Page 1

6(59,&(0$18$/

&RORU,QN-HW3ULQWHU

EPSON Stylus Pro 5000

®

4008867

Page 2

NOTICE

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

The contents of this manual are subject to change without notice.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be deteced, SEIKO EPSON would greatly

appreciate being informed of them.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their respective

owners. EPSON disclaims any and all rights in those marks.

Copyright © 1996 SEIKO EPSON CORPORATION. Printed in Japan.

Page 3

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

Signals a precaution which, if ignored, could result in damage to equipment.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR

REPAIR PROCEDURES.

2. NOWORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIER WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL

ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. W HEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POW ER

SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LI STED ON T HE SERIAL NUMBER/RATING PLAT E. IF

THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POW ER SOURCE, DO NOT CONNECT IT TO THE POW ER

SOURCE.

3. ALWAYS VERIFY THAT T HE EPSO N PRODUCT HAS BEEN DI SCONNECT ED FRO M THE POWER SOURCE BEFORE REMOVING OR REPLACING

PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC

WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECONDSOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

Page 4

PREFACE

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of Stylus Pro5000. The

instructions and procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on the

preceding page. The chapters are organized as follows:

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for troubleshooting.

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for disassembling and assembling the

product.

CHAPTER 5. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the lists of Epson-approved

lubricants and adhesives required for servicing the product.

APPENDIX

Provides the following additional information for reference:

• Connector pin assignments

• Electric circuit boards components layout

• Exploded diagram

• Electrical circuit boards schematics

Page 5

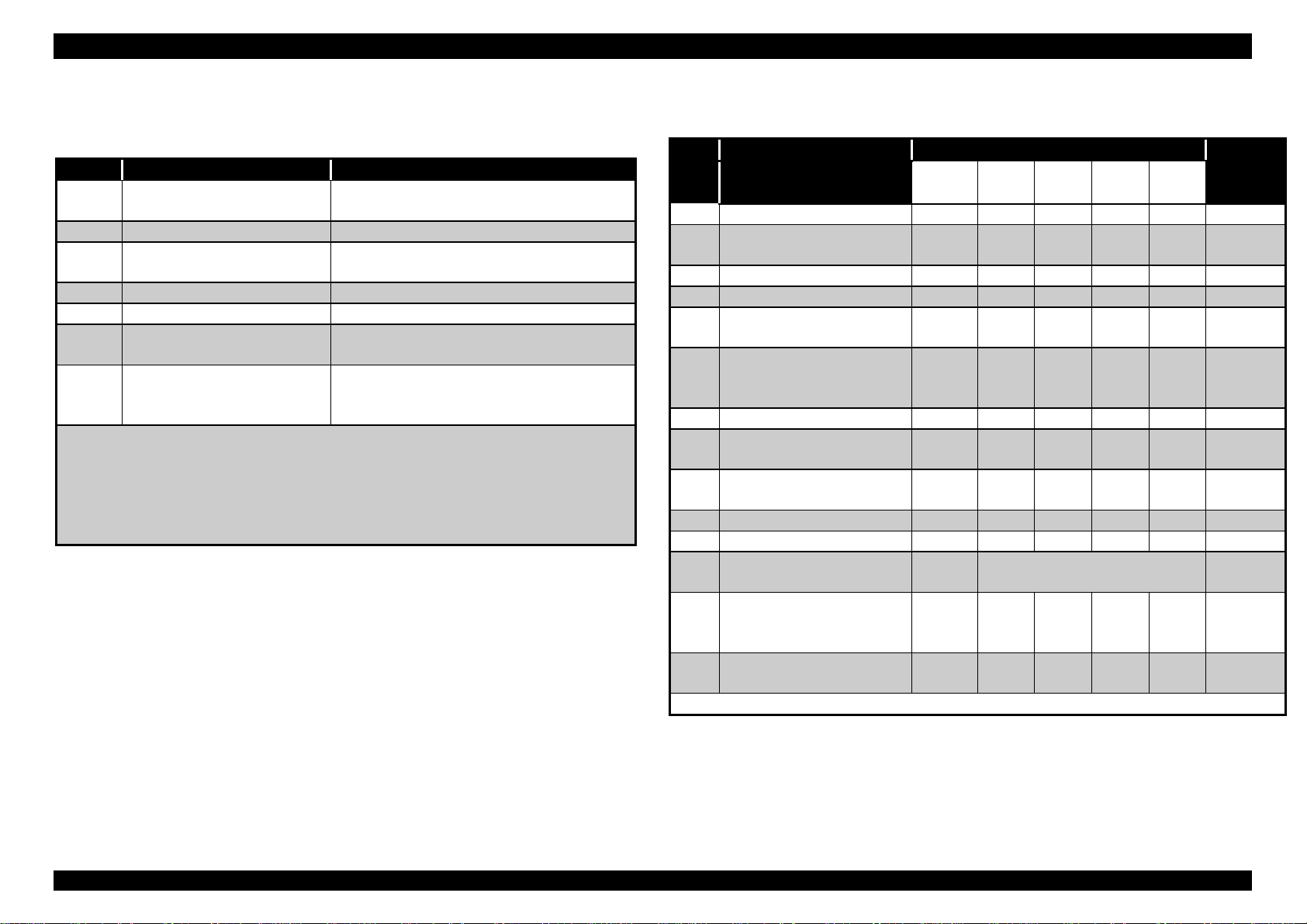

REVISION STATUS

Rev. Date Page(s) Contents

A 1998/01/23 All First release

B 1998/03/10

4-68∼4-93

4-8

4-59

4-60

Chapter4

• Added “Disassembly and Assembly for ASF Unit”.

• Modified flow chart for disassembling the mechanism

according to addition of “Disassembly and Assembly for ASF

Unit”.

• Added “CAUTION”.

• Added sentences to “CHECKPOINT”.

• Word “phase” is replaced by “alignment”.

Page 6

TABLE OF CONTENTS

PRODUCT DESCRIPTION

1.1 FEATURES....................................................................................................................................................................1-1

1.2 SPECIFICATIONS.........................................................................................................................................................1-4

1.3 ADDING PAPER GUIDE ROLLER UNIT.....................................................................................................................1-46

OPERATING PRINCIPLES

2.1 FEATURE......................................................................................................................................................................2-1

2.1.1 Operating Principles of Printer Mechanism.....................................................................................................................................2-1

2.1.1.1 Printing Mechanism...................................................................................................................................................................2-2

2.1.1.2 Carriage Mechanism.................................................................................................................................................................2-3

2.1.1.3 Paper Feed Mechanism............................................................................................................................................................2-5

2.1.1.4 Upper Surface Sensor Mechanism ...........................................................................................................................................2-7

2.1.1.5 Paper Return Mechanism..........................................................................................................................................................2-8

2.1.1.6 Lifter Gear Train Mechanism.....................................................................................................................................................2-9

2.1.1.7 Hopper 5mm Down Mechanism..............................................................................................................................................2-10

2.1.1.8 Sub Roller Gear Train Mechanism..........................................................................................................................................2-13

2.1.1.9 Gear Train Change with Hopper installed ...............................................................................................................................2-14

2.1.1.10 Ink Engage/Disengage Mechanism.......................................................................................................................................2-16

2.1.1.11 PG Disengage Mechanism....................................................................................................................................................2-18

2.1.1.12 Ink Valve Mechanism............................................................................................................................................................2-20

2.1.1.13 Friction Release Mechanism.................................................................................................................................................2-21

2.1.1.14 Gear Train Block Diagram.....................................................................................................................................................2-23

Page 7

2.1.2 Outline of Electrical Circuit..............................................................................................................................................................2-24

2.1.2.1 C228 PSB Board.....................................................................................................................................................................2-24

2.1.2.2 C228 DRV Board.....................................................................................................................................................................2-26

2.1.2.3 C228 Main Board ....................................................................................................................................................................2-27

TROUBLESHOOTING

3.1 FEATURES....................................................................................................................................................................3-1

3.1.1 Problems relating to the printer mechanism....................................................................................................................................3-1

ASSEMBLY AND DISASSEMBLY

4.1 OVERVIEW....................................................................................................................................................................4-1

4.1.1 Precautions.........................................................................................................................................................................................4-1

4.1.2 Tools....................................................................................................................................................................................................4-2

4.1.3 Screws.................................................................................................................................................................................................4-2

4.2 DISASSEMBLY................................................................................................................ .............................................4-2

4.2.1 Housing Upper Removal....................................................................................................................................................................4-3

4.2.2 Housing Front Unit Removal .............................................................................................................................................................4-5

4.2.3 Mechanism Unit Removal ..................................................................................................................................................................4-6

4.2.4 MB Rear Unit Removal .......................................................................................................................................................................4-7

4.2.5 Disassembling the Mechanism..........................................................................................................................................................4-8

4.2.5.1 Discharge Brush Removal.........................................................................................................................................................4-9

4.2.5.2 Paper Guide Assembly, Cover Removal.................................................................................................................................4-10

4.2.5.3 Print Head Removal................................................................................................................................................................4-11

4.2.5.4 MB Front Unit Removal...........................................................................................................................................................4-13

4.2.5.5 Fan Assembly Removal ..........................................................................................................................................................4-15

4.2.5.6 PS Unit Removal.....................................................................................................................................................................4-16

Page 8

4.2.5.7 Motor Assembly, PF Removal.................................................................................................................................................4-16

4.2.5.8 Motor Assembly, CR Removal ................................................................................................................................................4-17

4.2.5.9 Motor Assembly, ASF Removal ..............................................................................................................................................4-18

4.2.5.10 Carriage Unit Removal..........................................................................................................................................................4-19

4.2.5.11 Frame, Main, Paper Eject Removal ......................................................................................................................................4-22

4.2.5.12 Paper Guide Upper Unit Removal.........................................................................................................................................4-26

4.2.5.13 Pump Frame Removal ..........................................................................................................................................................4-27

4.2.5.14 Frame, Main, PF Removal ....................................................................................................................................................4-28

4.2.5.15 ASF Unit Removal.................................................................................................................................................................4-31

4.2.5.16 Upper Surface Sensor Removal............................................................................................................................................4-32

4.2.5.17 PE Sensor Removal..............................................................................................................................................................4-33

4.2.5.18 PR Sensor Removal..............................................................................................................................................................4-34

4.2.5.19 HP Sensor Removal..............................................................................................................................................................4-36

4.2.5.20 Cable Assembly, Sensor FPC Removal................................................................................................................................4-37

4.2.5.21 Interlock Assembly Removal.................................................................................................................................................4-37

4.3 DISASSEMBLY AND ASSEMBLY FOR GEAR TRAIN...............................................................................................4-38

4.3.1 Disassembly of Gear Train...............................................................................................................................................................4-38

4.3.2 Assembling Gear Train.....................................................................................................................................................................4-46

4.4 DISASSEMBLY AND ASSEMBLY FOR ASF UNIT ....................................................................................................4-68

4.4.1 Disassembly of ASF Unit..................................................................................................................................................................4-69

4.4.2 Assembling ASF Unit........................................................................................................................................................................4-75

ADJUSTMENT

5.1 OVERVIEW....................................................................................................................................................................5-1

5.1.1 Conditions which adjustment is required ........................................................................................................................................5-1

5.1.1.1 Resetting Initial Ink Charge Flag ...............................................................................................................................................5-3

5.1.1.2 Re-input the Model Name .........................................................................................................................................................5-6

5.1.1.3 Head Voltage Value Adjustment ...............................................................................................................................................5-8

Page 9

5.1.1.4 Head Angular Adjustment .......................................................................................................................................................5-11

5.1.1.5 Head Height Adjustment .........................................................................................................................................................5-18

5.1.1.6 Head Gap Adjustment.............................................................................................................................................................5-22

5.1.1.7 Bi-D Adjustment ......................................................................................................................................................................5-27

5.1.1.8 Uploading of Firmware............................................................................................................................................................5-32

5.1.1.9 Parallelism Adjustment............................................................................................................................................................5-34

5.1.1.10 Upper Surface Sensor Positioning Adjustment.....................................................................................................................5-37

MAINTENANCE

6.1 CLEANING ....................................................................................................................................................................6-1

6.2 MAINTENANCE.............................................................................................................................................................6-2

6.2.1 Head cleaning .....................................................................................................................................................................................6-2

6.2.2 Maintenance Request.........................................................................................................................................................................6-3

6.3 LUBRICATION AND ADHESION ..................................................................................................................................6-4

APPENDIX

7.1 CONNECTOR SUMMARY.............................................................................................................................................7-1

7.2 EEPROM ADDRESS MAP ............................................................................................................................................7-5

7.3 COMPONENT LAYOUT ..............................................................................................................................................7-10

7.4 CIRCUIT DIAGRAM.....................................................................................................................................................7-13

Page 10

PRODUCT DESCRIPTION

&+$37(5

Page 11

EPSON Stylus Pro 5000 Chapter1 Product Description

1.1 FEATURES

EPSON Stylus Pro 5000 is a 6-color ink jet printer , which can output colors

for the professional level. Major features are following.

Professional color print quality

1440(H) x 720(V) dpi printing at the highest resolution setting.

Photo reproduction quality(6 color printing, C.M, Y, K, LC, LM)

By micro dot + super micro dot, super fine printing equivalent to

Comoro Wide is available.

PostScript printing(option)

High speed printing

Color 360 dpi A4: 1.1 PPM

Color 720 dpi A4: 0.39 PPM

Built in 3 types of interfaces

Bi-directional parallel interface (IEEEP1284.4/ECP support)

Mac. Serial interface(up to approx. 1.8M bps)

Type-B interface (SIM for copying up to approx. 98M is available to

install on the same board;C228 main board)

Low running cost

Long life ink cartridge;

Black: 3200 papers, Yellow: 3200 papers, Cyan/Magenta:3000 papers

(5% ECOMA duty printing)

Independent 4 colors ink cartridges: Black, Yellow, Cyan including

with light cyan, Magenta including light magenta.

Ink quantity sensor.

Note)

After ink near end is detected by the mechanical switch, the

firmware counts the determined absorbing quantity.

Paper handling

Double bin ASF(second bin option)

Manual feeding from the top cover of first bin and from the rear with

opened rear cover.

Paper volume for ASF/Paper size sensor/Paper type sensor

Note)

Those sensors do not work correctly, if users set the paper size

or media type lever wrong.

Increased paper loading capacity in the paper tray (55 g/m

sheets/ Standard, option ASF)

Windows/Macintosh exclusive

2

250 cut

Rev.A

Note)

Cyan/Magenta ink is united as one, which light color and

ordinary color ink are separated. The reason why that ink life span is

not so different from others even though they are separated is that

users are usually unable to perform printing which require strict

separation of light color and ordinary color. Therefore, since light color

and ordinary color inks are adjusted to be used alternately on the

application, the life span of Cyan/Magenta does not become simply

half life span of the other inks.

1-1

Page 12

EPSON Stylus Pro 5000 Chapter1 Product Description

2

Following table shows optional items for Stylus Pro 5000.

CHECK POINT

9

Since there are many kinds of exclusive papers,

please refer to “Special Media” on the Reference

Guide for Stylus Pro 5000.

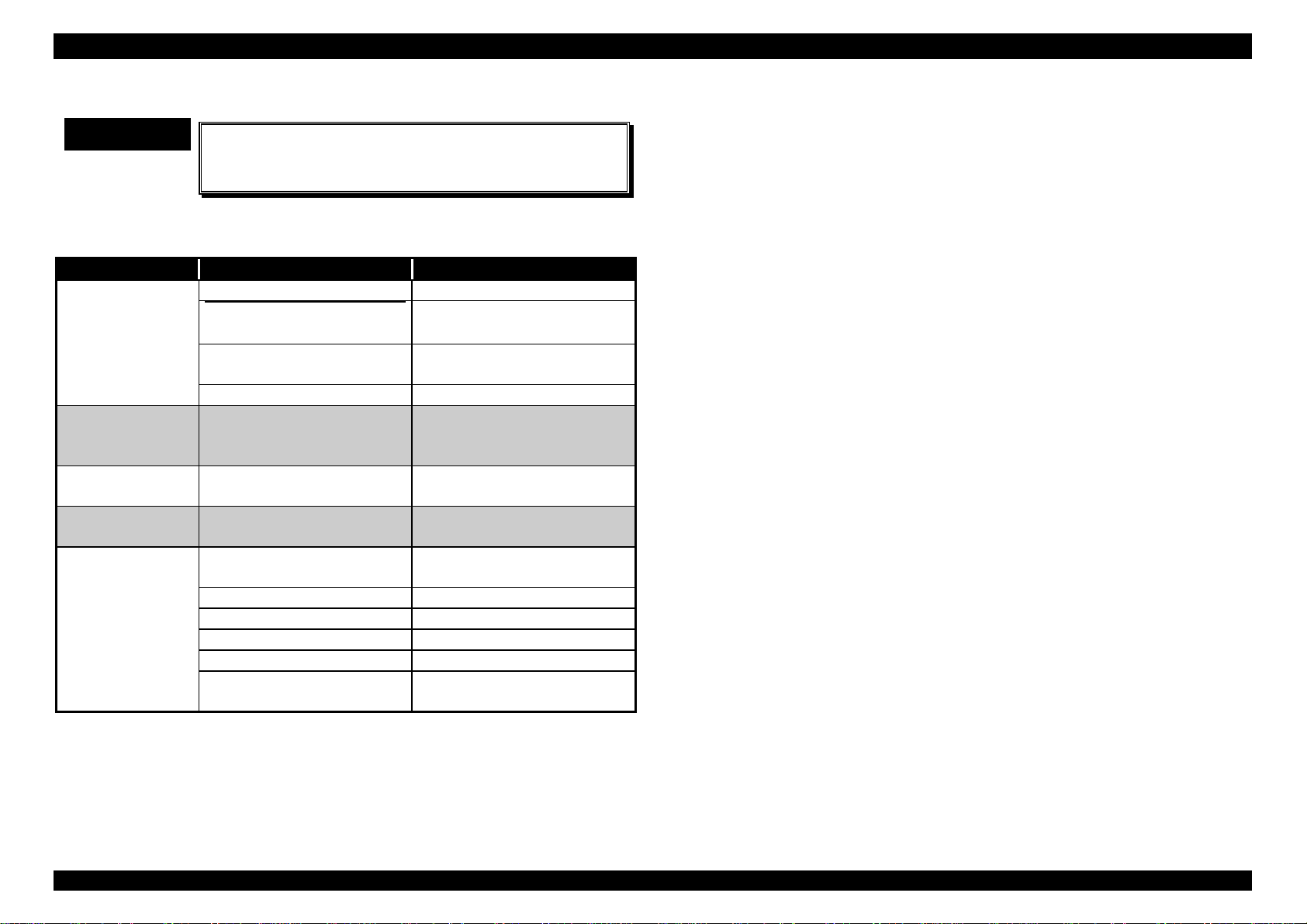

Table 1-1. Optional Items and Available Consumable

Name Remark Code No.

Ink cartridge Black ink cartridge S020118

Cyan (including light

cyan)

Magenta(including light

magenta)

Yellow S020122

Paper tray unit

Exclusive Paper Refer to the reference

SIMM memory Max.96MB(32MB x3), 72

Type-B I/F Card 32KB Serial interface

B5 ∼A3 (55g/m2:250

sheet)

guide

pins

card

LocalTalk

Co-ax interface card C82314*

Twin-ax interface card C82315*

Ethernet interface card C82357*

Bi-directional Parallel

interface card

TM

interface card C82312*

S020147

S020143

C81275*(lower paper

cassette)

C81276*

---

---

C82307*/C82308*

C82345*

Note) *

Rev.A

The asterisk is a substitute for the last digit, which varies by country.

1-

Page 13

EPSON Stylus Pro 5000 Chapter1 Product Description

3

1.2 SPECIFICATIONS

PRINTING SPECIFICATION

Print method: On demand MACH ink jet

Nozzle configuration Black - 64 nozzles

Color(5 colors) - 64 nozzles for each

color(total: 320 colors, Y, M, C, LM, LC)

Print direction Bi-direction with logic seeking

Print speed See the tables below

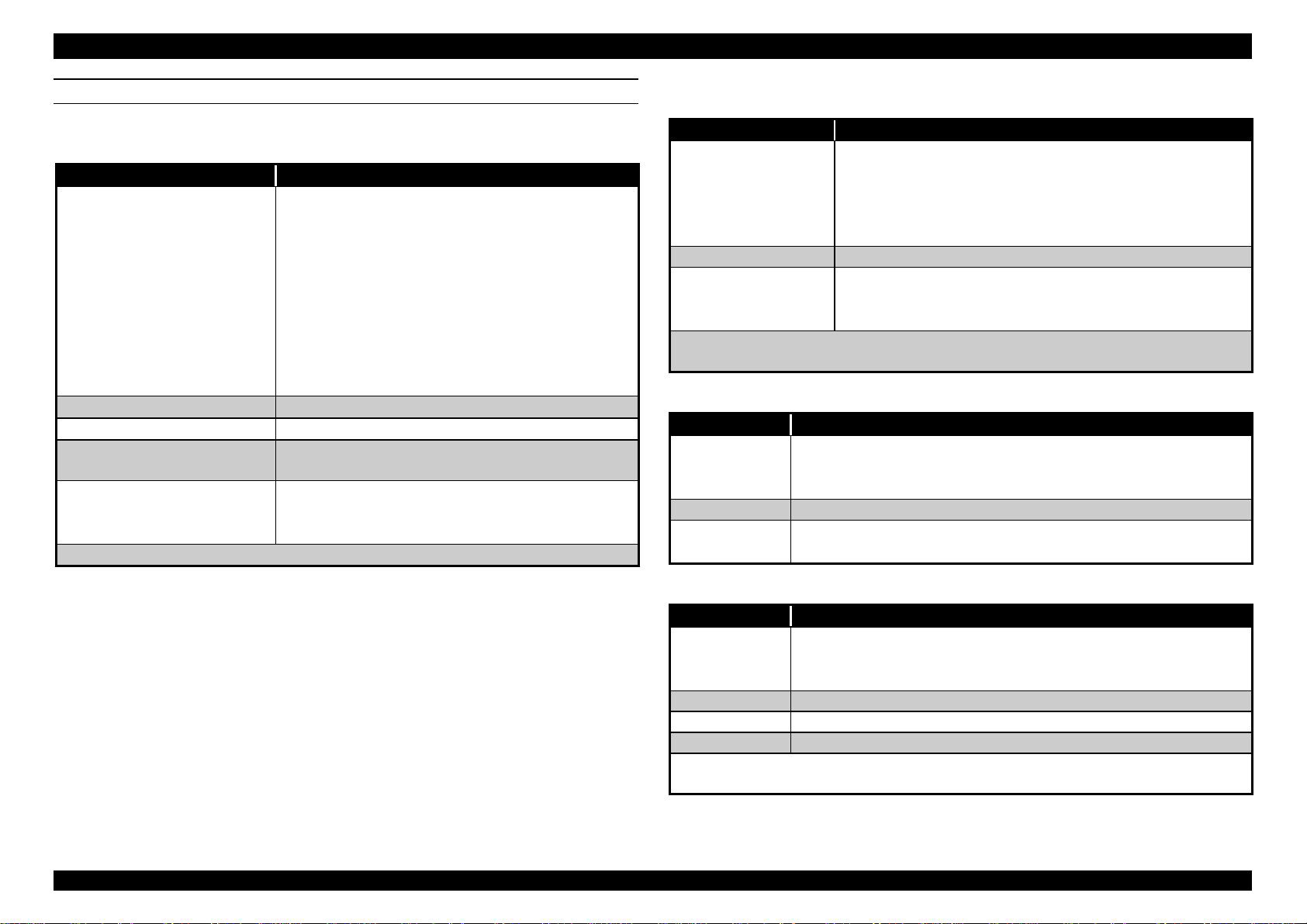

Table 1-2. Character Mode

Item Content

Character quality High quality

Character pitch 10 CPI (Pica)

Printable columns 127 columns

LQ speed 200 CPS*

Note*)

This value is the speed of one print-pass in which the ¼ of character

matrix is printed.

Table 1-3. Raster Graphics Mode

CHARACTER SPECIFICATION

Character tables: 2 international character sets;

PC437(US, Standard Europe)

PC850(Multilingual)

Type face: Bit map LQ font

EPSON courier 10 CPI

CONTROL CODE

ESC/P Raster

EPSON Remote command

PAPER FEED SPECIFICATION

Feeding method: Friction feed with ASF

Line spacing: 1/6 inch or programmable at 1/360 inch

Paper path: Cut-sheet ASF

Paper feeding: Standard cassette, optional lower paper

cassette, front manual feeding, rear manual

feeding.(All friction feeding)

Feed speed 79 ms. (1/6 inch paper feeding)

6 inch/sec.(Continuous paper)

Horizontal

Resolution

360 dpi 323mm(12.7 inch) 4578 20 IPS

720 dpi 323mm(12.7 inch) 9156 20 IPS

Note)

20 IPS is equivalent to 200 CPS at printing 10 CPI.

Printable Area Available dot CR speed (IPS)

Rev.A

1-

Page 14

EPSON Stylus Pro 5000 Chapter1 Product Description

4

PAPER SPECIFICATION

Table 1-4. Cut sheet specification

Item Remark

Paper size

Thickness

Weight

Quality Exclusive paper, Bond paper, PPC, Special

Paper

Note1)

No curled, wrinkled, scuffing or torn paper be used.

•Super A3 327 mm(W) x 483 mm(L)

•A3 297 mm(W) x 420 mm(L)

•A5 148mm(W) x 210 mm(L)

•B4 257 mm(W) x 364 mm(L)

•Letter 216 mm(W) x 279 mm(L)

•A4 210 mm(W) x 297 mm(L)

•B5 182 mm(W) x 257 mm(L)

•Legal 216 mm(W) x 356 mm(L)

•Statement 139.7 mm(W) x 215.9 mm(L)

•Exclusive 190.5 mm(W) x 254 mm(L)

0.08 mm(0.003”) ∼ 0.11 mm(0.004”)

64 g/m2 (17lb.) ∼ 90 g/m2 (24lb.)

papers.

•Regular plain paper

•EPSON Photo Quality Ink Jet Paper

•EPSON Photo Paper

Table 1-5. Transparency and Glossy film and paper specification

Item Remark

Paper size

Thickness 0.075 mm(0.003”) - 0.085 mm(0.0033”)

Paper

Note)

Note**)

Size

Thickness Less than 0.23 mm(0.0091”)

Paper

Transparency printing is only available at normal temperature.

Glossy film only.

Item Remark

•Super A3/B 13”(W) x 19”(L)

•A3 297 mm(W) x 420 mm(L)

•A4 210 mm(W) x 297 mm(L)

•Letter 216 mm(W) x 279 mm(L)

•A6 105 mm(W) x 148 mm(L)**

•EPSON Photo Quality Glossy Film

•EPSON Photo Quality Glossy Paper

•EPSON Ink Jet Transparencies

Table 1-6. Index card specification

•A6 Index card: 105 mm(4.1”)(W) x 148 mm(5.8”)(L)

•5x8” Index card 127 mm(5.0”)(W) x 203 mm(8.0”)(L)

•10x8” Index card 127 mm(5.0”)(W) x 203 mm(8.0”)(L)

•EPSON Photo Quality Ink Jet Card

•EPSON Photo Card

Rev.A

Table 1-7. Envelope specification

Item Remark

Size

Thickness 0.16 mm(0.006”) - 0.52 mm(0.02”)

Weight 45 g/m2 (12lb.) - 75 g/m2 (20lb.)

Quality Bond paper, Plain paper, Air mail

Note)

Note)

Envelope printing is only available at normal temperature.

Keep the longer side of the envelope horizontally at setting.

•No.10 241 mm(9 1/2”)(W) x 104.8 mm(4 1/8”)(L)

•DL 220 mm(8.7”)(W) x 110 mm(4.3”)(L)

•C6 162 mm(6.4”)(W) x 114 mm(4.5”)(L)

1-

Page 15

EPSON Stylus Pro 5000 Chapter1 Product Description

5

INK CARTRIDGE

Table 1-8. Black, Yellow Ink Cartridge

Item Specifications

Type Exclusive ink cartridge

Color Black, Yellow

Print capacity 3200 pages/A4 (360 dpi, ECOMA 5% duty)

Validity 2 years from production date(sealed in package, or

being installed to the printer)

Environmental

conditions

Dimension 25.1 mm(W) x 139.6 mm(D) x 105.3 mm(H)

Weight Approximately 200g

Item Specifications

Type Exclusive ink cartridge

Color Magenta +Light magenta(I/C1), Cyan + Light

Print capacity 3000 pages/A4 (360 dpi, 5% duty)

Validity 2 years from production date(sealed in package, or

Environmental

conditions

Dimension 35.1 mm(W) x 140.9 mm(D) x 105.3 mm(H)

Weight Approximately 200g

•Transit: −30°C ∼ 60°C

(within 120 hours at 60°C, and within a month at

40°C)

•Package storage: −30°C ∼ 40°C

(within a month at 40°C)

•Storage(installed to the printer):−20°C ∼ 40°C

(within a month at 40°C)

Table 1-9. Magenta and Cyan Ink Cartridge

cyan(I/IC2)

being installed to the printer)

•Transit: −30°C ∼ 60°C

(within 120 hours at 60°C, and within a month at

40°C)

•Package storage: −30°C ∼ 40°C

(within a month at 40°C)

•Storage(installed to the printer):−20°C ∼ 40°C

(within a month at 40°C)

Note1)

Note2)

Note3)

INPUT DATA BUFFER

ELECTRIC SPECIFICATION

1) 120V version

2) 220-240V version

Ink cartridge can not re-fill, only ink cartridge is prepared for article of

consumption.

Do not use the ink cartridge which was passed away the ink life.

Ink will be frozen under -15°C environment, however it will be

useable after placing it more than 3 hours at room temperature.

6 K-byte

Rated voltage: AC 120 V

Input voltage range: AC 99 V - 132 V

Rated frequency range: 50 - 60 K Hz

Input frequency range: 49.5 - 60.5 Hz

Rated current: 1.0A (Max.1.6A)

Energy Star compliant

Power consumption: Approx. 32W(ISO/IEC 10561 Letter pattern)

Insulation resistance: 10 M ohms min. (between AC line and chassis,

DC 500 V)

Dielectric strength: AC 1000 V rms. 1 minute or AC1200 V rms.

1 second(between AC line and chassis)

Sneak current: Less than 0.25 mA

Rated voltage: AC 220 V - 240 V

Input voltage range: AC 198 V - 264 V

Rated frequency range: 50 - 60 Hz

Input frequency range: 49.5 - 60.5Hz

Rated current: 0.5 A(Max.0.8 A)

Power consumption: Approx. 32 W(ISO/IEC 10561 Letter pattern)

Energy Star compliant

Insulation Resistance: 10 M ohms min.(between AC line and chassis,

DC 500 V)

Rev.A

1-

Page 16

EPSON Stylus Pro 5000 Chapter1 Product Description

6

Dielectric strength: AC 1500 V rms. 1 minute(between AC line and

ENVIRONMENT CONDITION

chassis)

Temperature: Operating: 10°C ∼ 35°C

RELIABILITY

Storage: −20°C ∼ 40°C

Non-operating: −20°C ∼ 60°C

Total print volume: 75,000 pages (A4, letter)

Print head life: 2000 million dots/nozzle

SAFETY APPROVALS

Note)

Within 1 month at 40°C, within 120 hours at 60°C

Humidity: Operating: 20% ∼ 80% RH (without condensation)

Storage: 20% ∼ 85% (without condensation)

Non-operating: 5% ∼ 85% (without condensation)

1)120 V version

Safety standards: UL1950 with D3

CSA22.2 No.950 with D3

EMI: FCC part15 subpart B class B

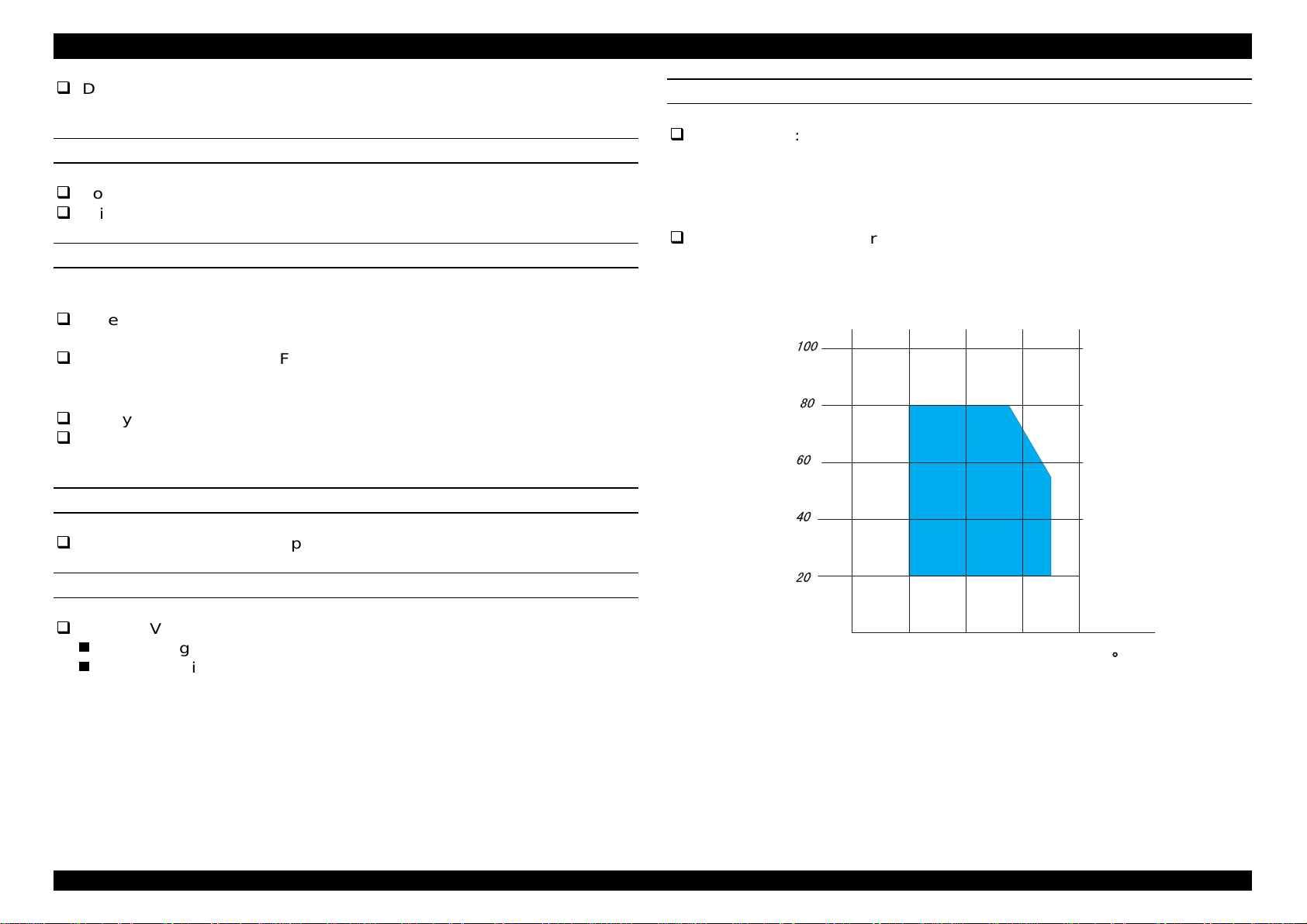

Note)

Refer to the figure below.

Humidity

(% RH)

CSA C108.8 class B

2)220-240 V version

Safety standards: EN 60950 (VDE, NEMKO)

EMI: EN 55022 (CISPR Pub.22) class B

AS/NZS 3548 class B

ACOUSTIC NOISE

Level: Approx.47dB(A) (According to ISO 7779)

CE MARKING

220-240 V version

Low Voltage Directive 73/23/EEC :EN60950

EMC Directive 89/336/EEC :EN55022 Class B

EN61000-3-2

EN61000-3-3

EN50082-1

IEC801-2

IEC801-3

IEC801-4

Rev.A

10 20 30 40

Tem perature

( C )

Figure 1-1. Temperature/Humidity Range

1-

Page 17

EPSON Stylus Pro 5000 Chapter1 Product Description

7

Resistance to vibration: Operating: 0.15G, 10 ∼ 55 Hz X,Y,Z directions

Non-operating: 0.50G, 10 ∼ 55 Hz X,Y,Z

directions

Resistance to shock: Operating: 1G, within 1 ms X,Y,Z directions

Non-operating:2G, within 2 ms X,Y,Z

directions

Note1)

Note2)

Note3)

Note4)

During non-operating, make sure that the cap is capped.

During the transport, make sure that the head is capped and ink

cartridge is installed to the printer.

If the head is not capped at the power-off state, turn the printer on

while the ink cartridge is installed, and turn off the power after

capping the head.

Ink will be frozen under −15°C environment, however it will be

useable after placing it more than 3 hours at 25°C.

SERIAL INTERFACE SPECIFICATION

Table 1-10. Serial Interface

Item Content

Transmission mode Based on RS-423

Synchronization Synchronous

Transfer speed About 1.8M bps

Data format Start bit: 1bit

Data bit: 8bit

Parity bit: none

Stop bit: 1bit

Handshaking X-ON/X-Off, DTR protocol

Adaptable connector 8-pin mini circular connector

Recommended I/F cable Apple system peripheral-8cable

PHYSICAL SPECIFICATION

Weight: 22 Kg (only a main frame)

Dimension: 640 mm(W) x 439 mm(D) x 224 mm(H)(Body only)

640 mm(W) x 704 mm(D) x 224 mm(H)(Printing on A3

size paper tray)

640 mm(W) x 584 mm(D) x 318 mm(H)(Printing on A4

size paper, optional cassette installed)

PARALLEL INTERFACE

[Compatibility Mode]

Table 1-11. Compatibility Mode

Item Content

Transmission mode 8-bit Parallel, IEEE-1284 compatibility

mode

Synchronization By STROBE pulse

Handshaking By BUSY and ACKLG signal

Logic Level TTL compatible level (IEEE-1284 Level 1

device)

Adaptable connector 57-30360(amphenol) or equivalent

Note1):

Note2):

Note)

Recommend to use short interface cable according to your

necessity.

Use the twist pair line for each control signal of input connector

and connect the return side to the signal ground.

BUSY signal is set high before setting either /ERROR low or PE high

and held high until all these signals return to their inactive state.

Rev.A

1-

Page 18

EPSON Stylus Pro 5000 Chapter1 Product Description

8

Busy signal is at high level in the following cases;

During data entry(see Data transmission timing)

When input data buffer is full

During /INT signal is at low level or during hardware initialization

During printer error (See /ERROR signal)

When the parallel interface is not selected

ERROR signal is at low level when the printer is one of the following states.

Printer hardware error (fatal error)

Paper out error

Paper jam error

Ink out error

Note)

PE signal is at high level during paper-out error.

[Nibble Mode]

Table 1-12. Nibble Mode

Item Content

Transmission

mode

Synchronization Refer to IEEE-1284 specification

Handshaking Refer to IEEE-1284 specification

Signal level TTL level (IEEE-1284 level 1 device)

Adaptable

connector

Data transfer

timing

Extensibility

request data

IEEE-1284 nibble mode

See forward channel

Refer to IEEE-1284 specification

The printer responds affirmatively when the

extensibility request values are 00H or 04H, that

mean,

00H :Request nibble mode reverse channel

transfer.

04H :Request device ID; Return Data using Nibble

Mode Rev channel transfer.

The printer sends following device ID string when it is

requested.

[00H] [3BH]

MFG : EPSON

CMD : ESCPL2, BDC

MDL : Stylus[SP]Pro[SP]5000;

CLS : PRINTER

Note)

[00H] denotes a hexadecimal value of zero.

MDL value depends on the EEPROM setting.

Rev.A

1-

Page 19

EPSON Stylus Pro 5000 Chapter1 Product Description

9

PARALLEL INTERFACE (CONT.)

[ECP Mode]

Table 1-13. ECP Mode

Item Content

Transmission mode IEEE-1284 ECP mode

Synchronization Refer to IEEE-1284 specification

Handshaking Refer to IEEE-1284 specification

Signal level TTL level (IEEE-1284 level 1 device)

See forward channel

Adaptable connector See forward channel

Data transfer timing Refer to IEEE-1284 specification

Extensibility request data The printer responds affirmatively when the

extensibility request values are 10H or 14H,

that mean,

10H :Request ECP mode reverse

channel transfer.

14H :Request device ID; Return Data

using ECP Mode Rev channel

transfer.

The printer sends following device ID string

when it is requested.

[00H] [3BH]

MFG : EPSON

CMD : ESCPL2, BDC

MDL : Stylus[SP]Pro[SP]5000

CLS : PRINTER

Note)

[00H] denotes a hexadecimal value of

zero. MDL value depends on the

EEPROM setting.

TYPE B OPTIONAL INTERFACE SPECIFICATION

Type-B interface level 2 is supported.

Reply message (Short version):

Case of using Co-ax / Twin-ax I/F card:

Main Type: MTP48p, PW127cl10cpi, PGR(KAxxxx)rev,

AP1200ma

Product Name: Stylus[SP]Pro[SP]5000

Emulation Type: ESCPL2-00

Entity Type: EPSONLQ2

Reply message

Case of using except Co-ax / Twin-ax I/F card

Main Type: MTP48p, PW127cl10cpi, PGR(KAxxx)rev,

AP1200ma, SPD0fast

Product Name: Stylus[SP]Pro[SP]5000

Emulation Type: ESCPL2-00

Entity Type: ESPONLQ2

BUFFER OPERATION

Stylus Pro5000 starts sending BUSY signal when it acknowledges no

available area left in the buffer. When the host keeps receiving this signal

for a long time, it acknowledges as time out and stops sending data.

INTERFACE SELECTION

The printer has 3-built in interfaces; the parallel interface and serial

interface, and has 1 optional Type-B interface card slot. These interfaces

are selected manually by the default setting mode or selected automatically.

(However, it is necessary to set these settings within the maintenance mode

level 1 of the panel operation.)

Manual Selection:

One of three interfaces can be selected by the default setting mode.

Rev.A

1-

Page 20

EPSON Stylus Pro 5000 Chapter1 Product Description

0

Automatic Selection:

The automatic interface selection is enabled by the default setting

mode. In this automatic interface selection mode, the printer is

initialized to the idle state scanning which interface receives data

when it is powered on. Then the interface that receives data first is

selected. When the host stops data transfer and the printer is in the

stand-by state for the seconds, the printer is returned to the idle

state. As long as the host sends data or the printer interface is busy

state, the selected interface is let as it is.

Following explains conditions of other interfaces when a particular interface

is selected.

When the parallel interface is not selected, the interface gets into

BUSY state. At this time, LH signal is set to “L”. That means blocking

power supply and no responds from 1284. Therefore, it is necessary

for the host, which requires Reverse transfer, to check LH state.

When the serial interface is not selected, the interface sets the DTR

signal MARK.

When the optional interface is not selected, Off-Line bit is set to Main

Status Register(MNSTS).

When the printer is initialized or returned to the idle state, Parallel

interface becomes the ready condition and DTR of serial interface

becomes SPACE(Low) condition and reset off-line bit of Main Status

Register(MNSTS)to, option interface.

/INIT signal on the parallel interface is not effective while that

interface is not selected or nibble Mode, ECP Mode.

Rev.A

1-1

Page 21

EPSON Stylus Pro 5000 Chapter1 Product Description

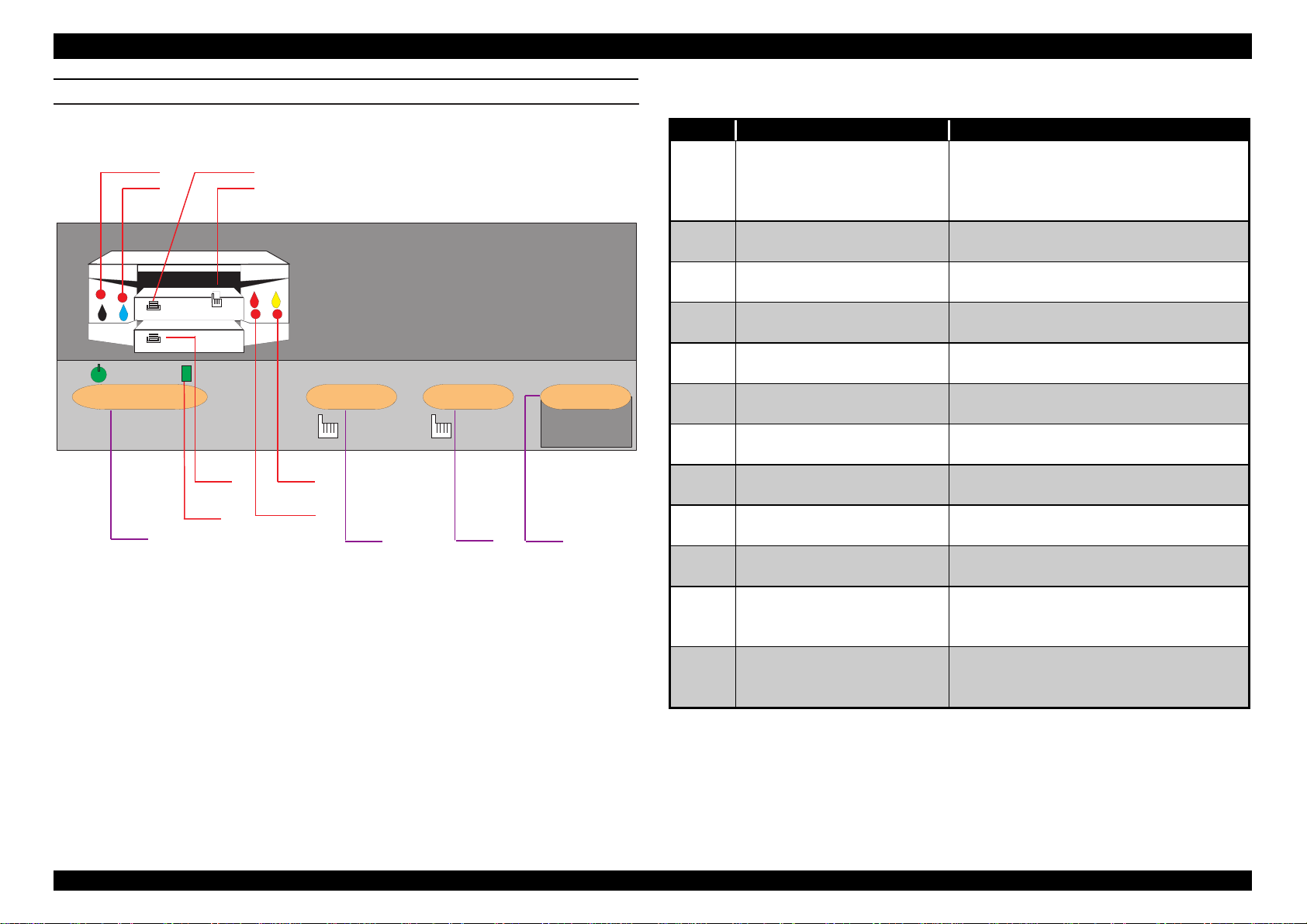

CONTROL PANEL

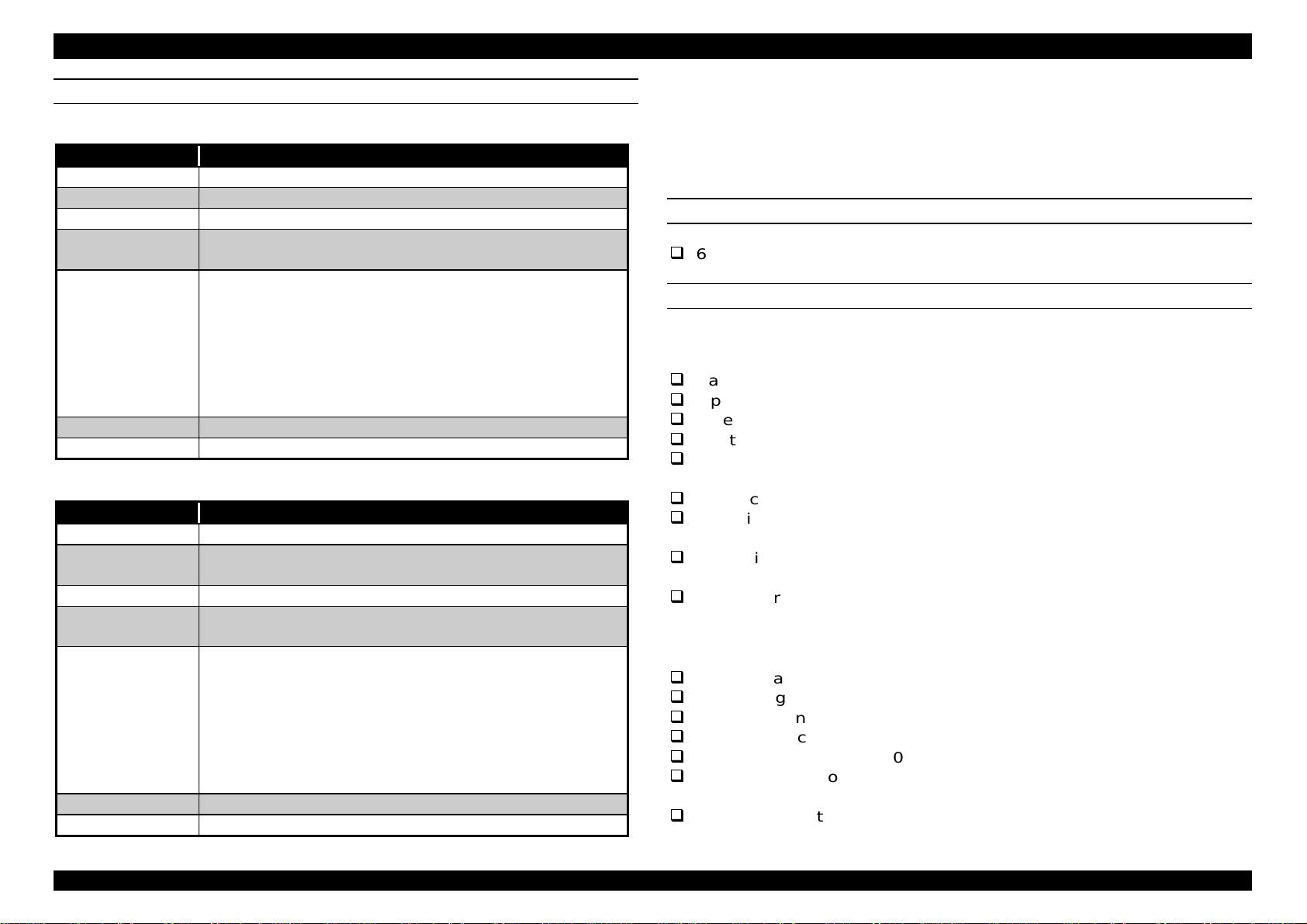

There are 4 non-lock push buttons and 8 LEDs. Each button function and

indicator are explained briefly below and on your right.

A

B

O perate

1

C

D

C leaningReset

3 se c 3 sec

G

H

E

F

2 3 4

Eject

C ontinue

Figure 1-2. Control Panel

Table 1-14. Control Panel Function

No. Button / Indicator Function

1 Operate button

(power)

Power source switch on the

secondary side.

Note)

Current is constantly flowing

in the primary side.

2 Reset button(Pressing for

Printer reset. Buffer clear.

3 sec.)

3 Cleaning button(Pressing

for 3 sec.)

4 Eject(Error recover)

button (2 sec.)

A Black I/C out indication

LED

B Cyan I/C out indication

LED

C Paper out indication LED

for cassette (paper tray) 1

D Paper out indication LED

for manual feed slots

Perform cleaning all heads of both

sides.

Ejects the paper, or recovers from

error.

Blinks for low ink quantity and light is

on for out of ink.

Blinks for low ink quantity and light is

on for out of ink.

Indication for paper out or paper

loading miss of cassette 1.

All 3 LEDs (C, D, G) blink at the

same time for paper loading miss.

E Magenta I/C out LED Blinks for low ink quantity, and light

is on for out of ink.

F Yellow I/C out LED Blinks for low ink quantity, and light

is on for out of ink.

G Paper out indication LED

for optional lower

Indication for paper out or paper

loading miss of cassette 2.

cassette (paper tray) 2.

H Operate LED

(power)

Green light is on while the current is

flowing, or receiving data, or CL

operation.

Rev.A

1-11

Page 22

EPSON Stylus Pro 5000 Chapter1 Product Description

2

Following table shows function when the power is turned on.

Table 1-15. Functions with power on

No. Name of switch Function

1 Reset Perform status printing (Refer to

Note1)

2 Cleaning Changes paper size, type verification.

3 Eject/Continue Changes platen gap adjustment for

the manual feed slots.

4 Reset + Cleaning Changes parallel I/F ECP mode

5 Reset + Eject/Continue Enters print head alignment mode.

6 Cleaning +

Eject/Continue

7 Reset +Cleaning +

Eject/Continue

(All SW)

Note1)

Note2):

mode.

:This status printing prints firmware version, ink counter, selected

code page and nozzle check patterns. Since the value of the

waste ink counter is indicated by HEX, it is recommended to use

the exclusive service program for checking the counter value.

Refer to Table1-17 for Download of Firmware and Maintenance

Enters the maintenance mode,

level1.(Factory use only)

Enters the Firmware uploading mode.

(Factory use only)

Following table shows LED indications.

Table 1-16. Printer condition and Panel status

No. Printer Status Indicators (Figure 1-2) Priority

H AB

EF

1 Power On On --- --- --- --- 9

2 Performing Ink

sequence

3 Receiving Data blink --- --- --- --- 8

4 Paper jam --- --- blink blink blink 3

5 Cassette 1/paper out,

wrong paper feeding

6 Out of paper in

Cassette 1(paper

tray1)

7 Cassette(Paper tray)2 --- --- --- --- On 5

8 Paper out in

Cassette(Paper tray)2

9 SIMM copy error

(over flow)

10 Ink end, No I/C --- On --- --- --- 7

11 Ink low --- blink --- --- --- 7

12 Reset, Timer IC reset,

EEPROM clear

13 Maintenance request

(waste ink counter

over flow)

14 Fatal error blink All

Note):

“---“ means no changes.

blink --- --- --- --- 6

--- --- --- blink --- 5

--- --- --- On --- 5

-- --- --- --- On 5

blink On On On On 4

--- On

blink AllOnblink blink blink 2

blink

D C G No.

---

(1 sec.)

blink blink blink 1

Rev.A

1-1

Page 23

EPSON Stylus Pro 5000 Chapter1 Product Description

3

Name of

Switch

All switches

+ Power on

Cleaning +

Eject Switch

+ Power on

(Level1)

Table 1-17. Download/Maintenance Mode

Function

1.Manual feed LED turns on when the printer enters this

mode correctly. Exclusive starting command(

is transmitted on the DOS (or DOS prompt). Black ink

LED blinks during this transmission and Cyan ink LED

will be turned on when the transmission is completed

correctly.

2.Wait 2 or 3 seconds after the Cyan ink LED is turned

on. Firmware

time, Magenta ink LED is turned one during this

transmission, and Yellow ink LED is turned on when it is

completed.

3.Turn off the power.

I/F

Diseng

age

Hexade

cimal

dump

(KEYWEST.HEX

1. After the operation written in the left column

is performed, press Reset switch until the

black ink LED is turned on. During entering

this mode, black, Cyan, Magenta and Yellow

LEDs are turned on alternatively, every time

the reset switch is pressed.

2.When the black ink LED turns on, press

Eject switch to determine.

3.Press the Reset switch until the

corresponding LED turns on, according to the

following explanation.

Black ink LED→Automatic, Cyan ink

LED→Parallel, Magenta ink LED→Serial,

Yellow ink LED→Option

4.Press either Eject switch or turn the power

off for registering to EEPROM.

1.After the operation written in the left column

is performed, press Reset switch until the

Magenta ink LED is turned on. During entering

mode, black, Cyan, Magenta and Yellow LEDs

are turned on alternatively, every time the

Reset switch is pressed. Press Eject switch to

determine after Magenta LED turns on.

2.Turning power off is the only way to escape.

) is transmitted. At this

IPL2.HEX

Table 1-18. Download/Maintenance Mode(Cont.)

Name of Switch Function

Cleaning + Eject

Switch + Power on

)

P-I/F

receiving

speed

CG

Disenga

ge

1.After the operation written in the left

column is performed, press Reset

switch until the Cyan ink LED is turned

on. During entering this mode, black,

Cyan, Magenta and Yellow LEDs are

turned on alternatively, every time the

reset switch is pressed.

2.Press Eject switch to determine after

Cyan ink LED is turned on.

3.Press the Reset switch until the

corresponding LED turns on, according

to the following explanation.

Black ink LED→High speed, Cyan ink

LED→Standard

4.Press Eject switch to register in the

EEPROM.

Note)It is not registered to EEPROM, if

power is turned off without pressing

Eject switch.

1. After the operation written in the left

column is performed, press Reset

switch until the Yellow ink LED is turned

on. During entering this mode, black,

Cyan, Magenta and Yellow LEDs are

turned on alternatively, every time the

reset switch is pressed.

2.Press Eject switch to determine after

Yellow ink LED is turned on.

3. Press the reset switch until the

corresponding LED turns on, according

to the following explanation.

Black ink LED→PC437, Cyan ink

LED→PC850

4. Press Eject switch to register in the

EEPROM.

Rev.A

1-1

Page 24

EPSON Stylus Pro 5000 Chapter1 Product Description

4

Table 1-19. Download/Maintenance Mode(Cont.)

Name of Switch Function

After inputting

modes written in

the previous page,

press Cleaning,

then, Reset switch.

(Level 2)

INITIALIZATION

Stylus Pro 5000 has following 3 initializations.

Note)After entering maintenance mode level1, it

becomes EEPROM reset function by pressing

Cleaning switch, then, Reset switch.

1.Make sure that black ink LED is on. If it is not

on, press Reset switch until the black ink LED

turns on.

2.After black ink LED turns on, press Eject switch

and confirm the reset.

3.To end this operation, turn the power off.

Operator(Panel) initialization

This printer is initialized when pushing the panel reset switch, or

printer recognized the /INT signal(negative pulse) of parallel

interface. When printer is initialized, following action is performed.

1. Caps the print head

2. Ejects a paper

3. Clears input data buffer

4. Clears print buffer

5. Resets default values

SETTING VALUES BY INITIALIZATION

By performing initialization, the following items return to the initial values.

Also, the panel setting, default setting, and item that can be saved on the

remote command will be default values.

Power on (Hardware) initialization:

This printer is initialized when turning the printer power on, or printer

recognized the cold-reset command (remote RS command). When

printer is initialized, following action is performed.

1. Initializes printer mechanism

2. Clears input data buffer

3. Clears print buffer

4. Resets default values

Software initialization

The ESC@ command also initializes the printer. When printer is

initialized, following action is performed.

1. Clears print buffer

2. Resets default values

1. Page position: Page heading location as present

paper location

2. Line spacing: 1/6 inch

3. Right margin position: 127 lines

4. Left margin position: First line

5. Word pitch: 10 CPI

6. Printing mode: Text mode(Not raster graphics mode)

Rev.A

1-1

Page 25

EPSON Stylus Pro 5000 Chapter1 Product Description

5

ERROR CONDITION

Stylus Pro5000 goes to error condition when it falls to the following

conditions. Out of Centronics interface signals, BUSY signal is set High and

/ERROR signal is set LOW. Then, the printer goes to unprintable state,

stopping data input from outside. Once the error happens, the printer can go

back to the standby position or ready status for printing again by removing

the error causes.

Ink near end and Ink out Error

When the printer runs out the most part of the ink of any one color, it

warns ink-low and keeps printing. When the printer runs out the whole

ink of any one color, it stops printing and indicates ink-out error. User is

requested to install a new ink-cartridge in this state.

A ink-cartridge once taken out should never be used again. Reinstallation of the cartridge not filled fully upsets the ink level detection

and may cause a serious problem in the print head as a result.

Paper out sensor

When there is no paper in the paper tray, or paper tray itself is not

installed, this sensor detects and goes paper out error.

Paper loading miss:

When printer fails to load a sheet or PE sensor does not detect the

paper on the path, it goes paper out error.

Paper Jam Error

Even when the paper feeding is performed at the power on, if the PE

sensor detects the paper on the paper path or fails to eject a paper by

FF command or Eject button, the printer considers it as paper jam and

goes to the error condition. In the Stylus Pro5000, the linear encoder

monitors detection of paper jam in the carriage running range.

No ink-cartridge

When the printer detects that ink cartridge comes off or is not installed, it

goes to the error condition.

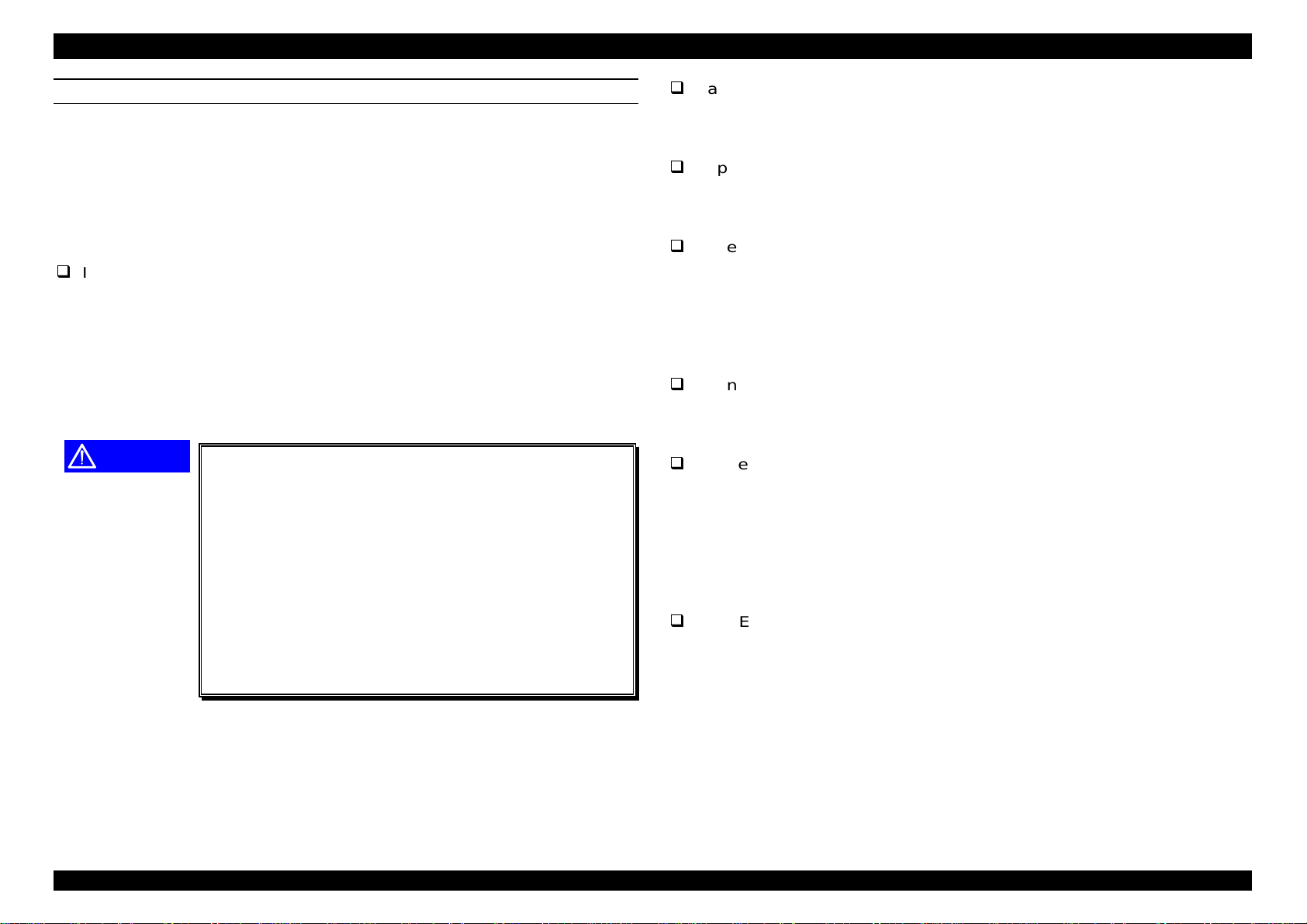

CAUTION

Rev.A

Although there is no worry of bubble invasion by

pulling out or installing the ink cartridge, it is

necessary to pay attention to the following points.

1)If the ink cartridge is once removed and installed

again in the condition that the ink out(end) sensor

detects the ink is still in, ink consumption based

on the previous ink life will be kept counting.

2)If the ink cartridge is once removed and the ink

cartridge whose left ink quantity is little is installed

again in the condition that the ink is still in, Stylus

Pro5000 goes to the ink out error condition, even

though there is still enough ink in it.

Maintenance Request

When the total quantity of ink wasted through the cleanings and flushing

reaches to the limit, printer indicates this error and stops. The

absorber(waste ink pad) in the printer enclosure is needed to be

replaced with new one by a service person. This error does not recover

until the waste ink pad is replaced and “0” is written to the particular

address in the EEPRON by a service man.

Fatal Errors

When fatal errors such as carriage control error or CG access error are

detected, the printer goes to error condition and stops. Repair service is

required for this error.

1-1

Page 26

EPSON Stylus Pro 5000 Chapter1 Product Description

6

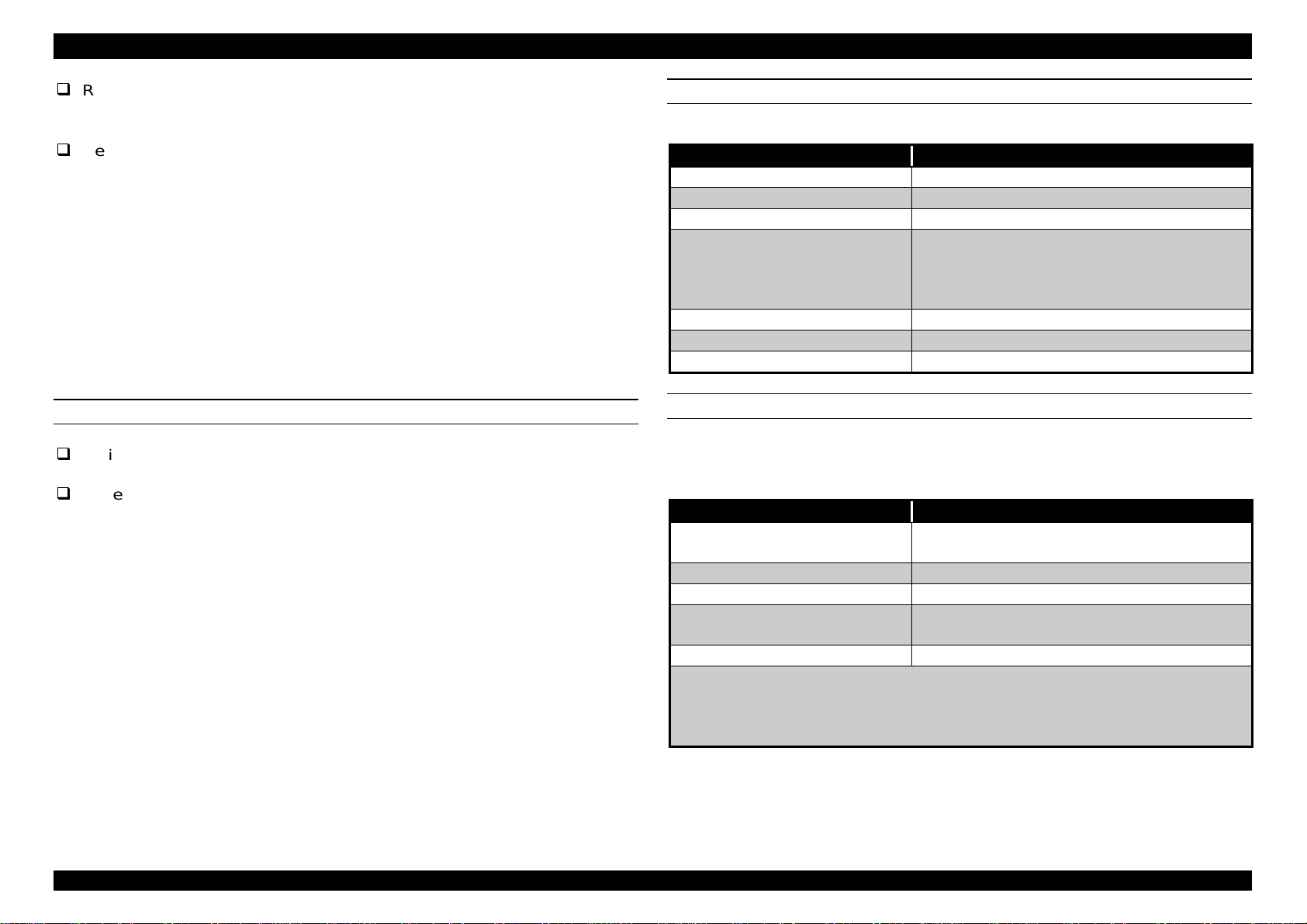

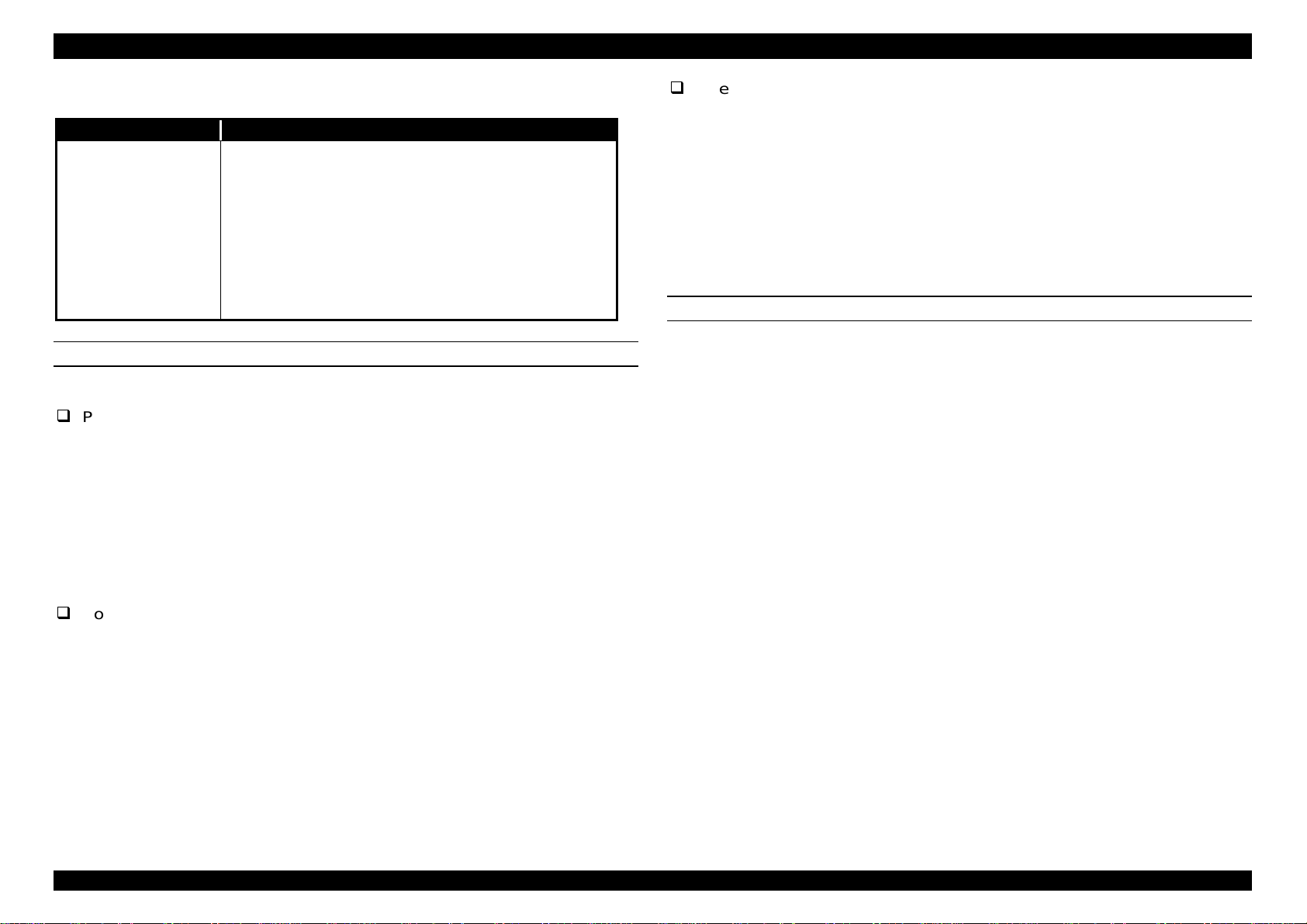

PANEL SETTING FUNCTION

Here explains input method for each panel setting.

Printing nozzle check pattern and printer configuration

•Operation: Reset SW + Power On

•Exit: Power Off

•Function: (Power LED blinking while in this mode)

1)Reset SW + Power on →2)Position change

to thick→3)Starts printing pattern→

4)Printing 1-page→5)Eject paper→6) Stand by

mode in self-test by pressing →Refer to

followings.

[Pressing Cleaning SW: in standby mode only]

1)Execute cleaning→2)Eject paper 3)Reprint self test

page→4)self-test stand by mode.

[Pressing Eject SW: in standby mode only]

1)Feed paper→2)Reprint self test page→3)self-test

stand by mode.

Note)

Ignore Cleaning SW while printing and Power off to exit this mode.

K 00227A A :0D 95 B :0D A F D :002C E 2C 0

Current Settings

P a p e r S iz e /T y p e C h e c k : O n

P a r a lle l I/F E C P M o d e : O ff

Platen G ap A djustm ent for M anual Feed S lots : Fixed (thick paper)

CHECK POINT

9

Even if Cleaning or Eject switch is pressed

during printing, the panel operation is ignored.

You can escape from the self-test mode only by

turning the power off.

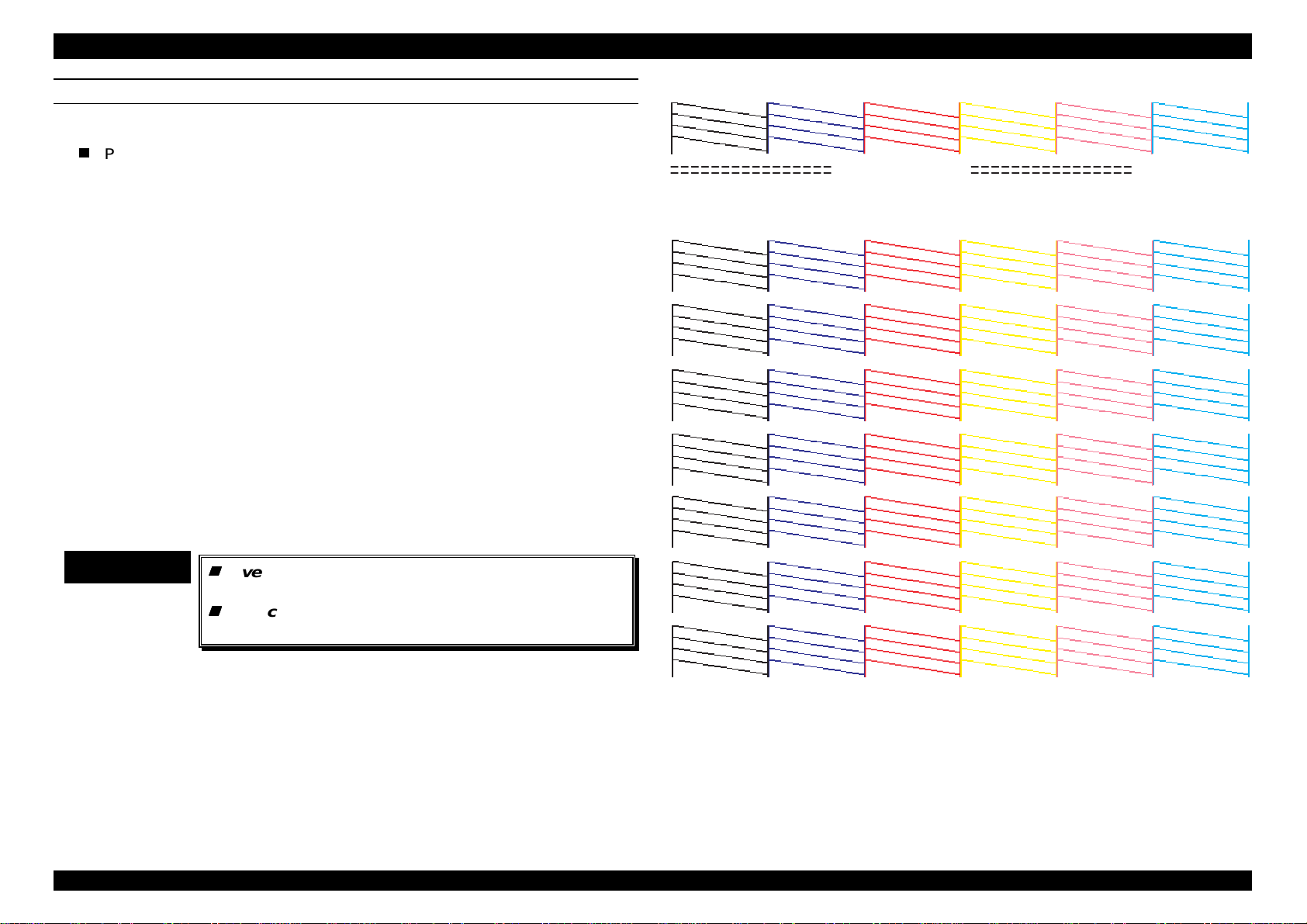

Printing Pattern: Print nozzle test pattern, firmware version, the value

of wasted ink count and current setting values are

printed. Following shows printing pattern.

Rev.A

Figure 1-3. Printing Sample

[Explanation]

K00227A: Firmware version.

A:0D95 : The present counting value of ink absorber only for

dark colors head.

1-1

Page 27

EPSON Stylus Pro 5000 Chapter1 Product Description

7

B:0DAF : The present counting value of ink absorber for light

color head only.

D: 002CE2C0 : The present counting value of waste ink absorber for

flushing.

Note)

By referring to the printing pattern on the previous page, it becomes

possible to check ink discharge conditions (or dot missing or alignment

failure) from all nozzles in each color. As an example, refer to “A” ∼ “D” lines

shown on the black nozzle pattern. “A” line is printed by black nozzle #1 to

#16, “B” line is by #17 to #32, “C” line is by #33 to #48, and “D” is #49 to

#64. Since the nozzle for different colors is also aligned in the same way,

you can consider in the same way.

Maintenance Error occurs at the point either A or B becomes full

counter condition. In other words, it occurs when A becomes 46650,

or B becomes 47200. Since the value is indicated by HEX indication,

it is recommended to use the exclusive program to check the counter

value.

Rev.A

1-1

Page 28

EPSON Stylus Pro 5000 Chapter1 Product Description

8

Paper check mode

This setting decides to turn the paper check function on or off. For

Stylus Pro5000, it is necessary to match the lever located paper feed

cassette(tray) above to the presently used paper type (media type)

and its size. If the PC which supports bi-directional communication is

used, it is not necessary to make this paper check setting

effective(on), because the user can change the lever positions on the

cassette, according to the error message on the PC screen.

However, if the user uses the PC which does not support the bidirectional communication, it is necessary to set this mode on the

printer body, since he/she can not check the error message on the

computer screen.

[After completing the setting, if the power is turned off]

1)Printer escapes from the selected paper check

mode.→2)Printer goes to the power off condition.

•Setting and LED indicator:

ECP mode off→Cyan LED on

ECP mode on→Black ink LED on.

•Function: 1)Reset SW+ Cleaning SW+ Power on to

enter this mode→2)Power LED turns on and

Cassette1LED blinks→

3)Indicate the current setting by blinking ink

LED.→4)Change ECP On/Off by Reset SW.

•Operation: Cleaning SW + Power on to enter this mode.

•To change paper check mode setting On/Off:

Reset SW

•Save setting: Press Eject switch or turn off the power.

•Setting and LED indicator:

Paper check On→ Black ink LED On.

Paper check Off→ Cyan ink LED On.

•Function: 1)Cleaning SW +Power on to enter this

mode→2)Power LED blinks, Cassette1 LED

turns on→3)Ink LED indicates current

setting→ 4)Change paper check On/Off by

Reset SW.

[After completing the setting, if the power is turned off]

1)Save setting→2)Exit mode→3)Power off

[After completing the setting, if Eject switch is pressed]

1)Save setting→2)Exit mode→3)Idle state

ECP Mode

•Operation: Reset SW + Cleaning SW + Power On to enter

this mode.

•To change ECP mode On/Off:

Reset SW

•Save setting : Turn off the power or press the Eject SW

[After completing the setting, if Eject switch is pressed]

1)Printer escapes from the selected paper check

mode. →2)Printer goes to the ordinal printing mode(idle state).

Rev.A

1-1

Page 29

EPSON Stylus Pro 5000 Chapter1 Product Description

9

Manual feed slots paper thickness - Auto mode

The setting for Manual feed thick paper and auto mode is the function

only to deal with using manual feed slots(front/rear). After checking the

result of the printing by the manual feeding, this function becomes

effective when the printing is blurry or faint. The reason why there is this

kind of function only for manual feeding is that the printer can not

recognize the paper thickness, unlike the other paper feed cassettes.

There is no influence on the other paper feeding path(or standard

cassette or optional cassette), when this function becomes effective.

Also, unless this function is set effective, manual paper feeding always

make PG(platen gap) big or wider and perform printing. Following shows

conditions when the PG becomes wider(big).

Table 1-20. Setting conditions when PG becomes thick paper mode

Setting No. Conditions

Setting on the

Driver side.

Lever setting on

the cassette side.

Special Panel

setting.

1 In case A4 size paper (landscape) is set.

2 In case SF exclusive paper (landscape) is set.

3 In case Media type is the combination of

ordinary paper and paper size A4(landscape).

4 In case Media type is the combination of SF

exclusive paper and A4 size(landscape).

5 In case of thick paper mode for the manual

feed.

CAUTION

Paper Feed from Manual Paper Feed Slot

Priority order1.:PG is wider(big) if thick paper

mode is set.

Priority order2.:In case, media type is set to the

envelope.

•Operation: Eject switch + Power on to enter this mode.

•To change setting Manual/Auto mode:

Reset SW

•Save setting: Turn off the power or press the Eject switch.

•Setting and LED indication: *Auto→Black ink LED On. Platen gap

is defined by platen gap command

‘PG’.

*Manual feed(thick paper)→Cyan ink

LED on. Platen gap ignores PG

command and uses platen gap thick

position.

•Function: 1)Eject SW + Power On to enter this

mode→2)Power LED blinks and

Cassette 2 LED turns on→3)Ink LED

indicates current setting→4)Automatic

or manual (thick paper) is changed

over everytime the Reset SW is

pressed.

Rev.A

CAUTION

According to the Table above, priority order for

each setting is determined as follows.

Paper Feed from paper feed cassette

(standard/option).

Priority order1.:In case the media type is set to

“Thick Paper”.

Priority order2.:In case there is mis-matching

between driver and lever position on the printer,

the priority is given to the driver setting, if “Ignore”

button is selected on the screen.

[After completing the setting, if the power is turned off]

1)Save setting→ 2)Exit setting mode →3)Printer goes

to the power off condition.

[After completing the setting, if Eject switch is pressed]

1)Save setting→ 2)Exit setting mode →3)Printer goes

to the ordinary printing mode.(idle state)

1-1

Page 30

EPSON Stylus Pro 5000 Chapter1 Product Description

0

Select I/F mode(Cont1. from Maintenance mode)

Maintenance Mode 1

• Operation: Cleaning SW + Eject SW + Power ON to enter this

mode.

• To change maintenance item:

Reset SW

• Determine the selection(maintenance item):

Eject SW

• Maintenance item and LED indicator:

I/F selection → Black ink LED is on.

Parallel input speed→Cyan ink LED is on.

HEX dump→Magenta ink LED is on.

Character set→Yellow ink LED is on.

• Function: 1)Cleaning SW + Eject SW+ Power ON to enter this

mode→2)Power LED blinks. Manual cassette(tray),

Cassette1 and 2 turn on→3)Ink LED indicates current

setting→4) Paper check, I/F selection, Parallel input

speed, Hex change is changed over everytime the

Reset SW is pressed.

Ink LED turn on in the order of left to right and returns

to left side.

[In case of pressing Eject SW]

1)Select item(Data registration)→2)Exit this mode→3)Enter each setting

mode.

CAUTION

Following explains setting of each item in the

maintenance mode selection.

• Operation: After Eject SW + Power ON, turn the black ink LED

on by pressing Reset SW, and determine that

selection by pressing Eject SW.

• To select I/F mode:

Reset SW(Parallel→Serial→Option)

• Save setting:

Eject SW or Power off

• Setting item and LED indicator:

Auto selection setting→Black ink LED is on.

Parallel I/F mode→Cyan ink LED is on.

Serial I/F mode→Magenta ink LED is on.

Option I/F mode→Yellow ink LED is on.

• Function: 1)Select “Black” in maintenance mode to enter this

mode.→2)Power LED blinks. Cassette1 and 2 turn on

→3)Ink LED indicates current setting. →4)By pressing

Reset SW, Auto, Parallel, Option is selected in this

order. Ink LED moves left to right and return to left.

[After completing the setting, if power is turned off]

1)Save setting(Data registration)→ 2)Exit setting mode →3)Printer goes

to the power off condition.

[After completing the setting, if Eject switch is pressed

1)Save setting(Data registration)→ 2)Exit setting mode →3)Printer goes

to the ordinary printing mode(idle state).

Rev.A

1-2

Page 31

EPSON Stylus Pro 5000 Chapter1 Product Description

HEX dump mode (Cont2. from Maintenance mode)

• Operation: After pressing Eject SW + power on, turn on the

Magenta ink LED by pressing Reset SW and

determine by Eject SW. After that, HEX dump and

ordinary mode is changed over by pressing Reset

SW.

• Save setting: Press Eject SW.

• Function: 1)Enter HEX dump mode →2)Hex dump idle →3)HEX

dump printing.

Exit mode by power off.

Parallel I/F speed(/ACK plus width) (Cont3. from Maintenance mode)

• Operation: After pressing Cleaning SW + Eject SW + Power on,

turn on the Cyan ink LED by pressing Reset SW

and determine by Eject SW. After that, High speed

and standard is changed over by pressing Reset SW.

• Save setting: Press Eject SW.

• Setting item and LED indicator:

/ACK with short(0.5us)→Black ink LED is on.

/ACK with standard(2us)→Cyan ink LED is on.

• Function: 1)Select “Cyan” in maintenance mode to enter this

mode. →2)Power LED and Cassette 1 blink.

Cassette2 LED turns on. →4) Ink LED indicates

current setting. →

5)Short or Standard is changed over everytime Reset

SW is pressed.

PC437-PC850 Code Page select(Cont4.from Maintenance mode)

• Operation: After pressing Cleaning SW +Eject SW +Power on,

turn on the Yellow ink LED by pressing Reset SW

and determine by Eject SW. After that, PC-437 and

PC-850 is changed over by pressing Reset SW.

• Save setting: Power off or Eject SW

• Setting item and LED indicator:

PC437→Black ink LED is on.

PC850→Cyan ink LED is on.

• Function: 1)Select maintenance mode “Yellow” to enter this

mode. →2)Power LED and cassette 2 LED blink.

→3)Ink LED indicates current setting. →4)PC437 and

PC850 is changed over every time Eject SW is

pressed.

[In case of turning power off]

1)Save setting(Data registration)→2)Exit this mode→3)Power off

[In case of pressing Eject SW]

1)Save setting→2)Exit this mode→3)Ordinary printing mode(idle state)

[In case of turning power off]

1)Save setting(Data registration)→2)Exit this mode→3)Power off

[In case of pressing Eject SW]

1)Save setting→2)Exit this mode→3)Ordinary printing mode(idle state)

Rev.A

1-21

Page 32

EPSON Stylus Pro 5000 Chapter1 Product Description

2

Maintenance Mode 2

Reset EEPROM (Cont. from Maintenance Mode2)

This operation is to input particular address “0” in the EEPROM.

• Operation: In maintenance mode, press Cleaning SW and

then Reset SW to enter maintenance mode2.

• Select maintenance mode2 setting item:

Reset SW

• Select item: Eject SW

• Setting item and LED indicator:

Reset EEPROM→Black ink LED is on.

• Function: 1)In maintenance mode, press Cleaning SW and then

press Reset SW to enter this mode. →2)Power LED

and manual tray LED blink. Cassette 1 and 2 turn on.

→3)Ink LED indicates current setting. →

4)Ink LED moves left to right and return to left by

every Reset SW.

[In case of pressing Eject SW]

1)Save setting→2)Exit this mode→3)Execute one of setting mode.

CAUTION

There is only one available item in the maintenance

2. See the item on your right.

There is only one item that you can actually operate in the maintenance

mode2. This function is the same reset as other EEPROM reset of other

EPSON printer products.

• Operation: After entering maintenance mode, press Cleaning

SW, then, press Reset SW to enter maintenance

mode2. At this time, black ink LED is on.

Select maintenance mode 2 “BLACK” to clear

EEPROM.

• Execute: Eject SW

• Function: Pressing Eject SW clears only particular address in

the EEPROM.

• Exit: Exit this mode by power off.

Following shows items which are actually cleared by this operation.

CHECK POINT

9

Following items are reset forcefully by executing

maintenance mode2.

Waste ink counter (protect counter) is cleared.

Total power off time(timer IC) is cleared.

Cleaning counter is cleared.

The value of Auto I/F returns to Auto(initial value).

Rev.A

1-2

Page 33

EPSON Stylus Pro 5000 Chapter1 Product Description

3

Gap Adjustment Mode

This adjustment is Bi-D adjustment and head gap adjustment.

By turning on power, pressing Cleaning SW and Eject SW, the printer

enters to the gap adjustment mode and prints out the present adjustment

values.

• Select: Select most appropriate No. of line from the

samples by referring to the table below.

In this selection, LED moves from 1→7

direction by Reset SW, and 7→1 direction by

Eject SW.

CAUTION

In this gap adjustment mode, 4 printing patterns

are printed out; 1. Normal dot, 2.Micro dot, 3.BiD printing of Super micro dot, 4.Head Gap

pattern. However, in this present model, Bi-D

printing by other dots except normal dot is not

performed. The reason why Bi-D adjustments for

micro and super micro are included is for the

future use, in case of specification changes.

• Operation: Rese SW+ Eject SW + Power On to enter this mode.

After entering to the gap adjustment mode, 4

patterns(#1∼#4) of Bi-D sample with present values is

printed out. At this time, set the sample number you

want to adjust by referring to the Table below.

Table 1-21. Number selection after entering adjustment mode

No. Ink LED #1 #2 #3 #4

1 Black On Off Off Off

2 Cyan Off On Off Off

3 Magenta Off Off On Off

4 Yellow Off Off Off On

• Select setting item: Number is changed from #1 to #4

everytime Reset SW is pressed.

• Determination: Press Eject SW, and the next pattern (1∼7) is

printed out.

Table 1-22. Selecting Adjustment values after selecting number

No. Ink LED #1 #2 #3 #4 #5 #6 #7

1 Black On Blink Off Off Off Off Off

2 Cyan Off Off On Blink Off Off Off

3 Magenta Off Off Off Blink On Off Off

4 Yellow Off Off Off Off Off Blink On

• Determination: Determine No. by Cleaning SW and perform

printing again.

• Exit: Exit this mode by power off. Also, it is written

to EEPROM at this time. By pressing

Eject SW, the printer exits from this mode and

stores the memory of adjustment values.

Firmware uploading

If any changes occur on the firmware after the products are sent, it is

possible to perform uploading from the PC without changing ROM of Stylus

Pro5000.

• Operation1: Turn on the power, pressing Cleaning SW, Reset SW

and Eject SW, in order to enter the firmware

uploading mode. IPL2.HEX file in the FD for

uploading, which will be distributed, is transferred first.

IPL2 file is the program to make the next firmware to

transfer. Without performing this operation, following

uploading program can not get started.

Rev.A

1-2

Page 34

EPSON Stylus Pro 5000 Chapter1 Product Description

4

CHECK POINT

9

• Opeation2: Check if the operation is completed correctly and wait

CHECK POINT

9

• Exit: Exit this mode by power off.

Type the following sentence on DOS screen or

on the DOS prompt for transmission.

Copy X :IPL2.HEX_LPT1

During transmission, black ink LED turns on

and Cyan ink LED turns on when the

transmission is completed correctly.

2 or 3 seconds. Main firmware K0xxxx.HEX is

transferred.

Type the following sentence on DOS screen or

on the DOS prompt for transmission.

Copy X: K0xxxx.HEX_LPT1

During transmission, Magenta ink LED turns on

and Yellow ink LED turns on when the

transmission is completed correctly.

Rev.A

1-2

Page 35

EPSON Stylus Pro 5000 Chapter1 Product Description

5

1.3 ADDING PAPER GUIDE ROLLER UNIT

Here explains installing and removing Paper Guide Roller Unit, which can be

installed to the paper feed cassette. Paper Guide Roller Unit is designed to

improve the credibility of paper feeding for large exclusive papers (especially

glossy paper), such as A3 or Super A3/B,.

Table 1-23. Parts Code List

Parts Name Parts Code

Paper Guide Roller Unit 1040445

[Installing Paper Guide Roller Unit]

Step1. As it is shown in Figure1-4, insert the yellow side of the unit, which is

located at left side of Paper Guide Roller Unit, into the yellow spaced

of paper feed cassette, and insert the other hook into the hole on the

paper feed cassette. (Refer to Figure1-4)

WARNING

When installing Paper Guide Roller Unit to the paper

feed cassette, be careful not to involve the

protection board for signal cable of paper type/size

sensor.

Protection board for signal cable of

paper type/size sensor

Paper Guide Roller Unit

Paper Feed Cassette

Hook

Figure 1-4. Installing Paper Guide Roller Unit

Step2. Push the Paper Guide Roller Unit hard until it clicks and the unit is

attached completely.

Rev.A

1-2

Page 36

EPSON Stylus Pro 5000 Chapter1 Product Description

6

Minus DriverBig Hook

[Removing Paper Guide Roller Unit]

Step1. Looking at the front side of paper feed cassette from its bottom,

release the big hook, which is located under its right side(paper type

lever), as it is shown in Figure1-5. (Refer to Figure1-5)

Step2. Looking at the front side of paper feed cassette from its bottom,

release the hook by inserting a minus driver into 2 small hooks from

their sides, which are located under the left side of paper feed

cassette(paper size lever), and remove Paper Guide Roller Unit.

(Refer to Figure1-6)

Figure 1-5. Paper Guide Roller Unit Removal (1)

Minus Driver

Rev.A

2 small hooks

Figure 1-6. Paper Guide Roller Unit Removal (2)

1-2

Page 37

OPERATING PRINCIPLES

&+$37(5

Page 38

Stylus Pro5000 Chapter2 Operating Principles

2.1 FEATURE

This section explains mechanical and electrical operating principles for

Stylus Pro5000.

2.1.1 Operating Principles of Printer Mechanism

The printer mechanism of Stylus Pro5000 consists of the following

mechanism parts.

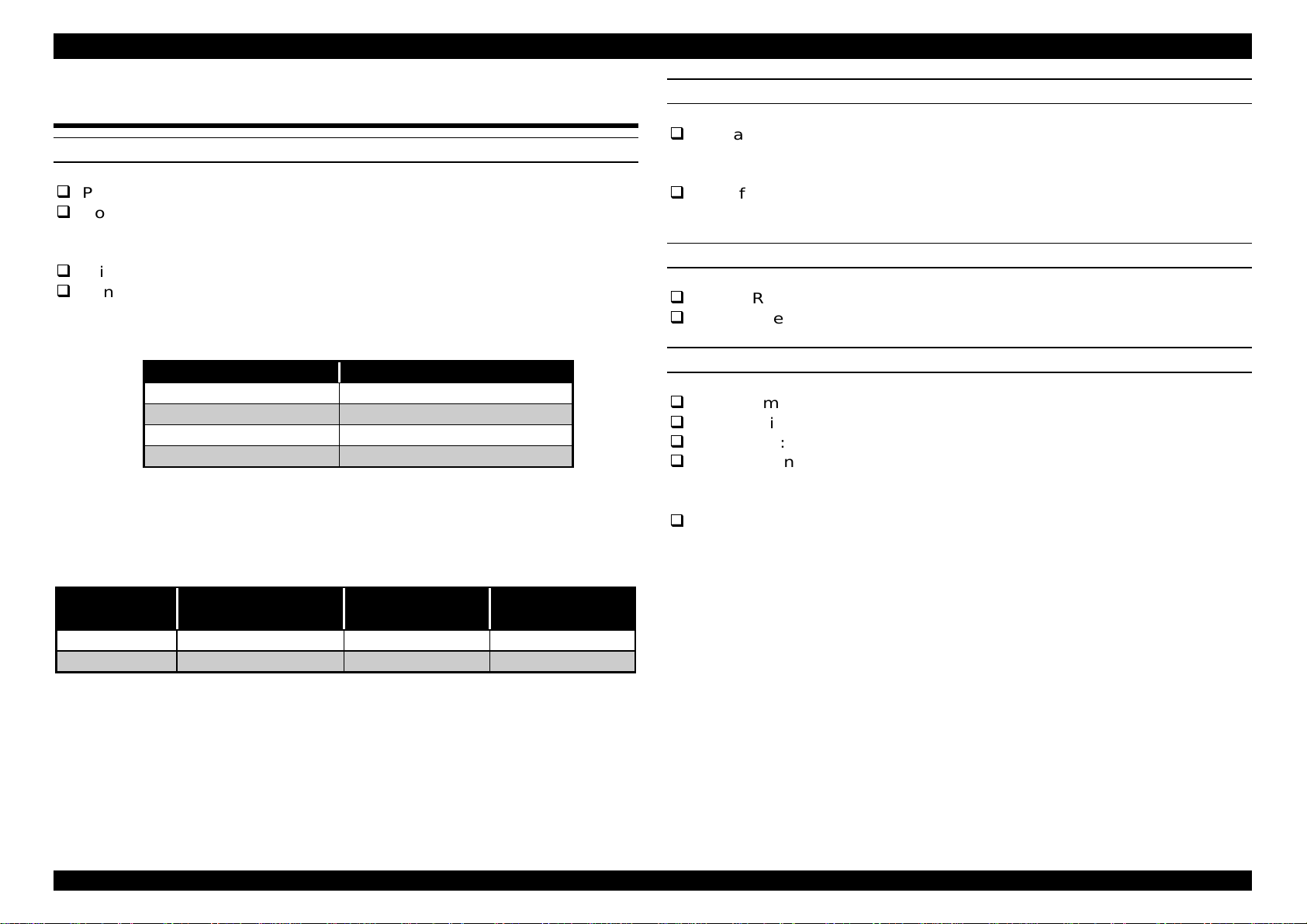

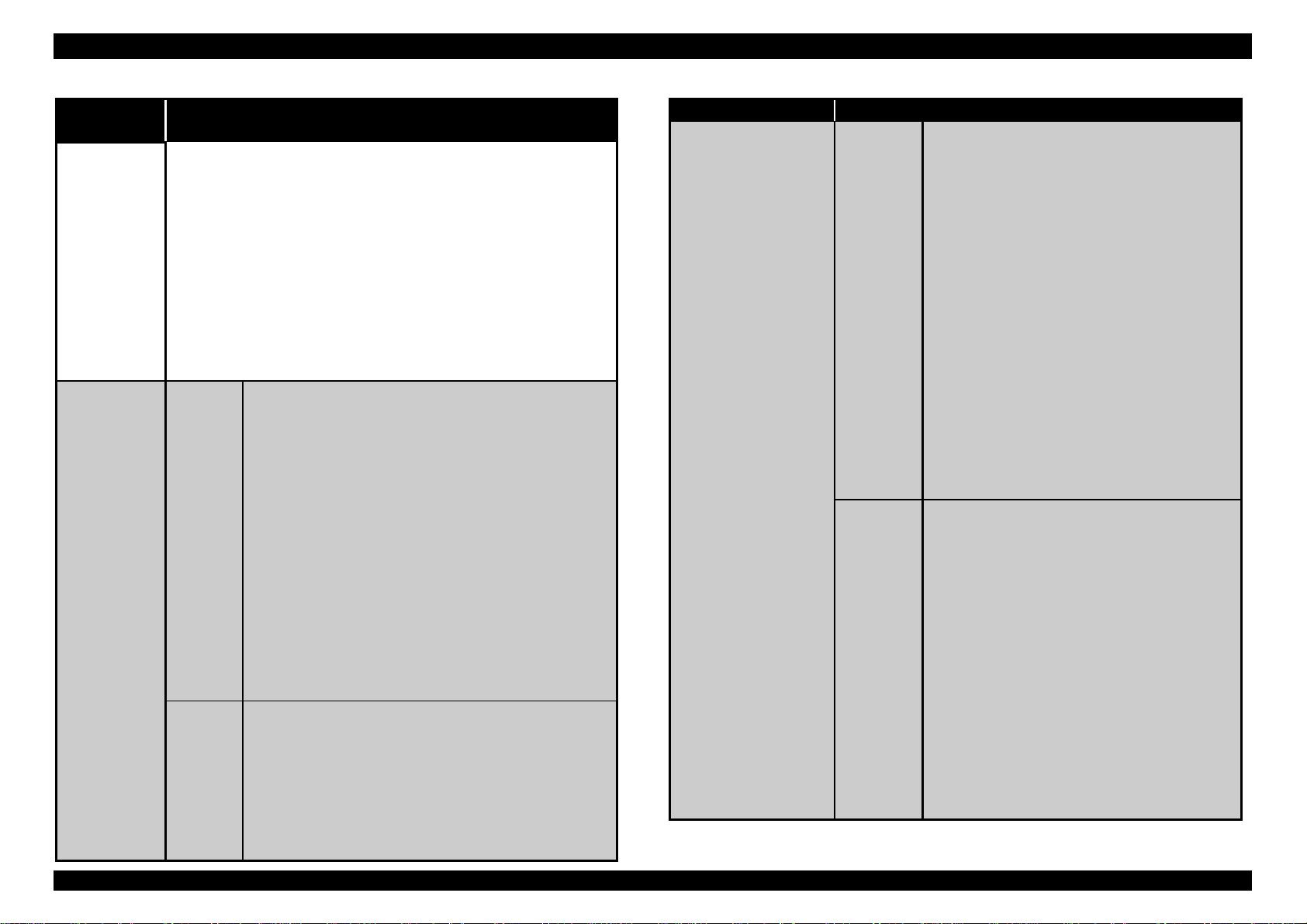

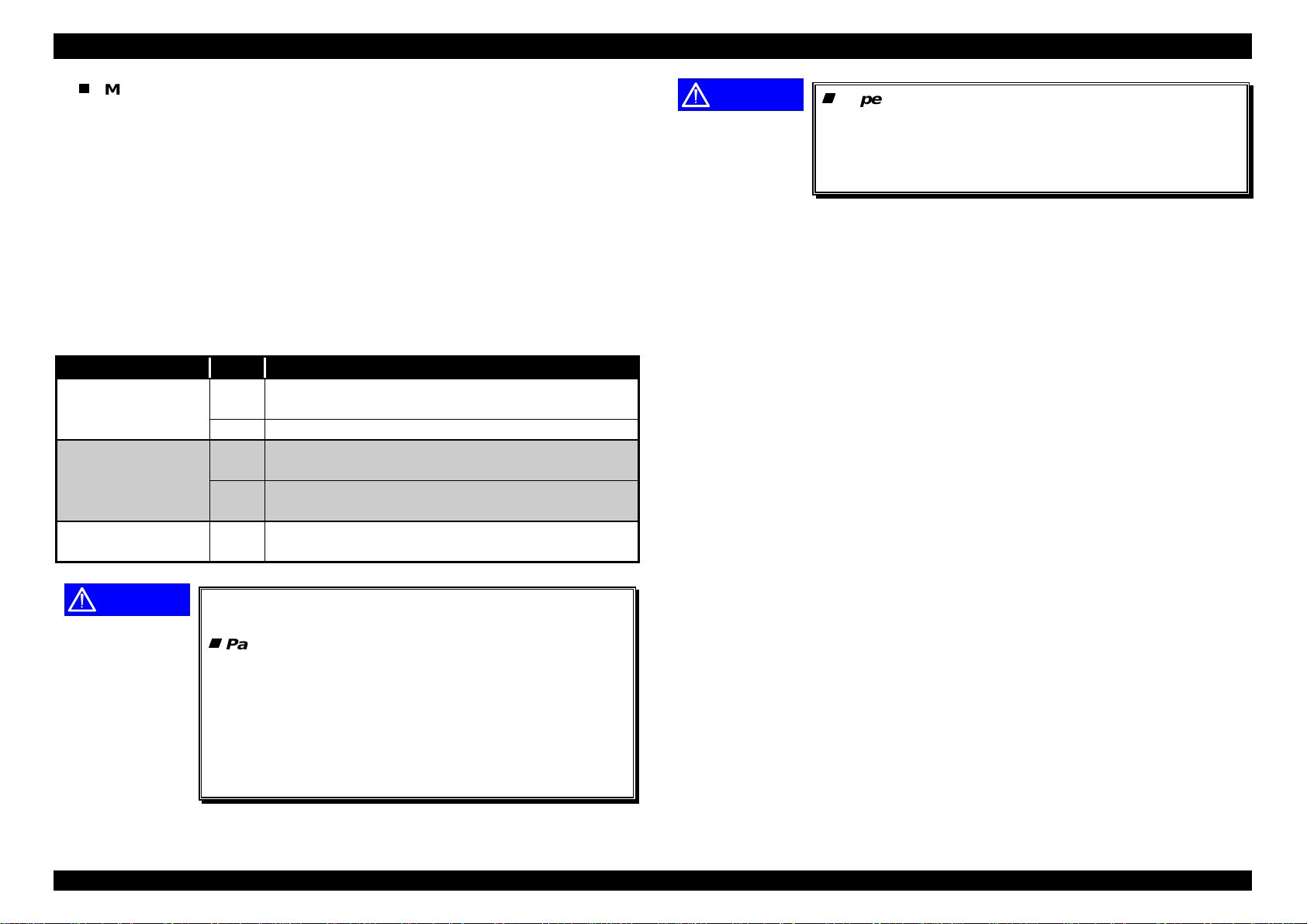

Table 2-1 . Mechanism Components

No. Mechanism Motor Function(Purpose)

1 Printing Mechanism ----2 Carriage Mechanism CR

3 Paper Load/Paper Feed

Mechanism

4 Upper Surface Sensor

Mechanism

5 Paper Return Mechanism

6 Lifter Gear Train

Mechanism

7 Hopper 5mm Down

Mechanism

8 Sub Roller Gear Train

Mechanism

PF+ASF

-----

Pump,

ASF

•Ink Discharge

•Driving Carriage

•Input or Output trigger

to ink mechanism

•Paper transport.

•Open or close the ink

valve.

•Load adjustment of

the Paper Load Roller,

according to the paper

volume.

•Prevention of multifeeding.

•Lifter Up/Down.

•Prevention of folding

paper on the paper

skew.

•Improvement of

credibility of paper

loading.

•Big roller for paper

transport.

Table 2-2. Mechanism Components(Con.)

No. Mechanism Motor Function(Purpose)

9 Gear Train Changes with

Hopper installed

10 Ink Engage/Disengage

Mechanism

11 PG Engage/Disengage

Mechanism

12 Ink Valve Mechanism PF

13 Friction Release

Mechanism

----PF

CR+PF

Pump,

ASF

•Engaging to the Lifter

Gear Train.

•Changes over Paper

Load line/ Pump line

•Changes PG

according to the paper

type.

•Prevention of ink

leaking during the retransportation.

•Friction Release

Mechanism in the

range 10cm of the

paper end edge.

Rev. A

2-1

Page 39

Stylus Pro5000 Chapter2 Operating Principles

2

2.1.1.1 Printing Mechanism

Printing method for Stylus Pro5000 uses EPSON original’s MACH method,

like the previous models. Although 2 color heads which are the same ones

used for Stylus Color 800, are used for Stylus Pro500, auto color

calibration function is added to the heads used for Stylus Pro5000.

Therefore, since the ID contents written in the head is completely different

from the ones of Stylus Color 800,

can not be used for Stylus Pro5000 on the service.

Table 2-3. Head Code

Head Name Parts Code

IJ192-AD(Left Head) F055040

IJ192-AE(Right Head) F055050