Page 1

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

BA01854T/09/EN/01.18

71413522

2018-07-10

Valid as of version

01.00 (device version)

Products Solutions Services

Operating Instructions

iTEMP TMT71/72

Temperature transmitter

Preliminary version:

03-12-2018

Page 2

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

Page 3

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

iTEMP TMT71/72 Table of contents

Table of contents

1 About this document . . . . . . . . . . . . . . . . 4

1.1 Document function . . . . . . . . . . . . . . . . . . . . . 4

1.2 Safety Instructions (XA) . . . . . . . . . . . . . . . . . . 4

1.3 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Tool symbols . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Documentation . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6 Registered trademarks . . . . . . . . . . . . . . . . . . . 6

2 Basic safety instructions . . . . . . . . . . . . 7

2.1 Requirements for the personnel . . . . . . . . . . . . 7

2.2 Designated use . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . 7

3 Incoming acceptance and product

identification . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Incoming acceptance . . . . . . . . . . . . . . . . . . . . 8

3.2 Product identification . . . . . . . . . . . . . . . . . . . . 8

3.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Certificates and approvals . . . . . . . . . . . . . . . . 9

3.5 Transport and storage . . . . . . . . . . . . . . . . . . . 9

4 Installation . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Installation conditions . . . . . . . . . . . . . . . . . . 10

4.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3 Post-installation check . . . . . . . . . . . . . . . . . . 14

5 Electrical connection . . . . . . . . . . . . . . 15

5.1 Connection conditions . . . . . . . . . . . . . . . . . . 15

5.2 Quick wiring guide . . . . . . . . . . . . . . . . . . . . . 15

5.3 Connecting the sensor cables . . . . . . . . . . . . . 16

5.4 Connecting the transmitter . . . . . . . . . . . . . . 16

5.5 Special connection instructions . . . . . . . . . . . . 16

5.6 Post-connection check . . . . . . . . . . . . . . . . . . 17

6 Operation options . . . . . . . . . . . . . . . . . 18

6.1 Overview of operation options . . . . . . . . . . . . 18

6.2 Structure and function of the operating

menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3 Access to the operating menu via the

operating tool . . . . . . . . . . . . . . . . . . . . . . . . 23

6.4 Access to the operating menu via the

SmartBlue App . . . . . . . . . . . . . . . . . . . . . . . 26

7 System integration . . . . . . . . . . . . . . . . 28

7.1 Overview of device description files . . . . . . . . . 28

7.2 Measured variables via HART protocol . . . . . . 28

8.2 Switching on the transmitter . . . . . . . . . . . . . 31

8.3 Configuring the measuring device . . . . . . . . . . 31

8.4 Protecting settings from unauthorized

access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9 Diagnostics and troubleshooting . . . 35

9.1 General troubleshooting . . . . . . . . . . . . . . . . . 35

9.2 Diagnostic information on local display . . . . . . 37

9.3 Diagnostic information via communication

interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.4 Diagnostic list . . . . . . . . . . . . . . . . . . . . . . . . 38

9.5 Event logbook . . . . . . . . . . . . . . . . . . . . . . . . 38

9.6 Overview of diagnostic events . . . . . . . . . . . . . 39

9.7 Firmware history . . . . . . . . . . . . . . . . . . . . . . 40

10 Maintenance . . . . . . . . . . . . . . . . . . . . . . 41

11 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

11.1 General information . . . . . . . . . . . . . . . . . . . 41

11.2 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . 41

11.3 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

11.4 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

12 Accessories . . . . . . . . . . . . . . . . . . . . . . . 41

12.1 Device-specific accessories . . . . . . . . . . . . . . . 42

12.2 Communication-specific accessories . . . . . . . . 42

12.3 Service-specific accessories . . . . . . . . . . . . . . . 43

12.4 System components . . . . . . . . . . . . . . . . . . . . 44

13 Technical data . . . . . . . . . . . . . . . . . . . . 45

13.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

13.2 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

13.3 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . 47

13.4 Performance characteristics . . . . . . . . . . . . . . 48

13.5 Environment . . . . . . . . . . . . . . . . . . . . . . . . . 55

13.6 Mechanical construction . . . . . . . . . . . . . . . . 56

13.7 Certificates and approvals . . . . . . . . . . . . . . . 58

13.8 Supplementary documentation . . . . . . . . . . . . 60

14 Operating menu and parameter

description . . . . . . . . . . . . . . . . . . . . . . . . 61

14.1 Menu: Diagnostics . . . . . . . . . . . . . . . . . . . . . 65

14.2 Menu: Application . . . . . . . . . . . . . . . . . . . . . 71

14.3 Menu: System . . . . . . . . . . . . . . . . . . . . . . . . 81

7.3

Supported HART® commands . . . . . . . . . . . . .

28

8 Commissioning . . . . . . . . . . . . . . . . . . . . 31

8.1 Post-installation check . . . . . . . . . . . . . . . . . . 31

Endress+Hauser V. 1, Rev. 2, 4-10-2018 3

Page 4

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

About this document iTEMP TMT71/72

1 About this document

1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to

troubleshooting, maintenance and disposal.

1.2 Safety Instructions (XA)

When using in hazardous areas, compliance with national regulations is mandatory.

Separate Ex-specific documentation is provided for measuring systems that are used in

hazardous areas. This documentation is an integral part of these Operating Instructions.

The installation specifications, connection data and safety instructions it contains must be

strictly observed! Make sure that you use the right Ex-specific documentation for the right

device with approval for use in hazardous areas! The number of the specific Ex

documentation (XA...) is provided on the nameplate. If the two numbers (on the Ex

documentation and the nameplate) are identical, then you may use this Ex-specific

documentation.

1.3 Symbols used

1.3.1 Safety symbols

Symbol Meaning

DANGER

WARNING

CAUTION

NOTICE

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.3.2 Electrical symbols

Symbol Meaning

Direct current

Alternating current

Direct current and alternating current

4 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

Page 5

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

iTEMP TMT71/72 About this document

Symbol Meaning

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system.

Protective Earth (PE)

A terminal which must be connected to ground prior to establishing any other

connections.

The ground terminals are situated inside and outside the device:

• Inner ground terminal: Connects the protectiv earth to the mains supply.

• Outer ground terminal: Connects the device to the plant grounding system.

1.3.3 Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

, , …

Series of steps

Result of a step

Help in the event of a problem

Visual inspection

1.4 Tool symbols

Symbol Meaning

Flat blade screwdriver

A0011220

Phillips head screwdriver

A0011219

Allen key

A0011221

Open-ended wrench

A0011222

Torx screwdriver

A0013442

Endress+Hauser V. 1, Rev. 2, 4-10-2018 5

Page 6

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

About this document iTEMP TMT71/72

1.5 Documentation

Document Purpose and content of the document

Technical Information

TI01392T/09/en

Brief Operating Instructions

KA01384T/09/en

Planning aid for your device

The document contains all the technical data on the device and provides

an overview of the accessories and other products that can be ordered for

the device.

Guide that takes you quickly to the 1st measured value

The Brief Operating Instructions contain all the essential information

from incoming acceptance to initial commissioning.

The document types listed are available:

In the Download Area of the Endress+Hauser Internet site: www.endress.com →

Download

1.6 Registered trademarks

HART®

Registered trademark of the HART® FieldComm Group

6 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

Page 7

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

iTEMP TMT71/72 Basic safety instructions

2 Basic safety instructions

2.1 Requirements for the personnel

The personnel for installation, commissioning, diagnostics and maintenance must fulfill

the following requirements:

‣

‣‣‣

‣

Trained, qualified specialists must have a relevant qualification for this specific function

and task

Are authorized by the plant owner/operator

Are familiar with federal/national regulations

Before beginning work, the specialist staff must have read and understood the

instructions in the Operating Instructions and supplementary documentation as well as

in the certificates (depending on the application)

Following instructions and basic conditions

The operating personnel must fulfill the following requirements:

Being instructed and authorized according to the requirements of the task by the

facility's owner-operator

‣

Following the instructions in these Operating Instructions

2.2 Designated use

The device is a universal and user-configurable temperature transmitter with one sensor

input for a resistance thermometer (RTD), thermocouples (TC), resistance and voltage

transmitters. The head transmitter version of the device is intended for mounting in a

terminal head (flat face) as per DIN EN 50446. It is also possible to mount the device on a

DIN rail using the optional DIN rail clip.

The manufacturer is not liable for damage caused by improper or non-designated use.

2.3 Operational safety

‣

‣

Operate the device in proper technical condition and fail-safe condition only.

The operator is responsible for interference-free operation of the device.

Hazardous area

To eliminate a danger for persons or for the facility when the device is used in the

hazardous area (e.g. explosion protection or safety equipment):

‣

‣

Based on the technical data on the nameplate, check whether the ordered device is

permitted for the intended use in the hazardous area. The nameplate can be found on

the side of the transmitter housing.

Observe the specifications in the separate supplementary documentation that is an

integral part of these Instructions.

Electromagnetic compatibility

The measuring system complies with the general safety requirements as per EN 61010-1,

the EMC requirements as per the IEC/EN 61326 series and the NAMUR recommendations

NE 21.

NOTICE

‣

The device must only be powered by a power unit that operates using an energy-limited

electric circuit according to IEC 61010-1, "SELV or Class 2 circuit".

Endress+Hauser V. 1, Rev. 2, 4-10-2018 7

‣

Page 8

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

Incoming acceptance and product identification iTEMP TMT71/72

3 Incoming acceptance and product

identification

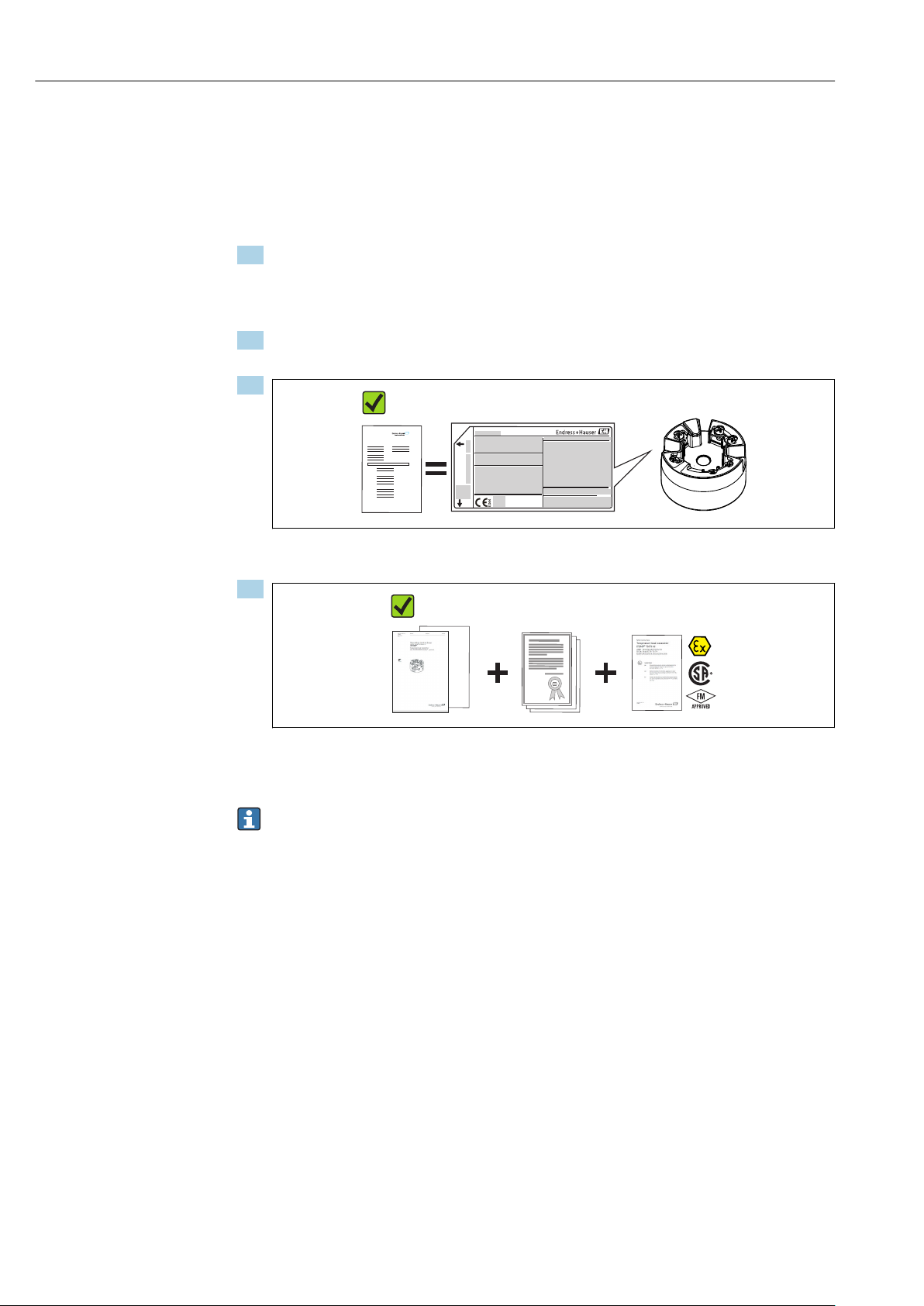

3.1 Incoming acceptance

1. Unpack the temperature transmitter carefully. Is the packaging or content damaged?

Damaged components may not be installed as the manufacturer can otherwise

not guarantee compliance with the original safety requirements or the material

resistance, and can therefore not be held responsible for any resulting damage.

2. Is the delivery complete or is anything missing? Check the scope of delivery against

your order.

3.

DELIVERY NOTE

A0037102

Does the nameplate match the ordering information on the delivery note?

4.

A0024858

Are the technical documentation and all other necessary documents provided? If

applicable: are the Safety Instructions (e.g. XA) for hazardous areas provided?

If one of these conditions is not satisfied, contact your Endress+Hauser Sales Center.

3.2 Product identification

The following options are available for identification of the device:

• Nameplate specifications

• Extended order code with breakdown of the device features on the delivery note

• Enter the serial number from the nameplate in the W@M Device Viewer

(www.endress.com/deviceviewer): All data relating to the device and an overview of the

Technical Documentation supplied with the device are displayed.

• Enter the serial number on the nameplate into the Endress+Hauser Operations App or

scan the 2-D matrix code (QR code) on the nameplate with the Endress+Hauser

Operations App: all the information about the device and the technical documentation

pertaining to the device is displayed.

3.2.1 Nameplate

The right device?

Compare and check the data on the nameplate of the device against the requirements of

the measuring point:

8 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

TMT71/72

Page 9

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

11-42V

012345678910

xx.yy.zz

TMT82- XXXXX/XX

iTEMP

Ser.no.:

FW:

Input:

12345678ABCDEFGH

12345678ABCDEFGH

Dev.Rev: x

Ext. ord. cd.:

XXXXXXXXXXXXX#

0044

iTEMP TMT71/72 Incoming acceptance and product identification

3

7

Made in Germany 201x

D-87484 Nesselwang

A0014561

1 Nameplate of the head transmitter (example, Ex version)

1 Power supply, current consumption and radio approval (Bluetooth)

2 Serial number, device revision, firmware version and hardware version

3 Data Matrix 2D code

4 2 lines for the TAG name and extended order code

5 Approval in hazardous area with number of the relevant Ex documentation (XA...)

6 Approvals with symbols

7 Order code and manufacturer ID

3.3 Scope of delivery

The scope of delivery of the device comprises:

• Temperature transmitter

• Mounting material (head transmitter), optional

• Hard copy of multi-language Brief Operating Instructions

• Additional documentation for devices which are suitable for use in the hazardous area

(0 1 ), such as Safety Instructions (XA...), Control or Installation Drawings (ZD...).

3.4 Certificates and approvals

The device left the factory in a safe operating condition. The device complies with the

requirements of the standards EN 61 010-1 "Safety Requirements for Electrical Equipment

for Measurement, Control, and Laboratory Use" and with the EMC requirements as per the

IEC/EN 61326 series.

3.4.1 CE/EAC mark, declaration of conformity

The device meets the legal requirements of the EU/EEU guidelines. The manufacturer

confirms that the device is compliant with the relevant guidelines by applying the CE/EAC

mark.

3.4.2

HART® protocol certification

The temperature transmitter is registered by the HART® FieldComm Group. The device

meets the requirements of the HART Communication Protocol Specifications, Revision 7

(HCF 7.6).

3.5 Transport and storage

Carefully remove all the packaging material and protective covers that are part of the

transported package.

Dimensions and operating conditions: → 56

When storing (and transporting) the device, pack it so that it is reliably protected

against impact. The original packaging offers the best protection.

Storage temperature

Head transmitter: –50 to +100 °C (–58 to +212 °F)

Endress+Hauser V. 1, Rev. 2, 4-10-2018 9

1

254

6

Page 10

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

Installation iTEMP TMT71/72

4 Installation

4.1 Installation conditions

4.1.1 Dimensions

The dimensions of the device are provided in the "Technical data" section → 56.

4.1.2 Mounting location

Head transmitter:

– In the terminal head, flat face, as per DIN EN 50446, direct mounting on insert with

cable entry (middle hole 7 mm)

– In the field housing, separated from the process→ 41

It is also possible to mount the head transmitter on a DIN rail as per IEC 60715 using

the DIN rail clip → 41accessory.

Information about the conditions (such as the ambient temperature, degree of protection,

climate class etc.) that must be present at the installation point so that the device can be

mounted correctly is provided in the "Technical data" section→ 55.

When using in hazardous areas, the limit values of the certificates and approvals must be

observed (see Ex Safety Instructions).

4.2 Installation

A Phillips head screwdriver is required to mount the head transmitter.

NOTICE

Do not overtighten the mounting screws as this could damage the head transmitter.

‣

Maximum torque = 1 Nm (¾ pound-feet).

10 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

Page 11

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

iTEMP TMT71/72 Installation

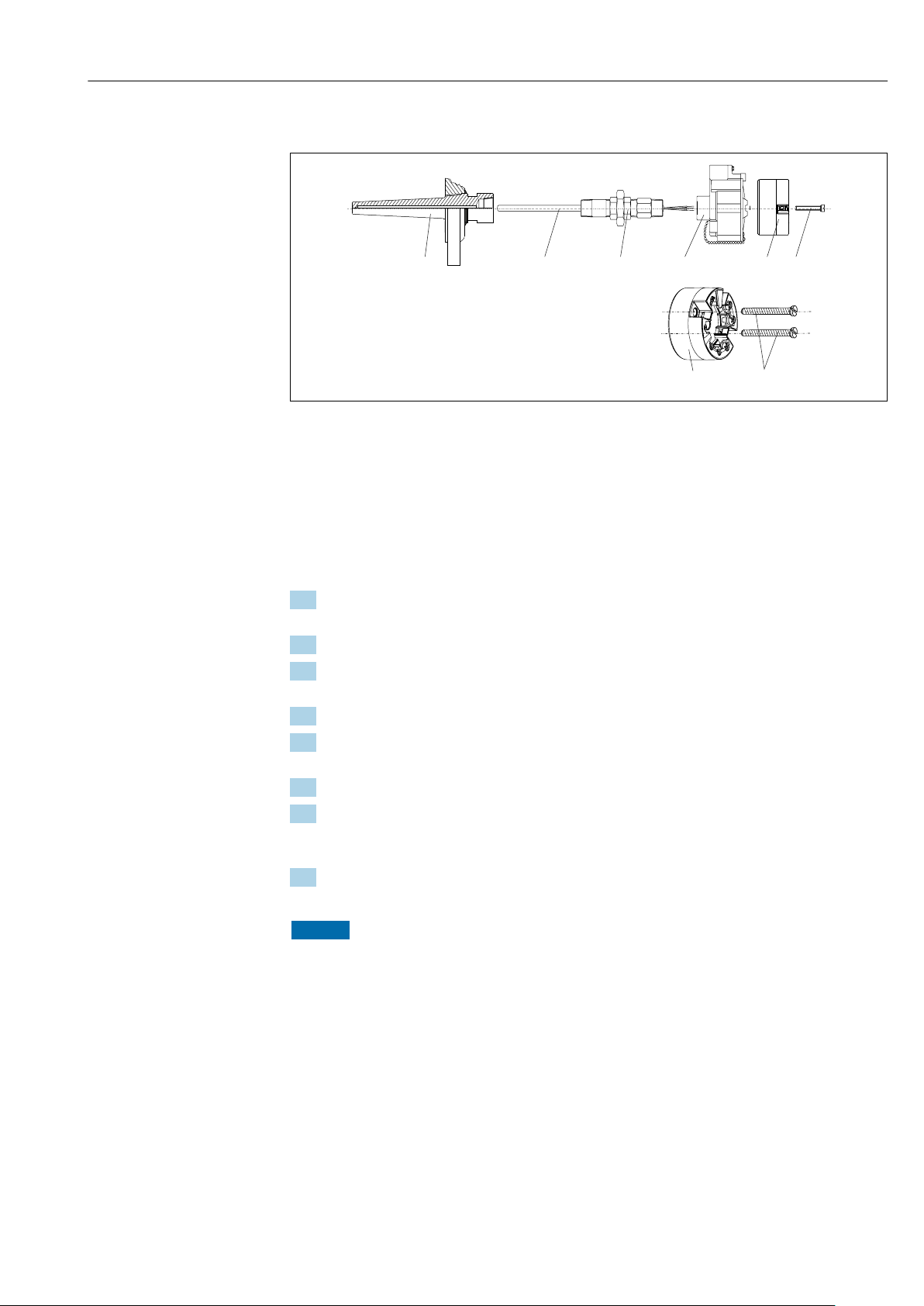

4.2.1 Mounting the head transmitter

Item A Item B

8

9

Item C

7

6

5

4

3

2

1

120 mm

(4.72 in)

120 mm

(4.72 in)

1 2 3 4 5

1

2

3 4

A0014269-EN

2 Head transmitter mounting (three versions)

Item A Mounting in a terminal head (terminal head flat face as per DIN 43729)

1 Terminal head

2 Circlips

3 Insert

4 Connection wires

5 Head transmitter

6 Mounting springs

7 Mounting screws

8 Terminal head cover

9 Cable entry

Procedure for mounting in a terminal head, pos. A:

1. Open the terminal head cover (8) on the terminal head.

2. Guide the connection wires (4) of the insert (3) through the center hole in the head

transmitter (5).

3. Fit the mounting springs (6) on the mounting screws (7).

4. Guide the mounting screws (7) through the side boreholes of the head transmitter

and the insert (3). Then fix both mounting screws with the snap rings (2).

5. Then tighten the head transmitter (5) along with the insert (3) in the terminal head.

6. After wiring→ 15, close the terminal head cover (8) tightly again.

Endress+Hauser V. 1, Rev. 2, 4-10-2018 11

Page 12

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

Installation iTEMP TMT71/72

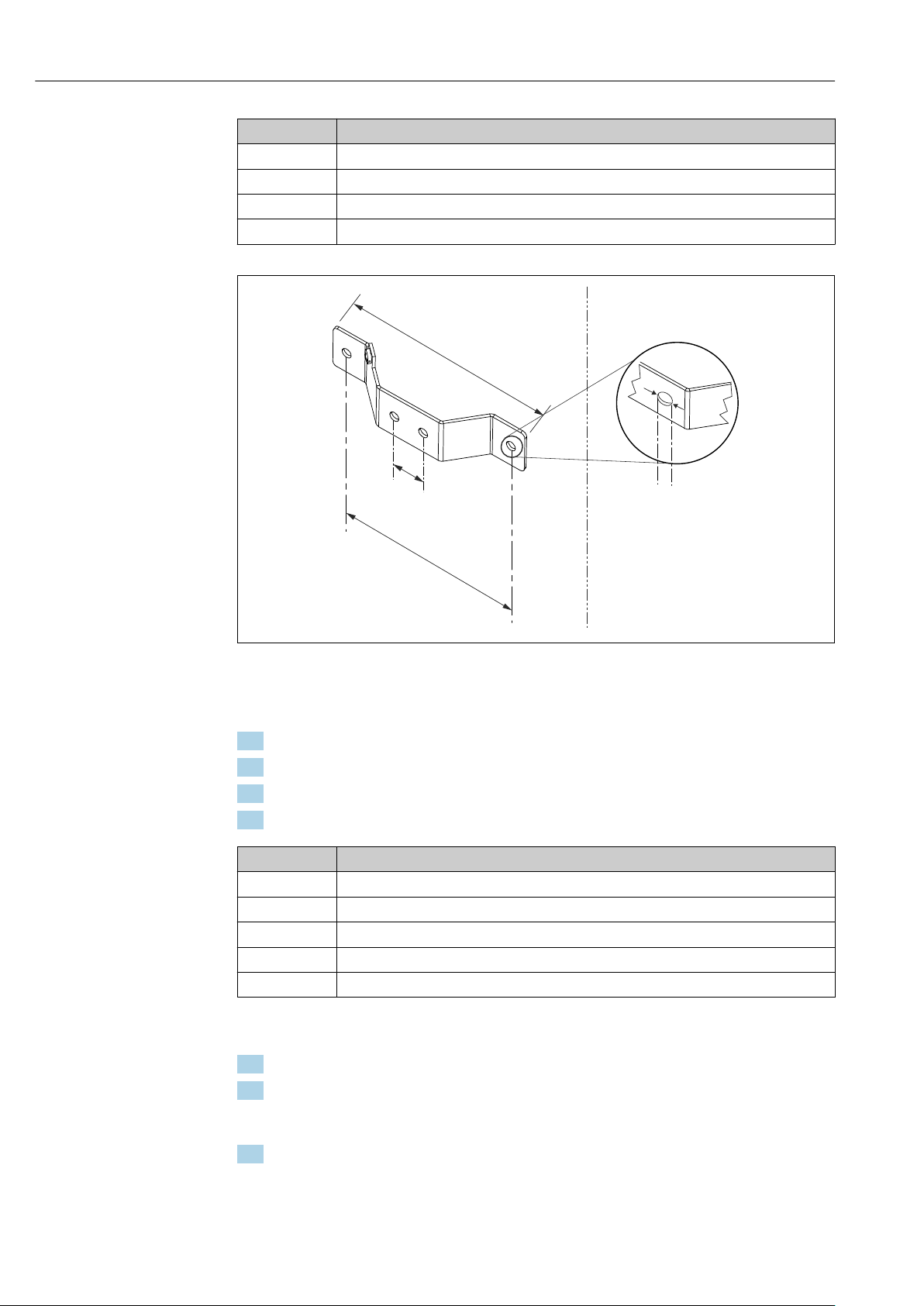

Item B Mounting in a field housing

1 Field housing cover

2 Mounting screws with springs

3 Head transmitter

5 Field housing

140 mm

(5.51 in)

21 mm

(0.83 in)

! 6.5 mm

(0.25 in)

120 mm

(4.72 in)

A0024604

3 Dimensions of angle bracket for wall mount (complete wall mounting set available as accessory)

Procedure for mounting in a field housing, pos. B:

1. Open the cover (1) of the field housing (4).

2. Guide the mounting screws (2) through the lateral bores in the head transmitter (3).

3. Screw the head transmitter to the field housing.

4. After wiring, close the field housing cover (1) → 15again.

Item C Mounting on DIN rail (DIN rail as per IEC 60715)

1 Mounting screws with springs

2 Head transmitter

3 Circlips

4 DIN rail clip

5 DIN rail

Procedure for mounting on a DIN rail, pos. C:

1. Press the DIN rail clip (4) onto the DIN rail (5) until it engages with a click.

2. Fit the mounting springs on the mounting screws (1) and guide the screws through

the side boreholes of the head transmitter (2). Then fix both mounting screws with

the snap rings (3).

3. Screw the head transmitter (2) onto the DIN rail clip (4).

12 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

Page 13

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

iTEMP TMT71/72 Installation

Mounting typical of North America

1

2 3 4 5

6

5

6

A0008520

4 Head transmitter mounting

1 Thermowell

2 Insert

3 Adapter, coupling

4 Terminal head

5 Head transmitter

6 Mounting screws

Thermometer design with thermocouples or RTD sensors and head transmitter:

1. Fit the thermowell (1) on the process pipe or the container wall. Secure the

thermowell according to the instructions before the process pressure is applied.

2. Fit the necessary neck tube nipples and adapter (3) on the thermowell.

3. Make sure sealing rings are installed if such rings are needed for harsh

environmental conditions or special regulations.

4. Guide the mounting screws (6) through the lateral bores of the head transmitter (5).

5. Position the head transmitter (5) in the terminal head (4) in such a way that the bus

cable (terminals 1 and 2) point to the cable entry.

6. Using a screwdriver, screw down the head transmitter (5) in the terminal head (4).

7. Guide the connection wires of the insert (3) through the lower cable entry of the

terminal head (4) and through the middle hole in the head transmitter (5). Wire the

connection wires up to the transmitter → 15.

8. Screw the terminal head (4), with the integrated and wired head transmitter, onto

the ready-mounted nipple and adapter (3).

NOTICE

The terminal head cover must be secured properly to meet the requirements for

explosion protection.

‣

After wiring, securely screw the terminal head cover back on.

Endress+Hauser V. 1, Rev. 2, 4-10-2018 13

Page 14

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

Installation iTEMP TMT71/72

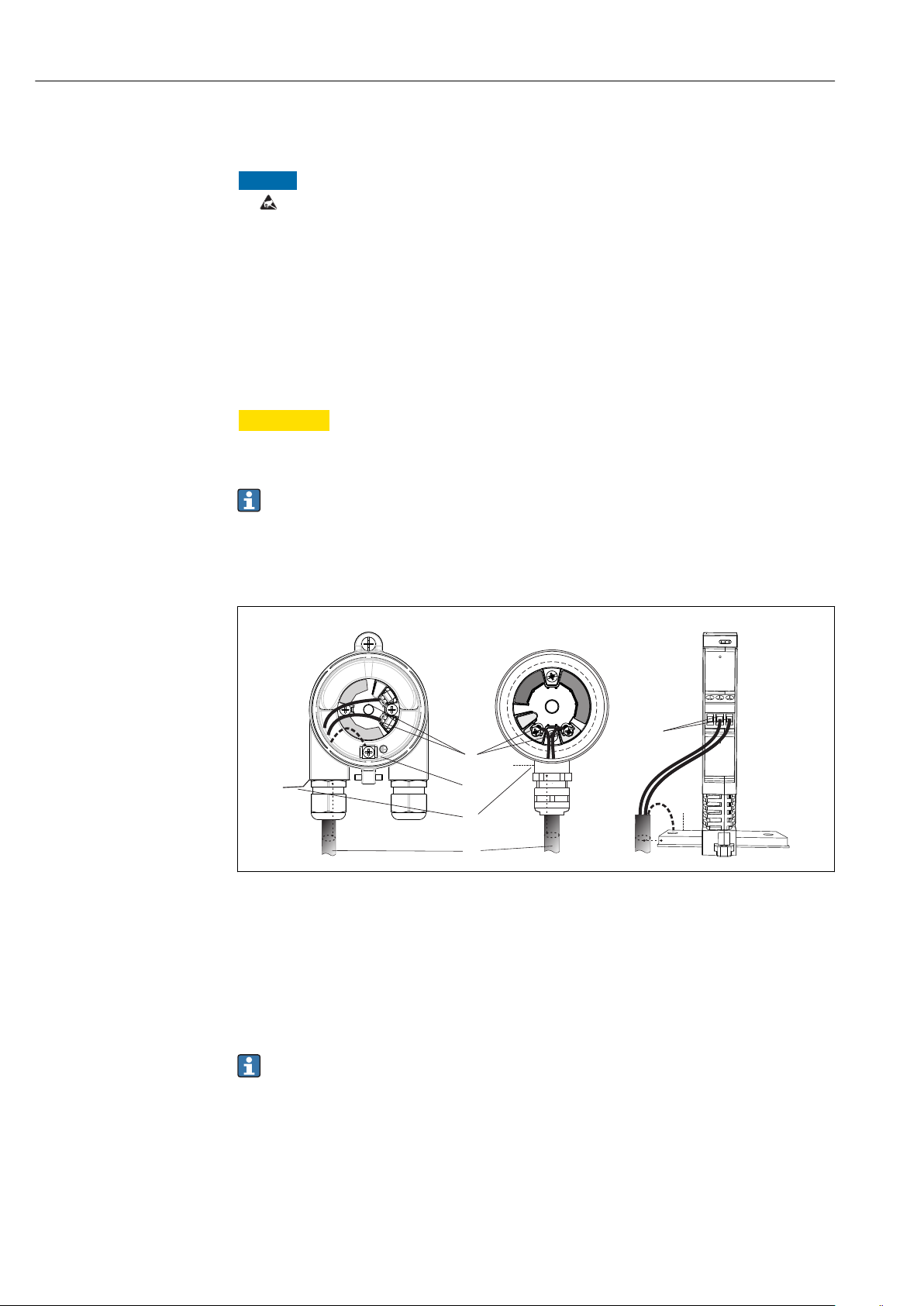

Mounting the display on the head transmitter

A0009852

5 Mounting the display

1. Loosen the screw on the terminal head cover. Flip back the terminal head cover.

2. Remove the cover of the display connection area.

3. Fit the display module onto the mounted and wired head transmitter. The fastening

pins must click securely into place on the head transmitter. After mounting, securely

tighten the terminal head cover.

The display can be used only with the appropriate terminal heads - cover with viewing

window (e.g. TA30 from Endress+Hauser).

4.3 Post-installation check

After installing the device, always run the following final checks:

Device condition and specifications Notes

Is the device undamaged (visual inspection)? -

Do the ambient conditions match the device specification (e.g. ambient temperature,

measuring range, etc.)?

See 'Technical data'

section

14 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

Page 15

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

-

+

+

-

iTEMP TMT71/72 Electrical connection

5 Electrical connection

5.1 Connection conditions

L

CAUTION

‣

‣

‣

Switch off the power supply before installing or connecting the device. Failure to

observe this may result in the destruction of parts of the electronics.

When connecting Ex-certified devices, please take special note of the instructions and

connection schematics in the Ex-specific supplement to these Operating Instructions.

Your supplier is available for assistance if required.

Do not occupy the display connection. An incorrect connection can destroy the

electronics.

NOTICE

Do not overtighten the screw terminals, as this could damage the transmitter. Use a

suitable screwdriver.

‣

‣

Maximum torque for securing screws = 1 Nm (¾ foot-pound), screwdriver: Pozidriv Z2

Maximum torque for screw terminals = 0.35 Nm (¼ foot-pound), screwdriver: Pozidriv

Z1

Proceed as follows to wire a mounted head transmitter:

1. Open the cable gland and the housing cover on the terminal head or the field

housing.

2. Feed the cables through the opening in the cable gland.

3. Connect the cables as shown in → 15.

4. Tighten the cable gland again and close the housing cover.

In order to avoid connection errors always follow the instructions in the post-connection

check section before commissioning!

5.2 Quick wiring guide

red

red

TC, mV

white

white

Sensor input

RTD, ! : 4-, 3- and 2-wire

6

5

4

3

5

463

Bus connection

and supply voltage

1

1

2

2

Display connection/

service interface

A0036348-EN

6 Terminal assignment of head transmitter

To operate the device via the HART® protocol (terminals 1 and 2), a minimum load of 250

Ω is required in the signal circuit.

Endress+Hauser V. 1, Rev. 2, 4-10-2018 15

Page 16

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

Electrical connection iTEMP TMT71/72

In the event of a thermocouple (TC) measurement, a 2-wire RTD can be connected to

measure the reference junction temperature. This is connected to terminals 4 and 6.

NOTICE

‣

ESD - electrostatic discharge. Protect the terminals from electrostatic discharge.

Failure to observe this may result in the destruction or malfunction of parts of the

electronics.

5.3 Connecting the sensor cables

Terminal assignment of the sensor connections→ 6, 15.

5.4 Connecting the transmitter

L

CAUTION

‣

Switch off power supply before installing or connecting the transmitter. Failure to

observe this may result in the destruction of parts of the electronics.

Cable specification

• A normal device cable suffices if only the analog signal is used.

• A shielded cable is recommended for HART® communication. Observe grounding

concept of the plant.

Please also observe the general procedure on → 15.

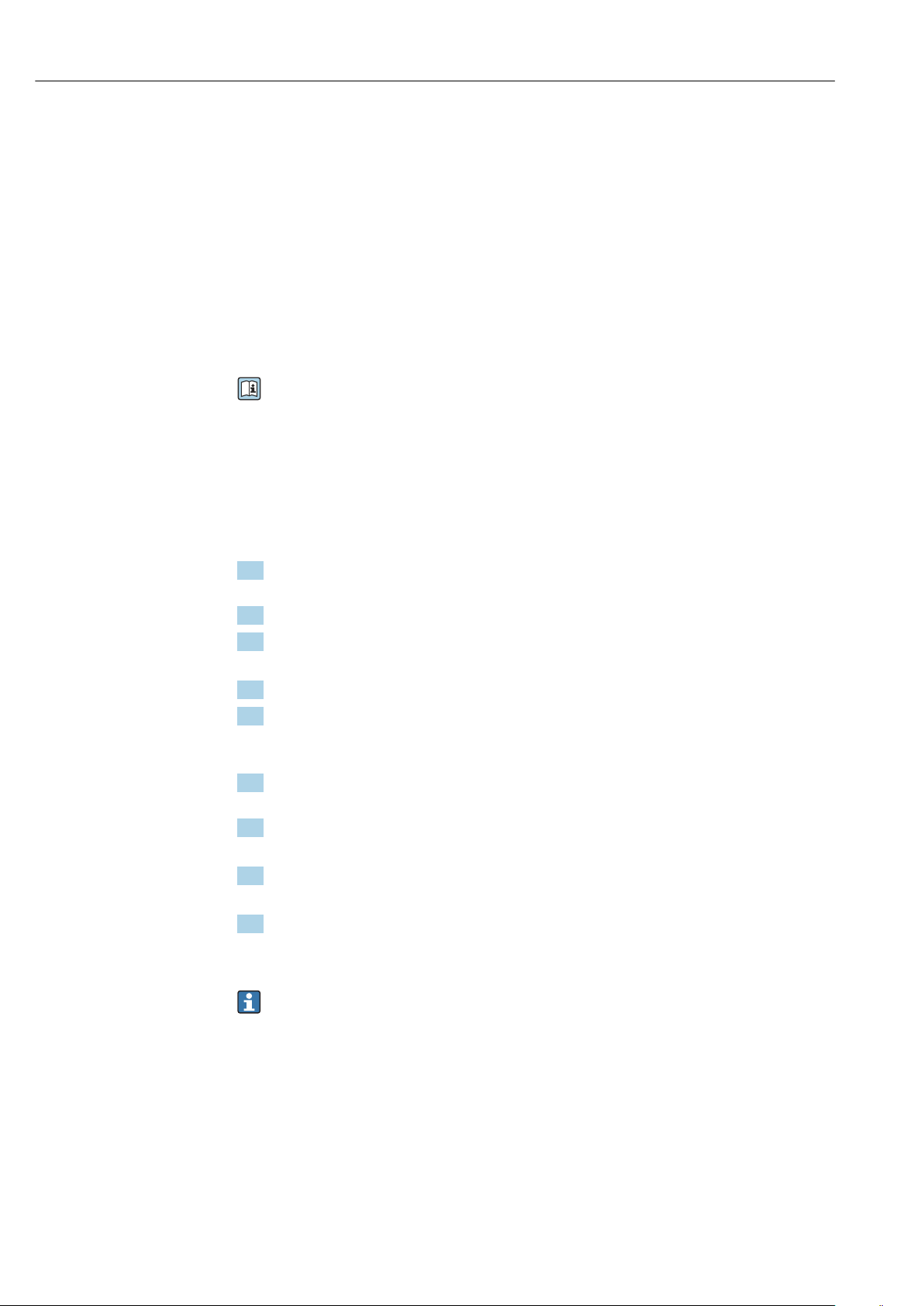

1 2 3

21+

2- 1+

2- 1+

!

4

5

6

7

!

4

7

!

5

A0017841

7 Connecting the signal cables and power supply

1 Head transmitter installed in field housing

2 Head transmitter installed in terminal head

3 DIN rail transmitter mounted on DIN rail

4

Terminals for HART® protocol and power supply

5 Internal ground connection

6 External ground connection

7

Shielded signal cable (recommended for HART® protocol)

• The terminals for connecting the signal cable (1+ and 2-) are protected against

reverse polarity.

• Conductor cross-section:

Max. 2.5 mm2 for screw terminals

5.5 Special connection instructions

Shielding and grounding

16 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

Page 17

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

iTEMP TMT71/72 Electrical connection

The specifications of the HART FieldComm Group must be observed during installation.

3

1

2

-

.

4

A0014463

8

Shielding and grounding the signal cable at one end with HART® communication

1 Optional grounding of the field device, isolated from cable shielding

2 Grounding of the cable shield at one end

3 Supply unit

4

Grounding point for HART® communication cable shield

5.6 Post-connection check

Device condition and specifications Notes

Is the device or cable undamaged (visual check)? --

Electrical connection Notes

Does the supply voltage match the specifications on

the nameplate?

• Head transmitter: U = e.g. 10 to 36 V

DC

• Other values apply in the hazardous area, see the

corresponding Ex Safety Instructions (XA).

Do the cables have adequate strain relief? -Are the power supply and signal cables correctly → 15

connected?

Are all the screw terminals well tightened? -Are all the cable entries installed, tightened and --

sealed?

Are all housing covers installed and firmly tightened? --

Endress+Hauser V. 1, Rev. 2, 4-10-2018 17

Page 18

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

Operation options iTEMP TMT71/72

6 Operation options

6.1 Overview of operation options

SmartBlue

App

FieldCare

PLC

TMT71/72

RN221N

HART Modem

A0036305

9 Operation options for the head transmitter

For the head transmitter, display and operating elements are available locally only if

the head transmitter was ordered with an attachable display unit!

The transmitter's optional Bluetooth interface is only active if a display unit is not

attached or the CDI interface is not used for device configuration.

6.1.1 Measured value display and operating elements

Option: display TID10 with transmitter

The display may also be subsequently ordered

at any time after purchasing the transmitter,

see the 'Accessories' section in the Operating

Instructions for the device.

A0010227

10 Attach the display to the transmitter

18 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

Page 19

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

iTEMP TMT71/72 Operation options

Display elements

Head transmitter

1

2

3

4

5

6

7

A0008549

11 Optional LC display for head transmitter

Item No. Function Description

1 Displays the TAG TAG, 32 characters long.

2 'Communication' symbol The communication symbol appears when read and write-accessing via

the fieldbus protocol.

3 Unit display Unit display for the measured value displayed.

4 Measured value display Displays the current measured value.

5 Value/channel display

DT, PV, I, %

6 'Configuration locked'

symbol

7 Status signals

e.g. PV for a measured value from channel 1 or DT for the device

temperature

The 'configuration locked' symbol appears when configuration is locked

via the hardware.

Symbols Meaning

Error message "Failure detected"

An operating error has occurred. The measured value is no longer valid.

The display alternates between the error message and "- - - -" (no valid

measured value present), see "Diagnostics events" section → 37.

The display alternates between the error message and "- - - -" (no valid

measured value present).

Detailed information on the error messages can be found in the

Operating Instructions.

"Service mode"

The device is in service mode (e.g. during a simulation).

"Out of specification"

The device is being operated outside its technical specifications (e.g.

during warm-up or cleaning processes).

"Maintenance required"

Maintenance is required. The measured value is still valid.

The display alternates between the measured value and the status

message.

Local operation

You can make hardware settings for the fieldbus interface using miniature switches (DIP

switches) on the rear of the optional display .

The user has the option of ordering the display with the head transmitter, or as an

accessory for subsequent mounting. → 41

NOTICE

‣

ESD - electrostatic discharge. Protect the terminals from electrostatic discharge.

Failure to observe this may result in the destruction or malfunction of parts of the

electronics.

Endress+Hauser V. 1, Rev. 2, 4-10-2018 19

Page 20

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

Operation options iTEMP TMT71/72

32

64

H W

S W

ADDR A C T IV E

SIM

W R IT E L O C K

D I S P L . 1 8 0 °

1

2

3

1: Connection to head transmitter

2: DIP switches (1 - 64, SW/HW, ADDR and SIM = simulation

mode) no function for this head transmitter

3: DIP switch (WRITE LOCK = write protection; DISPL. 180° =

switch, turn the display monitor 180°)

A0014562

12 Hardware settings via DIP switches

Procedure for setting the DIP switch:

1. Open the cover of the terminal head or field housing.

2. Remove the attached display from the head transmitter.

3. Configure the DIP switch on the rear of the display accordingly. In general: switch to

ON = function enabled, switch to OFF = function disabled.

4. Fit the display onto the head transmitter in the correct position. The head transmitter

accepts the settings within one second.

5. Secure the cover back onto the terminal head or field housing.

Switching write protection on/off

Write protection is switched on and off via a DIP switch on the rear of the optional

attachable display. When write protection is active, parameters cannot be modified. A lock

symbol on the display indicates that the write protection is on. Write protection prevents

any write access to the parameters. The write protection remains active even when the

display is removed. To deactivate the write protection, the display must be attached to the

transmitter with the DIP switch switched off (WRITE LOCK = OFF). The transmitter adopts

the setting during operation and does not need to be restarted.

Turning the display

The display can be rotated 180° using the "DISPL. 180°" DIP switch. The setting is retained

when the display is removed.

20 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

OFF

ON

1

2

4

8

16

Page 21

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

iTEMP TMT71/72 Operation options

6.2 Structure and function of the operating menu

6.2.1 Structure of the operating menu

Actual Diagnostics

Actual diagnostics list

Previous diagnostics n

Diagnostic event simulation

Properties

Sensor min value

Sensor value

Unit

4 mA value

Assig n curren t outpu t (PV)

HART short tag

Bluetooth

Display interval

Alarm delay

Call./ v. Dusen coeff. R0...

New password

Password

Recover password

Old password

Squawk

Device type

Latitude

A0037574-EN

User roles

Endress+Hauser's role-based access concept consists of two hierarchical levels for the user

and presents the various user roles with defined read/write authorizations, derived from

the NAMUR shell model.

Endress+Hauser V. 1, Rev. 2, 4-10-2018 21

Diagnostics

Actual diagnostics

Guidance

+

-

+

Commissioning

Diagnostic list

Event logbook

Simulation

Diagnostic settings

Min/ max values

Application

Measured values

Sensor

Linearization

Current output

HA RT con fig ura tion

System

Device managemen t

User m a nagemen t

Define password

Enter password

Recover password

Change password

Delete password

Bluetooth config.

Information

Device

HART-Info

Device location

Display

Delete password

Page 22

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

Operation options iTEMP TMT71/72

• Operator

The plant operator can only change settings that do not affect the application - and

particularly the measuring path - and simple, application-specific functions that are used

during operation. The operator is able to read all the parameters, however.

• Maintenance

The Maintenance user role refers to configuration situations: commissioning and

process adaptations as well as troubleshooting. It allows the user to configure and

modify all available parameters. In contrast to the Operator user role, in the

Maintenance role the user has read and write access to all the parameters.

• Changing the user role

A user role - and therefore existing read and write authorization - is changed by

selecting the desired user role (already pre-selected depending on the operating tool)

and entering the correct password when subsequently prompted. When a user logs out,

system access always returns to the lowest level in the hierarchy. A user is logged out

either by actively selecting the logout function when operating the device or is logged

out automatically if the device is not operated for a period of over 600 seconds.

Irrespective of this, actions that are already in progress (e.g. active upload/download,

data logging, etc.) continue to be executed in the background.

• As-delivered state

The Operator user role is not enabled when the device is delivered from the factory, i.e.

the Maintenance role is the lowest level in the hierarchy ex-works. This state makes it

possible to commission the device and make other process adaptations without having to

enter a password. Afterwards, a password can be assigned for the Maintenance user

role to protect this configuration. The Operator user role is not visible when the device is

delivered from the factory.

• Password

The Maintenance user role can assign a password in order to restrict access to device

functions. This activates the Operator user role, which is now the lowest hierarchy level

where the user is not asked to enter a password. The password can only be changed or

disabled in the Maintenance user role. A password can be defined at different points in

the operation of the device:

In the menu Guidance → Commissioning wizard: as part of guided device operation

In the menu: System → User management

22 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

Page 23

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

iTEMP TMT71/72 Operation options

Submenus

Menu Typical tasks Content/meaning

"Diagnostics" Fault elimination:

• Diagnosing and eliminating process errors.

• Error diagnostics in difficult cases.

• Interpretation of device error messages and

correcting associated errors.

"Application" Commissioning:

• Configuration of the measurement.

• Configuration of data processing (scaling,

linearization, etc.).

• Configuration of the analog measured value output.

Tasks during operation:

Reading measured values.

"System" Tasks that require detailed knowledge of the system

administration of the device:

• Optimum adaptation of the measurement for

system integration.

• Detailed configuration of the communication

interface.

• User and access administration, password control

• Information concerning the device identification,

HART information and display configuration

Contains all parameters for detecting and analyzing errors:

• Diagnostic list

Contains up to 3 error messages currently pending

• Event logbook

Contains the last 10 error messages (no longer pending)

• "Simulation" submenu

Used to simulate measured values, output values or diagnostic

messages

• "Diagnostic settings" submenu

Contains all the parameters for configuring error events

• "Min/max values" submenu

Contains the minimum/maximum indicator and the reset option

Contains all parameters for commissioning:

• "Measured values" submenu

Contains all the current measured values

• "Sensor" submenu

Contains all the parameters for configuring the measurement

• "Output" submenu

Contains all the parameters for configuring the analog current output

• "HART configuration" submenu

Contains the settings and the most important parameters for HART

communication

Contains all the higher-level device parameters that are assigned for

system, device and user management, including Bluetooth

configuration.

• "Device management" submenu

Contains parameters for general device management

• "Bluetooth configuration" submenu (option)

Contains the function for enabling/disabling the Bluetooth interface

• "Device and user management" submenus

Parameters for access authorization, password assignment, etc.

• "Information" submenu

Contains all the parameters for the unique identification of the device

• "Display" submenu

Configuration of the display

6.3 Access to the operating menu via the operating tool

6.3.1 DeviceCare

Function scope

DeviceCare is a free configuration tool for Endress+Hauser devices. It supports devices with

the following protocols, provided a suitable device driver (DTM) is installed: HART,

PROFIBUS, FOUNDATION Fieldbus, Ethernet/IP, Modbus, CDI, ISS, IPC and PCP. The tool is

aimed at customers without a digital network in plants and workshops and Endress

+Hauser service technicians. The devices can be connected directly via a modem (point-to-

point) or a bus system. DeviceCare is fast, easy and intuitive to use. It can run on a PC,

laptop or tablet with a Windows operating system.

Source for device description files

See information → 28

Endress+Hauser V. 1, Rev. 2, 4-10-2018 23

Page 24

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

Operation options iTEMP TMT71/72

6.3.2 FieldCare

Function scope

FDT/DTM-based plant asset management tool from Endress+Hauser. It can configure all

smart field units in a system and help you manage them. By using the status information,

it is also a simple but effective way of checking their status and condition. Access takes

place via the HART® protocol or CDI (= Endress+Hauser Common Data Interface).

Typical functions:

• Configuring parameters of transmitters

• Loading and saving device data (upload/download)

• Documentation of the measuring point

• Visualization of the measured value memory (line recorder) and event logbook

For details, see Operating Instructions BA027S/04/xx and BA059AS/04/xx

Source for device description files

See information → 28

Establishing a connection

Example: via HART® modem Commubox FXA195 (USB)

1. Make sure that the DTM library is updated for all the connected devices (e.g.

FXA19x, TMTxy).

2. Start FieldCare and create a project.

3. Go to View --> Network: right-click Host PC Add device...

The Add device window opens.

4. Select the HART communication option from the list and press OK to confirm.

5. Double-click HART communication DTM instance.

Check whether the correct modem is connected to the serial interface and press

OK to confirm.

6. Right-click HART communication and select the Add device option in the context

menu that opens.

7. Select the desired device from the list and press OK to confirm.

The device now appears in the network list.

8. Right-click the device and select the Connect option in the context menu.

The CommDTM is displayed in green.

9. Double-click the device in the network to establish the online connection to the

device.

The online configuration is available.

If transferring the device parameters following an offline configuration, the password

for Maintenance - if assigned -must first be entered in the "User management" menu.

24 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

Page 25

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

iTEMP TMT71/72 Operation options

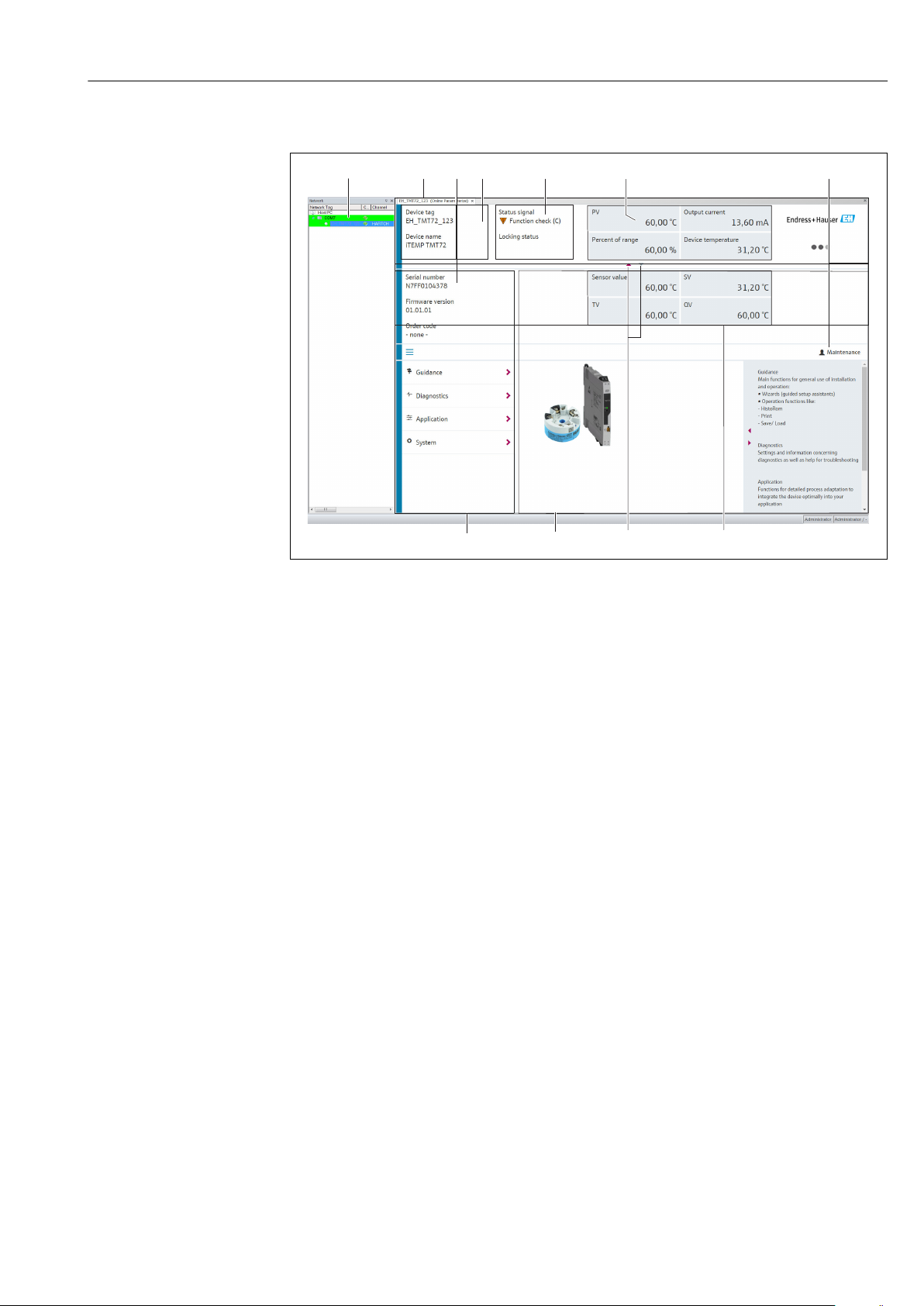

User interface

1 2 3 4 5 6 7

8

9

10

11

A0037232-EN

13 User interface with device information via HART® communication

1 Network view

2 Header

3 Extended header

4 Tag name and device name

5 Status signal

6 Measured values with device and measured value status information, simple presentation, e.g. PV, output

current, % span, device temperature

7 Current user role (with direct link to user management)

8 Navigation area with operating menu structure

9 Working area with fade in/fade out help area

10 Navigation arrows for fade in/fade out the extended header

11 Extended display of device and measured value information, e.g. sensor value, SV (TV, QV)

6.3.3 Field Xpert

Function scope

Field Xpert for mobile plant asset management is available as both a tablet PC and an

industrial PDA with an integrated touch screen for the commissioning and maintenance of

field devices in hazardous and non-hazardous areas. It enables the efficient configuration

of FOUNDATION fieldbus, HART and WirelessHART devices. Communication is wireless

via Bluetooth or WiFi interfaces.

Source for device description files

See information → 28.

6.3.4 AMS Device Manager

Function scope

Program from Emerson Process Management for operating and configuring measuring

devices via the HART® protocol.

Endress+Hauser V. 1, Rev. 2, 4-10-2018 25

Page 26

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

Operation options iTEMP TMT71/72

Source for device description files

See information → 28.

6.3.5 SIMATIC PDM

Function scope

SIMATIC PDM is a standardized, manufacturer-independent program from Siemens for

the operation, configuration, maintenance and diagnosis of intelligent field devices via the

HART ® protocol.

Source for device description files

See information → 28.

6.3.6 Field Communicator 375/475

Function scope

Industrial handheld terminal from Emerson Process Management for remote

configuration and measured value display via the HART ® protocol.

Source for device description files

See information → 28.

6.4 Access to the operating menu via the SmartBlue App

The device can be operated and configured via the SmartBlue App. The connection is

established via the Bluetooth® wireless technology interface.

Prerequisite:

• The device has the optional Bluetooth interface: order code "Communication; output

signal; operation", option P: "HART; 4-20 mA; HART/Bluetooth (App) configuration"

• A smartphone or tablet with the SmartBlue App installed.

Supported functions

• Device selection in Live List and access to the device (login)

• Configuration of the device

• Access to measured values, device status and diagnostics information

The SmartBlue App is available for free download for Android devices (Google Playstore)

and iOS devices (iTunes Apple Shop) : Endress+Hauser SmartBlue

Directly to the app with the QR code:

A0033202

26 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

Page 27

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

iTEMP TMT71/72 Operation options

System requirements

• Devices with iOS:

– iPhone 4S or higher, from iOS9.0

– iPad2 or higher, from iOS9.0

– iPod Touch 5th generation or higher, from iOS9.0

• Devices with Android:

Android 4.4 KitKat or higher

Download the SmartBlue App:

1. Install and start the SmartBlue App.

A Live List shows all the devices available.

2. Select the device from the Live List.

The Login dialog box opens.

Logging in:

3. Enter the user name: admin

4. Enter the initial password: serial number of the device.

5. Confirm your entry.

The device information opens.

Navigate through the various items of information about the device: swipe the screen

to the side.

• The range under reference conditions is:

– 10 m (33 ft) when installed in the terminal head or field housing with a display

window

– 5 m (16.4 ft) when installed in the terminal head or field housing

• Incorrect operation by unauthorized persons is prevented by means of encrypted

communication and password encryption.

• The Bluetooth® wireless technology interface can be deactivated

The transmitter's optional Bluetooth interface is only active if a display unit is not

attached or the CDI interface is not used for device configuration.

Endress+Hauser V. 1, Rev. 2, 4-10-2018 27

Page 28

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

System integration iTEMP TMT71/72

7 System integration

7.1 Overview of device description files

Version data for the device

Firmware version 01.01.zz • On the title page of the Operating instructions

• On the nameplate → 1, 9

• Parameter firmware version

Diagnostics → Device info→ Firmware Version

Manufacturer ID 0x11 Manufacturer ID parameter

Diagnostics → Device info→ Manufacturer ID

Device type ID 0x11D0 Device type parameter

Diagnostics → Device info → Device type

HART protocol revision 7 --Device revision 1 • On the transmitter nameplate → 1, 9

• Device revision parameter

Diagnostics → Device info → Device revision

The suitable device driver software (DD/DTM) for the individual operating tools can be

acquired from a variety of sources:

• www.endress.com --> Downloads --> Search field: Software --> Software type: Device

driver

• www.endress.com --> Products: individual product page, e.g. TMTx2 --> Documents /

Manuals / Software: Electronic Data Description (EDD) or Device Type Manager (DTM).

• Via DVD (please contact your local Endress+Hauser Sales Center)

Endress+Hauser supports all common operating tools from a variety of manufacturers (e.g.

Emerson Process Management, ABB, Siemens, Yokogawa, Honeywell and many others).

Endress+Hauser's FieldCare and DeviceCare operating tools are available for download

(www. endress.com --> Downloads --> Search field: Software --> Application software) or

on the optical data storage medium (DVD) which you can obtain from your local Endress

+Hauser Sales Center.

7.2 Measured variables via HART protocol

The following measured values are assigned to the device variables at the factory:

Device variable Measured value

Primary device variable (PV) Sensor

Secondary device variable (SV) Device temperature

Tertiary device variable (TV) Sensor

Quaternary device variable (QV) Sensor

7.3

Supported HART® commands

The HART® protocol enables the transfer of measuring data and device data between

the HART® master and the field device for configuration and diagnostics purposes.

HART® masters such as the handheld terminal or PC-based operating programs (e.g.

FieldCare) need device description files (DD, DTM) which are used to access all the

information in a HART® device. This information is transmitted exclusively via

"commands".

28 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

Page 29

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

iTEMP TMT71/72 System integration

There are three different types of command

• Universal commands:

All HART® devices support and use universal commands. These are associated with the

following functionalities for example:

– Recognition of HART® devices

– Reading digital measured values

• Common practice commands:

Common practice commands offer functions which are supported and can be executed by

many but not all field devices.

• Device-specific commands:

These commands allow access to device-specific functions which are not HART

®

standard. Such commands access individual field device information, among other

things.

Command No. Designation

Universal commands

0, Cmd0 Read unique identifier

1, Cmd001 Read primary variable

2, Cmd002 Read loop current and percent of range

3, Cmd003 Read dynamic variables and loop current

6, Cmd006 Write polling address

7, Cmd007 Read loop configuration

8, Cmd008 Read dynamic variable classifications

9, Cmd009 Read device variables with status

11, Cmd011 Read unique identifier associated with TAG

12, Cmd012 Read message

13, Cmd013 Read TAG, descriptor, date

14, Cmd014 Read primary variable transducer information

15, Cmd015 Read device information

16, Cmd016 Read final assembly number

17, Cmd017 Write message

18, Cmd018 Write TAG, descriptor, date

19, Cmd019 Write final assembly number

20, Cmd020 Read long TAG (32-byte TAG)

21, Cmd021 Read unique identifier associated with long TAG

22, Cmd022 Write long TAG (32-byte TAG)

38, Cmd038 Reset configuration changed flag

48, Cmd048 Read additional device status

Common practice commands

33, Cmd033 Read device variables

34, Cmd034 Write primary variable damping value

35, Cmd035 Write primary variable range values

40, Cmd040 Enter/Exit fixed current mode

42, Cmd042 Perform device reset

44, Cmd044 Write primary variable units

45, Cmd045 Trim loop current zero

46, Cmd046 Trim loop current gain

Endress+Hauser V. 1, Rev. 2, 4-10-2018 29

Page 30

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

System integration iTEMP TMT71/72

Command No. Designation

50, Cmd050 Read dynamic variable assignments

54, Cmd054 Read device variable information

59, Cmd059 Write number of response preambles

72, Cmd072 Squawk

95, Cmd095 Read device communications statistics

100, Cmd100 Write primary variable alarm code

516, Cmd516 Read device location

517, Cmd517 Write device location

518, Cmd518 Read location description

519, Cmd519 Write location description

520, Cmd520 Read process unit tag

521, Cmd521 Write process unit tag

523, Cmd523 Read condensed status mapping array

524, Cmd524 Write condensed status mapping array

525, Cmd525 Reset condensed status mapping array

526, Cmd526 Write simulation mode

527, Cmd527 Simulate status bit

30 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

Page 31

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

iTEMP TMT71/72 Commissioning

8 Commissioning

8.1 Post-installation check

Before commissioning the measuring point make sure that all final checks have been

carried out:

• "Post-installation check" checklist→ 14

• "Post-connection check" checklist → 17

8.2 Switching on the transmitter

Once you have completed the post-connection checks, switch on the supply voltage. The

transmitter performs a number of internal test functions after power-up. As this procedure

progresses, the following sequence of messages appears on the display:

Step Display

1 "Display" text and firmware version of the display

2 Firm logo

3 Device name with firmware version, hardware version and device revision

4 Displays the sensor configuration (sensor type and type of connection) along with the configured

measuring range

5a Current measured value or

5b Current status message

If the switch-on procedure is not successful, the relevant diagnostic event, depending on the cause,

is displayed. A detailed list of diagnostic events and the corresponding troubleshooting instructions

can be found in the "Diagnostics and troubleshooting" section → 35.

The device operates in normal mode after approx. 7 seconds, including the attached

display. Normal measuring mode commences as soon as the switch-on procedure is

completed. Measured values and status values appear on the display.

If the display is attached when the Bluetooth interface is activated, display

initialization is performed twice and Bluetooth communication is disabled

simultaneously.

8.3 Configuring the measuring device

Wizards

The Guidance menu contains various wizards. Wizards not only query individual

parameters but also guide the user through the configuration and/or verification of entire

sets of parameters with step-by-step instructions, including questions, that are

comprehensible for the user. The "Start" button can be disabled for wizards that require

specific access authorization (keyhole symbol appears on the screen).

Endress+Hauser V. 1, Rev. 2, 4-10-2018 31

Page 32

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

Commissioning iTEMP TMT71/72

The following five operating elements are supported for navigation in the wizards:

• Start

Only on the initial page: start the wizard and go to the first section

• Next

Go to the next page of the wizard. Is not enabled until parameters are entered or

confirmed.

• Back

Return to the previous page

• Cancel

If Cancel is selected, the status before the wizard was started is restored

• Finish

Closes the wizard and possibility of making additional parameter settings on the device.

Only enabled on the final page.

8.3.1 Commissioning wizard

Commissioning is the first step towards using the device for the designated application.

The Commissioning wizard contains an introductory page (with the "Start" operating

element) and a short description of the content. The wizard consists of several sections in

which the user is guided step-by-step through the commissioning of the device.

"Device management" is the first section that appears when the user runs the wizard, and

contains the following parameters. Its main purpose is to provide information about the

device:

Navigation Guidance→ Commissioning → Start

+

+

A0037378-EN

Device TAG

Device name

Serial number

Extended order code (n)

1)

HART short tag

HART date code

HART descriptor

HART message

1) n = placeholder for 1, 2, 3

The second section, "Sensor", takes the user through all the relevant settings for the sensor.

The number of parameters displayed depends on the corresponding settings. The following

parameters can be configured:

Navigation Guidance → Commissioning → Sensor

+

+

A0037389-EN

Unit

Sensor type

Connection type

2-wire compensation

Reference junction

RJ preset value

32 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

Page 33

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

iTEMP TMT71/72 Commissioning

In the third section, the settings are made for the analog output and the output's alarm

response. The following parameters can be configured:

Navigation Guidance → Commissioning → Current output

+

+

A0037390-EN

4 mA value

20 mA value

Failure mode

Failure current

In the final section, a password can be defined for the "Maintenance" user role. This is

strongly recommended to protect the device against unauthorized access. The following

steps describe how to configure a password for the "Maintenance" role for the first time.

Navigation Guidance → Commissioning → User management

+

+

A0037391-EN

Access status

New password

Confirm new password

1. The Maintenance role appears in the "Access status" picklist. The Maintenance user

role must first be selected when operating with the SmartBlue App.

Afterwards, the New password and Confirm new password input boxes appear.

2. Enter a user-defined password that meets the password rules indicated in the online

help.

3. Enter the password again in the Confirm new password input box.

Once the password has been entered successfully, parameter changes, particularly those

that are needed for commissioning, process adaptation/optimization and troubleshooting,

can only be implemented in the Maintenance user role and if the password is entered

successfully.

8.4 Protecting settings from unauthorized access

8.4.1 Hardware locking

The device can be protected against unauthorized access by hardware locking. In the

locking and access concept, hardware locking always has top priority. The device is write-

protected if the keyhole symbol appears in the header of the measured value display. To

disable write protection, switch the write protection switch on the back of the display to

the "OFF" position (hardware write protection). → 19

8.4.2 Software locking

By assigning a password for the Maintenance user role, it is possible to restrict access

authorization and protect the device against unauthorized access. See the Commissioning

wizard → 32

Commissioning wizard → 32

Endress+Hauser V. 1, Rev. 2, 4-10-2018 33

Page 34

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

Commissioning iTEMP TMT71/72

The parameters are also protected against modification if the user logs out of the

Maintenance user role and the system switches to the Operator role. No keyhole symbol

is displayed, however.

To disable the write protection, the user must log on with the Maintenance user role via

the relevant operating tool.

User role concept → 21

34 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

Page 35

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

iTEMP TMT71/72 Diagnostics and troubleshooting

9 Diagnostics and troubleshooting

9.1 General troubleshooting

Always start troubleshooting with the checklists below if faults occur after start up or

during operation. The checklists take you directly (via various queries) to the cause of the

problem and the appropriate remedial measures.

Due to its design, the device cannot be repaired. However, it is possible to send the

device in for examination. See the information in the "Return" section. .→ 41

General errors

Problem Possible cause Remedy

Device is not responding. Supply voltage does not match that

specified on the nameplate.

Connecting cables are not in contact

with the terminals.

Check the voltage at the transmitter

directly using a voltmeter and correct.

Check the contacting of the cables and

correct if necessary.

Electronics unit is defective. Replace the device.

Output current < 3.6 mA Signal line is not wired correctly. Check wiring.

Electronics unit is defective. Replace the device.

HART communication is not

working.

Missing or incorrectly installed

communication resistor.

Install the communication resistor (250

Ω) correctly.

Commubox is connected incorrectly. Connect Commubox correctly.

Commubox is not set to "HART". Set Commubox selector switch to

"HART".

Check display (optional in conjunction with head transmitter)

Problem Possible cause Remedy

No supply voltage • Check the supply voltage at the head

transmitter, terminals + and -.

• Ensure that the display module

holders are correctly seated and that

the display module is properly

connected to the head transmitter

→ 10.

No display visible

• If possible, test the display module

with other suitable head transmitters,

e.g. an Endress+Hauser head

transmitter.

The display module is defective. Replace the module.

The electronics of the head Replace the head transmitter.

transmitter are defective.

Local error messages on the display

→ 37

Endress+Hauser V. 1, Rev. 2, 4-10-2018 35

Page 36

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

Diagnostics and troubleshooting iTEMP TMT71/72

Faulty connection to the fieldbus host system

Problem Possible cause Remedy

Device is not

responding.

Supply voltage does not match that

specified on the nameplate.

Connecting cables are not in contact with

the terminals.

Check the voltage at the transmitter

directly using a voltmeter and correct.

Check the contacting of the cables and

correct if necessary.

Output current < 3.6

mA

Electronics unit is defective. Replace the device.

Signal line is not wired correctly. Check wiring.

Electronics unit is defective. Replace the device.

HART

communication is

not working.

Missing or incorrectly installed

communication resistor.

Install the communication resistor (250 Ω)

correctly.

Error messages in the configuration software

→ 38

Application errors without status messages for RTD sensor connection

Problem Possible cause Remedy

Incorrect sensor orientation. Install the sensor correctly.

Heat conducted by sensor. Observe the face-to-face length of the

Measured value is incorrect/

inaccurate

Device programming is incorrect

(number of wires).

Device programming is incorrect

(scaling).

sensor.

Change the Connection type device

function.

Change scaling.

Incorrect RTD configured. Change the Sensor type device function.

Sensor connection. Check that the sensor is connected

The cable resistance of the sensor (2wire) was not compensated.

correctly.

Compensate the cable resistance.

Offset incorrectly set. Check offset.

Faulty sensor. Check the sensor.

RTD connected incorrectly. Connect the connecting cables correctly

Failure current (≤ 3.6 mA or

≥ 21 mA)

Device programming is incorrect (e.g.

number of wires).

(terminal diagram).

Change the Connection type device

function.

Incorrect programming. Incorrect sensor type set in the Sensor

type device function. Set the correct

sensor type.

36 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

Commubox is connected incorrectly. Connect Commubox correctly.

Page 37

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

iTEMP TMT71/72 Diagnostics and troubleshooting

Application errors without status messages for TC sensor connection

Problem Possible cause Remedy

Incorrect sensor orientation. Install the sensor correctly.

Heat conducted by sensor. Observe the face-to-face length of the

Device programming is incorrect

(scaling).

sensor.

Change scaling.

Measured value is incorrect/

inaccurate

Incorrect thermocouple type (TC)

configured.

Incorrect reference measuring point

set.

Interference via the thermocouple

wire welded in the thermowell

(interference voltage coupling).

Change the Sensor type device function.

Set the correct reference measuring

point .

Use a sensor where the thermocouple

wire is not welded.

Failure current (≤ 3.6 mA or

≥ 21 mA)

Offset incorrectly set. Check offset.

Faulty sensor. Check the sensor.

Sensor is connected incorrectly. Connect the connecting cables correctly

(terminal diagram).

Incorrect programming. Incorrect sensor type set in the Sensor

type device function. Set the correct

sensor type.

9.2 Diagnostic information on local display

1

A

2

1

B

3

A0014837

A Display in the event of a warning

B Display in the event of an alarm

1 Status signal in the header

2 The display alternates between the primary measured value and the status - indicated by the appropriate

letter (M, C or S) - plus the defined error number.

3 The display alternates between "- - - -" (no valid measured value) and the status - indicated by the appropriate

letter (F) - plus the defined error number.

Endress+Hauser V. 1, Rev. 2, 4-10-2018 37

Page 38

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

Diagnostics and troubleshooting iTEMP TMT71/72

9.3 Diagnostic information via communication interface

NOTICE

Status signals and diagnostic behavior can be configured manually for certain

diagnostic events. If a diagnostic event occurs, however, it is not guaranteed that the

measured values are valid for the event and comply with the process for the status

signals S and M and the diagnostic behavior: 'Warning' and Disabled'.

‣

Reset the status signal assignment to the factory setting.

Status signals

Symbol Event

category

F Operating

error

Meaning

An operating error has occurred.

C Service mode The device is in service mode (e.g. during a simulation).

S Out of

specification

M Maintenance

required

N Not

categorized

The device is being operated outside its technical specifications (e.g. during warmup or cleaning processes).

Maintenance is required.

Diagnostic behavior

Alarm Measurement is interrupted. The signal outputs assume the defined alarm

condition. A diagnostic message is generated.

Warning The device continues to measure. A diagnostic message is generated.

Disabled The diagnosis is completely disabled even if the device is not recording a measured

value.

9.4 Diagnostic list

If two or more diagnostics events are pending simultaneously, only the message with the

highest priority is shown. Additional pending diagnostic messages are shown in the

Diagnostic list submenu . The status signal dictates the priority in which the diagnostic

messages are displayed. The following order of priority applies: F, C, S, M. If two or more

diagnostic events with the same status signal are active simultaneously, the numerical

order of the event number dictates the order of priority in which the events are displayed,

e.g.: F042 appears before F044 and before S044.

9.5 Event logbook

Past diagnostic messages that are no longer pending are shown in the Event logbook

submenu.→ 66

38 V. 1, Rev. 2, 4-10-2018 Endress+Hauser

Page 39

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

iTEMP TMT71/72 Diagnostics and troubleshooting

9.6 Overview of diagnostic events

Each diagnostic event is assigned a certain event behavior at the factory. The user can

change this assignment for certain diagnostic events.

Example:

Settings Device behavior

Configuration examples Diagnostic

number

Status

signal

Diagnostic

behavior from

the factory

Status signal

(output via HART®

communication)

Current PV, status Display

output

1. Default setting 047 S Warning S Measured

value

Measured value, S047

UNCERTAIN

2. Manual setting: status

signal S changed to F

3. Manual setting: Warning

diagnostic behavior changed

to Alarm

4. Manual setting: Warning

changed to Disabled

1) Setting is not relevant.

047 F Warning F Measured

value

047 S Alarm S Configured

failure

current

047 S

1)

Disabled -

2)

Last valid

measured

value

3)

Measured value,

UNCERTAIN

Measured value,

BAD

Last valid

measured value,

GOOD

F047

S047

S047

2) Status signal is not displayed.

3) The failure current is output if no valid measured value is available.

Diagnostic

number

Short text Corrective measure

Status

signal

from the

factory

Customizable

1)

Not

customizable

Diagnosti

c

behavior

from the

factory

Customizable

2)

Not

customizable

Diagnostics for the sensor

41 Sensor interrupted 1. Check electrical wiring.

2. Replace sensor.

3. Check connection type.

42 Sensor corroded 1. Check sensor.

2. Replace sensor.

43 Short-circuit 1. Check electrical connection.

2. Check sensor.

3. Replace sensor or cable.

047 Sensor limit reached sensor n 1. Check sensor.

2. Check process conditions.

145 Compensation reference point 1. Check terminal temperature.

2. Check external reference point.

Diagnostics for the electronics

201 Electronics faulty 1. Restart device.

2. Replace electronics.

F Alarm

M Warning

F Alarm

S Warning

F Alarm

F Alarm

221 Reference sensor defective Replace device. M Alarm

Diagnostics for the configuration

401 Factory reset active Factory reset active, please wait. C Warning

Endress+Hauser V. 1, Rev. 2, 4-10-2018 39

Page 40

DRAFT

DRAFT DRAFT DRAFT DRAFT DRAFT DRAFT

DRAFT DRAFT DRAFT

Diagnostics and troubleshooting iTEMP TMT71/72

Diagnostic

number

Short text Corrective measure

Status

signal

from the

factory

Customizable

1)

Not

customizable

Diagnosti

c

behavior

from the

factory

Customizable

2)

Not

customizable

402 Initialization active Initialization active, please wait. C Warning

410 Data transfer failed 1. Check connection. F Alarm

2. Retry data transfer.

411 Up-/download active Up-/download active, please wait. C Warning

435 Linearization faulty Check linearization. F Alarm

485 Process variable simulation

active

491 Current output simulation

495 Diagnostic event simulation

active

Deactivate simulation. C Warning

Deactivate simulation. C Warning

Deactivate simulation. C Warning

531 Factory adjustment missing 1. Contact service.

2. Replace device.

537 Configuration 1. Check device configuration

2. Upload and download new configuration.

(In case of current output: check

configuration of analog output.)

F Alarm

F Alarm

582 Sensor diagnostics TC

deactivated

Switch on diagnostics for thermocouple C Warning

measurement

Diagnostics for the process

801 Supply voltage too low

3)

Increase supply voltage. S Alarm

825 Operating temperature 1. Check ambient temperature. S Warning

2. Check process temperature.

844 Process value outside

specification

1) Can be set to F, C, S, M, N

1. Check process value. S Warning

2. Check application.

Check sensor.

2) Can be set to 'Alarm', 'Warning' and 'Disabled'