Page 1

Describes interfaces, connectors, and character code tables.

Describes how to control the printer and necessary information

when you develop applications.

Describes setup and installation of the product and peripherals.

Describes how to handle the product.

Describes features and general specifications for the product.

Technical Reference Guide

Product Overview

Setup

Application Development Information

Handling

Appendix

M00045002

Rev. B

Page 2

Cautions

• No part of this document may be reproduced, stored in a retrieval system, or transmitted in any form

or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior

written permission of Seiko Epson Corporation.

• The contents of this document are subject to change without notice. Please contact us for the latest

information.

• While every precaution has been taken in the preparation of this document, Seiko Epson Corporation assumes no responsibility for errors or omissions.

• Neither is any liability assumed for damages resulting from the use of the information contained

herein.

• Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third

parties for damages, losses, costs, or expenses incurred by the purchaser or third parties as a result of:

accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this

product, or (excluding the U.S.) failure to strictly comply with Seiko Epson Corporation’s operating

and maintenance instructions.

• Seiko Epson Corporation shall not be liable against any damages or problems arising from the use of

any options or any consumable products other than those designated as Original EPSON Products or

EPSON Approved Products by Seiko Epson Corporation.

Trademarks

EPSON and ESC/POS are registered trademarks of Seiko Epson Corporation in Japan and other

countries/regions.

Microsoft and Windows are registered trademarks of Microsoft Corporation.

ESC/POS® Command System

EPSON ESC/POS is a proprietary POS printer command system that includes patented or patentpending commands. ESC/POS is compatible with most EPSON POS printers and displays.

ESC/POS is designed to reduce the processing load on the host computer in POS environments. It

comprises a set of highly functional and efficient commands and also offers the flexibility to easily make

future upgrades.

2

Page 3

For Safety

Key to Symbols

The symbols in this manual are identified by their level of importance, as defined below. Read

the following carefully before handling the product.

You must follow warnings carefully to avoid serious bodily injury.

WARNING

Provides information that must be observed to prevent damage to the equipment or loss of

data.

CAUTION

Possibility of sustaining physical injuries.

Possibility of causing physical damage.

Possibility of causing information loss.

Provides information that must be observed to avoid damage to your equipment or a

malfunction.

Provides important information and useful tips.

3

Page 4

Warnings

WARNING

To avoid risk of electric shock, do not set up this product or handle cables during a

thunderstorm

Never insert or disconnect the power plug with wet hands.

Doing so may result in severe shock.

Handle the power cable with care.

Improper handling may lead to fire or electric shock.

Do not modify or attempt to repair the cable.

Do not place any heavy object on top of the cable.

Avoid excessive bending, twisting, and pulling.

Do not place the cable near heating equipment.

Check that the plug is clean before plugging it in.

Be sure to push the plug all the way in.

Be sure to use the specified power source.

Connection to an improper power source may cause fire or shock.

Do not place multiple loads on the power outlet.

Overloading the outlet may lead to fire.

Shut down your equipment immediately if it produces smoke, a strange odor, or

unusual noise.

Continued use may lead to fire. Immediately unplug the equipment and contact your

dealer or a Seiko Epson service center for advice.

Never attempt to repair this product yourself.

Improper repair work can be dangerous.

Never disassemble or modify this product.

Tampering with this product may result in injury or fire.

Do not allow foreign matter to fall into the equipment.

Penetration by foreign objects may lead to fire.

If water or other liquid spills into this equipment, do not continue to use it.

Continued use may lead to fire. Unplug the power cord immediately and contact your

dealer or a Seiko Epson service center for advice.

If you open the DIP switch cover, be sure to close the cover and tighten the screw

after adjusting the DIP switch.

Using this product with the cover open may cause fire or electric shock.

Do not use aerosol sprayers containing flammable gas inside or around this

product.

Doing so may cause fire.

4

Page 5

Cautions

Do not connect cables in ways other than those mentioned in this manual.

Different connections may cause equipment damage or fire.

CAUTION

Be sure to set this equipment on a firm, stable, horizontal surface.

The product may break or cause injury if it falls.

Do not use this product in locations subject to high humidity or dust levels.

Excessive humidity and dust may cause equipment damage or fire.

Do not place heavy objects on top of this product. Never stand or lean on this

product.

Equipment may fall or collapse, causing breakage and possible injury.

Take care not to injure your fingers on the manual cutter:

When you remove printed paper.

When you perform other operations, such as loading/replacing roll paper.

Do not open the roll paper cover without taking the necessary precautions, as this

can result in injury from the autocutter fixed blade.

To ensure safety, unplug this product before leaving it unused for an extended

period.

Restriction of Use

When this product is used for applications requiring high reliability/safety, s uch as

transportation devices related to aviation, rail, marine, automotive, etc.; disaster prevention

devices; various safety devices; or functional/precision devi

ces, you should use this product

only after giving consideration to including fail-safes and redundancies into your design to

maintain safety and total system reliability. B e c a use this product was not intended for use in

applications requiring extremely high reliability/safety, such as aerospace equipment, main

communication equipment, nuclear power control equipment, or medical equipment related to

direct medical care, etc., please make your own judgement on this product's suitability after a

full evalu

ation.

5

Page 6

About this Manual

Aim of the Manual

This manual was created to provide information on development, design, and installation of

systems and development and design of printer applications for developers.

Manual Content

The manual is made up of the following sections:

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Appendix

Product Overview

Setup

Application Development Information

Handling

Specifications of Interfaces and Connectors

Character Code Tables

6

Page 7

Contents

■ For Safety...............................................................................................................................3

Key to Symbols ....................................................................................................................................... 3

Warnings ................................................................................................................................................. 4

Cautions.................................................................................................................................................. 5

■ Restriction of Use ..................................................................................................................5

■ About this Manual ................................................................................................................6

Aim of the Manual................................................................................................................................. 6

Manual Content .................................................................................................................................... 6

Product Overview ........................................................................11

■ Features...............................................................................................................................11

■ Product Configurations ......................................................................................................12

Interfaces.............................................................................................................................................. 12

Colors .................................................................................................................................................... 12

Accessories........................................................................................................................................... 12

■ Part Names and Functions.................................................................................................13

Power Switch ........................................................................................................................................ 13

Control Panel ....................................................................................................................................... 14

Connectors........................................................................................................................................... 15

Offline .................................................................................................................................................... 15

■ Error Status...........................................................................................................................16

Printer Errors .......................................................................................................................................... 16

Unrecoverable Errors ........................................................................................................................... 17

Data Receive Error (Only with the Serial Interface Models) ........................................................... 17

■ Power-Saving Mode ...........................................................................................................18

Sleep 1 & Sleep 2 ................................................................................................................................. 18

Sleep 3 .................................................................................................................................................. 19

■ NV Memory (Non-Volatile Memory) ................................................................................20

Memory Switches................................................................................................................................. 20

Maintenance Counter ........................................................................................................................ 20

■ Product Specifications .......................................................................................................21

Printing Specifications ......................................................................................................................... 22

Paper Specifications............................................................................................................................ 23

Printable Area ...................................................................................................................................... 25

Printing and Cutting Positions............................................................................................................. 26

Black Marks........................................................................................................................................... 27

Electrical Characteristics .................................................................................................................... 28

Reliability............................................................................................................................................... 30

Environmental Conditions................................................................................................................... 30

External Dimensions and Mass ........................................................................................................... 31

7

Page 8

Power Supply Unit (PS-180) .................................................................................................................. 32

Setup .............................................................................................33

■ Flow of Setup....................................................................................................................... 33

■ Installing the Printer............................................................................................................ 34

Important Notes ...................................................................................................................................34

■ Changing the Paper Width................................................................................................ 34

Setting the Paper Width to 82.5 mm ..................................................................................................35

Setting the Paper Width to 79.5 mm ..................................................................................................36

Setting the Paper Width to 50.8 mm ..................................................................................................37

■ Setting the DIP Switches..................................................................................................... 38

Setting Procedure................................................................................................................................. 38

For Serial Interface................................................................................................................................ 40

For USB Interface................................................................................................................................... 41

For Ethernet Interface ..........................................................................................................................41

■ Connecting the Printer to the Host Computer................................................................. 42

For Serial Interface................................................................................................................................ 42

For USB Interface................................................................................................................................... 43

For Ethernet Interface ..........................................................................................................................44

■ Connecting the Power Supply Unit (PS-180).................................................................... 45

Connecting the Power Supply Unit .................................................................................................... 45

■ Setting the Memory Switches............................................................................................ 47

Functions ...............................................................................................................................................48

Application Development Information ......................................53

■ How to Control the Printer.................................................................................................. 53

EPSON Advanced Printer Driver (APD)......................................................................................53

ESC/POS Commands ...........................................................................................................................53

■ Software and Manuals....................................................................................................... 54

How to Get Drivers, Manuals, and the Utility.....................................................................................54

Printer Driver ..........................................................................................................................................54

Utilities ....................................................................................................................................................54

■ Self-Test Mode .................................................................................................................... 55

Starting the Self-Test .............................................................................................................................55

8

Page 9

Handling .......................................................................................57

■ Usage Precautions..............................................................................................................57

■ Installing and Replacing Paper.........................................................................................58

Installing Paper..................................................................................................................................... 58

Replacing Paper.................................................................................................................................. 59

■ Removing Jammed Paper.................................................................................................61

■ Cleaning the Printer............................................................................................................63

Cleaning the Printer Case .................................................................................................................. 63

Cleaning the Thermal Head ............................................................................................................... 63

■ Preparing for Transport .......................................................................................................65

Appendix......................................................................................67

■ Specifications of Interfaces and Connectors ..................................................................67

RS-232 Serial Interface......................................................................................................................... 67

10BASE-T/100BASE-TX Ethernet Interface........................................................................................... 70

USB (Universal Serial Bus) Interface .................................................................................................... 72

■ Character Code Tables......................................................................................................73

Common to All Pages ......................................................................................................................... 73

Page 0 [PC437: USA, Standard Europe]............................................................................................74

Page 1 (Katakana) .............................................................................................................................. 75

Page 2 (PC850: Multilingual) .............................................................................................................. 76

Page 3 (PC860: Portuguese)............................................................................................................... 77

Page 4 (PC863: Canadian-French)................................................................................................... 78

Page 5 (PC865: Nordic) ...................................................................................................................... 79

Page 11 (PC851: Greek) ..................................................................................................................... 80

Page 12 (PC853: Turkish) ..................................................................................................................... 81

Page 13 (PC857: Turkish) ..................................................................................................................... 82

Page 14 (PC737: Greek) .........................................................................................................

Page 15 (ISO8859-7: Greek) ............................................................................................................... 84

Page 16 (WPC1252)............................................................................................................................. 85

Page 17 (PC866: Cyrillic #2)................................................................................................................ 86

Page 18 (PC852: Latin2)...................................................................................................................... 87

Page 19 (PC858: Euro)......................................................................................................................... 88

Page 20 (KU42: Thai)............................................................................................................................ 89

Page 21 (TIS11: Thai) ............................................................................................................................ 90

Page 26 (TIS18: Thai) ............................................................................................................................ 91

Page 30 (TCVN-3: Vietnamese) ......................................................................................................... 92

Page 31 (TCVN-3: Vietnamese) ......................................................................................................... 93

Page 32 (PC720: Arabic) .................................................................................................................... 94

Page 33 (WPC775: Baltic Rim)............................................................................................................ 95

Page 34 (PC855: Cyrillic)..................................................................................................................... 96

Page 35 (PC861: Icelandic)................................................................................................................ 97

Page 36 (PC862: Hebrew) ........................................................................................................

............ 83

.......... 98

9

Page 10

Page 37 (PC864: Arabic).....................................................................................................................99

Page 38 (PC869: Greek)....................................................................................................................100

Page 39 (ISO8859-2: Latin2)...............................................................................................................101

Page 40 (ISO8859-15: Latin9).............................................................................................................102

Page 41 (PC1098: Farsi) ..................................................................................................................... 103

Page 42 (PC1118: Lithuanian)........................................................................................................... 104

Page 43 (PC1119: Lithuanian)........................................................................................................... 105

Page 44 (PC1125: Ukrainian)............................................................................................................. 106

Page 45 (WPC1250: Latin 2)..............................................................................................................107

Page 46 (WPC1251: Cyrillic) ....................................................................................................

Page 47 (WPC1253: Greek)...............................................................................................................109

Page 48 (WPC1254: Turkish) ..............................................................................................................110

Page 49 (WPC1255: Hebrew)............................................................................................................111

Page 50 (WPC1256: Arabic)..............................................................................................................112

Page 51 (WPC1257: Baltic Rim) ........................................................................................................113

Page 52 (WPC1258: Vietnamese) ....................................................................................................114

Page 53 (KZ1048: Kazakhstan).......................................................................................................... 115

Page 255 (User-Defined Page)..........................................................................................................116

International Character Sets .............................................................................................................117

..........108

10

Page 11

Product Overview

This chapter describes features and specifications of the product.

Features

The TM-L500A Ticket is a high-speed compact printer suited for issuing tickets.

The features are as follows:

Printing

Chapter 1 Product Overview

•High speed printing: Max. 250 mm/s {9.84"/s}

•Selection of 4 paper widths — 50.8 mm {2.00"}, 54.0 mm {2.13"}, 79.5 mm {3.13"}, and 82.5 mm

{3.24"}

•Auto printing position adjustment

Handling

•Compact body for flexible installation locations

•High-speed autocutter

•An optional paper supply device

Software

•Command protocol based on the ESC/POS Proprietary Command System

•Windows printer driver

•Bar code and two-dimensional symbol printing is possible.

•Maintenance counter

1

Environment

ENERGY STAR qualified.

11

Page 12

Product Configurations

Interfaces

•Serial (9 Pin D-Sub) UB + USB interface model

•Ethernet interface model

Colors

EDG (Epson Dark Gray)

Accessories

Included

•AC adapter (Model: PS-180)

•Cable hook

• User’s manual

Options

•Paper supply (Model: SU-RPL500/RPL500B)

•Interface boards (UB-U500/UB-E500)

These optional interface boards are only for the TM-L500A. Never use them with other

Epson printers. Also, never use other interface boards with the TM-L500A.

12

Page 13

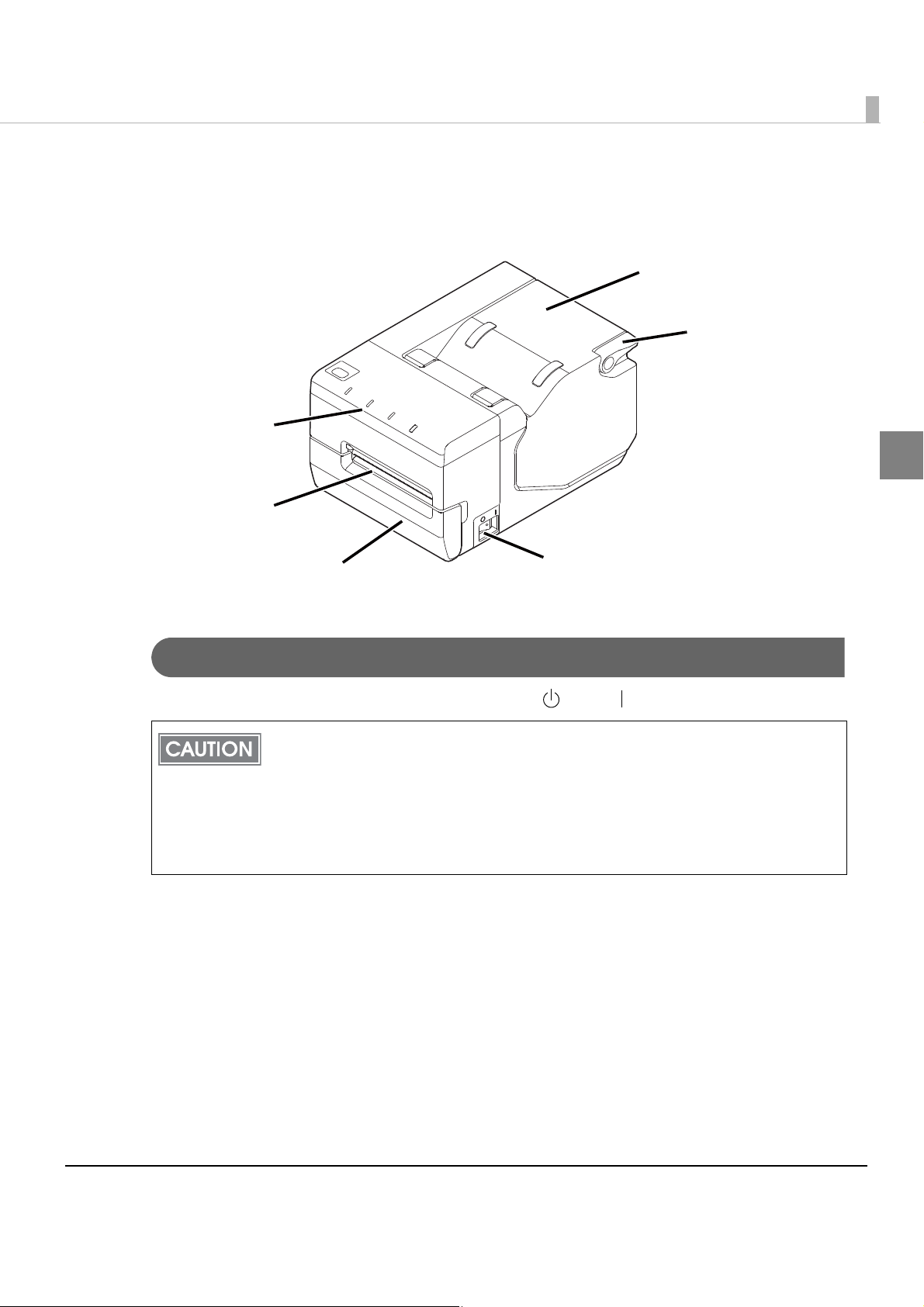

Part Names and Functions

Control panel

Manual cutter

Platen cover

Power switch

Cover open lever

Paper loading cover

Chapter 1 Product Overview

1

Power Switch

Turns the printer on or off. The marks on the switch: ( : OFF/ : ON)

Before turning on the printer soon after turning it off, make sure the LEDs on the control

panel are off.

Before turning the printer off, it is recommended to send a power-off command to the

printer. If you use the power-off sequence, the latest maintenance counter values are

saved. (Maintenance counter values are usually saved every two minutes.)

For detailed information about ESC/POS commands, see the ESC/POS Application

Programming Guide.

13

Page 14

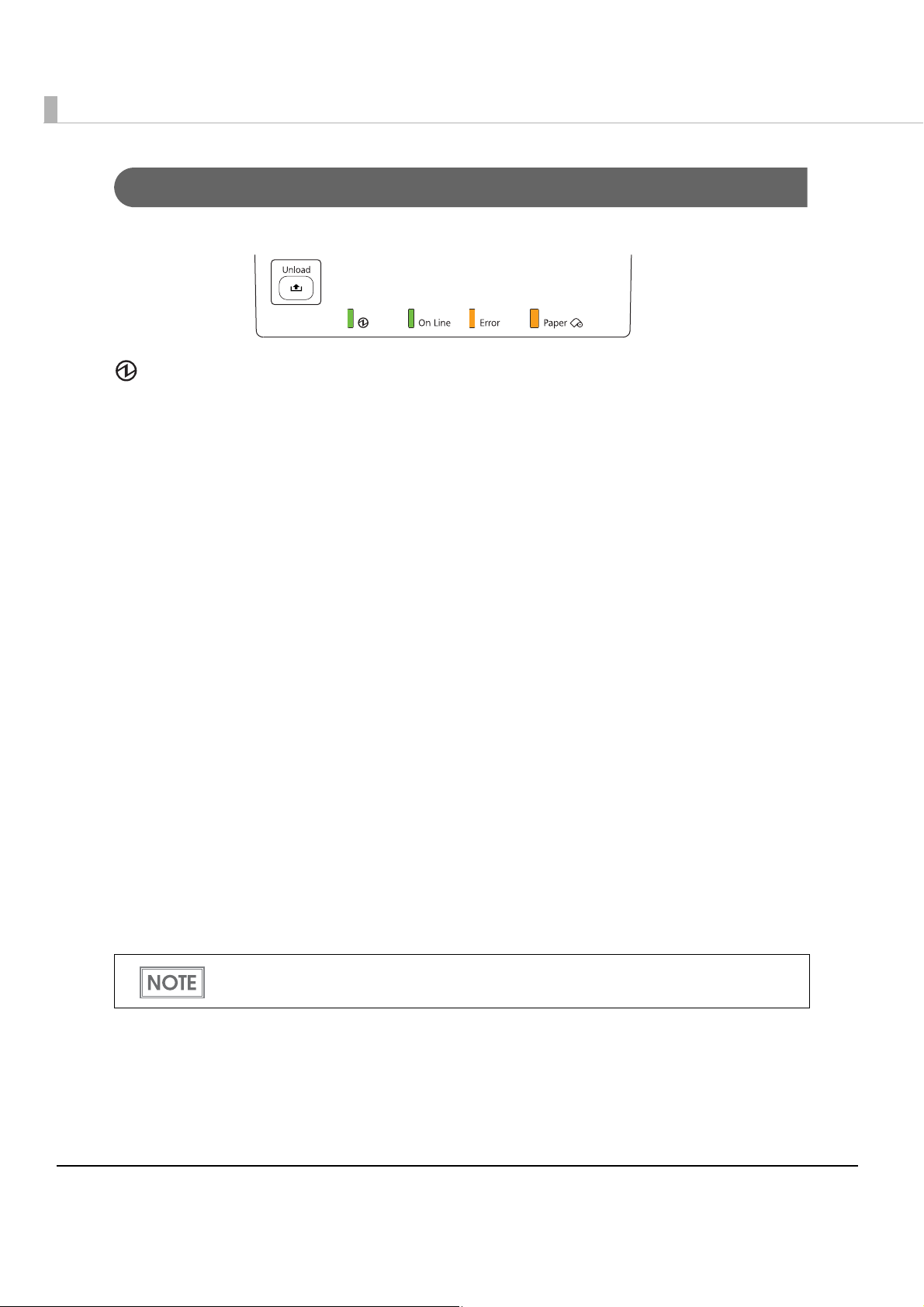

Control Panel

Power LED (Green)

•Lights when the power supply is on.

•Goes out when the power supply is turned off, or the printer is in the power-saving mode

(sleep 3).

On Line LED (Green)

•Lights when the printer is online.

•Goes out when the printer is offline (For details about offline, see "Offline" on page 15.) or in

the power-saving mode (sleep 3).

Error LED (Orange)

•Lights when the paper loading cover or the platen frame is open.

•Flashes when an error occurs. (For details about the flash codes, see "Error Status" on page 16.)

•Goes out during regular operation or the power-saving mode (sleep 3).

Paper LED (Orange)

•Lights when paper is out.

•Goes out when paper is loaded, or the printer is in the power-saving mode (sleep 3).

•Flashes in self-test printing standby state or autoloading standby state.

Unload () button

Holding down this button for 1 second or more feeds paper backward until the paper can be

removed from the back of the printer.

For information about the power-saving mode, see "Power-Saving Mode" on page 18.

14

Page 15

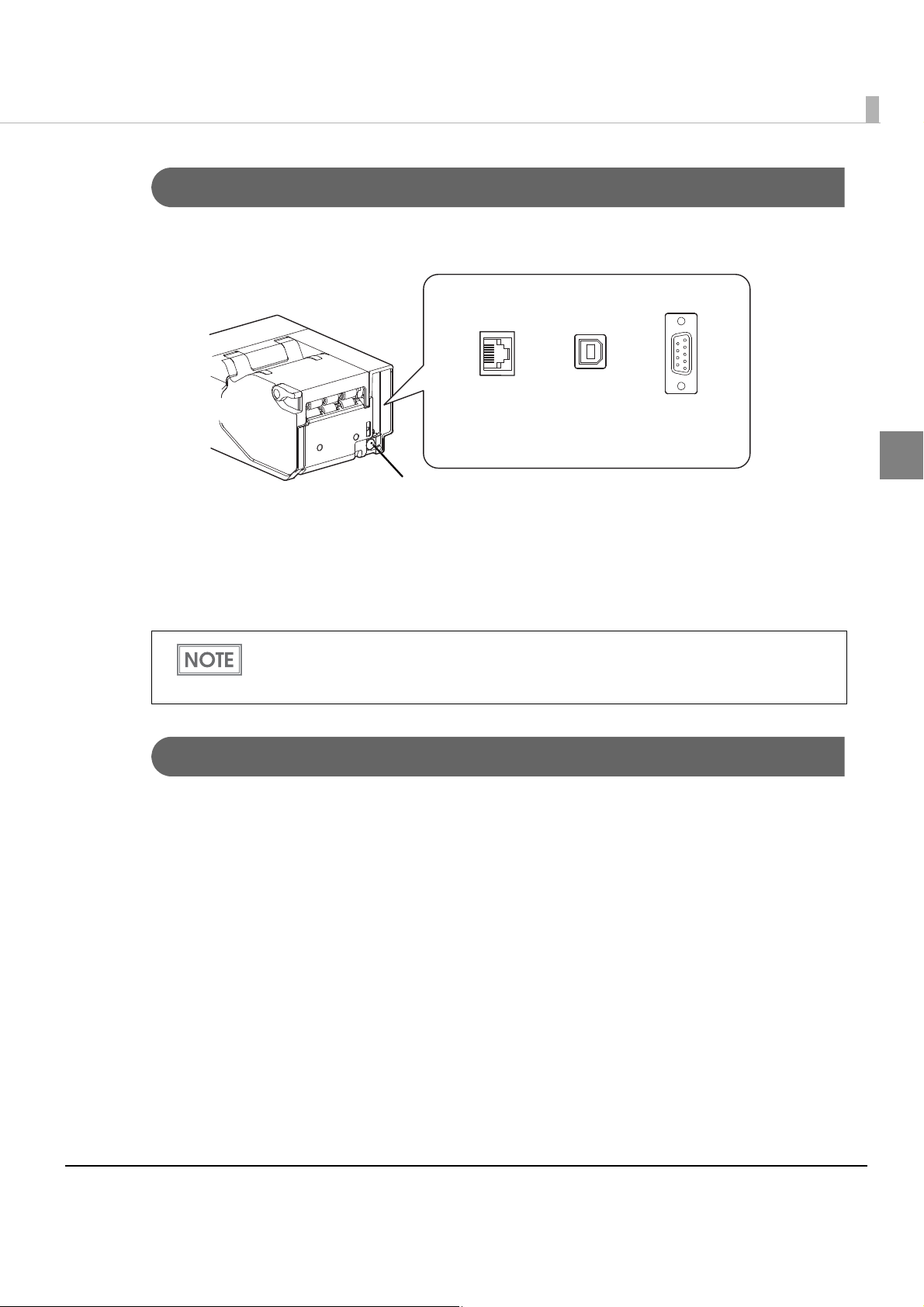

Chapter 1 Product Overview

Power supply connector

Serial (9-Pin D-

USB

Ethernet

Interface connectors

Connectors

All cables are connected to the connector panel on the lower rear of the printer.

•Interface connector: Connects the printer with the host computer interface.

The interface type differs depending on the model. (See

"Interfaces" on page 12.)

1

•Power supply connector: Connects the power supply unit.

For details on how to connect the interface connector and the power supply connector, see

"Connecting the Printer to the Host Computer" on page 42 and "Connecting the Power

Supply Unit (PS-180)" on page 45.

Offline

The printer automatically goes offline under the following conditions:

•During power on (including resetting with the interface) until the printer is ready

•During the self-test

•When a fatal error has occurred

15

Page 16

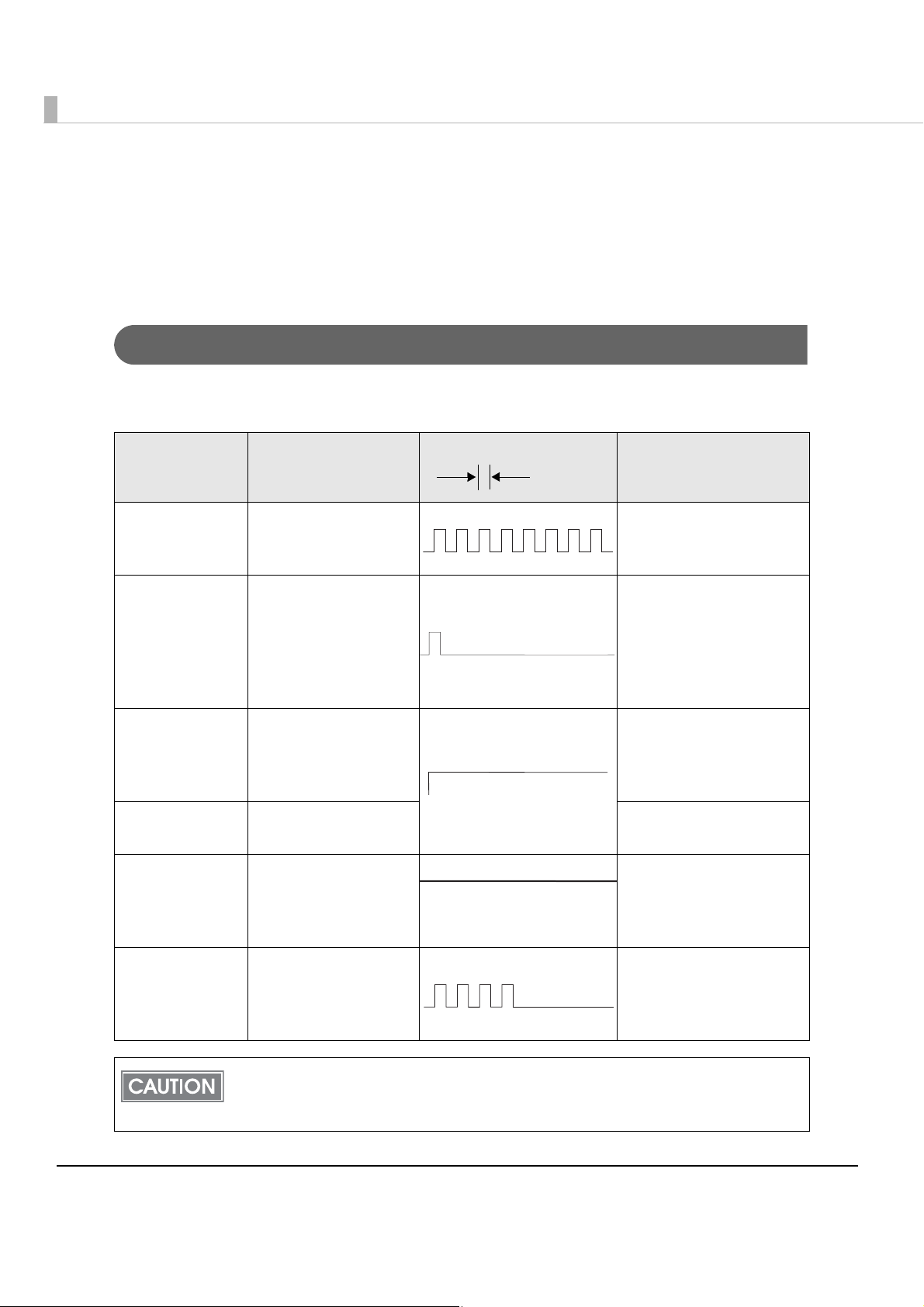

Error Status

Approx.

320 ms

When an error occurs, the printer stops operating, the Error LED or Paper LED lights or flashes,

and the buzzer beeps (only when the buzzer function is enabled). If the error is a fatal one, the

printer goes offline.

Printer Errors

Printing is no longer possible when printer errors occur. They can be recovered easily, as

described below.

Error LED flash code

Error Error description

Recovery measure

Print head/Moto r

temperature

error

Autocutter error Autocutting failed. Open the platen frame,

Platen frame

open (including

while printing)

Paper loading

cover open

Paper out Paper out sensor is in

Paper jam Paper jam sensor has

The temperature of

the print head is

extremely high.

Platen frame is open. Remove the paper in the

Paper loading cover is

open.

the status of paper

not present.

detected a paper

jam.

(Note: Paper LED comes

on when paper is out.)

Recovers automatically

when the print head/

motor cools.

remove the foreign

object, and then load the

appropriate paper. Or

send an error recovery

command.

paper path, and then

load the appropriate

paper.

Close the paper loading

cover.

Remove the paper in the

paper path, and then

load the appropriate

paper.

Remove the paper

wrapped around the

platen, and then load the

appropriate paper.

16

When an Autocutter error occurs, do not turn the printer power off. If the printer power is

turned off in occurring Autocutter error, the print starting position of the first sheet

immediately after the printer power is turned on is placed on the wrong position.

Page 17

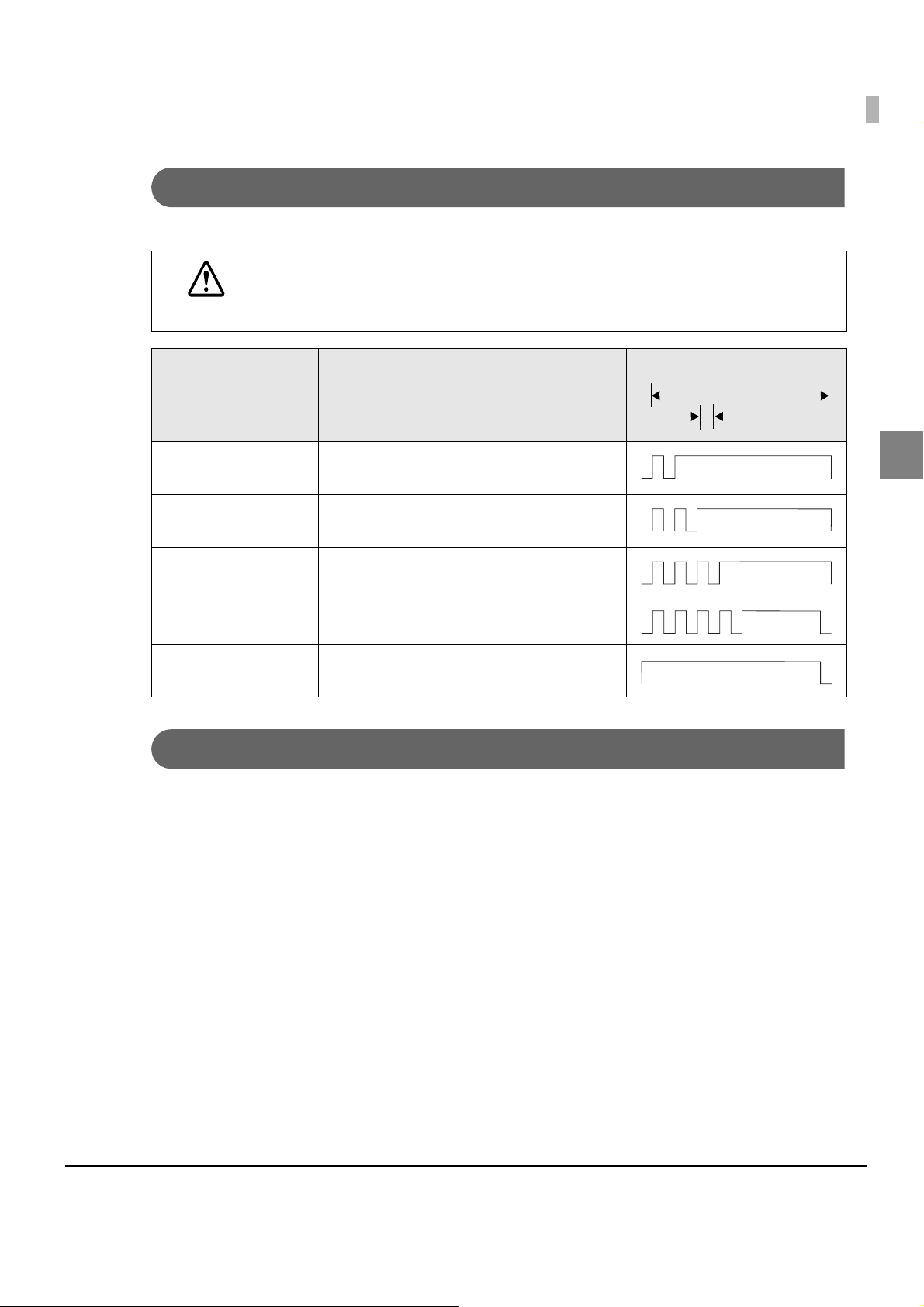

Chapter 1 Product Overview

Approx. 4800 ms

Approx.

320 ms

Unrecoverable Errors

Printing is no longer possible when unrecoverable errors occur. The p rinter must be repaired.

Turn off the power immediately when unrecoverable errors occur.

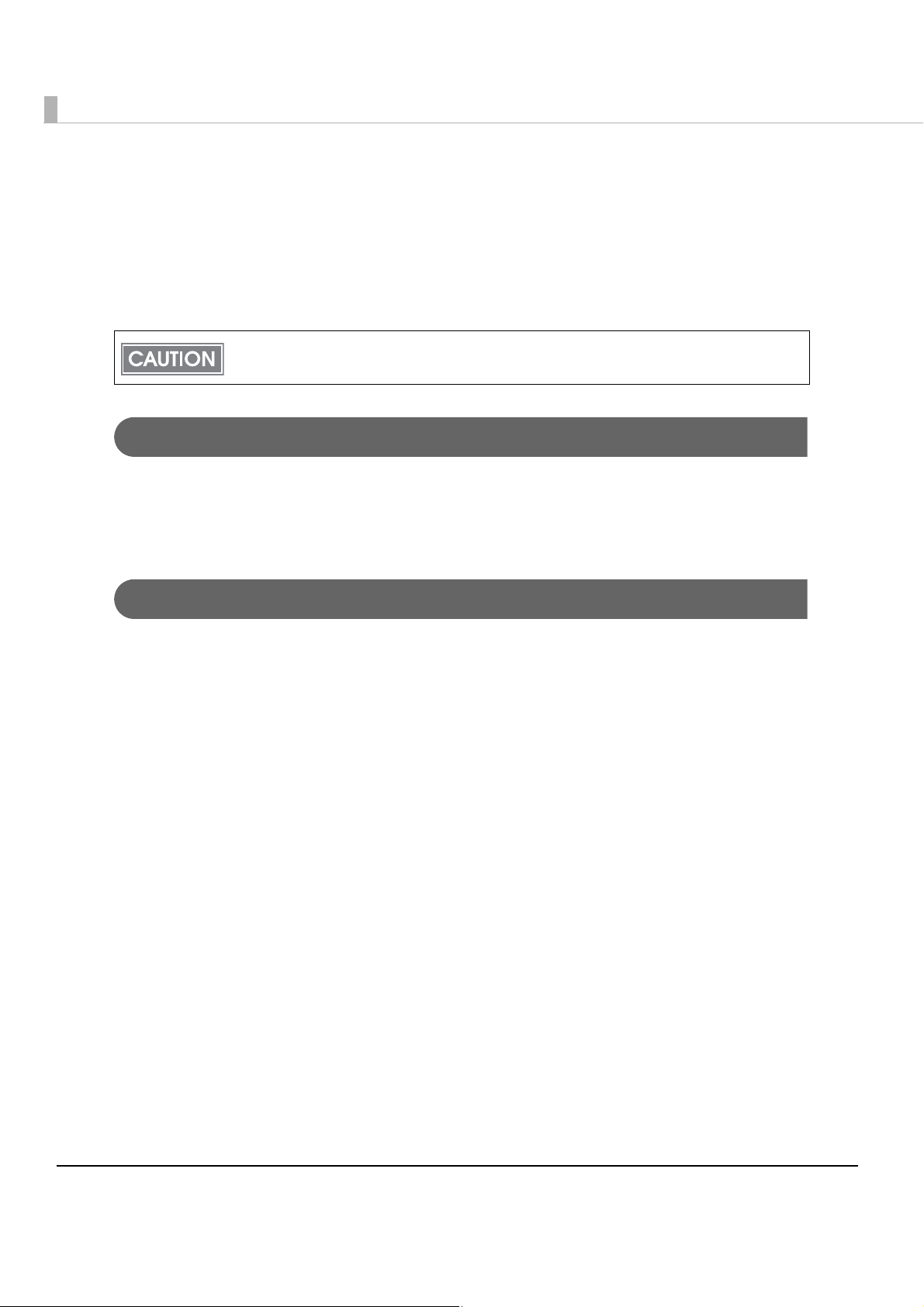

CAUTION

Error LED flash code

Error Error description

R/W error in memory After R/W checking, the printer does not

work correctly.

High voltage error The power supply voltage is extremely

high.

Low voltage error The power supply voltage is extremely low.

CPU execution error The CPU executes an incorrect address.

Internal circuit

connection error

The connection of internal circuit is not

correct.

Data Receive Error (Only with the Serial Interface Models)

If any of the following errors occurs during serial interface communication, the printer prints “?”

or ignores the data.

•Parity error

•Framing error

•Overrun error

1

17

Page 18

Power-Saving Mode

The TM-L500A Ticket has the power-saving mode function to reduce the power consumption.

There are 3 statuses, sleeps 1, 2, and 3 in the power-saving mode.

For the power consumption during standby in each sleep mode, see "Electrical

Characteristics" on page 28.

Sleep 1 & Sleep 2

Yo u can set the statuses, Sleeps 1 & 2 to any of the 3 patterns in the table below with the memory

switch.

• Sleep 1: The printer enters this mode 10 seconds after entering standby status.

• Sleep 2: The printer enters this mode 5 minutes after entering standby status.

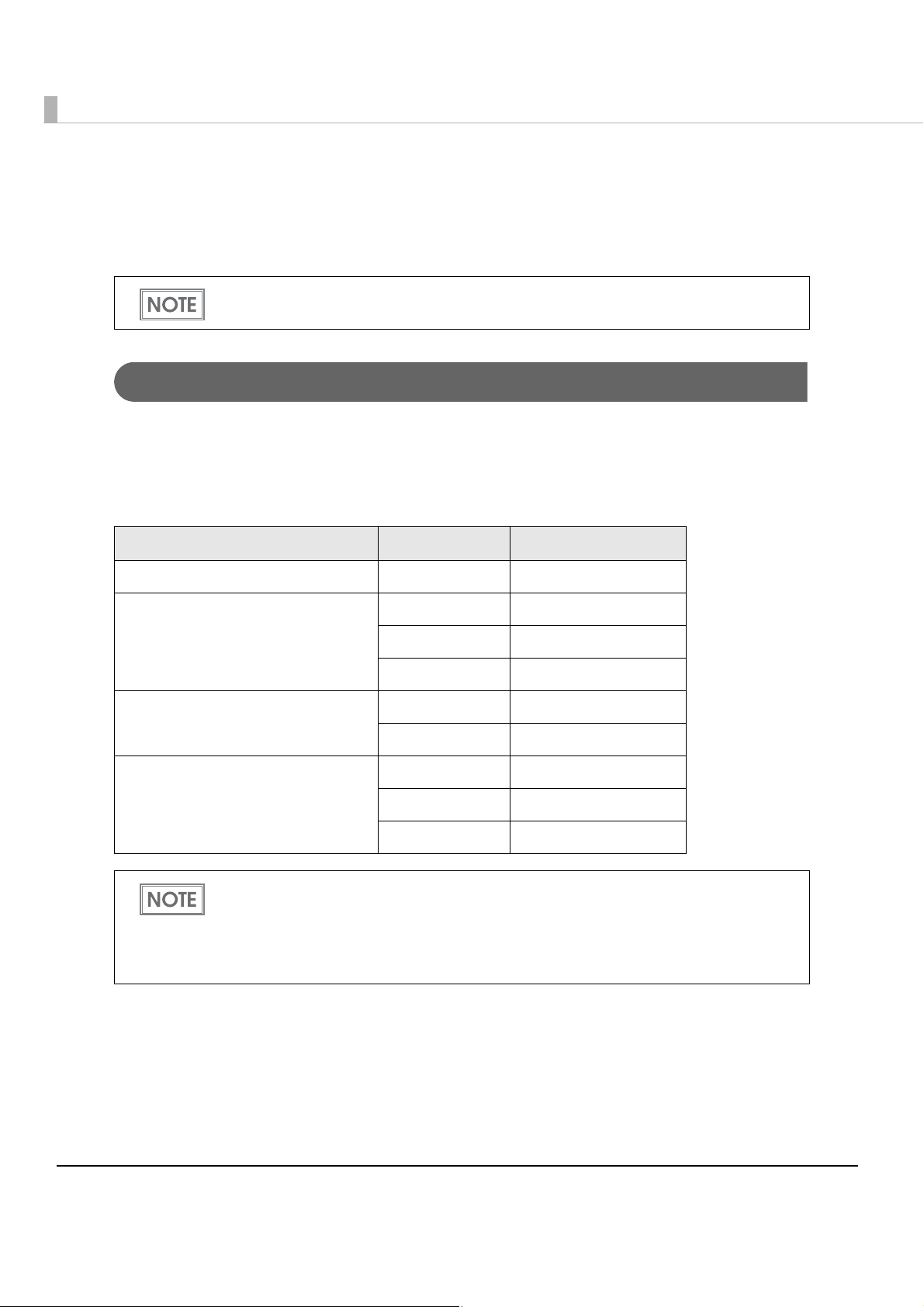

Patterns for sleep 1 and sleep2 Status LEDs brightness

No power saving — Bright

Pattern 1 (initial setting) Normal Bright

Sleep 1 Dim

Sleep 2 Dim

Pattern 2 Normal Bright

Sleep 1 Dim

Pattern 3 Normal Bright

Sleep 1 Bright

Sleep 2 Bright

Standby status is a status when no processing is being performed for printing or

communication, and the cover is closed.

When printing data is received, it is printed immediately.

For details on how to set the memory switch, see "Setting the Memory Switches" on

page 47.

18

Page 19

Chapter 1 Product Overview

Sleep 3

When Sleep 3 is enabled with the memory switch, the printer enters this mode 4 hours after

entering standby status.

During Sleep 3, the LEDs are off, and no operation is available.

The printer recovers to the normal status when you perform any of the following;

•Push one of the panel buttons.

•Turn t

he printer power off, and turn it back on. (Turn the printer power on after 3 seconds or

more have passed.)

1

19

Page 20

NV Memory (Non-Volatile Memory)

The printer's NV memory stores data even after the printer power is turned off. NV memory

contains the following memory areas for the user:

•Memory switches

•Maintenance counter

As a guide when you program applications, NV memory should be rewritten 10 or fewer

times a day.

Memory Switches

With the memory switches, which are software switches for the printer, you can configure

various settings of the printer.

For information about the memory switches see "Setting the Memory Switches" on page 47.

Maintenance Counter

With this function, printer information, such as the number of lines printed, the number of MICR

readings, the number of autocuts, and printer operation time after the printer starts working, is

automatically stored in NV memory. You can read or reset the information with the TM-L500A

Utility, the Status API of the APD, or OPOS ADK to use it for periodical checks or part

Ticket

replacement.

20

Page 21

Chapter 1 Product Overview

Product Specifications

Printing method Thermal line printing

Dot density 203 dpi × 203 dpi

Printing direction Unidirectional with friction feed

Paper width 50.8 mm {2.00"}, 54.0 mm {2.13"}(default), 79.5 mm {3.13"},

82.5 mm {3.24"}

Number of characters Alphanumeric characters: 95

Extended graphics: 128 × 43 pages

International characters: 16 character sets

Character structure Font A: 12 × 24 (including horizontal 2-dot spacing)

Font B: 9 × 17 (including horizontal 2-dot spacing)

Cutting type Full cut

Interfaces Serial (RS-232), USB (2.0 Full-speed),

Ethernet (10BASE-T/100BASE-TX)

Receive buffer 4 KB

Bar code/two-dimensional symbol

printing

Power supply Epson PS-180 (Model: M159B)

Overall dimensions (H × W × D) 122 × 156 × 230 mm {4.80 × 6.14 × 9.06"}

Weight (mass) Approx. 2.8 kg {6.2 lb}

dpi: dots per inch cpi: characters per inch

Two-dimensional symbols (PDF417, QR code, Maxi-

Code, GS1-DataBar)

Bar codes (UPC-A, UPC-E, EAN 13, EAN 8, Code 39,

Interleaved 2 of 5, CODABAR, Code 128, GS1-128, GS1DataBar)

CompositSymbology

1

21

Page 22

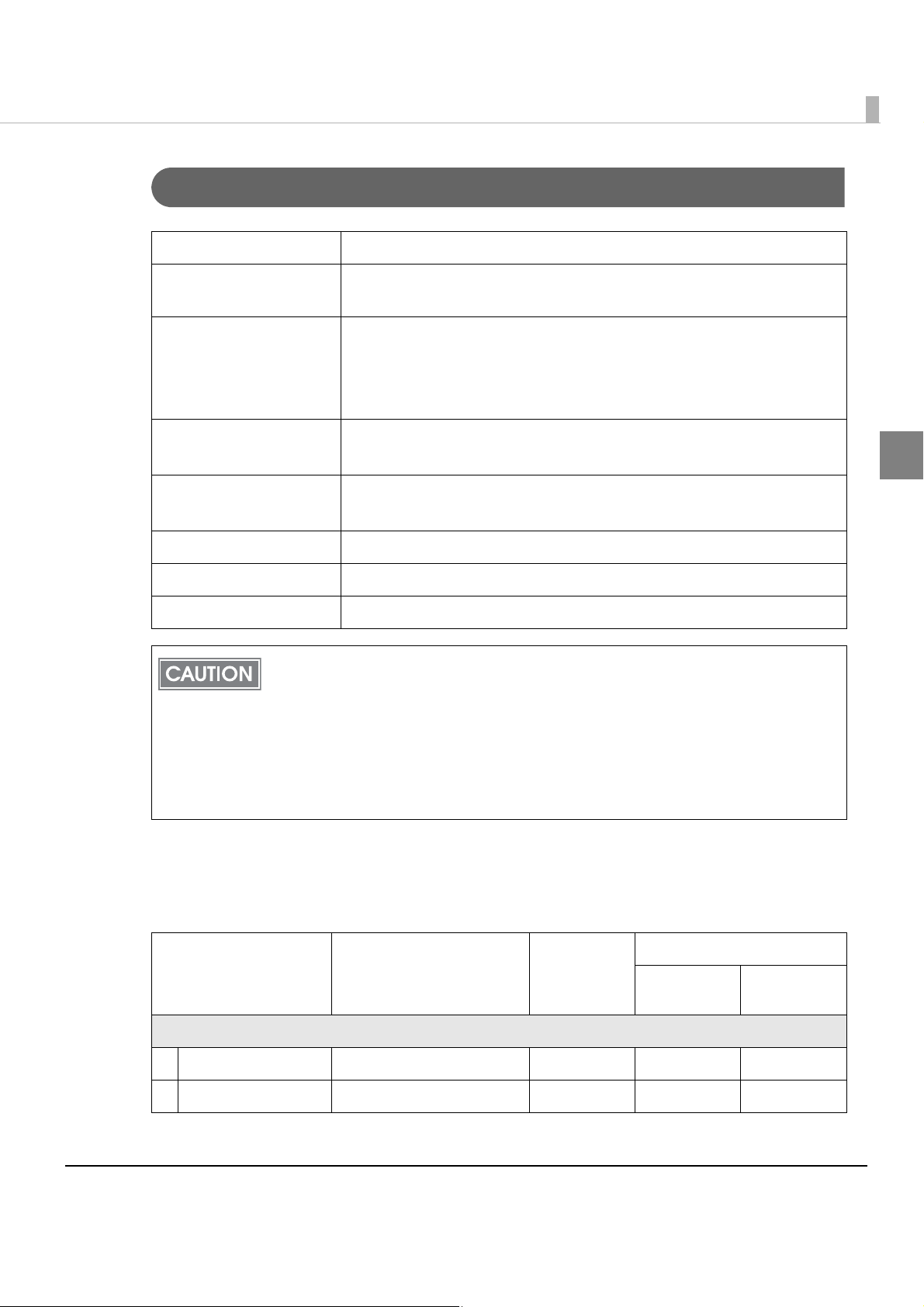

Printing Specifications

Printing method Thermal line printing

Dot density 203 dpi × 203 dpi

Printing direction Unidirectional with friction feed

Paper width 50.8 mm {2.00"}, 54.0 mm {2.13"}(default), 79.5 mm {3.13"},

82.5 mm {3.24"}

Printing width 50.8 mm printing 48.0 mm (1.89"), 384 dots

54.0 mm printing 51.0 mm (2.01"), 408 dots

79.5 mm printing 77.0 mm (3.03"), 616 dots

82.5 mm printing 80.0 mm (3.15"), 640 dots

Maximum printing speed

Text printing 250 mm/s {9.84"/s}

Bar code/2-dimensional symbol printing 126 mm/s {4.96"/s}

Note: The printing speeds listed above are the values when the printer prints with the standard print density

level at 24V and 25°C {77°F}.

When changing the paper width, you need to remove or move the paper guides. To

change the paper width, see "Changing the Paper Width" on page 34.

Because some parts of the print head contact the platen and they may become worn out

in narrower paper width printing, once you use the printer in narrower paper width

printing, you cannot change it back to wider one.

Printing speed can be changed with the memory switch. (See "Setting the Memory

Switches" on page 47.)

Printing speed may be slower, depending on such items as the data transmission speed.

22

Page 23

Paper Specifications

Type Thermal paper

Form Fanfold paper, Roll paper

(The chromogenic side must face outside.)

Width 50.8 mm ± 0.5 mm {2.00" ± 0.02"}

54.0 mm ± 0.5 mm {2.13" ± 0.02"}

79.5 mm ± 0.5 mm {3.13" ± 0.02"}

82.5 mm ± 0.5 mm {3.25" ± 0.02"}

Minimum length Fanfold paper: 40 mm {1.57"}

Roll paper: 30 mm {1.18"}

Length detection Optical hole detection, Black mark detection

(Roll paper without holes or black marks is also supported.)

Thickness 75 to 200 µm

Chapter 1 Product Overview

1

Roll paper diameter 184.2 mm {7.25"} maximum

Roll paper inside core 76.2 mm {3.00"}, 25.4 mm {1.00"})

Paper must not be pasted to the roll paper spool.

If preprinted thermal paper is used, sticking (a problem of the thermal head sticking to

the surface of the thermal paper during printing) may occur, causing faulty printing and

other problems. Preprinting may also cause drop in the print density.

Reflection rate of black marks must be 10% or less, and that of the areas without black

marks must be 75% or more.

Carefully design the print layout so that the printing position is away from the perforated

line.

For good print quality, s et the media type, print density, a nd print speed, depending on the

original paper number, as shown in the table below. They can be changed with the memory

switch. For information about the memory switches see "Setting the Memory Switches" on page

47.

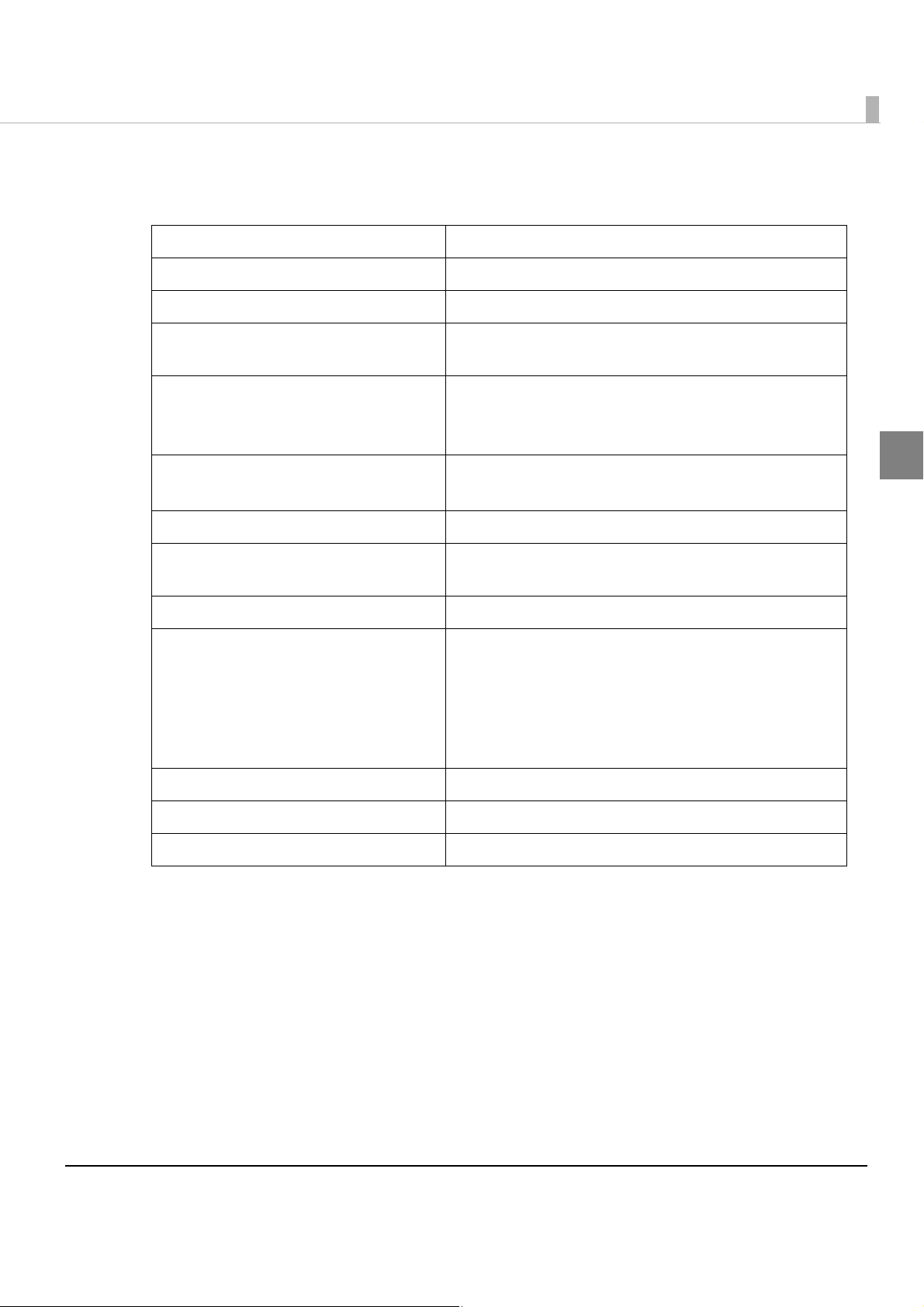

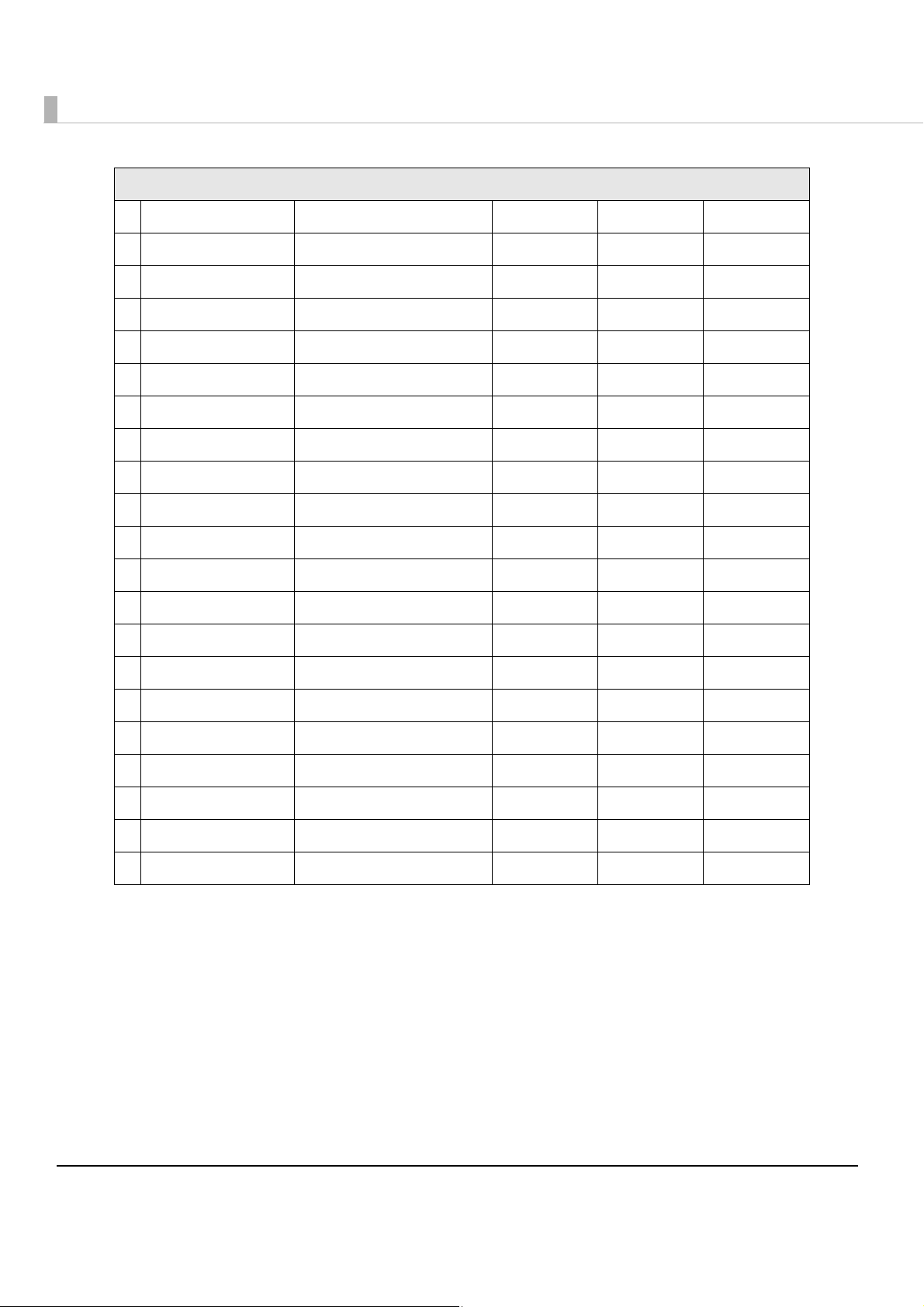

Recommended

Specified original

paper types

Manufacturer Media type

Print density

Print speed

(mm/s)

POS thermal paper

TF11KS-ET NIPPON PAPER INDUSTRIES Type 4 07 250*

PD160R OJI PAPER MFG Type 4 07 250*

23

Page 24

Ticket paper

Resiste 400-7.0 Appleton Type 2 04 150

Resiste 400-5.3 Appleton Type 2 01 150

Resiste 800-5.3 Appleton Type 2 01 150

Resiste 800-4.5 Appleton Type 1 03 150

Resiste 500-7.6 Appleton Type 1 05 150

P354 Kanzaki Specialty Papers Type 1 01 150

ST-5 Kanzaki Specialty Papers Type 2 04 150

KT-300 Kanzaki Specialty Papers Type 2 01 150

TF1767 Mitsubisi HiTec Type 2 03 150

T1733 Mitsubisi HiTec Type 2 03 150

KL615 s B+ Kanzan Type 1 01 150

PolyTherm 300-3.0 Appleton Type 3 02 200

PolyTherm 300-4.1 Appleton Type 3 01 200

PolyTherm 500-4.1 Appleton Type 2 02 200

Resiste 190-3.2 Appleton Type 3 05 200

KPT 3370 Kanzaki Specialty Papers Type 2 04 200

KPT 33100 Kanzaki Specialty Papers Type 3 04 200

KLS46 Kanzan Type 3 01 200

AL60KT-S Jujo Thermal Oy Type 1 06 200

140LES RICOH Type 2 05 200

150LCS-B RICOH Type 2 05 200

*: Roll paper diameter 152.4 mm {6.00"} maximum or fanfold

24

Page 25

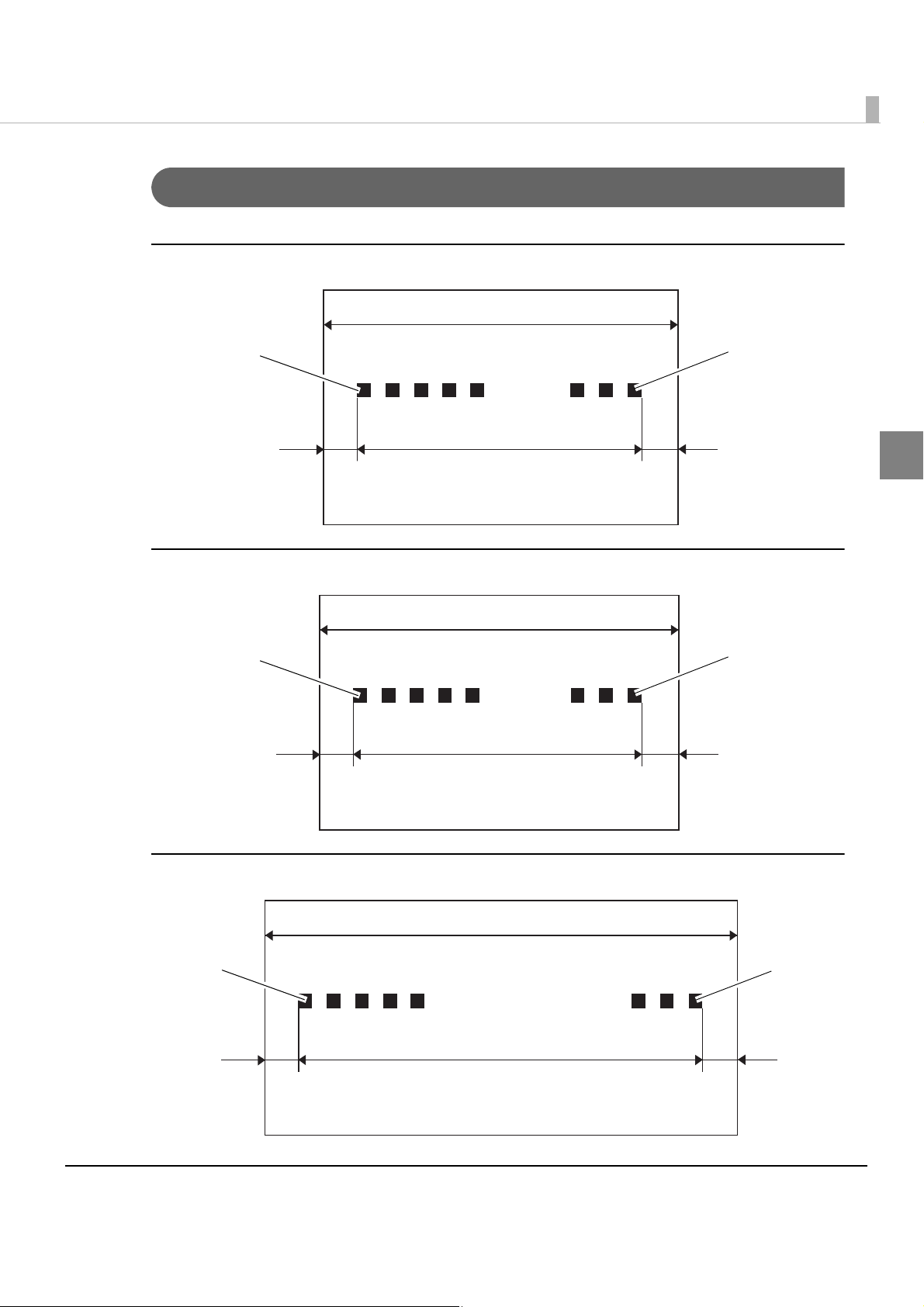

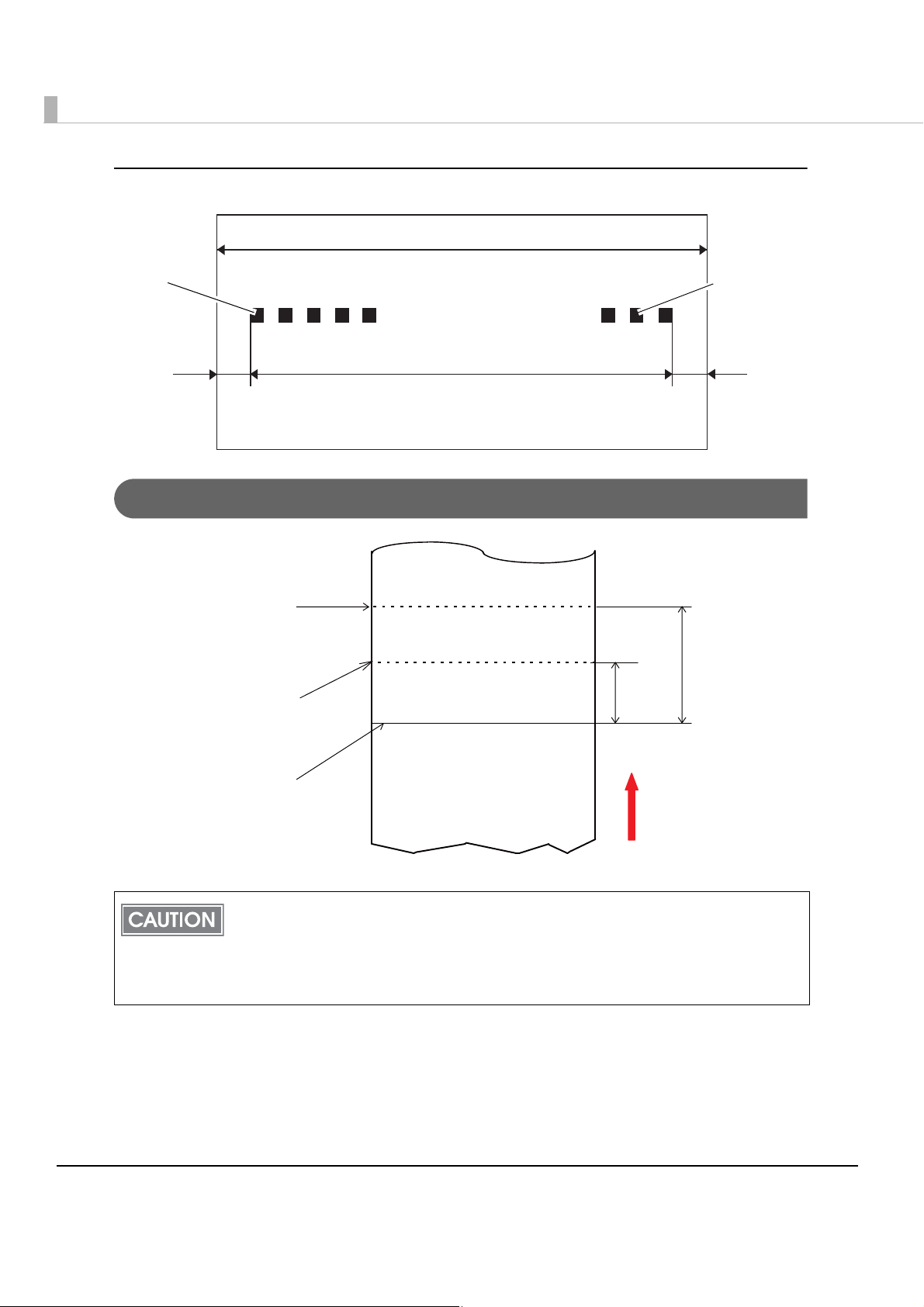

Printable Area

50.8 mm {2.00"} ± 0.5 mm

48.0 mm {1.89

"} (384 dots)1.25 mm {0.049"}

1.55 mm {0.061

"}

Dot no.1

Dot no.384

54.0 mm {2.13"} ± 0.5 mm

51.0 mm {2.01

"} (408 dots)1.25 mm {0.049"}

1.75 mm {0.069

"}

Dot no.1

Dot no.408

79.5 mm {3.13"} ± 0.5 mm

77.0 mm {3.03

"} (616 dots)

1.25 mm {0.049

"} 1.25 mm {0.049"}

Dot no.1

Dot no.616

50.8 mm paper width printing

Chapter 1 Product Overview

1

54.0 mm paper width printing

79.5 mm paper width printing

25

Page 26

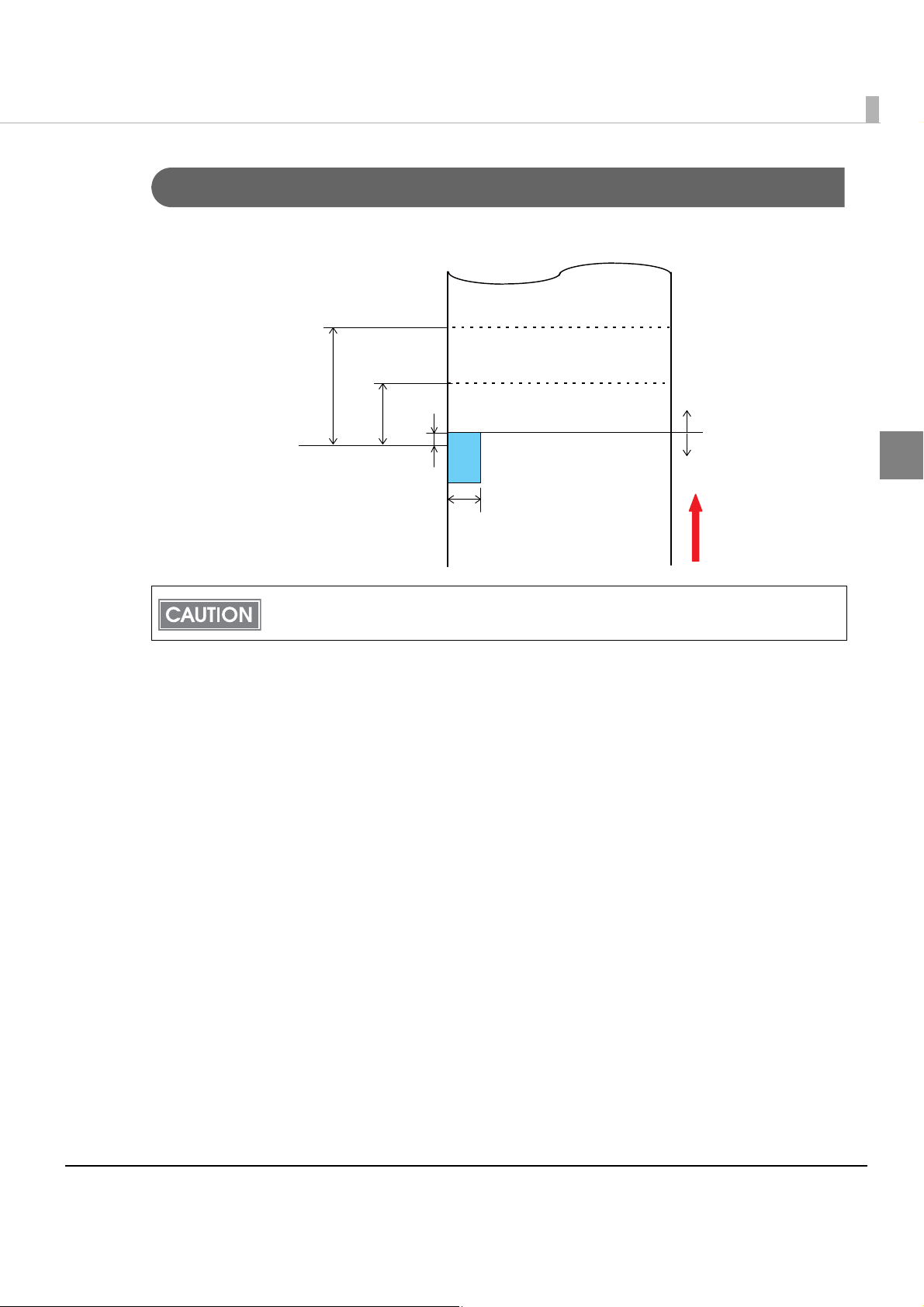

82.5 mm paper width printing

82.5 mm {3.25"} ± 0.5 mm

80.0 mm {3.15

"} (640 dots)

1.25 mm {0.049

"}

1.25 mm {0.049

"}

Dot no.1

Dot no.640

Autocutter blade position

Approx. 31 mm

Approx.

16 mm

Manual-cutter position

Center of the print dotline

Paper feed direction

The numeric values are typical values.

Printing and Cutting Positions

26

The values above may vary slightly as a result of paper slack or variations in the paper.

Take this into account when setting the cutting position of the autocutter.

When an Autocutter error occurs, do not turn the printer power off. If the printer power is

turned off in occurring Autocutter error, the print starting position of the first sheet

immediately after the printer power is turned on is placed on the wrong position.

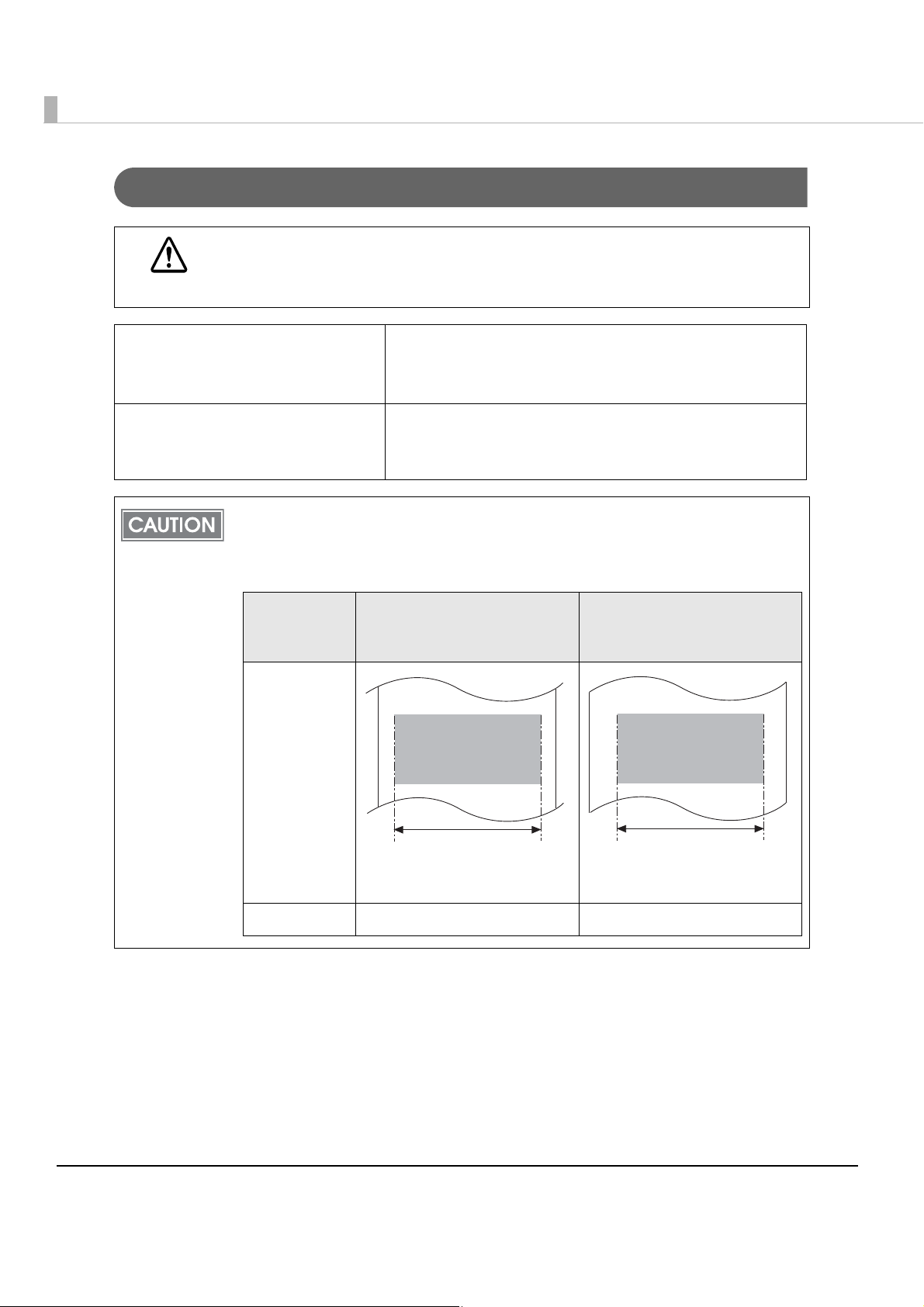

Page 27

Chapter 1 Product Overview

Paper feed direction

Autocutting position

Print starting position

Left on the face

33.6 mm

{1.32"}

17.6 mm

{0.69

"}

Approx.

2 mm

{0.079

"}

7 mm or longer

Center of

black mark sensor

~ +15 mm

~ -100 mm

Black Marks

Black marks are detected on the far left of the back of the paper (non-thermal face).

1

Reflection rate of black marks must be 10% or less, and that of the areas without black

marks must be 75% or more. (Measured with Macbeth density meter PCMII (filter D).)

27

Page 28

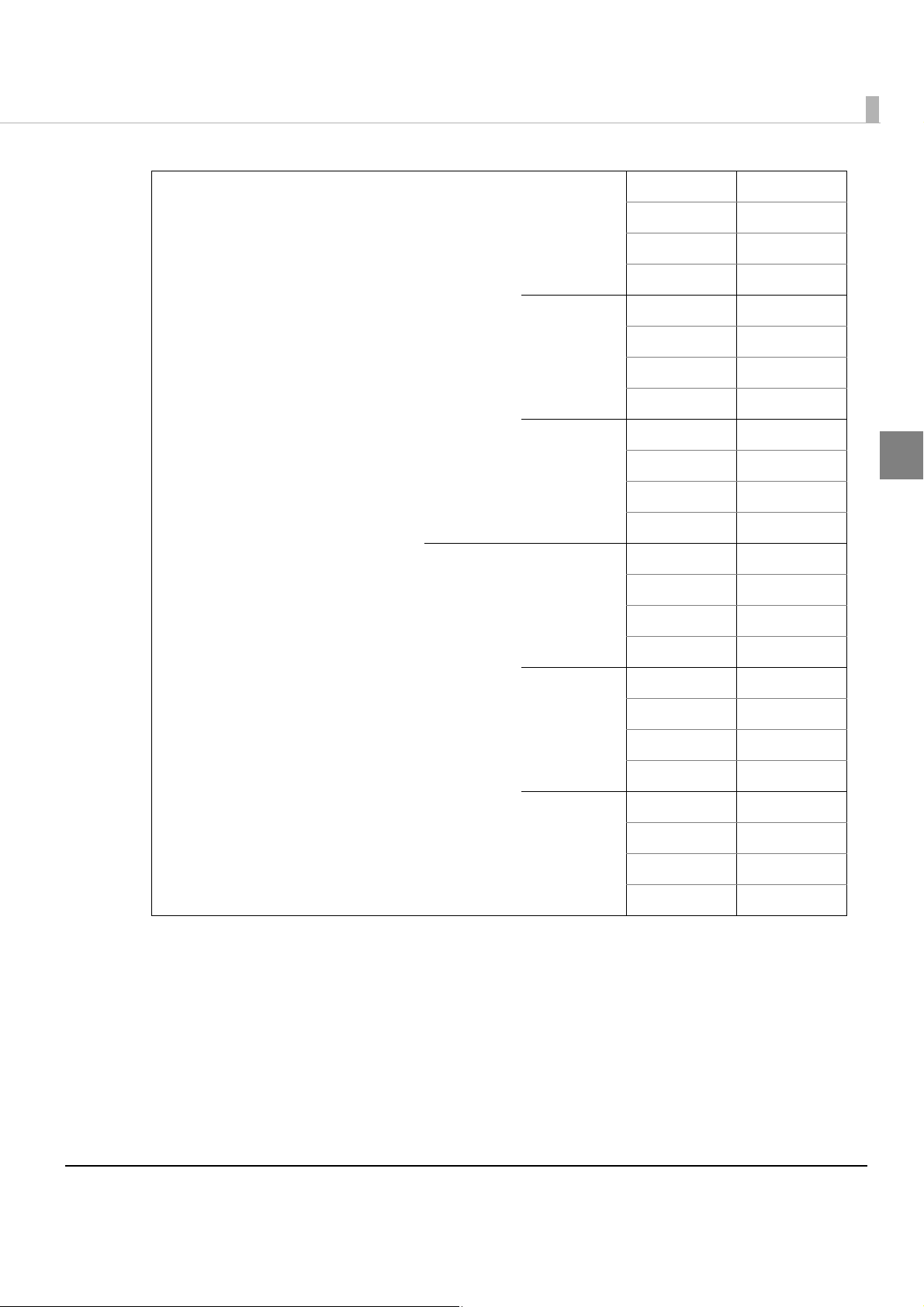

Electrical Characteristics

54 mm paper

Total print width:

408 dots (51.0 mm {2.01"})

82.5 mm paper

Total print width:

640 dots (80.0 mm {3.15"})

Print example

Print density must be 100%

maximum.

Print length 20 mm {0.79"} 20 mm {0.79"}

51 mm

64 mm

Be sure to use the power supply that came with your printer.

WARNING

Power supply Epson power supply PS-180

Rated voltage: 100 to 240V

Rated frequency: 50 to 60Hz

Power consumption during operating

(USB interface, at 23C {73.4F},

normal print density)

If printing is continuously performed with a high ratio, the overcurrent protection may be

activated and result in uneven print density or a low voltage error. Therefore, the printing

length must not exceed the following values when printing with high print ratio.

Print width: Number of dots being energized per one dot line

Mean: Approx. 24.1W (at 230V)

Approx. 24.2W (at 115V)

28

Page 29

Chapter 1 Product Overview

Power consumption during standby

(at 23C {73.4F}, normal print density)

115V/60Hz Serial I/F Sleep 1 0.6W

Sleep 2 0.6W

Sleep 3 0.3W

Powe r off 0.3W

USB I/F Sleep 1 0.6W

Sleep 2 0.5W

Sleep 3 0.3W

Powe r off 0.3W

Ethernet I/F Sleep 1 2.6W

Sleep 2 2.5W

Sleep 3 0.3W

Powe r off 0.3W

230V/50Hz Serial I/F Sleep 1 0.7W

Sleep 2 0.7W

Sleep 3 0.4W

1

Powe r off 0.4W

USB I/F Sleep 1 0.7W

Sleep 2 0.6W

Sleep 3 0.4W

Powe r off 0.4W

Ethernet I/F Sleep 1 2.7W

Sleep 2 2.7W

Sleep 3 0.4W

Powe r off 0.4W

29

Page 30

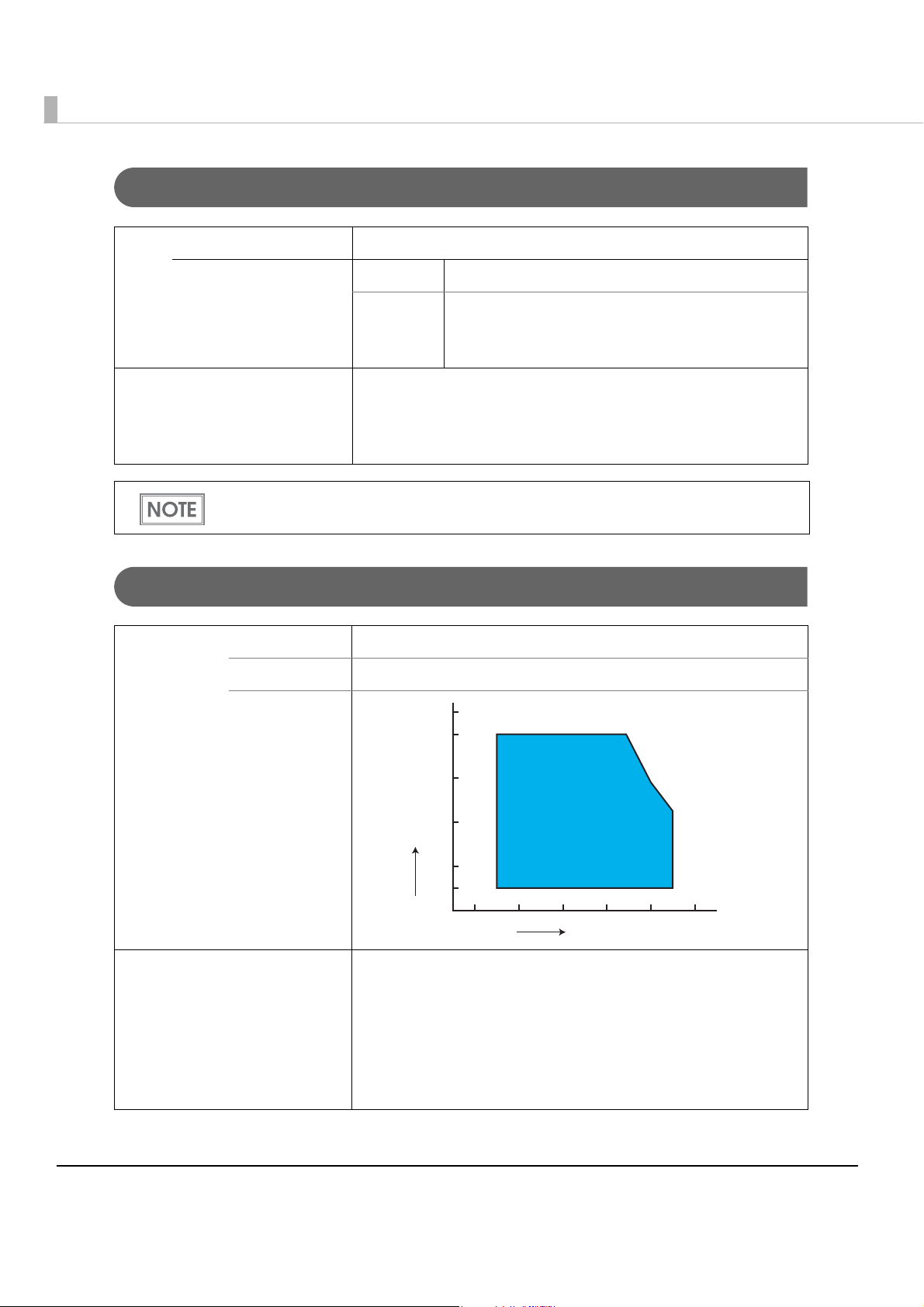

Reliability

4GNCVKXG*WOKFKV[

1RGTCVKPIGPXKTQPOGPV

TCPIG

90

60

80

10

20

40

0

0

10 20 30 40 50

#ODKGPVVGORGTCVWTG=?

[%RH]

34°C {93.2°F}, 80%

40°C {104°F}, 58%

45°C {113°F}, 46%

Life Printer 100 km paper feeding or 5 years, which comes first

Printer mechanism

(After-sales service parts)

MTBF

Print head 60 km

Autocutter 100,000-time autocutting of perforated area of

360,000 hours

(Failure is defined as a random

failure occurring during the time

of the random failure period.)

The life of printer mechanism may vary, depending on the media and printing pattern.

Environmental Conditions

Temperature/

Humidity

Operating 5 to 45°C {41 to 113°F}, 10 to 80% RH

Storage -20 to 50°C {-4 to 122°F}, 10 to 90% RH (except for paper)

thick paper

1000,000-time autocutting of non-perforated paper

30

Acoustic noise (operating) Approximately 57 dB (bystander position) (including autocutting)

Note:

The values above are measured in the Epson evaluation

condition.

Acoustic noise differs depending on the paper used, printing

contents, and the setting values, such as print speed or print

density.

Page 31

External Dimensions and Mass

•Height: Approximately 122 mm {4.80"}

•Width: Approximately 156 mm {6.14"}

•Depth: Approximately 230 mm {9.06"}

• Mass: Approximately 2.8 kg {6.17 lb}

Chapter 1 Product Overview

82.5

79.5

22.8

54.0

50.8

1

31

Page 32

Power Supply Unit (PS-180)

[Unit: mm]

136

68

33

Electric

characteristics

Case specifications Dimensions

For Energy Star printers, always use the power supply that came with your printer.

For detailed information about the PS-180, see the instruction manual for the PS-180.

Input conditions Input voltage: AC100V to AC240V

Output conditions Output voltage (rating): DC24V ± 5%

(H × W × D)

Weight Approx. 0.4 kg {14.11 oz} (excluding the AC cable)

Color Black (matte)

Frequency: 50-60 Hz

Input current (rating): 1.3A

Output current (rating): 2.1A

68 × 136 × 33 mm {2.68 × 5.35 × 1.30"}

(excluding projections)

32

Page 33

Setup

2. Changing the Paper Width (page 34)

6. Setting the Memory Switches (page 47)

4. Connecting the Printer to the Host Computer (page 42)

3. Setting the DIP Switches (page 38)

5. Connecting the Power Supply Unit (PS-180) (page 45)

1. Installing the Printer (page 34)

This chapter describes setup and installation of the product and peripherals.

Flow of Setup

This chapter consists of the following sections, along with the setup flow of the product and

peripherals.

Chapter 2 Setup

2

33

Page 34

Installing the Printer

ab cd

Important Notes

•The printer must be installed horizontally on a flat surface (not tilted).

•Do not place the printer in dusty locations.

•Do not knock or strike the printer. This may cause printing errors.

•Do not place any liquids or drinks on the printer case.

Changing the Paper Width

The printer is initially set to print on 54.0 mm width paper, but you can change the printer to

print on 82.5 mm, 79.5 mm, or 50.8 mm width paper by removing or moving the paper guides

installed in the printer.

Because some parts of the print head contact the platen and they may become worn out

in narrower paper width printing, once you use the printer in narrower paper width

printing, you cannot change it back to wider one.

When changing the paper width, be sure to change the setting for the paper width with

the customized value. To set the customized value, see "Setting the Memory Switches"

on page 47.

To cha nge the paper width to 82.5 mm, remove the paper guide installed in groove b. (See page

35.)

To cha nge the paper width to 79.5 mm, remove

and install one of them in groove c. (See page 36.)

To cha nge the paper width to 50.8 mm, remove the paper guide installed in groove b, and install

it in groove a. (See page 37.)

the paper guides installed in grooves b and d,

34

Page 35

Setting the Paper Width to 82.5 mm

Follow the steps below to set the paper width to 82.5 mm.

Make sure the printer is turned off.

1

Open the paper loading cover by pulling up the cover open lever.

2

Chapter 2 Setup

Remove the screw fixing the paper guide installed in groove b to remove

3

the paper guide.

2

35

Page 36

Setting the Paper Width to 79.5 mm

Follow the steps below to set the paper width to 79.5 mm.

Make sure the printer is turned off.

1

Open the paper loading cover by pulling up the cover open lever.

2

Remove the screws fixing the paper guides installed in grooves b and d

3

to remove the paper guides.

Install one of the removed paper guides in the groove c so that the

4

projections of the paper guide are aligned with the holes along the

groove.

Fix the paper guide with the screw.

5

36

Page 37

Setting the Paper Width to 50.8 mm

Follow the steps below to set the paper width to 50.8 mm.

Make sure the printer is turned off.

1

Open the paper loading cover by pulling up the cover open lever.

2

Chapter 2 Setup

Remove the screw fixing the paper guides installed in grooves b to

3

remove the paper guide.

Install the removed paper guide in the groove a so that the projection of

4

the paper guide is aligned with the hole along the groove.

2

Fix the paper guide with the screw.

5

37

Page 38

Setting the DIP Switches

DIP switches

Groove

Hooks

On this printer, you can make various settings with DIP switches.

Functions of the DIP switches differ depending on the interface.

Setting Procedure

Follow the steps below to change the DIP switch settings.

Before you remove the DIP switch cover, turn the printer off.

Otherwise, a short-circuit may cause the printer to malfunction.

CAUTION

DIP switch settings are enabled only when the power is turned on or the printer is reset via

the interface. If the settings are changed after that, the functions will not change.

Make sure the power supply for the printer is turned off.

1

Remove the screw that secures the left case.

2

3

4

Slide the left case to the rear to release the groove and two hooks of the

left case, and remove the left case.

OFF

Set the DIP switches, using the tip of a tool, such as a small screwdriver.

ON

38

Page 39

Chapter 2 Setup

Groove

Hooks

Holes

Rib

Install the left case and secure it with the screw.

5

Align the groove on top of the left case with the rib of the upper case.

Align the two hooks of the left case with the two holes of the board plate and slide it to the

front.

2

39

Page 40

For Serial Interface

SW Function ON OFF

1 Reserved (Do not change) Fixed to ON ON

2 Reserved (Do not change) Fixed to OFF OFF

3

Transmission speed selections

4 ON

5 DSR (hardware) reset Enabled Disabled OFF

6 Reserved (Do not change) Fixed to OFF OFF

7 Reserved (Do not change) Fixed to OFF OFF

8 Reserved (Do not change) Fixed to OFF OFF

See the “ Transmission Speed (DIP Switches 3/

4)” table below.

Transmission Speed (DIP Switches 3/4)

Transmission speed (bps) SW 3 SW 4

Setting with the memory switch*:

2400, 4800, 9600, 19200 (initial setting), 38400, 57600, 115200

9600 OFF ON

ON ON

Initial

setting

ON

19200 ON OFF

38400 OFF OFF

bps: bits per second

* When DIP switches 3 and 4 are set to ON, the value (initially 19200) can be set to any of the

values listed in the lower portion of the row using a command, memory switch setting mode, or

the TM-L500A Ticket Utility. (See "Setting the Memory Switches" on page 47.)

Depending on print conditions, such as print duty, print head temperature, and data

transmission speed, print speed is automatically adjusted, which can cause white lines due

to intermittent print (the motor sometimes stops). To avoid this, set the transmission speed

higher or keep the print speed constant by setting it lower. (See "Setting the Memory

Switches" on page 47.)

40

Page 41

For USB Interface

Chapter 2 Setup

SW Function ON OFF

1 Reserved (Do not change) Fixed to ON ON

2 Reserved (Do not change) Fixed to OFF OFF

3 Reserved (Do not change) Fixed to ON ON

4 Reserved (Do not change) Fixed to ON ON

5 Reserved (Do not change) Fixed to OFF OFF

6 Reserved (Do not change) Fixed to OFF OFF

7 USB interface class Printer class Vendor class OFF

8 Reserved (Do not change) Fixed to OFF OFF

setting

For Ethernet Interface

SW Function ON OFF

setting

Initial

2

Initial

1 Reserved (Do not change) Fixed to ON ON

2 Reserved (Do not change) Fixed to OFF OFF

3 Reserved (Do not change) Fixed to ON ON

4 Reserved (Do not change) Fixed to ON ON

5 Reserved (Do not change) Fixed to OFF OFF

6 Reserved (Do not change) Fixed to OFF OFF

7 Reserved (Do not change) Fixed to OFF OFF

8 Reserved (Do not change) Fixed to OFF OFF

41

Page 42

Connecting the Printer to the Host Computer

For Serial Interface

Connect the printer to a host computer by a serial interface (RS-232) cable.

Be sure to turn off the power supply for both the printer and host computer before

connecting the cables.

WARNING

Use a null modem serial cable to connect the printer.

Insert the interface cable connector firmly into the interface connector

1

on the connector panel.

When using connectors equipped with screws, tighten the screws to

2

secure the connectors firmly.

42

When using interface cables equipped with a grounding line, attach the

3

ground line to the screw hole marked “FG” on the printer.

Connect the other end of the interface cable to the host computer.

4

Page 43

For USB Interface

Connect the printer to a host computer by a USB interface cable.

Install the cable hook.

1

Put the USB cable through the cable hook.

2

Putting the USB cable through the cable hook prevents the cable from coming unplugged.

Chapter 2 Setup

2

Connect the USB cable from the host computer to the USB upstream

3

connector.

Connect the other end of the interface cable to the host computer.

4

43

Page 44

For Ethernet Interface

Connect the printer to a network by a LAN cable via a hub.

When LAN cables are installed outdoors, make sure devices without proper surge

protection are cushioned by being connected through devices that do have surge

CAUTION

Connect a 10/100BASE-T cable to the 10/100BASE-T LAN connector by pressing firmly until the

connector clicks into place.

protection.

Otherwise, the devices can be damaged by lightning.

Never attempt to connect the customer display cable, drawer kick-out cable, or a

standard telephone line cable to the 10/100BASE-T LAN connector.

For Ethernet interface communication settings, use TM-L500A Ticket Utility or EPSON

TMNet WinConfig utility. For detailed information about the setting methods, see the TML500A Ticket Utility User’s Manual or EPSON TM Net WinConfig User’s Guide.

44

Page 45

Chapter 2 Setup

DC cable

Power supply unit

AC ca ble

Power supply connector

Connecting the Power Supply Unit (PS-180)

Use the PS-180 as the power supply unit.

Before using the power supply unit, read carefully the user’s manual enclosed with it.

Always use the EPSON PS-180 as the power supply unit.

Using a nonstandard power supply can result in electric shock and fire.

WARNING

Should a fault ever occur in the EPSON PS-180, immediately turn off the power to

the printer and unplug the power supply cable from the wall socket.

Connecting the Power Supply Unit

Make sure the printer’s power supply is turned off and the AC cable has

1

been unplugged from the wall socket.

Insert the connector of the DC cable onto the power supply connector.

2

2

45

Page 46

Connect the plug of the AC cable to the wall socket.

3

Be sure to unplug the AC cable from the wall socket whenever connecting or

disconnecting the power supply unit to the printer.

WARNING

Failure to do so may result in damage to the power supply unit or the printer.

Make sure the wall socket power supply satisfies the rated voltage requirements

of the power supply unit. Never insert the power supply cable plug into a socket

that does not meet the rated voltage requirements of the power supply unit.

Doing so may result in damage to both the power supply and the printer.

46

Page 47

Chapter 2 Setup

Setting the Memory Switches

With the memory switch function, which is software setting for this printer, you can set the

various functions.

For an outline of the functions, see the following section. Use TM-L500A Ticket Utility or ESC/

POS commands to set the memory switches.

BUSY condition

Data receive error

Automatic line spacing

Paper jam detection

USB power saving

Default character code table

Default international character font

Transition pattern for power saving

Sleep 3

Adjustment of TOF-cut position

Memory Switches

Paper width

Print density

Customized Values

Print speed

Mark type

Media type

Buzzer volume

Transmission conditions for serial interface

For detailed information about the TM-L500A Ticket Utility, see the TM-L500A Ticket

Utility User’s Manual.

For detailed information about ESC/POS commands, see the ESC/POS Application

Programming Guide.

2

47

Page 48

Functions

BUSY condition

•Receive buffer full (initial setting)

•Receive buffer full or printer offline

Data receive error

•Ignored

•Receive error (initial setting)

Automatic line spacing

•Always enabled

•Always disabled (initial setting)

Paper jam detection

•Disabled

•Enabled (initial setting)

USB power saving

•Disabled

•Enabled (initial setting)

Default character code table

Selectable from 43 pages (initial setting: PC437 USA, Standard Europe)

The pages consist of Bitmap fonts.

Default international character font

Selectable from 16 types (initial setting: USA)

The types consist of Bitmap fonts.

48

Page 49

Transition pattern for power saving

~ +8 mm

~ -8 mm

Paper feed direction

Hole

•No power saving

•Pattern 1 (initial setting)

•Pattern 2

•Pattern 3

Sleep 3

For good print quality, set the media type, depending on the original paper number. (See

"Paper Specifications" on page 23.)

•Enabled

•Disabled (initial setting)

Adjustment of TOF-cut position

Selectable from -8 mm to 8 mm (The initial setting differs depending on the model.)

Chapter 2 Setup

2

49

Page 50

Paper width

• 50.8 mm

• 54.0 mm (initial setting)

• 79.5 mm

• 82.5 mm

When changing the paper width, you need to remove or move the paper guides. To change

the paper width, see "Changing the Paper Width" on page 34.

Print density

Selectable from levels 1 to 9 (70% 110%) (initial setting: level 7)

If the print density is set to a darker level, printing speed may be reduced.

If the print density is set to a darker level, paper dust accumulates on the print head and

print may be faint. For information on how to clean the thermal head, see "Cleaning the

Thermal Head" on page 63.

For good print quality, set the print density, depending on the original paper number.

(See "Paper Specifications" on page 23.)

Print speed

Selectable from levels 1 to 10 (Slow Fast) (initial setting: level 6)

Depending on print conditions, such as print duty, print head temperature, and data

transmission speed, print speed is automatically adjusted, which may cause white lines

due to intermittent print (the motor sometimes stops). To avoid this, keep the print speed

constant by setting it lower, or set the transmission speed higher for the serial interface.

(See "Transmission Speed (DIP Switches 3/4)" on page 40.)

For good print quality, set the print speed, depending on the original paper number. (See

"Paper Specifications" on page 23.)

Mark type

•Auto detection (initial setting)

•Hole

• Black mark

•No mark

50

Page 51

Chapter 2 Setup

Media type

Selectable from 4 types (initial setting: Type 2)

For good print quality, set the media type, depending on the original paper number. (See

"Paper Specifications" on page 23.)

Buzzer volume

Selectable from Off and levels 1 to 5 (initial setting: level 5)

Transmission conditions for serial interface

Transmission speed

When DIP switches 3 and 4 are set to ON, the value (initially 19200 bps) can be set to 2400, 4800,

9600, 19200, 38400, 57600, or 115200 bps. (See "Transmission Speed (DIP Switches 3/4)" on page

40.)

The transmission speed can be set with DIP switches 3 and 4 (See "Transmission Speed

(DIP Switches 3/4)" on page 40.) or the memory switch. When DIP switches 3 and 4 are set

to ON, the setting with the memory switch is enabled.

2

Parity bit

•None (initial setting)

•Odd

•Even

51

Page 52

52

Page 53

Chapter 3 Application Development Information

Application Development Information

This chapter describes how to control the printer and gives information useful for printer

application development.

How to Control the Printer

Use a driver or ESC/POS commands to control the printer.

EPSON Advanced Printer Driver (APD)

EPSON Advanced Printer Driver is a Windows printer driver for EPSON TM printers. The

Status API (Epson original DLL) that monitors printer status and sends ESC/POS commands is

also attached to this driver.

For information about the driver operating environment, see the installation manual for APD.

When you use APD, be sure to set the DIP switch for printer mode to enable ESC/POS

commands. (See "Setting the DIP Switches" on page 38.)

You can use all functions, including ones not supported by APD, by using ESC/POS commands through your driver. Use the control A command of APD, or Status API to send ESC/

POS commands from the driver.

ESC/POS Commands

ESC/POS is the Epson original printer command system. With ESC/POS commands, you can

directly control all the TM printer functions, but detailed knowledge of printer specifications or

combination of commands is required, compared to using a driver.

To use ESC/POS commands, you need to agree to a nondi

ESC/POS Application Programming Guide. Ask your dealer for details.

sclosure contract first and obtain the

3

53

Page 54

Software and Manuals

The following software and manuals are provided for application development.

How to Get Drivers, Manuals, and the Utility

Yo u can obtain drivers, manuals, and the TM-L500A Ticket Utility from one of the following

URLs.

For customers in North America, go to the following web site:

http://www.epsonexpert.com/ and follow the on-screen instructions.

For customers in other countries, go to the following web site:

https://download.epson-biz.com/?service=pos/

Printer Driver

Software Manual

EPSON Advanced Printer Driver (APD):

EPSON Advanced Printer Driver is a Windows printer

driver for EPSON TM printers. The Status API (Epson

original DLL) that monitors printer status and sends

ESC/POS commands is also attached to this driver.

Utilities

Software Manual

TM-L500A Ticket Utility:

Use for various settings.

EPSON TM Net WinConfig:

Use for IP address or wireless LAN setting.

APD Install Manual

APD TM/BA/EU Printer Manual

APD Printer Specification

Devmode API/PRINTERINFO Manual

Status API Manual

Sample Program Guide

TM-L500A Ticket Utility User’s Manual

EPSON TM Net WinConfig User’s Guide

54

Page 55

Chapter 3 Application Development Information

Self-Test Mode

In the self-test mode, the printer prints the current status of the printer and resident characters as

a test print.

Yo u can confirm the following information with the status print.

•Model name

•Control software version

•Printer settings

•User counter

•Maintenance counter

Starting the Self-Test

Follow the steps below to start the self-test.

Install the roll paper.

1

Close all covers.

2

While pressing the Unload () button, turn on the printer. (Keep pressing

3

the button until the printer starts printing.)

The printer starts printing the current status of the printer on the paper.

With the Ethernet interface, before printing starts, it takes 15 seconds if the IP address is

fixed and 20 seconds if the IP address is obtained with the automatic setting. (It may take

longer, depending on the response time from the host.)

When the printer finishes printing the current printer status, the following message is

printed and the Paper LED flashes. (The printer is now in the self-test printing standby

status.):

“If you want to continue SELF-TEST pr

To start the test print, press the Unload () button (less than 1 second).

4

The printer prints a rolling pattern on the paper, using only the built-in character set.

If you press the Unload () button for more than 1 second, the printer prints the other

settings and counter value.

inting, please press Unload button.”

3

After printing the following message and autocutting the paper, the printer is initialized and

returned to the normal mode.

“*** completed***”

55

Page 56

56

Page 57

Chapter 4 Handling

Handling

This chapter describes basic handling of the printer.

Usage Precautions

•Install the printer horizontally.

•When installing, leave enough space around the printer for loading paper, turning on/off the

power switch, removing jammed paper, and so on.

•Make sure cords and foreign objects are not caught in the printer.

•Do not open the covers during printing or autocutting.

•Make sure that t

•Do not put any food or drink on the printer case.

•Do not move the printer with the paper loading cover open. The cover may close

unexpectedly.

•To prevent a paper jam, do not prevent paper from being ejected from the paper exit and do

not pull the paper being ejected.

he printer is not subjected to any impact or vibration.

4

57

Page 58

Installing and Replacing Paper

Do not open the covers during printing/autocutting.

The printer may be damaged.

WARNING

Installing Paper

When the Paper LED is on, follow the steps below to load paper.

Turn on the printer.

1

Do not touch the manual cutter with your hands.

Otherwise, you may be injured because the manual cutter blade is sharp.

Use paper that meets the printer specifications. For details about paper specifications,

see "Paper Specifications" on page 23.

When changing the paper width, you need to remove or move the paper guide and to

change the setting for the paper width with the customized value. To change the paper

width, see "Changing the Paper Width" on page 34.

Open the paper loading cover by pulling up the cover open lever.

2

58

Page 59

Insert the end of the paper under the rollers.

3

The paper is fed automatically.

Close the paper loading cover.

4

The paper is fed to the position of a punch hole or a black mark, and cut automatically.

Close the paper loading cover immediately. If it is left open for 1 minute or longer, paper

feeding may not be correct.

Chapter 4 Handling

Replacing Paper

Follow the steps below to replace paper.

Turn on the printer.

1

Hold down the Unload () button until the paper starts feeding

2

backward.

After paper feeding stops, remove the paper by pulling it backward.

3

Open the paper loading cover by pulling up the cover open lever.

4

4

59

Page 60

Insert the end of the paper under the rollers.

5

The paper is fed automatically.

Close the paper loading cover.

6

The paper is fed to the position of a punch hole or a black mark, and cut automatically.

Close the paper loading cover immediately. If it is left open for 1 minute or longer, paper

feeding may not be correct.

60

Page 61

Removing Jammed Paper

When a paper jam occurs, never pull out the paper forcibly.

Follow the steps below to remove the jammed paper.

Do not touch the thermal head (See"Cleaning the Printer" on page 63.) because it can

be very hot after printing.

CAUTION

Turn off the printer.

1

Open the platen cover.

2

Chapter 4 Handling

Push down the platen lever to open the platen frame.

3

Pull out the jammed paper forward, and cut any distorted, crumpled, or

4

torn parts of the paper.

4

61

Page 62

Open the paper loading cover by pulling up the cover open lever.

5

Pull out the paper backward, and cut any distorted, crumpled, or torn

6

parts of the paper if there are any.

Close the platen frame and the platen cover.

7

62

Page 63

Chapter 4 Handling

Cleaning the Printer

Cleaning the Printer Case

Be sure to unplug the AC cable from the wall socket and turn off the printer before cleaning.

Wipe the dirt off the printer case with a dry cloth or a damp cloth.

Never clean the product with alcohol, benzine, thinner, or other such solvents. Doing so

may damage or break the parts made of plastic and rubber.

Cleaning the Thermal Head

Epson recommends cleaning the thermal head periodically (generally every 3 months) to

maintain receipt print quality.

After printing, the thermal head can be very hot. Do not touch it and let it cool

before you clean it.

CAUTION

Hold down the Unload () button until the paper starts feeding back-

1

ward.

After paper feeding stops, remove the paper by pulling it backward.

2

Turn off the printer.

3

Do not damage the thermal head by touching it with your fingers or any hard

object.

4

63

Page 64

Open the platen cover.

Thermal head

4

Push down the platen lever to open the platen frame.

5

Clean the thermal elements of the thermal head with a cotton swab

6

moistened with an alcohol solvent (ethanol or IPA).

Close the platen frame and the platen cover.

7

64

Page 65

Preparing for Transport

Follow the steps below to transport the printer.

Turn off the printer.

1

Remove the power supply connector.

2

Remove the roll paper.

3

Pack the printer upright.

4

Chapter 4 Handling

65

4

Page 66

66

Page 67

Appendix

Specifications of Interfaces and Connectors

RS-232 Serial Interface

Interface board specifications (RS-232-compliant)

Item Specifications

Data transfer method Serial

Synchronization Asynchronous

Handshake DTR/DSR

RTS/CTS

Appendix

Signal level MARK -3V to -15V logic “1”/OFF

SPACE +3V to +15V logic “0”/ON

Transmission speed

[bps: bits per second]

Bit lengths 8 bits

Parity selection Select one of the following with a memory switch:

Stop bit 1 or more bits

Connector Printer side DSUB 9-pin (male) connector

Select one of the following with DIP switches 3 and 4:

9600/19200/38400 bps

Select one of the following with a memory switch:

2400/4800/9600/19200/38400/57600/115200 bps

None

Even

Odd

However, the stop bit for data transfer from the printer is fixed to 1 bit.

67

Page 68

Functions of each connector pin

DSUB9

Pin no.

1 NC — Not connected

2 RXD Input Receive data

3 TXD Output Transmit data

4 DTR Output Indicates whether or not the printer is BUSY.

5 GND — Signal ground

6 DSR Input Indicates whether or not the host computer is ready to receive data.

7 RTS Output Same as DTR signal

8 CTS Input Indicates whether or not the host computer is ready to receive data.

9 NC — Not connected

Signal

name

Signal

direction

Function

SPACE indicates that the printer is ready to receive data, and MARK

indicates that the printer is BUSY.

The memory switch changes the BUSY condition for the printer. (See

"Setting the Memory Switches" on page 47.)

SPACE indicates that the host computer is ready to receive data, and

MARK indicates that the host computer is not ready to receive data.

The printer checks this signal before transmitting data. (Except when

transmitting data with some status commands.)

Changing the setting of DIP switch allows this signal to be used as a

reset signal for the printer. (See "For Serial Interface" on page 40.)

SPACE indicates that the host computer is ready to receive data, and

MARK indicates that the host computer is not ready to receive data.

The printer checks this signal before transmitting data. (Except when

transmitting data with some status commands.)

68

Page 69

The printer goes BUSY under the following conditions:

Printer status

Memory switch

1-3

ON OFF

Offline

1. During the period from when the power is turned on

(including resetting through the interface) to when

the printer becomes ready to receive data.

BUSY BUSY

2. During a self-test BUSY BUSY

3. When the cover is open. — BUSY

4. When the platen frame is open. — BUSY

5. When the printer stops printing due to a paper-end. — BUSY

6. When the printer stops printing due to a paper jam. — BUSY

7. When an error has occurred. — BUSY