Page 1

°C

10

0

20

30

40

BA01801T/09/EN/01.17

71380552

Valid as of version

04.01 (device version)

Products Solutions Services

Operating Instructions

iTEMP TMT162

Temperature field transmitter

Page 2

Page 3

iTEMP TMT162 Table of contents

Table of contents

1 Important document information .... 4

1.1 Function of document and how to use ........ 4

1.2 Symbols used .......................... 4

1.3

Documentation ........................ 6

1.4 Registered trademarks ................... 6

2 Basic safety instructions ............ 7

2.1 Requirements for the personnel ............ 7

2.2 Designated use ........................ 7

2.3 Workplace safety ....................... 7

2.4 Operational safety ...................... 7

2.5 Product safety ......................... 8

2.6 IT security ............................ 8

3 Incoming acceptance and product

identification ....................... 9

3.1 Incoming acceptance .................... 9

3.2 Product identification .................... 9

3.3 Transport and storage .................. 11

4 Installation ....................... 12

4.1 Installation conditions .................. 12

4.2 Mounting the transmitter ............... 12

4.3 Display mounting ...................... 14

4.4 Post-installation check .................. 14

5 Wiring ............................ 15

5.1 Connection conditions .................. 15

5.2 Connecting the sensor .................. 15

5.3 Connecting the measuring device .......... 17

5.4 Special connection instructions ............ 19

5.5 Ensuring the degree of protection .......... 20

5.6 Post-connection check .................. 21

9 Diagnostics and troubleshooting ... 34

9.1 Troubleshooting ...................... 34

9.2 Diagnostic events ...................... 36

9.3

Software history and overview of

compatibility ......................... 40

10 Maintenance ...................... 40

10.1 Endress+Hauser services ................ 40

11 Repair ............................ 41

11.1 General notes ........................ 41

11.2 Spare parts .......................... 41

11.3 Return .............................. 43

11.4 Disposal ............................ 43

12 Accessories ....................... 43

12.1 Device-specific accessories ............... 43

12.2 Communication-specific accessories ........ 44

12.3 Service-specific accessories ............... 44

12.4 System products ...................... 45

13 Technische Daten ................. 46

14 Operating menu and parameter

description ........................ 62

14.1 "Setup" menu ......................... 69

14.2 "Diagnostics" menu ..................... 84

14.3 "Expert" menu ........................ 91

Index ................................. 117

6 Operating options ................. 22

6.1 Overview of operation options ............ 22

6.2 Structure and function of the operating

menu .............................. 25

6.3 Access to the operating menu via the

operating tool ........................ 27

7 System integration ................ 29

7.1 HART device variables and measured values .. 29

7.2 Device variables and measured values ....... 30

7.3

Supported HART® commands ............. 30

8 Commissioning .................... 33

8.1 Post-installation check .................. 33

8.2 Switching on the transmitter ............. 33

8.3 Enabling configuration .................. 33

Endress+Hauser 3

Page 4

Important document information iTEMP TMT162

DANGER

WARNING

CAUTION

NOTICE

1 Important document information

1.1 Function of document and how to use

1.1.1 Document function

These Operating Instructions contain all the information that is required in various phases

of the life cycle of the device: from product identification, incoming acceptance and

storage, to mounting, connection, operation and commissioning through to

troubleshooting, maintenance and disposal.

1.1.2

Safety Instructions (XA)

When using in hazardous areas, the national safety requirements must be met. Separate

Ex documentation is contained in these Operating Instructions for measurement systems

that are to mounted in hazardous areas. Strict compliance with the installation

instructions, ratings and safety instructions as listed in this supplementary documentation

is mandatory. Make sure that you use the right Ex-specific documentation for the right

device with approval for use in hazardous areas! The number of the specific Ex

documentation (XA...) is provided on the nameplate. If the two numbers (on the Ex

documentation and the nameplate) are identical, then you may use this Ex-specific

documentation.

1.1.3 Functional safety

Please refer to Safety Manual SD01632T/09 for the use of approved devices in

protective systems according to IEC 61508.

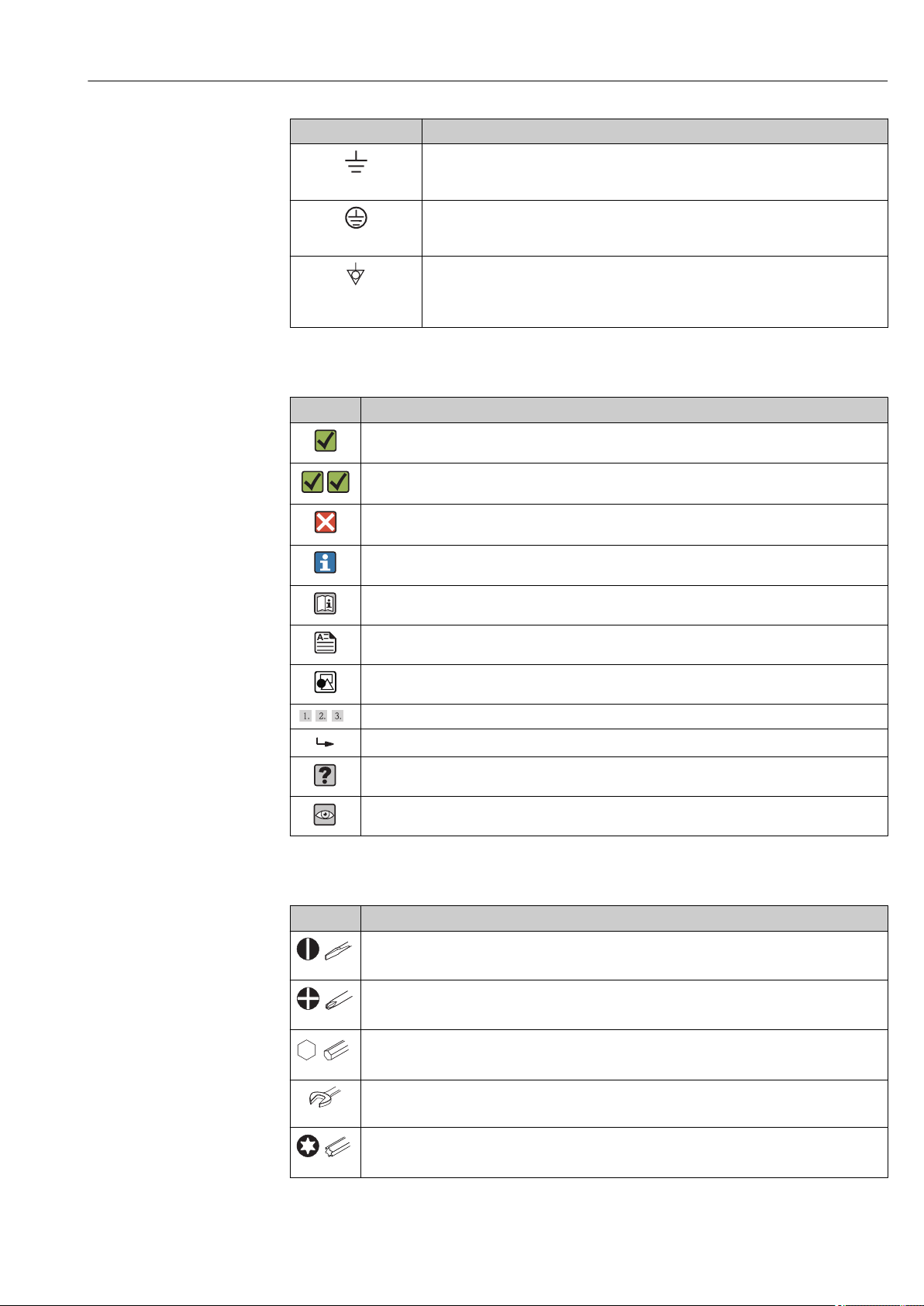

1.2 Symbols used

1.2.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will

result in serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can

result in minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.2.2 Electrical symbols

Symbol Meaning

Direct current

Alternating current

Direct current and alternating current

4 Endress+Hauser

Page 5

iTEMP TMT162 Important document information

,…,

Symbol Meaning

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system.

Protective ground connection

A terminal which must be connected to ground prior to establishing any other

connections.

Equipotential connection

A connection that has to be connected to the plant grounding system: This may be a

potential equalization line or a star grounding system depending on national or

company codes of practice.

1.2.3 Symbols for certain types of information

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Series of steps

Result of a step

Help in the event of a problem

Visual inspection

1.2.4 Tool symbols

Symbol Meaning

Flat-blade screwdriver

A0011220

Phillips screwdriver

A0011219

Allen key

A0011221

Open-ended wrench

A0011222

Torx screwdriver

A0013442

Endress+Hauser 5

Page 6

Important document information iTEMP TMT162

1.3 Documentation

Document Purpose and content of the document

Technical Information

TI01344T/09

Brief Operating Instructions

KA00250R/09

Functional safety manual (SIL)

SD01632T/09

The document types listed are available:

In the Download Area of the Endress+Hauser Internet site: www.endress.com →

Downloads

Planning aid for your device

The document contains all the technical data on the device and provides

an overview of the accessories and other products that can be ordered for

the device.

Guide that takes you quickly to the 1st measured value

The Brief Operating Instructions contain all the essential information

from incoming acceptance to initial commissioning.

Functional Safety Manual

This manual applies in addition to the Operating Instructions, Technical

Information and ATEX Safety Instructions. The requirements specific for

the protection function are described in this Safety Manual.

1.4 Registered trademarks

HART®

Registered trademark of the HART® FieldComm Group

6 Endress+Hauser

Page 7

iTEMP TMT162 Basic safety instructions

2 Basic safety instructions

2.1 Requirements for the personnel

NOTICE

The personnel for installation, commissioning, diagnostics and maintenance must

fulfill the following requirements:

Trained, qualified specialists must have a relevant qualification for this specific function

‣

and task

Are authorized by the plant owner/operator

‣

Are familiar with federal/national regulations

‣

Before beginning work, the specialist staff must have read and understood the

‣

instructions in the Operating Instructions and supplementary documentation as well as

in the certificates (depending on the application)

Following instructions and basic conditions

‣

The operating personnel must fulfill the following requirements:

Being instructed and authorized according to the requirements of the task by the

‣

facility's owner-operator

Following the instructions in these Operating Instructions

‣

2.2 Designated use

The device is a universal and configurable temperature field transmitter with either one or

two temperature sensor inputs for resistance thermometers (RTD), thermocouples (TC)

and resistance and voltage transmitters. The unit is designed for mounting in the field.

The manufacturer is not liable for damage caused by improper or non-designated use.

2.3 Workplace safety

For work on and with the device:

Wear the required personal protective equipment according to federal/national

‣

regulations.

2.4

CAUTION

L

Risk of injury!

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

Power supply

The device must only be powered by a 11.5 to 42 VDC voltage supply according to NEC

‣

class 02 (low voltage / current) with short circuit power limitation to 8 A / 150 VA.

Operational safety

Conversions to the device

Unauthorized modifications to the device are not permitted and can lead to unforeseeable

dangers.

If, despite this, modifications are required, consult with Endress+Hauser.

‣

Repair

To ensure continued operational safety and reliability:

Carry out repairs on the device only if they are expressly permitted.

‣

Observe federal/national regulations pertaining to repair of an electrical device.

‣

Endress+Hauser 7

Page 8

Basic safety instructions iTEMP TMT162

Use original spare parts and accessories from Endress+Hauser only.

‣

Hazardous area

To eliminate a danger for persons or for the facility when the device is used in the

hazardous area (e.g. explosion protection or safety equipment):

Based on the technical data on the nameplate, check whether the ordered device is

‣

permitted for the intended use in the hazardous area. The nameplate can be found on

the side of the transmitter housing.

Observe the specifications in the separate supplementary documentation that is an

‣

integral part of these Instructions.

Electromagnetic compatibility

The measuring system complies with the general safety requirements in accordance with

EN 61010-1, the EMC requirements of IEC/EN 61326 and NAMUR Recommendation NE

21 and NE 89.

2.5

This measuring device is designed in accordance with good engineering practice to meet

state-of-the-art safety requirements, has been tested, and left the factory in a condition in

which it is safe to operate.

It meets general safety standards and legal requirements. It also complies with the EC

directives listed in the device-specific EC Declaration of Conformity. Endress+Hauser

confirms this by affixing the CE mark to the device.

2.6

We only provide a warranty if the device is installed and used as described in the

Operating Instructions. The device is equipped with security mechanisms to protect it

against any inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide

additional protection for the device and device data transfer must be implemented by the

operators themselves.

Product safety

IT security

8 Endress+Hauser

Page 9

iTEMP TMT162 Incoming acceptance and product identification

DELIVERYNOTE

TMT162

0

1

2

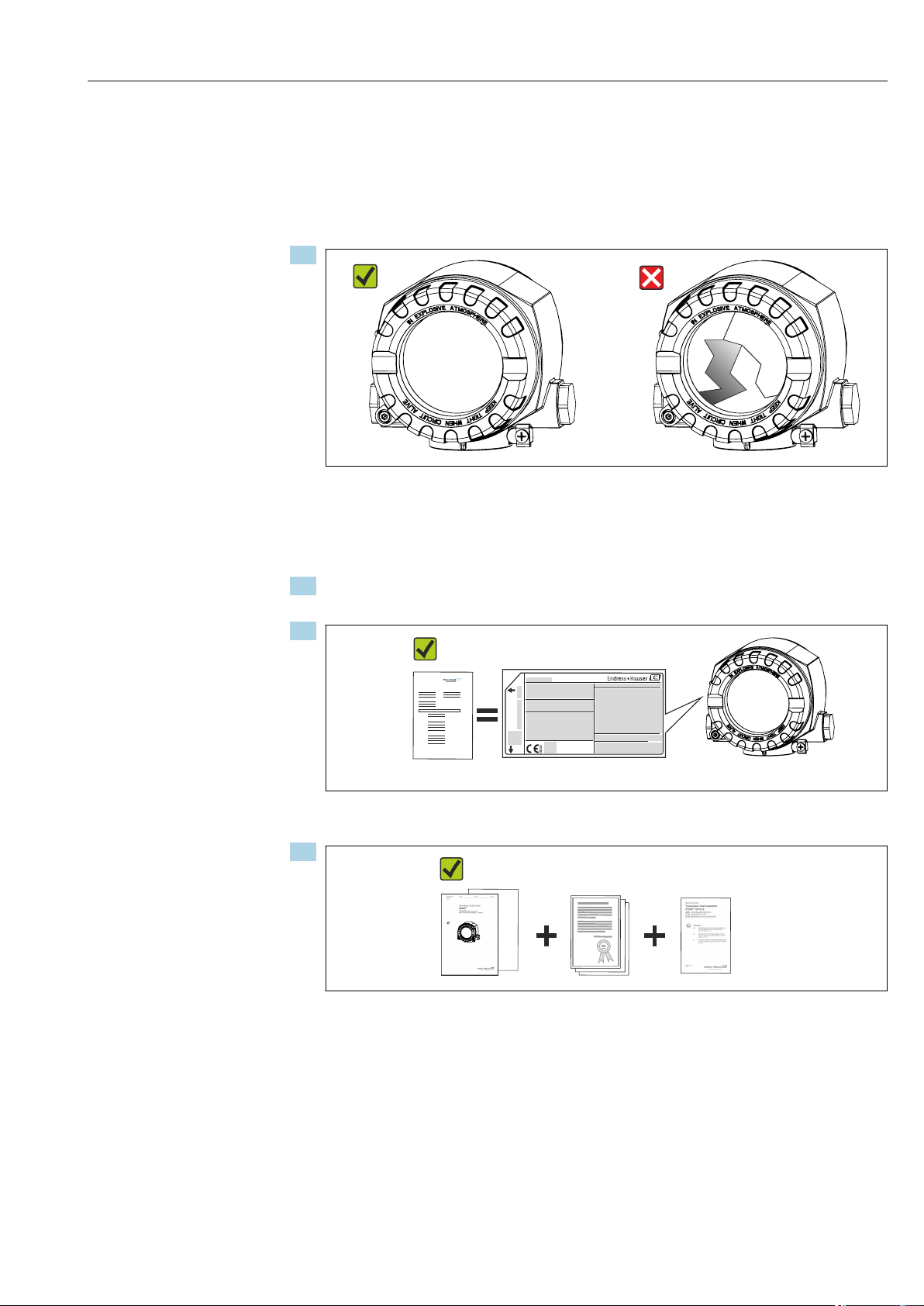

3 Incoming acceptance and product

identification

3.1 Incoming acceptance

1.

A0024856

Unpack the temperature transmitter carefully. Is the packaging or content damaged?

Damaged components may not be installed as the manufacturer can otherwise

not guarantee compliance with the original safety requirements or the material

resistance, and can therefore not be held responsible for any resulting damage.

2. Is the delivery complete or is anything missing? Check the scope of delivery against

your order.

3.

Does the nameplate match the ordering information on the delivery note?

4.

Are the technical documentation and all other necessary documents provided?

3.2 Product identification

The following options are available for identification of the device:

• Nameplate specifications

• Enter the serial number from the nameplate in the W@M Device Viewer

(www.endress.com/deviceviewer): All data relating to the device and an overview of

the Technical Documentation supplied with the device are displayed.

Endress+Hauser 9

A0024857

A0024858

Page 10

Incoming acceptance and product identification iTEMP TMT162

1

2

3

4

5

Install per XA00032R/09/a3/xx.yy

II2D Ex tb IIIC T110°C Db

Do not open when energized

11.5...40 V

4...20 mA HART

TMT162-

Ta=

-50 ...+55/70/85 °C T6/T5/T4 (-40...+75 °C SIL)

87484 Nesselwang

Made in Germany 2017

TMT162-SIL

IP66/67 TYPE4X Encl.

Current cosum.: 23 mA

0123456789

Ser.No.:

TAG No.: 0123456789ABCDEF

0123456789ABCDEF

Order Code:

Extended order code:

6

Threads M20x1.5

0044

3.2.1 Nameplate

Is this the correct device?

Check the data on the nameplate of the device and compare them against the requirements

of the measuring point:

1

Order code, serial number and TAG of device

2 Power supply, degree of protection, etc.

3 Ambient temperature range

4 Approvals in hazardous area with numbers of the

relevant Ex documentation (XA...)

5 Approvals with symbols

6 Device revision and firmware version

A0034479

1 Nameplate of the field transmitter

(example, Ex version)

3.2.2 Scope of delivery

The scope of delivery of the device comprises:

•

Temperature transmitter

Wall or pipe mounting bracket, optional

•

•

Dummy plugs

• Hard copy of multi-language Brief Operating Instructions

• Additional documentation for devices which are suitable for use in the hazardous area

(0

1), such as Safety Instructions (XA), Control or Installation Drawings (ZD).

• Hard copy of Functional Safety Manual (if SIL mode option selected)

3.2.3 Certificates and approvals

An overview of other approvals and certifications is provided in the "Technical data" section

→ 60

CE mark

The product meets the requirements of the harmonized European standards. As such, it

complies with the legal specifications of the EC directives. The manufacturer confirms

successful testing of the product by affixing to it the CE-mark.

EAC mark

The product meets the legal requirements of the EEU guidelines. The manufacturer

confirms the successful testing of the product by affixing the EAC mark.

UL approval

10 Endress+Hauser

UL recognized component (see www.ul.com/database, search for Keyword "E225237")

Page 11

iTEMP TMT162 Incoming acceptance and product identification

HART® protocol certification

The temperature transmitter is registered by the HART® FieldComm Group. The device

meets the requirements of the HART Communication Protocol Specifications, Revision 7

(HCF 7.6).

3.3 Transport and storage

Carefully remove all the packaging material and protective covers that are part of the

transported package.

Dimensions and operating conditions: → 59

Pack the device so that it is reliably protected against impact when it is stored (and

transported). The original packaging offers the best protection.

Storage temperature Without display –40 to +100 °C (–40 to +212 °F)

With display –40 to +80 °C (–40 to +176 °F)

Endress+Hauser 11

Page 12

Installation iTEMP TMT162

1

2 3 4 5

6

K

E

E

P

T

I

G

H

T

W

H

E

N

C

I

R

C

U

I

T

A

L

I

V

E

I

N

E

X

P

L

O

S

I

V

E

A

T

M

O

S

P

H

E

R

E

aaa

bbb

4 Installation

If stable sensors are used, the device can be fitted directly to the sensor. For remote

mounting to a wall or stand pipe, two mounting brackets are available. The illuminated

display can be mounted in four different positions.

4.1

Installation conditions

4.1.1 Dimensions

The dimensions of the device are provided in the "Technical data" section.→ 59

4.1.2

Installation point

Information about the conditions (such as the ambient temperature, degree of protection,

climate class etc.) that must be present at the installation point so that the device can be

mounted correctly is provided in the "Technical data" section.

When using in hazardous areas, the limit values of the certificates and approvals must be

observed (see Ex Safety Instructions).

4.2 Mounting the transmitter

NOTICE

Do not overtighten the mounting screws, as this could damage the field transmitter.

Maximum torque = 6 Nm (4.43 lbf ft)

‣

4.2.1 Direct sensor mounting

2 Direct field transmitter mounting on sensor

Thermowell

1

2 Insert

3 Neck tube nipple and adapter

4 Sensor cables

5 Fieldbus cables

6 Fieldbus shielded cable

1. Mount the thermowell and screw down (1).

2. Screw the insert with the neck tube nipple and adapter into the transmitter (2). Seal

the nipple and adapter thread with silicone tape.

3. Connect the sensor cables (4) to the terminals for the sensors, see the terminal

assignment.

4. Fit the field transmitter with the insert on the thermowell (1).

5. Mount the fieldbus shielded cable or fieldbus connector (6) on the other cable gland.

12 Endress+Hauser

A0024817

Page 13

iTEMP TMT162 Installation

1

3

2

25 (0.98)

180

(7.1)

160

(6.3)

!51

(2.01)

M10

10.5

(0.41)

72 (2.8)

72 (2.8)

56

(2.2)

M10

M10

≤ 50

(1.97)

6. Guide the fieldbus cables (5) through the cable gland of the fieldbus transmitter

housing into the connection compartment.

7. Screw the cable gland tight as described in the Ensuring the degree of protection

section→ 20. The cable gland must meet explosion protection requirements.

4.2.2 Remote mounting

3 Installation of the field transmitter using the mounting bracket, see chapter 'Accessories'. Dimensions in

mm (in)

Mounting with combined wall/pipe mounting bracket

1

2 Mounting with pipe mounting bracket 2"/V4A

3 Mounting with wall mounting bracket

A0027188

Endress+Hauser 13

Page 14

Installation iTEMP TMT162

1

2

3

4

90°

90°

90°

90°

3 mm

WRITE

LOCK

ON

OFF

Proof-

Test

4.3 Display mounting

A0025417

4 4 display installation positions, attachable in 90° stages

Cover clamp

1

2 Housing cover with O-ring

3 Display with fitting kit and twist protection

4 Electronics module

1. Remove the cover clamp (1).

2. Unscrew the housing cover together with the O-ring (2).

3. Remove the display with twist protection (3) from the electronics module (4). Fit the

display with the fitting kit in the desired position in 90° stages and plug it into the

correct slot on the electronics module.

4. Then screw the housing cover together with the O-ring.

5. Fit the cover clamp (1) back on.

4.4 Post-installation check

After installing the device, always run the following final checks:

Device condition and specifications Notes

Is the device undamaged (visual inspection)? -

Do the ambient conditions match the device specification (e.g. ambient temperature,

measuring range, etc.)?

→ 46

14 Endress+Hauser

Page 15

iTEMP TMT162 Wiring

5 Wiring

5.1 Connection conditions

CAUTION

L

The electronics could be destroyed

Switch off power supply before installing or connecting the device. Failure to observe

‣

this may result in destruction of parts of the electronics.

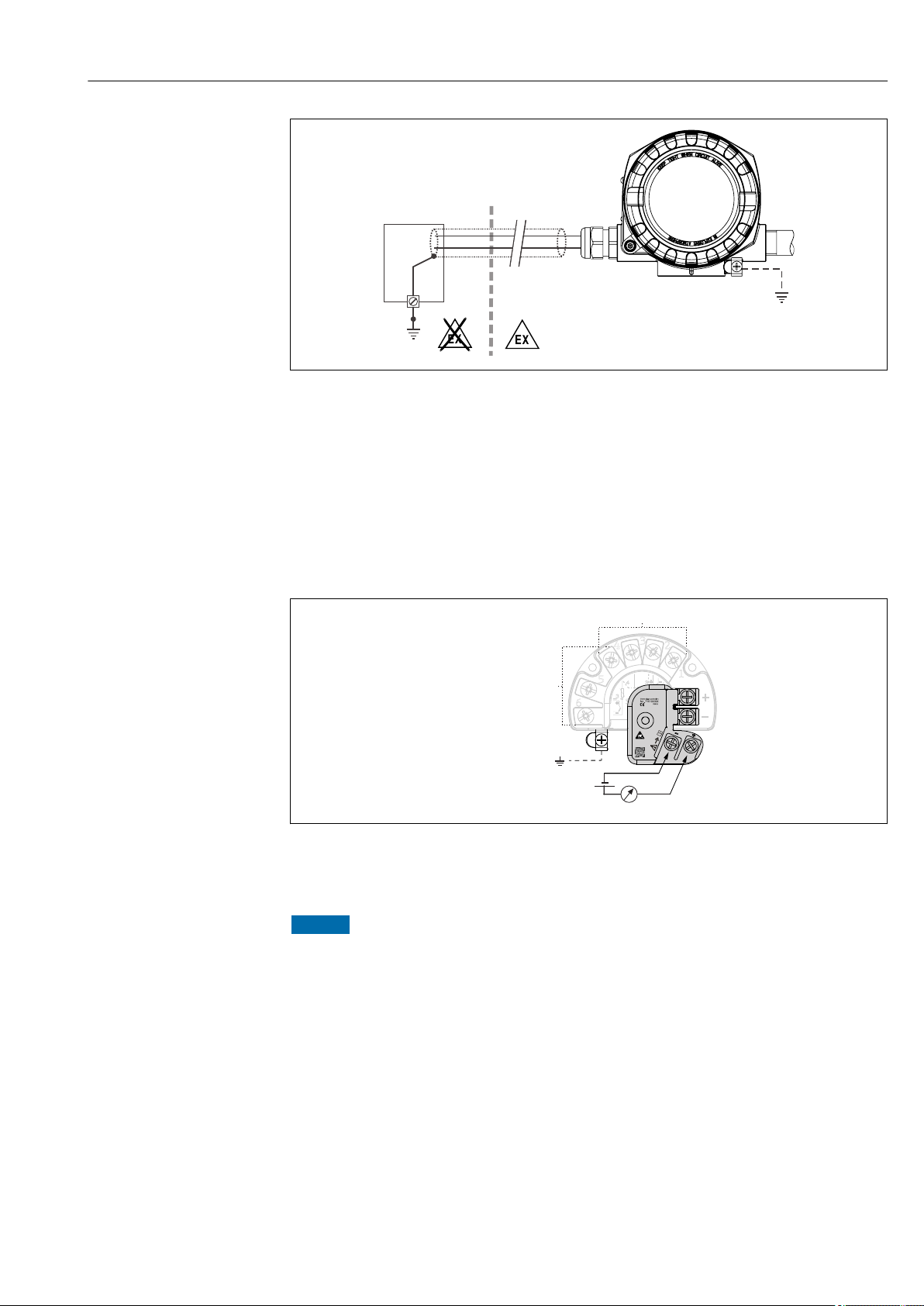

When connecting Ex-certified devices, please take special note of the instructions and

‣

connection schematics in the Ex-specific supplement to these Operating Instructions.

Contact the supplier if you have any questions.

A Phillips head screwdriver is required to wire the field transmitter at the terminals.

NOTICE

Do not overtighten the screw terminals, as this could damage the transmitter.

Maximum torque = 1 Nm (³⁄₄ lbf ft).

‣

Proceed as follows to wire the device:

1. Remove the cover clamp. → 24

2. Unscrew the housing cover on the connection compartment together with the O-ring.

→ 24. The connection compartment is opposite the electronics module.

3. Open the cable glands of the device.

4. Route the appropriate connecting cables through the openings of the cable glands.

5. Wire the cables in accordance with → 5, 16 and as described in the sections:

"Connecting the sensor" → 15 and "Connecting the measuring device" → 17.

On completion of the wiring, screw the screw terminals tight. Tighten the cable glands

again. Refer to the information provided in the 'Ensuring the degree of protection' section.

Screw the housing cover tight again and fit the cover clamp back on. → 24

In order to avoid connection errors always follow the instructions in the post-connection

check section before commissioning!

5.2 Connecting the sensor

NOTICE

ESD - electrostatic discharge. Protect the terminals from electrostatic discharge.

‣

Failure to observe this may result in destruction or malfunction of parts of the

electronics.

Endress+Hauser 15

Page 16

Wiring iTEMP TMT162

3

3

3

3

3

3

1

1

1

1

1

1

1

4

4

2

2

2

2

2

R

TD

RTD

RTD

Ω

5

5

5

6

6

6

6

RTD

RTD

6

4

4

4

4

T

C

TC

Ω Ω

ΩΩ

+

-

1

2

3

4

5

6

-

+

3

S2

-

+

-

3

4

S1

4-wire

2-wire 3-wire

Bus connection and

supply voltage

Sensor 1

Sensor 2

Sensor 1

Sensor 2

Terminal assignment

5 Wiring the field transmitter

NOTICE

When connecting 2 sensors ensure that there is no galvanic connection between the

sensors (e.g. caused by sensor elements that are not isolated from the thermowell).

The resulting equalizing currents distort the measurements considerably.

The sensors must remain galvanically isolated from one another by connecting each

‣

sensor separately to a transmitter. The transmitter provides sufficient galvanic isolation

(> 2 kV AC) between the input and output.

The following connection combinations are possible when both sensor inputs are assigned:

Sensor input 2

RTD or resistance

transmitter, two-wire

RTD or resistance

transmitter, threewire

RTD or resistance

transmitter, four-wire

Thermocouple (TC),

voltage transmitter

transmitter,

Sensor input 1

RTD or

resistance

two-wire

-

-

- - - -

RTD or

resistance

transmitter,

three-wire

RTD or

resistance

transmitter,

four-wire

A0024515-EN

Thermocouple

(TC), voltage

transmitter

16 Endress+Hauser

Page 17

iTEMP TMT162 Wiring

+

-

1

2

3

4

5

6

+

-

3

4

+

-

3

1

2

3

4

!

!

5.3 Connecting the measuring device

5.3.1

CAUTION

L

Cable glands or entries

Risk of damage

Switch off power supply before installing or connecting the device. Failure to observe

‣

this may result in destruction of parts of the electronics.

If the device has not been grounded as a result of the housing being installed, we

‣

recommended grounding it via one of the ground screws. Observe the grounding

concept of the plant! Keep the cable shield between the stripped fieldbus cable and the

ground terminal as short as possible! Connection of the functional grounding may be

needed for functional purposes. Compliance with the electrical codes of individual

countries is mandatory.

If the shielding of the fieldbus cable is grounded at more than one point in systems that

‣

do not have additional potential equalization, mains frequency equalizing currents can

occur that damage the cable or the shielding. In such cases the shielding of the fieldbus

cable is to be grounded on one side only, i.e. it must not be connected to the ground

terminal of the housing. The shield that is not connected should be insulated!

• The terminals for the fieldbus connection have integrated polarity protection.

• Cable cross-section: max. 2.5 mm²

• A shielded cable must be used for the connection.

Follow the general procedure. → 15.

6 Connecting the device to the fieldbus cable

1

Fieldbus terminals - fieldbus communication and power supply

2 Shielded fieldbus cable

3 Ground terminals, internal

4 Ground terminal (external, relevant for remote version)

5.3.2 Connecting the HART® communication resistor

If the HART® communication resistor is not integrated into the power supply unit, it is

necessary to incorporate a communication resistor of 250 Ω into the 2-wire cable. For

the connection, also refer to the documentation published by the HART® FieldComm

Group, particularly HCF LIT 20: “HART, a technical summary”.

Endress+Hauser 17

A0010823

Page 18

Wiring iTEMP TMT162

Commubox

1

2

3

4

5

6

+

-

1

2

3

4

5

6

+

-

3

4

+

-

3

PMC731: PIC0001

Online

1 >Group Select

2 PV 0.7 bar

HELP

SEND

HOME

1

2

3

4

5

6

³ 250 W

Commubox

PMC731: PIC0001

Online

1 >Group Select

2 PV 0.7 bar

HELP

SEND

HOME

A0033548

7 HART® connection with Endress+Hauser power supply unit, including integrated communication resistor

Temperature field transmitter

1

2 HART® handheld communicator

3 PLC/DCS

4 Configuration software, e.g. FieldCare

5 Configuration via Field Xpert SFX350/370

6 Power supply unit, e.g. RN221 from Endress+Hauser

8 HART® connection with other power supply units that do not have a built-in HART® communication

resistor

1

Temperature field transmitter

2 HART® communication resistor

3 PLC/DCS

4 Configuration software, e.g. FieldCare

5 HART® handheld communicator

6 Configuration via Field Xpert SFX350/370

5.3.3 Shielding and grounding

The specifications of the HART FieldComm Group must be observed during installation.

18 Endress+Hauser

A0033549

Page 19

iTEMP TMT162 Wiring

1

2

3

4

4

+

-

1

2

3

5

6

+

-

3

4

S1

3

S2

-

+

+

-

!

+

Sensor 2

Sensor 1

-

Bus connection and

supply voltage

A0010984

9 Shielding and grounding the signal cable at one end with HART® communication

Supply unit

1

2 Grounding point for HART® communication cable shield

3 Grounding of the cable shield at one end

4 Optional grounding of the field device, isolated from cable shielding

5.4 Special connection instructions

If the device is fitted with a surge arrester module, the bus is connected and the power is

supplied via the screw terminals on the surge arrester module.

A0033027-EN

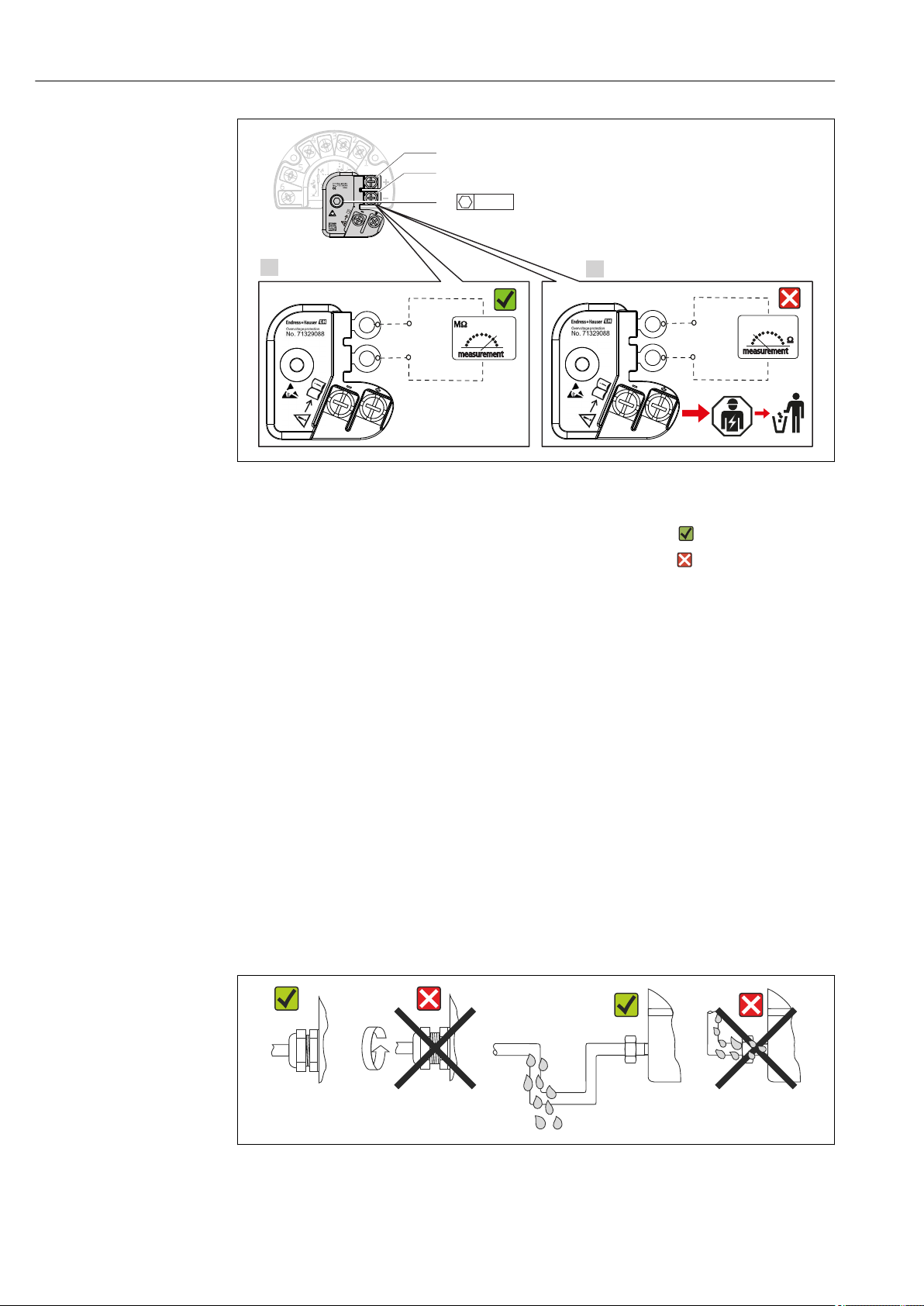

10 Electrical connection of surge arrester

5.4.1

NOTICE

To perform the function test on the surge arrester module correctly:

Remove the surge arrester module before performing the test.

‣

To do so, release screws (1) and (2) with a screwdriver as well as securing screw (3)

‣

with an allen key.

The surge arrester module can be lifted off easily.

‣

Perform the function test as shown in the following graphic.

‣

Surge arrester function test

Endress+Hauser 19

Page 20

Wiring iTEMP TMT162

1.

2.

4

+

-

1

2

3

5

6

+

-

3

4

S1

3

S2

-

+

+

-

!

1

2

3

3 mm

A0033829

11 Surge arrester function test

Ohmmeter in high-impedance range = surge arrester working .

Ohmmeter in low-impedance range = surge arrester defective . Notify Endress

+Hauser Service. Dispose of the defective surge arrester module as electronic waste.

For information on device disposal, see the Operating Instructions for the device.

→ 43

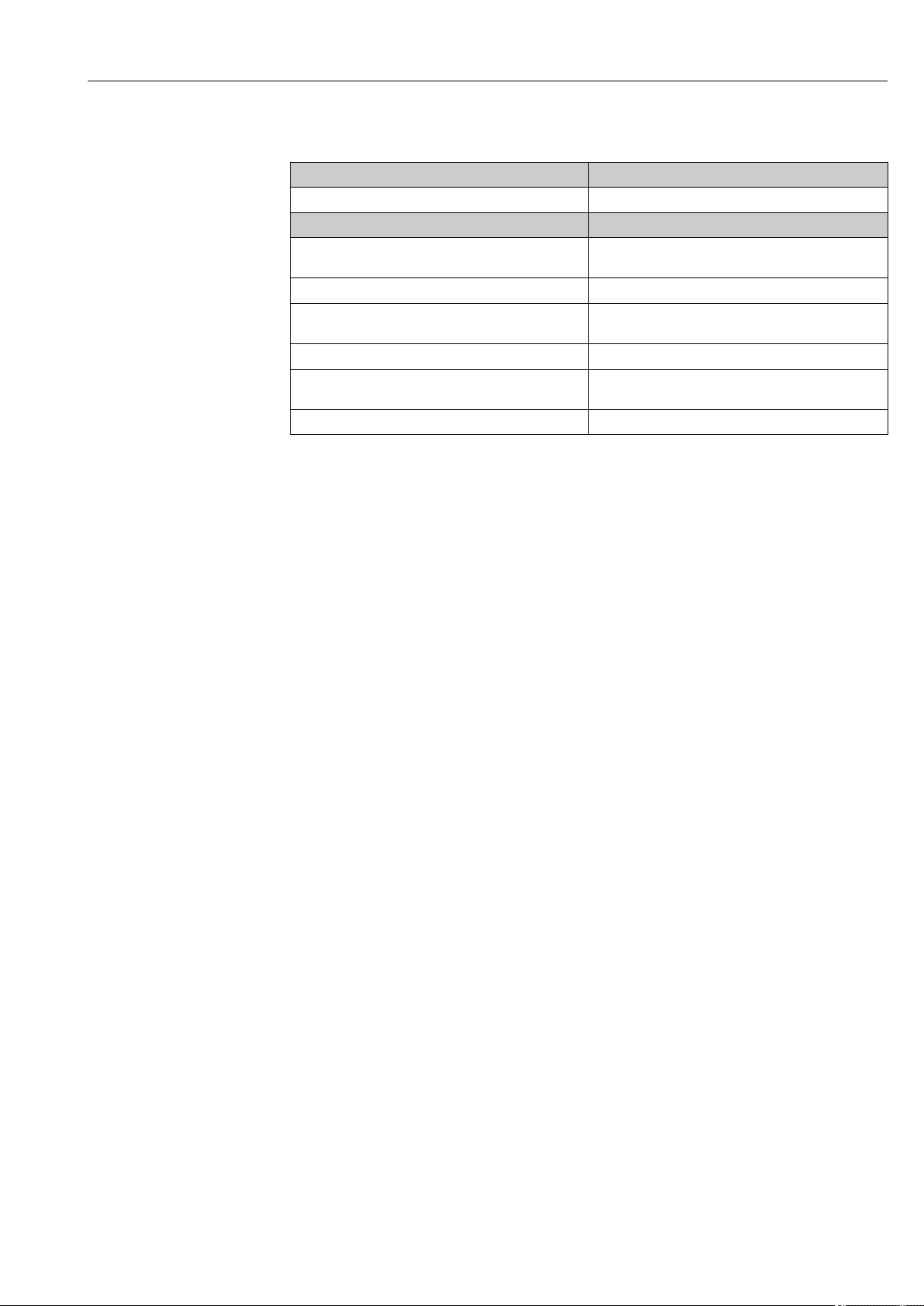

5.5 Ensuring the degree of protection

The measuring system meets all the requirements of IP67 protection. Compliance with the

following points is mandatory following installation in the field or servicing in order to

ensure that IP67 protection is maintained:

•

The housing seals must be clean and undamaged when inserted into their grooves. The

seals must be dried, cleaned or replaced if necessary.

• All housing screws and screw caps must be firmly tightened.

• The cables used for connection must be of the specified outside diameter (e.g. M20x1.5,

cable diameter 8 to 12 mm).

• Firmly tighten the cable gland. → 12, 20

• The cables must loop down before they enter the cable glands ("water trap"). This means

that any moisture that may form cannot enter the gland. Install the device so that the

cable glands are not facing upwards. → 12, 20

• Cable glands not used are to be blanked off using the dummy plugs provided.

• Do not remove the grommet from the cable gland.

12Connection tips to retain IP67 protection

20 Endress+Hauser

A0024523

Page 21

iTEMP TMT162 Wiring

5.6 Post-connection check

Device condition and specifications Notes

Is the device or cable undamaged (visual inspection)? --

Electrical connection Notes

Does the supply voltage match the specifications on

the nameplate?

Do the mounted cables have adequate strain relief? Visual inspection

Are the power supply and signal cables correctly

connected?

Are all the screws terminals sufficiently tightened? → 15

Are all the cable entries installed, tightened and

sealed?

Are all the housing covers installed and tightened? → 24

Standard mode and SIL mode: U = 11.5 to 42 V

→ 17

→ 20

DC

Endress+Hauser 21

Page 22

Operating options iTEMP TMT162

°C

WRITE

LOCK

ON

OFF

PMC731: PIC0001

Online

1 >Group Select

2 PV 0.7 bar

Commubox

2

3

4

5

7

1

Proof-

Test

6

HELP

SEND

HOME

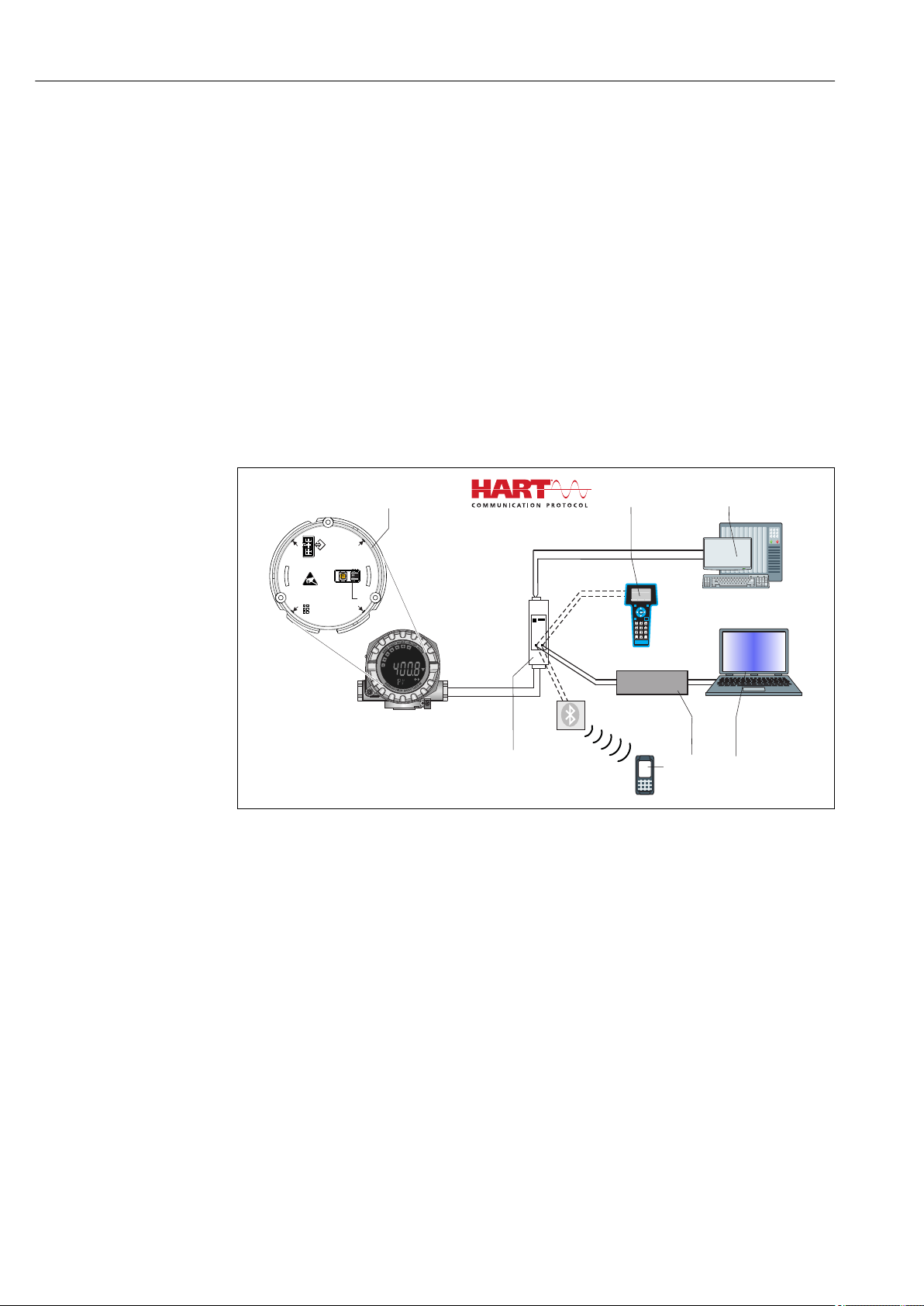

6 Operating options

6.1 Overview of operation options

Operators have a number of options for configuring and commissioning the device:

• Configuration software → 27

HART® functions and device-specific parameters are primarily configured via the

Fieldbus interface. Special configuration and operating programs are available from

various manufacturers for this purpose.

• Miniature switch (DIP switch) and proof-test button for various hardware settings

–

Hardware write protection is activated and deactivated via a miniature switch (DIP

switch) on the electronics module.

– Proof-test button for testing in SIL mode without HART operation. Pressing the button

triggers a device restart. The proof test checks the functional integrity of the

transmitter in the SIL mode during commissioning, in the event of changes to safetyrelated parameters or generally at appropriate intervals.

A0024548

13 Operating options of device

Hardware settings via DIP switch and proof-test button

1

2 HART® handheld communicator

3 PLC/DCS

4 Configuration software, e.g. FieldCare

5 Commubox: Power supply and modem for field devices with HART® protocol

6 Configuration via Field Xpert SFX350/370

7 Power supply unit and active barrier, .e.g. RN221 from Endress+Hauser

22 Endress+Hauser

Page 23

iTEMP TMT162 Operating options

°C

°F

%

K

10

0

20

30

40

50

60

70

80

90

100

!

1

2

3

4

5

6

7

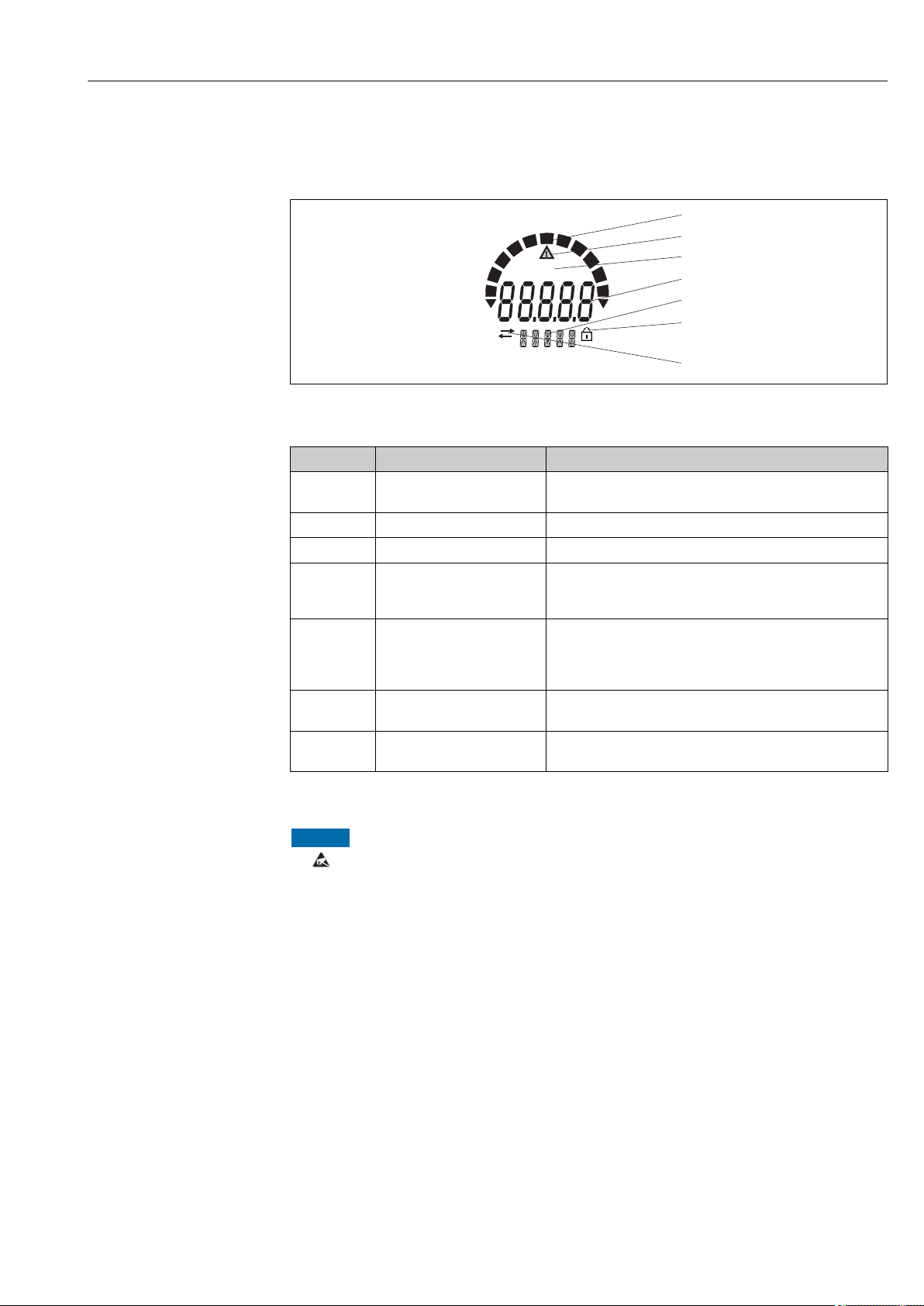

6.1.1 Display and operating elements

Display elements

A0034101

14 LC display of the field transmitter (backlit, attachable in 90° stages)

Item No. Function Description

1 Bar graph display In increments of 10% with indicators for underranging and

overranging.

2 'Caution' symbol This is displayed when an error or warning occurs.

3 Unit display K, °F, °C or % Unit display for the internal measured value displayed.

4 Measured value display, digit

height

20.5 mm

5 Status and information

display

6 'Configuration locked' symbol

7 'Communication' symbol

Displays the current measured value. In the event of an error

or warning, the corresponding diagnostics information is

displayed. → 36

Indicates which value is currently shown on the display. Text

can be entered for every value. In the event of an error or a

warning, the sensor input that triggered the error/warning is

also displayed where applicable, e.g. SENS1

The 'configuration locked' symbol appears when configuration

is locked via the hardware or software

The communication symbol appears when HART®

communication is active.

Local operation

NOTICE

ESD - electrostatic discharge. Protect the terminals from electrostatic discharge.

‣

Failure to observe this may result in destruction or malfunction of parts of the

electronics.

Hardware write protection and the proof test can be activated via a DIP switch or button on

the electronics module. When write protection is active, parameters cannot be modified. A

key symbol on the display indicates that the write protection is on. Write protection

prevents any write access to the parameters.

Endress+Hauser 23

Page 24

Operating options iTEMP TMT162

3 mm

1.

2.

3.

4.

5.

WRITE

LOCK

ON

OFF

Proof-

Test

A0033847

Procedure for setting the DIP switch or activating the proof test:

1. Remove the cover clamp.

2. Unscrew the housing cover together with the O-ring.

3. If necessary, remove the display with the fitting kit from the electronics module.

4. Configure the hardware write protection WRITE LOCK accordingly using the DIP

switch. In general, the following applies: switch to ON = function enabled, switch to

OFF = function disabled.

5. If performing a SIL commissioning test and a proof test, make a device restart using

the button.

Once the hardware setting has been made, re-assemble the housing cover in the reverse

order.

24 Endress+Hauser

Page 25

iTEMP TMT162 Operating options

Expert

System

Sensors

Communication

Diagnostics

Operating menu for experts

D

intervalisplay

Setup

Advanced setup

Device tag

Diagnostics

Operating menu for operators and maintenances

Operator, maintenance

Expert

Output

Unit

Sensor type

Lower range value

Upper range value

Enter access code

Sensor

Sensor offset

Current output

Output current

Actual diagnostics

Diagnostics list

Device reset

Enter access code

Unit

Display

Display interval

Sensor Sensor type

Lower range v.

Current trim.

HART config.

HART info

HART output

Burst mode

Device type

Assign PV

Actual d .iagn

D stics listiagno

Actual d stics countiagno

Event logbook

Device information

Simulation

Previous diagnostics

Device tag

Min/max values

Sensor value

Measured values

SIL

SIL Option

Administration

Sensor Min

Display

Device tag

Device reset

Administration

D stics set.iagno

Sensor switch s.

Burst config.

Event logbook

Device info.

Sensor value

Simulation

Simulation diagn.

Previous diagnostics

Device tag

Measured val.

Min/max values

Sensor1 Min

Actual diagnostics count

Simulation

Meas. channels

Diagnostic set.

Diagnostic behavior

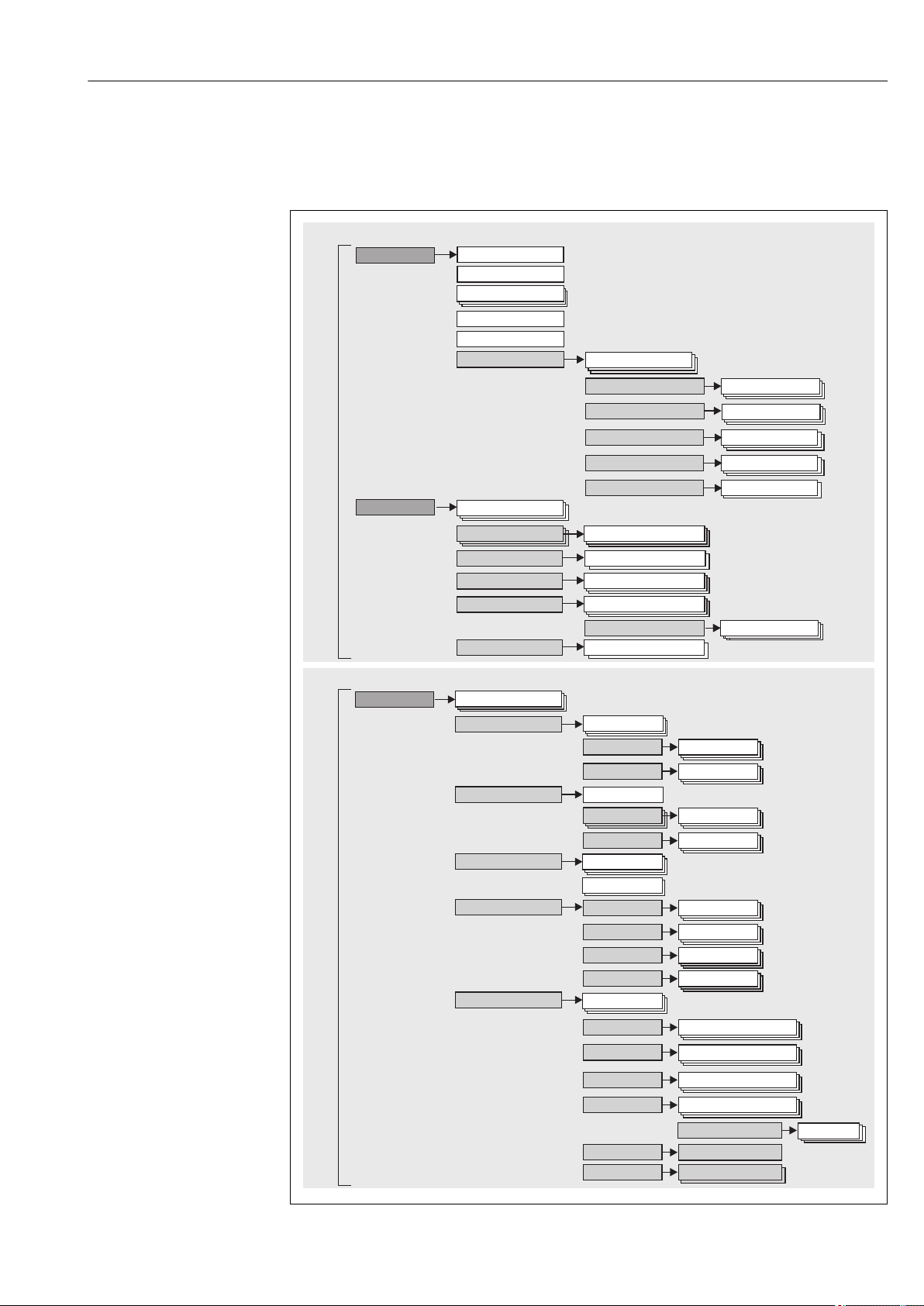

6.2 Structure and function of the operating menu

6.2.1

Structure of the operating menu

Endress+Hauser 25

A0033850-EN

Page 26

Operating options iTEMP TMT162

The configuration in the SIL mode is different from the configuration in the standard

mode. For more detailed information please refer to the Functional Safety Manual

(SD01632T/09).

Submenus and user roles

Certain parts of the menu are assigned to certain user roles. Each user role corresponds to

typical tasks within the lifecycle of the device.

User role Typical tasks Menu Content/meaning

Maintenance

Operator

Expert Tasks that require detailed knowledge of the function

Commissioning:

• Configuration of the measurement.

• Configuration of data processing (scaling,

linearization, etc.).

Configuration of the analog measured value output.

•

Tasks during operation:

• Configuration of the display.

• Reading measured values.

Fault elimination:

• Diagnosing and eliminating process errors.

• Interpretation of device error messages and

correcting associated errors.

of the device:

• Commissioning measurements under difficult

conditions.

• Optimal adaptation of the measurement to difficult

conditions.

• Detailed configuration of the communication

interface.

• Error diagnostics in difficult cases.

"Setup" Contains all parameters for commissioning:

• Setup parameters

Once values have been set for these parameters, the

measurement should generally be completely

configured.

• "Advanced setup" submenu

Contains additional submenus and parameters:

– For more accurate configuration of the

measurement (adaptation to special measuring

conditions).

– For converting the measured value (scaling,

linearization).

– For scaling the output signal.

– Required in ongoing operation: configuration of

the measured value display (displayed values,

display format, etc.).

"Diagnostics" Contains all parameters for detecting and analyzing

errors:

• Diagnostic list

Contains up to 3 currently active error messages.

• Event logbook

Contains the last 5 error messages (no longer active).

• "Device information" submenu

Contains information for identifying the device.

• "Measured values" submenu

Contains all current measured values.

• "Simulation" submenu

Used to simulate measured values, output values or

diagnostic messages.

• "Device reset" submenu

"Expert" Contains all parameters of the device (including those

that are already in one of the other menus). The

structure of this menu is based on the function blocks

of the device:

• "System" submenu

Contains all higher-level device parameters that do

not pertain either to measurement or the measured

value communication.

• "Sensor" submenu

Contains all parameters for configuring the

measurement.

• "Output" submenu

Contains all parameters for configuring the analog

current output.

• "Communication" submenu

Contains all parameters for configuring the digital

communication interface.

• "Diagnostics" submenu

Contains all parameters for detecting and analyzing

errors.

26 Endress+Hauser

Page 27

iTEMP TMT162 Operating options

6.3 Access to the operating menu via the operating tool

6.3.1

Function range

FDT/DTM-based plant asset management tool from Endress+Hauser. It can configure all

smart field devices in a system and helps you manage them. By using the status

information, it is also a simple but effective way of checking their status and condition.

Access is via the HART® protocol or CDI (= Endress+Hauser Common Data Interface).

Typical functions:

• Parameterization of transmitters

•

Loading and saving device data (upload/download)

• Documentation of the measuring point

• Visualization of the measured value memory (line recorder) and event logbook

Source for device description files

See information → 29

User interface

FieldCare

For details, see Operating Instructions BA00027S/04/xx and BA00059AS/04/xx

A0033862-EN

6.3.2 DeviceCare

Function range

The fastest way to configure Endress+Hauser field devices is with the dedicated DeviceCare

tool. DeviceCare's user-friendly design enables transparent and intuitive device connection

and configuration. Intuitive menus and step-by-step instructions with status information

ensure optimum transparency.

Quick and easy to install, connects devices in a single click (one-click connection).

Automatic hardware identification and driver catalog update. The devices are configured

using DTMs (Device Type Manager). Multilingual support, the tool is touch-enabled for

tablet use. Hardware interfaces for modems : (USB/RS232), TCP/IP, USB and PCMCIA.

Endress+Hauser 27

Page 28

Operating options iTEMP TMT162

Source for device description files

See data → 29

6.3.3

Function range

Field Xpert is an industrial PDA with integrated touchscreen for commissioning and

maintaining field devices in explosion hazardous and safe areas. It enables the efficient

configuration of FOUNDATION fieldbus, HART and WirelessHART devices.

Communication is wireless via Bluetooth or WiFi interfaces.

Source for device description files

See data → 29

Field Xpert

6.3.4 AMS Device Manager

Function range

Program from Emerson Process Management for operating and configuring measuring

devices via the HART® protocol.

Source for device description files

See data → 29

6.3.5 SIMATIC PDM

Function range

SIMATIC PDM is a standardized, vendor-independent program from Siemens for the

operation, configuration, maintenance and diagnosis of smart field devices via the HART

protocol.

Source for device description files

See data → 29

6.3.6 Field Communicator 475

Function range

Industrial handheld terminal from Emerson Process Management for remote

configuration and measured value display via the HART ® protocol.

Source for device description files

See data → 29

®

28 Endress+Hauser

Page 29

iTEMP TMT162 System integration

7 System integration

Version data for the device

Firmware version 04.01.zz • On the title page of the Operating instructions

• On the nameplate

• Firmware version

Diagnostics → Device info→ Firmware Version

Manufacturer ID 0x0011 Manufacturer ID parameter

Diagnostics → Device info→ Manufacturer ID

Device type ID 0x11CE Device type parameter

Diagnostics → Device info → Device type

HART protocol revision 7.6 ---

Device revision 4 • On the transmitter nameplate

• Device revision parameter

Diagnostics → Device info → Device revision

The suitable device description file (DD or DTM) for the individual operating tools is listed

in the table below, along with information on where the file can be acquired.

parameter

Operating tools

Operating tool Sources for obtaining device descriptions (DD) or device type

managers (DTM)

FieldCare

(Endress+Hauser)

DeviceCare

(Endress+Hauser)

AMS Device Manager

(Emerson Process Management)

SIMATIC PDM

(Siemens)

Field Communicator 475

(Emerson Process Management)

FieldXpert SFX350, SFX370

(Endress+Hauser)

• www.endress.com → Download Area → Software

CD-ROM (contact Endress+Hauser)

•

• DVD (contact Endress+Hauser)

www.endress.com → Download Area → Software

Please ask the operating tool manufacturer for information on where to

obtain the DD/DTM.

Use update function of handheld terminal

Use update function of handheld terminal

7.1 HART device variables and measured values

The following measured values are assigned to the device variables at the factory:

Device variables for temperature measurement

Device variable Measured value

Primary device variable (PV) Sensor 1

Secondary device variable (SV) Device temperature

Tertiary device variable (TV) Sensor 1

Quaternary device variable (QV) Sensor 1

It is possible to change the assignment of device variables to process variables in the

Expert → Communication → HART output menu.

Endress+Hauser 29

Page 30

System integration iTEMP TMT162

7.2 Device variables and measured values

The following measured values are assigned to the individual device variables:

Device variable code Measured value

0 Sensor 1

1 Sensor 2

2 Device temperature

3 Average of sensor 1 and sensor 2

4 Difference between sensor 1 and sensor 2

5 Sensor 1 (backup sensor 2)

6 Sensor 1 with switchover to sensor 2 if a limit value is exceeded

7 Average of sensor 1 and sensor 2 with backup

The device variables can be queried by a HART® master using HART® command 9 or

33.

7.3

Supported HART® commands

The HART® protocol enables the transfer of measuring data and device data between

the HART® master and the field device for configuration and diagnostics purposes.

HART® masters such as the handheld terminal or PC-based operating programs (e.g.

FieldCare) need device description files (DD, DTM) which are used to access all the

information in a HART® device. This information is transmitted exclusively via

"commands".

There are three different types of command

•

Universal commands:

All HART® devices support and use universal commands. These are associated with the

following functionalities for example:

– Recognition of HART® devices

– Reading digital measured values

• Common practice commands:

Common practice commands offer functions which are supported and can be executed by

many but not all field devices.

• Device-specific commands:

These commands allow access to device-specific functions which are not HART

®

standard. Such commands access individual field device information, among other

things.

Command No. Designation

Universal commands

0, Cmd0 Read unique identifier

1, Cmd001 Read primary variable

2, Cmd002 Read loop current and percent of range

3, Cmd003 Read dynamic variables and loop current

6, Cmd006 Write polling address

7, Cmd007 Read loop configuration

8, Cmd008 Read dynamic variable classifications

9, Cmd009 Read device variables with status

11, Cmd011 Read unique identifier associated with TAG

30 Endress+Hauser

Page 31

iTEMP TMT162 System integration

Command No. Designation

12, Cmd012 Read message

13, Cmd013 Read TAG, descriptor, date

14, Cmd014 Read primary variable transducer information

15, Cmd015 Read device information

16, Cmd016 Read final assembly number

17, Cmd017 Write message

18, Cmd018 Write TAG, descriptor, date

19, Cmd019 Write final assembly number

20, Cmd020 Read long TAG (32-byte TAG)

21, Cmd021 Read unique identifier associated with long TAG

22, Cmd022 Write long TAG (32-byte TAG)

38, Cmd038 Reset configuration changed flag

48, Cmd048 Read additional device status

Common practice commands

33, Cmd033 Read device variables

34, Cmd034 Write primary variable damping value

35, Cmd035 Write primary variable range values

36, Cmd036 Set primary variable upper range value

37, Cmd037 Set primary variable lower range value

40, Cmd040 Enter/Exit fixed current mode

42, Cmd042 Perform device reset

44, Cmd044 Write primary variable units

45, Cmd045 Trim loop current zero

46, Cmd046 Trim loop current gain

50, Cmd050 Read dynamic variable assignments

51, Cmd051 Write dynamic variable assignments

54, Cmd054 Read device variable information

59, Cmd059 Write number of response preambles

72, Cmd072 Squawk

95, Cmd095 Read device communications statistics

100, Cmd100 Write primary variable alarm code

103, Cmd103 Write burst period

104, Cmd104 Write burst trigger

105, Cmd105 Read burst mode configuration

107, Cmd107 Write burst device variables

108, Cmd108 Write burst mode command number

109, Cmd109 Burst mode control

516, Cmd516 Read device location

517, Cmd517 Write device location

518, Cmd518 Read location description

519, Cmd519 Write location description

520, Cmd520 Read process unit tag

521, Cmd521 Write process unit tag

Endress+Hauser 31

Page 32

System integration iTEMP TMT162

Command No. Designation

523, Cmd523 Read condensed status mapping array

524, Cmd524 Write condensed status mapping

525, Cmd525 Reset condensed status map

526, Cmd526 Write status simulation mode

527, Cmd527 Simulate status bit

32 Endress+Hauser

Page 33

iTEMP TMT162 Commissioning

8 Commissioning

8.1 Post-installation check

Before commissioning the measuring point make sure that all final checks have been

carried out:

• "Post-installation check" checklist,

• "Post-connection check” checklist, → 15

8.2 Switching on the transmitter

Once the final checks have been successfully completed, it is time to switch on the supply

voltage. The transmitter performs a number of internal test functions after power-up. As

this procedure progresses, the following sequence of messages appears on the display:

Step Display

1 "Display" text and firmware version of the display

2 Firm logo

3 Device name (scrolling text)

4 Firmware, hardware version, device version and device address

5 For devices in SIL mode: SIL-CRC is displayed

6a Current measured value or

6b Current status message

If the switch-on procedure is not successful, the relevant diagnostic event, depending on the cause,

is displayed. A detailed list of diagnostic events and the corresponding troubleshooting instructions

can be found in the "Diagnostics and troubleshooting" section .

→ 12

The device operates in normal mode after approx. 30 seconds! Normal measuring mode

commences as soon as the switch-on procedure is completed. Measured values and status

values appear on the display.

8.3 Enabling configuration

If the device is locked and the parameter settings cannot be changed, it must first be

enabled via the hardware or software lock. The device is write-protected if the lock symbol

is shown on the display.

To unlock the device

• either switch the write protection switch on the electronics module to the "OFF" position

(hardware write protection), or

deactivate the software write protection via the operating tool. See the description for

•

the 'Define device write protection' parameter. → 83

When hardware write protection is active (write protection switch set to the "ON"

position), write protection cannot be disabled via the operating tool. Hardware write

protection must always be disabled before software write protection can be enabled or

disabled via the operating tool.

Endress+Hauser 33

Page 34

Diagnostics and troubleshooting iTEMP TMT162

9 Diagnostics and troubleshooting

9.1 Troubleshooting

Always start troubleshooting with the checklists below if faults occur after start up or

during operation. This takes you directly (via various queries) to the cause of the problem

and the appropriate remedial measures.

In the event of a serious fault, a device might have to be returned to the manufacturer

for repair. Refer to the "Return" section before returning the device to Endress+Hauser.

→ 43

Check display (local display)

Display is blank - no connection to

the HART host system.

Display is blank - however,

connection has been established to

the HART host system.

1. Check the supply voltage → terminals + and -

2. Measuring electronics defective → order spare part, → 41

1. Check whether the display module fitting kit is correctly seated on the

electronics module → 14

2. Display module defective → order spare part, →

3. Measuring electronics defective → order spare part, → 41

41

Local error messages on the display

→ 36

Faulty connection to the fieldbus host system

Problem Possible cause Solution

Device is not

responding.

Output current < 3.6mASignal line is not wired correctly. Check wiring.

HART

communication is

not working.

Supply voltage does not match the value

indicated on the nameplate.

Connecting cables are not in contact with

the terminals.

Electronics unit is defective. Replace the device.

Communication resistor missing or

incorrectly installed.

Commubox is connected incorrectly. Connect Commubox correctly.

Apply correct voltage

Check the connection of the cables and

correct if necessary.

Install the communication resistor (250 Ω)

correctly.

Error messages in the configuration software

→ 37

Application errors without status messages for RTD sensor connection

Problem Possible cause Solution

Measured value is incorrect/

inaccurate

Incorrect sensor orientation. Install the sensor correctly.

Heat conducted by sensor. Observe the face-to-face length of the

sensor.

34 Endress+Hauser

Page 35

iTEMP TMT162 Diagnostics and troubleshooting

Application errors without status messages for RTD sensor connection

Problem Possible cause Solution

Failure current (

≥ 21 mA)

≤ 3.6 mA or

Device programming is incorrect

(number of wires).

Device programming is incorrect

(scaling).

Incorrect RTD configured. Change the Sensor type device function.

Sensor connection. Check that the sensor is connected

The cable resistance of the sensor

(two-wire) was not compensated.

Offset incorrectly set. Check offset.

Faulty sensor. Check the sensor.

Incorrect sensor connection. Connect the connecting cables correctly

Device programming is incorrect (e.g.

number of wires).

Incorrect programming. Incorrect sensor type set in the Sensor

Change the Connection type device

function.

Change scaling.

correctly.

Compensate the cable resistance.

(terminal diagram).

Change the Connection type device

function.

type device function. Set the correct

sensor type.

Application errors without status messages for TC sensor connection

Problem Possible cause Solution

Incorrect sensor orientation. Install the sensor correctly.

Heat conducted by sensor. Observe the face-to-face length of the

sensor.

Measured value is incorrect/

inaccurate

Failure current (≤ 3.6 mA or

≥ 21 mA)

Device programming is incorrect

(scaling).

Incorrect thermocouple type (TC)

configured.

Incorrect comparison measuring

point set.

Interference via the thermocouple

wire welded in the thermowell

(interference voltage coupling).

Offset incorrectly set. Check offset.

Faulty sensor. Check the sensor.

Sensor is connected incorrectly. Connect the connecting cables correctly

Incorrect programming. Incorrect sensor type set in the Sensor

Change scaling.

Change the Sensor type device function.

Set the correct comparison measuring

point .

Use a sensor where the thermocouple

wire is not welded.

(terminal diagram).

type device function. Set the correct

sensor type.

Endress+Hauser 35

Page 36

Diagnostics and troubleshooting iTEMP TMT162

9.2 Diagnostic events

9.2.1

Displaying diagnostic events

NOTICE

Status signals and diagnostic behavior can be configured manually for certain

diagnostic events. If a diagnostic event occurs, however, it is not guaranteed that the

measured values are valid for the event and comply with the process for the status

signals S and M and the diagnostic behavior: 'Warning' and Disabled'.

Reset the status signal assignment to the factory setting.

‣

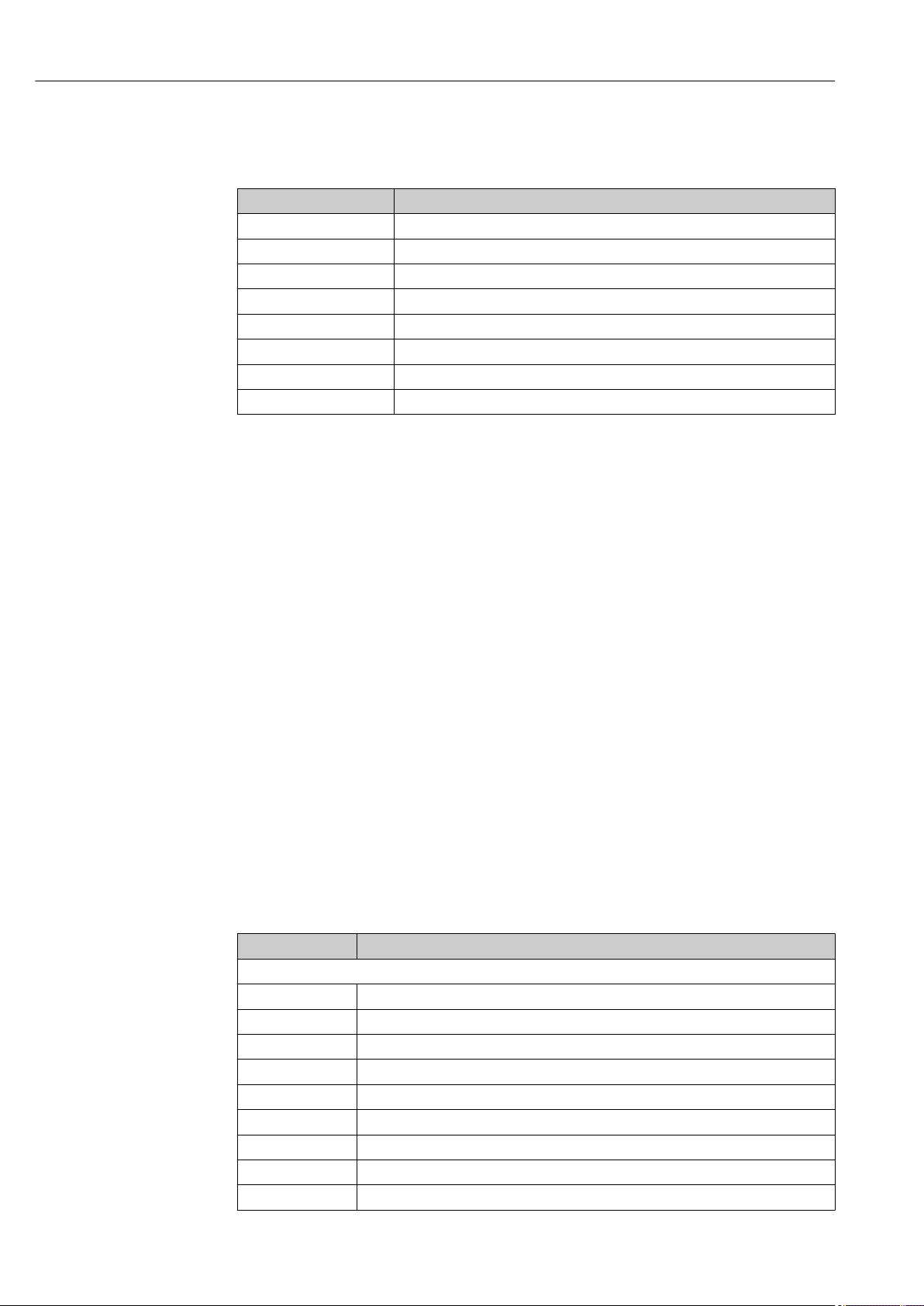

Status signals

Symbol Event

category

F Operating

error

C Service mode The device is in the service mode (during a simulation, for example).

S Out of

specification

M Maintenance

required

N Not

categorized

Meaning

An operating error has occurred.

The device is being operated outside its technical specifications (e.g. during

startup or cleaning).

Maintenance is required.

• If a valid measured value is not available, the display alternates between "- - -- -" and the

error message plus the defined error number and the ’’ symbol.

• If a valid measured value is present, the display alternates between the status plus the

defined error number (7-segment display) and the primary measured value (PV) with

the ’’ symbol.

Diagnostic behavior

Alarm Measurement is interrupted. The signal outputs assume the specified alarm

condition. A diagnostic message is generated.

Warning The device continues to measure. A diagnostic message is generated.

Disabled The diagnosis is completely disabled even if the device is not recording a measured

value.

36 Endress+Hauser

Page 37

iTEMP TMT162 Diagnostics and troubleshooting

Diagnostic event and event text

The fault can be identified by means of the diagnostic event. The event text helps you by

providing information on the fault.

Diagnostic event

Status signal Event number Event text

↓ ↓ ↓

Example F 042 Sensor corroded

3-digit number

If two or more diagnostic events are pending simultaneously, only the diagnostic message

with the highest priority is shown. Additional pending diagnostic messages are shown in

the Diagnostic list submenu → 85

. The status signal dictates the priority in which

the diagnostic messages are displayed. The following order of priority applies: F, C, S, M. If

two or more diagnostic events with the same status signal are active simultaneously, the

numerical order of the event number dictates the order of priority in which the events are

displayed, e.g.: F042 appears before F044 and before S044.

Past diagnostic messages that are no longer pending are shown in the Event logbook

submenu→ 86.

9.2.2

Overview of diagnostic events

Each diagnostic event is assigned a certain event behavior at the factory. The user can

change this assignment for certain diagnostic events.

Example:

Settings Device behavior

Configuration examples Diagnostic

number

1. Default setting 047 S Warning S Measured

2. Manual setting: status

signal S changed to F

3. Manual setting: Warning

diagnostic behavior changed

to Alarm

4. Manual setting: Warning

changed to Disabled

047 F Warning F Measured

047 S Alarm S Configured

047 S

Status

signal

1)

Diagnostic

behavior from

the factory

Disabled -

Status signal

(output via HART®

communication)

2)

Current

output

value

value

error current

Last valid

measured

value

PV, status Display

Measured value,

UNCERTAIN

Measured value,

UNCERTAIN

Measured value,

BAD

Last valid

3)

measured value,

GOOD

S047

F047

S047

S047

1) Setting is not relevant.

2) Status signal is not displayed.

3) The error current is output if no valid measured value is available.

The relevant sensor input for these diagnostic events can be identified with the

Actual diag channel parameter or on the display.

Endress+Hauser 37

Page 38

Diagnostics and troubleshooting iTEMP TMT162

Diagnosti

c

behavior

from the

factory

Diagnostic

number

Short text Corrective measure

Status

signal

from the

factory

Customizable

1)

Not

customizable

Diagnostics for the sensor

001 Device failure - sensor n

(sensor RJ)

041 Sensor interrupted - sensor n 1. Check electrical wiring.

3)

1. Restart device

F Alarm

2. Replace electronics

F Alarm

2. Replace sensor.

3. Check connection type.

042 Sensor n corroded 1. Check sensor.

M Warning

2. Replace sensor.

043 Short-circuit sensor n 1. Check electrical connection.

F Alarm

2. Check sensor.

3. Replace sensor or cable.

044 Sensor drift detected 1. Check sensor or main electronics.

M Warning

2. Replace sensor or main electronics.

047 Sensor limit reached sensor n

(sensor RJ)

048 Drift detection not possible 1. Check electrical connection.

1. Check sensor.

2. Check process conditions.

S Warning

M Warning

2. Check sensor.

3. Replace sensor.

062 Sensor connection faulty sensor

Check sensor connection. F Alarm

n (sensor RJ)

105 Calibration interval 1. Execute calibration and reset calibration

M Warning

interval.

2. Switch off calibration counter.

145 Compensation reference point

sensor n

1. Check terminal temperature.

2. Check external reference point.

F Alarm

Diagnostics for the electronics

201 Electronics faulty 1. Restart device.

F Alarm

2. Replace electronics.

221 Reference sensor defective

Replace device. M Alarm

sensor RJ

241 Firmware faulty 1. Restart device.

F Alarm

2. Power cycle device.

3. Replace electronics.

242 Firmware incompatible 1. Check firmware version.

F Alarm

2. Flash or replace main electronics.

261 Electronics module defective 1. Restart device.

F Alarm

2. Replace main electronics module.

283 Memory content inconsistent 1. Restart device.

F Alarm

2. Replace electronics.

286 Data storage inconsistent 1. Repeat safe parameterization.

F Alarm

2. Replace electronics.

Diagnostics for the configuration

401 Factory reset active Factory reset active, please wait. C Warning

Customizable

2)

Not

customizable

402 Initialization active sensor n

Initialization active, please wait. C Warning

(sensor RJ)

38 Endress+Hauser

Page 39

iTEMP TMT162 Diagnostics and troubleshooting

Diagnosti

c

behavior

from the

factory

Diagnostic

number

Short text Corrective measure

Status

signal

from the

factory

Customizable

1)

Not

customizable

410 Data transfer failed 1. Check connection.

2. Retry data transfer.

F Alarm

C

411 Up-/download active Up-/download active, please wait. Warning

412 Download active Download active, please wait C Warning

435 Linearization faulty sensor n

Check linearization. F Alarm

(sensor RJ)

438 Dataset different 1. Check data set file.

M Warning

2. Check device parameterization.

3. Download new device parameterization.

439 Data set Repeat the safe parameterization F Alarm

485 Process variable simulation

active sensor n (device

Deactivate simulation. C - Warning -

temperature)

491 Current output simulation

Deactivate simulation. C Warning

Customizable

2)

Not

customizable

495 Diagnostic event simulation

active

531 Factory adjustment missing

sensor n (current output)

537 Configuration sensor n (current

output)

Deactivate simulation. C Warning

1. Contact service.

F Alarm

2. Replace device.

1. Check device configuration

F Alarm

2. Upload and download new configuration.

(In case of current output: check

configuration of analog output.)

583 Input simulation sensor n Deactivate simulation.

C Warning

Diagnostics for the process

801 Supply voltage too low

825 Operating temperature 1. Check ambient temperature.

4)

Increase supply voltage. S Alarm

S Warning

2. Check process temperature.

844 Process value out of

specification-current output

1. Check process value.

2. Check application.

S Warning

Check sensor.

1) Can be set to F, C, S, M, N

2) Can be set to 'Alarm', 'Warning' and 'Disabled'

3) n = number of sensor inputs (1 and 2)

In the case of this diagnostic event, the device always outputs a "low" alarm status (output current ≤ 3.6 mA).

4)

Endress+Hauser 39

Page 40

Maintenance iTEMP TMT162

9.3 Software history and overview of compatibility

Revision history

The firmware version (FW) on the nameplate and in the Operating Instructions indicates

the device release: XX.YY.ZZ (example 01.02.01).

XX Change to main version. No longer compatible. The device and

Operating Instructions change.

YY Change to functions and operation. Compatible. The Operating

Instructions change.

ZZ Fixes and internal changes. No changes to the Operating Instructions.

Date Firmware

version

07/2017 04.01.zz HART protocol version 7.6 and addition of operating

Modification Documentation

BA01801T/09/en/01.17

parameters for functional safety (SIL3)

10 Maintenance

No special maintenance work is required for the temperature transmitter.

10.1

Endress+Hauser offers a wide variety of services for maintenance such as recalibration,

maintenance service or device tests.

Endress+Hauser services

Your Endress+Hauser Sales Center can provide detailed information on the services.

40 Endress+Hauser

Page 41

iTEMP TMT162 Repair

4

3

2

6

5

7

1

6

5

7

5

11 Repair

11.1 General notes

Repairs that are not described in these Operating Instructions must only be carried out

directly by the manufacturer or by the service department.

11.2 Spare parts

Spare parts currently available for the product can be found online at:

http://www.products.endress.com/spareparts_consumables. Always quote the serial

number of the device when ordering spare parts!

A0024557

15 Field transmitter spare parts

Item No. 1 Housing

Certificates:

A Non-hazardous area + Ex ia

B ATEX Ex d

Endress+Hauser 41

Material:

A Aluminum, HART 5

B Stainless steel 316L, HART 5

C T17, HART 5

F Aluminum, FF/PA

G Stainless steel 316L, FF/PA

H T17, FF/PA

K Aluminum, HART 7

L Stainless steel 316L, HART 7

M T17, HART 7

Page 42

Repair iTEMP TMT162

Item No. 1 Housing

Cable entry:

1 2 x thread NPT ½" + terminal block + 1 dummy plug

2 2 x thread M20x1.5 + terminal block + 1 dummy plug

4 2 x thread G ½" + terminal block + 1 dummy plug

Version:

A Standard

TMT162G- A ← order code

Item No. 4 Electronics

Certificates:

A Non-hazardous area

B ATEX Ex ia, FM IS, CSA IS

Sensor input; communication:

A 1x; HART 5, FW 01.03.zz, DevRev02

B 2x; HART 5, FW 01.03.zz, DevRev02, config. output sensor 1

C 2x; FOUNDATION Fieldbus Device Revision 1

D 2x; PROFIBUS PA, DevRev02

E 2x; FOUNDATION Fieldbus FW 01.01.zz, Device Revision 2

F 2x; FOUNDATION Fieldbus FW 02.00.zz, Device Revision 3

G 1x; HART7, Fw 04.01.zz, DevRev04

H 2x; HART7, Fw 04.01.zz, DevRev04, config. output sensor 1

Configuration:

A 50 Hz mains filter

B Produced as per original order (quote serial number) 50 Hz mains

filter

K 60 Hz mains filter

L Produced as per original order (quote serial number) 60 Hz mains

filter

TMT162E- ← order code

Item No. Order code Spare parts

2,3 TMT162X-DA Display HART 5 + fitting kit + twist protection

2,3 TMT162X-DB Display PA/FF + fitting kit + twist protection

2,3 TMT162X-DC Display fitting kit + twist protection

2,3 TMT162X-DD Display HART 7 + fitting kit + twist protection

5 TMT162X-HH Housing cover blind, aluminum Ex d, FM XP with seal, CSA approval, only

as cover of connection compartment

5 TMT162X-HI Housing cover blind, aluminum + seal

5 TMT162X-HK Housing cover cpl. display, aluminum Ex d with seal

5 TMT162X-HL Housing cover cpl. display, aluminum with seal

5 TMT162X-HA Housing cover blind, stainless steel 316L Ex d, ATEX Ex d, FM XP with

seal, CSA approval, only as cover of connection compartment

5 TMT162X-HB Housing cover blind, stainless steel 316L, with seal

5 TMT162X-HC Housing cover cpl. display, Ex d, stainless steel 316L, ATEX Ex d, FM XP,

CSA XP, with seal

42 Endress+Hauser

Page 43

iTEMP TMT162 Accessories

Item No. Order code Spare parts

5 TMT162X-HD Housing cover cpl. display, stainless steel 316L, with seal

5 TMT162X-HE Housing cover blind, T17, 316L

5 TMT162X-HF Housing cover cpl. display, polycarbonate, T17 316L

5 TMT162X-HG Housing cover cpl. display, glass, T17 316L

6 71158816 O-ring 88x3 EPDM70 PTFE slide coating

7 51004948 Cover clamp spare part set: screw, disk, spring washer

11.3 Return

The measuring device must be returned if it is need of repair or a factory calibration, or if

the wrong measuring device has been delivered or ordered. Legal specifications require

Endress+Hauser, as an ISO-certified company, to follow certain procedures when handling

products that are in contact with the medium.

To ensure safe, swift and professional device returns, please refer to the procedure and

conditions for returning devices provided on the Endress+Hauser website at

http://www.endress.com/support/return-material

11.4 Disposal

The device contains electronic components and must, therefore, be disposed of as

electronic waste in the event of disposal. Please pay particular attention to the local

regulations governing waste disposal in your country.

12

Accessories

Various accessories, which can be ordered with the device or subsequently from Endress

+Hauser, are available for the device. Detailed information on the order code in question is

available from your local Endress+Hauser sales center or on the product page of the

Endress+Hauser website: www.endress.com.

Always quote the serial number of the device when ordering accessories!

12.1 Device-specific accessories

Accessories Description

Dummy plugs • M20x1.5 EEx-d/XP

• G ½" EEx-d/XP

• NPT ½" ALU

• NPT ½" V4A

Cable glands •

Adapter for cable gland M20x1.5 outside/M24x1.5 inside

Wall and pipe mounting

bracket

Surge arrester The module protects the electronics from overvoltage. Not available for T17

M20x1.5

• NPT ½" D4-8.5, IP68

• NPT ½" cable gland 2 x D0.5 cable for 2 sensors

• M20x1.5 cable gland 2 x D0.5 cable for 2 sensors

Stainless steel wall/2" pipe

Stainless steel 2" pipe V4A

stainless steel housing.

Endress+Hauser 43

Page 44

Accessories iTEMP TMT162

12.2 Communication-specific accessories

Accessories Description

Field Xpert SFX350 Field Xpert SFX350 is a mobile computer for commissioning and maintenance. It

enables efficient device configuration and diagnostics for HART and FOUNDATION

Fieldbus devices in the non-Ex area.

For details, see Operating Instructions BA01202S

Field Xpert SFX370 Field Xpert SFX370 is a mobile computer for commissioning and maintenance. It

enables efficient device configuration and diagnostics for HART and FOUNDATION

Fieldbus devices in the non-Ex area and the Ex area.

For details, see Operating Instructions BA01202S

12.3 Service-specific accessories

Accessories Description

Applicator Software for selecting and sizing Endress+Hauser measuring devices:

• Calculation of all the necessary data for identifying the optimum measuring

device: e.g. pressure loss, accuracy or process connections.

• Graphic illustration of the calculation results

Administration, documentation and access to all project-related data and

parameters over the entire life cycle of a project.

Applicator is available:

Via the Internet: https://wapps.endress.com/applicator

•

• On CD-ROM for local PC installation.

W@M Life cycle management for your plant

W@M supports you with a wide range of software applications over the entire