Page 1

Operating Instructions

iTEMP® TMT82

Dual-input temperature transmitter

BA01028T/09/EN/14.12

71198558

Valid as of version

01.00 (device version)

Page 2

Brief overview

For quick and straightforward commissioning:

iTEMP® TMT82

Safety instructions

t

Installation instructions

t

Wiring

t

Display and operating elements

t

Commissioning

Commissioning using the HART® communication interface - Quick start for device

configuration for standard operation

Customer-specific configuration

Complex measurement tasks require the configuration of additional functions, which the

user can select, set and adapt to his/her process conditions by setting the appropriate device

parameters. A detailed description of all functions and device parameters.

(® ä 6)

(® ä 10)

(® ä 15)

(® ä 20)

(® ä 30)

(® ä 51)

2 Endress+Hauser

Page 3

iTEMP® TMT82

Table of contents

Table of contents

1 Important document information ..... 4

About this document ..................... 4

1.1

1.2 Document conventions .................... 4

2 Basic safety instructions .............. 6

2.1 Requirements for the personnel .............. 6

2.2 Designated use .......................... 6

2.3 Operational safety ........................ 6

3 Identification ....................... 7

3.1 Device designation ....................... 7

3.2 Scope of delivery ........................ 8

3.3 Certificates and approvals .................. 8

4 Installation instructions ............. 10

4.1 Incoming acceptance, transport, storage ........ 10

4.2 Installation conditions .................... 10

4.3 Installation instructions ................... 10

4.4 Post-installation check .................... 14

5 Wiring ............................ 15

5.1 Quick wiring guide ...................... 15

5.2 Connecting the sensor cables ............... 16

5.3 Connecting the power supply and signal cables .. 17

5.4 Shielding and grounding .................. 18

5.5 Post-connection check ................... 19

10.2 Communication-specific accessories .......... 31

10.3

System components and data manager ......... 32

11 Diagnostics and troubleshooting ..... 33

11.1 Troubleshooting ........................ 33

11.2 Diagnostics events ...................... 35

11.3 Spare parts ............................ 38

11.4 Return .............................. 38

11.5 Disposal ............................. 38

11.6 Software history and overview of compatibility ... 39

12 Technical data ..................... 40

13 Operating menu and parameter

description ........................ 51

13.1 "Display/operation" menu ................. 57

13.2 "Setup" menu .......................... 61

13.3 "Diagnostics" menu ...................... 72

13.4 "Expert" menu ......................... 80

Index .................................. 96

6 Operating options .................. 20

6.1 Overview of operation options .............. 20

6.2 Structure and function of the operating menu .... 21

6.3 Measured value display and operating elements .. 23

6.4 Access to the operating menu via the operating

tool ................................ 25

7

Integrating the transmitter via HART

®

protocol ........................... 28

7.1 HART device variables and measured values ..... 28

7.2 Device variables and measured values ......... 29

8 Commissioning .................... 30

8.1 Function check ........................ 30

8.2 Switching on the transmitter ............... 30

8.3 Enabling configuration .................... 30

9 Maintenance ...................... 30

10 Accessories ........................ 30

10.1 Optional accessories ..................... 31

Endress+Hauser 3

Page 4

Important document information

DANGER

CAUTION

NOTICE

iTEMP® TMT82

1 Important document information

1.1

About this document

1.1.1 Document function

These Operating Instructions contain all the information that is required in various phases of the

life cycle of the device: from product identification, incoming acceptance and storage, to

mounting, connection, operation and commissioning through to troubleshooting, maintenance

and disposal.

1.1.2 Additional standard documentation on the device

Document Purpose and content of the document

Technical Information

TI01010T/09/en

Brief Operating Instructions

KA01095T/09/en

The document types listed are available:

On the CD supplied with the device

•

•

In the Download Area of the Endress+Hauser Internet site: www.endress.com ®

Download

Planning aid for your device

The document contains all the technical data on the device and provides an

overview of the accessories and other products that can be ordered for the

device.

Guide that takes you quickly to the 1st measured value

The Brief Operating Instructions contain all the essential information from

incoming acceptance to initial commissioning.

1.1.3 Safety Instructions (XA)

When using in hazardous areas, the national safety requirements must be met. Separate Ex

documentation is contained in these Operating Instructions for measurement systems that are to

mounted in hazardous areas. Strict compliance with the installation instructions, ratings and

safety instructions as listed in this supplementary documentation is mandatory. Ensure you are

using the correct Ex documentation for the relevant Ex-approved device. The number of the

related Ex documentation (XA...) is indicated on the nameplate. You can use this Ex

documentation if the two numbers (i.e. in the Ex documentation and on the nameplate) are

identical.

1.2 Document conventions

1.2.1 Safety symbols

Symbol Meaning

DANGER!

A0011189-EN

A0011191-EN

A0011192-EN

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result

in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result

in minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

4 Endress+Hauser

Page 5

iTEMP® TMT82

)

*

-

.

Important document information

1.2.2 Electrical symbols

Symbol Meaning

Direct current

A terminal to which DC voltage is applied or through which direct current flows.

A0011197

Alternating current

A0011198

A terminal to which alternating voltage (sine-wave) is applied or through which alternating current flows.

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a grounding system.

A0011200

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

A0011199

Equipotential connection

A connection that has to be connected to the plant grounding system: This may be a potential

A0011201

equalization line or a star grounding system depending on national or company codes of practice.

1.2.3 Symbols and notation for certain types of information

Symbol Meaning

Allowed

Indicates procedures, processes or actions that are allowed.

A0011182

Preferred

Indicates procedures, processes or actions that are preferred.

A0011183

Forbidden

Indicates procedures, processes or actions that are forbidden.

A0011184

Tip

Indicates additional information.

A0011193

Reference to documentation

Refers to the corresponding device documentation.

A0011194

Reference to page

Refers to the corresponding page number.

A0011195

Reference to graphic

Refers to the corresponding graphic number and page number.

A0011196

1., 2., 3. Series of steps

Result of a sequence of actions

Ã

1.2.4 Symbols and notation in graphics

Symbol Meaning

1,2,3 ...

A, B, C, ...

A-A, B-B, C-C, ...

Endress+Hauser 5

Item numbers

Views

Sections

Hazardous area

Indicates a hazardous area.

A0011187

Safe area (non-hazardous area)

Indicates a non-hazardous area.

A0011188

Page 6

Basic safety instructions

iTEMP® TMT82

2 Basic safety instructions

2.1

Requirements for the personnel

The personnel for installation, commissioning, diagnostics and maintenance must fulfill the

following requirements:

►

Trained, qualified specialists must have a relevant qualification for this specific function and

task

►

Are authorized by the plant owner/operator

►

Are familiar with federal/national regulations

►

Before beginning work, the specialist staff must have read and understood the instructions in

the Operating Instructions and supplementary documentation as well as in the certificates

(depending on the application)

►

Following instructions and basic conditions

The operating personnel must fulfill the following requirements:

►

Being instructed and authorized according to the requirements of the task by the facility's

owner-operator

►

Following the instructions in these Operating Instructions

2.2 Designated use

The device is a universal and user-configurable temperature transmitter with either one or two

sensor inputs for a resistance thermometer (RT), thermocouples (TC), resistance and voltage

transmitters. The head transmitter version of the device is intended for mounting in a flat-face

terminal head as per DIN EN 50446. It is also possible to mount the device on a DIN rail using

the optional DIN rail clip. The device is also optionally available in a version suitable for DIN rail

mounting as per IEC 60715 (TH35).

The manufacturer is not liable for damage caused by improper or non-designated use.

2.3 Operational safety

►

Operate the device in proper technical condition and fail-safe condition only.

►

The operator is responsible for interference-free operation of the device.

Hazardous area

To eliminate a danger for persons or for the facility when the device is used in the hazardous area

(e.g. explosion protection or safety equipment):

►

Based on the technical data on the nameplate, check whether the ordered device is permitted

for the intended use in the hazardous area. The nameplate can be found on the side of the

transmitter housing.

►

Observe the specifications in the separate supplementary documentation that is an integral

part of these Instructions.

Electromagnetic compatibility

The measuring system complies with the general safety requirements in accordance with EN

61010, the EMC requirements of IEC/EN 61326 and NAMUR Recommendation NE 21 and NE

89.

NOTICE

►

The unit must only be powered by a power supply that operates using an energy-limited

electric circuit that is compliant with IEC 61010-1, "SELV or Class 2 circuit".

6 Endress+Hauser

Page 7

iTEMP® TMT82

1

2

3

4

5

11-42V

012345678910

xx.yy

.zz

TMT82- XXXXX/XX

iTEMP

®

Made in Germany 2011

D-87484 Nesselwang

Ser

.no.:

FW:

Input:

12345678ABCDEFGH

12345678ABCDEFGH

Current consum.: 23,6 mA

Dev.Rev: 1

Ext. ord. cd.:

XXXXXXXXXXXXX#

II3G Ex nA II T6/T5/T4 Ta= -40 ...+ 55/70/85°C

II3G Ex nL IIC T6/T5/T4 Ta= -40 ... +55/70/85°C

EH 08.001X

Install per XA00102R/09/a3/xx.xx

6

0044

Identification

3 Identification

3.1

Device designation

The following options are available for identification of the device:

• Nameplate specifications

•

Enter the serial number from the nameplate in W@M Device Viewer (www.endress.com/

deviceviewer): All data relating to the device and an overview of the technical documentation

supplied with the device are displayed.

3.1.1 Nameplate

The right device?

Compare and check the data on the nameplate of the device against the requirements of the

measuring point:

A0014561

å 1

Nameplate of the head transmitter (example, Ex version)

1 Power supply, current consumption and extended order code

2 Serial number, device revision and firmware version

3 Approvals with symbols

4 2 lines for the TAG name

5 Approval in hazardous area with number of the relevant Ex documentation (XA...)

6 Order code and manufacturer ID

Endress+Hauser 7

Page 8

Identification

1

2

3

4

5

6

0044

iTEMP®TMT82

Made in Germany 2012 D-87484 Nesselwang

TAGXXXXXXXXXXX

TAGXXXXXXXXXXX

FW: XX.XX.XX Dev. Rev.: X

Order code: TMT82-xxx/xx

Ext. ord. cd.: XXXXXXXXXXX

Ser

. no.: XXXXXXXXX

Input: 12-42 V

Current cunsum.: 23,0 mA

1

II3G Ex nAII T6/T5/T4 Ta= -40 ...+ 55/70/85°C

II3G Ex nLIIC T6/T5/T4 Ta= -40 ... +55/70/85°C

EH 08.001X

Install per XA0xxxxT/09/a3/xx.xx

7

Nameplate of DIN rail transmitter (example, Ex version)

å 2

1 Product description and manufacturer ID

2 Order code, extended order code and serial number

3 Power supply and current consumption

4 Approval in hazardous area with number of the relevant Ex documentation (XA...)

5 Firmware version and device version

6 Approval logos

7 2 lines for the TAG name

iTEMP® TMT82

A0017924

3.2 Scope of delivery

The scope of delivery of the device comprises:

•

Temperature transmitter

• Mounting material (head transmitter)

• Hard copy of multi-language Brief Operating Instructions

• Operating Instructions and additional documentation on CD-ROM

•

Additional documentation for devices which are suitable for use in hazardous areas (0

such as Safety Instructions (XA), Control or Installation Drawings (ZD).

3.3

Certificates and approvals

The device left the factory in a safe operating condition. The device complies with the standards

EN 61 010-1 "Protection Measures for Electrical Equipment for Measurement, Control,

Regulation and Laboratory Procedures" and with the EMC requirements of IEC/EN 61326.

3.3.1 CE mark, Declaration of Conformity

The device therefore meets the legal requirements of the EC guidelines. The manufacturer

confirms that the device is compliant with the relevant guidelines by applying the CE mark.

3.3.2

The temperature transmitter is registered by HART® Communication. The device meets the

requirements of the HART Communication Protocol Specifications, April 2001, Revision 6.0.

HART® protocol certification

1),

3.3.3 Registered trademarks

• HART

• iTEMP

®

Registered trademark of the HART® Communication Foundation

Registered trademark of Endress+Hauser Wetzer GmbH + Co. KG, Nesselwang, D

8 Endress+Hauser

®

Page 9

iTEMP® TMT82

Identification

An overview of other approvals and certifications is provided in the "Technical data"

section(® ä 50).

Endress+Hauser 9

Page 10

Installation instructions

iTEMP® TMT82

4 Installation instructions

4.1

Incoming acceptance, transport, storage

4.1.1 Incoming acceptance

• Is the packaging or content damaged?

• Is the delivery complete? Compare the scope of delivery against the information on your order

form.

4.1.2 Transport and storage

• Pack the device in such a way as to protect it reliably against impact for storage (and

transportation). The original packaging provides optimum protection.

• Permitted storage temperature:

– Head transmitter: –50 to +100 °C (–58 to +212 °F)

– DIN rail transmitter: –40 to +100 °C (–40 to +212 °F)

4.2 Installation conditions

4.2.1 Dimensions

The dimensions of the device are provided in the "Technical data" section. (® ä 40).

4.2.2 Mounting location

• Head transmitter:

– In the terminal head, flat face, as per DIN EN 50446, direct mounting on insert with cable

entry (middle hole 7 mm)

–

In the field housing, separated from the process(® ä 30)

• DIN rail transmitter:

Designed for mounting on DIN rail (IEC 60715 TH35).

It is also possible to mount the device on a DIN rail as per IEC 60715 using the DIN rail clip

accessory (® ä 30).

Information about the conditions (such as the ambient temperature, degree of protection, climate

class etc.) that must be present at the installation point so that the device can be mounted

correctly, is provided in the "Technical data" section(® ä 40).

When using in hazardous areas, the limit values of the certificates and approvals must be

observed (see Ex Safety Instructions).

4.3

A Phillips head screwdriver is required to mount the head transmitter.

NOTICE

Do not overtighten the mounting screws as this could damage the head transmitter.

►

Maximum torque = 1 Nm (¾ pound-feet).

Installation instructions

10 Endress+Hauser

Page 11

iTEMP® TMT82

1

2

3

4

5

6

7

9

8

1 2 3 4 5

1

2

3 4

Item A

Item B

Item C

Installation instructions

4.3.1 Mounting the head transmitter

A0014269-EN

å 3

Head transmitter mounting (three versions)

Item A Mounting in a terminal head (terminal head flat face as per DIN 43729)

1 Terminal head

2 Circlips

3 Insert

4 Connection wires

5 Head transmitter

6 Mounting springs

7 Mounting screws

8 Terminal head cover

9 Cable entry

Procedure for mounting in a terminal head, pos. A:

1. Open the terminal head cover (8) on the terminal head.

2. Guide the connection wires (4) of the insert (3) through the center hole in the head

transmitter (5).

3. Fit the mounting springs (6) on the mounting screws (7).

4. Guide the mounting screws (7) through the side boreholes of the head transmitter and the

insert (3). Then fix both mounting screws with the snap rings (2).

5. Then tighten the head transmitter (5) along with the insert (3) in the terminal head.

6.

After wiring, close the terminal head cover again (8) tightly.(® ä 15)

Endress+Hauser 11

Item B Mounting in a field housing

1 Field housing cover

2 Mounting screws with springs

Page 12

Installation instructions

1

2

3 4 5

6

5

6

iTEMP® TMT82

Item B Mounting in a field housing

3 Head transmitter

5 Field housing

Procedure for mounting in a field housing, pos. B:

1. Open the cover (1) of the field housing (4).

2. Guide the mounting screws (2) through the lateral bores of the head transmitter (3).

3. Screw the head transmitter to the field housing.

4.

After wiring, close the field housing cover (1) again. (® ä 15)

Item C Mounting on DIN rail (DIN rail as per IEC 60715)

1 Mounting screws with springs

2 Head transmitter

3 Circlips

4 DIN rail clip

5 DIN rail

Procedure for mounting on a DIN rail, pos. C:

1. Press the DIN rail clip (4) onto the DIN rail (5) until it engages with a click.

2. Fit the mounting springs on the mounting screws (1) and guide the screws through the side

boreholes of the head transmitter (2). Then fix both mounting screws with the snap rings

(3).

3. Screw the head transmitter (2) onto the DIN rail clip (4).

Mounting typical of North America

Head transmitter mounting

å 4

1 Protection tube

2 Insert

3 Adapter, coupling

4 Terminal head

5 Head transmitter

6 Mounting screws

A0008520

Thermometer design with thermocouples or RTD sensors and head transmitter:

12 Endress+Hauser

Page 13

iTEMP® TMT82

Installation instructions

1. Fit the thermowell (1) on the process pipe or the container wall. Secure the thermowell

according to the instructions before the process pressure is applied.

2. Fit the necessary neck tube nipples and adapter (3) on the thermowell.

3. Make sure sealing rings are installed if such rings are needed for harsh environmental

conditions or special regulations.

4. Guide the mounting screws (6) through the lateral bores of the head transmitter (5).

5. Position the head transmitter (5) in the terminal head (4) in such a way that the bus cable

(terminals 1 and 2) point to the cable entry.

6. Using a screwdriver, screw down the head transmitter (5) in the terminal head (4).

7. Guide the connection wires of the insert (3) through the lower cable entry of the terminal

head (4) and through the middle hole in the head transmitter (5). Wire the connection wires

and transmitter with one another (® ä 15).

8. Screw the terminal head (4), with the integrated and wired head transmitter, onto the readymounted nipple and adapter (3).

NOTICE

The terminal head cover must be secured properly to meet the requirements for

explosion protection.

►

After wiring, securely screw the terminal head cover back on.

Mounting the display on the head transmitter

å 5

Mounting the display

A0009852

1. Loosen the screw on the terminal head cover. Flip back the terminal head cover.

2. Remove the cover of the display connection area.

3. Fit the display module onto the mounted and wired head transmitter. The fastening pins

must click securely into place on the head transmitter. After mounting, securely tighten the

terminal head cover.

The display can only be used with the appropriate terminal heads - cover with viewing

window (e.g. TA30 from Endress+Hauser).

Endress+Hauser 13

Page 14

Installation instructions

4.3.2 Mounting the DIN rail transmitter

Mounting the DIN rail transmitter

å 6

iTEMP® TMT82

A0017821

1. Slide the upper DIN rail clip upwards and the lower clip downwards until they click into

place.

2. Fit the device on the DIN rail from the front.

3. Slide the two DIN rail clips back together until they click into place.

4.4

Post-installation check

After installing the device, always run the following final checks:

Device condition and specifications Notes

Is the device undamaged (visual inspection)? -

Do the ambient conditions match the device specification (e.g. ambient temperature, measuring

range, etc.)?

See 'Technical data'

section(® ä 40)

14 Endress+Hauser

Page 15

iTEMP® TMT82

-

+

+

1

-

2

7

6

5

4

3

1

2

7

6

5

4

3

Sensor input 2

Sensor input 1

Bus connection

and supply voltage

Display connection/

service interface

TC, mV

RTD, 4-, 3- and 2-wire:Ω

RTD, 3- and 2-wire:Ω

TC, mV

white

red

red

white

white

red

red

Wiring

5 Wiring

CAUTION

!

►

Switch off power supply before installing or connecting the device. Failure to observe this may

result in destruction of parts of the electronics.

►

When installing Ex-approved devices in a hazardous area please take special note of the

instructions and connection schematics in the respective Ex documentation added to these

Operating Instructions. Your supplier is available for assistance if required.

►

Do not occupy the display connection. An incorrect connection can destroy the electronics.

A Phillips head screwdriver is required to wire the head transmitter with screw terminals. A flatbladed screwdriver must be used for the version with spring terminals and for the DIN rail

transmitter.

NOTICE

Do not overtighten the screw terminals, as this could damage the transmitter.

►

Maximum torque = 1 Nm (¾ pound-feet).

For wiring a mounted head transmitter, proceed as follows:

1. Open the cable gland and the housing cover on the terminal head or the field housing.

2. Feed the cables through the opening in the cable gland.

3.

Connect the cables as shown in (® ä 15). If the head transmitter is fitted with spring

terminals, pay particular attention to the information in the "Connecting to spring terminals"

section" (® ä 17).

4. Retighten the cable gland and close the housing cover.

In order to avoid connection errors always take note of the hints given in the section "connection

check"!

5.1

Quick wiring guide

Terminal assignment of head transmitter

Wiring the head transmitter

å 7

Endress+Hauser 15

A0007285-EN

Page 16

Wiring

-

+

A

TMT82

ON

63748

5

1/+

2/- Test

8

7

6

5

6

4

3

1

2

Sensor input 2

Sensor input 1

Supply voltage

4...20 mA

HART

connection

®

Test

RTD, 3- and 2-wire:Ω

RTD, 4-, 3- and 2-wire:Ω

white

red

red

white

white

red

red

TC, mV

TC, mV

Terminal assignment of DIN rail transmitter

Assignment of terminal connections for DIN rail device

å 8

A To check the output current, an amperemeter (DC measurement) can be connected between the "Test" and "-" terminals.

iTEMP® TMT82

A0017807-EN

To operate the device via the HART® protocol (terminals 1 and 2), a minimum load of 250 W is

required in the signal circuit.

NOTICE

►

ESD - electrostatic discharge. Protect the terminals from electrostatic discharge. Failure to

observe this may result in destruction or malfunction of parts of the electronics.

5.2 Connecting the sensor cables

Terminal assignment of the sensor terminals(® å 7, ä 15).

NOTICE

When connecting 2 sensors ensure that there is no galvanic connection between the

sensors (e.g. caused by sensor elements that are not isolated from the thermowell). The

resulting equalizing currents distort the measurements considerably.

►

The sensors must remain galvanically isolated from one another by connecting each sensor

separately to a transmitter. The transmitter provides sufficient galvanic isolation (> 2 kV AC)

between the input and output.

The following connection combinations are possible when both sensor inputs are assigned:

Sensor input 1

Sensor input 2

RTD or resistance

transmitter, 2-wire

RTD or resistance

transmitter, 3-wire

RTD or resistance

transmitter, 4-wire

Thermocouple (TC),

voltage transmitter

RTD or

resistance

transmitter, 2-

wire

Â

Â

Â

- - - -

RTD or

resistance

transmitter, 3-

wire

RTD or

resistance

transmitter, 4-

wire

-

-

Thermocouple

(TC), voltage

transmitter

Â

Â

16 Endress+Hauser

Page 17

iTEMP® TMT82

A B C D

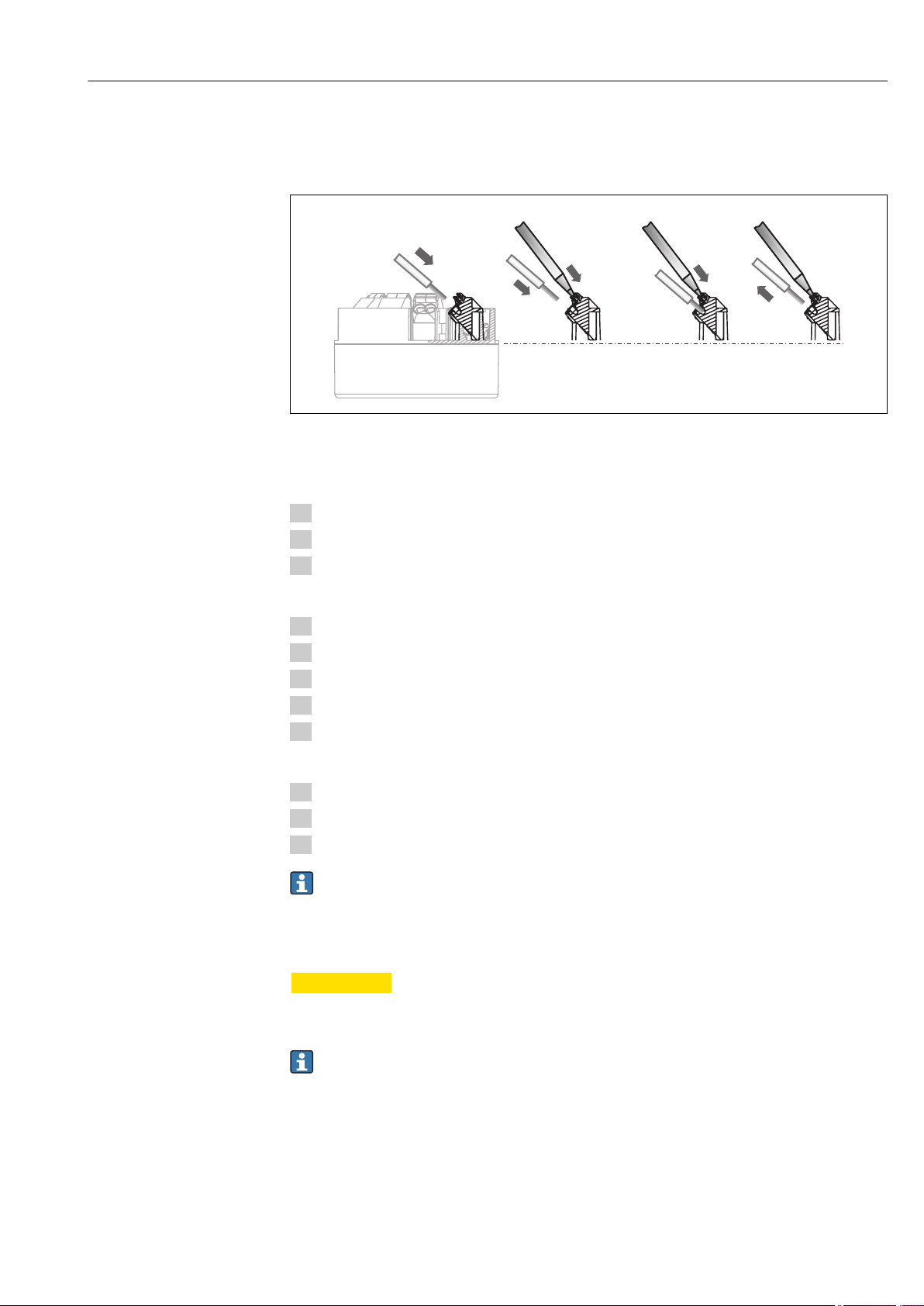

5.2.1 Connecting to spring terminals

A flat-bladed screwdriver, size 3 mm is required.

å 9

Pos. A, solid wire:

Spring terminal connection

1. Strip wire end. Min. stripping length 10 mm (0.39 in).

2. Insert the wire end into the terminal (A).

3. Pull the wire gently to ensure it is connected correctly. Repeat from step 1 if necessary.

Wiring

A0008322

Pos. B, fine-strand wire without ferrule:

1. Strip wire end. Min. stripping length 10 mm (0.39 in).

2. Operate lever opener with tool (B).

3. Insert the wire end into the terminal (B).

4. Release lever opener.

5. Pull the wire gently to ensure it is connected correctly. Repeat from step 1 if necessary.

Pos. C and D, releasing the connection:

1. Operate lever opener with tool (C).

2. Remove wire from terminal (D).

3. Release lever opener.

When connecting flexible cables and spring terminals, it is not recommended to use ferrules.

5.3

CAUTION

!

►

Switch off power supply before installing or connecting the transmitter. Failure to observe this

Connecting the power supply and signal cables

may result in destruction of parts of the electronics.

Cable specification

•

A normal device cable suffices if only the analog signal is used.

• A shielded cable is recommended for HART® communication. Observe grounding concept

of the plant.

Please also observe the general procedure on (® ä 15).

Endress+Hauser 17

Page 18

Wiring

*

*

1 2 3

4

2-

1+

21+

*

2-1+

5

6

7

4

5

7

Connecting the signal cables and power supply

å 10

1 Head transmitter installed in field housing

2 Head transmitter installed in terminal head

3 DIN rail transmitter mounted on DIN rail

4

Terminals for HART® protocol and power supply

5 Internal ground connection

6 External ground connection

7

Shielded signal cable (recommended for HART® protocol)

iTEMP® TMT82

A0017841

• The terminals for connecting the signal cable (1+ and 2-) are protected against reverse

polarity.

Conductor cross-section:

•

– Max. 2.5 mm2 for screw terminals

– max. 1.5 mm2 for spring terminals. Min. stripping length of wire 10 mm (0.39 in).

5.4 Shielding and grounding

Optimum electromagnetic compatibility (EMC) can only be guaranteed if the system components

and, in particular, the lines are shielded and the shield forms as complete a cover as possible. A

shield coverage of 90% is ideal.

• To ensure an optimum EMC protective effect when communicating with HART®, connect the

shield as often as possible to the reference ground.

• For reasons of explosion protection, you should refrain from grounding however.

To comply with both requirements, three different types of shielding are possible when

communicating with HART®:

• Shielding at both ends

• Shielding at one end on the feed side with capacitance termination at the field device

• Shielding at one end on the feed side

Experience shows that the best results with regard to EMC are achieved in most cases in

installations with one-sided shielding on the feed side (without capacitance termination at the

field device). Appropriate measures with regard to input wiring must be taken to allow

unrestricted operation when EMC interference is present. These measures have been taken into

account for this device. Operation in the event of disturbance variables as per NAMUR NE21 is

18 Endress+Hauser

thus guaranteed. Where applicable, national installation regulations and guidelines must be

observed during the installation! Where there are large differences in potential between the

individual grounding points, only one point of the shielding is connected directly with the

reference ground. In systems without potential equalization, therefore, cable shielding of fieldbus

systems should only be grounded on one side, for example at the supply unit or at safety barriers.

Page 19

iTEMP® TMT82

-

.

1

2

3

4

Wiring

A0014463

å 11

1 Optional grounding of the field device, isolated from cable shielding

2 Grounding of the cable shield at one end

3 Supply unit

4

Shielding and grounding the signal cable at one end with HART® communication

Grounding point for HART® communication cable shield

NOTICE

If the shielding of the cable is grounded at more than one point in systems without

potential matching, power supply frequency equalizing currents can occur that damage

the signal cable or have a serious effect on signal transmission.

►

In such cases the shielding of the signal cable is to be grounded on only one side, i.e. it must

not be connected to the ground terminal of the housing (terminal head, field housing). The

shield that is not connected should be insulated!

5.5

Device condition and specifications Notes

Is the device or cable undamaged (visual check)? --

Electrical connection Notes

Does the supply voltage match the specifications on the

nameplate?

Do the cables have adequate strain relief? --

Are the power supply and signal cables correctly

connected?

Are all the screw terminals well tightened and have the

connections of the spring terminals been checked?

Are all the cable entries installed, tightened and sealed? --

Are all housing covers installed and firmly tightened? --

Post-connection check

Head transmitter: U = 11 to 42 V

DIN rail transmitter: U = 12 to 42 V

(® ä 15)

--

DC

DC

Endress+Hauser 19

Page 20

Operating options

1

2

4

5

7

6

3

ON

OFF

1

2

4

8

16

32

64

HW

SW

ADDR

SIM

WRITE LOCK

DISPL. 180°

8

iTEMP® TMT82

6 Operating options

6.1

å 12

Overview of operation options

A0014460

Operating options of the head transmitter

1 PLC (programmable logic control)

2 Transmitter power supply unit, e.g. RN221N (with communication resistor)

3

Connection for HART® modem Commubox FXA191, FXA195

4 Field Communicator 375, 475

5 Computer with operating tool (e.g. FieldCare, AMS Device Manager, SIMATIC PDM)

6

HART® modem Commubox FXA191 (RS232) or FXA195 (USB)

7 Commubox FXA291 (USB) or TXU10 (USB) for connecting to the CDI interface

8 Temperature transmitter as head transmitter or DIN rail device, onsite operation via DIP switches on the rear of

the optional display possible only for head transmitter

For the head transmitter, display and operating elements are available locally only if the head

transmitter was ordered with a display unit!

20 Endress+Hauser

Page 21

iTEMP® TMT82

Expert

System

Sensor

Communication

Diagnostics

Operating menu for experts

Display/operat.

Display interval

Format display

Decimal places 1

Setup

Advanced setup

Device tag

Diagnostics

Operating menu for operators and maintenances

Value 1 display

Operator

Maintenance

Expert

Output

Unit

Sensor type

Lower range value

Upper range value

Enter access code

Locking status

Sensor Sensor offset

Current output

Output current

Actual diagnostics

Operating time

Diagnostics list Actual diagnostics count

Device reset Device reset

Enter access code

Unit

Mains filter

Display Display interval

Sensor Sensor type

Output current

Current trimming

HART config.

HART info

HART output

Burst mode

Device type

Assign PV

Actual diagnostics

Diagnostics list Actual diagnostics count

Event logbook

Device information

Simulation

Device reset

Previous diagnostics

Device tag

Min/max values

Sensor 1 min v.

Simulation current output

Device reset

Sensor value

Sensor value

Operating options

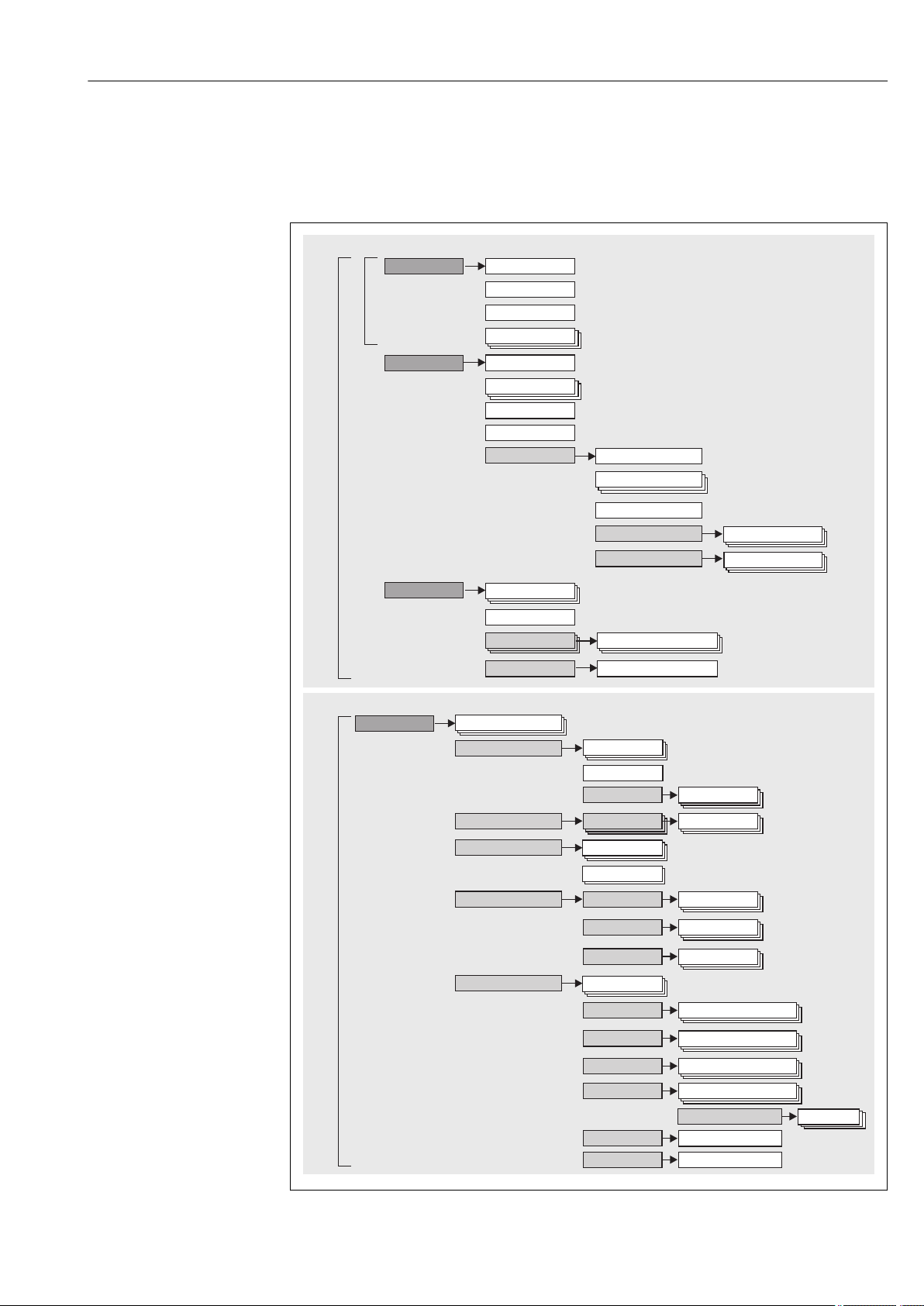

6.2 Structure and function of the operating menu

6.2.1

Structure of the operating menu

Endress+Hauser 21

A0014757-EN

Page 22

Operating options

6.2.2 Submenus and user roles

Certain parts of the menu are assigned to certain user roles. Each user role corresponds to typical

tasks within the lifecycle of the device.

User role Typical tasks Menu Content/meaning

Operator Tasks during operation:

Maintenance Commissioning:

Expert Tasks that require detailed knowledge of the function of

Configuration of the display.

•

• Reading measured values.

• Configuration of the measurement.

• Configuration of data processing (scaling, linearization,

etc.).

• Configuration of the analog measured value output.

Fault elimination:

• Diagnosing and eliminating process errors.

• Interpretation of device error messages and correcting

associated errors.

the device:

• Commissioning measurements under difficult

conditions.

• Optimal adaptation of the measurement to difficult

conditions.

• Detailed configuration of the communication interface.

• Error diagnostics in difficult cases.

"Display/operation" Contains all the parameters that are required in ongoing

operation: configuration of the measured value display

(displayed values, display format, etc.).

"Setup" Contains all parameters for commissioning:.

"Diagnostics" Contains all parameters for detecting and analyzing errors:

"Expert" Contains all parameters of the device (including those that

Setup parameters

•

Once values have been set for these parameters, the

measurement should generally be completely configured.

"Extended Setup" submenu

•

Contains additional submenus and parameters:

– For more accurate configuration of the measurement

(adaptation to special measuring conditions).

– For converting the measured value (scaling,

linearization).

– For scaling the output signal.

Diagnostics list

•

Contains up to 3 currently pending error messages.

Event logbook

•

Contains the last 5 error messages (no longer pending).

"Device information" submenu

•

Contains information for identifying the device.

"Measured values" submenu

•

Contains all current measured values.

"Simulation" submenu

•

Is used to simulate measured values or output values.

"Device reset" submenu

•

are already in one of the other menus). The structure of this

menu is based on the function blocks of the device:

"System" submenu

•

Contains all higher-order device parameters that do not

pertain either to measurement or the measured value

communication.

"Sensor" submenu

•

Contains all parameters for configuring the

measurement.

"Output" submenu

•

Contains all parameters for configuring the analog

current output.

"Communication" submenu

•

Contains all parameters for configuring the digital

communication interface.

"Diagnostics" submenu

•

Contains all parameters for detecting and analyzing

errors.

iTEMP® TMT82

22 Endress+Hauser

Page 23

iTEMP® TMT82

1

2

3

4

5

6

7

Operating options

6.3 Measured value display and operating elements

6.3.1

Display elements

Head transmitter

å 13

Optional LC display TID10 for head transmitter

Item No. Function Description

1 Displays the TAG TAG, 32 characters long.

2 'Communication' symbol The communication symbol appears when read and write-accessing via the

fieldbus protocol.

3 Unit display Unit display for the measured value displayed.

4 Measured value display Displays the current measured value.

5 Value/channel display S1,

S2, DT, PV, I, %

6 'Configuration locked'

symbol

7 Status signals

Symbols Meaning

e.g. S1 for a measured value from channel 1 or DT for the device

temperature

The 'configuration locked' symbol appears when configuration is locked via

the hardware.

Error message "Failure detected"

An operating error has occurred. The measured value is no longer valid.

The display alternates between the error message and "- - - -" (no valid

measured value present), see "Diagnostics events" (® ä 35) section.

"Service mode"

The device is in service mode (e.g. during a simulation).

"Out of specification"

The device is being operated outside its technical specifications (e.g. during

warm-up or cleaning processes).

"Maintenance required"

Maintenance is required. The measured value is still valid.

The display alternates between the measured value and the status message.

A0008549

DIN rail transmitter

Endress+Hauser 23

Page 24

Operating options

ON

OFF

1

2

4

8

16

32

64

HW

SW

ADDR ACTIVE

SIM

WRITE LOCK

DISPL. 180°

1

2

3

iTEMP® TMT82

The DIN rail transmitter version does not have an interface to the LC display TID10 and

therefore does not have a local display either.

Two LEDs on the front indicate the device status in accordance with NAMUR NE44.

Type Function and characteristic

Status LED (red) When the device is operating without errors, the device status is displayed. This

function can no longer be guaranteed in the event of an error.

LED off: without diagnostic message

•

• LED is lit: diagnostic display, category F

• LED flashing: diagnostic display of categories C, S or M

Power LED (green) 'ON' When the device is operating without errors, the operating status is displayed.

This function can no longer be guaranteed in the event of an error.

• LED off: Power failure or insufficient supply voltage

• LED is lit: Supply voltage is OK (either via CDI or via supply voltage,

terminals 1+, 2-)

6.3.2 Local operation

You can make hardware settings for the fieldbus interface using miniature switches (DIP

switches) on the rear of the optional display .

The user has the option of ordering the display with the head transmitter, or as an accessory

for subsequent mounting. (® ä 30)

NOTICE

►

ESD - electrostatic discharge. Protect the terminals from electrostatic discharge. Failure to

observe this may result in destruction or malfunction of parts of the electronics.

1: Connection to head transmitter

2: DIP switch (1 - 64, SW/HW, ADDR and SIM = simulation mode) no

function for this head transmitter

3: DIP switch (WRITE LOCK = write protection; DISPL. 180° = switch,

turn the display monitor 180°)

A0014562

Hardware settings via DIP switches

å 14

Procedure for setting the DIP switch:

1. Open the cover of the terminal head or field housing.

2. Remove the attached display from the head transmitter.

3. Configure the DIP switch on the rear of the display accordingly. In general: switch to ON =

function enabled, switch to OFF = function disabled.

4. Fit the display onto the head transmitter in the correct position. The head transmitter accepts

the settings within one second.

5. Secure the cover back onto the terminal head or field housing.

Switching write protection on/off

Write protection is switched on and off via a DIP switch on the rear of the optional attachable

display. When write protection is active, parameters cannot be modified. A key symbol on the

display indicates that the write protection is on. Write protection prevents any write access to the

24 Endress+Hauser

parameters. The write protection remains active even when the display is removed. To deactivate

the write protection, the device must be restarted with the display attached and the DIP switch

deactivated (WRITE LOCK = OFF).

Page 25

iTEMP® TMT82

Operating options

Turning the display

The display can be rotated 180° using the "DISPL. 180°" DIP switch. The setting is retained

when the display is removed.

6.4

Access to the operating menu via the operating tool

6.4.1 FieldCare

Function scope

FDT/DTM-based plant asset management tool from Endress+Hauser. It can configure all smart

field units in a system and help you manage them. By using the status information, it is also a

simple but effective way of checking their status and condition. Access takes place via the HART

protocol or CDI (= Endress+Hauser Common Data Interface).

Typical functions:

• Configuring parameters of transmitters

• Loading and saving device data (upload/download)

• Documentation of the measuring point

• Visualization of the measured value memory (line recorder) and event logbook

For details, see Operating Instructions BA027S/04/xx and BA059AS/04/xx

NOTICE

For use in hazardous areas: Before accessing the device with the Commubox FXA291

via the CDI (= Endress+Hauser Common Data Interface), disconnect the transmitter

from the power supply, terminals (1+) and (2-).

►

Failure to comply with this instruction can result in damage to parts of the electronics.

®

Source for device description files

See data (® ä 28)

Endress+Hauser 25

Page 26

Operating options

iTEMP® TMT82

User interface

A0014485-EN

6.4.2

AMS Device Manager

Function scope

Program from Emerson Process Management for operating and configuring measuring devices via

the HART® protocol.

Source for device description files

See data (® ä 28).

6.4.3 SIMATIC PDM

Function scope

SIMATIC PDM is a standardized, manufacturer-independent program from Siemens for the

operation, configuration, maintenance and diagnosis of intelligent field devices via the HART

protocol.

Source for device description files

See data (® ä 28).

®

6.4.4 Field Communicator 375/475

Function scope

Industrial handheld terminal from Emerson Process Management for remote configuration and

measured value display via the HART ® protocol.

26 Endress+Hauser

Page 27

iTEMP® TMT82

Operating options

Source for device description files

See data (® ä 28).

Endress+Hauser 27

Page 28

Integrating the transmitter via HART® protocol iTEMP® TMT82

7

Integrating the transmitter via HART® protocol

Version data for the device

Firmware version 01.00.zz • On the title page of the Operating instructions

•

On nameplate (® å 1, ä 7)

•

Parameter firmware version

Diagnostics ® Device info® Firmware version

Manufacturer ID 0x11 Manufacturer ID parameter

Diagnostics ® Device info® Manufacturer ID

Device type ID 0xCC Device type parameter

Diagnostics ® Device info ® Device type

HART protocol revision 6.0 ---

Device revision 1 •

On transmitter nameplate (® å 1, ä 7)

• Device revision parameter

Diagnostics ® Device info ® Device revision

The suitable device description file (DD) for the individual operating tools is listed in the table

below, along with information on where the file can be acquired.

Operating tools

Operating tool Sources for obtaining device descriptions (DD)

FieldCare •

AMS Device Manager

(Emerson Process Management)

SIMATIC PDM

(Siemens)

Field Communicator 375, 475

(Emerson Process Management)

www.endress.com ® Download Area

CD–ROM (contact Endress+Hauser)

•

• DVD (contact Endress+Hauser)

www.endress.com ® Download Area

www.endress.com ® Download Area

Use update function of handheld terminal

7.1 HART device variables and measured values

The following measured values are assigned to the device variables at the factory:

Device variables for temperature measurement

Device variable Measured value

Primary device variable (PV) Sensor 1

Secondary device variable (SV) Device temperature

Tertiary device variable (TV) Sensor 1

Quaternary device variable (QV) Sensor 1

It is possible to change the assignment of device variables to process variables in the Expert

® Communication ® HART output menu.

28 Endress+Hauser

Page 29

iTEMP® TMT82 Integrating the transmitter via HART® protocol

7.2 Device variables and measured values

The following measured values are assigned to the individual device variables:

Device variable code Measured value

0 Sensor 1

1 Sensor 2

2 Device temperature

3 Average of sensor 1 and sensor 2

4 Difference between sensor 1 and sensor 2

5 Sensor 1 (backup sensor 2)

6 Sensor 1 with switchover to sensor 2 if a limit value is exceeded

7 Average of sensor 1 and sensor 2 with backup

The device variables can be queried from a HART® master using HART® command 9 or 33.

Endress+Hauser 29

Page 30

Commissioning

iTEMP® TMT82

8 Commissioning

8.1

Before commissioning the measuring point make sure that all final checks have been carried out:

•

Checklist “Post-installation check”, (® ä 14)

•

Checklist “Post-connection check”, (® ä 19)

Function check

8.2 Switching on the transmitter

Once the final checks have been successfully completed, it is time to switch on the supply

voltage. The transmitter performs a number of internal test functions after power-up. As this

procedure progresses, the following sequence of messages appears on the display:

Step Display

1 "Display" text and firmware version of the display

2 Firm logo

3 Device name with firmware and hardware versions

4 Information on the sensor configuration (sensor element and type of connection)

5 Set measuring range

6a Current measured value or

6b Current status message

If the switch-on procedure is not successful, the relevant diagnostics event, depending on the cause, is

displayed. A detailed list of diagnostic events and the corresponding troubleshooting instructions can be

found in the "Diagnostics and troubleshooting" section (® ä 33).

The device is operational after approx. 8 seconds, and the plug-in display after approx. 12 seconds

in normal operating mode! Normal measuring mode commences as soon as the switch-on

procedure is completed. Measured values and status values appear on the display.

8.3

If the device is locked and the parameter settings cannot be changed, it must first be enabled via

the hardware lock. The device is locked using the hardware if the keyhole symbol appears in the

header of the measured value display. To unlock the device, switch the write protection switch

on the back of the display to the "OFF" position (® ä 24).

Enabling configuration

9 Maintenance

In general, no specific maintenance is required for this device.

10 Accessories

Different accessories are available for the device. These may be ordered separately from your

supplier. Contact your service organization for detailed information on the relevant order code.

When ordering accessories, please quote the serial number of the device!

30 Endress+Hauser

Page 31

iTEMP® TMT82

Accessories

Currently available accessories and spare parts for the product can be found online at:

http://www.products.endress.com/spareparts_consumables; HART® temperature transmitter:

TMT82

Accessories included in the scope of delivery:

Multilingual Brief Operating Instructions as hard copy

•

• Operating Instructions on CD-ROM

• ATEX supplementary documentation ATEX: ATEX Safety instructions (XA), Control Drawings

(CD)

• Mounting material for head transmitter

10.1 Optional accessories

Accessories Order number or

documentation code

Display unit TID10 for Endress+Hauser head transmitter iTEMP® TMT8x, attachable TID10-...

TID10 service cable; connecting cable for service interface, 40 cm 71086650

Field housing TA30x for Endress+Hauser head transmitter TA30x-...

Adapter for DIN rail mounting, clip as per IEC 60715 (TH35) 51000856

Standard - DIN mounting set (2 screws + springs, 4 securing disks and 1 display

connector cover)

US - M4 Mounting screws (2 M4 screws and 1 display connector cover) 71044062

Stainless steel wall mounting bracket

Stainless steel pipe mounting bracket

71044061

71123339

71123342

10.2 Communication-specific accessories

Accessories Description

Commubox FXA195 HART For intrinsically safe HART® communication with FieldCare via the USB interface.

For details, see Technical Information TI404F/00

Commubox FXA191 HART For intrinsically safe HART® communication with FieldCare via the RS232C interface.

For details, see Technical Information TI237F/00

Commubox FXA291 Connects Endress+Hauser field devices with a CDI interface (= Endress+Hauser

Common Data Interface) and the USB port of a computer or laptop.

For details, see Technical Information TI405C/07

WirelessHART adapter Is used for the wireless connection of field devices.

The WirelessHART® adapter can be easily integrated into field devices and existing

infrastructures, offers data protection and transmission safety and can be operated in

parallel with other wireless networks.

For details, see Operating Instructions BA061S/04

Fieldgate FXA320 Gateway for accessing connected 4-20 mA measuring devices via a web browser.

For details, see Technical Information TI025S/04

Fieldgate FXA520 Gateway for accessing connected HART® measuring devices via a web browser.

For details, see Technical Information TI025S/04

Endress+Hauser 31

Page 32

Accessories

10.3 System components and data manager

Accessories Description

Graphic Data Manager

Memograph M

The Memograph M graphic data manager provides information on all the relevant process

variables. Measured values are recorded correctly, limit values are monitored and

measuring points analyzed. The data are stored in the 256 MB internal memory and also

on a SD card or USB stick.

For details, see Technical Information TI133R/09

iTEMP® TMT82

Paperless recorder

Ecograph T

RN221N Active barrier with power supply for safe separation of 4 to 20 mA standard signal

RNS221 Supply unit for powering two 2-wire measuring devices solely in the non-Ex area.

RB223 One- or two-channel, loop-powered barrier for safe separation of 4 to 20 mA standard

RIA14, RIA16 Loop-powered field indicator for 4 to 20 mA circuit, RIA14 in flameproof metal enclosure

RIA15 Process display, digital loop-powered display for 4 to 20 mA circuit, panel mounting

Multi-channel data recording system with LC color graphic display (120 mm / 4,7"

screen size), galvanically isolated universal inputs (U, I, TC, RTD), digital input,

transmitter power supply, limit relay, communication interfaces (USB, Ethernet,

RS232/485), Internal flash memory and compact flash card.

For details, see Technical Information TI115R/09

circuits. Offers bidirectional HART® transmission.

For details, see Technical Information TI073R/09

Bidirectional communication is possible via the HART® communication jacks.

For details, see Technical Information TI081R/09

signal circuits. Bidirectional communication is possible via the HART communication

jacks.

For details, see Technical Information TI132R/09

For details, see Technical Information TI143R/09 and TI144R/09

For details, see Technical Information TI01043K/09

32 Endress+Hauser

Page 33

iTEMP® TMT82

Diagnostics and troubleshooting

11 Diagnostics and troubleshooting

11.1

Troubleshooting

Always start troubleshooting with the checklists below if faults occur after start up or during

operation. This takes you directly (via various queries) to the cause of the problem and the

appropriate remedial measures.

Due to its design, the device cannot be repaired. However, it is possible to send the device in

for examination. See the information in the "Return" section. (® ä 38)

General errors

Problem Possible cause Remedy

Device is not responding. Supply voltage does not match that

specified on the nameplate.

Connecting cables are not in contact

with the terminals.

Output current < 3.6 mA Signal line is not wired correctly. Check wiring.

Electronics unit is defective. Replace the device.

HART communication is not

working.

Status LED is lit or flashing red

(DIN rail transmitter only).

Power LED is not lit green (DIN

rail transmitter only).

Missing or incorrectly installed

communication resistor.

Commubox is not properly connected. Connect Commubox correctly .

Commubox is not set to "HART". Set Commubox selector switch to "HART".

Diagnostics events as per NAMUR

NE107 (® ä 35)

Power failure or insufficient supply

voltage

Apply correct voltage.

Check the contacting of the cables and

correct if necessary.

Install the communication resistor (250 W)

correctly.

Check diagnostics events:

LED is lit: diagnostic display, category F

•

• LED flashing: diagnostic display of

categories C, S or M

Check the supply voltage and check if

wiring is correct.

Check display (optional in conjunction with head transmitter)

Problem Possible cause Remedy

No supply voltage • Check the supply voltage at the head

transmitter, terminals + and -.

Ensure that the display module holders

•

are correctly seated and that the display

module is properly connected to the

head transmitter. (® ä 10).

No display visible

The display module is defective. Replace the module.

The electronics of the head transmitter

are defective.

• If possible, test the display module with

other suitable head transmitters e.g.

Endress+Hauser head transmitter.

Replace the head transmitter.

Application errors without status messages for RTD sensor connection

Problem Possible cause Remedy

Incorrect sensor orientation. Install the sensor correctly.

Measured value is incorrect/

inaccurate

Heat conducted by sensor. Observe the face-to-face length of the

sensor.

Device programming is incorrect

(number of wires).

Change the Connection type device

function.

Endress+Hauser 33

Page 34

Diagnostics and troubleshooting

Problem Possible cause Remedy

Failure current (≤ 3.6 mA or

≥ 21 mA)

Device programming is incorrect

(scaling).

Incorrect RTD configured. Change the Sensor type device function.

Sensor connection. Check that the sensor is connected

The cable resistance of the sensor (twowire) was not compensated.

Offset incorrectly set. Check offset.

Faulty sensor. Check the sensor.

RTD connected incorrectly. Connect the connecting cables correctly

Incorrect device programming (e.g.

number of wires).

Incorrect programming. Incorrect sensor type set in the Sensor

Change scaling.

correctly.

Compensate the cable resistance.

(terminal diagram).

Change the Connection type device

function.

type device function. Set the correct sensor

type.

iTEMP® TMT82

Application errors without status messages for TC sensor connection

Problem Possible cause Remedy

Incorrect sensor orientation. Install the sensor correctly.

Heat conducted by sensor. Observe the face-to-face length of the

sensor.

Measured value is incorrect/

inaccurate

Failure current (≤ 3.6 mA or

≥ 21 mA)

Device programming is incorrect

(scaling).

Incorrect thermocouple type (TC)

configured.

Incorrect comparison measuring point

set.

Interference via the thermocouple wire

welded in the thermowell (interference

voltage coupling).

Offset incorrectly set. Check offset.

Faulty sensor. Check the sensor.

Sensor is connected incorrectly. Connect the connecting cables correctly

Incorrect programming. Incorrect sensor type set in the Sensor

Change scaling.

Change the Sensor type device function.

Set the correct comparison measuring

point(® ä 62).

Use a sensor where the thermocouple wire

is not welded.

(terminal diagram).

type device function. Set the correct sensor

type.

34 Endress+Hauser

Page 35

iTEMP® TMT82

1

2

1

3

A

B

Diagnostics and troubleshooting

11.2 Diagnostics events

11.2.1

A Display in the event of a warning

B Display in the event of an alarm

1 Status signal in the header

2 The display alternates between the primary measured value and the status - indicated by the appropriate letter (M,

C or S) - plus the defined error number.

3 The display alternates between "- - - -" (no valid measured value) and the status - indicated by the appropriate

letter (F) - plus the defined error number.

Displaying diagnostics events

A0014837

Status signals

Symbol Event

category

Operating error An operating error has occurred. The measured value is no longer valid.

Service mode The device is in service mode (e.g. during a simulation).

Out of

specification

Maintenance

required

Meaning

The device is being operated outside its technical specifications (e.g. during warm-up or

cleaning processes).

Maintenance is required. The measured value is still valid.

Diagnostic behavior

Alarm

Warning

Measurement is interrupted. The signal outputs assume the defined alarm condition. A

diagnostic message is generated (status signal F).

The device continues to measure. A diagnostic message is generated (status signals M, C

or S).

Endress+Hauser 35

Page 36

Diagnostics and troubleshooting

iTEMP® TMT82

Diagnostics event and event text

The fault can be identified by means of the diagnostics event. The event text helps you by

providing information about the fault.

Diagnostics event

Status signal Event number Event text

¯ ¯ ¯

Example

042 Sensor corroded

3-digit number

If two or more diagnostics events are pending simultaneously, only the message with the highest

priority is shown. Additional pending diagnostic messages are shown in the Diagnostics list

submenu (® ä 73).

Past diagnostic messages that are no longer pending are shown in the Event logbook

submenu (® ä 74).

11.2.2

Overview of diagnostics events

Each diagnostics event is assigned a certain event level at the factory. The user can change this

assignment for certain diagnostics events.

Valid for diagnostics numbers 006, 041, 042, 043, 101 and 102.

The relevant sensor input for these diagnostics events can be identified by the Actual diag.

channel parameter or on the optional attachable display.

Status

signal

Diagno

stic

number

001 Device malfunction Replace electronics. F Alarm

006 Redundancy active 1. Check electrical wiring.

041 Sensor broken 1. Check electrical wiring.

042 Sensor corroded 1. Check electrical wiring of sensor.

043 Short circuit 1. Check electronic wiring.

044 Sensor drift 1. Check sensors.

045 Working area 1. Check ambient temperature.

101 Sensor value too

Short text Corrective measure

Diagnostics for the sensor

2. Replace sensor.

3. Check connection type.

2. Replace sensor.

3. Check connection type.

2. Replace sensor.

2. Replace sensor.

2. Check process temperatures.

2. Check external reference measuring point.

1. Check process temperatures.

low

2. Inspect sensor.

3. Check sensor type.

from the

factory

Can be

changed

M Warning

F Alarm

M Warning

F

F Alarm

M Warning

F, S

F Alarm

F Alarm

Diagnostic

behavior

from the

factory

to

1)

1)

36 Endress+Hauser

Page 37

iTEMP® TMT82

Diagnostics and troubleshooting

Status

signal

Diagno

stic

number

102 Sensor value too

104 Backup active 1. Check electrical wiring of sensor 1.

105 Calibration interval 1. Execute calibration and reset calibration interval.

106 Backup not

201 Device malfunction Replace electronics. F Alarm

221 Reference

241 Software 1. Restart device.

261 Electronic modules Replace electronics. F Alarm

262 Module connection

283 Memory content Replace electronics. F Alarm

301 Supply voltage 1. Increase supply voltage.

401 Factory reset Please wait until the reset procedure is complete. C Warning

402 Initialization Please wait until the start-up procedure is complete. C Warning

411 Up-/download Please wait until the up-/download is complete. C Warning

431 Factory

435 Linearization 1. Check configuration of sensor parameters.

437 Configuration 1. Check configuration of sensor parameters.

451 Data processing Please wait until data processing is complete. C Warning

483 Simulation input

485 Measured value

491 Simulation current

Short text Corrective measure

1. Check process temperatures.

high

available

measurement

short circuit

calibration

simulation

output

2)

2. Inspect sensor.

3. Check sensor type.

2. Replace sensor 1.

3. Check connection type.

2. Switch off calibration counter.

1. Check electrical wiring of sensor 2.

2. Replace sensor 2.

3. Check connection type.

Diagnostics for the electronics

Replace electronics. F Alarm

2. Perform device reset.

3. Replace device.

1. Ensure that display module is correctly seated on the head

transmitter.

2. Test the display module using other suitable head

transmitters.

3. Display module defective? Replace module.

2. Check connection wires for corrosion.

Diagnostics for the configuration

Replace electronics. F Alarm

2. Check configuration of special sensor linearizion.

3. Contact service.

4. Replace electronics.

2. Check configuration of special sensor linearizion.

3. Check configuration of transmitter settings.

4. Contact service.

Deactivate simulation. C Warning

from the

factory

Can be

changed

F Alarm

M Warning

M Warning

F

M Warning

F Alarm

M Warning

F Alarm

F Alarm

F Alarm

Diagnostic

behavior

from the

factory

to

1)

Endress+Hauser 37

Page 38

Diagnostics and troubleshooting

iTEMP® TMT82

Status

signal

Diagno

stic

number

803 Current loop 1. Check wiring.

842 Process limit value Check scaling of analog output. M Warning

925 Device

1) Diagnostic behavior can be changed in: "Alarm" or "Warning"

2)

Short text Corrective measure

Diagnostics for the process

2. Replace electronics.

Observe ambient temperature in accordance with

temperature

In the case of this diagnostics event, the device always issues a "low" alarm status (output current £ 3.6 mA).

specification.

from the

factory

Can be

changed

F Alarm

F, S

S Warning

F

Diagnostic

behavior

from the

factory

to

1)

11.3 Spare parts

Currently available spare parts for your product can be found online at:

http://www.products.endress.com/spareparts_consumables, HART® Temperature transmitter:

TMT82. When ordering spare parts, please quote the serial number of the device!

Type Order number

Standard - DIN securing set (2 screws and springs, 4 shaft lock-down rings, 1 plug for the display

interface)

US - M4 securing set (2 screws and 1 plug for the display interface) 71044062

TID10 service cable; connecting cable for service interface, 40 cm 71086650

Commubox FXA195 HART®, for intrinsically safe HART communication with FieldCare via the USB

interface.

Spare parts kit for DIN rail transmitter (terminals and DIN rail clips) 71203361

71044061

FXA195-.......

11.4 Return

The measuring device must be returned if repairs or a factory calibration are required, or if the

wrong measuring device has been ordered or delivered. According to legal regulations, Endress

+Hauser, as an ISO-certified company, is required to follow certain procedures when handling

returned products that are in contact with medium.

To ensure swift, safe and professional device returns, please read the return procedures and

conditions on the Endress+Hauser website at www.services.endress.com/return-material

11.5

Disposal

The device contains electronic components and must therefore be disposed of as electronic waste.

Please pay particular attention to the national disposal regulations in your country.

38 Endress+Hauser

Page 39

iTEMP® TMT82

Diagnostics and troubleshooting

11.6 Software history and overview of compatibility

Revision history

The firmware version (FW) on the nameplate and in the Operating Instructions indicates the

device release: XX.YY.ZZ (example 01.02.01).

XX Change to main version. No longer compatible. The device and Operating

Instructions change.

YY Change to functions and operation. Compatible. The Operating Instructions

change.

ZZ Fixes and internal changes. No changes to the Operating Instructions.

Date Firmware Version Modifications Documentation

01/11 1.00.zz Original firmware BA01028T/09/en/13.10

10/12 1.00.zz No changes to functions and operation. BA01028T/09/en/14.12

Endress+Hauser 39

Page 40

Technical data

iTEMP® TMT82

12 Technical data

12.1

Input

Measured variable Temperature (temperature-linear transmission behavior), resistance and voltage.

Type of input Two independent sensors can be connected. The measuring inputs are not galvanically isolated

from each other.

Type of input Designation Measuring range limits Min. span

Resistance

thermometer (RTD)

as per IEC

60751:2008

(a = 0.003851)

as per JIS

C1604:1984

(a = 0.003916)

as per DIN 43760

IPTS-68

(a = 0.006180)

as per GOST 6651-94

(a = 0.003910) (for

Cu: a = 0.004280)

as per OIML R84:

2003

and GOST 6651-94

(a = 0.006170) (for

Cu: a = 0.004260)

as per OIML R84:

2003 (a = 0.004280)

Resistance

transmitter

Thermocouples

(TC)

to IEC 584 part 1

As per ASTM E988 Type C (W5Re-W26Re)

to DIN 43710 Type L (Fe-CuNi)

Pt100

Pt200

Pt500

Pt1000

Pt100 –200 to +510 °C (–328 to +950 °F) 10 K

Ni100

Ni120

Pt100

Pt50

Cu50

Cu50

Ni100

Ni120

Cu50 –180 to +200 °C (–292 to +392 °F) 10 K

Pt100 (Callendar van

Dusen)

Nickel polynomial

Copper polynomial

•

Type of connection: 2-wire, 3-wire or 4-wire connection, sensor current: £ 0.3 mA

•

With 2-wire circuit, compensation of wire resistance possible (0 to 30 W)

•

With 3-wire and 4-wire connection, sensor wire resistance up to max. 50 W per wire

Resistance W 10 to 400 W

Type B (PtRh30-PtRh6)

Type E (NiCr-CuNi)

Type J (Fe-CuNi)

Type K (NiCr-Ni)

Type N (NiCrSi-NiSi)

Type R (PtRh13-Pt)

Type S (PtRh10-Pt)

Type T (Cu-CuNi)

Type D (W3Re-W25Re)

Type U (Cu-CuNi)

–200 to +850 °C (–328 to +1 562 °F)

–200 to +850 °C (–328 to +1 562 °F)

–200 to +500 °C (–328 to +932 °F)

–200 to +250 °C (–328 to +482 °F)

–60 to +250 °C (–76 to +482 °F)

–60 to +250 °C (–76 to +482 °F)

–200 to +850 °C (–328 to +1 562 °F)

–185 to +1 100 °C (–301 to +2 012 °F)

–175 to +200 °C (–283 to +392 °F)

–50 to +200 °C (–58 to +392 °F)

–60 to +180 °C (–76 to +356 °F)

–60 to +180 °C (–76 to +356 °F)

The measuring range limits are specified by entering the limit values that depend on the

coefficients A to C and R0.

10 to 2 000 W

Recommended temperature range:

+40 to +1 820 °C (+104 to +3 308 °F)

–270 to +1 000 °C (–454 to +1 832 °F)

–210 to +1 200 °C (–346 to +2 192 °F)

–270 to +1 372 °C (–454 to +2 501 °F)

–270 to +1 300 °C (–454 to +2 372 °F)

–50 to +1 768 °C (–58 to +3 214 °F)

–50 to +1 768 °C (–58 to +3 214 °F)

–260 to +400 °C (–436 to +752 °F)

0 to +2 315 °C (+32 to +4 199 °F)

0 to +2 315 °C (+32 to +4 199 °F)

–200 to +900 °C (–328 to +1 652 °F)

–200 to +600 °C (–328 to +1 112 °F)

+100 to +1 500 °C (+212 to +2 732 °F)

0 to +750 °C (+32 to +1 382 °F)

+20 to +700 °C (+68 to +1 292 °F)

0 to +1 100 °C (+32 to +2 012 °F)

0 to +1 100 °C (+32 to +2 012 °F)

0 to +1 400 °C (+32 to +2 552 °F)

0 to +1 400 °C (+32 to +2 552 °F)

–185 to +350 °C (–301 to +662 °F)

0 to +2 000 °C (+32 to +3 632 °F)

0 to +2 000 °C (+32 to +3 632 °F)

0 to +750 °C (+32 to +1 382 °F)

–185 to +400 °C (–301 to +752 °F)

10 K

10 K

10 K

10 K

10 K

10 W

100 W

50 K

50 K

50 K

50 K

50 K

50 K

50 K

50 K

50 K

50 K

40 Endress+Hauser

Page 41

iTEMP® TMT82

Type of input Designation Measuring range limits Min. span

• Internal cold junction (Pt100)

External cold junction: configurable value –40 to +85 °C (–40 to +185 °F)

•

•

Max. sensor resistance k10 kW (if sensor resistance is greater than 10 kW, an error message as per NAMUR NE89 is output)

Voltage transmitter

(mV)

Millivolt transmitter

(mV)

–20 to 100 mV 5 mV

Technical data

The following connection combinations are possible when both sensor inputs are assigned:

Sensor input 1

Sensor input 2

RTD or resistance

transmitter, 2-wire

RTD or resistance

transmitter, 3-wire

RTD or resistance

transmitter, 4-wire

Thermocouple (TC),

voltage transmitter

RTD or

resistance

transmitter, 2-

wire

Â

Â

- - - -

Â

RTD or

resistance

transmitter, 3-

wire

RTD or

resistance

transmitter, 4-

wire

-

-

Thermocouple

(TC), voltage

transmitter

Â

Â

Output signal

Failure information

12.2 Output

Analog output 4 to 20 mA, 20 to 4 mA (can be inverted)

Signal encoding FSK ±0.5 mA via current signal

Data transmission rate 1200 baud

Galvanic isolation U = 2 kV AC (input/output)

Failure information as per NAMUR NE43:

Failure information is created if the measuring information is missing or not valid. A complete list

of all the errors occurring in the measuring system is created.

Underranging Linear drop from 4.0 to 3.8 mA

Overranging Linear increase from 20.0 to 20.5 mA

Failure, e.g. sensor breakage, sensor short-circuit ≤ 3.6 mA ("low") or ≥ 21 mA ("high"), can be selected

The "high" alarm setting can be set between 21.5 mA and 23 mA,

thus providing the flexibility needed to meet the requirements of

various control systems.

Endress+Hauser 41

Page 42

Technical data

Ub

42 V

1348

1098

250

11 V

0

36.25 V16.75 V

Supply voltage (V DC)

Load (

)Ω

iTEMP® TMT82

Load