Page 1

LQ-510/AP-4000

TECHNICAL MANUAL

EPSON

Page 2

FCC COMPLIANCE STATEMENT

FOR AMERICAN USERS

This equipment uses and generates radio frequency energy and if not installed and used properly, that is,

in strict accordance with the manufacturer’s instructions, may cause interference to radio and television reception. It has been type tested and found to comply with limits for a Class B computing device in accordance

with Sub-part J of Part 15 of FCC Rules, which are designed to provide reasonable protection against such

interference in a residential installation. However, there is no guarantee that interference will not occur in

a particular installation. If this equipment does cause interference to radio or television reception, which can

be determined by turning the equipment on and off, the user is encouraged to try to correct the interference

by one or more of the following measures:

l reorient the receiving antenna

l relocate the computer with respect to the receiver

l move the computer away from the receiver

l plug the computer into a different outlet so that the computer and receiver are on different branch circuits.

If necessary, the user should consult the dealer or an experienced radio/television technician for additional

suggestions. The user may find the following booklet, prepared by the Federal Communications Commission, helpful: “ How to Identify and Resolve Radio-TV Interference Problems.

the U.S. Government Printing Office, Washington, D.C., 20402, Stock No. 004-000-00345-4.

© 1989 Seiko Epson Corporation

” This booklet is available from

Epson America, Inc.

Customer Service Department

23610 Telo Avenue

Torrance, California 90505

All rights reserved. No portion of this document may be reproduced, stored in a retrieval system, or transmit-

ted in any form or by any means, electric, mechanical, photocopying, recording, or otherwise, without the

written permission of Epson America, Inc. No patent liability is assumed with respect to use of the informa-

tion contained herein. While every precaution has been taken in the preparation of this book, Epson America,

Inc., assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of the information contained herein.

Epson@

is a registered trademark of Seiko Epson Corporation.

LQ-510TM is a trademark of Epson America, Inc.

ii

LQ-510

Page 3

REV.-A

Precautionary notations throughout the text are categorized relative to 1) personal injury, and 2) damage

to equipment:

DANGER

Signals a precaution which, if ignored, could result in serious or fatal personal in-

jury. Great caution should be exercised in performing procedures preceded by a

DANGER heading.

WARNING

Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance

procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM BOTH THE POWER SOURCE AND

PERIPHERAL DEVlCES BEFORE PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURE.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH

BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS TECHNICIANS IN

THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN THE

POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. Repairs on Epson products should be performed on/y by an Epson-certified repair

technician.

2. Make certain that the source voltage is the same as the rated voltage, listed on the serial

number/rating plate. If the Epson product has a primary AC rating different from the

available power source, do not connect it to the power source.

3. Always verify that the Epson product has been disconnected from the power source before

removing or replacing printed circuit boards and/or individual chips.

4. In order to protect sensitive microprocessors and circuitry, use static discharge equipment, such as anti-static wrist straps, when accessing internal components.

5. Replace malfunctioning components only with those components recommended by the

manufacturer; introduction of second-source ICs or other nonapproved components may

damage the product and void any applicable Epson warranty.

LQ-510

-iii-

Page 4

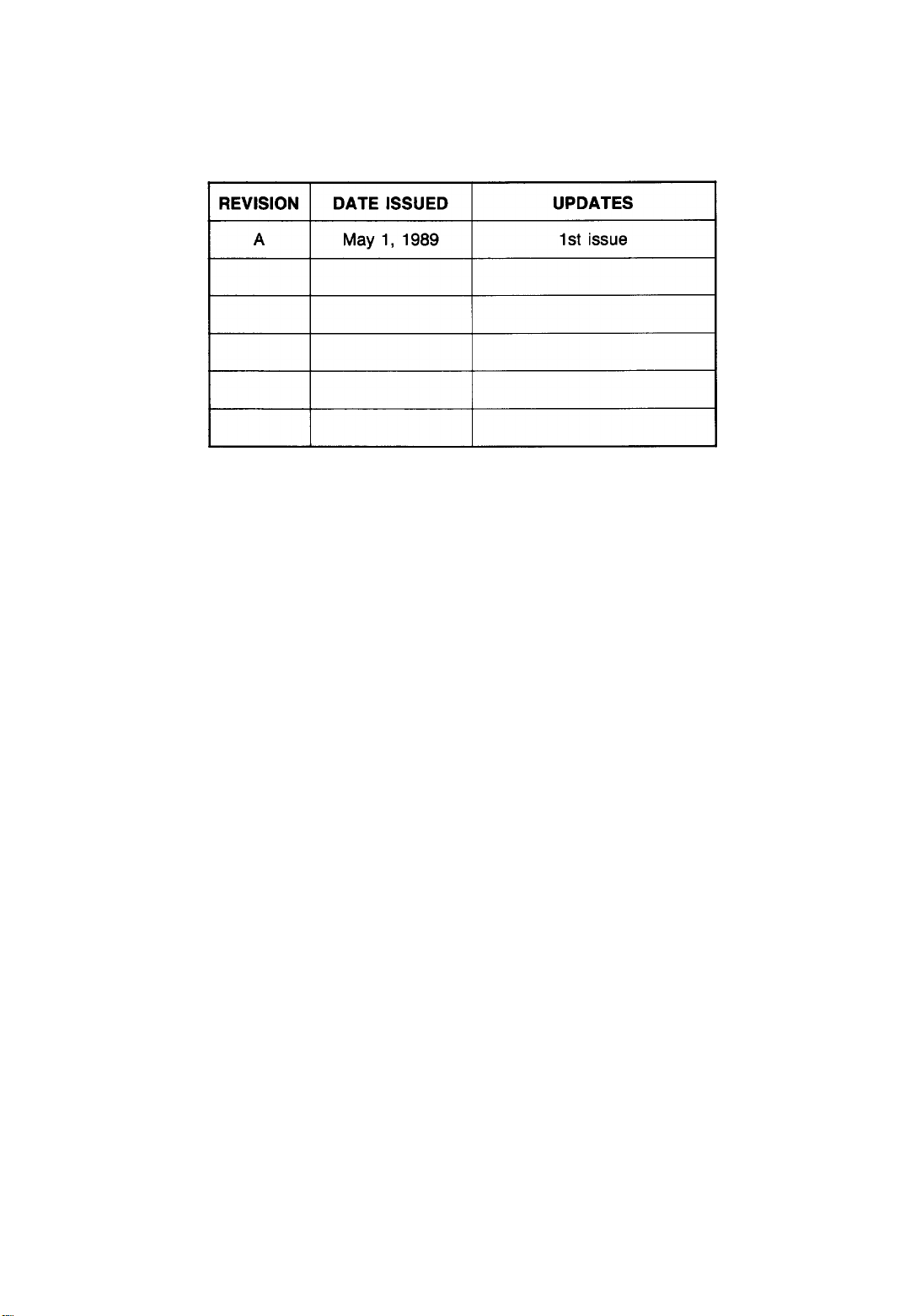

REVISION SHEET

REV-A

-iv-

LQ-510

Page 5

FCC Compliance Statement for American Users

This equipment has been tested and found to comply with limits for a Class B digital device,

pursuant to Part 16 of the FCC Rules. These limits are designed to provide reasonable protections

against harmful interference in a residential installation. This

radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio or television reception, which can be determined by turning

the equipment off and on. The user is encouraged to try to correct the interference by one or more of

the following measures:

l

Reorient or relocate the receiving antenna

l

Increase the separation between the equipment and the receiver

l

Connect

connected

l

Consult the dealer or an experienced radio/TV technician for help.

the equipment to an outlet on a circuit different from that to which the receiver is

WARNING: The connection of a nonshielded interface cable to this equipment will

invalidate the FCC Certification of this device and may cause interference levels that

exceed the limits established by the FCC for this equipment. If this equipment has more

than one interface connector, do not leave cables connected to unused interfaces.

For Canadian Users

This digital apparatus does not exceed the Class B limits for radio noise emissions from digital

apparatus as set out in the radio interference regulations of the Canadian Department of

Communications.

equipment

generates, uses, and can

Le p&sent appareil

applicable6 aux

radio&ctriques

num&ique n’emet

appareils

act4

numeriques

par le Ministire des Communications du Canada.

pas de bruits radio&ctxiques

de Classe B

prescrites

dans le

dbpassant

reglement

les

limites

sur le brouillage

Subsequent product modifications will be brought to your attention via service bulletins. Please

revise the text when you receive these bulletins.

This document is subject to change without notice.

All rights reserved. No part of this publication may be reproduced, stored in

a

retrieval system, or

transmitted in any form or by any means, mechanical, photocopying, recording, or otherwise,

without the prior written permission of Epson America, Inc. No patent liability is assumed with

respect to use of the information contained herein. While every precaution has been taken in the

preparation of this book, Epson America, Inc., assumes no responsibility for errors or omissions.

Neither is any liability assumed for damages resulting from the use of the information contained

herein.

e 1990 Epson America, Inc.

Epson America, Inc.

23610 Telo Avenue

Torrance,

California 90505

Epson is a registered trademark of Seiko Epson Corporation

ActionPrinter is a trademark of Epson America, Inc.

ActionPrinter 4000

Page 6

Addendum

The AP4000 is mechanically and electronically the same

as the LQ-510.

All the information contained herein is equally

applicable to both printers.

Below is a list of unique parts for the Epson ActionPrinter 4000:

Part Number

ActionPrinter 4000 parts not listed above are identical to those for the LQ-510.

Description

Logo plate

Individual carton box

Pad sleeve

Page 7

REV.-A

TABLE OF CONTENTS

CHAPTER 1.

CHAPTER 2.

CHAPTER 3.

CHAPTER 4.

CHAPTER 5.

CHAPTER 6.

APPENDIX

GENERAL DESCRIPTION

PRINCIPLES OF OPERATION

OPTIONAL EQUIPMENT

DISASSEMBLY, ASSEMBLY, AND ADJUSTMENT

TROUBLESHOOTING

MAINTENANCE

LQ-510

vi

Page 8

REV.-A

GENERAL DESCRIPTION

CHAPTER 1

GENERAL DESCRIPTION

1.1

FEATURES

1.2

SPECIFICATIONS

1.2.1 Hardware Specifications

1.2.2 Firmware Specifications (ESC/P)

INTERFACE OVERVIEW

1.3

1.4

DIP SWITCHES AND JUMPER SETTING

1.4.1 DIP Switch Settings

1.4.2 Jumper Setting

SELECTYPE FUNCTION

1.5

1.6

SHEET LOADING AND SHEET EJECTION

TEAR-OFF FUNCTION

1.7

OPERATING INSTRUCTIONS

1.8

1.8.1 Self-Test.............................................................................

1.8.2 Hexadecimal Dump Function

1.8.3 Bit-Image Printing

1.8.4 Error Conditions

1.8.5 Buzzer Operation

1.8.6 Printer Initialization

1.8.7 Default Values

1.8.8 Adjust Lever Operation

1.8.9 Printer Protection for Heavy-Duty Printing

1.9

MAIN COMPONENTS

1.9.1 SAMA Board .......................................................................

1.9.2 SANPNL Control Panel

1.9.3 SANPS(E) Board

1.9.4 Printer Mechanism (M-5710)

1.9.5 Housing..............................................................................

....................................................................................

...........................................................................

..................................................................

.............................................................

...................................................................

..................................................................

....................................................................

...........................................................

...............................................................

..................................................................

................................................................

.............................................................

....................................................................

........................................................

......................................................................

........................................................

..................................................................

......................................................

..........................................

...........................................

.........................................

................................................

...............................

.................................................

1-1

1-3

1-3

1-9

1-13

1-16

1-16

1-17

1-17

1-18

1-18

1-19

1-19

1-20

1-21

1-22

1-22

1-22

1-23

1-23

1-24

1-25

1-26

1-27

1-28

1-28

1-29

LQ-510

1-i

Page 9

GENERAL DESCRIPTION

REV.-A

LIST OF FIGURES

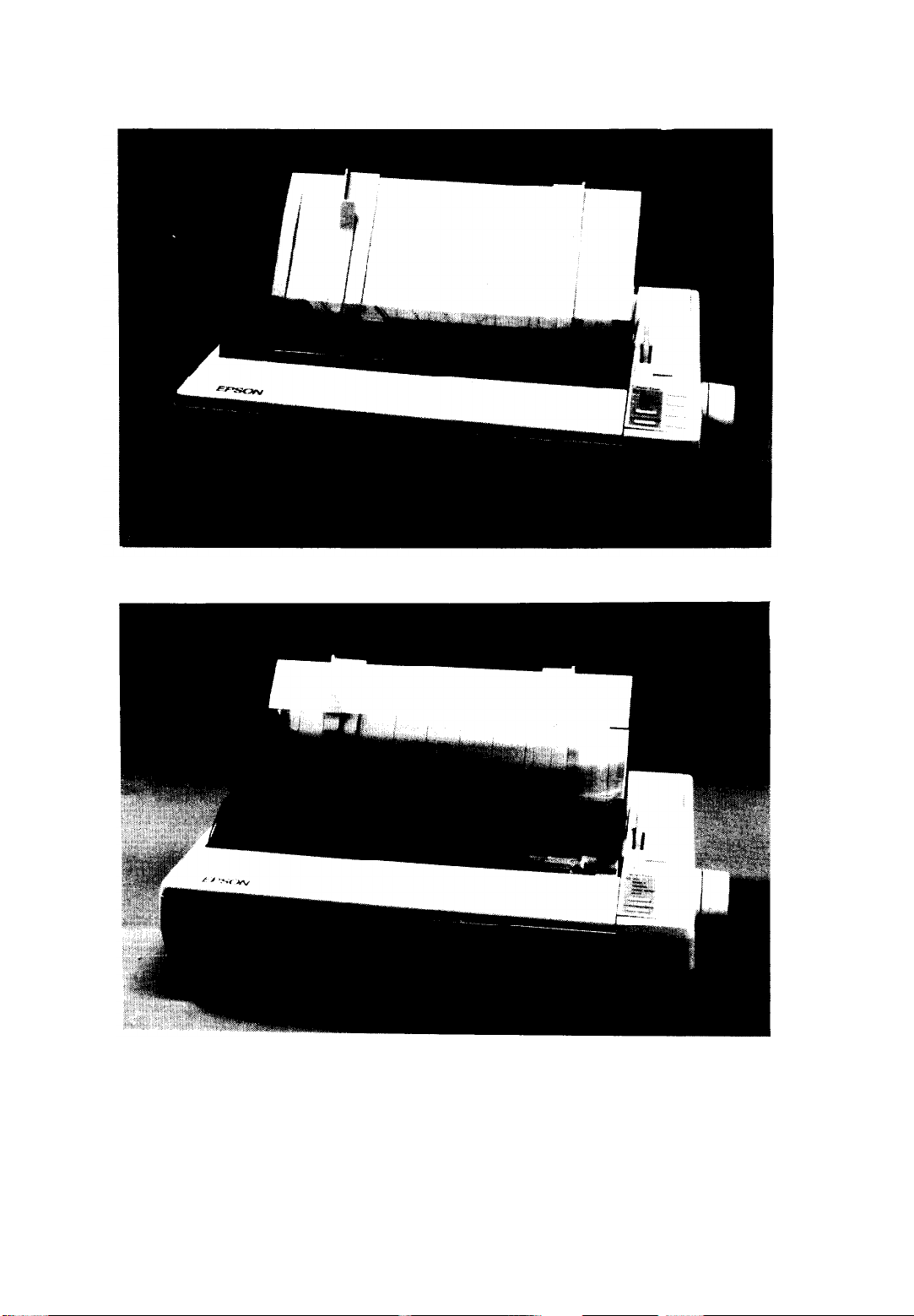

Figure 1-1. Exterior Views of the LQ-510

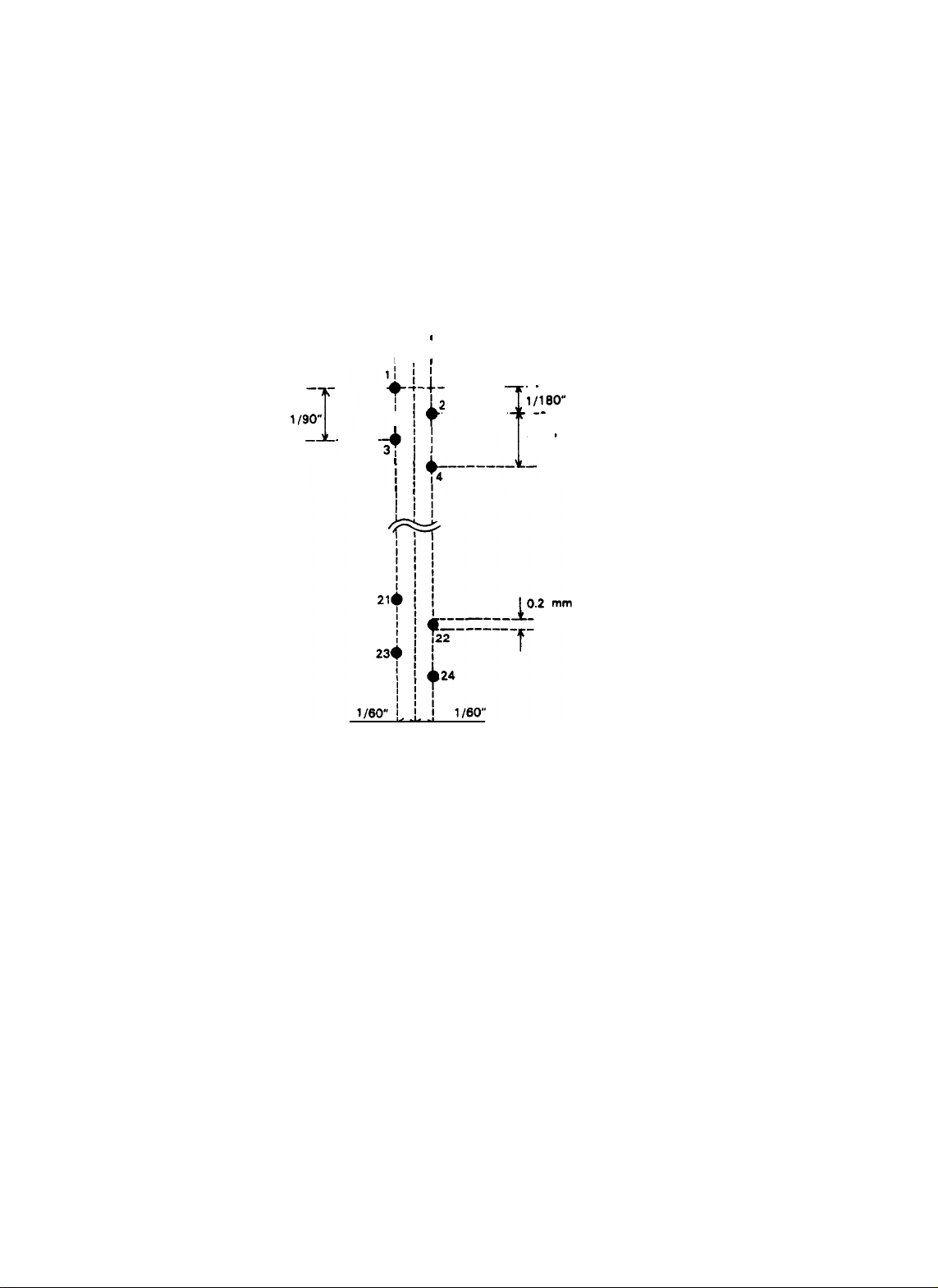

Figure 1-2. Pin Configuration

Figure 1-3. Label Dimensions

Figure 1-4.

Figure 1-5.

Figure 1-6. Character Matrix

Figure 1-7. Data Transmission Timing

Figure 1-8.

Figure 1-9. Hexadecimal Dump Function

Figure 1-10.

Figure 1-11.

Figure 1-12. SAMA Main Control Board

Figure 1-13.

Figure 1-14. Power Supply Filter Board

Figure 1-15. Model 5710 Printer Mechanism

Figure 1-16. Housing

Printable Area for Cut Sheets

Printable Area for Continuous Paper

Self-Test Printout

Lever Position

LQ-510 Component Layout

SANPNL Control Panel

..........................................................................

............................................................

............................................................

..............................................................

............................................................

.................................................................

............................................

...........................................

................................................

............................................

...............................................

...............................................

....................................................

...............................................

.........................................

LIST OF TABLES

.................................

1-2

1-3

1-5

1-6

1-7

1-12

1-13

1-19

1-20

1-23

1-25

1-26

1-27

1-26

1-28

1-29

Table 1-1. Interface Options

Table 1-2. Optional Units

Table 1-3. Cut-Sheet Specifications

Table 1-4.

Table 1-5.

Table 1-6.

Table 1-7. Printing Mode

Table 1-8.

Table 1-9.

Table 1-10.

Table 1-11.

Table 1-12.

Table 1-13.

Table 1-14.

Table 1-15. Character

Table 1-16.

Table 1-17.

Table 1-18.

Continuous Paper Specifications

Envelope Specifications

Label Specifications

Character Matrix and Character Size

Data Transmission Timing

Printer Select/Deselect Control

Settings for DIP Switch 1 (SW1)

Settings for DIP Switch 2 (SW2)

International Character Set Selection

Font Selection

Pitch

Print

Density..

Bit-Image Printing

Lever Position

.............................................................

.................................................................

..................................................

...................................................

.........................................................

..................................................................

.................................................................

Selection..

.................................................................

............................................................

.................................................................

......................................

................................

................................................

........................................

.......................................

.......................................

................................

...............................................

1-1

1-1

1-4

1-4

1-5

1-5

1-10

1-11

1-13

1-15

1-16

1-16

1-16

1-17

1-17

1-21

1-21

1-23

1 -ii

LQ-510

Page 10

REV.-A

GENERAL DESCRIPTION 1

1.1 FEATURES

The LQ-510 is a small, light-weight, low-cost printer, comparable to the LQ-500 with advanced paper-handling.

Its main features are as follows:

1. Advanced paper handling: auto back-out and cut-sheet loading.

2.

Expanded ESC/P-code printing, implemented as a standard feature.

3.

Printing speeds in characters per second (cps):

4. Optional 8100 series interface.

5.

Clear, easy-to-read printing with a standard Epson font.

6. Two built-in LQ fonts (Roman and Sans Serif).

7.

An optional multi-font module can provide a wide variety of fonts.

8.

Control panel switch selection of Draft, Roman, Sans Serif, or slot-mounted (optional multi-font module)

font.

9.

Control panel switch selection of normal or condensed printing.

10. Optional cut-sheet feeder (CSF) for easy handling of cut sheets.

180 cps (alphanumeric Draft 12 cpi)

150 cps (alphanumeric Draft 10 cpi)

60 cps (alphanumeric LQ 12 cpi)

50 cps (alphanumeric LQ 10 cpi)

The LQ-510 is equipped with the standard Epson 8-bit parallel interface. Various interface options allow printing from a wide variety of computers, Table l-l lists the interface options, Table 1-2 lists the optional units

available, and Figure l-l shows an exterior view of the printer.

Table l-l. Interface Options

Intelligent serial interface board

Intelligent IEEE-488 interface board

NOTE:

Refer to the “Optional Interface Technical Manual” for details.

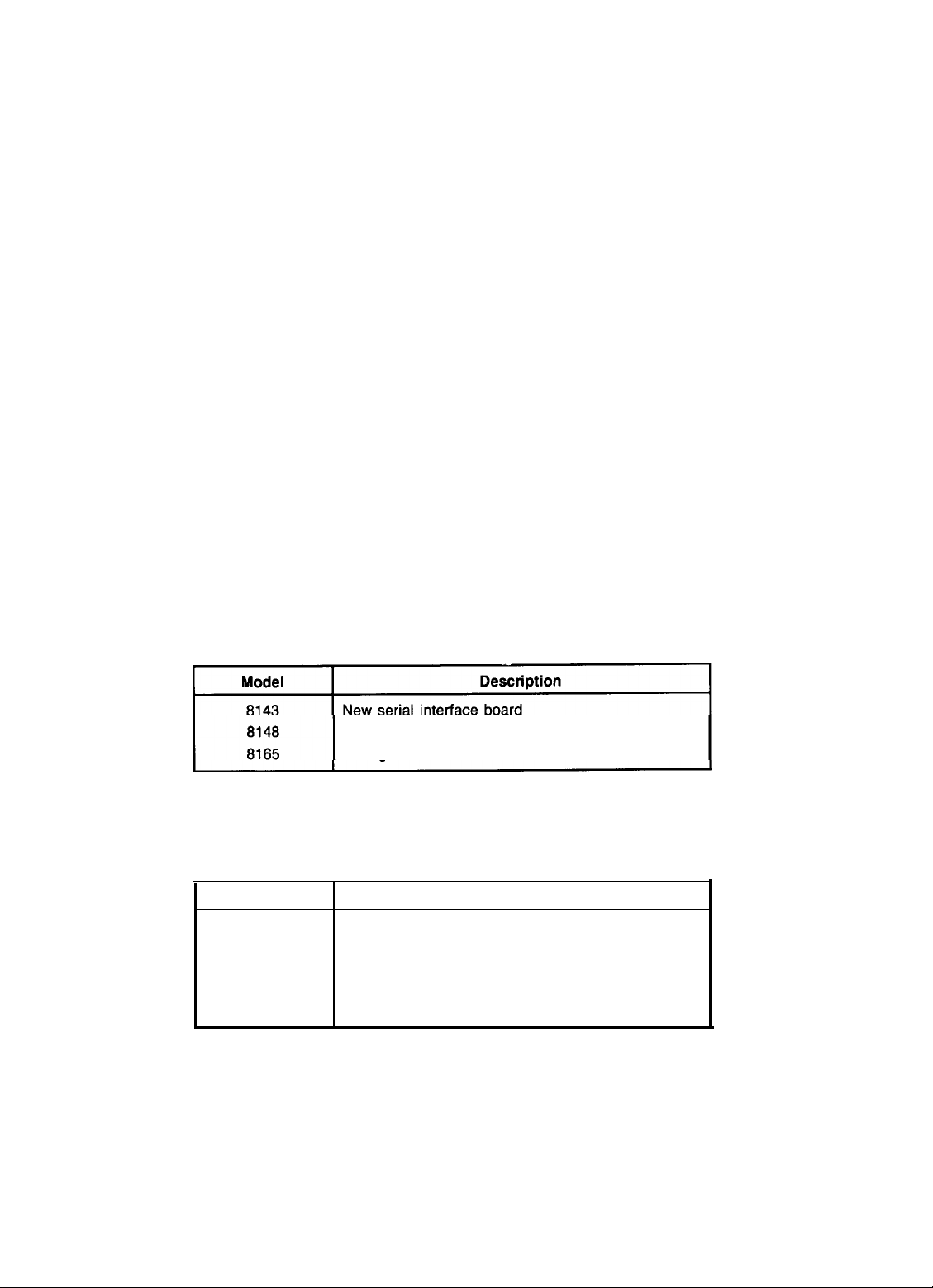

Table 1-2. Optional Units

Model

C80612

C80006

7753

7768

7407

Single-bin cut-sheet feeder

Pull tractor unit

Ribbon cartridge (black)

Film ribbon cartridge

Multi-font cartridge

Description

LQ-510

1-1

Page 11

GENERAL DESCRIPTION

REV.-A

(Printer Cover A)

(Printer Cover B)

1-2

Figure l-l. Exterior Views of the LQ-510

LQ-510

Page 12

REV.-A

1.2 SPECIFICATIONS

This section describes the specifications for the LQ-510 printer.

1.2.1 HARDWARE SPECIFICATIONS

GENERAL DESCRIPTION

Printing Method

Pin Configuration

Serial, impact, dot matrix

24 wires (12 x 2, staggered, 0.2 mm diameter)

Wires

-

-----

lf90"

_I

(Column 1) Wires (Column 2)

-----

II

I .

I

.t;

l+j-

I

+

' i

8i

+----A-

/ i

I

I .

II

II

II

I

------ --

-------

I

I

i

11190"

_-

1190"

Figure 1-2. Pin Configuration

Feeding Method

NOTE:

Be aware of the following points regarding paper handling.

Friction feed, tractor feed (push tractor: standard; pull tractor: optional)

Friction Feed:

1.

Do not use continuous paper.

2.

Do not use a single sheet shorter than 7.28 inches (182 mm) or longer than 10.28 inches (257 mm).

3.

Do not perform a reverse paper feed when the paper is within .34 inch (8.5 mm) from the top or within

.88 inch (22 mm) from the bottom.

4.

Do not perform a reverse feed greater than 1/6 inch after the paper end has been detected.

5. Use the pull-out unit.

6. Do not use multi-part single-sheet forms.

Tractor Feed

1. Release the friction-feed mechanism.

2.

Multiple copies must be joined by pasting at the perforation or tractor holes.

3.

Paper for copies must be carbonless, multi-part paper.

LQ-510

1-3

Page 13

GENERAL DESCRIPTION

REV.-A

Push Tractor Feed

1. Use the pull-out unit.

2.

Do not perform reverse feeding for distances greater than 1/6 inch.

3.

Accuracy of paper feed cannot be assured, and reverse feeding cannot be performed, after the paper

end is detected.

Push-Pull Feed

1.

Remove the pull-out unit and attach the pull tractor unit.

2.

Do not lose the paper between the platen and pull tractor unit.

3.

Precisely adjust the horizontal positions of the pull and the push tractors.

4.

Do not perform reverse feeding for distances greater than 1/6 inch.

5.

Do not perform reverse feeding after the paper end is detected.

Pull Tractor Feed

1.

Remove the pull-out unit and attach the pull tractor unit.

Line Spacing

Paper Insertion

Paper-Feed Speed

Paper Specifications

Width

Length

Thickness

Weight

Quality

Copies

1/6 inch, or programmable in units of 1/360 inch

From rear

Friction, without CSF

100 ms/line (at 1/6-inch line feed)

2.2 inches per second (continuous feed)

Friction, with CSF

100 ms/line (at 1/6-inch line feed)

2.2 inches per second (continuous feed)

Tractor

100 ms/line (at 1/6-inch line feed)

2.2 inches per second (continuous feed)

See Tables 1-3 through 1-6.

Table 1-3. Cut-Sheet Specifications

7.15 to 10.1 inches (182 to 257 mm)

14.3 inches, maximum (364 mm, maximum)

0.0025 to 0.0055 inch (0.065 to 0.14 mm)

14 to 24 pounds (52.3 g/m2 to 90 g/m2)

Xerographic, bond, airmail paper, etc.

Not available

Table 1-4. Continuous-Paper Specifications

1-4

Width

Copies

Quality

Total Thickness

Weight

4 to 10 inches (101 to 254 mm)

3 sheets (1 original and 2 copies)

Bond, xerographic, airmail, etc.

0.0025 to 0.01 inch (0.065 to 0.25 mm)

1 sheet - 14 to 22 pounds (52.3 g/m2 to 82 g/m2)

3 sheets - 12 to 15 pounds (40 g/m2 to 58.2 g/m2) each

LQ-510

Page 14

REV.-A

GENERAL DESCRIPTION

Table 1-5. Envelope Specifications

Size

Quality

Thickness

Number 6: 6.64 x 3.68 inches (166 x 92 mm)

Number 10: 9.6 x 4.16 inches (240 x 104 mm)

Bond paper, xerographic paper, airmail

0.0063 to 0.0197 inch (0.16 to 0.52 mm)

(Within the printing area, the thickness differential must not exceed 0.0098 inch [0.25

mm]).)

12 to 24 pounds (45 g/m2 to 91 g/m2)

NOTES:

1. Printing on envelopes can be performed only when the temperature is normal.

2. Envelopes should be positioned horizontally.

3. For Number 6 envelopes, set the left side so that it matches the setting mark on the sheet guide.

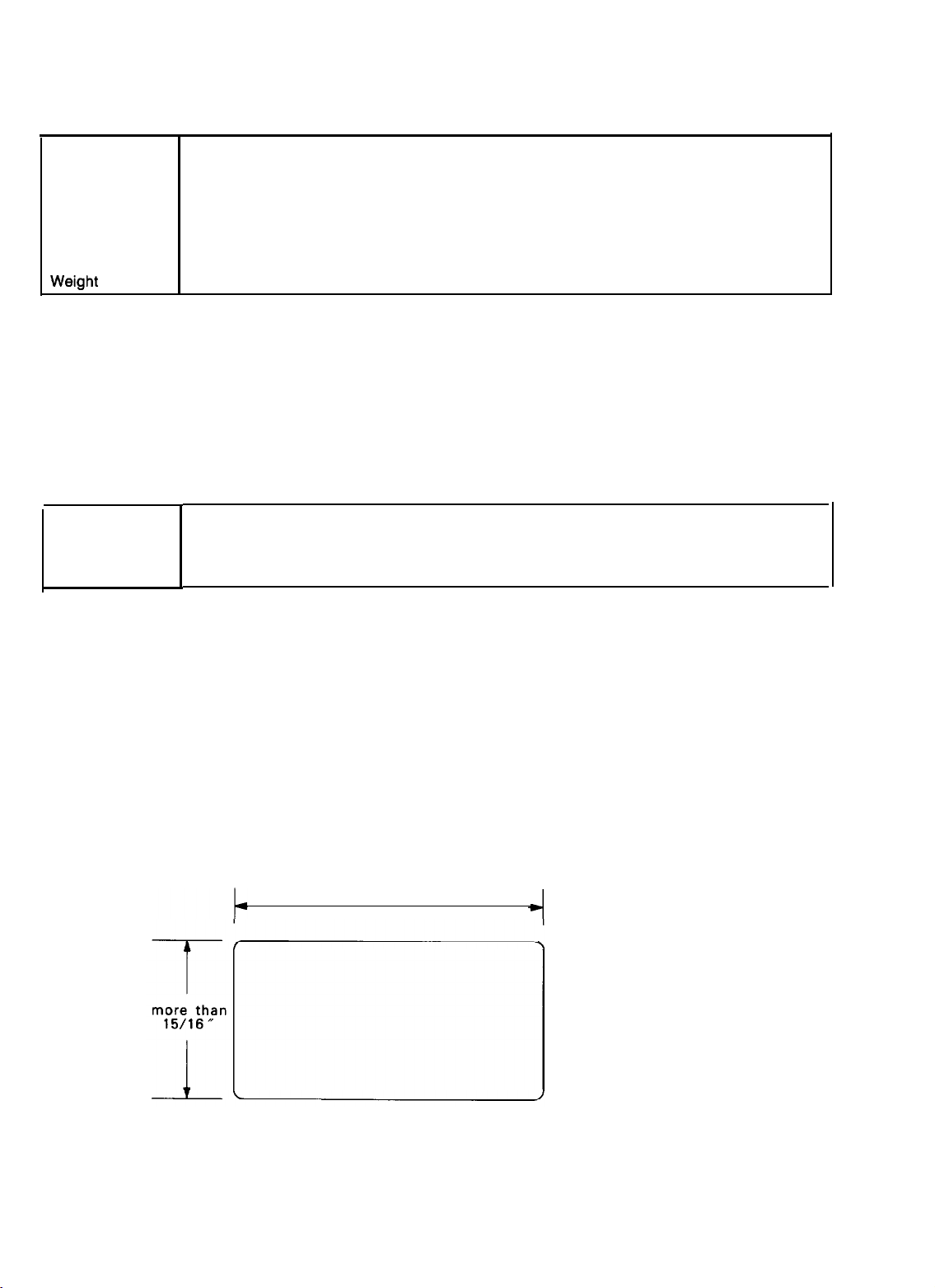

Table 1-6. Label Specifications

Sire

Thickness

Greater than 2½ x 15/16 inches (63.5 x 23.8 mm)

0.0063 to 0.0075 inch (0.16 to 0.19 mm)

*Thickness of the base paper must be 0.0028 to 0.0031 inch (0.07 to 0.09 mm)

NOTES:

1. Printing on labels is available only at normal temperatures.

2. Labels must be fanfold.

3. For printing on labels with pressure sensitive paper, the following conditions must be met:

(1)

sheets of labels must be joined at the perforation or tractor holes.

(2) the total thickness may not be greater than 0.0118 inch (0.3 mm)

(3) the temperature must be between + 41 °F and + 95 °F (+ 5° and + 35°C), and relative humidity

between 10% and 80%

4. Examples of acceptable labels: Avery Continuous-Form Labels

Avery Mini-Line Labels

5. Do not perform reverse feed.

more than 2 1/2 "

\

/

R : more than 2.5 mm

LQ-510

Figure 1-3. Label Dimensions

1-5

Page 15

GENERAL DESCRIPTION

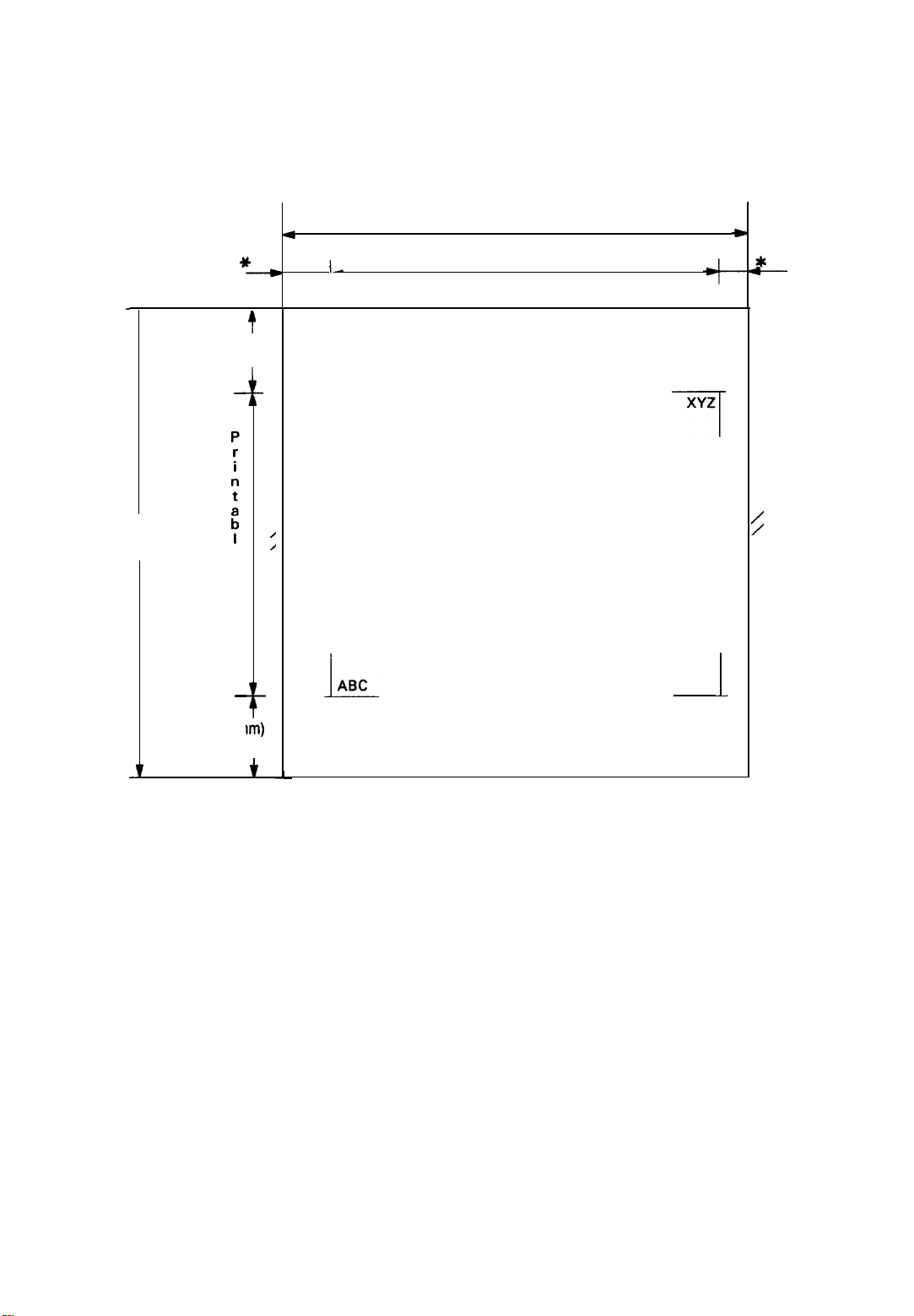

Printable Area

The figure below illustrates the printable area for cut sheets.

7.2-10.1 ” (182-257mm)

I

REV.-A

*

.33” (8.5

or more

14.3” (364 mm),

maximum

.53” (13.5 m

or more

*

mm)

-

7

e

a

r

e

a

-

I-

t

ABC

›r

,

/

/

ABC

L

Printable area

I

XYZ

XYZ

1

Figure 1-4. Printable Area for Cut Sheets

* At least 0.12 inch (3 mm) when paper width is less than 9 inches (229 mm); at least .9 inch (24 mm) when

the paper width is 10.1 inches (257 mm).

Printing is possible approximately 1.12 inches (28 mm) from the paper’s detected bottom edge; the .53 inch

(13.5 mm) value (lowest print position) is for reference only. Paper feed accuracy cannot be assured within

0.87 inch (22 mm) of either the top or bottom edge.

1-6

LQ-510

Page 16

REV.-A

GENERAL DESCRIPTION

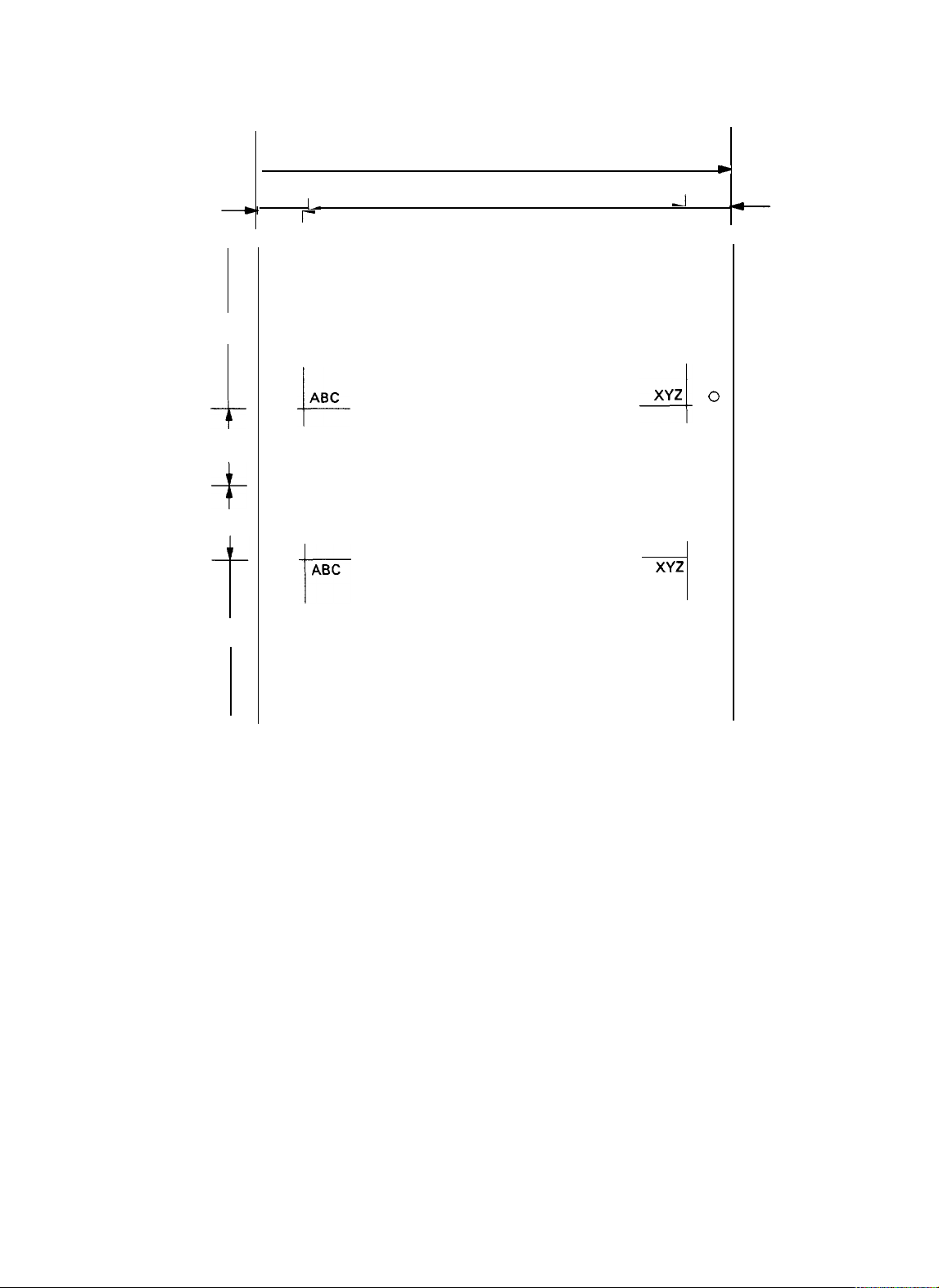

Printable

area

--t

9 mm, 0.35"

or more

9 mm ,0.35”

t

or more

Printable

area

4

*1)

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

4.0" -10.0",

I_

I_

101 mm-254 mm

Printable area

_I

*2)

I

m

0

0

0

0

0

0

0

i-

ABC

XYZ

-I

0

0

0

0

---------

0

0

0

0

0

ABC

0

+

0

0

0

0

0

0

XYZ

0

0

t

0

0

0

0

0

0

*

NOTES:

LQ-510

Figure 1-5. Printable Area for Continuous Paper

1. .52 inch (13 mm) or greater for paper widths of 4 to 9.5 inches (101 to 242 mm).

1.04 inches (26 mm) or greater for paper widths of 10 inches (254 mm).

2. .52 inch (13 mm) or greater for paper widths of 4 to 9.5 inches (101 to 242 mm).

.96 inch (24 mm) or greater for paper widths of 10 inches (254 mm).

1-7

Page 17

GENERAL DESCRIPTION

Ink Ribbon

REV.-A

Fabric

Film

Reliability

Printhead Life

Safety Approvals

Safety Standards

Radio Frequency

Interference (RFI)

Model: 7753 ribbon cartridge

Color: black

Reliability: 2 million (LQ characters at 48 dots/character)

Dimensions:

Model: 7768 ribbon cartridge

Color: black

Reliability: 2

Dimensions:

Mean Cycles Between Failures (MCBF): 3 million lines (excluding

printhead)

Mean Time Before Failure (MTBF): 4000 Power-On Hours (25% duty)

200 million strokes/wire

UL478 (U.S. version)

CSA22.2#154

VDE0806 (TUV) (European version)

FCC class B (U.S. version)

VDE0871 (self-certification) (European version)

11.6 (width) x 1.36 (height) x 2.84 (depth)

(290 mm x 34 mm x 71 mm)

million characters at 48 dots/character

11.6 (width) x 1.36 (height) x 2.84 (depth)

(290 mm x 34 mm x 71 mm)

inches

inches

Electrical Specifications

Power Conditions

Frequency Range

Rating Current

Insulation Resistance

Dielectric Strength

Environmental Requirements

Temperature

Humidity

Shock Resistance

Resistance to Vibration

Physical Specifications

Weight

Dimensions

108 VAC to 132 VAC (120 V version)

198 VAC to 264 VAC (220/240 V version)

49.5 to 60.5 Hz

1.8 A AC (120 V version)

1 A AC (220/240 V version)

10 megohms minimum (between AC line and chassis)

1250 VAC (rms), 1 minute (120 V version) (between AC line and

chassis)

3750 VAC (rms), 1 minute (220/240 V version)

41° to 95°F (5 to 35°C) - operating

-22° to 140° F (-30 to 60° C) - with shipment container

10 to 80% RH - operating

5 to 85% RH

1 G, within 1 ms - operating

2 G, within 1 ms - non-operating

0.25 G, 55 Hz maximum - operating

0.50 G, 55 Hz maximum - storage

13.23 pounds (6 kg)

16.72 (width) x 13.88 (depth) x 5.6 (height) inches

(418 x 347 x 139.9 mm), excluding knobs and paper guides

- non-operating

1-8

LQ-510

Page 18

REV.-A

1.2.2 FIRMWARE SPECIFICATIONS (ESC/P)

GENERAL DESCRIPTION

Control Codes

Printing Direction

Input Data Buffer

Character Code

Character Sets

Family

Font

Printing Mode

Printing Speed

Printing Columns

Character Matrix

Character Size

ESC/P-84 (Epson Standard Code for Printers)

Bidirectional (text)

Bidirectional (bit-image) (when SW 2-6 is ON and control command [ESC

U 1] input)

Unidirectional (bit-image)

8K bytes (when SW 2-5 is ON)*

1K byte (when SW 2-5 is OFF)

* If DIP SW 2-5 is set to ON, downloading will be ignored.

8-bit

96-character ASCII and 15 international character sets

Epson Roman (Family number: 0)

Epson Sans Serif (Family number: 1)

Epson Roman 10, Epson Roman 12, Epson Roman 15,

Epson Roman Proportional

Epson Sans Serif 10, Epson Sans Serif 12,

Epson Sans Serif 15, Epson Sans Serif Proportional

Epson Draft 10, Epson Draft 12, Epson Draft 15

Selection and mixing of the following modes are allowed (except that 15 cpi

Condensed Mode is not available):

l

Printing quality (draft/letter quality)

0 Character pitch (10, 12, 15, or proportional)

0 Condensed

0 Double-width

0 Double-height

0

Bold

0 Double-strike

0

Italic

0 Underlined

0 Double-underlined

0 Overscore

0 Strike-through

0

Outline

0 Shadow

See Table 1-7.

See Table 1-7.

See Table 1-8.

See Table 1-8.

LQ-510

1-9

Page 19

GENERAL DESCRIPTION

Print

pitch

10

12

15

REV.-A

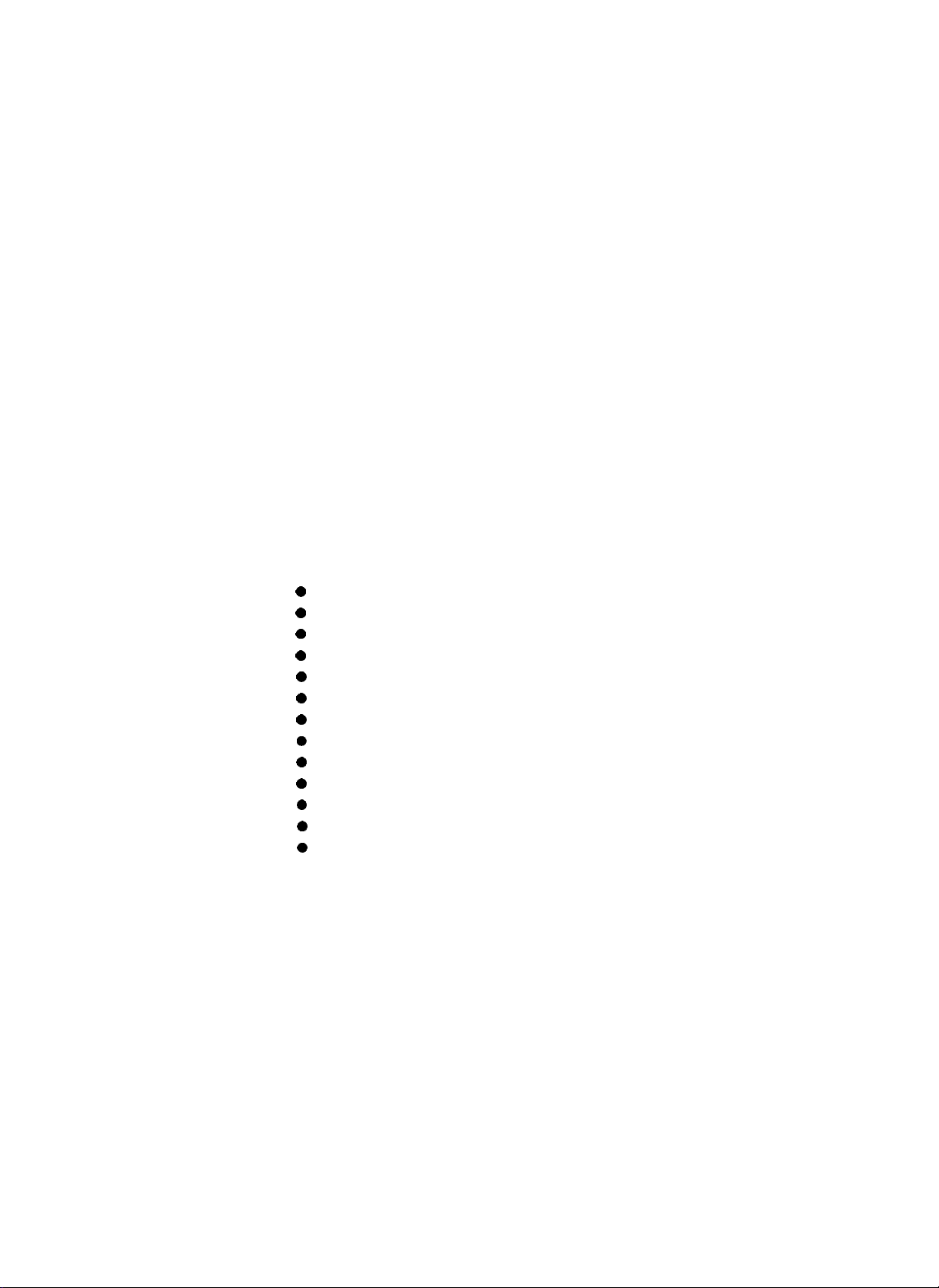

Table 1-7. Printing Mode

Pro-

portional

Pro-

portional

super/

subscript

NOTES:

1. The

2. The

“maximum”

“minimum”

value applies when only characters of maximum width are printed.

value applies when only characters of minimum width are printed.

3. “-” indicates that the “LQ” character set is automatically selected when proportional pitch

is specified.

1-10

LQ-510

Page 20

REV.-A

GENERAL DESCRIPTION

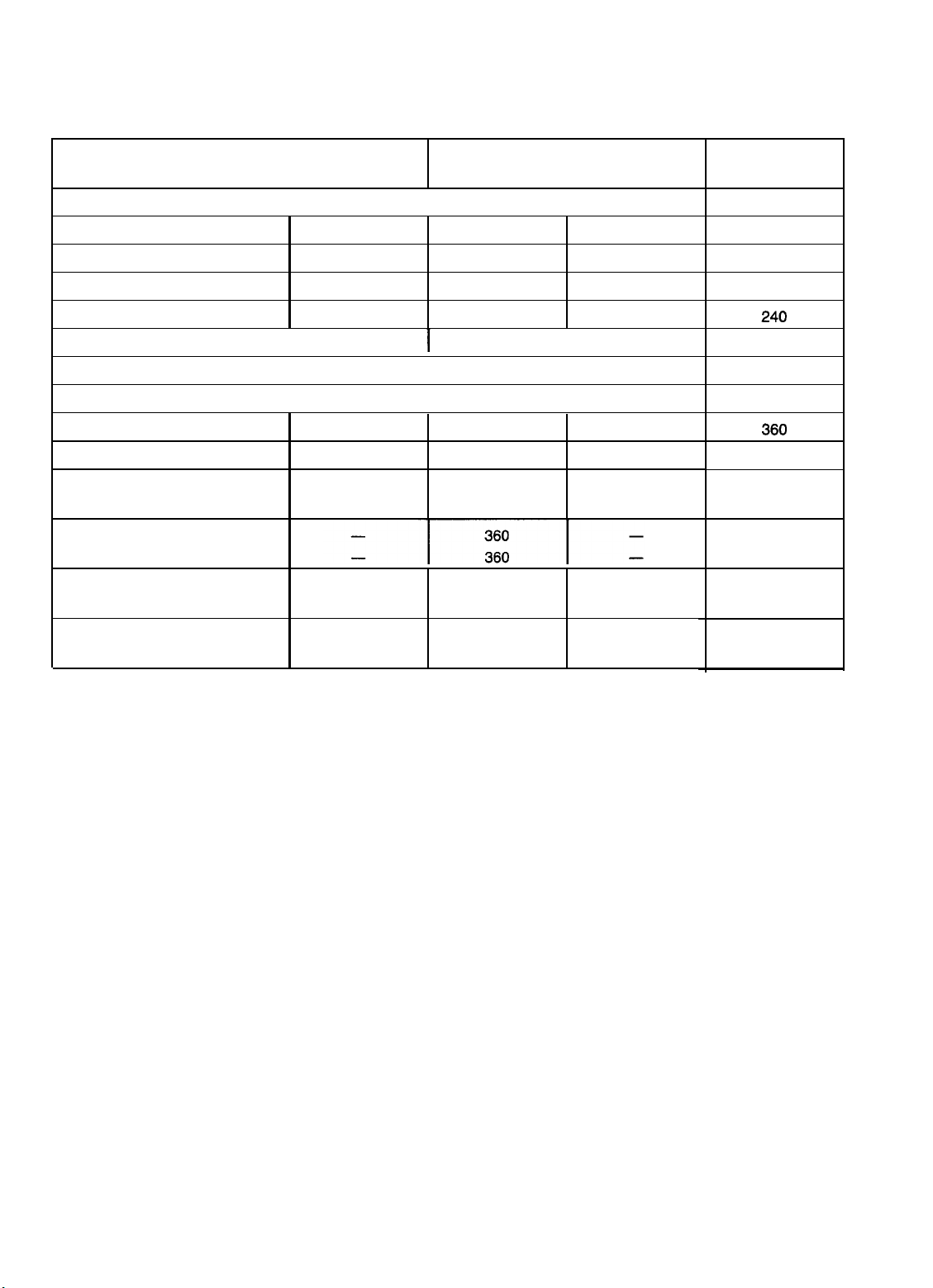

Table 1-8. Character Matrix and Character Size

Printing mode

Draft

10-pitch

Draft 12-pitch

Draft

15-pitch

Draft 10-pitch,

Draft

12-pitch.

LQ 10-pitch

LQ 12-pitch

LQ 15-pitch

LQ

10-pitch, condensed

LQ

12-pitch, condensed

LQ

proportional

LQ proportional, condensed

LQ

proportional, super/

subscript

LQ

proportional,

subscript, condensed

condensed

condensed

super/

Face matrix

I

9 x 23

I

9

x 23

9

X 16

29 x 23

I

29 x 23

I

15 x 16

I

37x23

18

x 23 minimum

28x16

12x16

-

-

-

-

maximum

maximum

minimum

-

-

HDD

I

I

I

I

120

120 1.9x3.2

120

240

240

360

360

360

360

360

360 2.6

360

360

360

360

360

Character size

H x V (mm)

I

1.9 x 3.2

I

1.0x2.3

-

-

2.0 x 3.2

I

2.0 x 3.2

I

1.0 x 2.3

I

-

x 3.2

1.Ox3.2

1.8 x 2.3

0.7 x

2.3

-

-

Unit ESC sp

120

120

120

240

180

180

180

360

180

180

360

360

180

180

360

360

NOTES: 1.HDD is horizontal dot density in dots per inch.

2.

Face matrix and character size indicate maximum character size. This value changes according to differences in paper, ribbon, etc.

3.

Unit ESC sp (which also can be sent as the unit followed by the character string CHR$(&h20))

indicates the minimum length to be added to the right of the character that can be specified

with the ESC sp control code.

4. “_”

indicates that character matrix is reshaped by printer firmware. Character width becomes

half of noncondensed character width.

LQ-510

1-11

Page 21

GENERAL DESCRIPTION

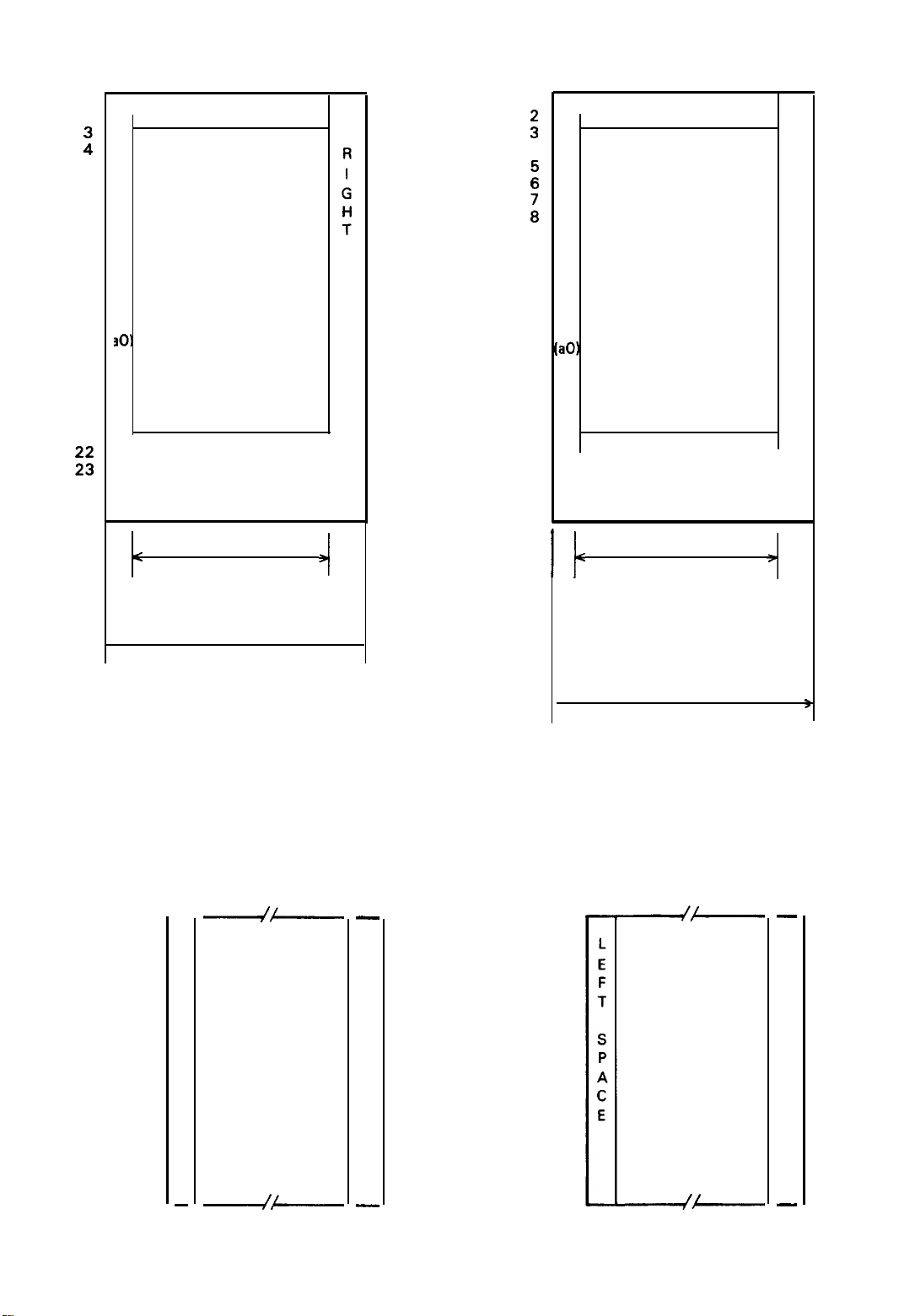

(Normal character)

1

10

11

12

13

14

15

16

17

18

19

20

21

s3

24

2

:

L

5

E

6

F

T

3

9

S

P

A

C

E

30’

Ascender area

I

Descender area

(a2)

I

REV.-A

( LQ)

1

:

4

L

E

:

F

T

i

9

S

S

P

A

C

E

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

P

A

C

E

30

Ascender area

R

I

G

H

T

S

P

A

C

E

(a2)

Descender area

1

Face width (a1)

Character width (CW)

12

dots

(10 pitch) 120 DPI

15

dots

(12 pitch) 180 DPI

16

dots

(15 pitch) 240 DPI

14

dots

(condensed 10 pitch)

12

dots

(condensed 12 pitch)

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

//

L

E

F

T

S

P

A

C

E

-

/-

4

l

240

DPI

240

DPI

* 15 dots are made from 29 dots by printer firm-

ware.

-

R

I

G

H

T

S

P

A

C

E

-

Figure 1-6. Character Matrix

1 1

Face width (a1)

29 dots

(Normal LQ, excluding 15 pitch)

l

15 dots

(15 pitch and condensed LQ)

<

36

30

24

21

18

10

11

12

13

14

15

16

Character width (CW)

dots

(10 pitch) 360

dots

(12 pitch) 360

dots

(15 pitch) 360

dots

(condensed 10

dots

(condensed 12

1

3

4

5

6

7

8

9

d/

DPI

DPI

DPI

pitch)

pitch)

/-

d

360

360

>

DPI

DPI

-

R

I

G

H

T

S

P

A

C

E

-

1-12

LQ-510

Page 22

REV.-A

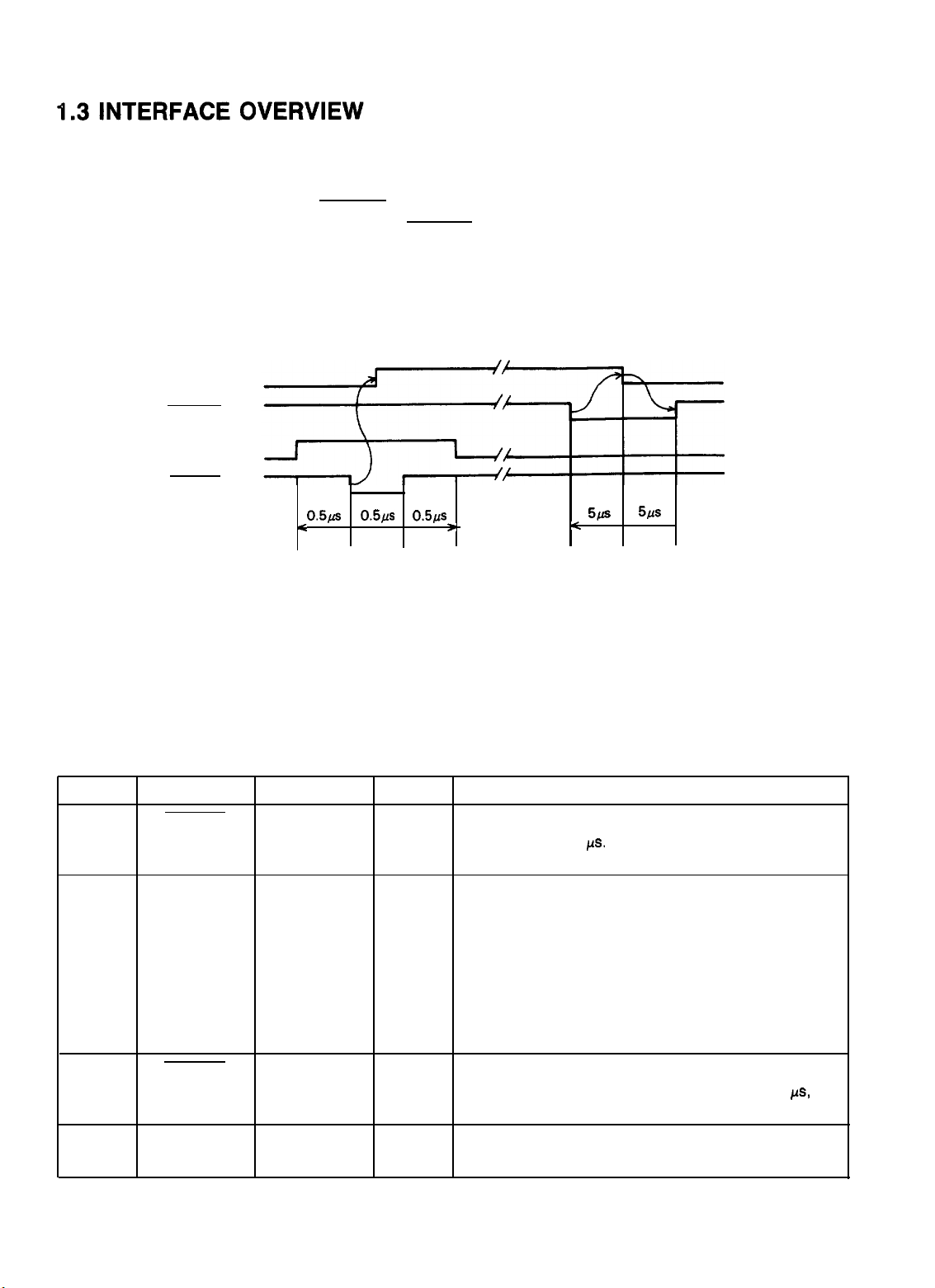

The standard 8-bit parallel interface has the following specifications:

GENERAL DESCRIPTION

Data Format

Synchronization

Handshaking

Signal Level

Connector

Data Transmission Timing

BUSY

ACKNLG

DATA

STROBE

8-bit parallel

By STROBE pulse

By BUSY and ACKNLG signals

TTL-compatible

57-30360 (Amphenol) or equivalent

See Figure 1-7.

0.5jfs

<

min.

0.5jJs 0.5@

min.

min. typ.

LD

5Ifs 5M

<

Figure 1-7. Data Transmission Timing

typ.

Table 1-9 shows the connector pin assignments and signal functions of the 8-bit parallel interface.

Table 1-9. Connector Pin Assignments and Signal Functions

Pin No.

1

2 DATA 1

3

4

5

6

7

8

9

10

11

Signal Name

STROBE

DATA 2

DATA 3

DATA 4

DATA 5

DATA 6

DATA 7

DATA 8

ACKNLG

BUSY

Return

Pin No.

19 In

20

21

22

23

24

25

26

27

28

29

Dir.

In

In

In

In

In

In

In

In

out

out

Functional Description

Strobe pulse to read the input data. Pulse width must

be more than 0.5

ing edge of this signal.

Parallel input data to the printer.

“HIGH” level means data “1.”

“LOW” level means data “0.”

This pulse indicates data was received and the printer

is ready to accept more data. Pulse width is 11

approximate.

“HIGH” indicates the printer cannot accept more

data.

ps.

Input data is latched at the fall-

ps,

LQ-510

1-13

Page 23

GENERAL DESCRIPTION

REV.-A

Pin No.

12

13

14

15

16

17

18

19 - 30

31

32

33

34

35

36

Table 1-9

Signal Name

PE

SLCT

AUTOFEED-XT

GND

Chassis GND

GND

INIT

ERROR

GND

SLCT-IN

Connector Pin Assignments and Signal Functions (Cont.)

Return

Pin No. Dir.

30

-

-

- -

16

-

- -

-

-

-

out

out

In

In

out

-

out

In

Functional Description

“HIGH” indicates paper out. This signal is effective

only when the ERROR signal is “LOW.”

Always “HIGH” output. (Pulled up to +5 V through

3.3K-ohm register.)

If “LOW” when the printer is initialized, a line feed is

automatically performed when the carriage return (CR)

code is received (auto LF).

Not used.

Ground for twisted pair grounding.

Chassis ground level of printer.

Not used.

Grounds for twisted pair grounding.

Pulse (width: 50

1

printer initialization.

“LOW” indicates an error occurred in the printer.

Ground for twisted pair grounding.

Not used.

Always “HIGH.” (Pulled up to +5 V through 3.3K-ohm

register.)

If “LOW,” when printer is initialized, DC1/DC3 control

is disabled.

ps,

minimum, active “LOW”) input for

NOTES:

1.

“Dir.” refers to the signal flow direction as viewed from the printer.

2.

“Return” denotes a twisted-pair return line.

3.

The cable used must be shielded to prevent noise.

4.

All interface conditions are based on TTL levels. Both the rise and fall times of all signals must

be less than 0.2

5.

The AUTO FEED-XT signal can be set to LOW by DIP switch 2-4.

6.

The SELECT-IN signal can be set to LOW by jumper 10.

7.

Printing tests, including those of the interface circuits, can be performed without using external

p.s.

equipment by setting DATA 1-8 of the interface connector to certain codes and connecting theACKNLG signal to the STROBE signal.

1-14

LQ-510

Page 24

REV.-A

GENERAL DESCRIPTION

Table 1-10 shows the printer select/deselect (DC1/DC3) control, including relations among ON-LINE,

SELECT-IN input, DC1/DC3,

and interface signals.

Table 1-10. Printer Select/Deselect Control

ON-LINE SW

Off-Line

On-Line

SLCT-IN

HIGH/LOW

HIGH

LOW

DC1 / DC3

DC1 / DC3

DC1

DC3

DC1

DC3

ERROR

LOW

HIGH

HIGH

HIGH

HIGH

BUSY

HIGH

LOW/HIGH

(during data

entry)

LOW/HIGH

(during data

entry)

LOW/HIGH

(during data

entry)

LOW/HIGH

(during data

entry)

ACKNLG

No pulse

Pulse output

after entry

Pulse output

after entry

Pulse output

after entry

Pulse output

after entry

DATA ENTRY

Disable

Enable (normal

process)

Enable (waits

for DC1, see

Note 2.)

Enable (normal

process)

NOTES: 1. In Table 1-10, it is assumed that no ERROR status exists other than that attributable to

OFF-LINE mode.

2.

Once the printer has been put in the deselected state by the DC3 code, the printer will not revert

to the selected state unless the DC1 code is input again. (In the deselected state, the printer

ignores input data until the DC1 code is received.)

3. The DC1 and DC3 codes are enabled only when the SLCT-IN signal (Input Connector Number

36 for the parallel interface unit) is HIGH and printer power is initialized.

4. If the SLCT-IN signal is LOW when the printer is initialized, DC1 /DC3 printer select/deselect

control is invalidated, and these control codes are ignored.

5.

If the SLCT-IN signal is HIGH, and is not set to LOW by jumper 10 when the printer is initialized,

the printer starts from the selected (DC1) state.

LQ-510

1-15

Page 25

GENERAL DESCRIPTION

4/3/91

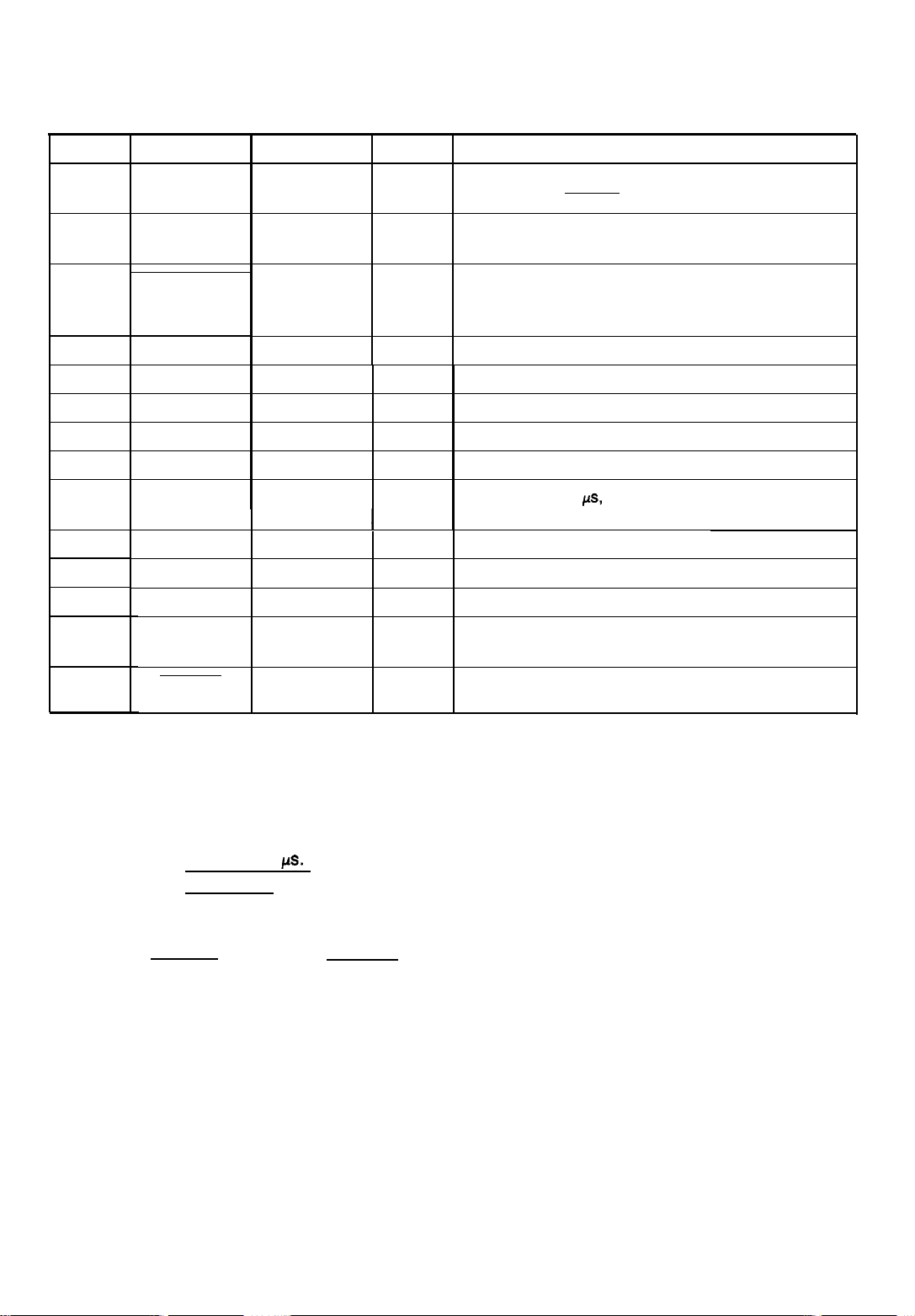

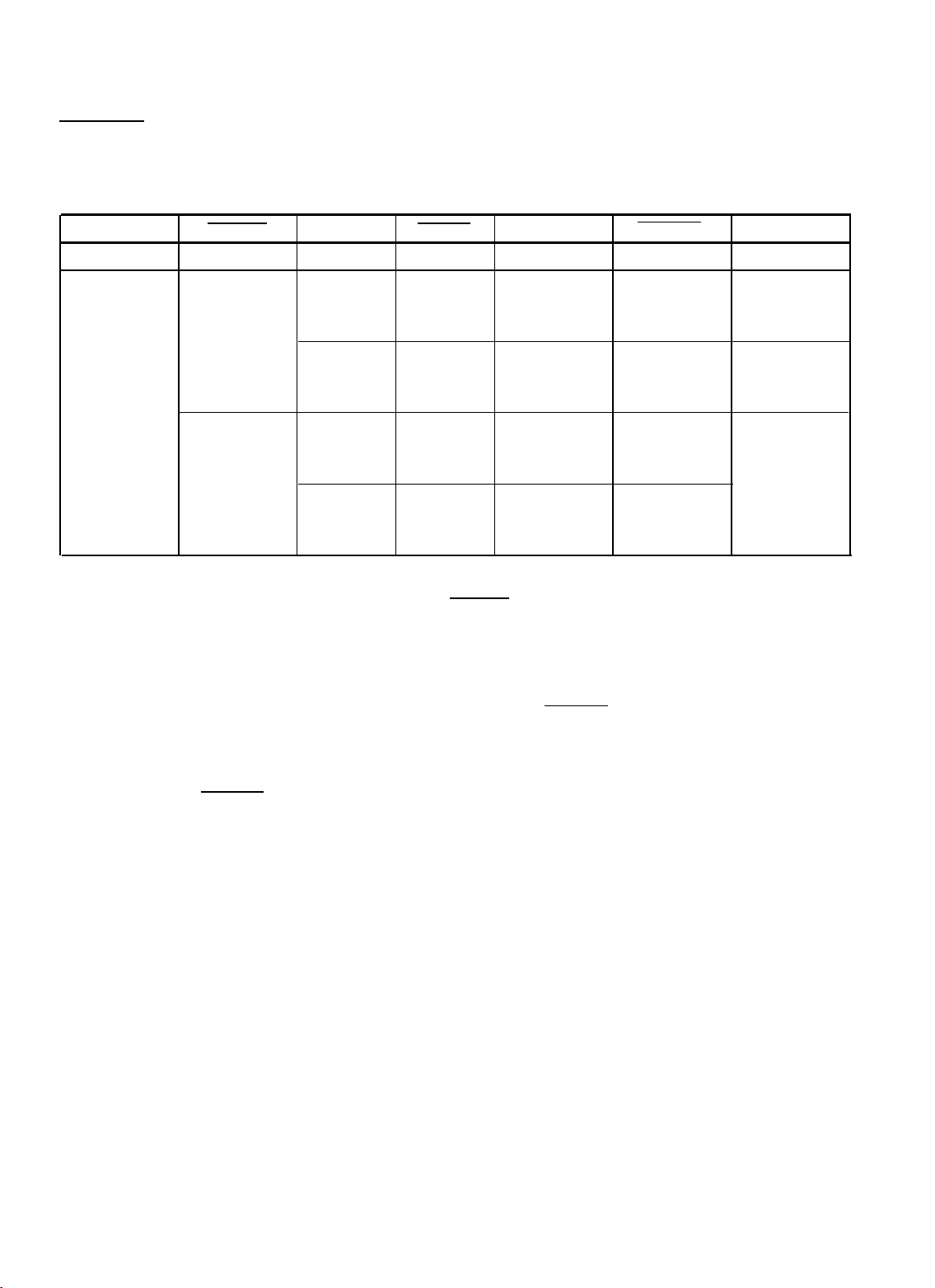

1.4 DIP SWITCHES AND JUMPER SETTING

This section describes the DIP switch selections and jumper setting for the LQ-510 printer.

1.4.1 DIP SWITCH SETTINGS

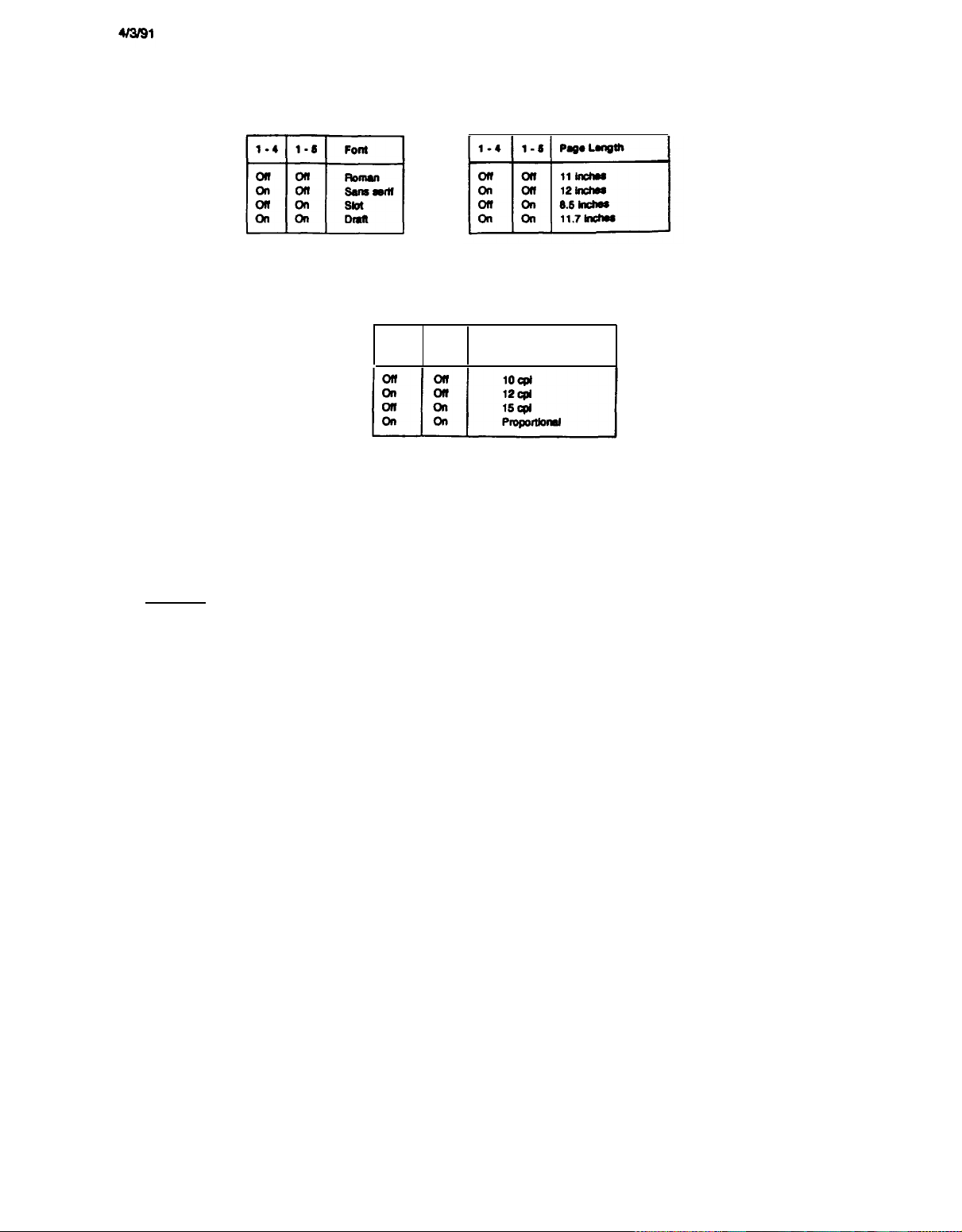

The two DIP switches for the printer are located on the control panel, and function as shown in Tables 1-11

through 1-15. (Note that the status of the DIP switches is read only at power up or upon receipt of the INIT

signal.)

1-16 LQ-510

Page 26

GENERAL DESCRIPTION

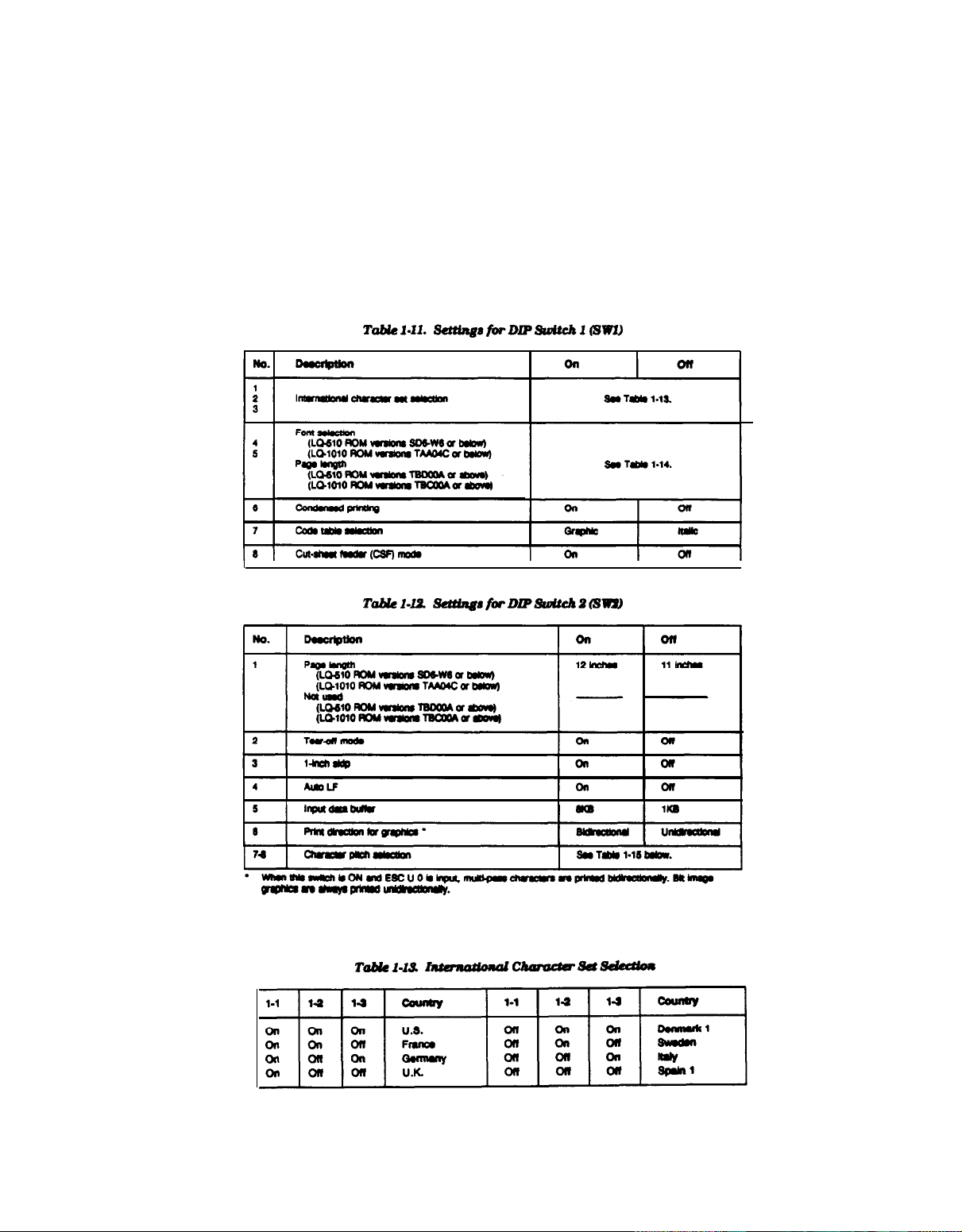

Table 1-14. Font Select&n

(ROM Version SD6-W6 or Below

or TAA04C or Below)

Table 1-15. Character Pitch Selection

2-7

Tab& 1-14. Page Length Selection

(ROM Version TBD00A or Above

or TBC00A or Above

Character Pitch

2-6 (ln characters per inch)

1.4.2 JUMPER SETTING

Jumper 10, which is user-selectable, is located inside the option board cover. If the jumper is connected,

the SLCT-IN signal is fixed to LOW, and DC1 /DC3 printer select control is ignored.

1.5 SELECTYPE FUNCTION

SelecType

fonts listed on the control panel for either condensed or normal printing.

optional slot-mounted multi-font (ROM cartridge), these fonts also can be selected from the control

panel. SelecType functions only when the printer is not printing, at which time the font can be

selected

switch (again,

printer’s control panel.

enables easy selection of fonts and

by pressing the FONT switch.

The printing

only when the printer is not printing).

printing modes, and can be used to select any of the

If the printer uses an

mode is selected by pressing the CONDENSED

The selected font and mode are indicated on the

LQ-510

1-17

Page 27

GENERAL DESCRIPTION

REV.-A

1.6 SHEET LOADING AND SHEET EJECTION

The release lever enables disengaging of the push tractor unit drive mechanism. The printer therefore provides some improved paper-handling functions through combination of the release lever and LOAD/EJECT

control panel switch.

Cut-Sheet Loading and Ejection

To load a sheet of paper, position the paper-release lever back, place the sheet along the paper guide, and

press the LOAD/EJECT switch. This loads the paper to the top-of-form position. Pressing the LOAD/EJECT

switch after the paper has been loaded will cause the paper to be ejected.

Continuous-Paper Loading and Ejection (Back-Out)

To load fanfold paper, move the paper-release lever forward, and insert the paper into the push tractor. Pressing

the LOAD/EJECT switch will then cause paper to be automatically loaded to the top-of-form position. Pressing the LOAD/EJECT switch after the fanfold paper has been loaded causes the printer to eject the paper

backward from the push tractor. To back out several pages, press the LOAD/EJECT switch several times

(reverse feed is performed on a page-by-page basis).

The MULTI-PART LED will flash only when the paper is loaded and the ON LINE switch pressed. This in-

dicates that the printer has entered “top-of-form adjust” mode, and that the user may adjust the top-of-form

position, as well as the loading positions for subsequent forms. Adjustment is made using the FORM FEED

button, which will increment the paper forward, and the LINE FEED switch, which will increment the paper

in reverse. (The minimum feed amount is 1/,80 inch.) When the cut-sheet feeder is used, the adjusted position

for the top of form will be lost after the printer is reinitialized, and the top of form will be reset to the default

value. When continuous paper is used, however, printer memory maintains the adjusted top-of-form position

even after printer initialization.

1.7 TEAR-OFF FUNCTION

If the tear-off function is enabled by making the appropriate DIP switch setting, it operates when the release

lever is set to the tractor position. In this case, if the input data buffer is empty and the printer is on line,

the paper is automatically fed to the tear-off position, and the MULTI-PART LED flashes to indicate that the

FORM FEED and LINE FEED switches are now available to perform micro-adjustment. The user may then

adjust the paper to the desired tear-off position. This position becomes the new tear-off position default, and

will remain valid even if the printer is reset and reinitialized, and regardless of whether the main power has

been interrupted. When new data is input to the printer, the paper is automatically returned to its original

position, and printing then starts. Paper that was advanced to the tear-off position will also be returned to

its original position if the ON LINE switch is pressed (switching the printer from on line to off line).

1-18

LQ-510

Page 28

REV.-A

GENERAL DESCRIPTION

1.8 OPERATING INSTRUCTIONS

This section describes the self-test and hexadecimal dump functions, error states, printer initialization, and

buzzer operation.

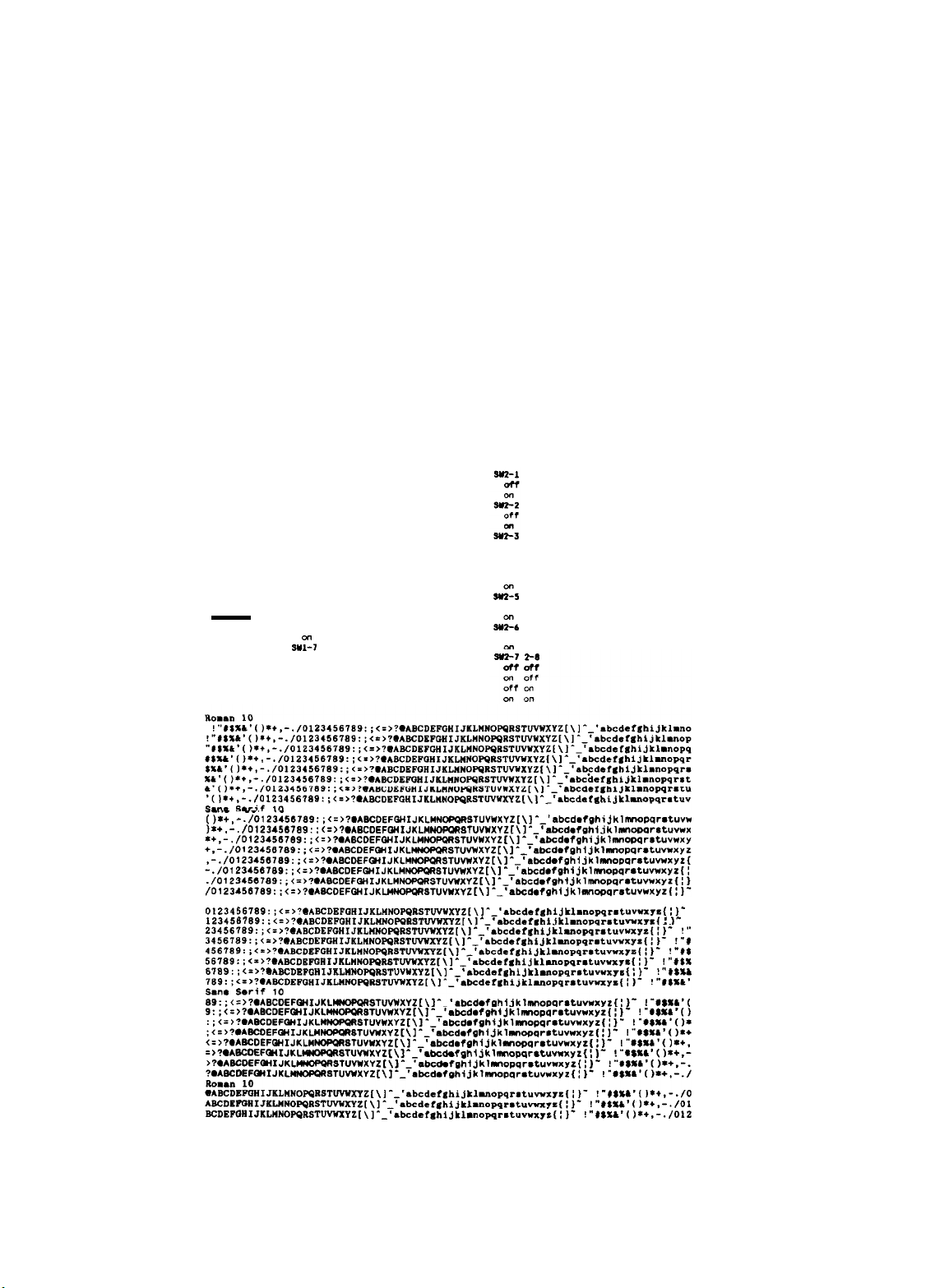

1.8.1 SELF-TEST

To begin self-test printing in draft mode, turn the printer on while depressing the LINE-FEED button. To begin

printing in letter-quality (LQ) mode, turn the printer on while depressing FORM FEED.

Self-test printing can be stopped and restarted by pressing ON LINE (this will not affect the ON-LINE in-

dicator). To conclude the self-test, press the ON-LINE switch to stop the printing; then turn off the printer.

The first printed line of the self-test indicates the firmware revision number. Following this line, the current

DIP switch settings are printed.

xxxxx

Country

USA

France

Germany

U.K.

Denmark

Sweden

Italy

Spain

Font

Roman

Sans serif

slot

Draft

Invalid

Valid

CG table

Italic

Graphic

CSF mode

Invalid

Valid

SW1-1 1-2 1-3

on on on

on on off

on off on

on off off

off on on

off on off

off off on

off off off

SW1-4 1-5

off off

on off

off on

on on

SW1-6

off

.3,:7

off

on

SW1-8

off

on

Page length

11"

12”

Tear off mode

Invalid

V&lid

I” skip

Invalid

Valid

Auto LF

Invalid

Valid

Receive buffer

1kbytes

8kbytes

Graphics print

uni-d

Bi-d

Pitch

10

pitch

12 Pitch

15 pitch

Proportional

off

on

Sw2-4

off

slz

off

2A

off

LQ-510

__.._ _-.

()a+.-

l*+.-./01234557S9::~=>?gAECDEFOHIJKLMNOWRSTUVNXYZ~\l-

Roman 10

01234567B9::~=~?6ABCDEPQHIJKLHNO~RSTWUXYZ~\]-~’~bcd.f6hijtl~no~r~tUVUX~6f:l1234667B9::<=>?~ABCDEFGHIJKLMNOWPSTVVYXYZl\1-

._

./0123456769:;~=~?OABCDEF(WIJKLNNOWRSTUVWXYZ(\]~~‘abcd~fghijklmnoPqr~tuvw

‘~bcd*fahljklmMKlratuvwx

‘abcd.fchl.ikl~nouar~tu~x~c(

Figure 1-8. Self-Test Printout

: I” !

1-19

Page 29

GENERAL DESCRIPTION

REV.-A

1.8.2 HEXADECIMAL DUMP FUNCTION

HEX dump mode is activated if the printer is switched on while both the LINE-FEED and FORM-FEED buttons are depressed. When this mode is in effect, the hexadecimal representation of the input data is printed

beside the corresponding printable ASCII characters. Periods (.) are printed beside control code input data.

This function is useful for checking the data the printer is receiving from the host.

Data Dump Mode

1B 40 0D 1B 55 00 1B 33 1E 00 0D 0A 0D 0A 0D 0A

12 1B 70 00 1B 78 01 1B 57 00 1B 4D 20 20 20 20

43 48 41 50 54 45 52 20 31 0D 0A 20 20 20 20 47

45 4E 45 52 41 4C 20 44

4F 4E 0D 0A 0D 0A 20 20 20 20 31 2E 31 20 46 45

41 54 55 52 45 53 0D 0A

53 50 45 43 49 46 49 43 41 54 49 4F 4E 53 0D 0A

20 20 20 20 20 20 20 20 31 2E 32 2E 31 20 46 61

72 64 77 61 72 65 20 53 70 65 63 69 66 69 63 61

74 69 6F 6E 73 0D 0A 20 20 20 20 20 20 20 20 31

2E 32 2E 32 20 46 69 72 6D 77 61 72 65 20 53 70

65 63 69 66 69 63 61 74 69 6F 6E 73 20 28 45 53

43 2F 50 29 0D 0A 20 20 20 20 31 2E 33 20 49 4E

54 45 52 46 41 43 45 20 4F 56 45 52 56 49 45 57

0D 0A 20 20 20 20 31 2E 34 20 44 49 50 20 53 57

49 54 43 40 45 53 20 41 4E 44 20 4A 55 4D 50 45

52 20 53 45 54 54 49 4E 47 0D 0A 20 20 20 20 20

20 20 20 31 2E 34 2E 31 20 44 49 50 20 53 77 69

74 63 68 20 53 65 74 74 69 6E 67 73 0D 0A 20 20

20 20 20 20 20 20 31 2E 34 2E 32 20 4A 75 6D 70

65 72 20 53 65 74 74 69 6E 67 0D 0A 20 20 20 20

31 2E 35 20 53 45 4C 45 43 54 59 50 45 20 46 55

4E 43 54 49 4F 4E 0D 0A 20 20 20 20 31 2E 36 20

53 48 45 45 54 20 4C 4F 41 44 49 4E 47 20 41 4E

44 20 53 48 45 45 54 20 45 4A 45 43 54 49 4F 4E

0D 0A 20 20 20 20 31 2E 37 20 54 45 41 52 2D 4F

46 46 20 46 55 4E 43 54 49 4F 4E 0D 0A 20 20 20

20 31 2E 38 20 4F 50 45 52 41 54 49 4E 47 20 49

4E 53 54 52 55 43 54 49 4F 4E 53 0D 0A 20 20 20

20 20 20 20 20 31 2E 38 2E 31 20 53 65 6C 66 2D

54 65 73 74 0D 0A 20 20 20 20 20 20 20 20 31 2E

30 2E 32 20 48 65 78 61 64 65 63 69 6D 61 6C 20

44 75 6D 70 20 46 75 6E 63 74 69 6F 6E 0D 0A 20

20 20 20 20 20 20 20 31 2E 38 2E 33 20 42 69 74

2D 49 6D 61 67 65 20 50 72 69 6E 74 69 6E 67 0D

0A 20 20 20 20 20 20 20 20 31 2E 38 2E 34 20 4.5

72 72 6F 72 20 43 6F 6E 64 69 74 69 6F 6E 73 0D

0A 20 20 20 20 20 20 20 20 31 2E 38 2E 35 20 42

75 7A 7A 65 72 20 4F 70 65 72 61 74 69 6F 6E 0D

0A 20 20 20 20 20 20 20 20 31 2E 38 2E 36 20 50

72 69 6E 74 65 72 20 49 6E 69 74 69 61 6C 69 7A

61 74 69 6F 6E 0D 0A 20 20 20 20 20 20 20 20 31

2E 38 2E 37 20 44 65 66 61 75 6C 74 20 56 61 6C

75 65 73 0D 0A 20 20 20 20 20 20 20 20 31 2E 38

2E 38 20 41 64 6A 75 73 74 20 4C 65 76 65 72 20

4F 70 65 72 61 74 69 6F 6E 0D 0A 20 20 20 20 20

20 20 20 31 2E 38 2E 39 20 50 72 69 6E 74 65 72

20 50 72 6F 74 65 63 74 69 6F 6E 20 66 6F 72 20

48 65 61 76 79 2D 44 75 74 79 20 50 72 69 6E 74

69 6E 67 0D 0A 20 20 20 20 31 2E 39 20 4D 41 49

4E 20 43 4F 4D 50 4F 4E 45 4E 54 53 0D 0A 20 20

20 20 20 20 20 20 31 2E 39 2E 31 20 53 41 4D 41

20 42 6F 61 72 64 0D 0A 20 20 20 20 20 20 20 20

31 2E 39 2E 32 20 53 41 4E 50 4E 4C 20 42 6F 61

72 64 0D 0A 20 20 20 20 20 20 20 20 31 2E 39 2E

33 20 53 41 4E 50 53 28 45 29 20 42 6F 61 72 64

0D 0A 20 20 20 20 20 20 20 20 31 2E 39 2E 34 20

50 72 69 6E 74 65 72 20 4D 65 63 68 61 6E 69 73

6D 20 28 4D 2D 35 37 31 30 29 0D 0A 20 20 20 20

20 20 20 20 31 2E 39 2E 35 20 48 6F 75 73 69 6E

67 0D 0A 0D 0A 20 20 20 20 31 2E 31 20 46 45 41

54 55 52 45 53 0D 0A 0D 0A 20 20 20 20 54 68 65

20 4C 51 2D 35 31 30 2F 35 35 30 20 69 73 20 61

45 53 43 52 49 50 54 49

20 20 20 20 31 2E 32 20

.@..U..3........

X..W..M

. .p..

CHAPTER 1..

ENERAL DESCRIPTI

ON.... 1.1 FE

ATURES. 1.2

SPECIFICATIONS..

rdware Specifica

tions..

.2.2 Firmware Sp

1.2.1 Ha

ecifications (ES

C/P). .

TERFACE OVERVIEW

ITCHES AND JUMPE

R SETTING..

1.4.1 DIP Swi

tch Settings..

er Setting..

1.5 SELECTYPE FU

NCTION.. 1.6

SHEET LOADING AN

D SHEET EJECTION

_ .

FF FUNCTION..

1.8 OPERATING I

NSTRUCTIONS..

1.3 IN

1.4 DIP SW

1.4.2 Jump

1.7 TEAR-O

1.8.1 Self-

Test. . 1.

8.2 Hexadecimal

Dump Function..

1.8.3 Bit

-Image Printing.

rror Conditions.

uzzer Operation.

rinter Initializ

1.8.4 E

1.8.5 B

1.8.6 P

ation..

.8.7 Default Val

ues.. 1.8

.8 Adjust Lever

Operation..

1.8.9 Printer

Protection for

Heavy-Duty Print

ing. _ 1.9 MAI

N COMPONENTS..

1.9.2 SANPNL Boa

rd.. 1.9.

3 SANPS(E) Board

. .

Printer Mechanis

m (M-5710)..

g.. . . 1.1 FEA

TURES.... The

1.9.1 SAMA

Board. _

1.9.4

1.9.5 Housin

LQ-510/550 is a

G

1

1

1-20

Figure 1-9. Hexadecimal Dump Function

LQ-510

Page 30

REV.-A

GENERAL DESCRIPTION

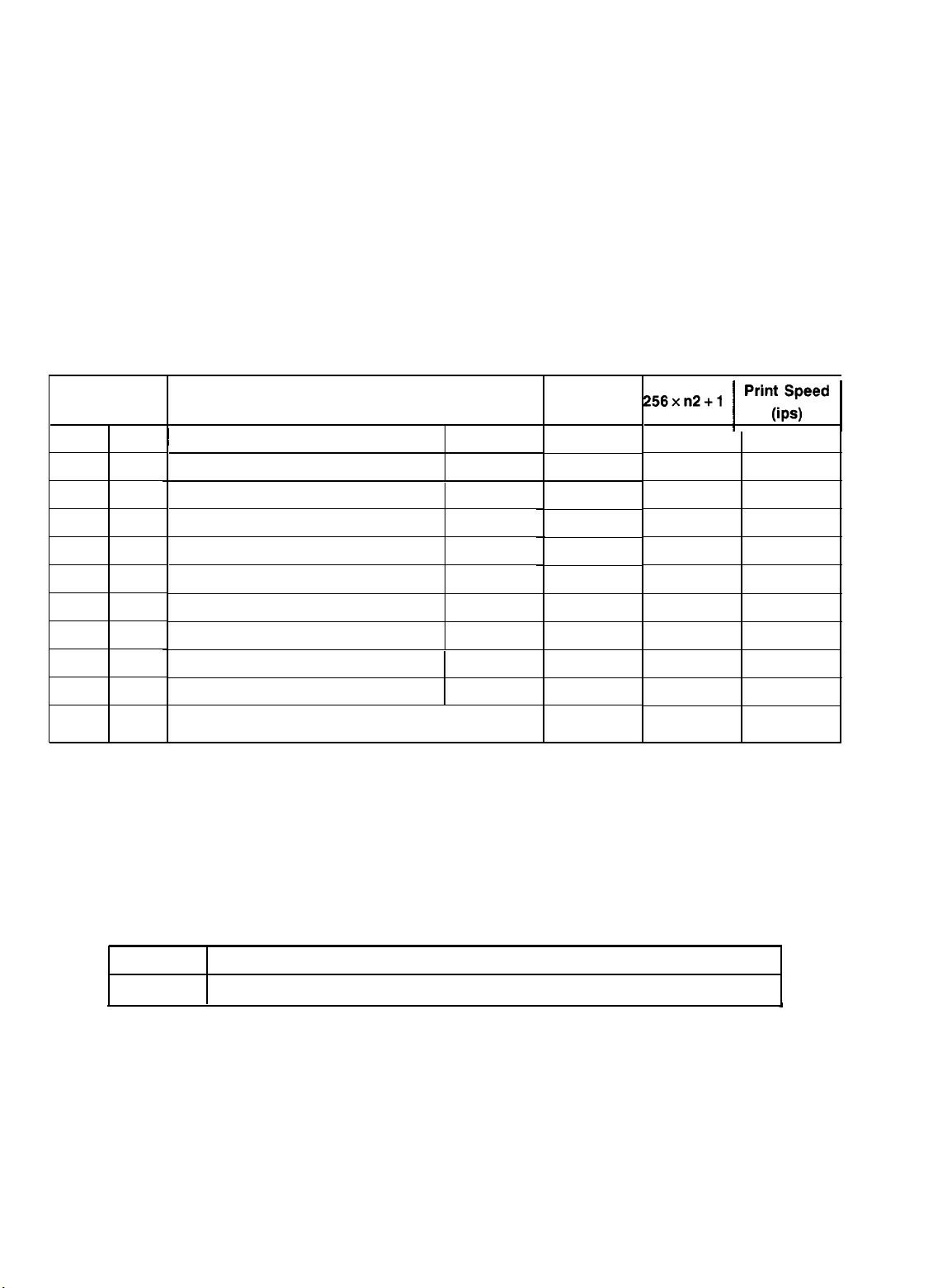

1.8.3 BIT-IMAGE PRINTING

This printer offers the following four standard print densities (“dpi” indicates “dots per inch”):

120 dpi (including half dots): Triple speed

180 dpi (including half dots): Double speed

240 dpi (including half dots): 1.5 speed

360 dpi (including half dots): Normal speed

The firmware implements the print densities as shown in Table 1-16.

Table 1-16. Print Density

Pins m

8 0

8

8 2

8

8

8 6

24

24

24

24 39

24

NOTES:

Bit Image Printing Mode

~

Single-density

1

Dual density

Double speed, dual density

Quadruple density

3

4

CRT graphics

CRT graphics II

32

33

Single density

Dual density

CRT graphics II

38

Triple density

40

Hex. density

1. Dot density is in dots per inch; print speed is in inches per second.

Dot Density

(dpi)

60

120

120

240

80

I

90

60

120

90

180

360

I

2. The format of the graphics command is ESC* m n1 n2 [DATA]. Column 2 of the table shows

the significance of the various options for m.

The firmware handles the print densities as shown in Table 1-17.

Dot

Printing

yes

yes

no

no

yes

yes

yes

yes

yes

yes

no

256xn2+1 ! Prinii:eed 1

660

1320

1320

2640 7.5

880

990

660

1320 7.5

990

1980

3960

15

7.5

15

7.5

10

15

10

5

5

LQ-510

Dot Density

80 dpi

Table 1-17. Bit-Image Printing

Printing Method

Prints at 240 dpi by expanding the bit image by three: 80 x 3 = 240

I

1-21

Page 31

GENERAL DESCRIPTION

REV.-A

1.8.4 ERROR CONDITIONS

If any of the following error conditions are detected, the printer automatically enters off-line mode.

0 Home position is not detected at printer mechanism initialization.

0 Home position is detected during printing.

l

ON LINE is pressed when the printer is already on line. This will switch the printer to off line.

0 When a paper-out signal is detected and forms-override is finished.

l

If “paper out” is detected after the printer performs a paper-loading operation with the cut-sheet feeder

enabled.

The following interface signals are output to indicate the error and to halt data transmission:

BUSY signal becomes HIGH.

ERROR becomes LOW.

No ACKNLG pulse is sent.

1.8.5 BUZZER OPERATION

The buzzer operates as follows:

l

When the BEL code is sent to the printer, the buzzer sounds continuously for 0.5 seconds.

0

When the paper-out error is detected, the buzzer sounds 3 times, for 0.1 second each time. The interval

between sounds is 0.1 second.

0

When abnormal carriage movement is detected, the buzzer sounds 5 times, for 0.5 seconds each time.

The interval between sounds is 0.5 seconds.

0 When the panel setting is accepted, the buzzer sounds for 0.1 second.

1.8.6 PRINTER INITIALIZATION

There are two types of initialization: hardware initialization and software initialization.

Hardware Initialization

Hardware initialization occurs when the printer power switch is turned on (provided that the AC power cord

is plugged in), or when the INIT signal is received over the parallel interface line.

Upon hardware initialization, the printer does the following:

(a) Initializes the printer mechanism.

(b) Clears the input data buffer.

(c) Clears the downloaded character set.

(d) Clears the print buffer.

(e) Returns the printer settings to their default values.

Software Initialization

Software initialization occurs when the printer receives the software initialize code. For a software initialization, the printer does not perform the functions listed under (a), (b), and (c) above. Instead, the settings changed

by the last SelecType operation are reset.

1-22

LQ-510

Page 32

REV.-A

GENERAL DESCRIPTION

1.8.7 DEFAULT VALUES

When the printer is initialized, the following default values and functions are set:

Page Position

Left and Right Margin

Line Spacing

Vertical Tabs

Horizontal Tabs

VFH Channel

The current paper position becomes the top-of-form position

Released

1/6 inch

Cleared

Every 8 characters (relative)

Channel 0

Family Number of Type

Style

Download Characters

Font selected by DIP switch

Deselected (if software initialization)

Cleared (if hardware initialization)

Justification

Character Spacing

Bit-Image Mode Assignment

Printing Effects

Condensed Printing

Left justification

10 cpi

ESC K = ESC* 0, ESC L = ESC * 1

ESC Y =

ESC * 2, ESC Z = ESC * 3

All effects other than condensed printing are cleared

Setting selected by DIP switch

1.8.8 ADJUST LEVER OPERATION

The position of the adjust lever must be set to accord with the paper thickness. If the lever is set to position

four or above, the MULTI-PART indicator lights and the printing speed is increased. See Table 1-18 and

Figure 1-10.

Table 1-18. Lever Position

l

If the printing density is light, position the adjust lever one step lower.

2nd position

I

4th position

Figure 1-10. Lever Position

LQ-510/550

1-23

Page 33

GENERAL DESCRIPTION

1.8.9

PRINTER PROTECTION FOR HEAVY-DUTY PRINTING

REV.-A

The printer incorporates “printhead protection” to safeguard it from overheating and from the potential ill

effects of a voltage drop to the head driver. If the temperature of the head exceeds a specified value, printing

is automatically suspended. Printing automatically resumes when the temperature drops to another specified

value.

If heavy-duty printing causes the voltage to the head drive circuit to drop to a specified value, printing is

immediately suspended. If the voltage recovers, the line that was being printed is completed. This protection

occurs when half or more of the wires are activated simultaneously and continuously.

1-24

LQ-510

Page 34

REV.-A

GENERAL DESCRIPTION

1.9 MAIN COMPONENTS

To facilitate maintenance and repair, the main components of the LQ-510 printer are designed so that they

can be removed and replaced easily.

The main components are:

1) SAMA board:

The main control board. The CPU, which is contained on

this board, controls all the main functions.

2) SANPNL control panel:

3) SANPS board: (120 V Version)

The control panel.

The power supply circuit board.

SANPSE Board (220/240 V Version)

4) M-5710: The printer mechanism.

I

SANPS(E) Board

M

SAMA Board

LQ-510

M-5710 Printer Mechanism

Figure 1-11. LQ-510 Component Layout

1-25

Page 35

GENERAL DESCRIPTION

1.9.1 SAMA BOARD

REV.-A

The use of the

E05A02 Gate Array (1A)

pPD7810HG

CPU simplifies the circuitry design of the main control board.

1MCG M10A17 or M10A20

PSRAM (5A)

27256 PROM (6A)

Gate

Array

(71

pPD7810HG CPU (5B)

Figure 1-12. SAMA Main Control Board

1-26

LQ-510

Page 36

REV.-A

1.9.2 SANPNL CONTROL PANEL

The SANPNL control panel, which is the LQ-510’s control panel, contains the switches and the indicator

LEDs illustrated below.

GENERAL DESCRIPTION

LQ-510

Figure 1-13. SANPNL Control Panel

1-27

Page 37

GENERAL DESCRIPTION

REV.-A

1.9.3 SANPS(E) BOARD

The power supply circuit (SANPS/SANPSE board), which is housed at the upper left of the lower case, consists of a line filter, fuse, power switch, and switching regulator circuit. It converts the AC line voltage to

the + 24 V, + 12 V, - 12 V, and + 5 VDC voltages used by the printer.

(SANPS Board)

(SANPSE Board)

Figure 1-14. Power Supply Filter Board

1.9.4 PRINTER MECHANISM (M-5710)

The M-5710 printer mechanism was developed expressly for use with LQ-510 printer. Its components include a carriage motor, carriage mechanism, paper-feed motor, paper-feed mechanism, ribbon-feed

mechanism, printhead, and sensors.

1-28

Figure 1-15. Model 5710 Printer Mechanism

LQ-510

Page 38

REV.-A

1.9.5 HOUSING

GENERAL DESCRIPTION

The housing for the LQ-510 consists of upper and lower

cases.

The upper case houses the control panel.

The lower case contains the printer mechanism and the main control board. The printer cartridge can be

removed and replaced easily.

Figure 1-16. Housing

LQ-510

1-29

Page 39

REV.-A

PRINCIPLES OF OPERATION

CHAPTER 2

PRINCIPLES OF OPERATION

2.1

OVERVIEW

2.1.1

2.1.2 Outline of Printer Mechanism Operation

2.1.3 Circuit Overview

2.2 OPERATION OF THE POWER SUPPLY CIRCUIT

2.2.1

2.2.2 Filter Circuit........................................................................

2.2.3 Rectifier and Smoothing Circuit

2.2.4

2.2.5

2.2.6

2.2.7 Voltage Limiting Circuit .......................................................

2.2.8 ± 12 VDC Supply Circuit

2.3 PRINTER MECHANISM AND CONTROL CIRCUIT OPERATION

2.3.1

2.3.2 Reset Circuit

2.3.3 Address Decoder and Bank Register

2.3.4 Carriage Operation

2.3.5 Paper Feed .........................................................................

....................................................................................

Connectors Summary

2.1.2.1 Sensors

2.1.2.2

2.1.2.3 Printhead

2.1.3.1 Overview of Power Supply Circuit

2.1.3.2

Power Supply Circuit Block Diagram

Starting Circuit (Main Switching Circuit)

+ 24 VDC Voltage Control Circuit

+ 5 VDC Regulator Circuit

Vx Voltage Supply Circuit

2.3.4.1 Carriage Mechanism

2.3.4.2 Carriage Motor Specifications

2.3.4.3 Carriage Motor Drive Circuit Block Description..

2.3.4.4

2.3.4.5

2.3.4.6

2.3.5.1 Paper-Feed Mechanism Operation

2.3.5.2 Paper-Feed Motor Specifications

2.3.5.3

2.3.5.4

Motors

Control Circuit Block Diagram

.......................................................................

Gate Array E01A05 Operation in Carriage Motor

Drive Circuit

Carriage Motor Drive Circuit

Carriage Motor Software Control

Paper-Feed Motor Drive Circuit

Paper-Feed Motor Software Control

..........................................................

...............................

...............................................................

.................................................................

.............................................................

.................................................................

..........................

................................

...............................

....................................

............................................

................................

.........................................

....................................................

......................................................

............

....................................................

....................................

..............................................................

..............................................

................................

.........................................................

..................................

............................

..........................

............................

..............................

.......................

.....

2-1

2-1

2-3

2-4

2-9

2-9

2-10

2-10

2-11

2-13

2-13

2-14

2-15

2-15

2-19

2-21

2-25

2-26

2-27

2-27

2-28

2-33

2-35

2-35

2-36

2-36

2-37

2-38

2-47

2-51

2-51

2-52

2-53

2-54

LQ-510

2-i

Page 40

PRINCIPLES OF OPERATION

REV.-A

2.3.6 Printhead

2.3.6.1 Printhead Printing Operation

2.3.6.2 Printhead Specifications

2.3.6.3

2.3.6.4

2.3.6.5 Printhead Drive Circuit ..........................................

2.3.6.6 Printhead Software Control

2.3.7 A/D Converter Circuit

2.3.8 Host Interface

2.3.9 EEPROM Circuit ..................................................................

2.3.10 Ribbon-Feed Mechanism

............................................................................

.................................

........................................

Printhead Drive Circuit Block Diagram..

Gate Array E05A02 Operation in Printhead

Drive Circuit

.....................................................................

.........................................................

...................................

..........................................................

......................................................

LIST OF FIGURES

Figure 2-1.

Figure 2-2.

Figure 2-3.

Figure 2-4.

Figure 2-5.

Figure 2-6.

Figure 2-7.

Figure 2-8.

Figure 2-9.

Figure 2-10.

Figure 2-11.

Figure 2-12.

Figure 2-13.

Figure 2-14.

Figure 2-15.

Figure 2-16.

Figure 2-17.

Figure 2-18.

Figure 2-19.

Figure 2-20.

Figure 2-21.

Figure 2-22.

Cable Connections

Printer Mechanism Block Diagram

Paper-End Sensor Mechanism

Paper-End Sensor Circuit

Home-Position Sensor Mechanism

Home-Position Sensor Circuit

Thermal Sensor Mechanism (Printhead Temperature

Detection)

Thermal Sensor Circuit

Platen Gap Sensor Mechanism

Platen Gap Sensor Circuit

Friction/Tractor Sensor Mechanism

Friction/Tractor Sensor Circuit

Printhead

Overview of

Control Circuit Block Diagram

Power Supply Circuit Block Diagram

Filter Circuit (SANPS Board,

Filter Circuit (SANPSE Board, 220/240 V Version)

Rectifier and Smoothing Circuit

Starting Circuit (Main Switching Circuit)

Main Switching Circuit Waveforms

+24 VDC Voltage Control Circuit

.......................................................................

........................................................................

...........................................................

....................................

..........................................

.................................................

....................................

...........................................

....................................................

.........................................

................................................

..................................

.........................................

Power Supply Circuit Operation

..........................................

.................................

120 V Version).

........................................

............................

....................................

......................................

..................

.....................

.....................

.............

2-55

2-55

2-55

2-56

2-57

2-56

2-59

2-60

2-63

2-64

2-65

2-2

2-3

2-4

2-4

2-5

2-5

2-6

2-6

2-7

2-7

2-8

2-8

2-9

2-10

2-11

2-13

2-14

2-14

2-15

2-17

2-18

2-19

2-ii

LQ-510

Page 41

REV.-A

PRINCIPLES OF OPERATION

Figure 2-23.

Figure 2-24.

Figure 2-25.

Figure 2-26.

Figure 2-27.

Figure 2-28.

Figure 2-29.

Figure 2-30.

Figure 2-31.

Figure 2-32.

Figure 2-33.

Figure 2-34.

Figure 2-35.

Figure 2-36.

Figure 2-37.

Figure 2-38.

Figure 2-39.

Figure 2-40.

Figure 2-41.

Figure 2-42.

Figure 2-43.

Figure 2-44.

Figure 2-45.

Figure 2-46.

Figure 2-47.

Figure 2-48.

Figure 2-49.

Figure 2-50.

Figure 2-51.

Figure 2-52.

Figure 2-53.

Figure 2-54.

Figure 2-55.

Figure 2-56.

Figure 2-57.

Figure 2-58.

Figure 2-59.

Figure 2-60.

Figure 2-61.

Figure 2-62.

Switching Circuit (During PCI Operation)

Over-Current Protection (OCP)

+ 5 VDC Regulator Circuit

Oscillator Waveforms

.......................................................

Constant Voltage Control

EAI Output

......................................................................

Over-Current Protection (OCP)

lC494 Internal Circuit

PWM Output

....................................................................

Voltage Limiting Circuit

.......................................................

....................................................

± 12 VDC Supply Circuit

Vx Voltage Circuit

Reset Circuit

RESET Output

............................................................

...................................................................

.................................................................

..........................................

................................................

.................................................

..........................................

.................................................

...........................

RESET Pulse Oscillation Process (Module Mounted).

RESET Pulse Oscillation Process (Module Removed)

INIT Signal Input Circuit

Address Decoder

Bank Register

.............................................................

..................................................................

Carriage Mechanism

Carriage Drive Circuit Block Diagram

Gate Array Operation

Carriage Motor Drive Circuit

SLA7020M Circuit Diagram

Phase Data Input Timing (2-2 Phase)

Phase Signal Timing Chart (2-2 Phase)

Phase Data Input Circuit (1-2 Phase)

Phase Signal Timing Chart (1-2 Phase)

Phase Data Conversion Circuit

Reference Voltage Generation Circuit

Constant Current Control Circuit

Waveforms

......................................................................

Carriage Motor Control

Home-Position Seek

Printing Area and Printing Timing

Friction-Feed Operation

Push-Tractor-Feed Operation

Paper-Feed Motor Drive Circuit

Paper-Feed Motor Drive Timing Chart

Printhead Printing Operation

...................................................

........................................................

................................

.......................................................

.............................................

...............................................

................................

.............................

.................................

.............................

.........................................

...............................

.......................................

.....................................................

.........................................................

.....................................

...................................................

............................................

.........................................

...............................

............................................

.........

.........

2-20

2-20

2-21

2-22

2-22

2-22

2-23

2-24

2-24

2-25

2-26

2-27

2-28

2-29

2-30

2-31

2-32

2-33

2-34

2-35

2-36

2-37

2-38

2-39

2-40

2-40

2-41

2-41

2-42

2-43

2-44

2-45

2-48

2-49

2-50

2-51

2-52

2-53

2-54

2-55

LQ-510

2-iii

Page 42

PRINCIPLES OF OPERATION

REV.-A

Figure 2-63.

Figure 2-64.

Figure 2-65.

Figure 2-66.

Figure 2-67.

Figure 2-68.

Figure 2-69.

Figure 2-70.

Figure 2-71.

Table 2-1.

Table 2-2.

Table 2-3.

Table 2-4.

Table 2-5.

Table 2-8.

Table 2-7.

Table 2-8.

Table 2-9.

Table 2-10.

Printhead Drive Circuit Block Diagram

Printhead Drive Circuit

Printhead Drive Waveforms

Print Timing

Relationship Between Head Driving Voltage and Print

Driving Pulse Width

A/D Converter Circuit

Host Interface

EEPROM Circuit

Ribbon-Feed Mechanism

....................................................................

.................................................................

.....................................................

..............................................

.........................................................

......................................................

..............................................................

..................................................

..............................

LIST OF TABLES

Board Connector Summary

Power Supply Applications

Reference Voltages

Phase-Excitation Method

Drive Sequence (2-2 Excitation)

Drive Sequence (1-2 Excitation)

Excitation Sequence

E05A02 Gate Array Functions

Scan Lines and DIP Switches

Ribbon-Feed Gear Train

..........................................................

........................................................

..............................................

...............................................

..................................................

........................................

........................................

...........................................

...........................................

...................................................

2-66

2-57

2-58

2-59

2-59

2-61

2-63

2-64

2-65

2-1

2-10

2-43

2-47

2-47

2-47

2-54

2-57

2-62

2-66

2-iv

LQ-510

Page 43

REV.-A

PRINCIPLES OF OPERATION 2

2.1 OVERVIEW

This chapter describes the signals at the connectors linking the primary components of the LQ-510. These

components include the printer mechanism, power supply circuits, and control circuits. The chapter also

describes the operation of the printer’s circuitry and printer mechanism.

2.1.1 CONNECTOR SUMMARY

The interconnection of the primary components is illustrated in Figure 2-1. Table 2-1 summarizes the functions, sizes, and types of the connectors shown in the figure.

LQ-510

2-1

Page 44

PRINCIPLES OF OPERATION

REV.-A

SANPNL-W

Control Panel

Board

Model 5710 Printer Mechanism