Page 1

rating Procedure for Pipettes

Register your instrument!

www.eppendorf.com/myeppendorf

P

N)Operating Procedure for Pipettes

Eppendorf SOP

Standard Operating Procedure for Pipettes

Page 2

Copyright

©

2013 Eppendorf AG, Hamburg. No part of this publication may be

reproduced without the prior permission of the copyright owner.

®

eppendorf

Eppendorf Multipette

Biomaster

, the Eppendorf logo, Eppendorf Reference®, Eppendorf Research®,

®

, Eppendorf Xplorer®, Varipette®, Varispenser®,

®

, Combitips® and PICASO® are registered trademarks of

Eppendorf AG.

AESOP13640-08/052013

Page 3

Table of contents

Eppendorf SOP

English (EN)

Table of contents

1 Test and pipette conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.1 Balances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.1.1 Balance type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.1.2 Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1.3 Minimum requirements for balances . . . . . . . . . . . . . . . . . .6

1.2 Measuring station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.2.1 Evaporation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.2.2 Measuring station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.2.3 Test room . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.2.4 Temperature differences. . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.2.5 Test liquid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.2.6 Operating Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.1 Scope of testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.1.1 Adjusting adjustable volume pipettes . . . . . . . . . . . . . . . . . . 8

2.1.2 Multi-channel pipettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.1.3 Multipette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.1.4 Bottle-top dispenser and Top Buret . . . . . . . . . . . . . . . . . . .9

2.2 Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Work method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.2 Removing the test volume from the reservoir. . . . . . . . . . . . 9

2.2.3 Dispensing the test volume into the weighing vessel . . . . . 10

3

3 Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.1 Calculating the systematic error . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Calculating the random error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4 Sterilization and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.1 Sterilization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1.1 Reference and Biomaster . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.1.2 Research plus and Reference 2. . . . . . . . . . . . . . . . . . . . . . 12

4.1.3 Research and Research pro . . . . . . . . . . . . . . . . . . . . . . . .13

4.1.4 Top Buret . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.1.5 Varipette and Multipette . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.1.6 Varispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.1.7 Xplorer and Xplorer plus . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Page 4

Table of contents

4

Eppendorf SOP

English (EN)

5 Leakage check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Pipette leakage check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6.1 Potential error causes and corrections . . . . . . . . . . . . . . . . . . . . . . . 15

7 Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

7.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

7.2 Adjusting adjustable-volume pipettes. . . . . . . . . . . . . . . . . . . . . . . .17

7.2.1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

7.2.2 Biomaster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.2.3 Reference variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

7.2.4 Reference 2 adjustable-volume. . . . . . . . . . . . . . . . . . . . . .20

7.2.5 Research variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7.2.6 Research plusadjustable volume - adjustment to

environmental parameters. . . . . . . . . . .. . . . . . . . . . .. . . . . . 25

7.2.7 Research plus adjustable volume - change to the factory

adjustment.. . . . . . . . .. . . . .. . . . . . . . . . .. . . . . . . . . . . . . . . .26

7.2.8 Research Multi-channel . . . . . . . . . . . . . . . . . . . . . . . . . . .31

7.2.9 Research plus Multi-channel . . . . . . . . . . . . . . . . . . . . . . .31

7.2.10 Varispenser plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

7.2.11 Xplorer and Xplorer plus . . . . . . . . . . . . . . . . . . . . . . . . . .32

7.3 Adjusting fixed-volume pipettes. . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7.3.1 Reference fixed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7.3.2 Reference2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

7.3.3 Research fixed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.3.4 Research plus fixed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

7.4 Physical influences of liquids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

8 Factor Z for distilled water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

8.1 Factor Z overview table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Page 5

Table of contents

Eppendorf SOP

English (EN)

9 Technical specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.1 Fixed-volume pipettes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

9.1.1 Reference fixed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

9.1.2 Reference 2 fixed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

9.1.3 Research fixed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.1.4 Research plus fixed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

9.2 Adjusting adjustable volume pipettes. . . . . . . . . . . . . . . . . . . . . . . .41

9.2.1 Reference variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

9.2.2 Reference 2 adjustable-volume. . . . . . . . . . . . . . . . . . . . . .42

9.2.3 Research adjustable-volume . . . . . . . . . . . . . . . . . . . . . . . .44

9.2.4 Research pro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

9.2.5 Research plus adjustable-volume . . . . . . . . . . . . . . . . . . . .46

9.2.6 Biomaster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.2.7 Varipette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.2.8 Xplorer and Xplorer plus . . . . . . . . . . . . . . . . . . . . . . . . . .48

9.3 Multi-channel pipettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.3.1 Research . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.3.2 Research pro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

9.3.3 Research plus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

9.3.4 Reference2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

9.3.5 Xplorer and Xplorer plus . . . . . . . . . . . . . . . . . . . . . . . . . .53

9.4 Multipette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

9.4.1 MultipettePlus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

9.4.2 MultipetteM4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9.4.3 Multipette stream / Multipette Xstream . . . . . . . . . . . . . . .56

9.5 Varispenser / Top Buret . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9.5.1 Varispenser and Varispenser plus. . . . . . . . . . . . . . . . . . . .57

9.5.2 Top Buret . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

9.6 Error limits in accordance with EN ISO 8655. . . . . . . . . . . . . . . . . . 57

9.6.1 Air-cushion pipettes, fixed and adjustable volume. . . . . . .58

9.6.2 Positive displacement pipettes (Biomaster) . . . . . . . . . . . .58

9.6.3 Dispenser (Multipette) . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

9.6.4 Single-stroke dispenser (Varispenser) . . . . . . . . . . . . . . . .60

9.6.5 Piston stroke burets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

5

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Page 6

Test and pipette conditions

6

Eppendorf SOP

English (EN)

1 Test and pipette conditions

These test and pipetting conditions are valid for all Eppendorf pipettes

and dispensers.

Follow EN ISO 8655 "Volume-measuring equipment with pistons".

For the calibration or adjustment of pipettes, the scales and measuring station

should fulfill the following requirements:

1.1 Balances

1.1.1 Balance type

Use semi-microbalances and microbalances to calibrate pipettes.

Some companies offer balances that are specially designed to meet the

requirements of pipette calibration, e.g. Sartorius and Mettler.

1.1.2 Accuracy

When selecting the balances, ensure that they are suitable for the accuracy of

the pipette. This helps to ensure that deviations within a measuring series are

recorded exactly for the assessment of the systematic and random measurement

deviations in accordance with EN ISO 8655.

For a pipette volume of less than or equal to 10 µl, balances with a 6-digit

display must be used. With larger volumes, balances with a 5-digit display are

sufficient.

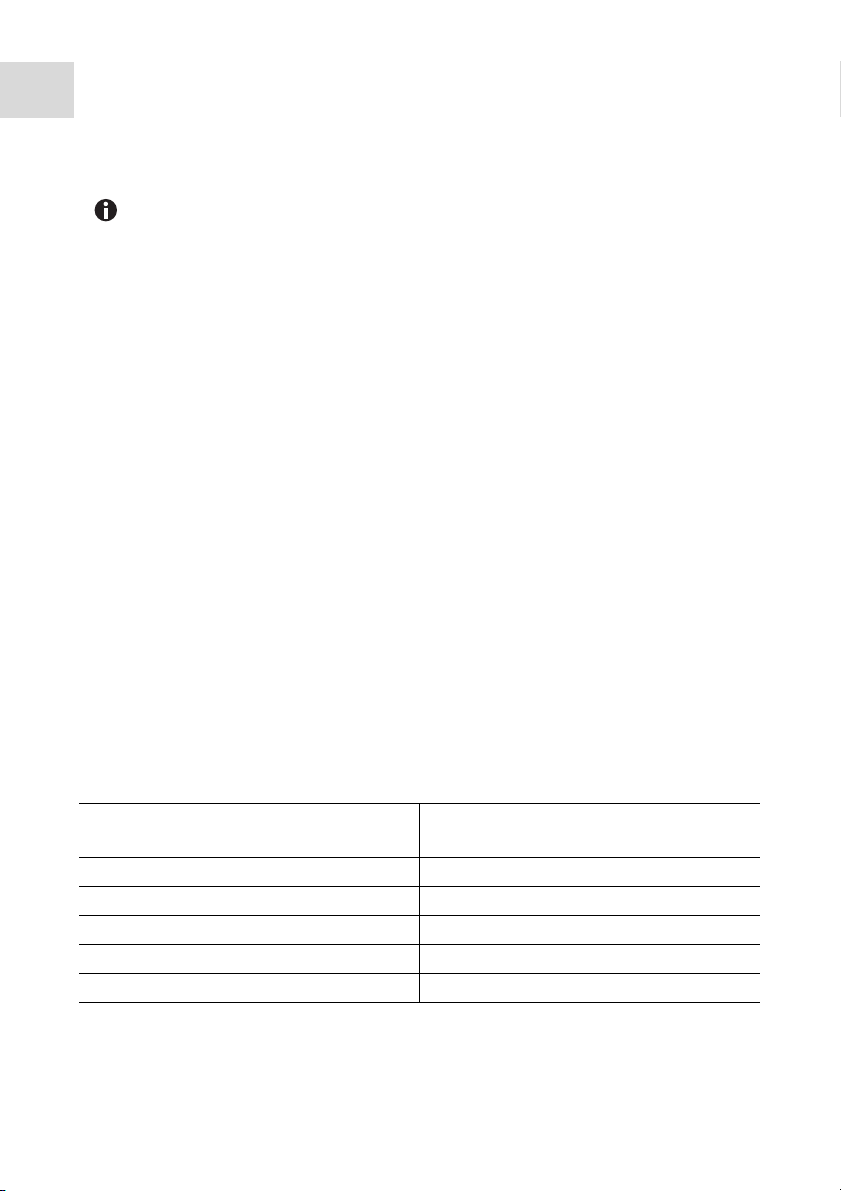

1.1.3 Minimum requirements for balances

Selected volume* of the pipette to be

tested

1 µL to 10 µL 0.001

>10 µL to 100 µL 0.01

>100 µL to 1 000 µL 0.1

>1 mL to 10 mL 0.1

>10 mL to 200 mL 1

* For practical reasons, the nominal volume can be used for the selection of the

balances.

Display resolution (mg)

Page 7

Test and pipette conditions

Eppendorf SOP

English (EN)

1.2 Measuring station

1.2.1 Evaporation

Take evaporation protection into account while carrying out the measurement.

With volumes < 50 µl in particular, errors caused by the evaporation of the test

liquid must be taken into consideration.

This can be ensured by using a liquid trap or other equipment to prevent

evaporation.

1.2.2 Measuring station

For electronic measurement data processing, we recommend calibration

software and accessories for your balance (PICASO, order no. 3113 004.001).

(see also EN ISO 8655, Part 6)

1.2.3 Test room

The tests should be carried out in a draft-free room under constant climatic

conditions.

The test room should have a constant temperature between 15 °C and 30 °C and

a constant relative humidity above 50 %.

7

1.2.4 Temperature differences

Before the test, the device to be tested and test liquid must have stood in the test

room for a sufficient amount of time, at least 2 hours, in order to reach

equilibrium with the storage conditions.

Direct sunlight and other influences which could affect the temperature should

be avoided at all costs.

1.2.5 Test liquid

Distilled or deionized water of "Quality 3 in accordance with ISO 3696",

degassed or at equilibrium with air. The water must be at room temperature.

1.2.6 Operating Manual

Observe the operating instructions for your pipette.

Page 8

Calibration

8

Eppendorf SOP

English (EN)

2 Calibration

2.1 Scope of testing

Note concerning the nominal volume:

The nominal volume of an adjustable-volume pipette is the largest volume to be

set by the user and specified by the manufacturer.

When using the Combitip with the Multipette, the nominal volume is the largest

possible dispensing volume of the Combitip. This means that for the Multipette

plus and Multipette M4, the nominal volume is 1/5 of the filling volume of the

Combitip advanced. For the Multipette stream / Xstream, the nominal volume is

the filling volume of the Combitip advanced.

2.1.1 Adjusting adjustable volume pipettes

For variable pipettes, check 3 different volumes with 10 measured values each:

• the nominal volume,

• approx. 50 % of the nominal volume,

• 10 % of the nominal volume.

2.1.2 Multi-channel pipettes

For Multi-channel pipettes check each channel separately with 3 different

volumes, each with 10 measured values:

• the nominal volume,

• approx. 50 % of the nominal volume,

• 10 % of the nominal volume.

2.1.3 Multipette

With the

• Multipette,

• Multipetteplus,

• Multipette stream,

• MultipetteXstream

• MultipetteM4

check the nominal volume with 10 measured values with the Eppendorf

Combitip used.

Page 9

Calibration

Eppendorf SOP

English (EN)

2.1.4 Bottle-top dispenser and Top Buret

For bottle-top dispensers and the Top Buret, check the nominal volume with 10

measured values.

2.2 Measurement

2.2.1 Work method

1. Place the selected pipette tip on the tip cone of the pipette or on the

corresponding Combitip in the Multipette.

2. Implement the following settings:

• Adjustable-volume piston-stroke pipettes: the smallest volume to be tested

• Multipettes: the nominal volume

• Bottle-top dispenser and Top Buret: the nominal volume

3. For all Multipettes with fully drawn up Combitip, always discard the first

dispensing step.

4. Fill test liquid up to a height of min. 3 mm in the weighing vessel.

5. For piston-stroke pipettes fill the pipette tip 5x with test liquid and empty it

(pre-wet), in order to create a moisture balance in the dead air volume.

6. Replace the single-use tip.

7. Pre-wet the tip 1x.

9

2.2.2 Removing the test volume from the reservoir

1. Hold the pipette vertically.

2. Dip the pipette tip into the test liquid by a few millimeters.

3. Draw in the volume to be tested slowly and evenly. The waiting time of 1 to

3 seconds, for Research 1 to 10 mL 5 seconds must be observed.

(the waiting time corresponds to the size of the tip, see operating

instructions.)

4. Pull the pipette tip slowly out of the liquid, wiping it on the vessel wall.

Page 10

Calibration

10

Eppendorf SOP

English (EN)

2.2.3 Dispensing the test volume into the weighing vessel

1. Rest the filled tip up against the wall of the weighing vessel at an angle.

2. Dispense the test liquid slowly until the first stop (measuring stroke).

3. Press the control button to the second stop (blow-out) and dispense the

remaining liquid in the tip (does not apply for dispensers and burets).

4. Hold down the control button and pull the tip up the vessel wall.

5. Let the control button slide back into position.

6. Determine the weight.

7. Complete all measurements of a measuring series as described and calculate

the systematic and random error (see p. 11).

8. In case of adjustable-volume pipettes, determine the measurement with the

nominal volume, 50 % and 10 % of the nominal volume. Always begin the

test with 10 % of the nominal volume.

Page 11

Evaluation

Eppendorf SOP

English (EN)

3 Evaluation

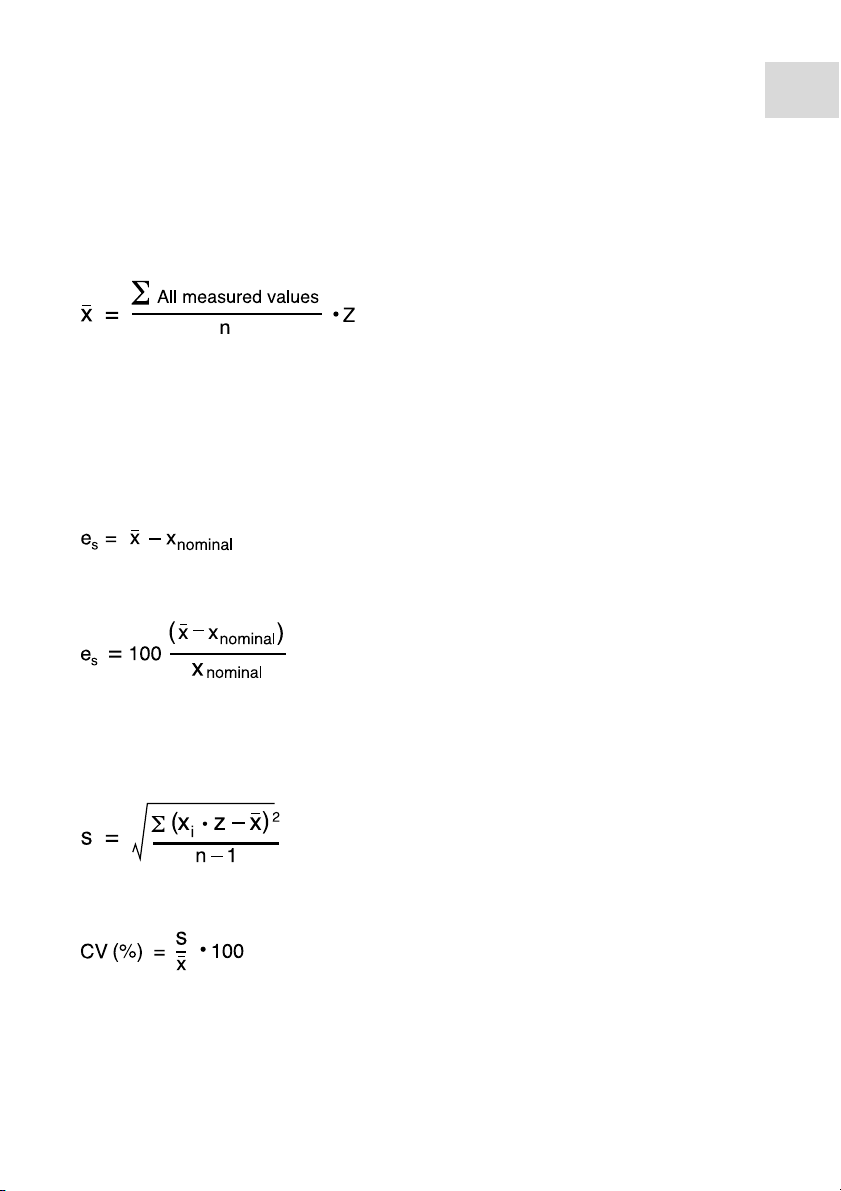

3.1 Calculating the systematic error

Mean value of the dispensed volume:

n = Number of measured values

To convert the measured values into volume values, use correction factor Z for

the dependency of the test liquid on temperature and air pressure for each

individual value (see Factor Z for distilled water on p. 36).

11

Systematic error e

Systematic error e

in micro liter:

s

in percent:

s

3.2 Calculating the random error

Random error as repeat standard s:

Random error as coefficient of variation CV:

The specifications of the tested pipette can be found in the relevant operating

instructions or technical specifications (see Technical specifications on p. 37).

Page 12

Sterilization and cleaning

12

Eppendorf SOP

English (EN)

4 Sterilization and cleaning

Further notes on cleaning and sterilization can found in the relevant

operating manual.

4.1 Sterilization

Parameter for autoclaving

• 121 °C

• 20 minutes

• 1 bar overpressure

4.1.1 Reference and Biomaster

The Reference pipettes and the Biomaster are fully autoclavable.

1. Prior to autoclaving, unscrew the upper and lower part of the pipette apart by

approx. one turn to enable the vapor to enter more easily.

2. After autoclaving, allow the pipette to cool down to room temperature and to

dry completely and then screw together.

4.1.2 Research plus and Reference 2

The Research plus pipettes and Reference 2 pipettes are fully autoclavable.

1. You can put the Research plus and Reference 2 into the autoclave as a

complete unit or with the lower part removed. Do not disassemble the lower

part.

2. For 2.5 mL, 5 mL and 10 mL pipettes: remove the old protection filter. Add a

new protection filter and install it after autoclaving. Only autoclave the

protection filter once.

After autoclaving:

3. Cool the pipette down to room temperature and leave to dry.

4. For 2.5 mL, 5 mL / 10 mL pipettes: the protection filter swells during

autoclaving. Slightly squeeze the protection filter when installing it into the

cone tip.

Page 13

Sterilization and cleaning

Eppendorf SOP

English (EN)

4.1.3 Research and Research pro

With the Research and Research pro pipettes, the lower section is autoclavable.

With single-channel models prior to autoclaving

1. Pull off the ejector sleeve with depressed ejector.

2. Unscrew the lower part of the pipette.

With the Multi-channel versions, you can autoclave the entire lower section.

After autoclaving, assemble the parts only after room temperature has been

reached and the parts have been dried.

4.1.4 Top Buret

The Top Buret can not be autoclaved.

4.1.5 Varipette and Multipette

The

• Varipette,

• Multipette,

• Multipetteplus,

• Multipette stream

• MultipetteXstream

• MultipetteM4

13

are not autoclavable.

4.1.6 Varispenser

The Varispenser and Varispenser plus are only autoclavable when fully

assembled.

With theVarispenser plus

1. Set the discharge valve toggle to the dispensing position (–>).

2. Release the volume setting knob, move to the middle position and leave

released.

3. Place the dispenser on a cloth and autoclave, avoiding contact with hot

surfaces.

4. Only use the dispenser again when it has cooled down to room temperature.

Page 14

Sterilization and cleaning

14

Eppendorf SOP

English (EN)

4.1.7 Xplorer and Xplorer plus

The lower part of theXplorer and Xplorer plus pipettes can be autoclaved.

1. Pull off the ejector sleeve with depressed ejector.

2. On the lower part of the pipette, push the ring labeled PUSH UP TO

RELEASE upward until the lower part is released.

After autoclaving, assemble the parts only after room temperature has been

reached and the parts have been dried.

4.2 Cleaning

All areas of the underside of the pipette can be cleaned in a soap

solution or isopropanol 60 % provided that no differing instructions are

given in the operating manual.

1. Clean the parts in soap solution or isopropanol.

2. Rinse the parts in distilled water.

3. Allow the parts to dry completely and then assemble.

4. Lightly lubricate the piston of the pipette (Eppendorf special grease

Page 15

Leakage check

Eppendorf SOP

English (EN)

5 Leakage check

5.1 Pipette leakage check

In order to carry out a leakage check on a pipette, follow the procedure outlined

below:

1. For adjustable-volume pipettes: set the nominal volume.

2. For volumes <20 µl pre-wet the tip several times.

3. Hold the pipette vertically with a full tip for approx. 30 sec. Do not touch the

pipette tip.

4. Observe the meniscus of the liquid on the tip opening. If there is a leak in the

pipette, a drip will form on the tip opening.

6 Troubleshooting

6.1 Potential error causes and corrections

Observe the error descriptions in the operating instructions.

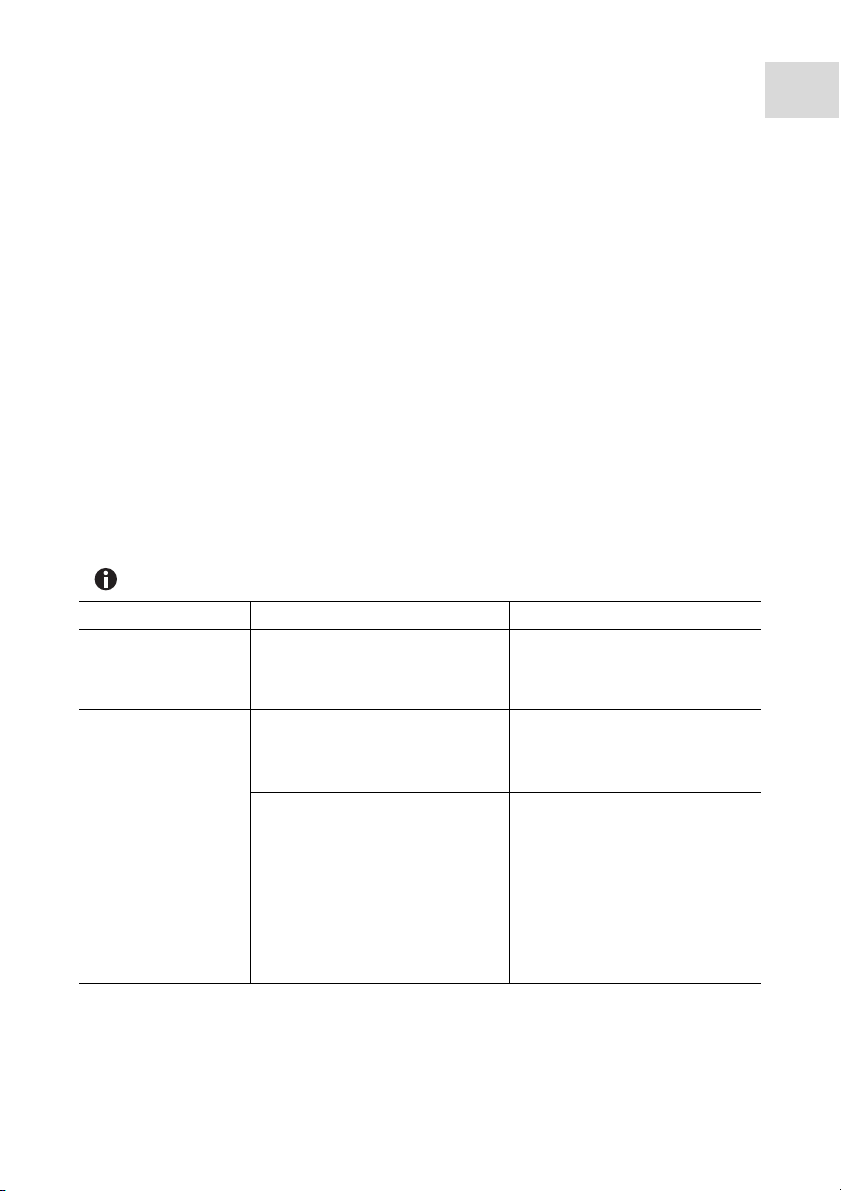

Error Cause Elimination

Droplets on the

inner wall of the

pipette tip.

Pipette is dripping,

pipetted volume is

incorrect.

Uneven wetting of the plastic

wall.

• Tip loose.

• Incorrect pipette tip.

Pipette is leaking because:

•The piston is

contaminated.

• The piston is damaged.

• The seal is damaged.

Attach a new pipette tip.

Press the tip on firmly.

Use an original Eppendorf

tip.

Clean the piston and

lubricate slightly.

Replace the piston and

piston sealing and

lubricate slightly.

Replace the seal.

15

Page 16

Troubleshooting

16

Eppendorf SOP

English (EN)

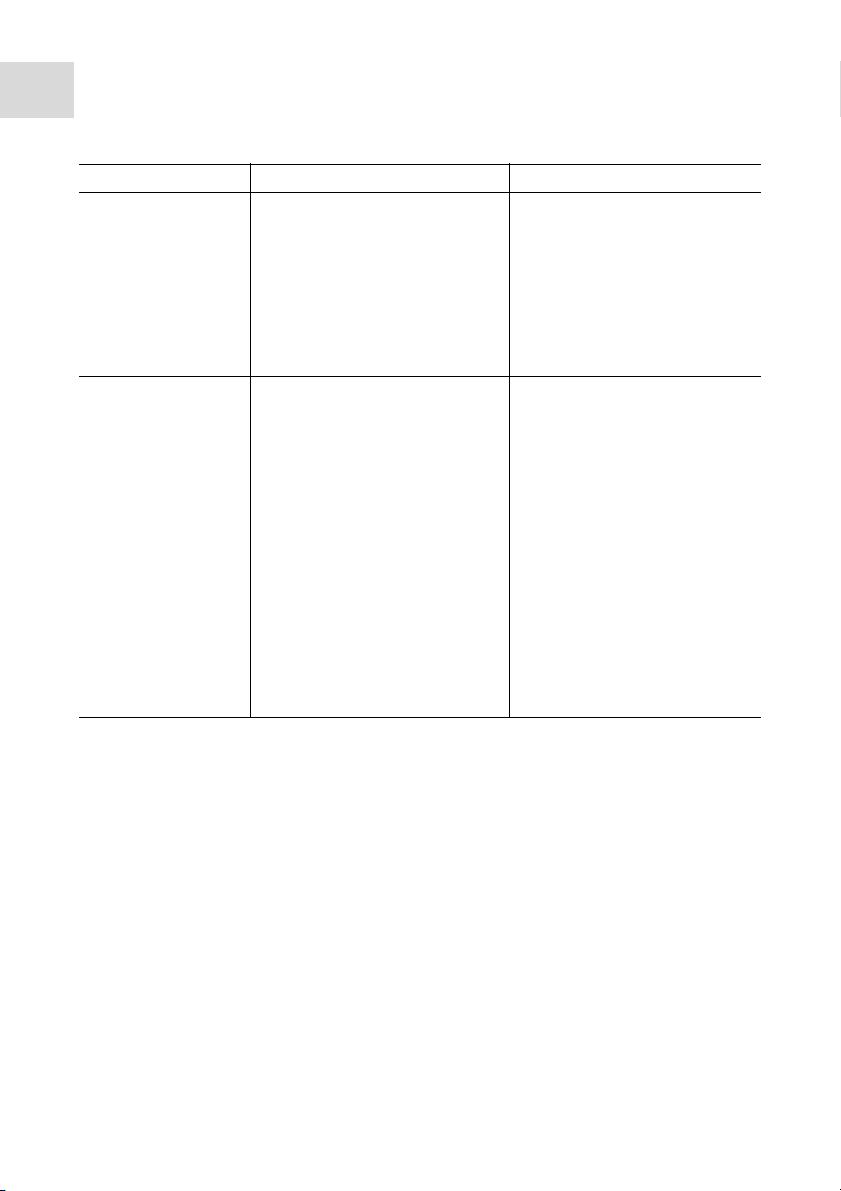

Error Cause Elimination

Liquid cannot be

aspirated correctly

or dripping occurs.

• Leakage in the Combitip

advanced.

• Combitip advanced has

heated up.

Replace the Combitip

advanced with a new

Combitip advanced.

Ensure that the

temperature is uniform as

the liquid expands when

heated.

The control button

is jammed, runs

jerky.

•The piston is

contaminated.

• The seal is contaminated.

Clean the piston and

lubricate slightly.

Disassemble the pipette,

clean all seals, replace if

necessary.

• The piston is damaged.

Replace the piston and

piston seal and lubricate

slightly.

• Penetration of solvent

vapors

Unscrew the lower part of

the pipette and aerate the

lower part.

Clean the piston and

lubricate slightly.

Page 17

Adjustment

Eppendorf SOP

English (EN)

7Adjustment

7.1 General information

Prior to delivery, all pipettes are adjusted with distilled or de-ionized, degassed

water under the conditions described in Chapters 1 to 3 and according to ISO

3696 (see Calibration on p. 8).

If you have doubts regarding the accuracy of the volume entered, please check

the following points first:

• Is there a leak in the device (see Leakage check on p. 15)?

Exception: Biomaster

• Does the temperature of the pipetted liquid correspond to:

– the temperature of the device?

– the ambient air temperature?

• Is the set volume correct?

• Has the liquid density and air pressure been taken into consideration?

• Does the density of the pipetted liquid deviate from the double-distilled,

degassed water?

• Was the work completed correctly, as described in the "Calibration" chapter

(see p. 8) and "Evaluation" chapter (see p. 11)?

• Were original Eppendorf pipette tips used?

Volume errors can also occur when pipetting liquids with high vapor pressure,

where the density or viscosity deviates considerably from the values of water.

Adjustments should only be carried out on the device after these conditions have

been taken into consideration.

17

7.2 Adjusting adjustable-volume pipettes

Observe the operating instructions for your pipette. There you will find

detailed descriptions on adjustment.

The adjustment of the following adjustable-volume pipettes is a zero point offset:

• Research

• Research plus

• Reference

•Biomaster

• Reference2

Page 18

Adjustment

18

Eppendorf SOP

English (EN)

7.2.1 Procedure

Requirements

Device, original Eppendorf tip, test liquid and ambient air must have the same

temperature (15 – 30°C) at a constant temperature of ±0.5°C during the test

(according to EN ISO 8655, Part 6).

If your Research, Research plus or Reference has an adjustment, remove

it before carrying out the adjustment.

After adjusting, lock the adjustment opening with a new adjustment

seal.

Adjustment seals can be reordered (see operating manual).

1. Set the pipette to the smallest volume to be tested.

2. Use a matching original Eppendorf tip for single-channel pipettes. For

Multi-channel pipettes, use any channel.

3. Pipette the set volume 10 times.

4. Conduct a weighing after every volume dispensing.

5. Calculate the mean value after 10 measurements (see Evaluation on p. 11).

The calculated mean value of these weighings (observe conversion factor Z =

mg to µL) yields the actual volume.

6. For adjusting, introduce the suitable tool into the opening intended for this

purpose, or place it on the designated location, and adjust the actual volume

(see the following figures or operating manual).

7. Check the set volume by measuring again. If the target volume does not

match the result of the measurement, repeat steps 2 to 6.

8. After the adjustment, check the measured values for accuracy at 50% of the

nominal volume and check the nominal volume for accuracy.

Page 19

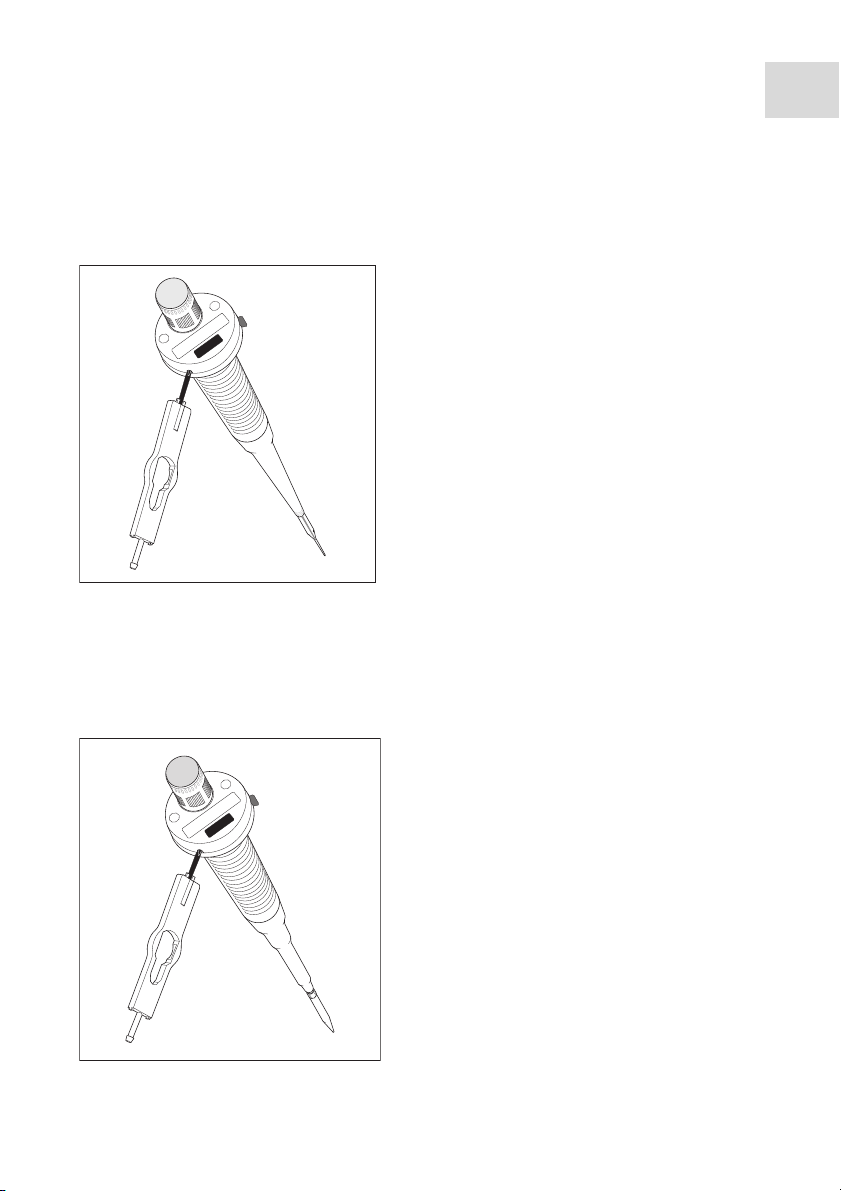

7.2.2 Biomaster

1

0

2

0

Auxiliary equipment

• Supplied pipette wrench (order no. 4910 092.001)

1. Use the pipette wrench to adjust the

volume display of the pipette, with

the piston stroke unchanged, to the

actual volume value of the

measurement.

2. Pull off the pipette wrench.

3. Set the pipette to the target volume

in the usual manner.

4. Mark the adjustment on the pipette.

7.2.3 Reference variable

Adjustment

Eppendorf SOP

English (EN)

19

Auxiliary equipment

• Supplied pipette wrench (order no. 4910 092.001)

• Supplied red CAL seal

1. Insert side B of the pipette wrench

into the adjustment opening in the

lid.

0

6

2

6

2. Using the pipette wrench, set the

digital display of the pipette, with

unaltered piston stroke, to the actual

volume value of the measurement.

3. Pull off the pipette wrench.

4. Set the pipette to the target volume

in the usual manner.

5. After the adjustment has been

successfully completed, lock the

adjustment opening with a red CAL

seal.

Page 20

Adjustment

Reference 2

ADJ

Reference 2

Reference 2

20

Eppendorf SOP

English (EN)

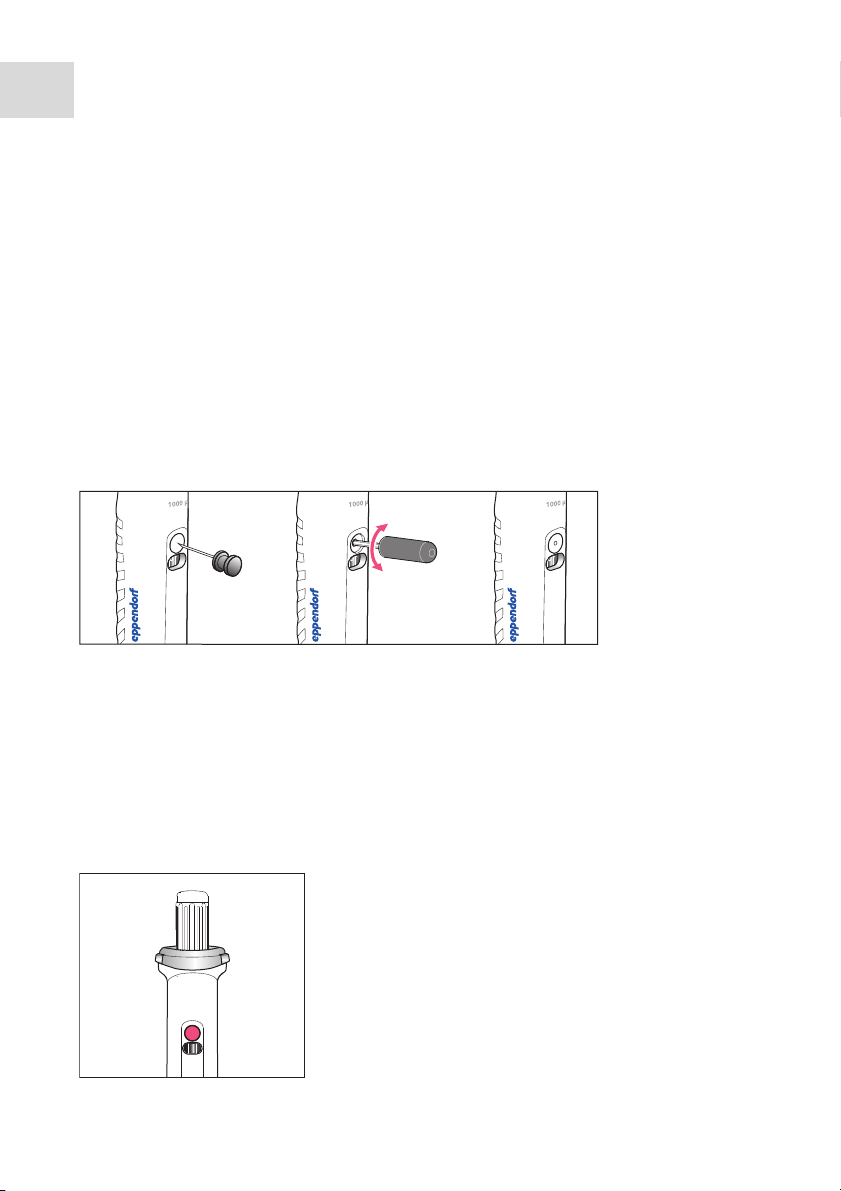

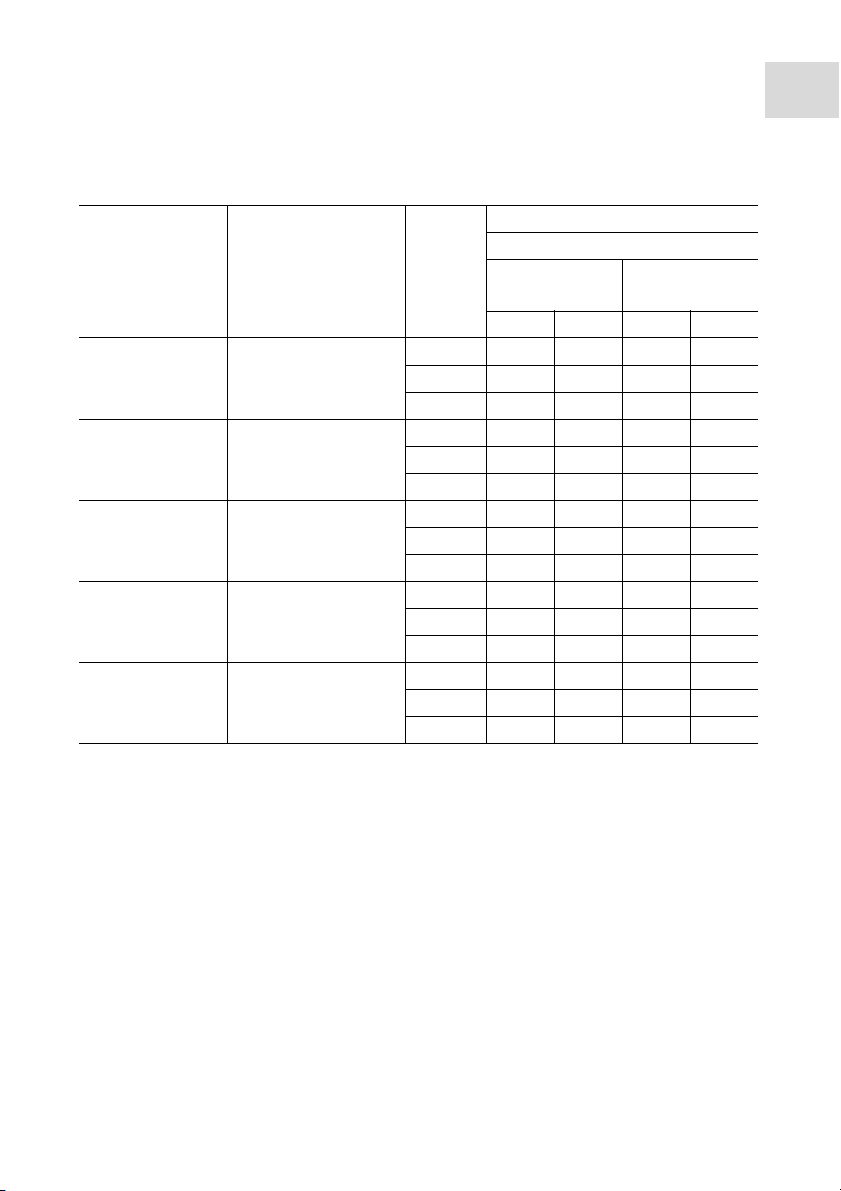

7.2.4 Reference 2 adjustable-volume

7.2.4.1 User adjustment

Changing the adjustment will change the volume by a specific value. Strictly

speaking, the change only applies to the testing volume.

Example:

You readjust a 10 – 100 µL pipette, with a volume setting of 100 µL, by 1 µL

(1 µL 1%). If the volume setting is 10 µL, the pipette is also adjusted by 1 µL

( 10%).

Auxiliary aids from the delivery package

•Pin

• Red plastic adjustment seal (ADJ)

1. Insert the pin in the middle of the gray adjustment seal (ADJ).

2. Remove the adjustment seal.

3. Insert the adjustment tool.

4. Turn the adjustment tool until the adjustment display shows the desired

value.

5. Read the set value distortion-free using the aligning aid in the viewing

window.

6. Carry out weighings to check the accuracy and precision.

1000 µL

ADJ

+-

11

Page 21

Adjustment

Eppendorf SOP

English (EN)

7. Attach the red adjustment seal after the inspections.

If the adjustment only applies to a specific liquid, mark the pipette accordingly.

Use the labeling area on the pipette and mark it with the liquid and the volume.

Carry out a gravimetric test for each adjustment change. Follow the EN ISO

8655-2 and EN ISO 8655-6 test procedures.

7.2.4.2 Changing the factory adjustment

Auxiliary aids from the delivery package

• Red plastic safety plug

•Pin

The factory adjustment can be changed using the

corresponding accessories.

The factory adjustment will be marked by a safety plug.

The color of the safety plug indicates the implementing

authority:

ADJ

•Gray - Eppendorf AG

• Red - User

21

The random and systematic errors recorded on delivery can be found in the .

This certificate is included in delivery. The certificate is no longer valid if the

default settings have been changed.

If the dispensing accuracy is only be to changed temporarily, the correct method

is to change the user adjustment. Before changing the user or factory

adjustment, observe the general notes and the associated gravimetric tests.

For the factory setting, the volume display will be set to match the piston stroke

and the detected actual volume. If a gravimetric test indicates that an error

needs to be corrected and you will be required to change to factory adjustment,

proceed as follows:

Page 22

Adjustment

e

e

e

22

Eppendorf SOP

English (EN)

ADJ

1. Check whether the adjustment display is set

to "0".

If the adjustment display is not set to “0”, it

must be set to “0” first using the adjustment

1000 µL

tool. In this case, instead of continuing with

the factory adjustment changes, carry out a

ADJ

+-

11

gravimetric test of the Reference2 with the

adjustment display set to "0".

2. Use the plug to pierce the safety plug, and

remove it.

R

3. Insert the adjustment tool.

ADJ

R

4. Hold the control button with one

hand.

ADJ

R

Page 23

Adjustment

e

Eppendorf SOP

English (EN)

5. Turn the adjustment tool to set the volume display. Set the volume display

(from the volume setting used during the inspection to the calculated volume

of the gravimetric test). The volume change applies to the entire volume

range. For the volume change, you should initially set the value for 10% of

the nominal volume of the value calculated during the gravimetric test. Then

carry out gravimetric tests to check 50% and 100% of the nominal volume

with this setting. If necessary, change the selected setting again to achieve

the best possible correction for all volumes. Use the error limits in accordance

with ISO 8655-2 and the technical data provided by Eppendorf AG to decide

whether the data obtained meets your requirements.

6. Carry out a gravimetric check of the changes that have been completed.

7. Insert the red safety plug into the

adjustment opening.

The red safety plug on the pipette indicates

that the pipette has been adjusted and

calibrated by the user.

ADJ

R

23

8. Record executed changes and measurements.

Page 24

Adjustment

200

200

Research

C

B

A

D

24

Eppendorf SOP

English (EN)

7.2.5 Research variable

Auxiliary equipment

• Supplied pipette wrench (order no. 3111 501.016)

• Supplied red CAL seal

1. Insert side D of the pipette wrench

vertically into the lateral adjustment

opening of the pipette grip.

2. Move the pipette wrench into the

vertical position.

3. Turn the volume setting ring toward

– or +.

This adjusts the piston stoke of the

pipette. The digital display does not

change in the process.

4. A revolution corresponds to:

Volume range Vol. per revolution

0.1 – 2.5 µL approx. 0.1 µL

0.5 - 10 µL approx. 0.5 µL

2 - 20 µL approx. 1 µL

10 - 100 µL approx. 5 µL

20 - 200 µL approx. 10 µL

100 - 1 000 µL approx. 50 µL

500 - 5 000 µL approx. 250 µL

1 - 10 mL approx. 510 µL

5. Pull off the pipette wrench.

6. Move the volume setting ring slightly forwards and backwards so that the

counting and stroke systems engage again.

7. After the adjustment has been successfully completed, lock the adjustment

opening with a red CAL seal.

Page 25

Adjustment

Eppendorf SOP

English (EN)

7.2.6 Research plusadjustable volume - adjustment to

environmental parameters

Adjustment change for specific liquid densities, changed altitudes or pipette tips

that are not used to calculate the random and systematic error.

The Research plus was adjusted, tested and fitted with a gray adjustment seal

with the abbreviation "ADJ" before delivery. The adjustment display on the side

reads "0". Changing the adjustment will change the volume by a specific value.

Strictly speaking, the change only applies to the testing volume.

Auxiliary equipment

• Supplied adjustment tool (order no. 3120 633.006)

• Supplied red adjustment seal (ADJ)

25

1. Remove the gray adjustment seal.

2. Keep the ejector pressed.

3. Insert the adjustment tool (from the delivery package).

4. Turn the adjustment tool until the adjustment display shows the desired value.

5. Place the Research plus on a horizontal

surface (table). When completing the

adjustment, look absolutely vertically at the

window and read the set value via the

backsight in the viewing window.

6. Carry out weighing procedures to check the accuracy and precision.

7. After the tests, close the opening with the red adjustment seal (from the

delivery package).

If the adjustment only applies to a specific liquid, mark the pipette accordingly.

Use the labeling area on the pipette and mark it with the liquid and the volume.

Page 26

Adjustment

26

Eppendorf SOP

English (EN)

7.2.7 Research plus adjustable volume - change to the factory

adjustment

Auxiliary equipment

• Supplied safety plug tool

• Supplied pin to loosen the safety plug

The factory adjustment can be changed with

the corresponding accessories on a Research

plus with variable volume setting.

You can recognize a change to the factory adjustment that was made by the user

of the Research plus from the red safety plug behind the ejector. If the Research

plus has been adjusted and calibrated by Eppendorf AG, this is indicated by a

gray safety plug.

1. Check whether the adjustment display on

the side is set to “0”.

If the adjustment display is not set to “0”, it

must be set to “0” first using the adjustment

tool. In this case, instead of continuing with

the factory adjustment changes, carry out a

gravimetric test of the Research plus with

the adjustment display set to “0”.

Page 27

Adjustment

Eppendorf SOP

English (EN)

2. Provide the volume setting ring and the

ejector with a common mark with a pen.

This mark is used for orientation purposes

when changing the factory adjustment.

When changing the factory adjustment, you

can turn the volume setting ring without

changing the volume display. The mark on

the volume setting ring and the ejector

informs you how far you have moved from

the factory setting.

3. Keep the ejector pressed and remove the

safety plug with the pin.

27

Page 28

Adjustment

28

Eppendorf SOP

English (EN)

4. Continue to keep the ejector pressed. Insert

the safety plug tool in such a way that the

counter locking mechanism is pushed down.

5. Turn the volume setting ring slightly to

change the volume. Proceed as shown in the

illustration.

Page 29

6. This results in the following approximate volume changes:

single-channel

Nominal volume

Color code

2.5 µL

+½

revolution

+¼

revolution

–¼

revolution

0.106 µL 0.053 µL -0.053 µL -0.106 µL

Dark gray

10 µL

0.53 µL 0.27 µL -0.27 µL -0.53 µL

Medium gray

20 µL

1.06 µL 0.53 µL -0.53 µL -1.06 µL

light gray

20 µL

1.07 µL 0.54 µL -0.54 µL -1.07 µL

Yellow

100 µL

5.4 µL 2.7 µL -2.7 µL -5.4 µL

Yellow

200 µL

10.8 µL 5.4 µL -5.4 µL -10.8 µL

Yellow

300 µL

10.7 µL 5.4 µL -5.4 µL -10.7 µL

Orange

1,000 µL

54 µL 27 µL -27 µL -54 µL

Blue

5 mL

271 µL 135 µL -135 µL -271 µL

Purple

10 mL

542 µL 271 µL -271 µL –542 µL

Turquoise

Adjustment

Eppendorf SOP

English (EN)

–½

revolution

29

multi-channel

Nominal volume

Color code

10 µL

+½

revolution

+¼

revolution

–¼

revolution

–½

revolution

0.53 µL 0.27 µL -0.27 µL -0.53 µL

Medium gray

100 µL

5.4 µL 2.7 µL -2.7 µL -5.4 µL

Yellow

300 µL

10.7 µL 5.4 µL -5.4 µL -10.7 µL

Orange

The values mentioned are theoretical values and are for orientation purposes

only. The volume changes mentioned apply to each volume setting.

Page 30

Adjustment

30

Eppendorf SOP

English (EN)

7. Push the locking mechanism upwards and

carry out a gravimetric test of the changes

made.

8. If the values measured during the

gravimetric test meet your requirements:

insert the red safety plug in the tool in the

opening of the Research plus and snap it off

the tool.

The red safety plug on the pipette indicates

that the Research plus has been adjusted

and calibrated by the user. If the adjustment

display had also been set to "0" previously,

you must close the opening with a new, red

adjustment seal at the position for the

adjustment seal.

9. Document the changes made and the measurements conducted. Remove the

mark on the volume setting ring and on the ejector. The red safety plug on the

pipette indicates that the Research plus has been adjusted and calibrated by

the user.

Page 31

7.2.8 Research Multi-channel

C

B

A

D

Auxiliary equipment

• Supplied pipette wrench (order no. 3111 501.016)

•Supplied red ADJ seal

1. Insert the D side of the pipette

wrench horizontally into the

adjustment opening on the side of

the pipette grip.

2. Move the pipette wrench into the

vertical position.

3. Turn the volume setting ring toward

– or +. This adjusts the piston stoke

of the pipette. The digital display

does not change in the process.

Adjustment

Eppendorf SOP

English (EN)

31

4. A revolution corresponds to:

Volume range Vol./turn

0.5 - 10 µL approx. 0.5 µL

10 - 300 µL approx. 5 µL

30 µL approx. 10 µL

5. Pull off the pipette wrench.

6. Move the volume setting ring slightly forwards and backwards so that the

counting and stroke systems engage again.

7. After the adjustment has been successfully completed, lock the adjustment

opening with a red ADJ-seal.

7.2.9 Research plus Multi-channel

Carry out the adjustment as described for the Research plus single-channel

pipette (see p. 25).

Page 32

Adjustment

32

Eppendorf SOP

English (EN)

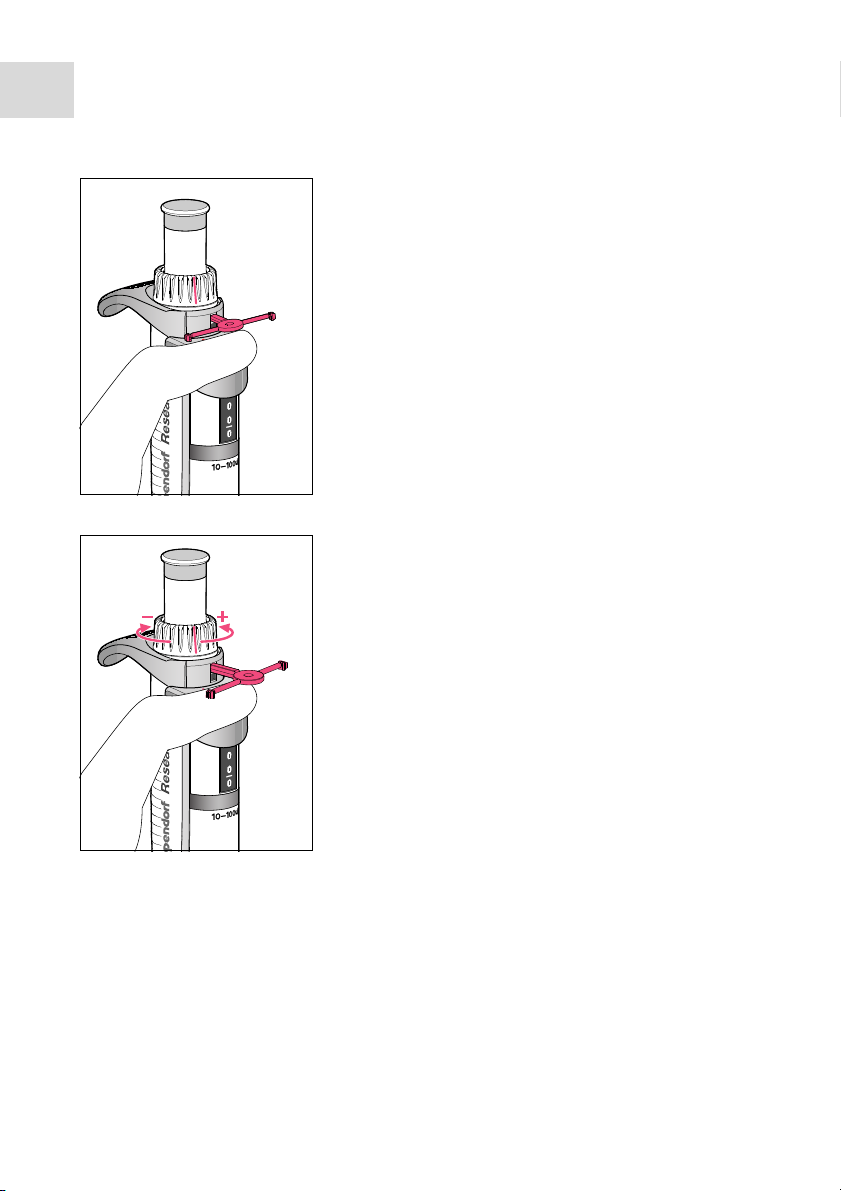

7.2.10 Varispenser plus

7.2.11 Xplorer and Xplorer plus

The re-adjustment of the Xplorer pipette is described on the CD which is

enclosed with the pipette.

If you have selected a different adjustment in the Xplorer

pipette options, a wrench symbol will be displayed in the

header of the display.

Turn the fine adjustment toward + or

–. A revolution corresponds to the

smallest dispensing step:

Reduce volume:

Turn toward -.

Increase volume:

Turn toward +.

The factory adjustment was carried out

at 20 °C, using double-distilled,

degassed water.

Another symbol showing the selected adjustment is

displayed to the right of the wrench symbol. If you are

changing back to the factory adjustment at a later stage,

the previously selected adjustment will be deleted and

both symbols will disappear from the header.

Page 33

Adjustment

Eppendorf SOP

English (EN)

7.3 Adjusting fixed-volume pipettes

The adjustment process for fixed-volume pipettes is identical to the adjustment

process for variable pipettes

(see Adjusting adjustable-volume pipettes on p. 17)

For fixed-volume pipettes, 10 measured values of the nominal volume are checked.

7.3.1 Reference fixed

Auxiliary equipment

• Adhesive label as an adjusting aid for the basic setting

• Supplied pipette wrench (order no. 4910 092.001)

1. In order to simplify relocating the basic

setting, attach the adhesive label

0

4

4

0

supplied as an adjusting aid to the

control button.

2. Using the B side of the pipette wrench,

loosen the inside screw until the control

button can be turned.

3. Set the control button to the calculated

actual volume value of the measurement

(see Adjusting adjustable-volume

pipettes on p. 17).

.

33

One revolution of the control button corresponds to the following (based on water):

Reference fixed-volume Vol./turn

1, 2, 5, 10 µL approx. 0.5 µL

10, 20 µL approx. 1 µL

25, 50 µL approx. 2.4 µL

100 µL approx. 5 µL

200, 250 µL approx. 12 µL

500, 1 000 µL approx. 46 µL

1 500, 2 000, 2 500 µL approx. 118 µL

Page 34

Adjustment

C

B

A

D

34

Eppendorf SOP

English (EN)

7.3.2 Reference2

Adjustment is carried out as described for the Reference 2 adjustable-volume

(see p. 20).

7.3.3 Research fixed

Auxiliary equipment

• Supplied pipette wrench (order no. 3111 501.016)

1. Insert side D of the pipette wrench

vertically into the lateral adjustment

opening of the pipette grip.

2. Move the tool into the vertical

position.

3. Turn the volume setting ring toward

– or +. This adjusts the piston stoke

of the pipette.

With reference to water, one revolution of the volume setting ring corresponds to:

Volume range Vol./turn

10 approx. 0.8 µL

20 approx. 0.8 µL

25 approx. 0.8 µL

50 approx. 0.8 µL

100 approx. 0.8 µL

200 approx. 38 µL

250 approx. 38 µL

500 approx. 38 µL

1 000 approx. 38 µL

Page 35

Adjustment

Eppendorf SOP

English (EN)

7.3.4 Research plus fixed

Adjustment is carried out as described for the Research plus

adjustable-volume(see p. 25).

7.4 Physical influences of liquids

It is possible to adjust the previously described devices for a volume of a liquid

with a different density than water so that the displayed volume value

corresponds to the pipetted volume.

With adjustable-volume pipettes, all other values are then readjusted, as

the adjustable-volume pipette then becomes a fix-volume pipette.

The adjustment process is comparable to the described procedure (see p. 18).

The difference is that the mean value of the weighings is converted to

microliters according to the formula:

.

35

1. Determine the mean value and convert it to microliters.

The calculated value is the nominal value.

2. The digital display of variable pipettes, or the volume of fix-volume pipettes,

must be set to the calculated actual value.

3. Check the value set for the liquid gravimetrically. The accordingly set device

only delivers a dispensing value, which corresponds to the digital display, for

the used liquid and set volume.

4. If necessary correct and check the setting.

5. Label the measuring device following adjustment with the measured value

and the name of the liquid which was used for the adjustment.

Following adjustment, the certificate accompanying the pipette

becomes invalid.

Page 36

Factor Z for distilled water

36

Eppendorf SOP

English (EN)

8 Factor Z for distilled water

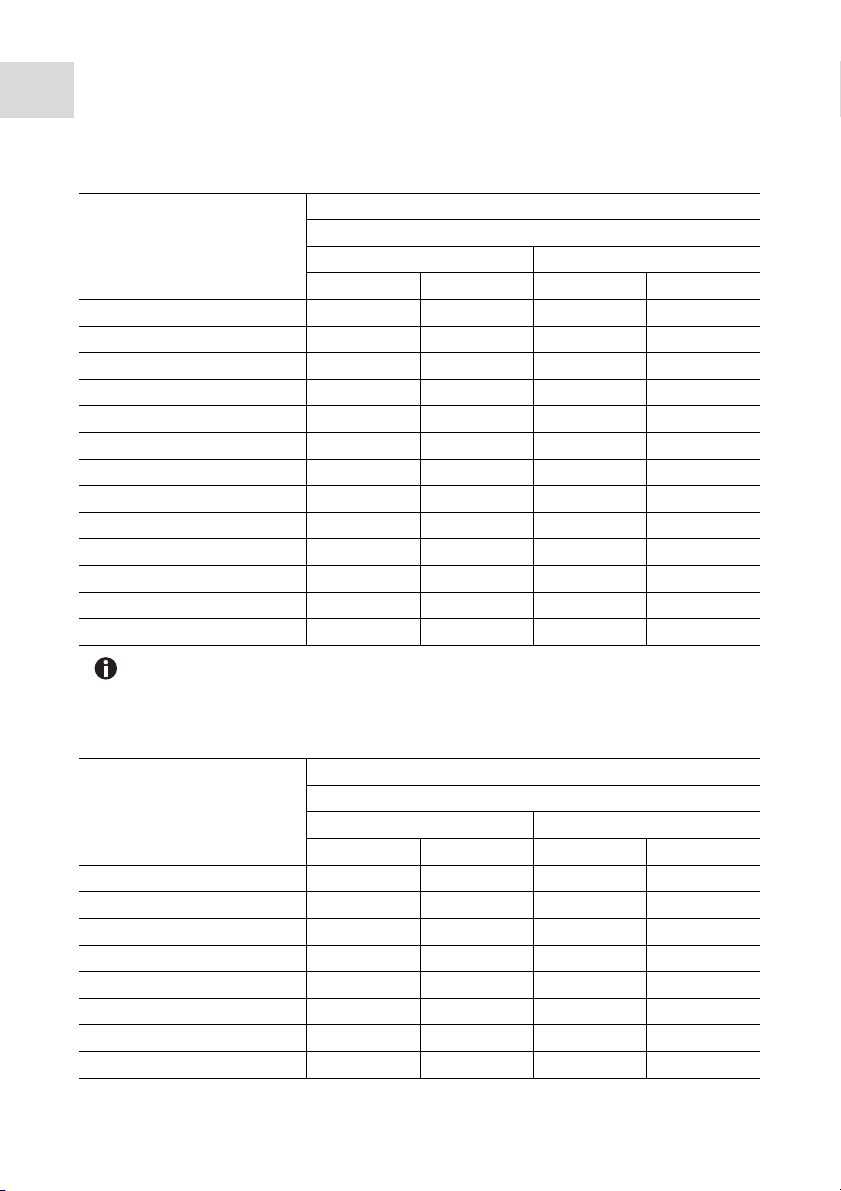

8.1 Factor Z overview table

Factor Z (µl/mg) in accordance with EN ISO 8655 for distilled water depending

on test temperature and air pressure:

Tem pera ture

(°C)

15

15.5

16

16.5

17

17.5

18

18.5

19

19.5

20

20.5

21

21.5

22

22.5

23

23.5

24

24.5

25

25.5

26

26.5

27

27.5

28

28.5

29

29.5

30 1.0052 1.0052 1.0053 1.0053 1.0054 1.0054 1.0054

80 85 90 95 100 101.3 105

1.0017

1.0018

1.0019

1.0020

1.0021

1.0022

1.0022

1.0023

1.0024

1.0025

1.0026

1.0027

1.0028

1.0030

1.0031

1.0032

1.0033

1.0034

1.0035

1.0037

1.0038

1.0039

1.0040

1.0042

1.0043

1.0045

1.0046

1.0047

1.0049

1.0050

1.0018

1.0019

1.0020

1.0020

1.0021

1.0022

1.0023

1.0024

1.0025

1.0026

1.0027

1.0028

1.0029

1.0030

1.0031

1.0032

1.0033

1.0035

1.0036

1.0037

1.0038

1.0040

1.0041

1.0042

1.0044

1.0045

1.0046

1.0048

1.0049

1.0051

Air pressure (kPa)

1.0019

1.0019

1.0020

1.0021

1.0022

1.0023

1.0023

1.0024

1.0025

1.0026

1.0027

1.0028

1.0029

1.0031

1.0032

1.0033

1.0034

1.0035

1.0036

1.0038

1.0039

1.0040

1.0041

1.0043

1.0044

1.0046

1.0047

1.0048

1.0050

1.0051

1.0019

1.0020

1.0021

1.0021

1.0022

1.0023

1.0024

1.0025

1.0026

1.0027

1.0028

1.0029

1.0030

1.0031

1.0032

1.0033

1.0034

1.0036

1.0037

1.0038

1.0039

1.0041

1.0042

1.0043

1.0045

1.0046

1.0047

1.0049

1.0050

1.0052

1.0020

1.0020

1.0021

1.0022

1.0023

1.0024

1.0025

1.0025

1.0026

1.0027

1.0028

1.0029

1.0031

1.0032

1.0033

1.0034

1.0035

1.0036

1.0037

1.0039

1.0040

1.0041

1.0042

1.0044

1.0045

1.0047

1.0048

1.0049

1.0051

1.0052

1.0020

1.0020

1.0021

1.0022

1.0023

1.0024

1.0025

1.0026

1.0027

1.0028

1.0029

1.0030

1.0031

1.0032

1.0033

1.0034

1.0035

1.0036

1.0038

1.0039

1.0040

1.0041

1.0043

1.0044

1.0045

1.0047

1.0048

1.0050

1.0051

1.0052

1.0020

1.0021

1.0022

1.0022

1.0023

1.0024

1.0025

1.0026

1.0027

1.0028

1.0029

1.0030

1.0031

1.0032

1.0033

1.0034

1.0036

1.0037

1.0038

1.0039

1.0040

1.0042

1.0043

1.0044

1.0046

1.0047

1.0048

1.0050

1.0051

1.0053

Page 37

Technical specifications

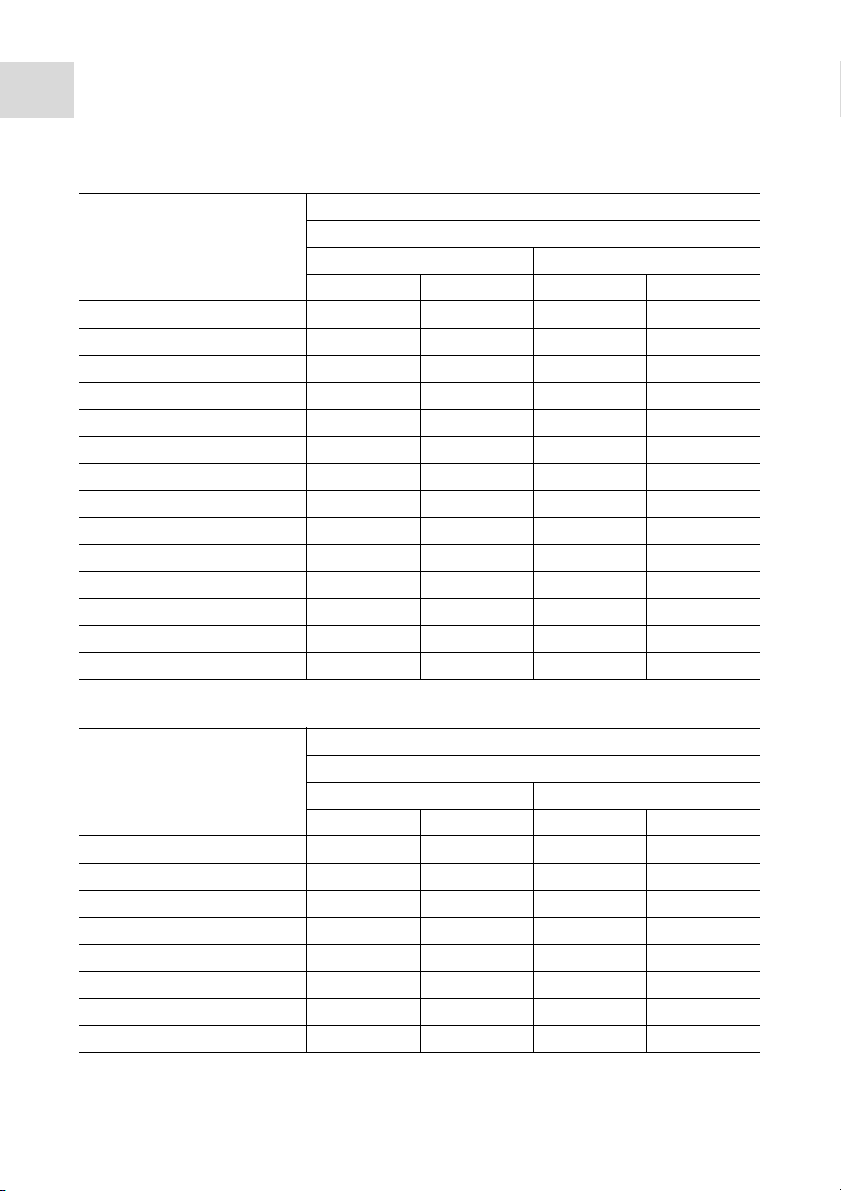

9 Technical specifications

The following specifications are valid for the following conditions:

Liquid: Distilled or deionized water

Reference temperature: 20 °C to 25 °C ±0.5 °C

Number of

determinations:

Technical specifications subject to change!

10, in accordance with EN ISO 8655 with original

Eppendorf pipette tips

9.1 Fixed-volume pipettes

9.1.1 Reference fixed

Eppendorf SOP

English (EN)

37

Model Test tip

epT.I.P.S. Color code

Volume range

Length

1 µL light gray

2 µL ±2.0 ±0.04 ±1.2 ±0.024

5 µL ±1.5 ±0.075 ±0.8 ±0.04

10 µL ±1.0 ±0.1 ±0.5 ±0.05

10 µL Yellow

20 µL ±0.8 ±0.16 ±0.3 ±0.06

25 µL ±0.8 ±0.2 ±0.3 ±0.075

50 µL ±0.7 ±0.35 ±0.3 ±0.15

100 µL ±0.6 ±0.6 ±0.2 ±0.2

200 µL Blue

250 µL ±0.6 ±1.5 ±0.2 ±0.5

500 µL ±0.6 ±3.0 ±0.2 ±1.0

1,000 µL ±0.6 ±6.0 ±0.2 ±2.0

1 500 µL Red

2 000 µL ±0.6 ±12 ±0.2 ±4.0

2,500 µL ±0.6 ±15 ±0.2 ±5.0

0.5 - 20 L L

46 mm

2 - 200 µL

53 mm

50 - 1 000 µL

71 mm

500 – 2 500 µL

115 mm

Systematic error Random error

± % ± µL ± % ± µL

±2.5 ±0.025 ±1.8 ±0.018

±1.0 ±0.1 ±0.5 ±0.05

±0.6 ±1.2 ±0.2 ±0.4

±0.6 ±9.0 ±0.2 ±3.0

Error limits

Error

Page 38

Technical specifications

38

Eppendorf SOP

English (EN)

9.1.2 Reference 2 fixed

Fixed-volume Reference2

Model Test tip

epT.I.P.S. Color code

Volume range

Length

1 µL Dark gray

2 µL ±2.0 ±0.04 ±1.2 ±0.024

0.1 µL – 10 µL

34 mm

5 µL Medium gray

10 µL ±1.0 ±0.1 ±0.5 ±0.05

0.1 µL – 20 µL

40 mm

20 µL light gray

0.5 µL – 20 µL L

46 mm

10 µL Yellow

20 µL ±1.0 ±0.2 ±0.3 ±0.06

25 µL ±1.0 ±0.25 ±0.3 ±0.075

2 L – 200 µL

53 mm

50 µL ±0.7 ±0.35 ±0.3 ±0.15

100 µL ±0.6 ±0.6 ±0.2 ±0.2

200 µL ±0.6 ±1.2 ±0.2 ±0.4

200 µL Blue

250 µL ±0.6 ±1.5 ±0.2 ±0.5

500 µL ±0.6 ±3.0 ±0.2 ±1.0

50 µL – 1 000 µL

71 mm

1,000 µL ±0.6 ±6.0 ±0.2 ±2.0

Eppendorf AG error limits

Error

Systematic error Random error

± % ± µL ± % ± µL

±2.5 ±0.025 ±1.8 ±0.018

±1.2 ±0.06 ±0.6 ±0.03

±0.8 ±0.16 ±0.3 ±0.06

±1.2 ±0.12 ±0.6 ±0.06

±0.6 ±1.2 ±0.2 ±0.4

Fixed-volume Reference2

Model Test tip

epT.I.P.S. Color code

Volume range

Length

2.0 mL Red

2.5 mL ±0.6 ±0.015 ±0.2 ±0.005

0.5 mL – 2.5 mL

Eppendorf AG error limits

Error

Systematic error Random error

± % ± mL ± % ± mL

±0.6 ±0.012 ±0.2 ±0,004

115 mm

Page 39

9.1.3 Research fixed

Technical specifications

Eppendorf SOP

English (EN)

39

Model Test tip

epT.I.P.S. Color code

Volume range

Length

10 µL Yellow

20 µL ±1.0 ±0.2 ±0.3 ±0.06

25 µL ±1.0 ±0.25 ±0.3 ±0.075

2 - 200 µL

53 mm

Systematic error Random error

± % ± µL ± % ± µL

±1.2 ±0.12 ±0.6 ±0.06

Error limits

Error

50 µL ±0.7 ±0.35 ±0.3 ±0.15

100 µL ±0.6 ±0.6 ±0.2 ±0.2

200 µL Blue

250 µL ±0.6 ±1.5 ±0.2 ±0.5

500 µL ±0.6 ±3.0 ±0.2 ±1.0

0.05 - 1 mL

71 mm

±0.6 ±1.2 ±0.2 ±0.4

1,000 µL ±0.6 ±6.0 ±0.2 ±2.0

Page 40

Technical specifications

40

Eppendorf SOP

English (EN)

9.1.4 Research plus fixed

Research plus fixed volume

Model Test tip

epT.I.P.S. Color

code

Volume range

Length

10 µL Medium gray

0.1 µL – 20 µL

40 mm

20 µL light gray

0.5 µL – 20 µL L

46 mm

10 µL Yellow

20 µL ±1.0 ±0.2 ±0.3 ±0.06

25 µL ±1.0 ±0.25 ±0.3 ±0.08

2 µL - 200 µL

53 mm

50 µL ±0.7 ±0.35 ±0.3 ±0.15

100 µL ±0.6 ±0.6 ±0.2 ±0.2

200 µL ±0.6 ±1.2 ±0.2 ±0.4

200 µL Blue

250 µL ±0.6 ±1.5 ±0.2 ±0.5

500 µL ±0.6 ±3.0 ±0.2 ±1.0

50 µL – 1 000 µL

71 mm

1,000 µL ±0.6 ±6.0 ±0.2 ±2.0

Eppendorf AG error limits

Error

Systematic

Random error

error

± %± µL± %± µL

±1.2 ±0.12 ±0.6 ±0.06

±0.8 ±0.16 ±0.3 ±0.06

±1.2 ±0.12 ±0.6 ±0.06

±0.6 ±1.2 ±0.2 ±0.4

Page 41

9.2 Adjusting adjustable volume pipettes

9.2.1 Reference variable

Technical specifications

Eppendorf SOP

English (EN)

41

Model Test tip

epT.I.P.S. Color code

Volume range

Length

0.1 - 2.5 µL Dark gray

0.1 - 10 µL

34 mm

0.5 - 10 µL light gray

0.5 – 20 µL

46 mm

2 - 20 µL light gray

0.5 – 20 µL

46 mm

2 - 20 µL Yellow

2 - 200 µL

53 mm

10 - 100 µL Yellow

2 - 200 µL

53 mm

50 – 200 µL Yellow

2 - 200 µL

53 mm

50 – 250 µL Blue

50 - 1 000 µL

71 mm

100 – 1 000 µL Blue

50 – 1 000 µL

71 mm

500 – 2 500 µL Red

500 – 2 500 µL

115 mm

Tes ting

volume

Systematic error

Error limits

Error

Random error

± % ± µL ± % ± µL

0.25 µL ±12.0 ±0.03 ±6.0 ±0.015

1.25 µL ±2.5 ±0.031 ±1.5 ±0.019

2.5 µL ±1.4 ±0.035 ±0.7 ±0.018

1 µL ±2.5 ±0.025 ±1.8 ±0.018

5 µL ±1.5 ±0.075 ±0.8 ±0.04

10 µL ±1.0 ±0.1 ±0.4 ±0.04

2 µL ±3.0 ±0.06 ±2.0 ±0.04

10 µL ±1.0 ±0.1 ±0.5 ±0.05

20 µL ±0.8 ±0.16 ±0.3 ±0.06

2 µL ±5.0 ±0.1 ±1.5 ±0.03

10 µL ±1.2 ±0.12 ±0.6 ±0.06

20 µL ±1.0 ±0.2 ±0.3 ±0.06

10 µL ±3.0 ±0.3 ±0.7 ±0.07

50 µL ±1.0 ±0.5 ±0.3 ±0.15

100 µL ±0.8 ±0.8 ±0.15 ±0.15

50 µL ±1.0 ±0.5 ±0.3 ±0.15

100 µL ±0.9 ±0.9 ±0.3 ±0.3

200 µL ±0.6 ±1.2 ±0.2 ±0.4

50 µL ±1.4 ±0.7 ±0.3 ±0.15

100 µL ±1.1 ±1.1 ±0.3 ±0.3

250 µL ±0.6 ±1.5 ±0.2 ±0.5

100 µL ±3.0 ±3.0 ±0.3 ±0.3

500 µL ±1.0 ±5.0 ±0.2 ±1.0

1,000 µL ±0.6 ±6.0 ±0.2 ±2.0

0.5 mL ±1.5 ±7.5 ±0.3 ±1.5

1.25 mL ±0.8 ±10 ±0.2 ±2.5

2.5 mL ±0.6 ±15 ±0.2 ±5.0

Page 42

Technical specifications

42

Eppendorf SOP

English (EN)

9.2.2 Reference 2 adjustable-volume

Reference2 single-channel variable

Model Test tip

epT.I.P.S. Color code

Volume range

Length

0.1 µL – 2.5 µL

Increment:

0.002 µL

0.5 µL – 10 µL

Increment:

0.01 µL

2 µL – 20 µL

Increment:

0.02 µL

2 µL – 20 µL

Increment:

0.02 µL

10 µL – 100 µL

Increment:

0.1 µL

20 µL - 200 µL

Increment:

0.2 µL

30 µL – 300 µL

Increment:

0.2 µL

100 µL – 1 000 µL

Increment:

1 µL

Dark gray

0.1 µL – 10 µL

34 mm

Medium gray

0.1 µL – 20 µL

40 mm

light gray

0.5 µL – 20 µL L

46 mm

Yellow

2 µL - 200 µL

53 mm

Yellow

2 µL - 200 µL

53 mm

Yellow

2 µL - 200 µL

53 mm

Orange

20 µL – 300 µL

55 mm

Blue

50 µL – 1 000 µL

71 mm

Tes ting

volume

Eppendorf AG error limits

Error

Systematic

Random error

error

± % ± µL ± % ± µL

0.1 µL ±48.0 ±0.048 ±12.0 ±0.012

0.25 µL ±12.0 ±0.03 ±6.0 ±0.015

1.25 µL ±2.5 ±0.031 ±1.5 ±0.019

2.5 µL ±1.4 ±0.035 ±0.7 ±0.018

0.5 µL ±8.0 ±0.04 ±5.0 ±0.0025

1 µL ±2.5 ±0.025 ±1.8 ±0.018

5 µL ±1.5 ±0.075 ±0.8 ±0.04

10 µL ±1.0 ±0,10 ±0.4 ±0.04

2 µL ±5.0 ±0,10 ±1.5 ±0.03

10 µL ±1.2 ±0.12 ±0.6 ±0.06

20 µL ±1.0 ±0.20 ±0.3 ±0.06

2 µL ±5.0 ±0.12 ±1.5 ±0.03

10 µL ±1.2 ±0.12 ±0.6 ±0.06

20 µL ±1.0 ±0.2 ±0.3 ±0.06

10 µL ±3.0 ±0.3 ±0.7 ±0.07

50 µL ±1.0 ±0.5 ±0.3 ±0.15

100 µL ±0.8 ±0.8 ±0.2 ±0.2

20 µL ±2.5 ±0.5 ±0.7 ±0.14

100 µL ±1.0 ±1.0 ±0.3 ±0.3

200 µL ±0.6 ±1.2 ±0.2 ±0.4

30 µL ±2.5 ±0.75 ±0.7 ±0.21

150 µL ±1.0 ±1.5 ±0.3 ±0.45

300 µL ±0.6 ±1.8 ±0.2 ±0.6

100 µL ±3.0 ±3.0 ±0.6 ±0.6

500 µL ±1.0 ±5.0 ±0.2 ±1.0

1,000 µL ±0.6 ±6.0 ±0.2 ±2.0

Page 43

Reference2 single-channel variable

Model Test tip

epT.I.P.S. Color code

Volume range

Length

0.25 mL – 2.5 mL

Increment:

0.002 mL

0.5 mL – 5 mL

Increment:

0.005 mL

1 mL – 10 mL

Increment:

0.01 mL

Red

0.25 mL – 2.5 mL

115 mm

Purple

0.1 mL – 5 mL

120 mm

Turquoise

1 mL – 10 mL

165 mm

Tes ting

volume

Technical specifications

Eppendorf AG error limits

Systematic

error

Eppendorf SOP

English (EN)

Error

Random

error

± % ± mL ± % ± mL

0.25 mL ±4.8 ±0.012 ±1.2 ±0,003

1.25 mL ±0.8 ±0,010 ±0.2 ±0.0025

2.5 mL ±0.6 ±0.015 ±0.2 ±0.005

0.5 mL ±2.4 ±0.012 ±0.6 ±0,003

2.5 mL ±1.2 ±0,030 ±0.25 ±0.006

5.0 mL ±0.6 ±0,030 ±0.15 ±0.0075

1.0 mL ±3.0 ±0,030 ±0.6 ±0.006

5.0 mL ±0.8 ±0,040 ±0.2 ±0,010

10.0 mL ±0.6 ±0,060 ±0.15 ±0.015

43

Page 44

Technical specifications

44

Eppendorf SOP

English (EN)

9.2.3 Research adjustable-volume

Model Test tip

epT.I.P.S. Color code

Volume range

Length

0.1 - 2.5 µL Dark gray

0.1 - 10 µL

34 mm

0.5 - 10 µL light gray

0.5 – 20 µL L

46 mm

2 - 20 µL Yellow

2 - 200 µL

53 mm

10 - 100 µL Yellow

2 – 200 µL

53 mm

20 - 200 µL Yellow

2 - 200 µL

53 mm

100 –

1 000 µL

Blue

0.05 – 1 mL

71 mm

0.5 – 5 mL Purple

0.1 – 5 mL

120 mm

1 – 10 mL Turquoise

1 – 10 mL

165 mm

Tes ting

volume

Systematic

error

Error limits

Error

Random

error

± % ± µL ± % ± µL

0.25 µL ±12.0 ±0.03 ±6.0 ±0.015

1.25 µL ±2.5 ±0.031 ±1.5 ±0.019

2.5 µL ±1.4 ±0.035 ±0.7 ±0.018

1 µL ±2.5 ±0.025 ±1.8 ±0.018

5 µL ±1.5 ±0.075 ±0.8 ±0.04

10 µL ±1.0 ±0.1 ±0.4 ±0.04

2 µL ±5.0 ±0.1 ±1.5 ±0.03

10 µL ±1.2 ±0.12 ±0.6 ±0.06

20 µL ±1.0 ±0.2 ±0.3 ±0.06

10 µL ±3.0 ±0.3 ±1.0 ±0.1

50 µL ±1.0 ±0.5 ±0.3 ±0.15

100 µL ±0.8 ±0.8 ±0.2 ±0.20

20 µL ±2.5 ±0.5 ±0.7 ±0.14

100 µL ±1.0 ±1.0 ±0.3 ±0.3

200 µL ±0.6 ±1.2 ±0.2 ±0.4

100 µL ±3.0 ±3.0 ±0.6 ±0.6

500 µL ±1.0 ±5.0 ±0.2 ±1.0

1,000 µL ±0.6 ±6.0 ±0.2 ±2.0

0.5 mL ±2.4 ±12 ±0.6 ±3.0

2.5 mL ±1.2 ±30 ±0.25 ±6.25

5.0 mL ±0.6 ±30 ±0.15 ±7.5

1.0 mL ±3.0 ±30 ±0.6 ±6.0

5.0 mL ±0.8 ±40 ±0.2 ±10

10.0 mL ±0.6 ±60 ±0.15 ±15

Page 45

9.2.4 Research pro

Technical specifications

Eppendorf SOP

English (EN)

45

Model Test tip

epT.I.P.S. Color code

Volume range

Length

0.5 - 10 µL light gray

0.5 – 20 µL L

46 mm

5 - 100 µL Yellow

2 - 200 µL

53 mm

20 – 300 µL Orange

20 – 300 µL

55 mm

50 - 1 000 µL Blue

50 - 1 000 µL

71 mm

500 – 5 000 µL Purple

0.1 – 5 mL

120 mm

Tes ting

volume

Systematic

Error limits

error

Error

Random

error

± % ± µL ± % ± µL

1 µL ±2.5 ±0.025 ±1.8 ±0.018

5 µL ±1.5 ±0.075 ±0.8 ±0.04

10 µL ±1.0 ±0.1 ±0.4 ±0.04

10 µL ±2.0 ±0.2 ±1.0 ±0.1

50 µL ±1.0 ±0.5 ±0.3 ±0.15

100 µL ±0.8 ±0.8 ±0.2 ±0.2

30 µL ±2.5 ±0.75 ±0.7 ±0.21

150 µL ±1.0 ±1.5 ±0.3 ±0.45

300 µL ±0.6 ±1.8 ±0.2 ±0.6

100 µL ±3.0 ±3.0 ±0.6 ±0.6

500 µL ±1.0 ±5.0 ±0.2 ±1.0

1,000 µL ±0.6 ±6.0 ±0.2 ±2.0

0.5 mL ±3.0 ±15 ±0.6 ±3.0

2.5 mL ±1.2 ±30 ±0.25 ±6.25

5.0 mL ±0.6 ±30 ±0.15 ±7.5

Page 46

Technical specifications

46

Eppendorf SOP

English (EN)

9.2.5 Research plus adjustable-volume

Research plus adjustable single-channel

Model Test tip

epT.I.P.S. Color code

Volume range

Length

0.1 µL – 2.5 µL

Increment:

0.002 µL

0.5 µL – 10 µL

Increment:

0.01 µL

2 µL – 20 µL

Increment:

0.02 µL

2 µL – 20 µL

Increment:

0.02 µL

10 µµL – 100 µL

Increment:

0.1 µL

20 µL - 200 µL

Increment:

0.2 µL

30 µL – 300 µL

Increment:

0.2 µL

100 µL – 1 000 µL

Increment:

1 µL

Dark gray

0.1 µL – 10 µL

34 mm

Medium gray

0.1 µL – 20 µL

40 mm

light gray

0.5 µL – 20 µL L

46 mm

Yellow

2 µL - 200 µL

53 mm

Yellow

2 µL - 200 µL

53 mm

Yellow

2 µL - 200 µL

53 mm

Orange

20 µL – 300 µL

55 mm

Blue

50 µL – 1 000 µL

71 mm

Tes ting

volume

Eppendorf AG error limits

Error

Systematic

error

Random

error

± % ± µL ± % ± µL

0.1 µL ±48 ±0.048 ±12 ±0.012

0.25 µL ±12 ±0.03 ±6.0 ±0.015

1.25 µL ±2.5 ±0.031 ±1.5 ±0.019

2.5 µL ±1.4 ±0.035 ±0.7 ±0.018

0.5 µL ±8.0 ±0.04 ±5.0 ±0.025

1 µL ±2.5 ±0.025 ±1.8 ±0.018

5 µL ±1.5 ±0.075 ±0.8 ±0.04

10 µL ±1.0 ±0.1 ±0.4 ±0.04

2 µL ±5.0 ±0.1 ±1.5 ±0.03

10 µL ±1.2 ±0.12 ±0.6 ±0.06

20 µL ±1.0 ±0.2 ±0.3 ±0.06

2 µL ±5.0 ±0.1 ±1.5 ±0.03

10 µL ±1.2 ±0.12 ±0.6 ±0.06

20 µL ±1.0 ±0.2 ±0.3 ±0.06

10 µL ±3.0 ±0.3 ±1.0 ±0.1

50 µL ±1.0 ±0.5 ±0.3 ±0.15

100 µL ±0.8 ±0.8 ±0.2 ±0.2

20 µL ±2.5 ±0.5 ±0.7 ±0.14

100 µL ±1.0 ±1.0 ±0.3 ±0.3

200 µL ±0.6 ±1.2 ±0.2 ±0.4

30 µL ±2.5 ±0.75 ±0.7 ±0.21

150 µL ±1.0 ±1.5 ±0.3 ±0.45

300 µL ±0.6 ±1.8 ±0.2 ±0.6

100 µL ±3.0 ±3.0 ±0.6 ±0.6

500 µL ±1.0 ±5.0 ±0.2 ±1.0

1,000 µL ±0.6 ±6.0 ±0.2 ±2.0

Page 47

Research plus adjustable single-channel

Model Test tip

epT.I.P.S. Color code

Tes ting

volume

Volume range

Length

0.5 µL – 5 mL

Increment:

0.005 mL

1 µL – 10 mL

Increment:

0.01 mL

Purple

0.1 µL – 5 mL

120 mm

Turquoise

1 µL – 10 mL

165 mm

0.5 mL ±2.4 ±12 ±0.6 ±3.0

2.5 mL ±1.2 ±30 ±0.25 ±6.0

5.0 mL ±0.6 ±30 ±0.15 ±8.0

1.0 mL ±3.0 ±30 ±0.6 ±6.0

5.0 mL ±0.8 ±40 ±0.2 ±10

10.0 mL ±0.6 ±60 ±0.15 ±15

9.2.6 Biomaster

Technical specifications

Eppendorf SOP

English (EN)

Eppendorf AG error limits

Error

Systematic

error

Random

error

± % ± µL ± % ± µL

47

Model Pipette tip Testing

volume

Systematic error

Error limits

Error

Random error

± % ± µL ± % ± µL

Biomaster 4830 Mastertip 2 µL ±6.0 ±0.12 ±4.0 ±0.08

3 µL ±5.0 ±0.15 ±3.0 ±0.09

5 µL ±4.0 ±0.2 ±2.0 ±0.1

10 µL ±3.0 ±0.3 ±1.5 ±0.15

20 µL ±2.5 ±0.5 ±0.8 ±0.16

9.2.7 Varipette

Model Pipette tip Testing

volume

Systematic error

± % ± mL ± % ± mL

Varipette 4720 Varitip S 2.5 mL ±1.0 ±0.025 ±0.2 ±0.005

5 mL ±0.4 ±0.02 ±0.2 ±0.01

10 mL ±0.3 ±0.03 ±0.2 ±0.02

Varipette 4720 Varitip P 1 mL ±0.6 ±0.006 ±0.2 ±0.002

5 mL ±0.5 ±0.025 ±0.1 ±0.005

10 mL ±0.3 ±0.03 ±0.1 ±0.01

Error limits

Error

Random error

Page 48

Technical specifications

48

Eppendorf SOP

English (EN)

9.2.8 Xplorer and Xplorer plus

pipette

Increment

Pipette tip

Color code

Volume range

Length

Tes ting

volume

Error limits

Systematic

error

Error

Random

error

µL µL ±% ± µL ±% ± µL

0.5 µL – 10 µL

Increment:

0.01 µL

5 µL– 100 µL

Increment:

0.1 µL

15 µL – 300 µL

Increment:

0.2 µL

50 µL – 1 000 µL

Increment:

1 µL

Medium gray

0.1 µL – 20 µL

40 mm

Yellow

2 µL - 200 µL

53 mm

Orange

15 µL – 300 µL

55 mm

Blue

50 µL – 1000 µL

71 mm

1 µL ±2.5 ±0.025 ±1.8 ±0.018

5 µL ±1.5 ±0.075 ±0.8 ±0.04

10 µL ±1.0 ±0.1 ±0.4 ±0.04

10 µL ±2.0 ±0.2 ±1.0 ±0.1

50 µL ±1.0 ±0.5 ±0.3 ±0.15

100 µL ±0.8 ±0.8 ±0.2 ±0.2

30 µL ±2.5 ±0.75 ±0.7 ±0.21

150 µL ±1.0 ±1.5 ±0.3 ±0.45

300 µL ±0.6 ±1.8 ±0.2 ±0.6

100 µL ±3.0 ±3.0 ±0.6 ±0.6

500 µL ±1.0 ±5.0 ±0.2 ±1.0

1000 µL ±0.6 ±6.0 ±0.2 ±2.0

mL mL mL ±% ± mL ±% ± mL

0.25 mL – 5 mL

Increment:

0.005 mL

0.5 mL – 10 mL

Increment:

0.01 mL

Purple

0.1 mL – 5 mL

120 mm

Turquoise

1 mL – 10 mL

165 mm

0.5 mL ±3.0 ±15.0 ±0.6 ±3.0

2.5 mL ±1.2 ±30.0 ±0.25 ±6.25

5 mL ±0.6 ±30.0 ±0.15 ±7.5

1 mL ±3.0 ±30.0 ±0.60 ±6.0

5 mL ±0.8 ±40.0 ±0.20 ±10.0

10 mL ±0.6 ±60.0 ±0.15 ±15.0

Page 49

9.3 Multi-channel pipettes

9.3.1 Research

Technical specifications

Eppendorf SOP

English (EN)

49

Model Test tip

epT.I.P.S. Color

code

Volume range

Length

Research8-channel

0.5 - 10 µL

light gray

0.5 – 20 µL

46 mm

Research12-channel

0.5 - 10 µL

Research8-channel

10 - 100 µL

Yellow

2 - 200 µL

53 mm

Research12-channel

10 - 100 µL

Research8-channel

30 - 300 µL

Orange

20 – 300 µL

55 mm

Research12-channel

30 - 300 µL

Volume

in µL

Systematic

Error limits

Error

Random error

error

± % ± µL ± % ± µL

1 ±8.0 ±0.08 ±5.0 ±0.05

5 ±4.0 ±0.2 ±2.0 ±0.1

10 ±2.0 ±0.2 ±1.0 ±0.1

see 8-channel

10 ±3.0 ±0.3 ±2.0 ±0.2

50 ±1.0 ±0.5 ±0.8 ±0.4

100 ±0.8 ±0.8 ±0.3 ±0.3

see 8-channel

30 ±3.0 ±0.9 ±1.0 ±0.3

150 ±1.0 ±1.5 ±0.5 ±0.75

300 ±0.6 ±1.8 ±0.3 ±0.9

see 8-channel

Page 50

Technical specifications

50

Eppendorf SOP

English (EN)

9.3.2 Research pro

Model Test tip

epT.I.P.S. Color code

Volume range

Length

Research pro

8-channel /12-channel

0.5 - 10 µL

Research pro

8-channel /12-channel

5 - 100 µL

Research pro

8-channel /12-channel

20 – 300 µL

Research pro

8-channel /12-channel

50 – 1 250 µL

light gray

0.5 – 20 µL L

46 mm

Yellow

2 - 200 µL

53 mm

Orange

20 – 300 µL

55 mm

Green

50 – 1 250 µL

76 mm

Tes ting

volume

Error limits

Error

Systematic

error

Random

error

± % ± µL ± % ± µL

1 µL ±5.0 ±0.05 ±3.0 ±0.03

5 µL ±3.0 ±0.15 ±1.5 ±0.075

10 µL ±2.0 ±0.2 ±0.8 ±0.08

10 µL ±2.0 ±0.2 ±2.0 ±0.2

50 µL ±1.0 ±0.5 ±0.8 ±0.4

100 µL ±0.8 ±0.8 ±0.25 ±0.25

30 µL ±2.5 ±0.75 ±1.0 ±0.3

150 µL ±1.0 ±1.5 ±0.5 ±0.75

300 µL ±0.6 ±1.8 ±0.25 ±0.75

120 µL ±6.0 ±7.2 ±0.9 ±1.08

600 µL ±2.7 ±16.2 ±0.4 ±2.4

1 200 µL ±1.2 ±14.4 ±0.3 ±3.6

Page 51

9.3.3 Research plus

Research plus adjustable multi-channel

Model Test tip

epT.I.P.S. Color code

Volume range

Length

0.5 µL – 10 µL

Increment:

0.01 µL

10 µL – 100 µL

Increment:

0.1 µL

30 µL – 300 µL

Increment:

0.2 µL

Medium gray

0.1 µL – 20 µL

40 mm

Yellow

2 µL - 200 µL

53 mm

Orange

20 µL – 300 µL

55 mm

Tes ting

volume

Technical specifications

Eppendorf AG error limits

Systematic

error

Eppendorf SOP

English (EN)

Error

Random

error

± % ± µL ± % ± µL

0.5 µL ±12 ±0.06 ±8.0 ±0.04

1 µL ±8.0 ±0.08 ±5.0 ±0.05

5 µL ±4.0 ±0.2 ±2.0 ±0.1

10 µL ±2.0 ±0.2 ±1.0 ±0.1

10 µL ±3.0 ±0.3 ±2.0 ±0.2

50 µL ±1.0 ±0.5 ±0.8 ±0.4

100 µL ±0.8 ±0.8 ±0.3 ±0.3

30 µL ±3.0 ±0.9 ±1.0 ±0.3

150 µL ±1.0 ±1.5 ±0.5 ±0.75

300 µL ±0.6 ±1.8 ±0.3 ±0.9

51

Page 52

Technical specifications

52

Eppendorf SOP

English (EN)

9.3.4 Reference2

Reference2 Variable multi-channel (8-channel/12-channel)

Model Test tip

epT.I.P.S. Color code

Volume range

Length

0.5 µL – 10 µL Medium gray

0.1 µL – 20 µL

40 mm

10 µL – 100 µL Yellow

2 µL - 200 µL

53 mm

30 µL – 300 µL Orange

20 µL – 300 µL

55 mm

Tes ting

volume

0.5 µL ±12.0 ±0.06 ±8.0 ±0.04

1 µL ±8.0 ±0.08 ±5.0 ±0.05

5 µL ±4.0 ±0.2 ±2.0 ±0.1

10 µL ±2.0 ±0.2 ±1.0 ±0.1

10 µL ±3.0 ±0.3 ±2.0 ±0.2

50 µL ±1.0 ±0.5 ±0.8 ±0.4

100 µL ±0.8 ±0.8 ±0.3 ±0.3

30 µL ±3.0 ±0.9 ±1.0 ±0.3

150 µL ±1.0 ±1.5 ±0.5 ±0.75

300 µL ±0.6 ±1.8 ±0.3 ±0.9

Eppendorf AG error limits

Error

Systematic

error

Random

error

± % ± µL ± % ± µL

Page 53

9.3.5 Xplorer and Xplorer plus

Technical specifications

Eppendorf SOP

English (EN)

53

pipette

Increment

Pipette tip

Color code

Volume range

Length

Testing

volume

Error limits

Systematic

error

Error

Random error

µL µL % µL % µL

0.5 µL – 10 µL

Increment:

0.01 µL

5 µL – 100 µL

Increment:

0.1 µL

15 µL – 300 µL

Increment:

0.2 µL

50 µL – 1200 µL

Increment:

1 µL

Medium gray

0.1 µL – 20 µL

40 mm

Yellow

2 µL –200 µL

53 mm

Orange

15 µL –300 µL

55 mm

Green

50 µL–1250 µL

76 mm

1 µL ±5.0 ±0.05 ±3.0 ±0.03

5 µL ±3.0 ±0.15 ±1.5 ±0.075

10 µL ±2.0 ±0.2 ±0.8 ±0.08

10 µL ±2.0 ±0.2 ±2.0 ±0.2

50 µL ±1.0 ±0.5 ±0.8 ±0.4

100 µL ±0.8 ±0.8 ±0.25 ±0.25

30 µL ±2.5 ±0.75 ±1.0 ±0.3

150 µL ±1.0 ±1.5 ±0.5 ±0.75

300 µL ±0.6 ±1.8 ±0.25 ±0.75

120 µL ±6.0 ±7.2 ±0.9 ±1.08

600 µL ±2.7 ±16.2 ±0.4 ±2.4

1200 µL ±1.2 ±14.2 ±0.3 ±3.6

Page 54

Technical specifications

54

Eppendorf SOP

English (EN)

9.4 Multipette

The following specifications for the Multipette plus, Multipette stream /

Multipette Xstream, Multipette M4 apply to the following conditions:

• Using the Combitips advanced

• Liquid: Distilled or deionized water

• Reference temperature: 20 to 25 °C, ±0.5 °C

• Number of determinations: 10 according to EN ISO 8655, with the original

Eppendorf Combitip advanced

Multipette stream / Multipette Xstream:

• Volume test in "DIS" mode

• Set speed level: 7

9.4.1 MultipettePlus

Combitip advanced Testing volume Error limits

Error

Systematic error Random error

± % ± µL ± % ± µL

0.1 mL

(beige piston)

0.2 mL

(blue piston)

0.5 mL 10 µL ±0.9 ±0.09 ±1.5 ±0.15

1 mL 20 µL ±0.9 ±0.18 ±0.9 ±0.18

2.5 mL 50 µL ±0.8 ±0.4 ±0.8 ±0.4

5 mL 100 µL ±0.6 ±0.6 ±0.6 ±0.6

10 mL 200 µL ±0.5 ±1.0 ±0.6 ±1.2

25 mL

(blue adapter)

50 mL

(dark gray adapter)

2 µL ±1.6 ±0.032 ±3.0 ±0.06

20 µL ±1.0 ±0.2 ±2.0 ±0.4

4 µL ±1.3 ±0.052 ±2.0 ±0.08

40 µL ±0.8 ±0.32 ±1.5 ±0.6

100 µL ±0.8 ±0.8 ±0.6 ±0.6

200 µL ±0.6 ±1.2 ±0.4 ±0.8

500 µL ±0.5 ±2.5 ±0.3 ±1.5

1,000 µL ±0.5 ±5.0 ±0.25 ±2.5

2 000 µL ±0.5 ±10 ±0.25 ±5.0

500 µL ±0.4 ±2.0 ±0.6 ±3.0

5,000 µL ±0.3 ±15 ±0.25 ±12.5

1,000 µL ±0.3 ±3.0 ±0.5 ±5.0

10,000 µL ±0.3 ±30 ±0.3 ±30

Page 55

Technical specifications

9.4.2 MultipetteM4

Combitip advanced Testing volume Error limits

Error

Systematic error Random error

± % ± µL ± % ± µL

0.1 mL

white

Increment: 1 µL

0.2 mL

light blue

Increment: 2 µL

0.5 mL

purple

Increment: 5 µL

1 mL

yellow

Increment: 10 µL

2.5 mL

green

Increment: 25 µL

5 mL

blue

Increment: 50 µL

10 mL

orange

Increment: 0.1 mL

25 mL

red

Increment: 0.25 mL

50 mL

light gray

Increment: 0.5 mL

2 µL ±1.6 ±0.032 ±3.0 ±0.06

20 µL ±1.0 ±0.2 ±2.0 ±0.4

4 µL ±1.3 ±0.052 ±2.0 ±0.08

40 µL ±0.8 ±0.32 ±1.5 ±0.6

10 µL ±0.9 ±0.09 ±1.5 ±0.15

100 µL ±0.8 ±0.8 ±0.6 ±0.6

20 µL ±0.9 ±0.18 ±0.9 ±0.18

200 µL ±0.6 ±1.2 ±0.4 ±0.8

50 µL ±0.8 ±0.4 ±0.8 ±0.4

500 µL ±0.5 ±2.5 ±0.3 ±1.5

100 µL ±0.6 ±0.6 ±0.6 ±0.6

1 000 µL ±0.5 ±5.0 ±0.25 ±2.5

200 µL

±0.5 ±1.0 ±0.6 ±1.2

0.2 mL

2 000 µL

±0.5 ±10 ±0.25 ±5.0

2 mL

500 µL

±0.4 ±2.0 ±0.6 ±3.0

0.5 mL

5 000 µL

±0.3 ±15 ±0.25 ±12.5

5 mL

1 000 µL

±0.3 ±3.0 ±0.5 ±5.0

1 mL

10 000 µL

±0.3 ±30 ±0.3 ±30

10 mL

Eppendorf SOP

English (EN)

55

Page 56

Technical specifications

56

Eppendorf SOP

English (EN)

9.4.3 Multipette stream / Multipette Xstream

Combitip

advanced

0.1 mL

(white piston)

Increment: 0.1 µL

0.2 mL

(blue piston)

Increment: 0.2 µL

0.5 mL

Increment: 0.5 µL

1 mL

Increment: 1 µL

2.5 mL

Increment: 2.5 µ

5 mL

Increment: 5 µL

10 mL

Increment: 10 µL

25 mL

(blue adapter)

Increment: 25 µL

50 mL

(dark gray adapter)

Increment: 50 µL

Volume range Testing

volume

Systematic

error

Error limits

Error

Random

error

± % ± µL ± % ± µL

1 µL - 100 µL 10 µL ±1.6 ±0.16 ±2.5 ±0.25

50 µL ±1.0 ±0.5 ±1.5 ±0.75

100 µL ±1.0 ±1.0 ±0.5 ±0.5

2 µL - 200 µL 20 µL ±1.3 ±0.26 ±1.5 ±0.3

100 µL ±1.0 ±1.0 ±1.0 ±1.0

200 µL ±1.0 ±2.0 ±0.5 ±1.0

5 µL - 500 µL 50 µL ±0.9 ±0.45 ±0.8 ±0.4

250 µL ±0.9 ±2.25 ±0.5 ±1.25

500 µL ±0.9 ±4.5 ±0.3 ±1.5

10 µL – 1 000 µL 100 µL ±0.9 ±0.9 ±0.55 ±0.55

500 µL ±0.6 ±3.0 ±0.3 ±1.5

1,000 µL ±0.6 ±6.0 ±0.2 ±2.0

25 µL – 2 500 µL 250 µL ±0.8 ±2.0 ±0.45 ±1.125

1,250 µL ±0.5 ±6.25 ±0.3 ±3.75

2,500 µL ±0.5 ±12.5 ±0.15 ±3.75

50 µL - 5 000 µL 500 µL ±0.8 ±4.0 ±0.35 ±1.75

2,500 µL ±0.5 ±12.5 ±0.25 ±6.25

5,000 µL ±0.5 ±25 ±0.15 ±7.5

0.1 mL – 10 mL 1 mL ±0.5 ±0.005 ±0.25 ±0.0025

5 mL ±0.4 ±0.02 ±0.25 ±0.0125

10 mL ±0.4 ±0.04 ±0.15 ±0.015

0.25 mL - 25 mL 2.5 mL ±0.3 ±0.0075 ±0.35 ±0.0088

12.5 mL ±0.3 ±0.0375 ±0.25 ±0.0313

25 mL ±0.3 ±0.075 ±0.15 ±0.0375

0.5 mL - 50 mL 5 mL ±0.3 ±0.015 ±0.50 ±0.025

25 mL ±0.3 ±0.075 ±0.20 ±0.05