Page 1

Receipt Printer

TM-T88R / TM-T88IIR

Installation Manual

400844502

Page 2

Safety Precautions

Copyright© 1997 by Seiko Epson Corporation

This document presents important information intended to ensure safe and effective use of this product.

Please read this document carefully, and store it in an accessible location near your installation.

Precaution Markings

This document uses the two markings shown below to call attention to potential hazards. Failure to

observe the information provided under or alongside these markings may lead to injury or property

damage. Be sure that you understand the meaning of each marking before you proceed.

WARNING

Indicates a potentially lethal hazard. Failure to observe a WARNING may result in severe

injury or death.

CAUTION

Failure to observe a CAUTION may result in personal injury, or in damage to equipment or

other property.

Note

Notes have important information and useful tips on the operation of your printer.

Safety Precautions

WARNINGS

●Shut down your equipment immediately if it produces smoke, a strange odor, or unusual noise.

Continued use may lead to fire or electric shock.

Immediately turn the power off and contact your dealer or a SEIKO EPSON service center for advice.

●Never attempt to repair this product yourself. Improper repair work can be dangerous.

●Never disassemble or modify this product.

Tampering with this product may result in injury, fire, or electric shock.

●Be sure to use the specified power source.

Connection to an improper power source may cause fire or shock.

●Do not allow foreign matter to fall into the equipment.

Penetration of foreign objects may lead to fire or shock.

●If water or other liquid spills into this equipment, immediately turn the power off and contact your

dealer or a SEIKO EPSON service center for advice.

Continued usage may lead to fire or shock.

1

Page 3

CAUTIONS

●Do not plug the cable differently from the instruction in this manual.

Wrong connection may cause equipment damage and fire.

●Be sure to set this equipment on a firm, stable, horizontal surface.

Product may break or cause injury if it falls.

●Do not use in locations subject to high humidity or dust levels.

Excessive humidity and dust may cause equipment damage, fire, or shock.

●Do not place heavy objects on top of this product. Never stand or lean on this product.

Equipment may fall or collapse, causing breakage and possible injury.

●If water or other liquid spills into this equipment, immediately turn the power off and contact your

dealer or a SEIKO EPSON service center for advice.

Continued usage may lead to fire or shock.

CAUTION:

Thermal head is hot.

VORSICHT:

Der Thermalkopf ist heiß.

2

Page 4

EMC and Safety Standards Applied

Product Name: Printer

Model Name: M138A

Europe: CE Marking

North America: EMI: FCC/ICES-003 Class A

Japan: EMI: VCCI Class A

Oceania: EMC: AS/NZS 3548

The connection of a non-shielded printer interface cable to this printer will invalidate the EMC standards of this device.

You are cautioned that changes or modifications not expressly approved by SEIKO EPSON Corporation could void your

authority to operate the equipment.

CE Marking

The printer conforms to the following Directives and Norms:

FCC Compliance Statement For American Users

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case the user will be

required to correct the interference at his own expense.

Safety: EN60950

Safety: UL1950/CSA C22.2 No. 950

Electrical Appliance and material Control Law

Guide lie for Harmonic Current

WARNING

Directive 89/336/EEC

EN 55022 Class A

EN 50082-1

IEC 801-2

IEC 801-3

IEC 801-4

FOR CANADIAN USERS

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

3

Page 5

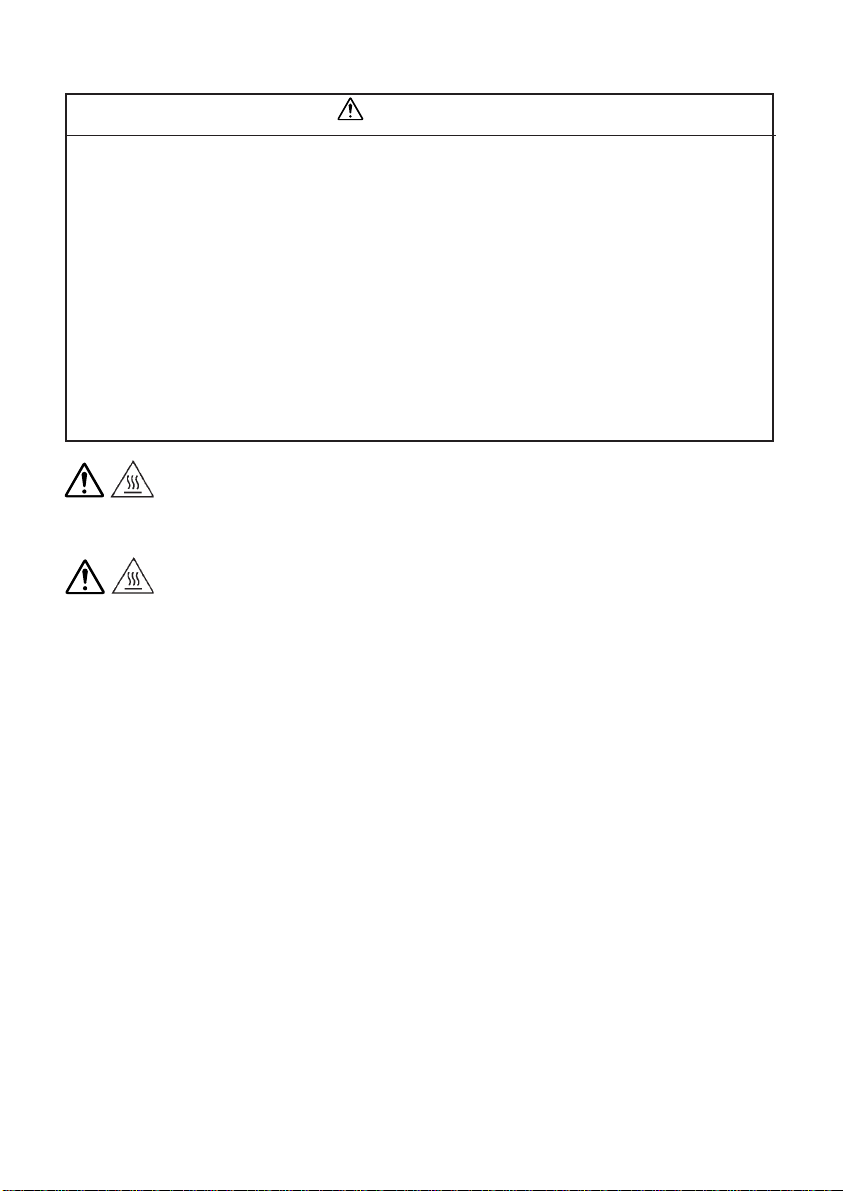

1 Unpacking

The illustration below shows the items included

for the standard specification printer .

Printer

Screws

For details, see page 7.

If any items are damaged, please contact your

dealer for assistance.

2 Machine Layout

Paper roll

Cable

Connects the printer to

the IM-300.

Printer cover

Cutter cover

Cover open button

4

Page 6

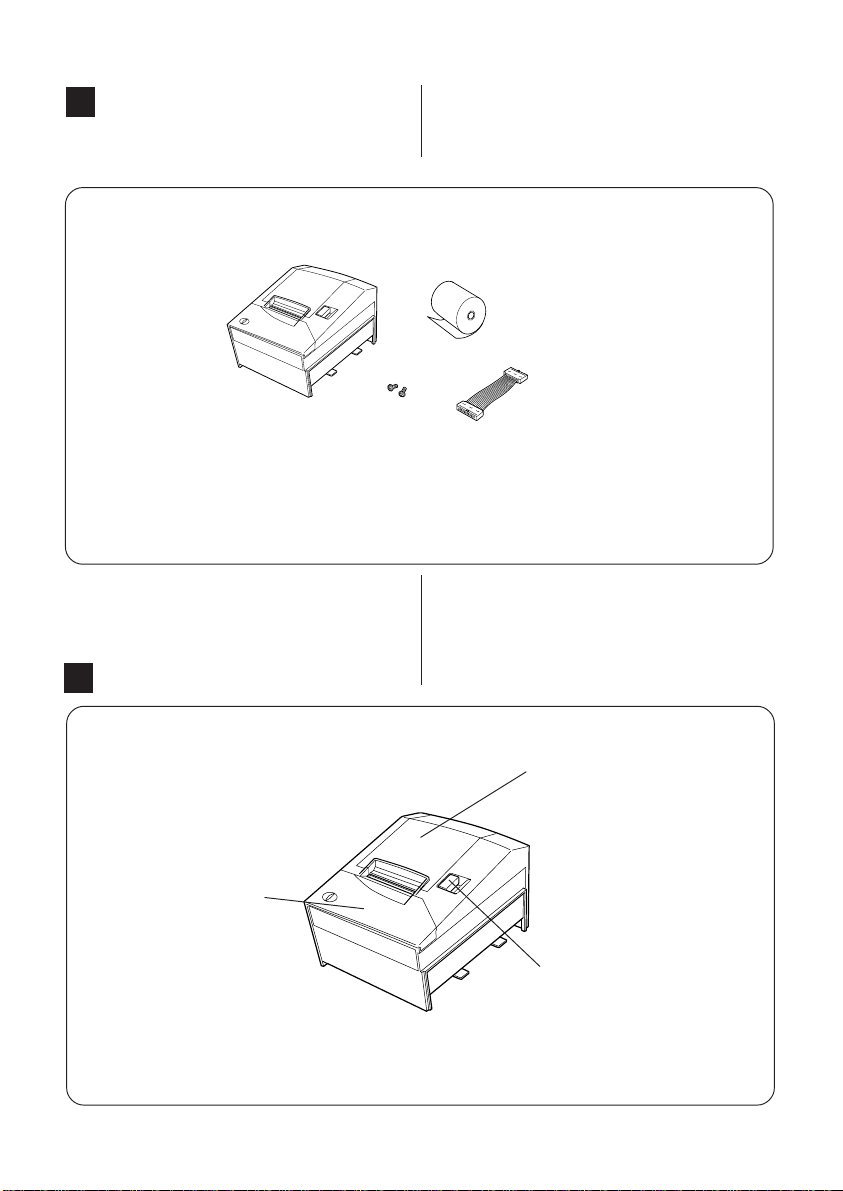

Labels

Paper-roll replacement guide label

Affixed to the inside of the print cover.

3 Confirming the DIP switches

Some application may require the alternation

of the DIP switches setting. Please confirm the

DIP switches setting before connecting the

printer. Please refer to P.14 for the DIP switches

setting.

Auto-cutter label

Affixed to the inside of the

cutter cover.

4 Connecting to the IM-300

Use the following procedure to connect the

printer to the IM-300.

1.Connect one end of the cable to connector

CN401 on the rear of the printer.

5

Page 7

2.Bend the cable as shonw below.

3.Remove the slot cover at the side of the IM-

300.

4.Connect the other end of the cable to the

connector on the IM-300.

5.Bend the cable as shown below.

6

Page 8

6. Slide the printer in the direction indicated

by the arrow so that the hooked area on the

printer fits into the groove on the base unit.

Make sure the cable isn't hooked at the projection of the plate.

7. Open the cover on the side of the printer,

and fasten the printer to the base unit using

the 2 screws included in the package.

8. Attach the slot cover to the IM-300.

7

Page 9

If necessary, you can remove the printer from

the IM-300 as follows.

1.Switch off the power on the base unit.

2. Remove the slot cover at the side of the IM-

300.

3.Remove the two screws holding the printer

to the IM-300.

4.Slide the printer to the left to remove it.

5. Disconnect the cable from the connector on

the IM-300.

5

Installing or Replacing the Paper Roll

Notes:

Be sure to use paper rolls that meet the

specifications.

Notes:

Do not use paper rolls that have the paper

glued to the core because the printer cannot detect the paper and correctly.

Installing

1.Make sure that the printer is not receiving

data; otherwise, data may be lost. Open the

paper roll cover by pressing the cover-open

button. If the cover-open button will not open

the cover, see page 12 in Troubleshooting.

8

Page 10

2.Insert the paper roll as shown.

Notes:

Be sure to note the correct direction that

the paper comes off the roll.

3.Pull out a small amount of paper, as shown.

4.Then close the cover.

9

Page 11

5.Tear off the paper as shown.

Replacing

1.Remove the used paper roll core.

6 Running a self-test

(printer operation check)

You can use the self-test feature to confirm that

the printer is operating correctly. Although it

is not strictly necessity to run this test, it is

generally a good idea to run it at least once to

check the operation. If the printer is not attached

to the IM-300, the self-test can't be executed.

The self-test checks the following.

・Control circuits

・Printer mechanism

・Print quality

・Control ROM version

・DIP-switch settings

Execution of Self-test

1.Turn off the IM-300.

10

Page 12

2. Confirm that the roll paper is set to the

printer.

3.Keep pressing the FEED button on the IM300 base unit.

4. Turn on the IM-300 to start the self-test.

5.Press the FEED button to continue printing.

The printer prints a pattern using the builtin character set.

Note:

If you want to pause the self test manually,

press the FEED button. Press the FEED

button again to continue the self test.

6. The self test automatically ends cuts the paper after

printing the following: ***completed***

The printer is ready to receive data as soon

as it completes the self test.

7 Paper jam

Cautions

Do not touch the print head because it can

be very hot after printing continuously for

a long time.

To clear a paper jam, follow the steps below:

1. Press the cover open button to open the

cover.

2.Remove the jammed paper and put the roll

back in the printer and close the cover.

11

Page 13

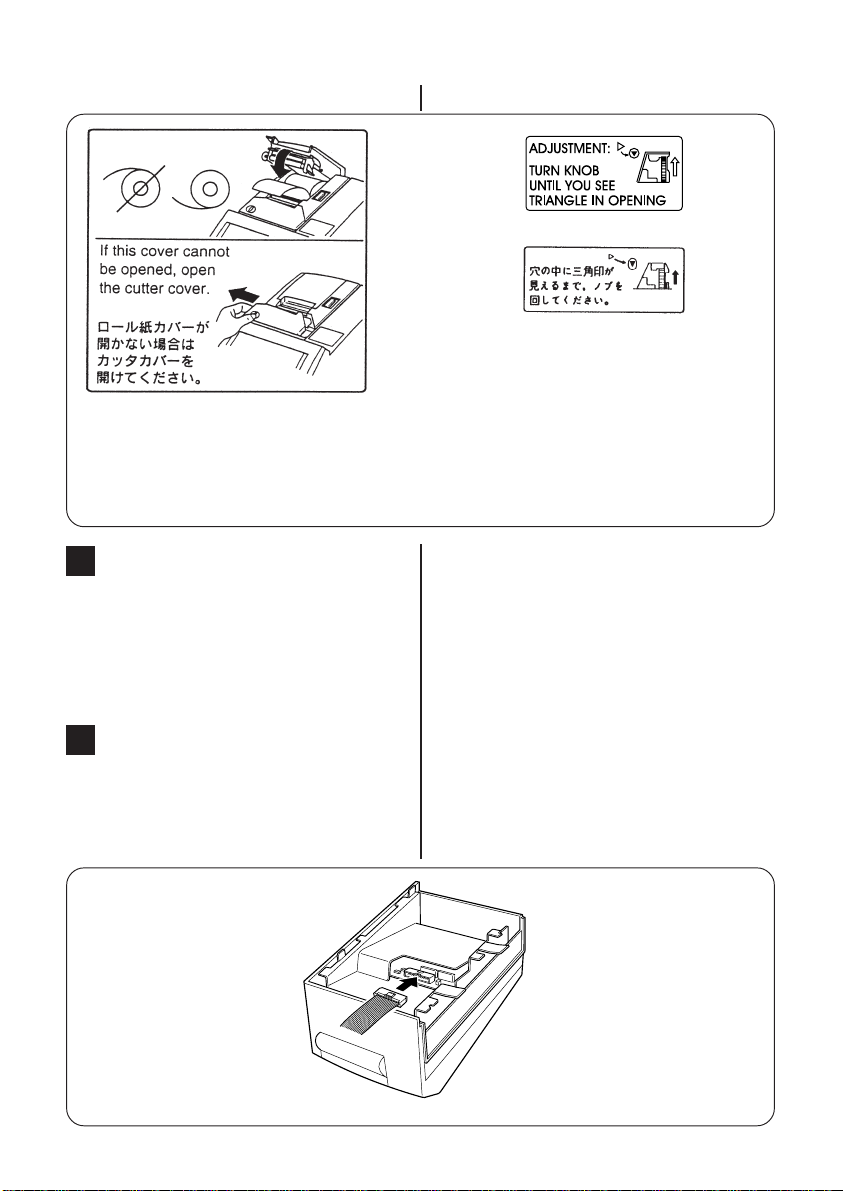

Note:

If paper is caught in the automatic cutter and

the printer cover cannot be opened, slide the

cutter cover as shown below.

If the auto cutter does not return to its normal

position by itself, follow the steps below to

correct the problem:

Slide the auto cutter cover as shown below so

that you can rotate the cutter motor knob.

Following the instructions on the label, rotate the knob until the ▽ appears in the hole.

Note:

If foreign object such as a push pin or paper clip drops in the auto cutter and causes

the auto cutter to lock up, the printer enters an error state and begins the recovery

operation automatically.

Note:

Do not open the auto cutter cover unless

the printer cover won't open.

12

Page 14

8 Setting the DIP Switches

TM-T88R

The functions of the switches are shown in the

following tables.

DIP Switch 1

SW Function ON OFF

Data receive error

1

Receive buffer capacity

2

3 Handshaking XON/XOFF DTR/DSR

4 Data word length 7 bits 8bits

5 Parity check Enabled Dsabled

6 Parity selection Even Odd

7 Transmission speed

8 (See the table below)

Transmission Speed

Transmission Speed

[BPS] 7 8

2400 ON ON

4800 OFF ON

9600 ON OFF

19200 OFF OFF

DIP Switch 2

SW Function ON OFF

1 Handshaking Receive Off line or

(BUSY condition)

2 Reserved do not change settings

Selects print density

3

4

5 Reserved do not change settings

6 Reserved do not change settings

I/F pin 12 reset signal

7

Unused

8

• lgnored Prints"?"

45 bytes 4K bytes

Switch No.

buffer full receive buffer

•iRefer to table below•j

Enabled Disabled

Unused

Print Density Selection

Print Density

Level

1 (Light) ON ON

2 OFF OFF

3 ON OFF

4 (Dark) OFF ON

Switch No.

34

13

Page 15

TM-T88IIR

The functions of the switches are shown in the

following tables.

DIP Switch 1

SW Function ON OFF

Data receive error

1

Receive buffer capacity

2

3 Handshaking XON/XOFF DTR/DSR

4 Data word length 7 bits 8bits

5 Parity check Enabled Dsabled

6 Parity selection Even Odd

7 Transmission speed

8 (See the table below)

lgnored Prints"?"

45 bytes 4K bytes

Transmission Speed

Transmission Speed

[BPS] 7 8

2400 ON ON

4800 OFF ON

9600 ON OFF

19200 OFF OFF

Switch No.

DIP Switch 2

SW Function ON OFF

1 Handshaking Receive Off line or

(BUSY condition)

2 Reserved Fixed to OFF.

Selects Print density

3

/Low power mode

4

5 Reserved Fixed to OFF

6 Reserved Fixed to OFF

I/F pin 12 reset signal

7

8 Unused Unused

buffer full receive buffer

(Refer to table below)

Enabled Disabled

Print Density Selection

Print Density

Level

1

Low power mode ON ON

2 OFF OFF

3 ON OFF

4 Dark OF F ON

Switch No.

3 4

Normal

14

Page 16

If you need to change settings, follow the steps

below to make your changes:

Caution

Turn off the IM-300 remove the printer from

it while changing the settings of the DIP

switches to prevent an electric short, which

can damage the printer.

1.Make sure the IM-300 is turned off.

2.Remove the printer from the IM-300. Please

refer to 4 for the removal procedure.

3.Remove the screw from the printer bottom

cover. Then take off the printer bottom cover,

as shown in the illustration below.

4. Set the switches using a pointed tool, such as

tweezers or a small screwdriver.

5.Replace the printer bottom cover. Then secure it with the screw.

Note:

The new settings take effect when you turn

on the IM-300.

15

Page 17

9 Adjusting the Remaining-

Paper Detector

Read this section only if you are using the remaining-paper detection feature.

Note

Rolls should be of specified paper type, and should

have an inner diameter (core diameter) of 12mm

and an outer diameter of 18mm.

1.Open the cover of the paper-roll area, and

remove the current paper roll.

2. Loosen the adjustment screw holding the de-

tector in place, and align the top of the positioning plate to the adjustment scale.

Approximate remaining paper level for each

scale setting is as follows.

#1 23mm

#2 27mm

3.Tighten the adjustment screw.

4. Confirm that the detection lever moves

smoothly.

5.Load a paper roll.

16

Page 18

17

Printed in Japan

1999.12

Loading...

Loading...