips.

3

Warnings

WARNING

To avoid risk of electric shock, do not set up this product or handle cables during a thunder-

storm.

Never insert or disconnect the power plug with wet hands.

Doing so may result in severe shock.

Handle the power cable with care.

Improper handling may lead to fire or electric shock.

Do not modify or attempt to repair the cable.

Do not place any heavy object on top of the cable.

Avoid excessive bending, twisting, and pulling.

Do not place the cable near heating equipment.

Check that the plug is clean before plugging it in.

Be sure to push the plug all the way in.

Be sure to use the specified power source.

Connection to an improper power source may cause fire or shock.

Do not place multiple loads on the power outlet.

Overloading the outlet may lead to fire or shock.

Shut down your equipment immediately if it produces smoke, a strange odor, or unusual

noise.

Continued use may lead to fire. Immediately unplug the equipment and contact your dealer

or a Seiko Epson service center for advice.

Never attempt to repair this product yourself.

Improper repair work can be dangerous.

Never disassemble or modify this product.

Tampering with this product may result in injury or fire.

Do not allow foreign matter to fall into the equipment.

Penetration by foreign objects may lead to fire.

If water or other liquid spills into this equipment, do not continue to use it.

Continued use may lead to fire. Unplug the power cord immediately and contact your dealer

or a Seiko Epson service center for advice.

Do not use aerosol sprayers containing flammable gas inside or around this product.

Doing so may cause fire.

4

Cautions

CAUTION

Do not connect cables in ways other than those mentioned in this manual.

Different connections may cause equipment damage or fire.

Be sure to set this equipment on a firm, stable, horizontal surface.

The product may break or cause injury if it falls.

Do not use this product in locations subject to high humidity or dust levels.

Excessive humidity and dust may cause equipment damage or fire.

Do not place heavy objects on top of this product. Never stand or lean on this product.

Equipment may fall or collapse, causing breakage and possible injury.

Take care not to injure your fingers on the manual cutter

Do not open the roll paper cover without taking the necessary precautions, as this can result

in injury from the autocutter fixed blade.

To ensure safety, unplug this product before leaving it unused for an extended period.

To power off the product, use the application or OS function.

Do not use the operations shown below unless the product cannot be turned off due to an

application or OS problem. Doing so may cause loss of unsaved data, require OS recovery, or

damage the HDD, SSD or other hardware.

Forced termination by holding down the power button for approx. 4 sec.

Power shutdown by turning off the circuit breaker on the distribution board or by discon-

necting the AC cable/DC cable.

The same phenomenon may also occur due to power shutdown caused by power failure/temporary power failure.

To prevent power shutdown due to power failure/temporary power failure, using an uninterruptible power supply (UPS) is recommended.

Restriction of Use

When this product is used for applications requiring high reliability/safety, such as transportation devices

related to aviation, rail, marine, automotive, etc.; disaster prevention devices; various safety devices, etc.; or

functional/precision devices, etc., you should use this product only after giving consideration to including failsafes and redundancies into your design to maintain safety and total system reliability. Because this product was

not intended for use in applications requiring extremely high reliability/safety, such as aerospace equipment,

main communication equipment, nuclear power control equipment, or medical equipment related to direct

medical care, etc., please make your own judgment on this product's suitability after a full evaluation.

5

Contents

■ For Safety..................................................................................................................................3

Key to Symbols.................................................................................................................................................................... 3

Warnings ............................................................................................................................................................................... 4

Cautions................................................................................................................................................................................. 5

■ Restriction of Use....................................................................................................................5

■ Contents....................................................................................................................................6

Product Overview ..........................................................................................11

■ Features ................................................................................................................................. 11

■ System Outline ..................................................................................................................... 13

PC-POS system ..................................................................................................................................................................13

Thin-Client system ...........................................................................................................................................................14

Systems that Use TM-DT software..............................................................................................................................15

■ Development Information ................................................................................................. 16

Common to All Systems.................................................................................................................................................16

PC-POS system ..................................................................................................................................................................16

Thin-Client system ...........................................................................................................................................................17

Systems that Use TM-DT software..............................................................................................................................18

Printer Functions and Settings.....................................................................19

■ Part Names and Functions ................................................................................................. 19

Main Unit Front .................................................................................................................................................................19

Product Rear.......................................................................................................................................................................24

■ Installing the Product..........................................................................................................26

Security Hook ....................................................................................................................................................................26

■ Connecting the AC Adapter ............................................................................................... 27

■ Turning Power On and Off.................................................................................................. 29

Turning Power On............................................................................................................................................................29

Turning Power On for the First Time..........................................................................................................................29

Turning Power Off............................................................................................................................................................29

Power Button Settings....................................................................................................................................................30

Prevention of Accidental Operation of Power Button ........................................................................................30

Forced Termination..........................................................................................................................................................30

6

■ Online and Offline................................................................................................................ 31

Online ...................................................................................................................................................................................31

Offline...................................................................................................................................................................................31

■ Handling the Roll Paper...................................................................................................... 32

Changing the Paper Width ...........................................................................................................................................32

Installing and Replacing Roll Paper ...........................................................................................................................34

Removing Jammed Paper .............................................................................................................................................36

Adjusting the Roll Paper Near-End ............................................................................................................................38

■ Attaching and Setting Peripherals.................................................................................... 39

Keyboard / Mouse............................................................................................................................................................39

Display..................................................................................................................................................................................39

USB Interface Printer .......................................................................................................................................................40

Network Printer.................................................................................................................................................................40

Customer Display .............................................................................................................................................................40

Cash Drawer .......................................................................................................................................................................42

Key Input Device ..............................................................................................................................................................44

Serial Communication Device .....................................................................................................................................44

Powered USB Hub Unit ..................................................................................................................................................44

■ Network Settings ................................................................................................................. 45

Connect to Wired LAN....................................................................................................................................................45

Connect to Wireless LAN ...............................................................................................................................................46

■ Attaching Accessories ......................................................................................................... 48

Power Button Cover ........................................................................................................................................................48

Connector Cover...............................................................................................................................................................49

Affixing Tape (Optional).................................................................................................................................................51

■ Cleaning................................................................................................................................. 52

Thermal Head ....................................................................................................................................................................52

Case.......................................................................................................................................................................................52

■ Preparing for Transport....................................................................................................... 53

■ Setting the Memory Switches............................................................................................ 54

Functions.............................................................................................................................................................................55

■ Printer Setting / Checking Modes..................................................................................... 57

Self-test mode ...................................................................................................................................................................58

NV Graphics Information Print Mode........................................................................................................................59

Receipt Enhancement Information Print Mode ....................................................................................................60

Software Setting Mode ..................................................................................................................................................61

Hexadecimal Dumping Mode .....................................................................................................................................62

7

Windows Settings ..........................................................................................63

■ Windows Embedded POSReady 7..................................................................................... 63

Windows Initial Settings ................................................................................................................................................63

Starting Up and Shutting Down Windows..............................................................................................................63

Enabling or Disabling ePOS-Device ..........................................................................................................................64

Speaker Volume Setting ................................................................................................................................................64

Windows Hibernation.....................................................................................................................................................65

Windows Recovery ..........................................................................................................................................................67

Specification ......................................................................................................................................................................68

■ Windows Embedded POSReady 2009.............................................................................. 69

Windows Initial Settings ................................................................................................................................................69

Starting Up and Shutting Down Windows..............................................................................................................69

Enabling or Disabling ePOS-Device ..........................................................................................................................70

Speaker Volume Setting ................................................................................................................................................70

Windows Recovery ..........................................................................................................................................................71

Specification ......................................................................................................................................................................72

System Development Using TM-DT Software.............................................73

■ Systems that Use TM-DT software .................................................................................... 73

Network Printer Control.................................................................................................................................................73

Controlling for POS Peripherals ..................................................................................................................................74

Spooler and Forward Printing .....................................................................................................................................76

Software Access Point ....................................................................................................................................................82

Communication Box .......................................................................................................................................................83

Server Direct Print ............................................................................................................................................................85

Device Data Notification................................................................................................................................................87

Web Server .........................................................................................................................................................................89

Method Used to Set multiple TM-DT devices ........................................................................................................91

Controlling POS Peripherals from Smart Devices.................................................................................................93

Controlling POS Peripherals from Web Applications ..........................................................................................94

Printing from Web Service Compatible Applications..........................................................................................95

Controlling POS Peripherals from Socket Communication Compatible Applications............................96

■ TM-DT Software Settings.................................................................................................... 97

Starting EPSON TMNet WebConfig............................................................................................................................97

Help Screen Display.........................................................................................................................................................98

Version Screen Display ...................................................................................................................................................98

Updating TM-DT Software ............................................................................................................................................98

Information - Current status.........................................................................................................................................99

Information - System settings - Network.............................................................................................................. 100

Information - System settings - Date and Time.................................................................................................. 101

Settings - Web service settings - Startup settings.............................................................................................101

Settings - Web service settings - Printer ............................................................................................................... 102

Settings - Web service settings - Customer Display......................................................................................... 103

Settings - Web service settings - Key input device............................................................................................ 104

Settings - Web Service settings - Serial communication Device.................................................................. 105

Settings - Web Service settings - Other Device .................................................................................................. 106

8

Settings - Web service settings - Control script - Add/delete........................................................................ 106

Settings - Web service settings - Control program - Device registration.................................................. 107

Settings - Web service settings - Control program - Add/delete ................................................................. 107

Settings - Web service settings - Print Settings - Spooler ............................................................................... 108

Settings - Web Service settings - Web Content - Update settings............................................................... 109

Settings - Web service settings - Server access - Direct Print........................................................................ 110

Settings - Web Service settings - Server access - Status notification.......................................................... 111

Settings - Web Service settings - Server access - Device Data Notification ............................................. 112

Settings - System settings - Network - Wired LAN - TCP/IP ............................................................................ 113

Settings - System settings - Network - Wireless LAN........................................................................................114

Settings - System settings - Network - Wireless LAN - TCP/IP ....................................................................... 115

Settings - System settings - Security - SSL ........................................................................................................... 115

Settings - System settings - Web access - Proxy settings................................................................................ 116

Settings - System settings - Web access - Server authentication.................................................................116

Settings - System settings - Access Point - Software access point settings ............................................. 117

Settings - System settings - Date and time - Time settings............................................................................ 117

Settings - System settings - Power - Shutdown settings ................................................................................ 118

Settings - Admin settings - Maintenance - Store restore settings ............................................................... 118

Settings - Admin settings - Maintenance - Initialization................................................................................. 124

Settings - Admin settings - Maintenance - Log .................................................................................................. 124

Settings - Admin settings - Maintenance - Update Web service function................................................ 125

Settings - Admin settings - Maintenance - Deployment ................................................................................ 126

Settings - Admin settings - Admin information - Admin information ....................................................... 126

Settings - Admin settings - Admin information - Password........................................................................... 127

■ TM-DT Software Specification ......................................................................................... 128

Controllable printer......................................................................................................................................................128

Controllable customer display ................................................................................................................................. 129

PC-POS System Development.................................................................... 130

■ PC-POS System Development ......................................................................................... 130

Interface............................................................................................................................................................................ 130

■ How to Control Peripherals.............................................................................................. 131

Printer................................................................................................................................................................................ 131

Cash drawer..................................................................................................................................................................... 131

Customer display........................................................................................................................................................... 131

Other devices.................................................................................................................................................................. 131

■ Software and Manuals ...................................................................................................... 132

Development kit............................................................................................................................................................ 132

Driver ................................................................................................................................................................................. 132

Utility ................................................................................................................................................................................. 133

ESC/POS command reference .................................................................................................................................. 133

■ System Development using the Thin-Client Environment......................................... 134

Desktop Virtualization ................................................................................................................................................. 134

Application Virtualization........................................................................................................................................... 134

9

Product Specifications................................................................................ 135

■ Computer Specifications .................................................................................................. 135

N2600 CPU model.........................................................................................................................................................135

N2800 CPU model.........................................................................................................................................................137

D2550 CPU model.........................................................................................................................................................138

■ Printer Specifications ........................................................................................................ 139

Printing Specifications................................................................................................................................................. 139

Character Specifications ............................................................................................................................................. 140

Printable Area................................................................................................................................................................. 141

Printing and Cutting Positions ................................................................................................................................. 143

Roll Paper Specifications ............................................................................................................................................ 144

■ Power supply capacity for external devices.................................................................. 145

■ Environmental Conditions ............................................................................................... 145

■ External Dimensions ......................................................................................................... 146

■ AC Adapter Specifications ................................................................................................ 149

■ Option .................................................................................................................................. 149

■ Setting Items for Software Setting Mode...................................................................... 150

■ Character Code Tables....................................................................................................... 152

10

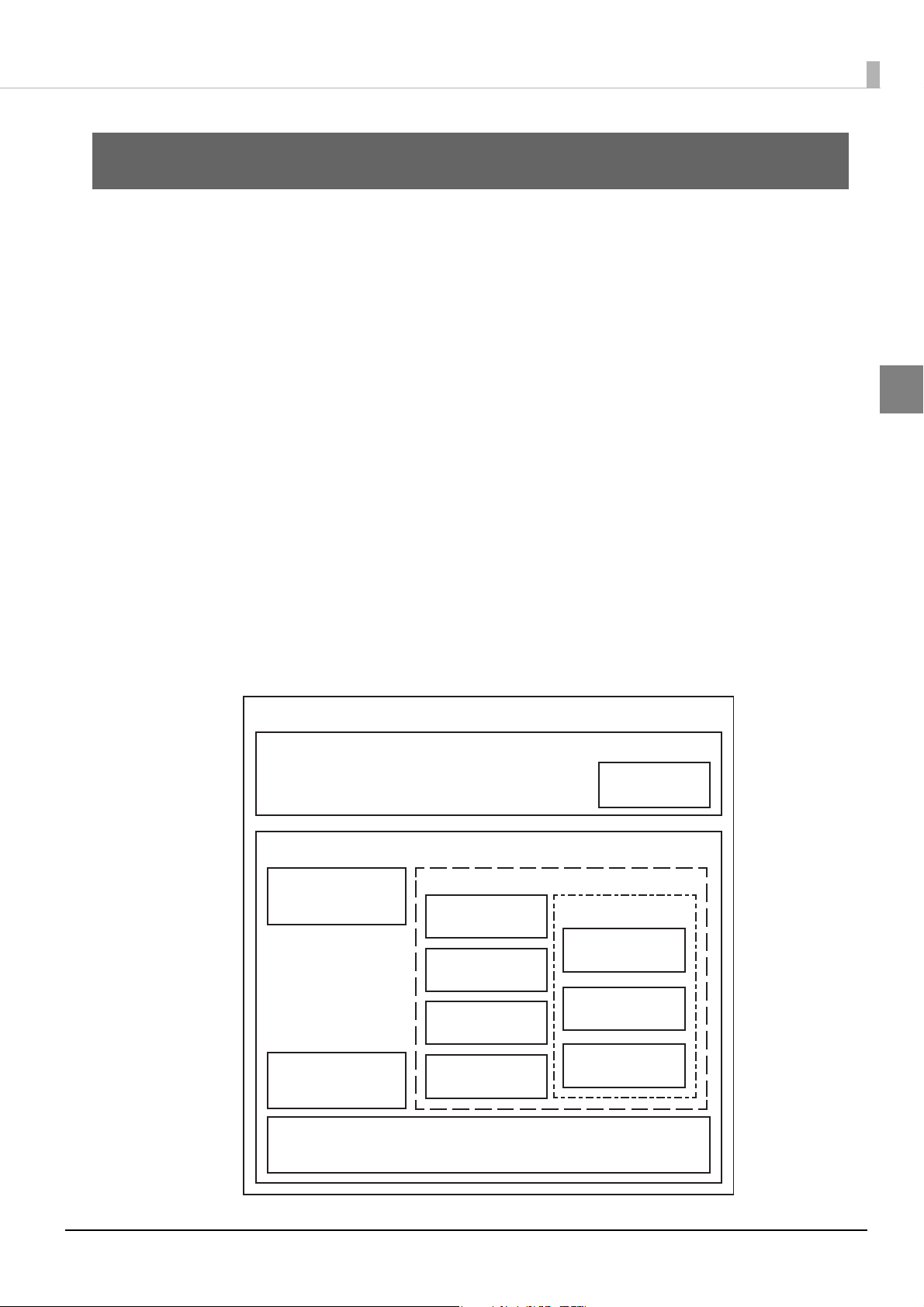

Chapter 1 Product Overview

TM-T88V-DT

TM-T88V (Printer)

Control

program

Software

TM-DT Software

Utility

EPSON TMNet

WebCong

Deployment

Server Direct

Print

ePOS-Print

Service

ePOS-Device

Service

Device Data

Notication

Windows OS

Printer driver

for Windows

Apache

HTTP Server

Easy Setup

Product Overview

This chapter describes features of this product.

Features

The TM-T88V-DT is a highly-functional receipt printer used in tandem with a Windows computer.

A number of modules that operate on Window can be used to configure an effective POS System.

TM-DT software

TM-DT software provides features for controlling the TM printer and POS peripherals from smart devices

and Web applications, and connecting with Web servers. There is also a feature for efficiently configuring the

TM-DT software and setting up the TM-DT.

TM-DT software may be subject to upgrading with additional or improved features. For details, see

Development Using TM-DT Software" on page 73

Windows printer driver

You can also conduct Windows POS application development using the Windows EPSON Advanced Printer

Driver or OPOS ADK, and system development utilizing existing Windows POS applications.

For details, see

"PC-POS System Development" on page 130.

.

1

"System

Apache HTTP Server

You can use this product as a Web server. You can execute Web applications for server-side scripting (Perl or

php). You can also use SQLite database.

For details, see

"Web Server" on page 89.

11

Chapter 1 Product Overview

The printer has the following features.

Space-saving design through integrating computer with printer.

*1

Interfaces for connecting with peripherals (USB x6, serial x1, DisplayPort x1

*2

Printing and control of peripherals from smart device applications

Server direct print function

The server direct print functions allows print data to be directly obtained and printing results to be notified

from the Web server.

1 Not equipped on all models.

2 TM-DT software Ver.3.0 or later.

or Web applications.

, VGA x1)

1

12

System Outline

Application

As shown below, you can configure various systems using this product.

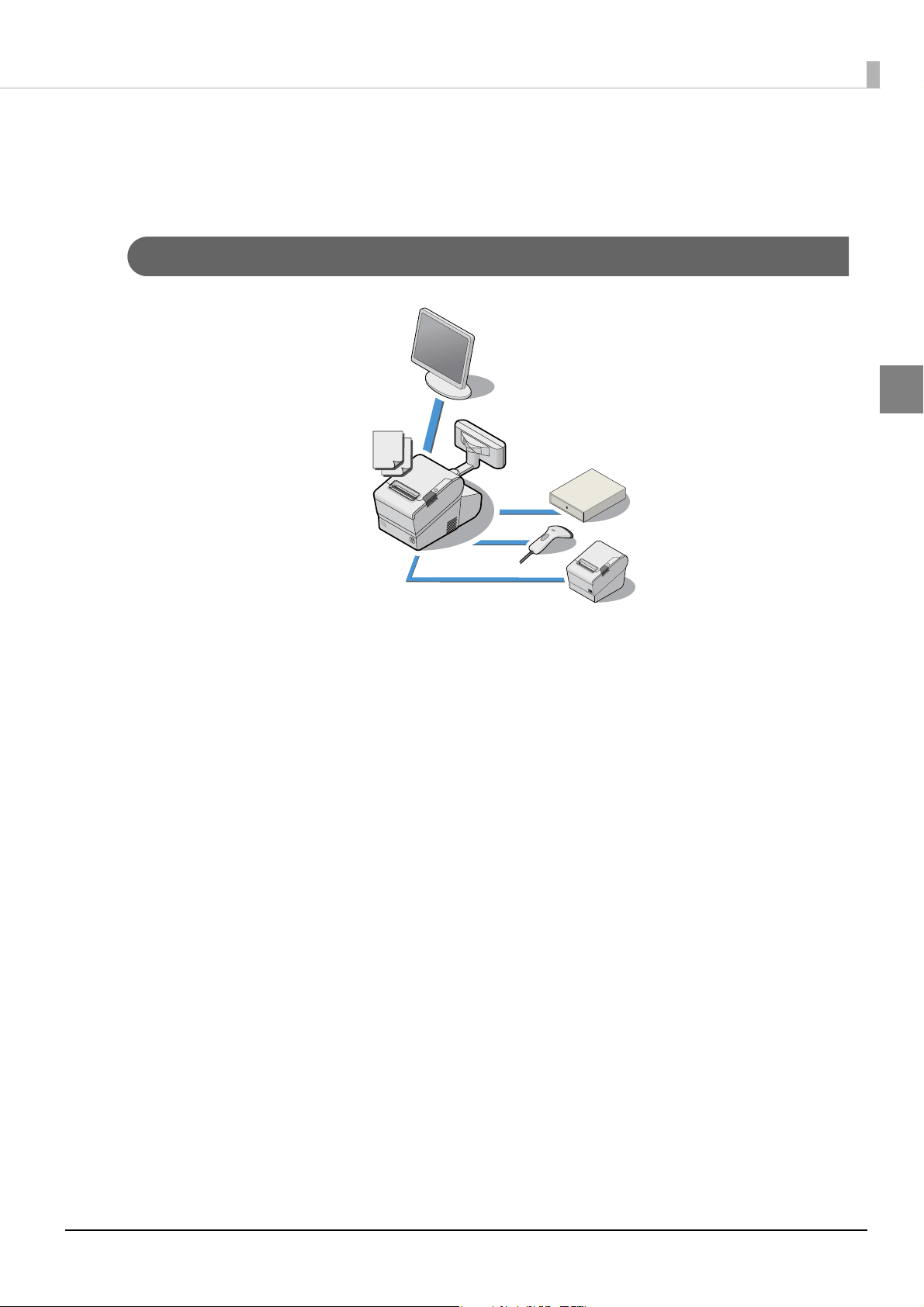

PC-POS system

Chapter 1 Product Overview

1

13

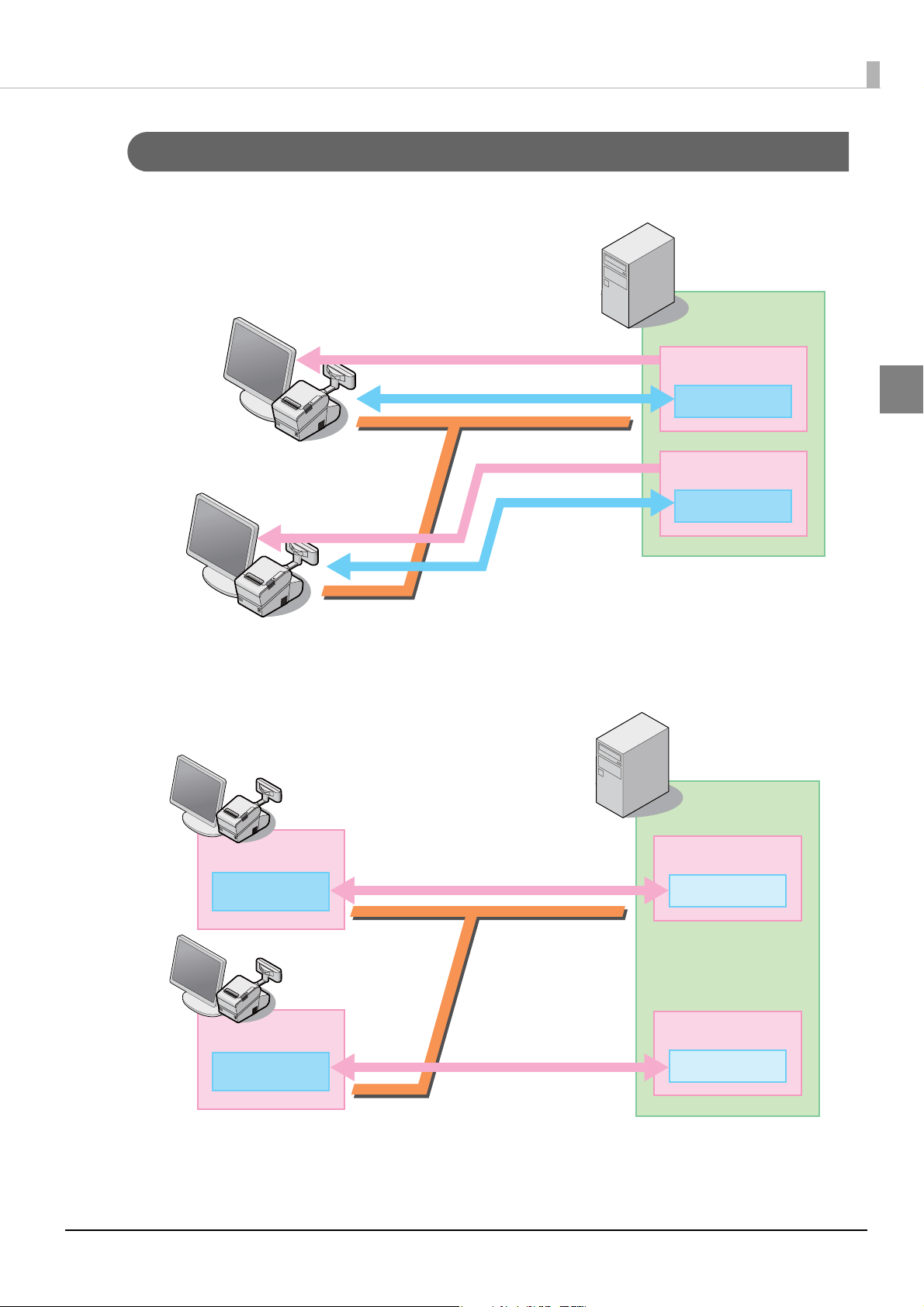

Thin-Client system

Application

Guest OS

Server

Display

Device control

Guest OS desktop

Application

Guest OS

Display

Device control

Guest OS desktop

Application

OS data

Server

Application

Client OS

Application

Client OS

Application

OS data

Virtual Desktop Infrastructure (VDI)

Chapter 1 Product Overview

1

Application virtualization system

14

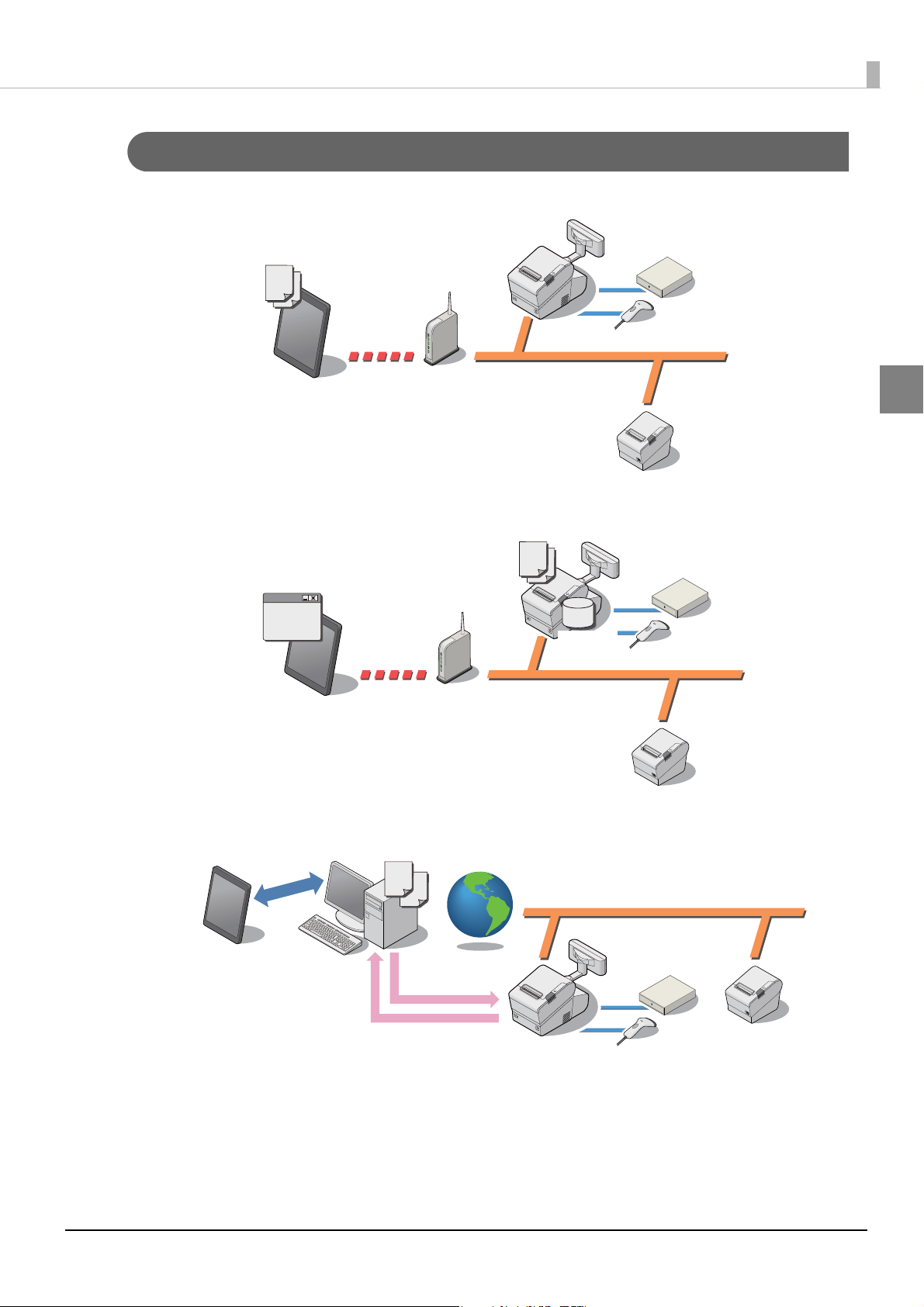

Chapter 1 Product Overview

Application

Application

Browser

Database

Application

Notice of

printing results

Acquisition of

print data

Systems that Use TM-DT software

Systems that implemented application in the smart device (TM-DT Software Ver.3.0 or later)

Web application system

1

Server Direct Print system

15

Chapter 1 Product Overview

Development Information

Development tools, drivers, related manuals, and utilities are provided for developing systems that make use of

this product. These can be obtained from the following URL.

For customers in North America, go to the following web site:

http://www.epson.com/support/ and follow the on-screen instructions.

For customers in other countries, go to the following web site:

https://download.epson-biz.com/?service=pos

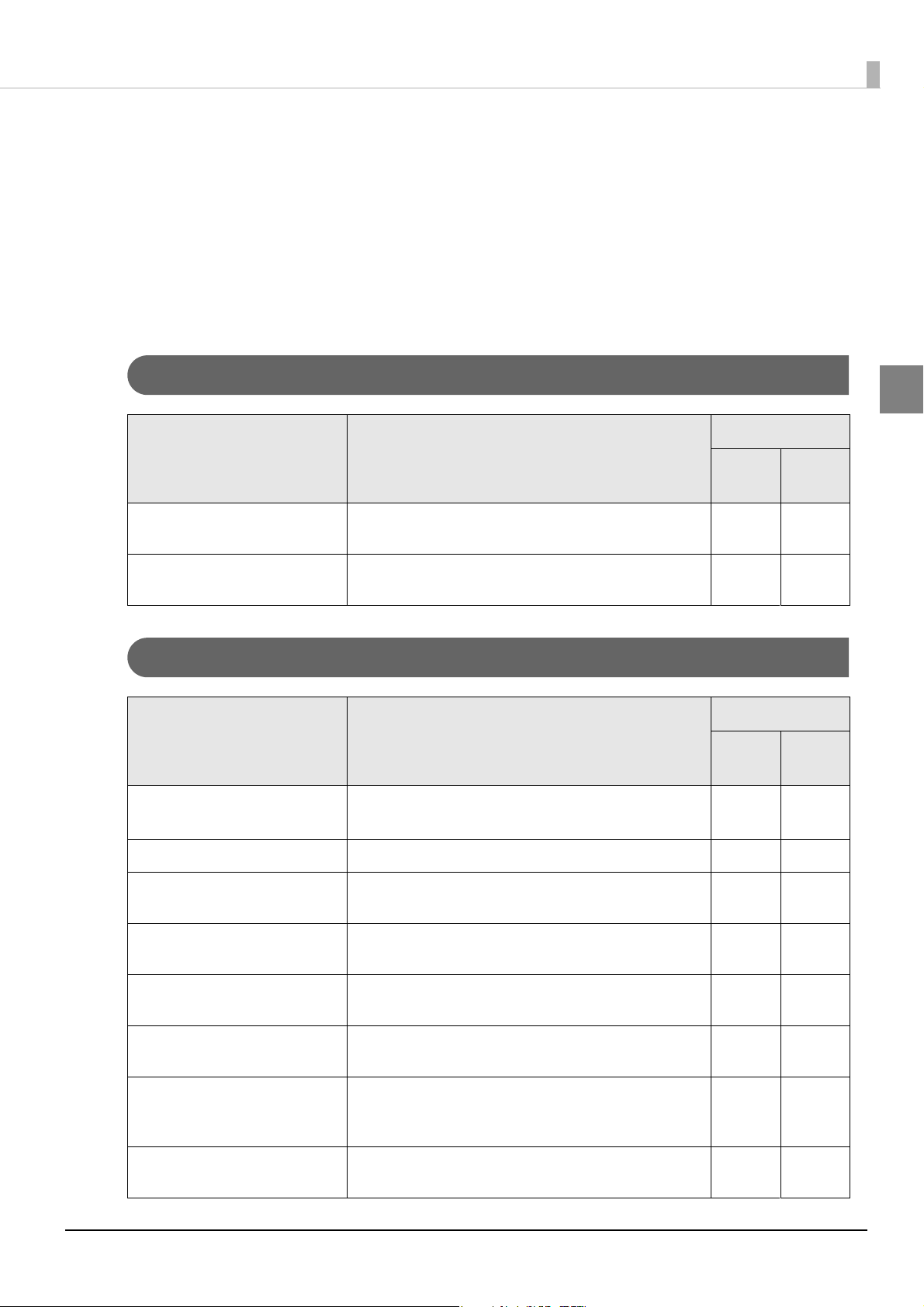

Common to All Systems

How to Obtain

1

Name Descriptions

TM-T88V-DT Technical Reference

Guide

TM-T88V Utility This utility is for confirming and changing printer settings. It

This document.

is already installed in this product.

Web

site

✔ -

✔ -

Other

PC-POS system

How to Obtain

Name Descriptions

EPSON Advanced Printer Driver

for TM-T88V

EPSON Advanced Printer Driver Windows printer driver for the TM printer. ✔ -

EPSON Advanced Printer Driver

for DM-D

Dedicated Windows printer driver for the TM-T88V.

This is already installed in this product.

Windows printer driver for the customer display.

Web

site

✔ -

✔ -

Other

EPSON OPOS ADK Driver with UPOS (UnifiedPOS) specifications for use with

Win32 API compatible applications.

EPSON OPOS for .NET Driver with UPOS (UnifiedPOS) specifications for use with

.Net compatible applications.

EPSON JavaPOS ADK Driver with UPOS (UnifiedPOS) specifications for use with

Java compatible applications.

ESC/POS Command Reference Provides ESC/POS for controlling the TM printer and the

customer display command detailed information, character

code table as a Web reference.

DM-D110/DM-D210 Technical

Reference Guide

Provides information necessary for system development

using the DM-D110 for TM-T88V-DT (customer display).

✔ -

✔ -

✔ -

Web

-

✔ -

Refer-

ence

16

Chapter 1 Product Overview

How to Obtain

Name Descriptions

DM-D30 Technical Reference

Guide

Provides information necessary for system development

using the DM-D30 (customer display).

Thin-Client system

Name Descriptions

TM-DT Thin-Client system Setup

Tool

IP Address Setting Tool Tool for setting the IP address of this product (client) from

Tool for assisting Thin-Client system construction.

the Thin-Client system server.

Web

site

✔ -

How to Obtain

Web

site

✔ -

✔ -

Other

Other

1

17

Systems that Use TM-DT software

Chapter 1 Product Overview

How to Obtain

Name Descriptions

Epson ePOS SDK Software development kit for controlling the printer and

for iOS

for Android

for Universal Windows apps

for JavaScript

TM-DT Series Peripheral Device

Control Guide

ePOS-Device XML User’s Manual Manual describing the method for transmitting XML data

ePOS-Print XML User’s Manual Manual describing the method for using Web services from

Server Direct Print User’s Manual Manual describing the method for developing systems

*1

*1

peripherals from Web applications and smart device applications.

*2

Manual describing the method for controlling peripherals

with TM-DT series printers.

It explains device control programs and scripts.

This manual is included in the Epson ePOS SDK package.

from applications via socket communication to control

printing and peripherals.

applications to conduct printing.

using server direct print.

Web

site

✔

✔ -

✔ -

✔ -

✔ -

Other

Web

Refer-

ence

1

Device Data Notification

User’s Manual

Deployment Guide

*2

*2

1 TM-DT Software Ver.2.5 or later

2 TM-DT Software Ver.3.0 or later

Manual describing the method for developing systems

using device data notification.

This guide includes the information needed to configure

settings for multiple products efficiently.

✔ -

✔ -

18

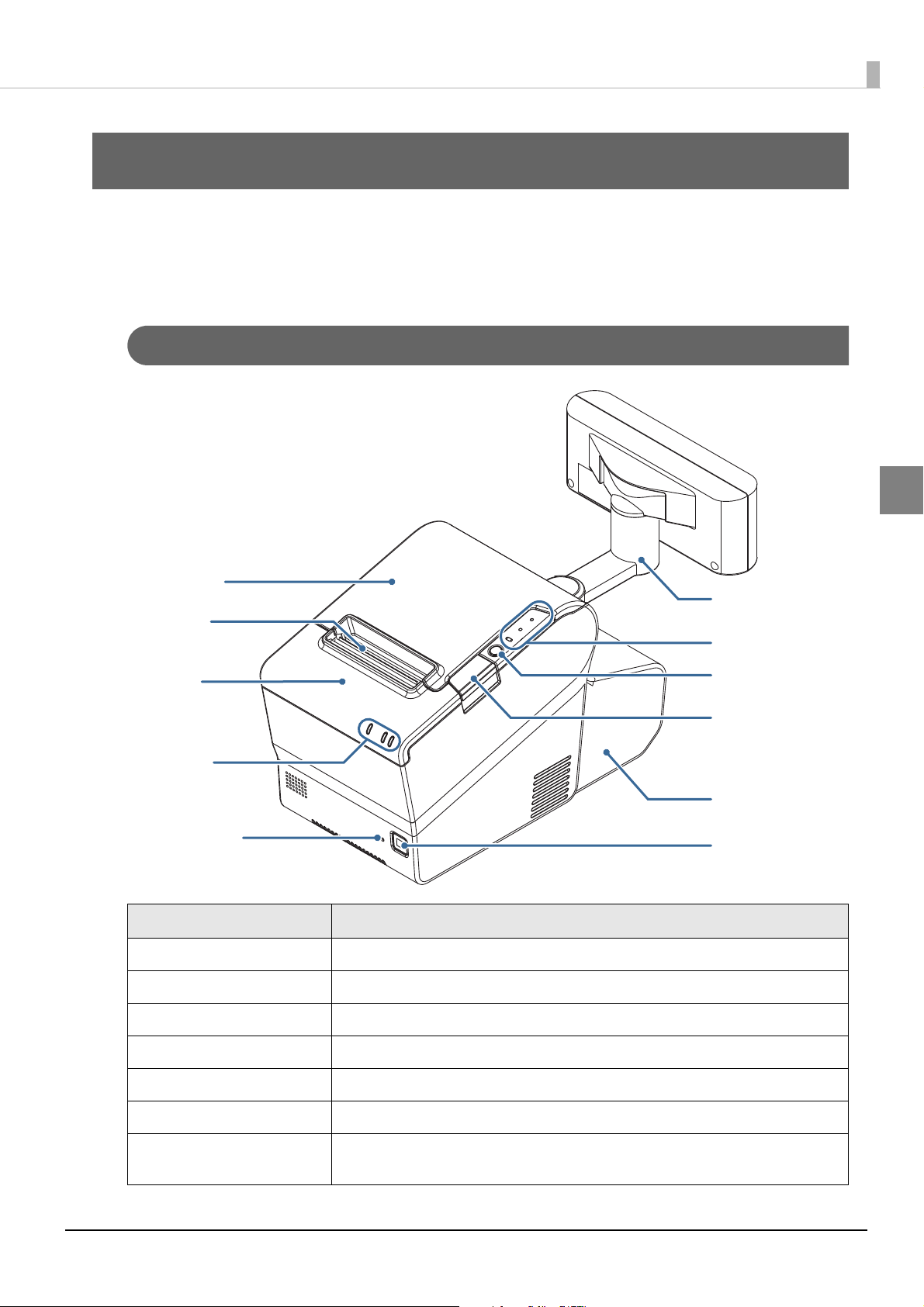

Chapter 2 Printer Functions and Settings

Roll paper cover

Manual cutter

Cutter cover

Controller LED

Printer reset button

Power button

Cover button

Feed button

Customer display

(option)

Connector cover

Printer LED

Printer Functions and Settings

This chapter describes the printer functions and setting methods.

Part Names and Functions

Main Unit Front

2

Name Description

Power button Turns this product power on or off.

Printer reset button Resets this product's printer. This product's computer is not reset.

Manual cutter A cutter for cutting the roll paper by hand.

Cover open button Opens the roll paper cover.

Cutter cover If there is a paper jam in the printer, open the cover and remove the paper.

Customer display (optional) Displays characters from applications.

Feed button Pressing this button once feeds the roll paper by one line.

Holding this button down feeds the roll paper continuously.

19

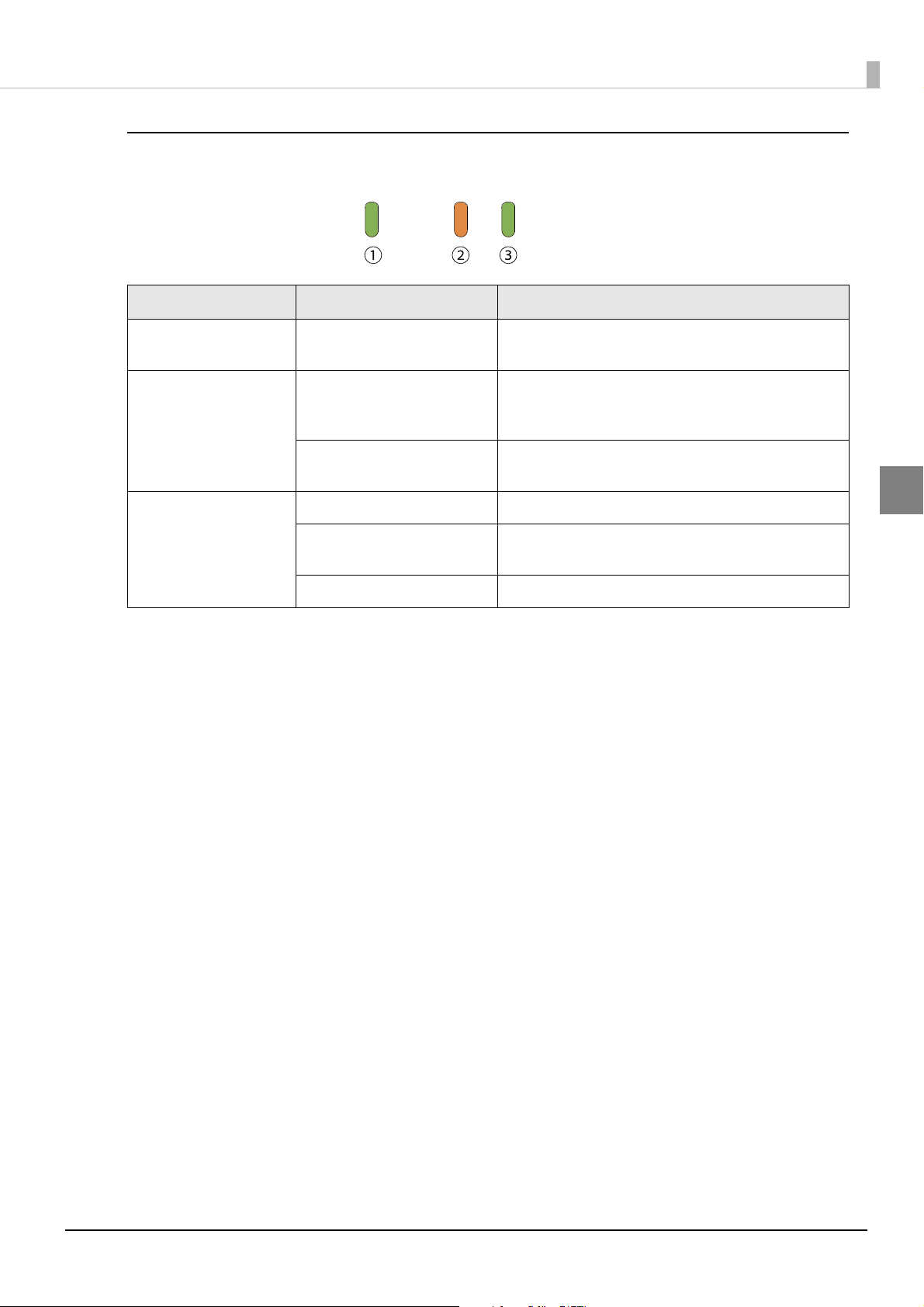

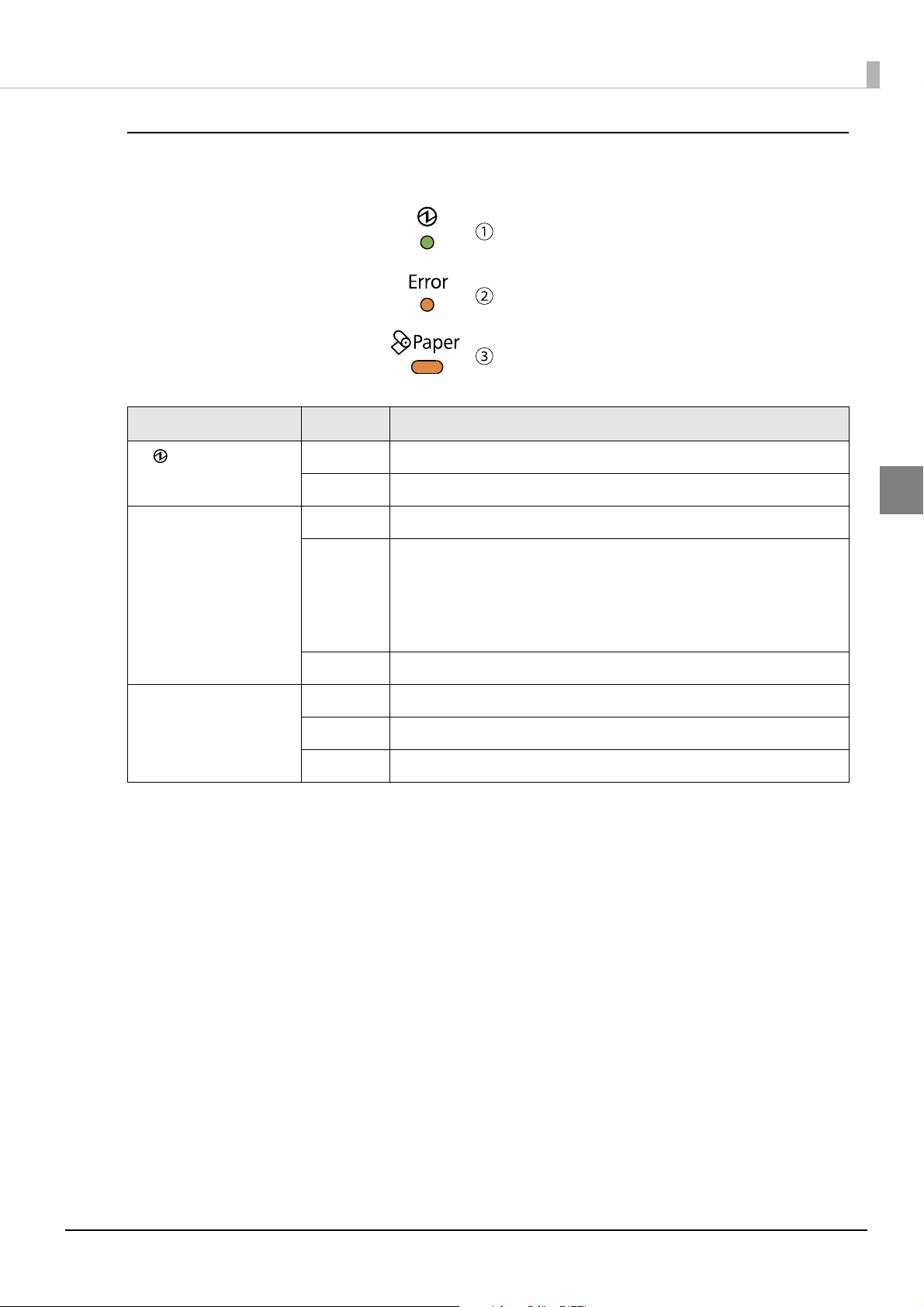

Controller LED

These display this product's computer status.

Name Status Description

Chapter 2 Printer Functions and Settings

(1) Storage Access LED

(Green)

(2) Status LED (Orange) Flashing

(3) Status LED (Green) On Windows in operation

On Accessing the storage

OS start sequence

(Approx. 1 second intervals)

Flashing (Approx. 160 millisecond intervals)

Flashing

(Approx. 1 second intervals)

Off Power off

(Accessing the storage device; Do not turn the power off.

Doing so may result in data loss.)

CPU high-temperature warning

(Failure has occurred. Please contact Epson.)

Standby or hibernate status

2

20

Printer LED

These display the printer status.

Name Status Description

(1) (Power) LED On Power is being supplied

Chapter 2 Printer Functions and Settings

Off Power is not being supplied

(2) Error LED Off Normal printing is possible (online).

On Printing is not possible. (For details, see

Immediately after power comes on or after resetting, the LED will go out

when printing becomes possible.

If the Paper LED is also on, replace the roll paper. For the roll paper replacement method, see

Flashing Printer error has occurred. (For details, see

(3) Paper LED Off There is a sufficient amount of roll paper remaining

Flashing A self-test printing standby state

On There is little or no roll paper remaining

"Installing and Replacing Roll Paper" on page 34.

"Offline" on page 31)

"Error Status" on page 22.)

2

21

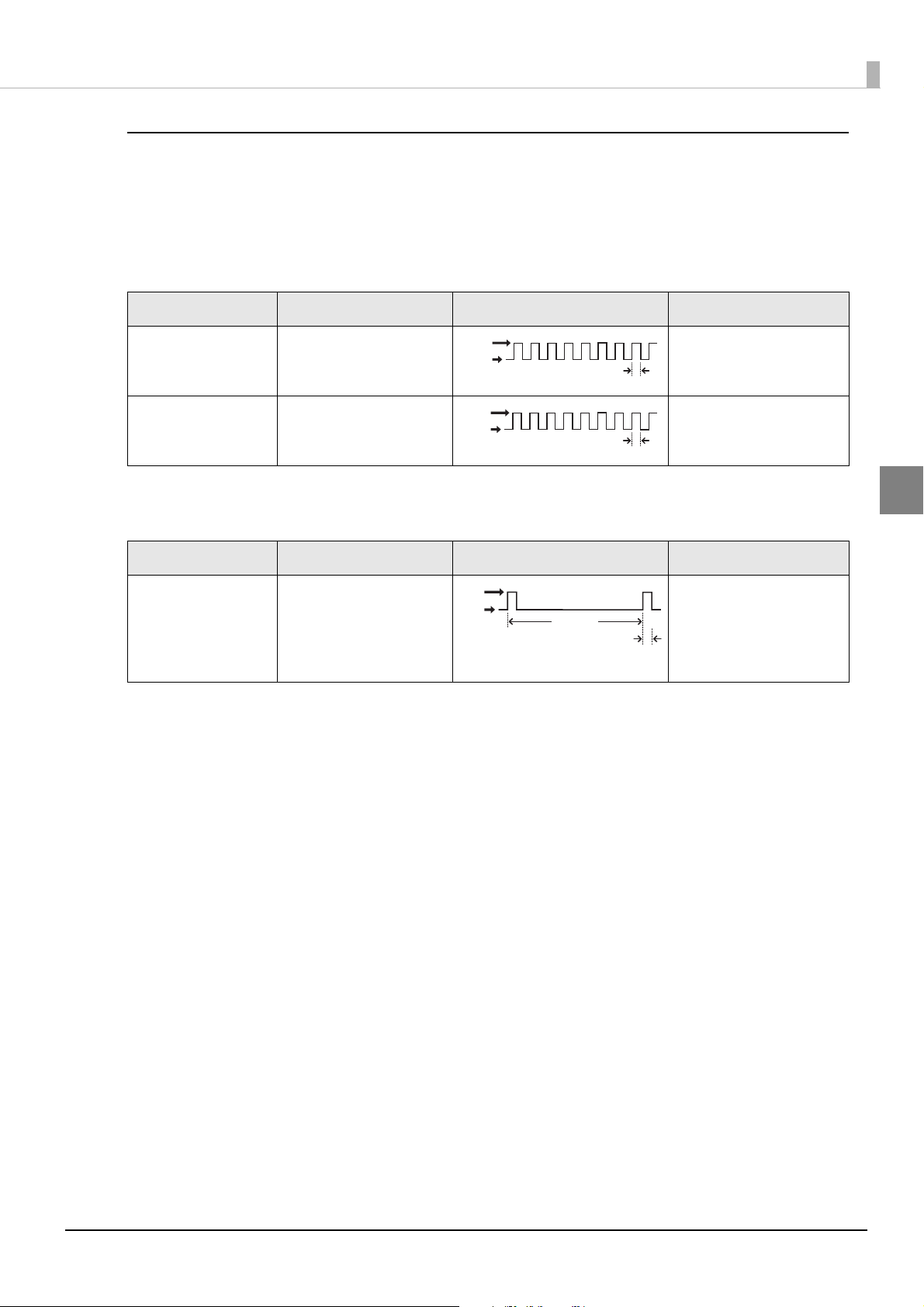

Chapter 2 Printer Functions and Settings

LED ON

LED OFF

Approx. 160 ms

Approx, 2.56 s

LED ON

LED OFF

Approx. 160 ms

Error Status

Printing cannot be done when there is a printer error. There are three possible error types: automatically recoverable errors, recoverable errors, and unrecoverable errors. Check the error LED flash code.

Automatically Recoverable Errors

Online status can be restored by the methods described below.

Error Error description Error LED flash code Recovery measure

Roll paper cover open

error

The roll paper cover was

opened during printing.

Recovers automatically

when the roll paper cover is

closed.

Print head temperature error

A high temperature outside the head drive operating range was detected.

LED ON

LED OFF

Approx. 160 ms

Recovers automatically

when the print head cools.

Recoverable Errors

After removing the cause of error, online status can be restored by pressing the printer reset button.

Error Error description Error LED flash code Recovery measure

Autocutter error Autocutter does not work

correctly.

Remove the jammed paper

or foreign matter in the

printer, close the roll paper

cover, and then press

printer reset button.

2

22

Chapter 2 Printer Functions and Settings

LED ON

LED OFF

Approx. 160 ms

LED ON

LED OFF

Approx. 160 ms

LED ON

LED OFF

Approx. 160 ms

LED ON

LED OFF

Approx. 160 ms

Approx. 2.56 s

LED ON

LED OFF

Approx. 160 ms

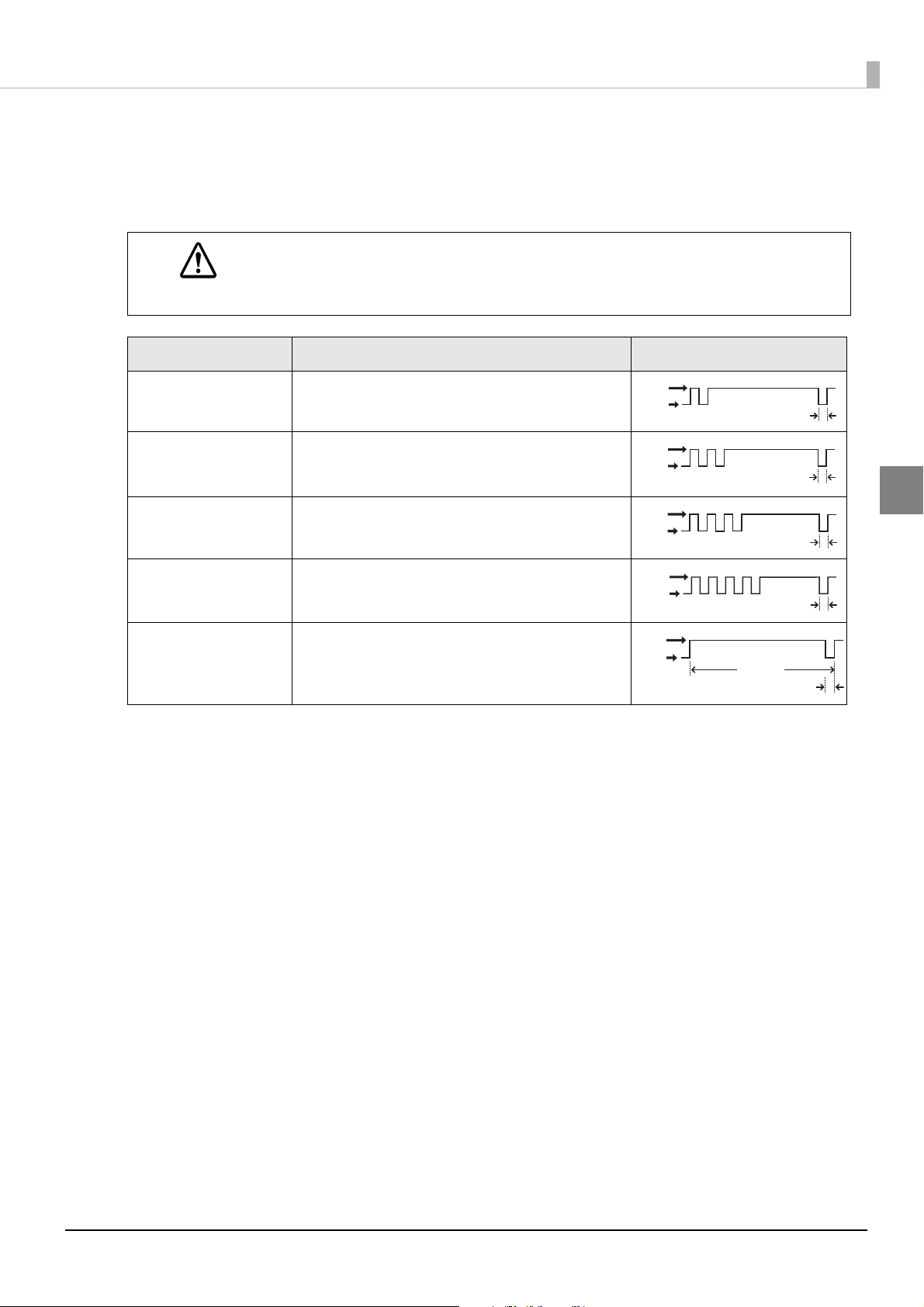

Unrecoverable Errors

If an unrecoverable error occurs, immediately press the printer reset button. If the same error still occurs, turn

the printer power off. Since it is possible a failure has occurred in the printer, contact your dealer or a Seiko

Epson service center for advice.

If an unrecoverable error occurs after resetting the printer, immediately turn the printer power off.

CAUTION

Error Error description Error LED flash code

Memory R/W error After R/W checking, the printer does not work correctly.

High voltage error The power supply voltage is extremely high.

Low voltage error The power supply voltage is extremely low.

CPU execution error The CPU is executing an incorrect address.

Internal circuit connec-

Internal circuits are not connected correctly.

tion error

2

23

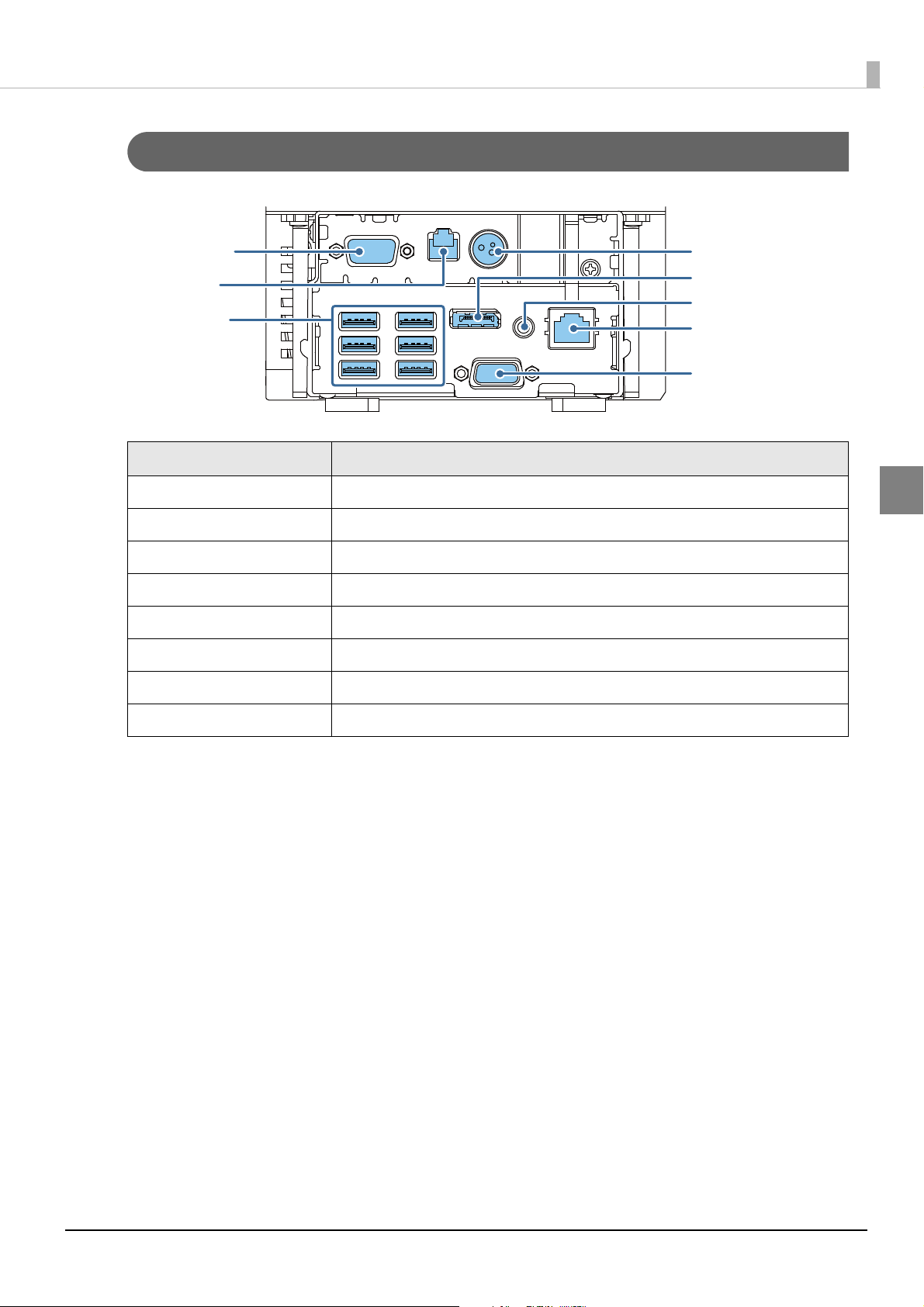

Product Rear

COM connector

DK connector

USB connector

VGA connector

LAN connector

Line-out connector

DisplayPort

DC-in connector

Name Description

Chapter 2 Printer Functions and Settings

DK connector Connect the cash drawer here.

LAN connector Connect the LAN cable here.

USB connector Connect external devices with USB interface here.

DC-In connector Connect the AC adapter here.

VGA connector Connect the display here.

DisplayPort * Connect the display here.

COM connector Connect a serial communication device.

Line-Out connector Connect an external speaker here.

This may not be provided, depending on the product specifications.

2

24

Chapter 2 Printer Functions and Settings

LAN Status LED

The LAN status LEDs are the LEDs on the LAN connector. They indicate the network communication status of

this product.

LED (Yellow)

LED (Green / Orange)

LED Status Description

Green/Orange On (Green) 1 Gbps link established

On (Orange) 100 Mbps link established

Off 10 Mbps link established or link not established

Yellow On Data is being exchanged.

Off Data is not being exchanged.

2

25

Installing the Product

Display caution regarding the following points when installing the Product.

The Product must be installed horizontally on a flat surface (not tilted).

Do not place the product in dusty locations.

Do not knock or strike the product. This may cause defective print.

Do not catch cables and do not place foreign matter under the product.

Security Hook

Commercially available theft prevention wire can be attached.

Chapter 2 Printer Functions and Settings

2

Security hock

26

Connecting the AC Adapter

Be sure to use the specified AC adapter (AC adapter, T).

If you use a non-standard AC adapter, there is a risk of causing fire or electric shock.

WARNING

CAUTION

If an abnormality arises despite using this product's attachments, immediately turn the power off

and remove the power cord from the wall socket.

When connecting or detaching the AC adapter to and from this product, remove the AC

adapter's power cord from the wall socket.

If the power cord is not removed, there is a risk that the adapter and/or this product will be damaged.

Use the AC adapter separated from the main unit.

When using this product connected to the powered USB hub unit (Model: OT-PH10), connect the AC

adapter to the Powered USB Hub Unit. See "the OT-PH10 Installation Guide" for details.

Chapter 2 Printer Functions and Settings

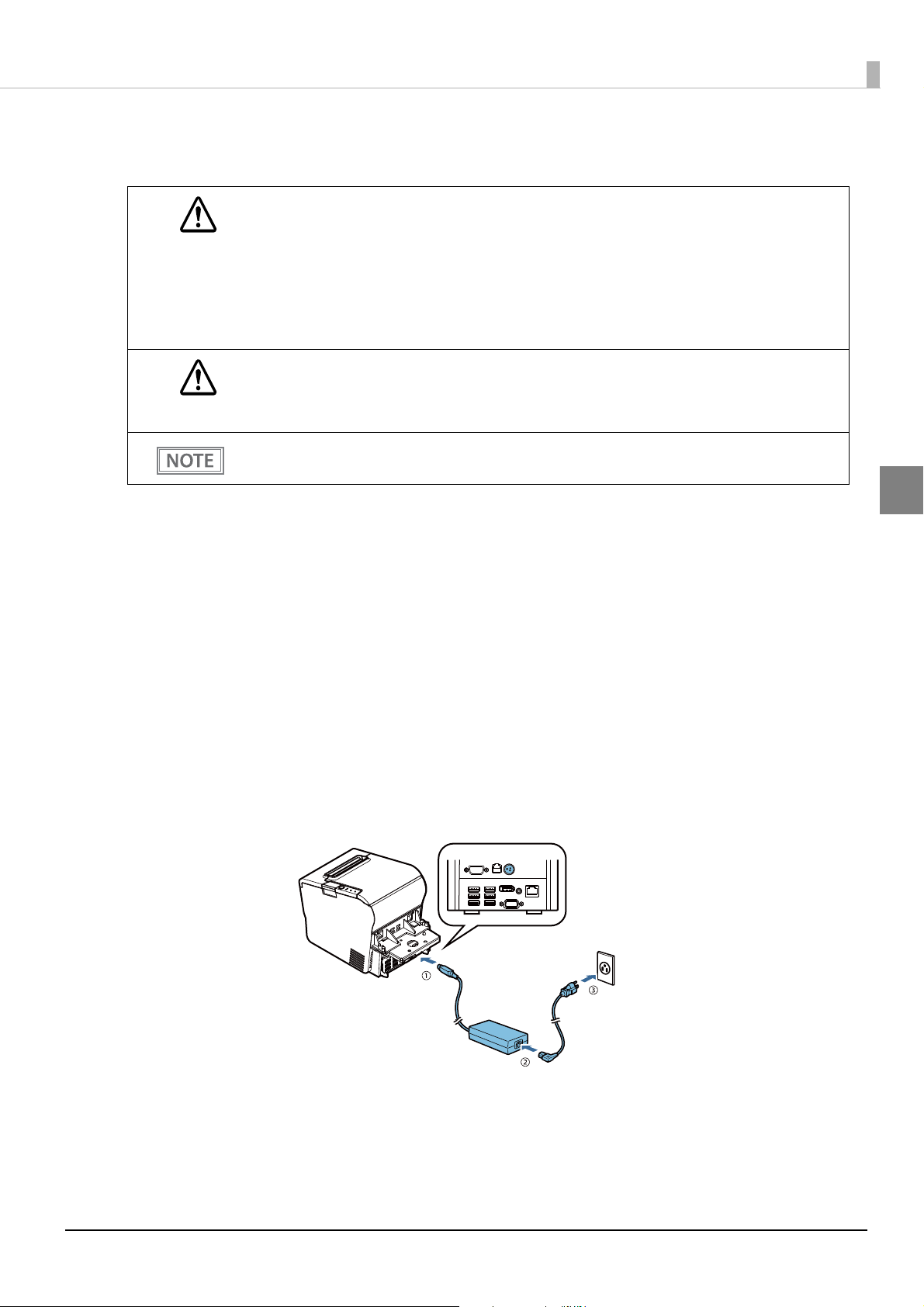

Connect the AC adapter to this product by the following procedure.

Make sure that power is off and that the AC adapter power cord is detached from the

1

wall socket.

Firmly insert the DC connector of the AC adapter all the way into the DC-in connector

2

on the product. ((1) in the illustration)

Firmly insert the connector of the AC cable all the way into the AC inlet on the AC

3

adapter. ((2) in the illustration)

Firmly insert the plug all the way into the grounded wall outlet. ((3) in the illustration)

4

Set the AC adapter so that its label side is facing down.

5

2

27

Detaching the AC Adapter

Detach the AC adapter from this product by the following procedure.

Make sure that power is off.

1

Detach the power cord from the wall socket.

2

Detach the AC adapter DC connector from this product.

3

Chapter 2 Printer Functions and Settings

2

28

Chapter 2 Printer Functions and Settings

Turning Power On and Off

Turning Power On

With product power turned off, press the power button.

The power LED and the status LED (green) comes on.

The status LED (orange) flashes during startup of the OS, when OS startup is finished, goes out.

Turning Power On for the First Time

When turning power on for the first time, it is necessary to perform Windows initial settings.

For details, see

"Windows Initial Settings" on page 63.

Turning Power Off

Turn the power off from an application or OS function.

To power off the product, use the application or OS function.

Do not use the operations shown below unless the product cannot be turned off due to an

application or OS problem. Doing so may cause loss of unsaved data, require OS recovery, or

damage the HDD, SSD or other hardware.

Forced termination by holding down the power button for approx. 4 sec.

Power shutdown by turning off the circuit breaker on the distribution board or by discon-

necting the AC cable/DC cable.

The same phenomenon may also occur due to power shutdown caused by power failure/temporary power failure. To prevent power shutdown due to power failure/temporary power

failure, using an uninterruptible power supply (UPS) is recommended.

Product power can also be turned off from EPSON TMNet WebConfig (

Product power can also be turned off from the Web application. For details, see "Epson ePOS

SDK for JavaScript User's Manual".

2

page 118).

29

Chapter 2 Printer Functions and Settings

Power Button Settings

You can set the functions that are available when you press the power button while power is on to this product.

Revisions are made by means of Windows "Power Options" or EPSON TMNet Config "Shutdown Settings."

The functions that can be set, and the setting methods are described below.

Function Description

Shutdown Shuts down Windows and turns power off

(initial settings).

Do nothing Invalid (does nothing) ✔✔

Standby Switches to Windows standby ✔ -

Hibernation Switches to Windows hibernation ✔ -

In standby, the current work contents are saved in the memory. On returning from standby, work can be immediately resumed from where you left off.

If the AC adapter is removed in the standby mode, the work contents saved in the memory will be lost.

For settings when using Windows hibernation, see

"Windows Hibernation" on page 65.

Setting from

Windows

✔✔

Setting from EPSON

TMNet WebConfig

2

Return from Standby / Hibernation

When this product is in Windows standby or hibernate mode, press the power button to restore the original

state.

Prevention of Accidental Operation of Power Button

The power button cover supplied with this product can be attached to prevent accidental operation of the power

button.

For details, see

"Power Button Cover" on page 48.

Forced Termination

If you cannot turn this product power off using applications or the OS, you can execute forced termination as a

last resort. Keep pressing the power button for approximately 4 seconds until this product is turned off.

Be careful; when forced termination is executed, all unsaved data is lost.

30

Chapter 2 Printer Functions and Settings

Online and Offline

This section describes the conditions in which the printer goes online and offline.

This product's printer can print when it is online but not when it is offline.

Because this product's computer and printer operate independently, the computer operates irrespective of the

printer status.

The printer LEDs display the following.

Printer Status Power LED Error LED

Online On Off

Offline On On

Online

This is the online status when no offline events or printer errors are happening.

Offline

The printer automatically goes offline under the following conditions:

During power on (including resetting with the interface) until the printer is ready

During the self-test

When the roll paper cover is open

While roll paper is feed using the Feed button

When printing stops due to end of paper. (When the roll paper end sensor detects the end of paper or the

printer is set so that printing stops upon detection of roll paper near-end.)

When an error has occurred (For detail, see

"Error Status" on page 22.)

2

31

Chapter 2 Printer Functions and Settings

Hole

Handling the Roll Paper

Changing the Paper Width

The printer is initially set to print on 80 mm width paper and you can change the printer to print on 58 mm

width paper by installing the roll paper guide and changing the paper width setting with the customized value.

Follow the steps below to install the roll paper guide.

Once you change the paper width from 80 mm to 58 mm, you cannot change it back to 80

mm.

If changing the paper width, use TM-T88V-Utility, and change the width on the TM-T88V-DT or

via the network.

Open the roll paper cover.

1

Install the roll paper guide so that the projection on its bottom is aligned with the

2

hole at the right of the roll paper holder.

2

32

Chapter 2 Printer Functions and Settings

Tighten the enclosed screw to fix the roll paper guide.

3

Paste the enclosed 2 small strips along the roll paper guide on the bottom of the roll

4

paper holder.

Make sure the space between the top edge of the strip and the line of the groove in the roll paper

guide is 0.5 mm {0.020”} or less.

2

33

Installing and Replacing Roll Paper

Do not open the roll paper cover during printing.

The product may be damaged.

WARNING

Press the cover open button to open the roll paper cover.

1

Do not touch the manual cutter with your hands when installing or replacing the roll paper.

Otherwise, you may be injured because the manual cutter blade is sharp.

Use roll paper that meets the product specification. For details about paper specification, see

"Roll Paper Specifications" on page 144.

Paper must not be pasted to the roll paper core.

Chapter 2 Printer Functions and Settings

2

Remove the used roll paper core, if any.

2

Install the roll paper in the correct direction.

3

34

Pull out some roll paper, and close the roll paper cover.

4

Chapter 2 Printer Functions and Settings

Tear off the roll paper with the manual cutter.

5

2

35

Chapter 2 Printer Functions and Settings

Removing Jammed Paper

When roll paper gets jammed inside the printer, remove the paper and reset the printer as follows.

Open the roll paper cover.

1

Remove the jammed paper.

2

Press the printer reset button to reset the printer.

3

The roll paper cover will not open (the autocutter blade is locked)

The roll paper cover will not open if the auto cutter blade is locked.

Restore the auto cutter blade to its normal position and remove the jammed paper by the following procedure.

Turn off the product.

1

Slide the cutter cover toward the front to open it.

2

Do not touch the thermal head because it can be very hot after printing.

CAUTION

2

36

Chapter 2 Printer Functions and Settings

Turn the knob until you see a triangle in the opening. This returns the cutter blade to

3

the normal position.

There is a label near the cutter to assist you.

Close the cutter cover.

4

Close the roll paper cover.

5

2

Remove the jammed paper.

6

Turn on the product.

7

37

Chapter 2 Printer Functions and Settings

Adjustment screw

Positioning plate

Detection lever

Adjusting the Roll Paper Near-End

Below are two situations where a roll paper near-end sensor adjustment is required.

To adjust the detection position to suit the diameter of the roll paper core used.

To adjust the detection position of remaining amount of paper.

Since roll paper cores vary slightly in shape, depending on roll paper design and manufactur-

ing tolerances, it is impossible to detect the remaining paper exactly.

Use roll paper with a core whose inner diameter is 12 mm {0.47"} and outer diameter is 18 mm

{0.71"} so that the near-end sensor can detect the remaining paper as accurately as possible.

Follow the steps below to adjust the roll paper near-end sensor.

Open the roll paper cover, and remove the roll paper.

1

Loosen the adjustment screw fastening the sensor, and align the upper edge of the

2

positioning plate with the adjustment position.

2

Adjustment position

Upper Approx. 27 {1.06"}

Lower (Initial setting) Approx. 23 {0.97"}

Tighten the adjustment screw.

3

After adjustment, make sure that the detection lever operates smoothly.

4

Remaining amount of paper

(outer diameter: mm)

38

Chapter 2 Printer Functions and Settings

Attaching and Setting Peripherals

Connect the peripheral cables to each connector.

When attaching and detaching peripherals, be sure to turn this product power off and remove

the power cord. Doing so without detaching the power cord could lead to failure.

When connecting USB cable, DisplayPort cable, line output cable, and other connector-less cables to this product, fix the interface cables with wire saddles to prevent detachment.

Wire saddle

Keyboard / Mouse

Connect when you want to operate from Windows or applications.

Connect a USB keyboard and USB mouse to the USB connectors.

Fix the USB cables with wire saddles to prevent detachment.

Display

Connect when you want to display Windows and operate from applications.

Connect the display to the VGA connector or DisplayPort. If this product is compatible with touch panel inputting or audio outputting, connect to the respective ports.

Connect the display when power to this product is off. If you connect the display while power

is on, it may not display properly.

Fix the DisplayPort cable, USB cables, and line output cable with wire saddles to prevent

detachment.

2

Conduct display settings with the Windows function.

39

Chapter 2 Printer Functions and Settings

USB Interface Printer

Connect the USB interface TM printer to a USB connector. For printer settings, see the "Technical Reference

Guide" of each TM printer.

PC-POS System

Set the driver, etc. according to each system of use. For details, see

130

.

Systems that use TM-DT software cannot be used.

Fix the USB cables with wire saddles to prevent detachment.

"PC-POS System Development" on page

Network Printer

Network printers are connected to the same network as this product. For printer settings, see the "Technical

Reference Guide" of each TM printer.

PC-POS System

Set the driver, etc. according to each system of use. For details, see

.

130

Systems that use TM-DT software

Set the device ID, IP address, printer model, and other settings with EPSON TMNet WebConfig. For details,

"Settings - Web service settings - Printer" on page 102.

see

"PC-POS System Development" on page

Customer Display

Connect the customer display (optional) to a USB connector.

For how to connect the customer display and make dip switch settings, etc., see the "Technical Reference Guide"

of each customer display.

PC-POS System

This product is installed with a customer display COM-USB conversion driver, so it is recognized as a virtual

COM port.

Set the driver, etc. according to each system of use. For details, see

130

.

"PC-POS System Development" on page

2

Systems that use TM-DT software

Set whether or not to use the customer display, communication speed and so on with EPSON TMNet WebConfig. For details, see

"Settings - Web service settings - Customer Display" on page 103.

Fix the USB cables with wire saddles to prevent detachment.

40

Chapter 2 Printer Functions and Settings

48°

300°

270°

Operation

When changing the direction and angle of the customer display, move the display section and L-shaped support

while holding this product down by hand. When the movement stops, do not move it any more.

Do not rotate the display with excessive force. Doing so may break it.

CAUTION

The mobile range of the display is as follows.

Display tilt: Maximum angle of 48° (5 levels)

Display rotation: Maximum angle of 300°

2

Arm rotation: Maximum angle of 270°

41

Chapter 2 Printer Functions and Settings

DK connector

Cash Drawer

Connect the connector of the drawer kick-out cable to the printer.

Push the connector of the drawer kick-out cable into the product until you hear a click.

Specifications of drawers differ a great deal, depending on makers or models. When you use a

drawer other than the specified, make sure its specifications meet the following conditions.

WARNING

Otherwise, devices may be damaged.

The load, such as a drawer kick-out solenoid, must be connected between pins 4 and 2 or

pins 4 and 5 of the drawer kick-out connector.

When the drawer open/close signal is used, a switch must be provided between drawer

kick-out connector pins 3 and 6.

The resistance of the load, such as a drawer kick-out solenoid, must be 24

input current must be 1A or less.

Be sure to use the 24V power output on drawer-kick out connector pin 4 for driving the

equipment.

Use a shield cable for the drawer connector cable.

Two driver transistors cannot be energized simultaneously.

Leave intervals longer than 4 times the drawer driving pulse when sending it continuously.

Be sure to use the printer power supply (connector pin 4) for the drawer power source.

Do not insert a telephone line into the DK connector.

Doing so may damage the telephone line or printer.

or more or the

2

PC-POS System

The cash drawer is controlled from this product's printer. There is no dedicated driver for the cash drawer you can use the printer driver.

Systems that use TM-DT software

The cash drawer is controlled from this product's printer. Configure the printer to use.

42

DK Connection Circuitry

F.G

+24V

Shielded DK connector

Printer side

User side [Drawer kick-out side]

Drawer open/close switch

Drawer kick-out solenoid

Control device

1

2

3

4

5

6

Chapter 2 Printer Functions and Settings

2

43

Chapter 2 Printer Functions and Settings

Key Input Device

Connect the key input device to a USB connector. For how to set barcode scanners and so on, see the respective

product manuals.

PC-POS System

Since it is recognized as a HID device, setting is not required.

Systems that use TM-DT software

Set the device ID, control script and so on with EPSON TMNet WebConfig. For details, see

service settings - Key input device" on page 104

Fix the USB cables with wire saddles to prevent detachment.

.

"Settings - Web

Serial Communication Device

Connect the serial communication device to a COM connector. For how to set the device, install the driver and

so on, see the respective product manuals.

PC-POS System

Align communication conditions between this product and the device.

Systems that use TM-DT software

Align communication conditions between EPSON TMNet WebConfig and the device.

Set the device ID, communication conditions, control script and so on with EPSON TMNet WebConfig. For

details, see

"Settings - Web Service settings - Serial communication Device" on page 105.

Powered USB Hub Unit

Attach the powered USB hub unit to the base of this product, and connect the cables to this product's DC connector and USB connector.

For details on the powered USB hub unit, see "OT-PH10 Installation Guide".

2

44

Chapter 2 Printer Functions and Settings

Network Settings

Connect to Wired LAN

LAN Cable Connections

When LAN cables are installed outdoors, make sure devices without proper surge protection

are cushioned by being connected through devices that do have surge protection.

CAUTION

Push the 10BASE-T/100BASE-TX LAN cable into the LAN connector until you hear a click.

Otherwise, the devices can be damaged by lightning.

Never attempt to connect the customer display cable, drawer kick-out cable, or a telephone

line cable to the Ethernet connector.

Network Settings

Set the IP address and other network settings. Settings can be made as follows.

Setting on Windows

Perform the same settings as with the Windows PC.

Setting on EPSON TMNet WebConfig (

page 113)

2

45

Chapter 2 Printer Functions and Settings

Connect to Wireless LAN

You can use the optional wireless LAN cable set (OT-WL01) to connect this product to a wireless LAN.

Wireless LAN Cable Set Connections

Connect the wireless LAN cable set to a USB connector.

Connect the wireless LAN cable set by the following procedure.

Attach the included rubber cover to the connector of the USB extension cable into

1

which the wireless LAN unit will be inserted, to prevent the unit from coming off.

2

Insert the wireless LAN unit into the connector of the cable.

2

Adjust the position of the rubber cover so that the description on the label on the back side of

the wireless LAN unit is not covered.

Connect the USB extension cable to the USB connector of the printer.

3

If you want to fix the wireless LAN unit, cut the included affixing tape to fit and put on the unit,

and fix the unit in a place with good communication.

46

Chapter 2 Printer Functions and Settings

Wireless LAN cable set’s indicator

With the LED on the wireless LAN unit, you can check the communication status of the product.

LED

LED Description

Off The wireless LAN unit is not connected to the product. Or the product power is Off.

Flashing This wireless LAN unit is in operation.

Flashing rapidly This unit is communicating on a wireless LAN.

2

Network Settings

Set the IP address and other network settings. Settings can be made as follows.

Setting on Windows

Perform the same settings as with the Windows PC.

Setting on EPSON TMNet WebConfig (

page 114, page 115)

47

Chapter 2 Printer Functions and Settings

Align the inside edge of the power button cover

with the upper edge of the power button.

Align the left edge of the power button cover

with the right edge of the printer reset button.

Printer reset button

Power button

Attaching Accessories

Power Button Cover

The power button cover supplied with this product can be attached to prevent accidental operation of the power

button.

If the area around the power button is dirty, Epson recommends wiping clean before attaching

the cover.

Open the power button cover.

1

2

Peel off the backing paper.

2

Attach the power button cover as shown in the illustration.

3

48

Chapter 2 Printer Functions and Settings

Connector Cover

Attaching the Connector Cover

The connector cover can be attached to protect cables that are connected to this product.

When attaching the connector cover, always hold both sides. Otherwise the connector cover

could break.

CAUTION

Attach the connector cover by the following procedure.

When attaching the customer display (optional) to this product, remove the U-

1

shaped component from the connector cover.

2

Align the hooks on the connector cover with the dents on the main body.

2

Push the connector cover to click onto the main body.

3

Make sure the cables are not pinched.

4

49

Chapter 2 Printer Functions and Settings

Detaching the Connector Cover

Detach the hooks from this product while pushing the bottom parts on both sides of the connector cover

inwards.

2

50

Chapter 2 Printer Functions and Settings

Positioning lines

Affixing Tape (Optional)

When fixing this product onto a mounting surface using the optional affixing tape (model number: DF-10), follow the procedure below.

Turn over the product so that you can see its bottom.

1

With two pieces of the affixing tape combined, peel off the backing paper of a pair on

2

one side, and paste it to one of the specified positions on the bottom of the product.

In the same way, paste other three pairs of tape in the specified positions.

3

Peel off the backing paper of each pair on the other side of the affixing tape, turn

4

over the product back on its bottom, and place and secure it firmly to the installation

surface.

2

51

Chapter 2 Printer Functions and Settings

Thermal Head

Cleaning

Thermal Head

Epson recommends cleaning the thermal head periodically (every 3 months or so) to maintain the receipt print

quality.

After printing, the thermal head and the surrounding frame can be very hot. Do not touch the

thermal head right away. Wait for the thermal head to cool down sufficiently before cleaning.

CAUTION

Open the roll paper cover, and clean the thermal elements of the thermal head with a cotton swab slightly

moistened with an alcohol solvent (ethanol or isopropyl alcohol).

Do not damage the thermal head by touching it with your fingers or any hard object.

2

Depending on the roll paper used, paper dust may stick to the platen roller and roll paper end sensor. To remove

the paper dust, clean the platen roller and roll paper end sensor with a cotton swab slightly moistened with

water.

Case

Wipe the dirt off the case with a dry cloth or a cloth slightly damp with water. If it is very dirty, soak a cloth in a

neutral liquid detergent, tightly wring it out, and wipe the dirt away. Always unplug the power cord from the

socket at this time.

Never clean the product with alcohol, benzine, thinner, or other such solvents. Doing so may

damage or break the parts made of plastic and rubber.

52

Preparing for Transport

Follow the steps below to transport the product.

Turn off the product.

1

Remove the peripherals and the AC adapter.

2

Remove the roll paper.

3

Pack this product upright.

4

Chapter 2 Printer Functions and Settings

2

53

Chapter 2 Printer Functions and Settings

Setting the Memory Switches

This product contains memory switches (customized value). The memory switch settings determine the operations of the built-in printer.

To change the memory switch settings, use the software setting mode or the TM-T88V Utility.

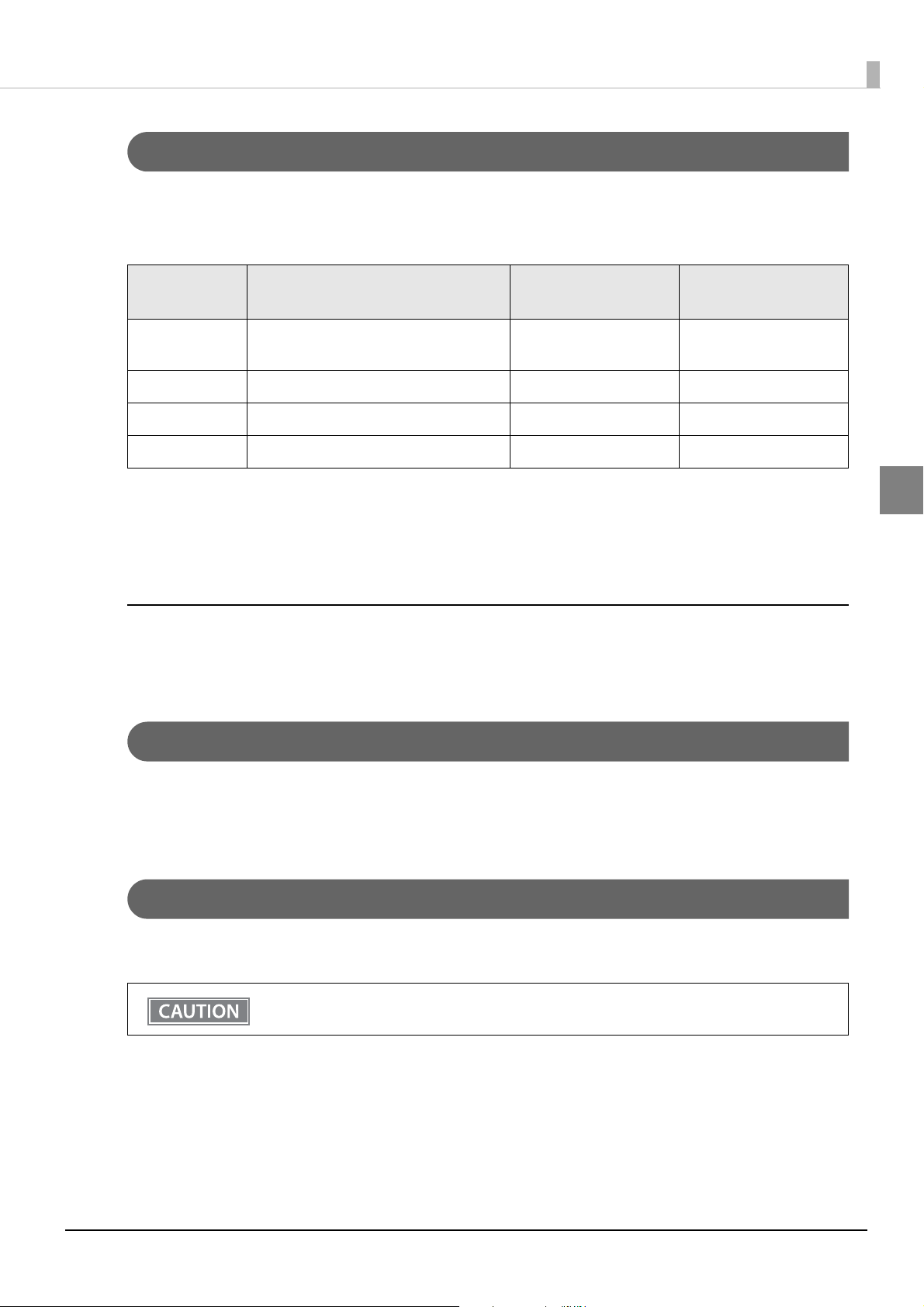

The settings that can be changed with each of these are shown below.

Function Software Setting Mode TM-T88V Utility

Paper width

Print density

Multi-tone print density

Print speed

Font

Code page

International character set

Font A/B replacement

Optional Buzzer

Number of head energizing parts

Power supply unit capacity

Automatic paper cut

Paper reduction

Upper space reduction

Lower space reduction

Line space reduction rate

Line feed reduction rate

Barcode height reduction rate

--

✔✔

✔✔

✔✔

✔✔

--

✔

✔✔

✔✔

✔✔

-

2

Concerning TM-T88V Utility, see the User's Manual included in TM-T88V Utility.

To directly configure the product in the software setting mode, see "Software Setting Mode"

on page 61

.

54

Chapter 2 Printer Functions and Settings

Functions

Paper width

Be sure to install the roll paper guide when you select the 58 mm paper width.

80 mm (initial setting)

58 mm

Once you change the paper width from 80 mm to 58 mm, you cannot change it back to 80 mm.

Print density

Selectable from “Depends On Dip Switch”, or levels 1 to 13 (70% ~ 130%)

When the print density setting is configured to "Depends On Dip Switch" (default setting), the

print density will be standard. Use in this setting at normal times. Other settings can also be configured.

Multiple tone density

Selectable from levels 1 to 13 (70% ~ 130%) (initial setting: level 7)

First change the print density, and then configure the multiple tone print density.