Page 1

promass 60 (HART )

Mass Flow Measuring System

Operating Manual

BA 013D/06/en/12.99

No. 50091878

CV 4.2

Valid as of software version

V4.00.XX (amplifier)

V3.02.XX (communications)

Page 2

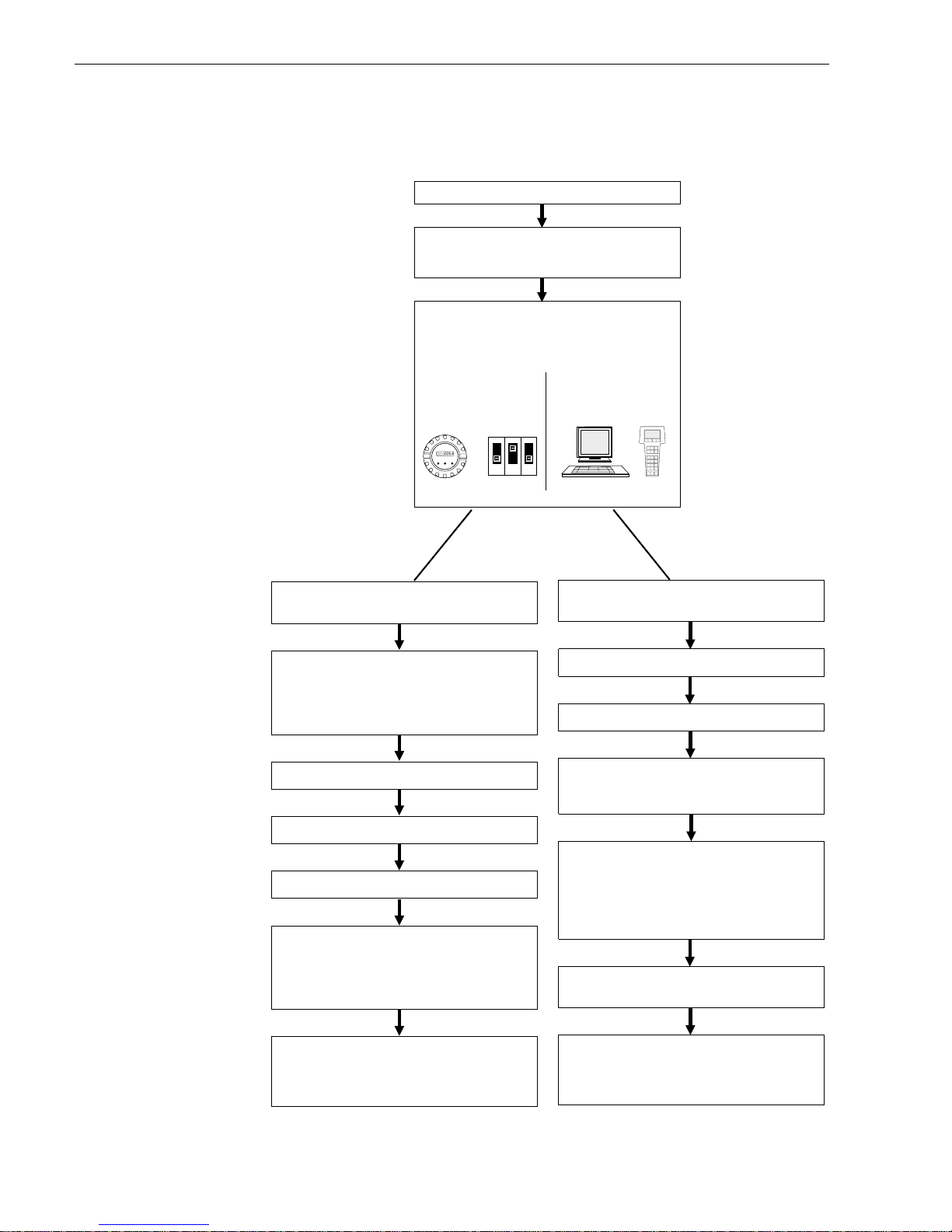

Brief Operating Instructions

With the following instructions, you may configure your measuring instrument quickly

and easily.

HART protocol

Configuration overview

→

page 25

Switching on the instrument

→

page 27

Engineering units

→

page 45

Configuration of outputs

•

Current output

→

page 47

•

Frequency output

→

page 48

More complex applications

require the configuration of additional functions,

for which the following are available:

•

Function overview

→

page 97

•

Operating matrices

→

page 26, 28

•

Index

→

page 101

Status output

→

page 55

Auxiliary input

→

page 55

For optimum measuring accuracy

•

Zero point adjustment

→

page 53

•

Density calibration

→

page 54

•

Empty pipe detection

→

page 51

DIP switches

Configuration overview

→

page 22

Configuration of i nstrument parameters

•

Engineering units (US/SI)

→

page 22

•

Current range (0/4...20 mA)

→

page 22

•

Full scale value (current outp.)→ page 22, 38

•

Pulse value

→

page 22, 37

Status output

→

page 22, 32

Auxiliary input

→

page 22, 35

Switching on the instrument

→

page 27

Configuration of di splay

→

page 24

Operating mode (mass/volume)

displayed value, units, etc.

For optimum measuring accuracy

•

Zero point adjustment

→

page 35, 39

•

Density calibration

→

page 41

Safety instructions

→

page 5

Mounting and electrical connection

•

Mounting

→

page 11

•

Electrical connection

→

page 17

Selection of operating mode

→ page 21

DIP switches & HART protocol

local display via

Commuwin II DXR 275

Promass 60

2 Endress+Hauser

Page 3

1ContentsContents

1 Safety Instructions . . . . . . . 5

1.1 Correct usage . . . . . . . . . . . 5

1.2 Dangers and notes . . . . . . . . . 5

1.3 Operational safety . . . . . . . . . 5

1.4 Personnel for installation, start-up

and operation . . . . . . . . . . . 6

1.5 Repairs, dangerous chemicals . . . . 6

1.6 Technical improvements . . . . . . . 6

2 Description of the System . . . . 7

2.1 Application . . . . . . . . . . . . 7

2.2 Measuring principle . . . . . . . . . 7

2.3 The Promass 60 measuring system . . 9

3 Mounting and Installation . . . 11

3.1 General information . . . . . . . . . 11

3.2 Transport to the measuring point

(DN 40...100) . . . . . . . . . . . 12

3.3 Mounting . . . . . . . . . . . . . 13

3.4 Rotating the transmitter housing

and local display . . . . . . . . . . 16

4 Electrical Connection . . . . . 17

4.1 General information . . . . . . . . . 17

4.2 Connecting the transmitter . . . . . . 17

4.3 Connecting the remote version . . . . 19

4.4 Connecting HART Handheld DXR 275 . 20

4.5 Connecting Commubox FXA 191

(Commuwin II) . . . . . . . . . . . 20

5 Operation . . . . . . . . . . 21

5.1 Selection of operating mode

(DIP switches/display, HART) . . . . . 21

5.2 Configuration with DIP switches . . . . 22

5.3 Configuration with the local display . . . 23

5.4 Configuration with the HART protocol . . 25

5.5 Commissioning . . . . . . . . . . 27

6 Function Description . . . . . 31

6.1 DIP switch functions . . . . . . . . 31

6.2 Local display functions . . . . . . . 39

6.3 HART protocol functions . . . . . . . 43

7 Diagnosis and Trouble-shooting . 59

7.1 Response of the measuring system

on error . . . . . . . . . . . . . 59

7.2 Trouble-shooting instructions

(operation via DIP switch) . . . . . . 61

7.3 Trouble-shooting instructions

(operation via HART protocol) . . . . . 62

7.4 Error, alarm and status messages . . . 63

7.5 Replacing the transmitter electronics . . 68

7.6 Replacing the fuse . . . . . . . . . 69

8 Dimensions . . . . . . . . . . 71

8.1 Dimensions Promass 60 A . . . . 71

8.2 Dimensions Promass 60 I . . . . . . 73

8.3 Dimensions Promass 60 M . . . . . 74

8.4 Dimensions Promass 60 M

(high pressure) . . . . . . . . . . 75

8.5 Dimensions Promass 60 M

(without process connections) . . . . 76

8.6 Dimensions Promass 60 F . . . . . . 77

8.7 Dimensions of process connections

Promass 60 I, M, F . . . . . . . . . 78

8.8 Dimensions of purge connections

(pressure vessel monitoring) . . . . 85

9 Technical Data . . . . . . . . . 87

10 Functions at a Glance . . . . . . 97

11 Index . . . . . . . . . . . . 101

Promass 60 1 Contents

Endress+Hauser 3

Page 4

Registered Tradem arks

HART

Registered trademark of HART Communication Foundation, Austin, USA

KALREZ

Registered trademark of E.I. Du Pont de Nemours & Co., Wilmington, USA

SWAGELOK

Registered trademark of Swagelok & Co., Solon, USA

TRI-CLAMP

Registered trademark of Ladish & Co., Inc. Kenosha, USA

VITON

Registered trademark of E.I. Du Point de Nemours & Co., Wilmington, USA

1 Contents Promass 60

4 Endress+Hauser

Page 5

1 Safety Instructions

1.1 Correct usage

•

The Promass 60 is only to be used for measuring the mass flow rate of liquids and

gases. At the same time, the system also measures fluid density and thus allows

calculation of volume flow.

•

The manufacturer assumes no liability for damage caused by incorrect use of the

instrument.

•

Instruments which are used in the explosion hazardous area are supplied with a

separate “Ex documentation”, which is an

integral part of this Operating Manual.

The instructions and connected loads provided in this supplement must absolutely

be observed. An appropriate icon is shown on the front page of the Ex documentation according to the approval given and the test centre.

1.21.2 Dangers and notes

All instruments are designed to meet state-of-the-art safety requirements. They have

been tested, and have left the works in an operationally perfectly safe condition.

The devices were developed according to EN 61010 “Protection Measures for

Electronic Equipment for Measurement, Control, Regulation and Laboratory

Procedures”). A hazardous situation may occur if the flowmeter is not used for

the purpose it was designed for or is used incorrectly. Please carefully note the

information provided in this Operating Manual indicated by the following pictograms:

Warning!

A “warning” indicates actions or procedures which, if not performed correctly,

may lead to personal injury or a safety hazard.

Please strictly observe the instructions supplied and proceed carefully.

Caution!

A “caution” indicates actions or procedures which, if not performed correctly,

may lead to faulty operations or the destruction of the instrument.

Please strictly observe the respective instructions.

Note!

A “note” indicates actions or procedures which, if not performed correctly,

may indirectly affect operations or lead to an unexpected instrument

response.

1.31.3 Operational safety

•

The Promass 60 measuring system fulfils all general requirements for electromagnetic compatibility (EMC) according to EN 50081 Part 1 and 2 / EN 50082 Part 1

and 2 as well as the NAMUR recommendations.

•

Extensive self-monitoring of the measuring system gives operational safety.

Any errors which may occur are given at the configured status output, e.g. power

failure, system error, etc.

•

On power failure, all data of the measuring system are safely stored in the EEPROM

(no batteries required).

Promass 60 1 Safety Instructions

Endress+Hauser 5

Page 6

1.41.4 Personnel for installation, start-up and operation

•

Mounting, electrical installation, start-up and maintenance of the instrument may

only be carried out by trained personnel authorized by the operator of the facility.

Personnel must absolutely and without fail read and understand this Operating

Manual before carrying out its instructions.

•

The instrument may only be operated by personnel who are authorized and trained

by the operator of the facility. All instructions in this Manual are to be observed

without fail.

•

In case of corrosive fluids, the resistance of the material of all wetted parts

such as measuring tubes, gaskets, and process connections is to be verified.

This also applies to fluids used to clean the Promass sensor (for wetted parts

materials → see page 92). Endress+Hauser will be glad to provide information

and help.

•

Please observe all provisions valid for your country and pertaining to the opening

and repairing of electrical devices.

•

The installer has to make sure that the measuring system is correctly wired

according to the wiring diagrams. The measuring system is to be grounded.

1.51.5 Repairs, dangerous chemicals

The following procedures must be carried out before a Promass 60 flowmeter is sent

to Endress+Hauser for repair:

•

A note must always be enclosed with the instrument, containing a description of the

fault, the application, and the chemical and physical properties of the product

being measured.

•

Remove all residue which may be present. Pay special attention to the gasket

grooves and crevices where fluid may be present. This is especially important if the

fluid is dangerous to health, e.g. corrosive, poisonous, carcinogenic, radioactive,

etc.

•

No instrument should be returned to us without all dangerous material being

removed first, e.g. in scratches or diffused through plastic.

Incomplete cleaning of the instrument may result in waste disposal or cause harm to

personnel (burns, etc.). Any costs arising from this will be charged to the owner of the

instrument.

1.6 Technical improvements

The manufacturer reserves the right to modify technical data without prior notice.

Your local E+H Sales Office will supply you with all current information and any

updates to this Operating Manual.

Danger from electric shock!

With the housing cover removed, protection against accidental contact

is no longer present.

Components with high voltages are exposed below the local display (danger from

electric shock). When programming according to section 5.3, avoid any contact

with the electronic components which lie below the local display, and do not use

any electrically conductive object to depress the programming keys.

1 Safety Instructions Promass 60

6 Endress+Hauser

Page 7

2 Description of the System

2.1 Application

The Promass 60 measuring system measures the mass and volume flow of fluids

having widely differing characteristics:

• Chocolate, condensed milk, syrup

• Oils, fats

• Acids, alkalis

• Varnishes, paints

• Suspensions

• Pharmaceuticals, catalytic converters, inhibitors

• Gases, etc.

The Promass 60 is used wherever mass flow measurement is of critical importance:

• Mixing and batching of various raw materials

• Controlling of processes

• Measurement of fluids with quickly changing densities

• Control and monitoring of product quality

The advantages of this measurement process are demonstrated by its successful use

in food processing, the pharmaceutical industry, the chemical and petrochemical

industries, waste disposal, energy production, etc.

2.22.2 Measuring principle

The measuring principle is based on the controlled generation of Coriolis forces.

These forces are always present when both translational (straight line) and angular

(rotational) movement occur simultaneously.

F

C

= 2 ⋅ ∆m (ω x v)

F

C

= Coriolis force

∆m = mass of moving body

ω = angular velocity

v = radial velocity in a rotating or oscillating system

The amplitude of the Coriolis force depends on the moving mass ∆m, its velocity in

the system v and therefore its mass flow.

→

→

→

→

→

→

→

ωω

∆

∆

Schematic diagram of a measuring tube

ba013y02

Fig. 1:

Coriolis forces in the Promass

measuring tubes

Promass 60 2 Description of the System

Endress+Hauser 7

Page 8

The Promass uses an oscillation instead

of a constant angular velocity ω and two

parallel measuring tubes (Promass M

and F), with fluid flowing through them,

are made to oscillate in antiphase so that

they act like a tuning fork.

The Coriolis forces produced at the

measuring tubes cause a phase shift in

the tube oscillation (see Fig. 2):

• When there is zero flow, i.e. with the

fluid standing still, both tubes oscillate

in phase (1).

• When there is mass flow, the tube

oscillation is decelerated at the inlet

(2) and accelerated at the outlet (3).

As the mass flow rate increases, the

phase difference also increases (A-B).

The oscillations of the measuring tubes

are determined using electrodynamic

sensors at the inlet and outlet.

Unlike Promass M and F, Promass A

and I only has a single measuring tube.

However, the measuring principle and

function of all sensors are identical.

The operating principle is independent

of temperature, pressure, viscosity,

conductivity or flow profile.

Density measurement

The measuring tubes are always made to oscillate at their resonant frequency.

This excitation frequency adjusts automatically as soon as the mass, and therefore

the density, of the oscillating system changes (measuring tubes and fluid).

The resonant frequency is thus a function of the density of the fluid and enables the

microprocessor to produce a density signal.

Temperature measurement

The temperature of the measuring tubes is determined and used to compensate for

temperature effects. The signal produced is a function of the product temperature.

→

ba013y04

ba013y03

1

2

3

Two tub e system

⋅

Fig. 2:

Phase shift of tube vibration with

mass flow.

Balanced Measuring

System

Two-tube system

(Promass M, F)

The system balance is ensured

by the two measuring tubes

vibrating in antiphase.

Single tube system

(Promass A, I)

For single tube systems, other

design solutions are necessary

for system balance than for twotube systems.

Promass A:

For Promass A, an internal

reference mass is used for this

purpose.

Promass I:

For Promass I, the system

balance necessary for flawless

measurement is generated by

exciting an eccentrically located,

counter-oscillating pendulum

mass.

This TMB

TM

(Torsion Mode

Balanced) system is patented

and guarantees accurate measurement, also with changing

process and ambient conditions.

The installation of Promass I is

for this reason just as easy as

with two-tube systems! Special

fastening measures before and

after the meter are therefore not

necessary.

∆

t =

∆ ϕ

2 ⋅ π ⋅ f

≈ m

2 Description of the System Promass 60

8 Endress+Hauser

Page 9

2.3 The Promass 60 measuring system

The Promass 60 measuring system is mechanically and electronically designed for

maximum flexibility with the transmitters and sensors being combined in any variation.

The measuring system consists of:

• Transmitter: Promass 60

• Sensor: Promass A, I, M or F

Caution!

The Promass 60 measuring system is available with various Ex approvals.

Your E+H representative will be pleased to supply information on the approvals

available at present.

All Ex information and specifications are included in a separate documentation which

can be sent by E+H on request.

ba013y05

A

I

M

F

Sensor Transmitter

Promass 60

Without onsite operation

(Blind version)

With onsite operation

With wall mounting

(Remote version)

•

Compact version

•

Remote version (up to 20 meters)

A

DN 1... 4: For very small flow quantities, single tube system in SS or Alloy C-22

I

DN 8... 50: Single straight tube system (titanium), completely welded version

M

DN 8... 80: Two straight measuring tubes (titanium), containment vessel up to 100 bar

DN 8... 25: High pressure version, system pressure up to 350 bar

F

DN 8...100: Two slightly curved measuring tubes in SS or Alloy C-22 (only for DN 8...80),

completely welded version

Technical data: see page 87

Fig. 3:

Promass 60 measuring system

Promass 60 2 Description of the System

Endress+Hauser 9

Page 10

2 Description of the System Promass 60

10 Endress+Hauser

Page 11

3 Mounting and Installation

Warning!

• All instructions given in this section are to be observed at all times in order to

ensure safe and reliable operation of the measuring system.

• Mounting regulations and technical specifications for Ex-certified instruments may

differ from those given below. All mounting regulations and connection values in the

Ex documentation must, therefore, be strictly observed.

3.1 General information

Protection IP 67 (EN 60529)

The instruments fulfil all the requirements for IP 67. After successful installation in

the field or after servicing, the following points must always be observed in order to

ensure protection to IP 67:

• Housing gaskets must be clean and

undamaged when inserted in the gasket groove. The gaskets may need to

be dried, cleaned or replaced.

• All housing screws and the housing

cover must be firmly tightened.

• The cables used for connecting must

have the correct outer diameter.

• The cable gland must be firmly

tightened (see Fig. 4).

• The cable must loop down before enter-

ing the cable gland to ensure that no

moisture can enter it (see Fig. 4).

• Any cable gland not used must be

replaced with a blind plug.

• The protective bush should not be

removed from the cable gland.

Temperature ranges

• The maximum approved ambient and fluid temperatures must be observed

(see page 91)

• An all-weather cover should be used to protect from direct sunlight when mounting

in the open. This is especially important in warmer climates and with high ambient

temperatures.

Tracing, thermal insulation

With certain fluids heat transfer at the sensor must be avoided. A wide range of

materials can be used to assure the necessary insulation.

Heating can be provided either electrically, e.g. by heating sheets or supplied by

copper pipes with heated water or steam. Heating elements for heat tracing are

available for all sensors.

Caution!

Danger of the electronics overheating! The connector between the sensor/transmitter

housings of the compact version must not be insulated or heated.

The connection housing of the remote version should also be kept free.

Depending on the fluid temperature, certain installation positions are to be observed

(see Fig. 8).

ba013y07

Fig. 4:

Mounting notes for

cable glands

Promass 60 3 Mounting and Installation

Endress+Hauser 11

Page 12

System pressure

It is important to avoid cavitation as this can affect the oscillation of the measuring

tubes.

• No special measures need be taken for fluids which have properties similar to those

of water under normal conditions.

• With volatile liquids (hydrocarbons, solvents, liquified gas), the vapour pressure

must not drop below a point where the liquid then begins to boil.

It is also important not to release gases which are found naturally in many liquids.

This can be prevented by maintaining a high enough system pressure.

Note!

Ideally the sensor should be mounted

• on the discharge side of pumps (avoiding low pressure)

• at the lowest point of a vertical piping

Purge connections

The sensor second containment vessel is filled with dry nitrogen (N

2

). The purge

connection is only to be opened when the vessel is afterward immediately filled with a

dry, inert gas (corrosion protection!).

3.2 Transport to the measuring point (DN 40...100)

For transport, measuring instruments with nominal diameters of DN 40...100 may not

be lifted at the transmitter housing or at the connection housing of the remote version.

Use shoulder straps for transport to the measuring points and wrap them around both

process connections (see Fig. 5). Avoid using chains as this might damage the

housing, e.g. scratch the coat of lacquer.

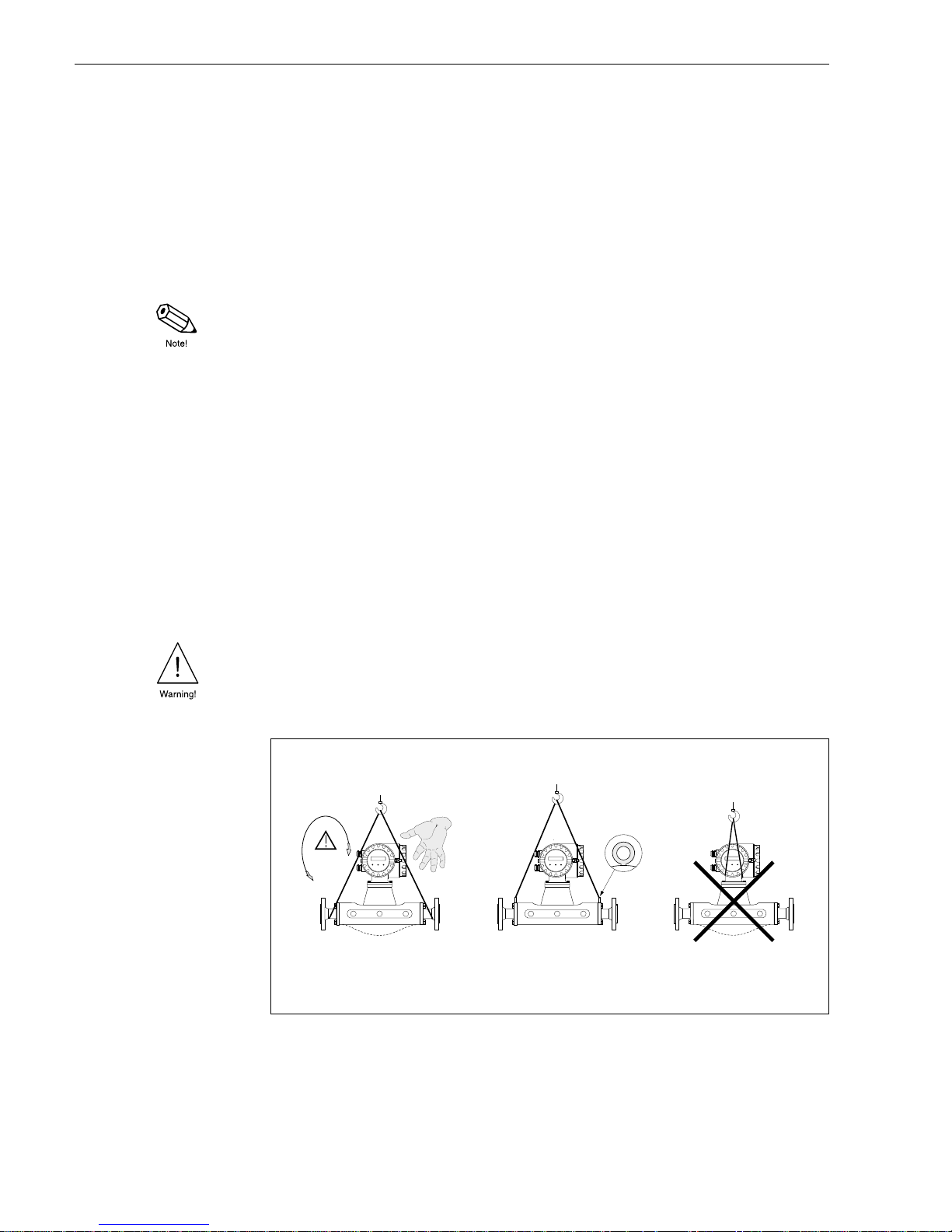

Warning!

Danger of injury by slipping measuring instrument. The centre of gravity of the entire

device is higher than the two suspension points of the shoulder straps. Make sure that

the device does not turn or slip due to the higher centre of gravity during transport.

ba013y46

DN 40...100

DN 80

Promass M

DN 40...100

Correct

Correct

Incorrect

Fig. 5:

Transporting the sensor

DN 40...100

3 Mounting and Installation Promass 60

12 Endress+Hauser

Page 13

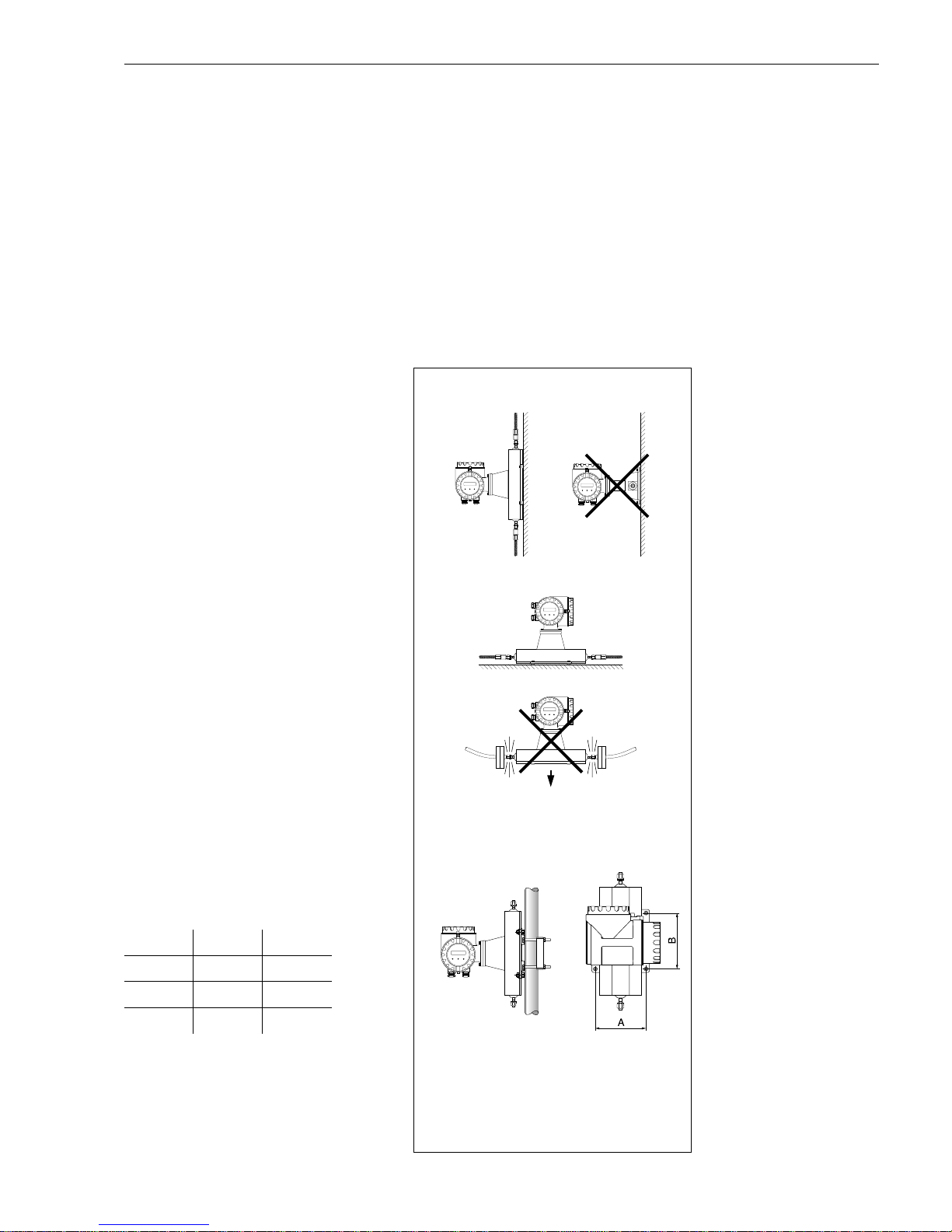

3.3 Mounting

• No special fittings such as brackets are required. External forces are absorbed by

the construction of the device, e.g. by the containment vessel.

• For mechanical reasons, and to protect the pipeline, support is recommended for

heavy sensors.

• Due to the high frequency of the measuring tubes, the Promass 60 measuring

system is unaffected by plant vibration.

• When mounting, no special precautions need to be taken for turbulence-generating

devices (valves, bends, T-pieces, etc.) as long as no cavitation occurs.

The following installation instructions are to be carried out for correct operation of the

measuring system:

Orientation (Promass A)

Vertical

This is best with the flow direction

upwards. Entrained solids sink downward and gases rise away from the

measuring tube when the product is not

flowing. This also allows the measuring

tube to be completely drained and protects it from solids build-up.

Horizontal

When correctly installed, the transmitter

housing is either above or below the

piping. This assures that no gas bubbles

may collect or solids be deposited in the

curved measuring tube.

Wall and post mounting

The sensor may not be suspended in the

piping, that is, without support or

fixation to avoid excessive stress on the

material around the process connection.

The sensor housing base plate allows

a table, wall, or post mounting. The post

mounting requires a special mounting

set:

DN 1, 2: Order No. 50077972

DN 4: Order No. 50079218

DN A [mm] B [mm]

1 145 160

2 145 160

4 175 220

ba013y63

10...14 kg

Post mountng set for Promass A

(∅

3

/4...3")

Fig. 6:

Orientation Promass A

Promass 60 3 Mounting and Installation

Endress+Hauser 13

Page 14

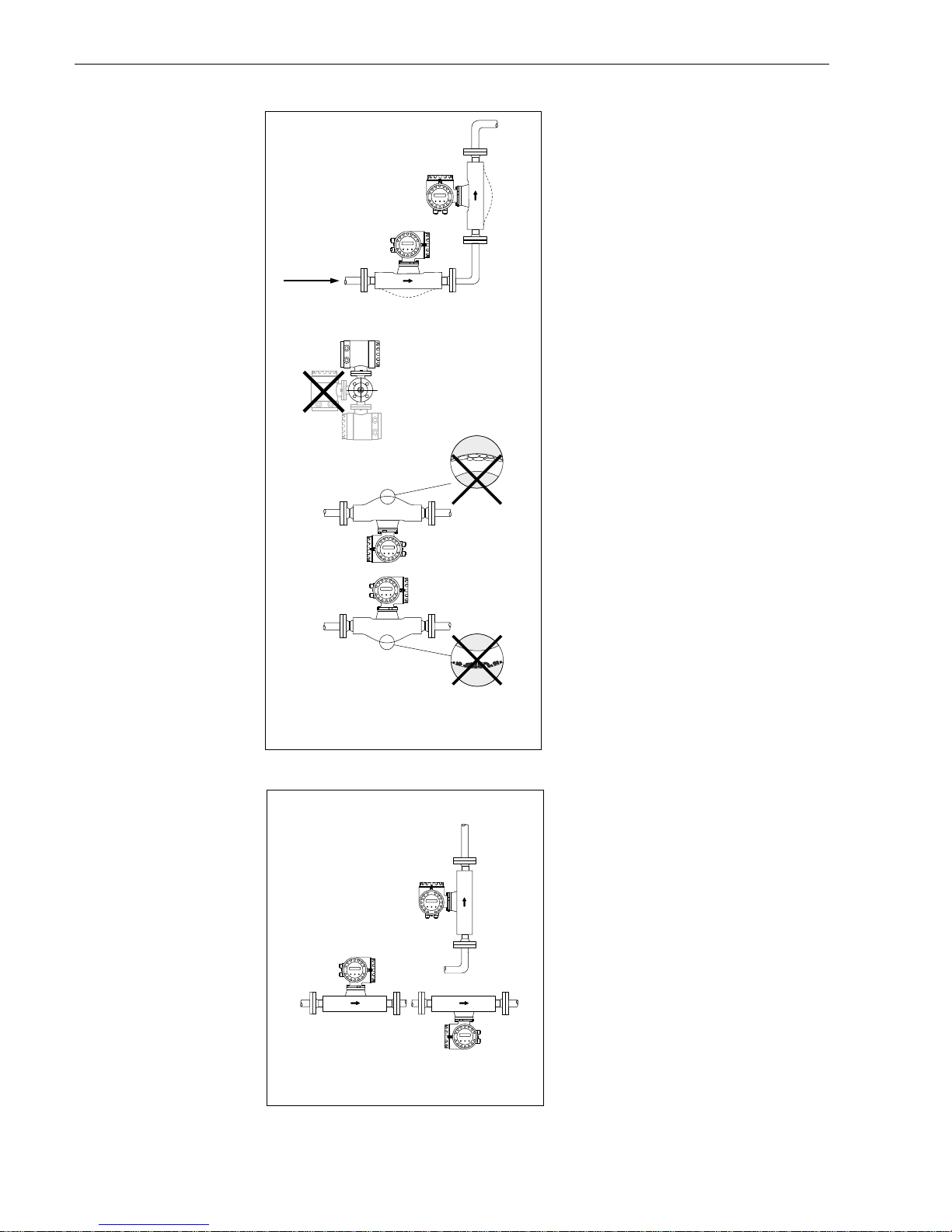

Orientation (Promass I, M, F)

Vertical

This is best with the flow direction

upwards. Entrained solids sink downward and gases rise away from the

measuring tubes when the product is not

flowing. This also allows the measuring

tubes to be completely drained and

protects them from solids build-up.

Horizontal

• Promass I (single tube):

Because of the straight measuring

tube, the sensor can be mounted in

any position of the piping.

• Promass M, F:

The measuring tubes must lie side by

side. When correctly installed, the

transmitter housing is either above or

below the piping (see view A).

• Promass F:

Promass F measuring tubes are

slightly curved. Therefore, the sensor

position is to be adapted to the fluid

properties for horizontal installation:

F1: not suitable for outgassing fluids

F2: not suitable for fluids with solids

content

Fluid temperature/orientation

To ensure that the permitted ambient

temperature range for the transmitter is

not exceeded (-25...+60 °C) positioning

is recommended as follows:

High fluid temperature

• Vertical piping: Position A

• Horizontal piping: Position C

Low fluid temperature

• Vertical piping: Position A

• Horizontal piping: Position B

View A

View A

(Promass M, F)

F1

ba013y08

Positioning

Promass F

Promass I

(can be mounted in any position)

F2

Fig. 7:

Orientation Promass I, M, F

ba013y09

A

B

C

Fig. 8:

Fluid temperature and orientation

3 Mounting and Installation Promass 60

14 Endress+Hauser

Page 15

Mounting location

Air or entrained gases in the measuring

tube may cause errors in measurement

and therefore the following mounting

installations are to be avoided:

• Do not install at the highest point of

the piping.

• Do not install in a vertical pipeline

directly upstream of a free pipe outlet.

Correct installation is still possible using

the recommendation in the adjacent

Figure. Restrictions in the piping or an

orifice with a smaller cross section than

the measuring instrument can prevent

the sensor from running empty during

measurement.

Nominal diameter Ø Orifice/restriction

DN 1

DN 2

DN 4

DN 8

DN 15

DN 15 *

DN 25

DN 25 *

DN 40

DN 40 *

DN 50

DN 80

DN 100

0.8 mm

1.5 mm

3.0 mm

6.0 mm

10.0 mm

15.0 mm

14.0 mm

24.0 mm

22.0 mm

35.0 mm

28.0 mm

50.0 mm

65.0 mm

* DN 15, 25, 40 “FB” =

Full bore versions of Promass I

Mounting the transmitter

A wall bracket for the transmitter housing and a 10 or 20 meter, ready-to-use,

sensor connection cable is in the scope

of supply for the remote version.

Caution!

• Please pay attention to page 19

“Connecting the Remote Version”.

• Fix the cable or fix it in a conduit.

• Do not lay cable in the vicinity of

electrical machines or switching

elements.

• In case of the remote version, the

connection housing of the sensor

may not be insulated.

• Ensure potential equalisation between

the transmitter and the sensor

(see page 19).

For post mounting a special mounting

set is available (Order No. 50076905).

Sensor

Orifice

Pipe restriction

Valve

Batching tank

Storage tank

ba013y10

Fig. 9:

Mounting location (vertical piping)

ba013y11

cable length

max. 20 m

Wall mounting Post mounting

(

∅

3

⁄

4

...3")

Fig. 10:

Mounting the transmitter

(Remote version)

Promass 60 3 Mounting and Installation

Endress+Hauser 15

Page 16

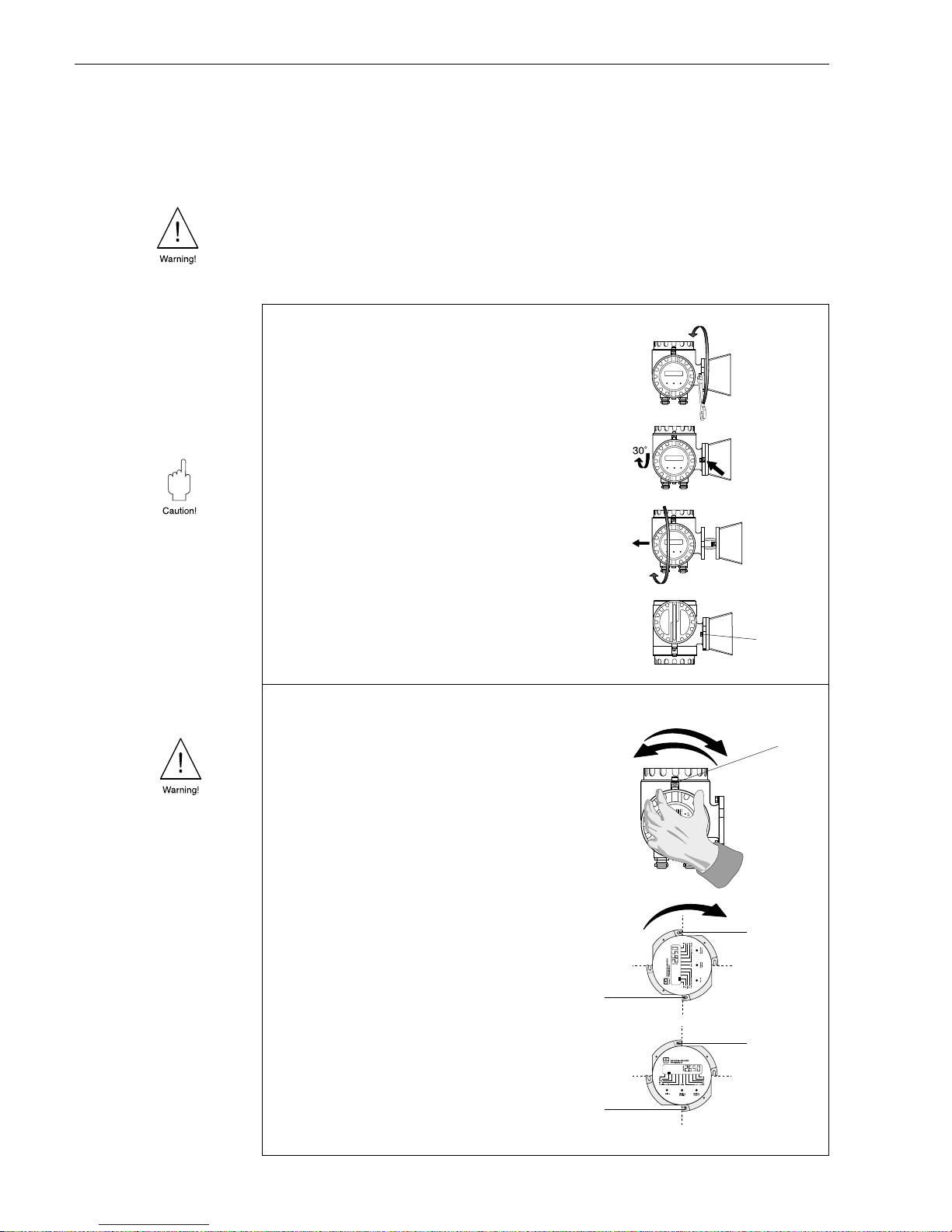

3.4 Rotating the transmitter housing and local display

With the compact version, the transmitter housing and the display field can be rotated

in 90° steps so that the instrument can be mounted in almost any position in the

piping to ensure easy handling and read-off.

Warning!

The following description does not apply to Ex-certified measuring instruments.

Please observe the respective, separate Ex documentation in every detail.

➋

➊

➐

➍

➌

➌

➎

➎

ba013y13

➏

➊

➋

➌

➍

➎

ba013y12

Rotating the transmitter housing

➊

Loosen the mounting screws

(approx. two turns).

➋

Rotate the transmitter housing as far as

the groove of the nut.

➌

Carefully pull out the transmitter housing.

Caution!

Do not damage the connection cable

between the transmitter and sensor!

➍

Rotate the transmitter housing to the

position required.

➎

Push back into the latch again and tighten

the two screws securely.

Rotating the local disp la y

Warning !

Danger from electric shock.

Switch off power supply before opening the housing.

➊

Loosen the safety grip (3 mm Allen key).

➋

Unscrew the cover from the electronics area.

➌

Undo both Phillips screws.

➍

Rotate the display.

➎

Tighten the Phillips screws again.

➏

Replace the cover of the electronics area on

the transmitter housing.

➐

Tighten the Allen screws of the

safety grip securely.

Fig. 11:

Rotating the transmitter housing

and the local display

3 Mounting and Installation Promass 60

16 Endress+Hauser

Page 17

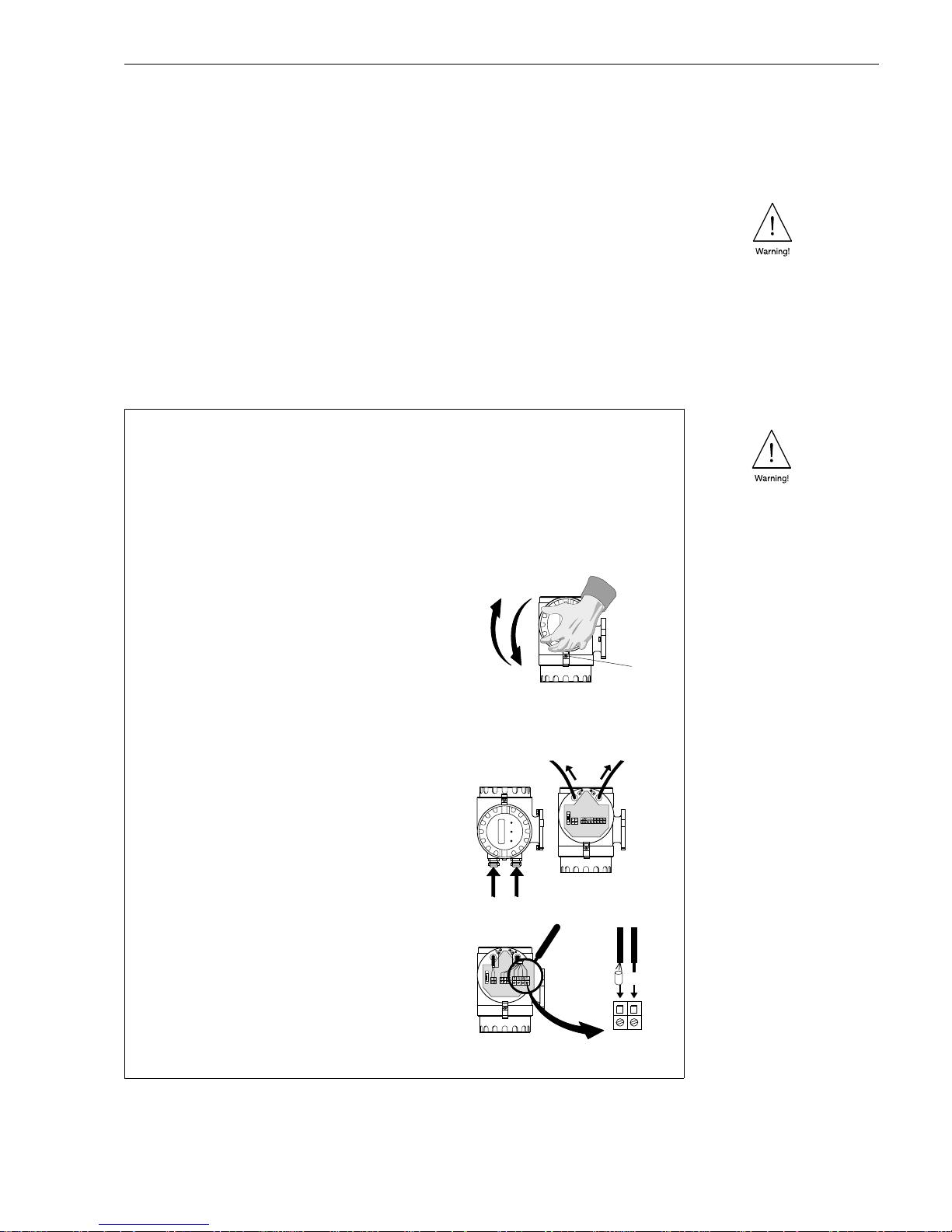

4 Electrical Connection

4.1 General information

Warning!

• The information in Section 3.1 must be observed in order to maintain protection

to IP 67.

• When connecting Ex-certified flowmeters, all appropriate instructions and connec-

tion diagrams in the separate Ex documentation to this Operating Manual must be

observed.

• When using the remote version, only sensors and transmitters with the same serial

number are to connected together. Communication errors if this is not the case.

4.2 Connecting the transmitter

➊ ➏

Signal

cable

Power supply

cable

➎

➋

➍

➌

ba013y14

➊

Loosen the screws of the safety grip

(3 mm Allen key).

➋

Unscrew the cover of the terminal

compartment.

➌

Push the power and signal cables

through the appropriate cable glands.

➍

Wire up according to the connection

diagrams (see diagram in the screw

cover or Fig. 13):

The power supply is connected to

Terminal 1 (L1 or L+), Terminal 2 (N or L–)

and the ground terminal.

– Stranded-wire cabling: cover with an

end sleeve max. 4 mm

2

– Single wire cabling: max. 6 mm

2

➎

Screw the cover of the terminal

compartment securely back onto the

transmitter housing.

➏

Tighten the Allen screws of the safety grip

securely.

Warning !

•

Danger from electric shock! Switch off the power supply before unscrewing the cover!

•

Connect the ground wire to the ground terminal on the housing before turning on the power supply.

•

Check that the local power supply and frequency agree with the information on the

nameplate. All relevant national regulations for mounting must also be observed.

Fig. 12:

Connecting the Promass 60

transmitter

Promass 60 4 Electrical Connection

Endress+Hauser 17

Page 18

L1

}

for AC

L +

} for DC power supply

NL–

0...400 Hz (f

max

= 500 Hz)

max. 30 V / 250 mA

max. 30 V / 250 mA

→

System error indication

→

Flow directi on

3...30 V DC, Ri = 1.8 k

Ω

→

Positive zero return, Z ero point ca libration

→

Totalizer reset

0/4...20 mA, RL < 700

Ω

HART protocol: 4...20 mA, R

L

≥

250

Ω

Pulse output (passive)

Status output (passive)

Auxiliary input

Current output (active)

Ground connection (screening of signal cable)

Fuse:

•

Power supply 20...55 V AC / 16...62 V DC:

2.5 A slow-acting / 250 V; 5.2 x 20 mm

•

Power supply 85...230 + 10% V AC:

1 A slow-acting / 250 V; 5.2 x 20 mm

Power supply cable

Ground terminal for ground wire

Ground terminal for cable screening

Signal cable

Ground connection (ground wire)

ba013y15

Fig. 13:

Electrical connection:

power supply, input and outputs

4 Electrical Connection Promass 60

18 Endress+Hauser

Page 19

4.3 Connecting the remote version

The remote version is supplied with a 10 or 20 meter ready-to-use cable which is

already connected to the sensor.

Sensor

connection housing

Transmitter

connection housing

ba013e58

Cable specifications:

brn = brown; wht = white; pnk = pink; yel = yellow; grn = green; gry = grey

6 x 0.38 mm

2

PVC cable with

common

screening and individually screened cores.

Conductor resistance: ≤ 50 Ω/km; Capacitance: core/screen ≤ 420 pF/m

Permanent operating temperature: –25...+90 °C

With the remote-mounted version the cables between sensor and transmitter must always

be screened and grounded at both ends. This is done at the ground terminals

inside the connection housing of sensor and transmitter.

➊

Transmitter

connection housing

➋ ➎

➌

Sensor

cable length

max. 20 m

Warning!

Danger from electrical shock! Switch off the power supply before unscrewing the cover

of the electronics area from the transmitter housing and the cover from the connection housing.

➊

Connection in the terminal area is carried out as described for the compact

version (see page 17, 18)

➋

Loosen the safety grip (3 mm Allen key). Unscrew the cover of the transmitter

connection area.

➌

Push the connection cable through the appropriate cable gland.

➍

Connect the cable according to the electrical connection diagram

(see Figure below or diagram in the screw cover).

➎

Screw on the connection housing cover again securely. Tighten the Allen screws

of the safety grip securely.

ba013y57

➍

Fig. 14:

Connecting the remote version

Promass 60 4 Electrical Connection

Endress+Hauser 19

Page 20

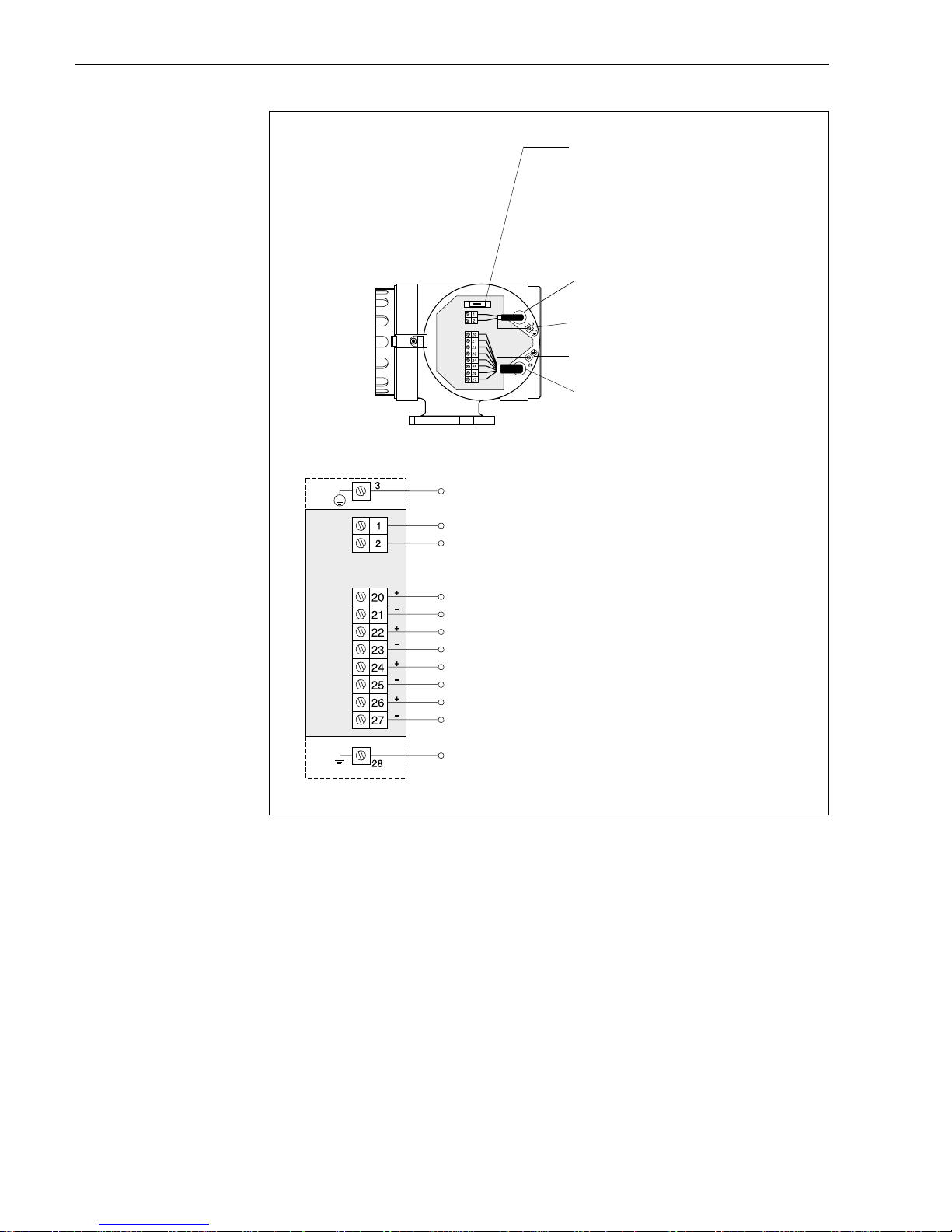

4.4 Connecting HART Handheld DXR 275

The following connection versions are available to the user:

• Direct connection to the Promass transmitter via Terminals 26 / 27

• Connection via the analogue 4...20 mA cable of the current output

Note!

In both cases the measuring loop must have a minimum resistance of 250 Ω.

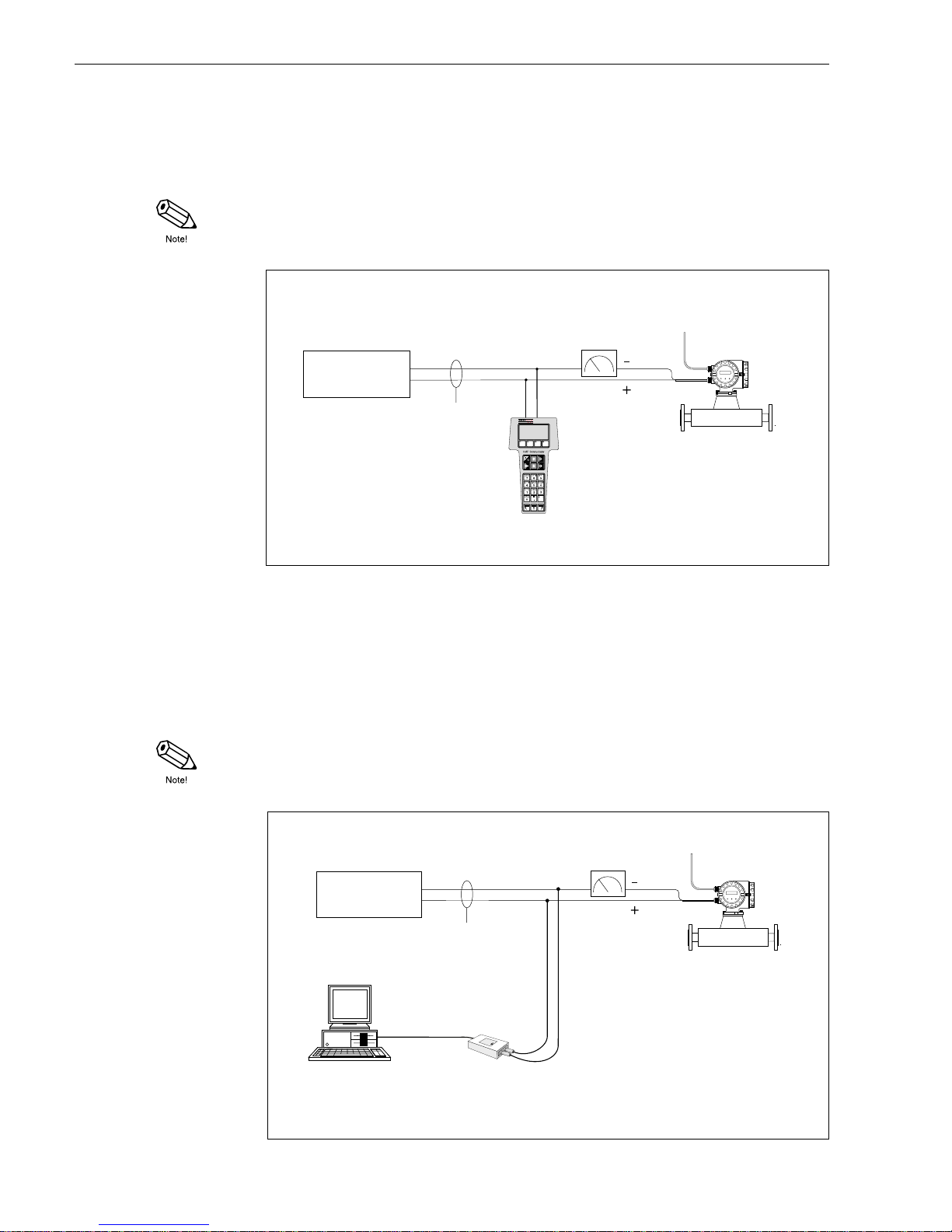

4.5 Connecting Commubox FXA 191 (Commuwin II)

The following connection versions are available to the user:

• Direct connection to the Promass transmitter via Terminals 26/27

• Connection via the analogue 4...20 mA cable of the current output

Note!

• In both cases the measuring loop must have a minimum resistance of 250 Ω .

• Move the switch on the Commubox to ‘HART’!

Sreening

HART handheld terminal

DXR 275

Power supply

ba013y84

≥

250

Ω

27

26

Other instruments or

PLC with passive input

Fig. 15:

Electrical connection

HART-handheld DXR 275

other instruments or

PLC with passive input

Screening

Power supply

Personal Computer

with E+H software

“Commuwin II” and

HART DDE server

Commubox

FXA 191

ba013y83

≥

250

Ω

RS 232C

27

26

Fig. 16:

Electrical connection

Commubox FXA 191

4 Electrical Connection Promass 60

20 Endress+Hauser

Page 21

5 Operation

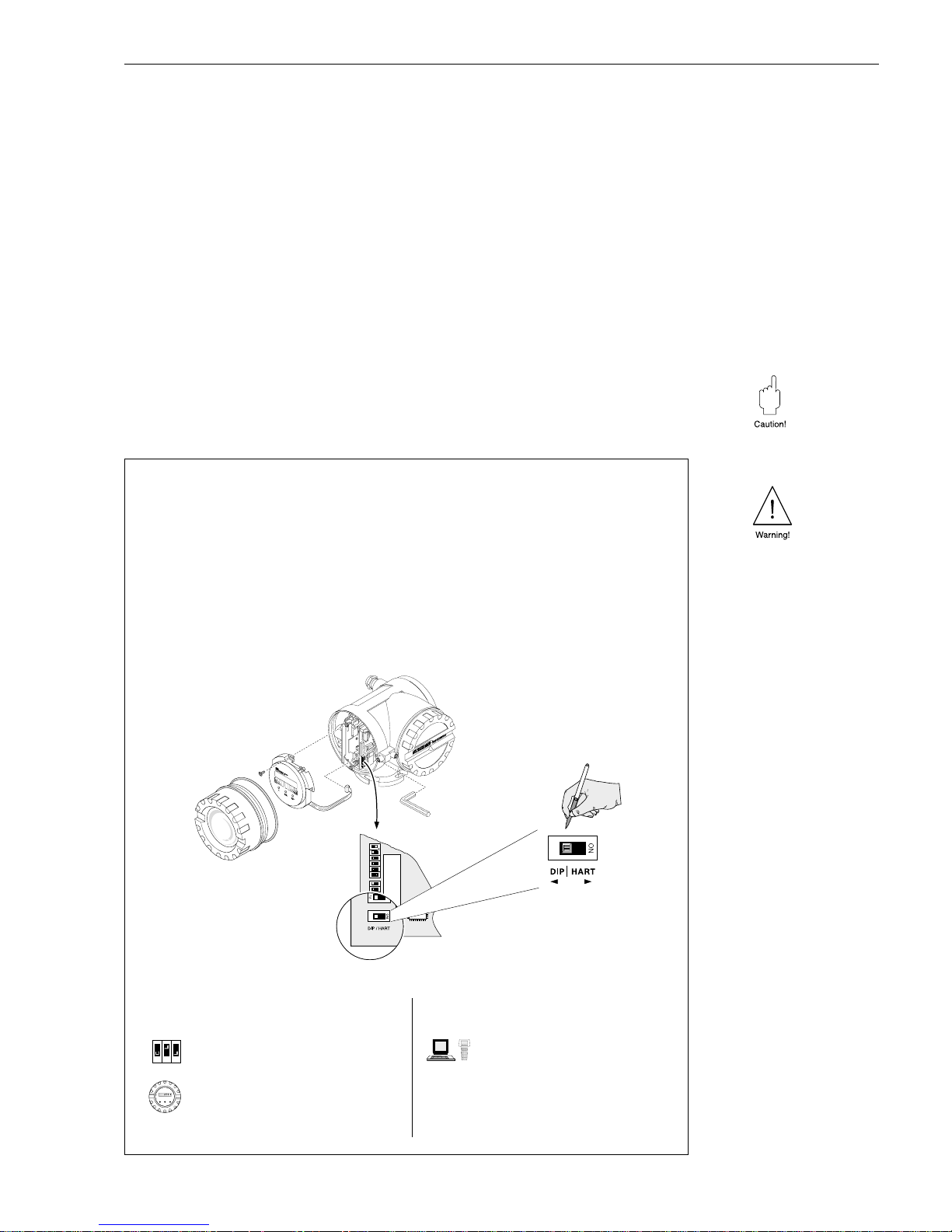

5.1 Selection of operating mode (DIP switches/display, HART)

Promass 60 can basically be operated in two different ways:

• Configuration with DIP switches and/or the local display

• Configuration with HART protocol (e.g. via Commuwin II, HART handheld, etc.)

The two operating modes can not be used simultaneously. By using the “DIP/HART”

switch on the communication pcb (see Fig. 17), the operating mode is fixed and

thereby also the instrument’s functionality. An overview of all instrument functions,

depending on the operating mode, can be found in Chapter 10.

Caution!

With the switch in the “HART” position, switches Nr. 1–12 are deactivated. Switching

back to the “DIP” switch operating mode overwrites settings or data entries previously

made in the HART or Commuwin matrix.

ba013y87

➀

➁

➂

➃

Warning!

•

Danger from electrical shock! Switch off the power supply before unscrewing the cover

of the electronics area from the transmitter housing.

•

Do not fail to observe the supplementary Ex documentation for Ex-certified instruments,

especially the waiting time before opening the housing.

1. Loosen the screws of the safety grip (3 mm Allen key).

2. Unscrew the cover of the electronics area.

3. Remove the local display if present.

4. Set “DIP/HART” to the desired position (also DIP switch Nrs. 1–12 if applicable, see page 22)

5. Reassemble in reverse sequence.

Fig. 17:

Selection of operating mode

(function overview: see page 97)

“DIP”

→Configuration with

DIP switches & display

DIP switches:

Basic instrument functions → page 22

Local display:

Additional functions → page 24

“HART” (ON)

→ Configuration with

HART protocol

HART handheld → page 25

Commuwin II → page 27

Promass 60 5 Operation

Endress+Hauser 21

Page 22

5.2 Configuration with DIP switches

Factory settings

DIP switches No. 1–12

ON Creep suppression activated

OFF Creep suppression deactivated

ON Status output: flow direction

OFF Status output: indication of system errors

ON US engineering units [lb, gal]

OFF SI engineering units [kg, t; l, m

3

]

ON 0...20 mA current range

OFF 4...20 mA current range

Setting pulse value:

For switch settings → see

Tables

on page 37

Scaling the full scale value (= flow at 20 mA)

For switch settings → see

Ta bles

on page 38

(Current output)

ON Short-cycle batching on **)

OFF Short-cycle batching off

ON Auxiliary input: Positive zero return *)

OFF Auxiliary input: Zero point calibration *)

client settings

✍

ba013y25

Warning!

•

Danger from electrical shock! Switch off the power supply before unscrewing the

cover of the electronics area from the transmitter housing.

•

Do not fail to observe the supplementary Ex documentation for Ex-certified

instruments, especially the waiting time before opening the housing.

1. Loosen the screws of the safety grip (3 mm Allen key).

2. Unscrew the cover of the electronics area.

3. Remove the local display if present (see page 16).

4. Set the DIP switches (description of functions → see page 31 ff.) .

5. Reassemble in reverse sequence.

➀

➁

➂

➃

Fig. 18:

Setting instrument functions

with DIP switches

Note!

On request, Promass 60

measuring instruments are also

available with customised

parameterisation.

*) or totalizer reset via local

display (see page 35)

**) For filling cycle up to <60 sec.

5 Operation Promass 60

22 Endress+Hauser

Page 23

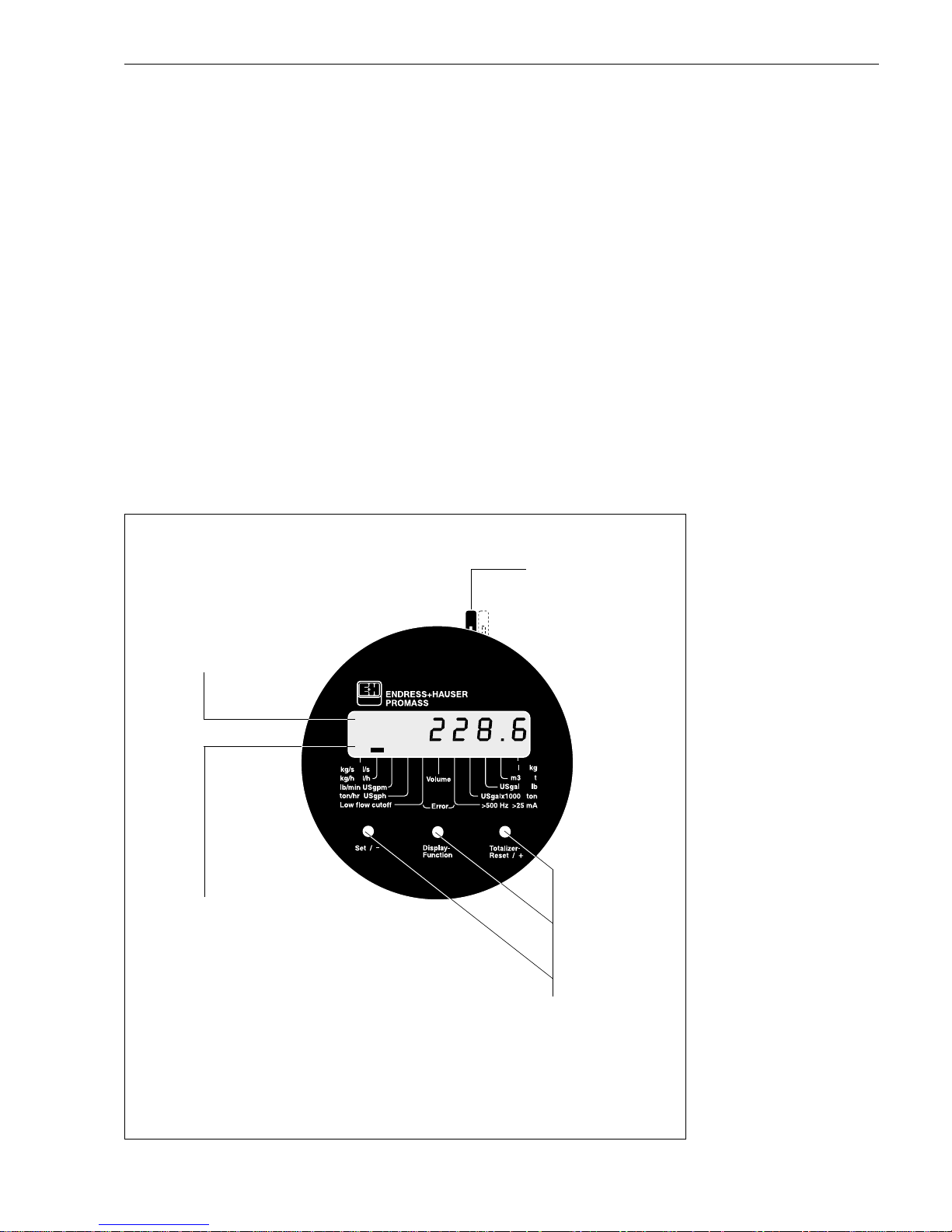

5.3 Configuration with the local display

Using the Promass 60 local display, important variables can be read off and controlled directly at the measuring point. Three operating keys are used to select and

activate the various functions.

• Actual flow rate (display function)

• Actual totalizer value (display function)

• Number of totalizer overflows (display function)

• Alternating display flow/totalizer

• Static zero point calibration

• Enter zero point

• Density-value display/start density calibration

• Mass or volume measurement

• Pressure pulse suppression (batching)

• Test function for checking the display elements

The function of the auxiliary input may additionally be changed with the help of a

jumper positioned on the local display (see page 35).

All measurement data (e.g. totalizer value) and configuration values are safely stored

on power supply failure. With system errors the outputs respond as described on

page 59.

ba013y64

Operating keys

With these three keys, functions may be

accessed, activated, and/or numbers

entered (see next page).

11 Display segmen ts

The segments displayed allow an immediate

reading of the engineering unit, process,

and instrument status.

Example:

If the creep falls below of a certain value

(see Table on page 31), the display segment

above “Low-flow cutoff” becomes immediately

visible.

LCD

Display of all measured

values, operating, and

status reports

Jumper

Configuration of

the auxiliary input

Fig. 19:

Local display Promass 60

Promass 60 5 Operation

Endress+Hauser 23

Page 24

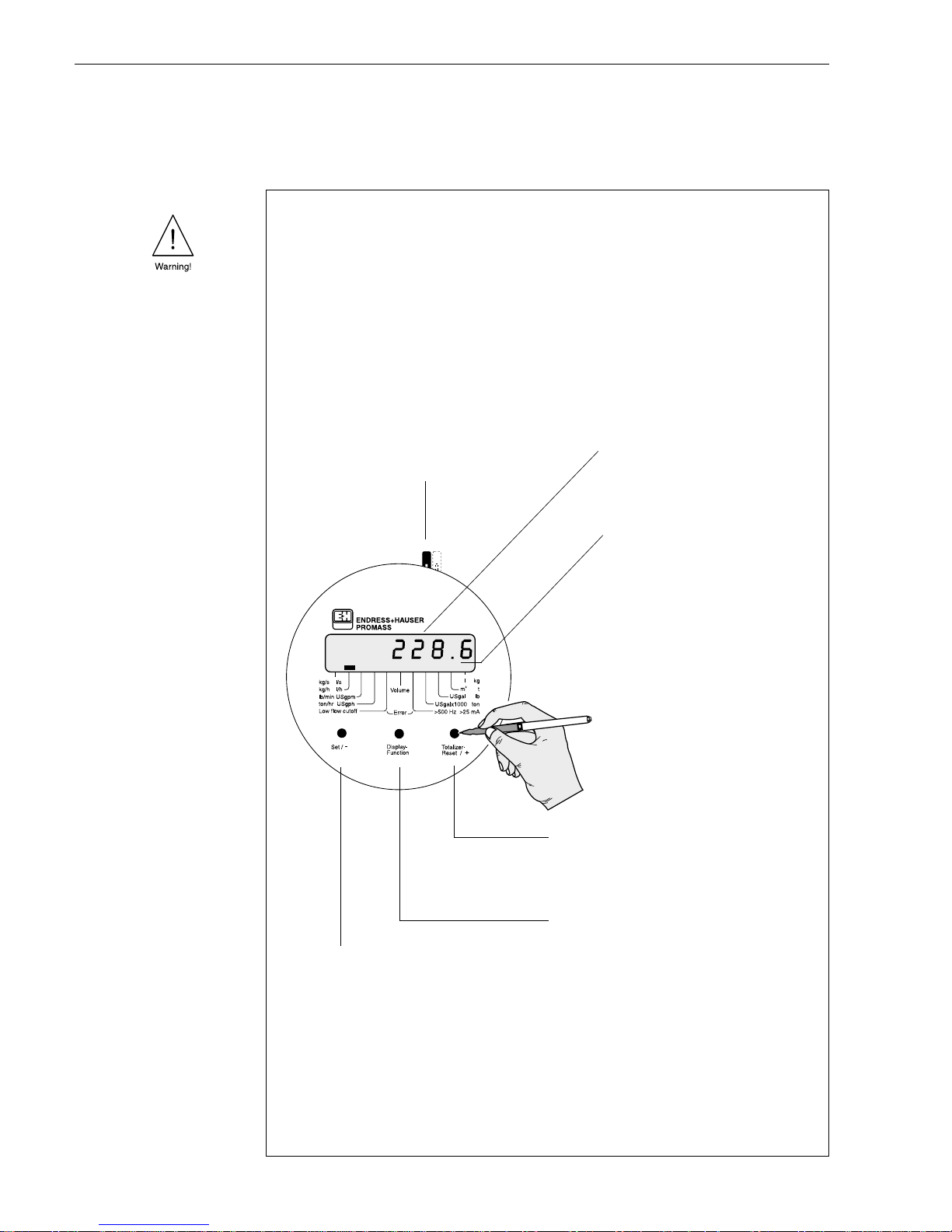

Operation of the local display

It is possible to access, activate, and set various functions in sequence with the help

of the three operating keys on the local display.

ba013y28

Jumper

Configuration of auxiliary input

→

see page 35

Set / –

✍

This key is used for carrying out the following

operations within the appropriate function:

•

Selecting the engineering units

•

Entering of numerical values (–)

•

Zero point or density calibration.

Totali zer reset / +

✍

•

This key is used for resetting the

totalizer to ’0’ (in the “

tot

” function only).

•

Entering of numerical values (+)

Display function

✍

This key is used for selecting the function

resp. the display mode required:

–

rAtE

Flow rate display

–

tot

Totalizer display

–

dISP-OF

Display totalizer overflow

–

rAtE-tot

Display flow rate and totalizer

–

O.-AdJuSt

Zero point adjustment

–

PIPO

Zero point value

–

dEnSItY

Density adjustment

–

MAS-VOL

Operating mode (mass/volume)

–

PrES-SUP

Pressure pulse suppression

–

tESt

Display test function

Function description → see page 39

LCD, 8-character

All measured values, operating and

status indications are shown here.

11 display seg ments

The appropriate segments serve to

provide clear identification of

engineering units, instrument and

process status:

•

Creep too low (Low flow cutoff)

•

Velocity of fluids is too high:

full scale value exceeded,

>500 Hz >25 mA

•

System fault (Error)

•

Present engineering units

•

Volume measuring activated/

de-activated

Warning!

Danger from electrical shock! With the housing cover removed, protection against accidental

contact is no longer present.

Components with high voltages are exposed below the local display (danger from electric shock).

Avoid any contact with the electronic components which lie below the local display, and do not use

any electrically conductive object to depress the programming keys.

1. Loosen Allen screw (3 mm) of the safety grip. Unscrew the cover of the electronics

compartment.

2. The keys may now be operated by pressing with a thin (non-conductive) pin.

A switching cycle takes about 0.5...0.8 seconds.

3. Firmly screw back the cover of the electronics compartment to the transmitter housing

once the settings have been entered. Firmly tighten the Allen screw of the safety grip.

Fig. 20:

Operation of the local display

5 Operation Promass 60

24 Endress+Hauser

Page 25

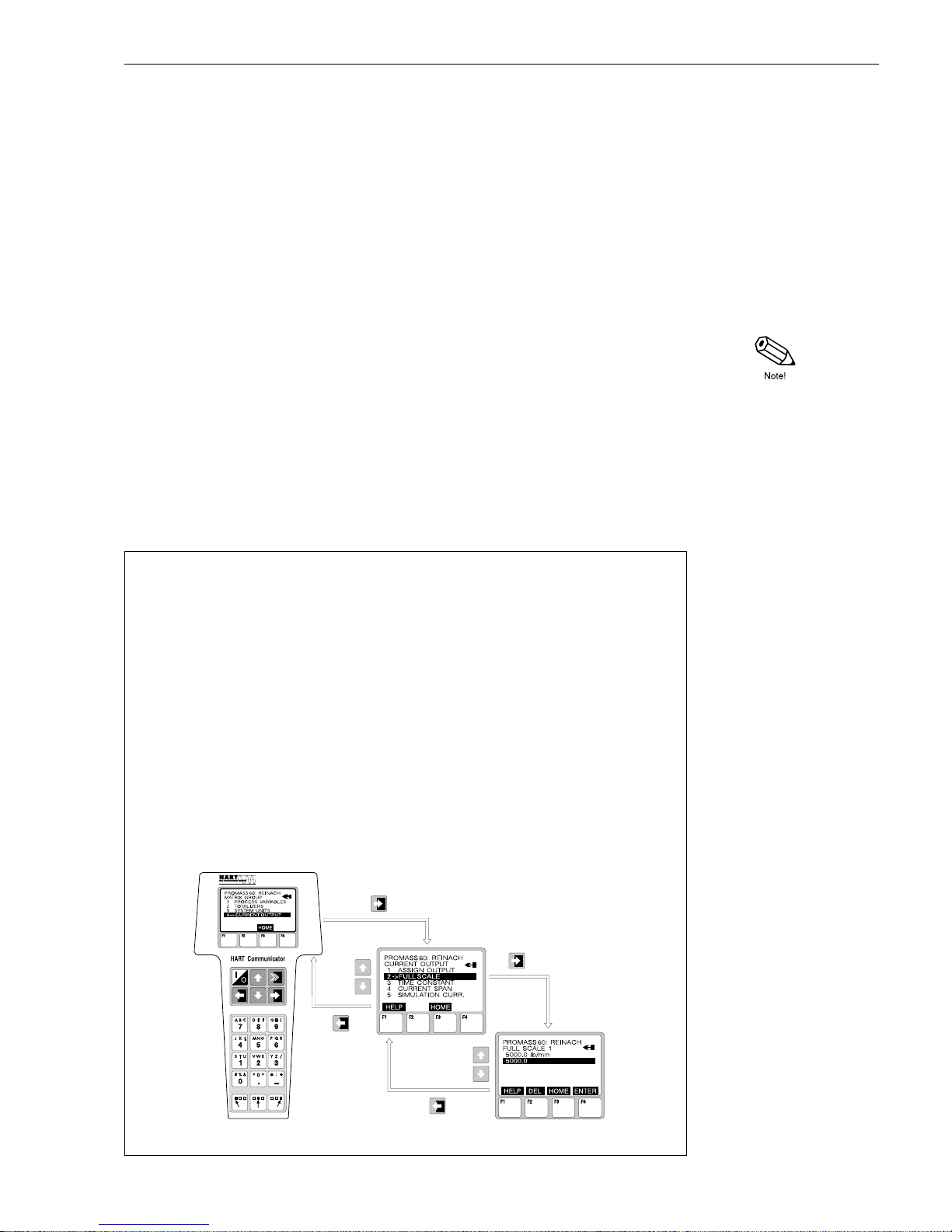

5.4 Configuration with the HART protocol

For configuration with HART protocol, there are basically two possibilities:

• Configuration with the “HART handheld DXR 275”.

• Configuration with a PC using special software, e.g. “Commuwin II” and the

“Commubox FXA 191” HART modem.

All functions available with HART protocol are fully described in Chapter 6.3.

Configuration using the “HART handheld DXR 275”

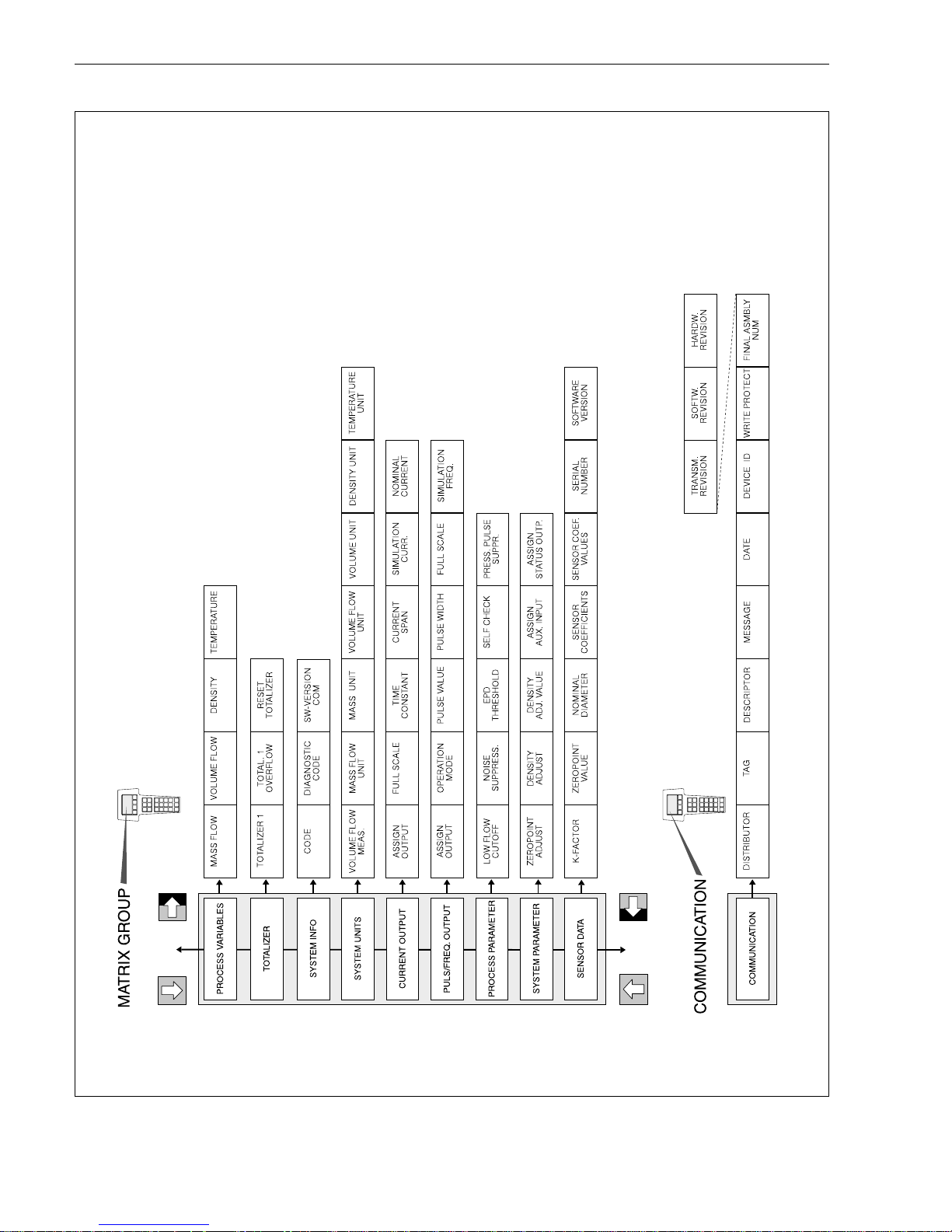

Selection of Promass 60 instrument functions when using the HART handheld

is via various menu levels or using the HART operating matrix respectively

(see Fig. 22).

Notes!

• The HART protocol requires a 4...20 mA setting for the current output.

The 0...20 mA setting is only selectable with the DIP switches.

• All functions are accessible at all times with the HART handheld terminal i.e.

programming is not locked.

The HART operating matrix can, however, be locked by entering any value except

“0 or 60” in the function “ACCESS CODE”. Data can then no longer be changed.

The operating matrix can again be enabled by entering the code number “0 or 60”.

• Further information on the HART handheld is given in the appropriate operating

manual in the carrying case.

Procedure

1. Switch on handheld terminal:

a. The transmitter is not yet connected → The HART main menu is displayed → Continue with

“Online”

b. The transmitter is already connected → The menue level “Online” is immediately shown.

2. “Online” menu level:

→

Actual measurement data including flow, totalizer sum, etc. are continually shown.

→

Via “MATRIX GROUP” you have access to the HART operating matrix (see page 26),

then to the function group (e.g. CURRENT OUTPUT) and finally to the desired function,

e.g. “FULL SCALE”.

3. Enter values or change the setting.

4. The field “SEND” is shown by pressing the “F2” function key. By pressing the “F2” key,

all values and settings entered with the handheld terminal are registered by the Promass

measuring system. Confirm with the “F4” key.

5. Press “F3” HOME function key to return to the “Online” menu level. The actual values measured

by the Promass flowmeter with the new settings can now be read off.

ba013y81

Fig. 21:

Operating the HART handheld

(example)

Promass 60 5 Operation

Endress+Hauser 25

Page 26

ba013e82

Fig. 22:

HART operating matrix Promass 60

(Function description: see page 43)

5 Operation Promass 60

26 Endress+Hauser

Page 27

Configuration using “Commuwin II” software

Commuwin II is a universal program for remote operation of field and control-room

devices.

With the Commubox FXA 191, the Promass 60 can be connected to the RS 232 serial

interface of a personal computer. This makes remote configuration possible using the

E+H Commuwin II program.

Commuwin II offers the following functions:

• parameterization of functions (see operating matrix, page 28),

• visualization of measuring values,

• saving of instrument parameters,

• device diagnostics (see page 63 ff.),

• measuring-point documentation.

Commuwin II may also be combined with other software packages to visualize

processes.

Note!

For additional information on Commuwin II, see the following E+H documentation:

• System Information: SI 018F/00/en “Commuwin II”

• Operating Manual: BA 124F/00/en “Commuwin II Operating Program”

5.5 Commissioning

Before switching on the measuring system, the following checks should be carried

out again:

•

Installation (see page 11)

Does the directional arrow on the nameplate agree with the actual flow direction in

the piping?

•

Electrical connection (see page 17)

Check electrical connections and terminal coding. Check that the local power

supply and frequency agree with the information stated on the nameplate.

•

Configuration mode (see page 21)

Is the “DIP / HART” DIP switch in the desired position?

If these checks are successful, then switch on the power supply.

The instrument is now ready for use.

Promass 60 5 Operation

Endress+Hauser 27

Page 28

“Commuwin II” operating matrix

H0 H1 H2 H3

V0 PROCESS VARIABLE

MASS FLOW VOLUME FLOW DENSITY TEMPERATURE

V1 TOT ALIZERS

TOT ALIZER 1 TOTAL. 1

OVERFLOW

RESET TOTALIZER

0: CANCEL

1: TOTALIZER 1

V2 SYSTEM INFO

ACCESS CODE DIAGNOSTIC CODE MULTI DROP ADDRESS SOFTWARE VER. COM

V3 SYSTEM UNITS

VOLUME FLOW MEAS

0: OFF

1: VOLUME FLOW

MASS FLOW UNIT

3: kg/s

5: kg/h

10: lb/min

13: ton/hr

MASS UNIT

1: kg

2: t

3: lb

4: ton

FLOW RATE UNIT

5: l/s

7: l/h

18: Ugpm

19: Ugph

V4 CURRENT OUTPUT

ASSIGN OUTPUT

0: MASS FLOW

1: VOLUME FLOW

FULL SCALE 1 TIME CONSTANT CURRENT RANGE

1: 4–20 mA

3: 4–20 mA NAMUR

V5 PULS / FREQ. OUTPUT

ASSIGN PULS / FREQ

0: MASS FLOW

1: VOLUME FLOW

OPERATION MODE

0: PULSE

1: FREQUENCY

PULSE VALUE PULSE WIDTH

V6 PROCESSING

PARA.

LOW FLOW CUTOFF NOISE SUPPRESSION EPD THRESHOLD SELF CHECK

1: CYCLIC

2: SMARTPLUS

V7 SYSTEM PARAMETER

ZERO ADJUST

0: CANCEL

1: START

CALIBR. MODE

0: FLUID 1

2: DENSITY ADJUST

4. CANCEL

DENS. ADJ. V ALUE ASSIGN AUX. INPUT

0: RESET TOTAL. 1

1: ZEROPOINT ADJUST

2: POS. ZERO RETURN

V8 SENSOR DATA

K-FACTOR ZEROPOINT NOMINAL DIAMETER SENSOR DATA

V9 SERVICE & ANALYSIS

VA SETUP

TAG NUMBER

5 Operation Promass 60

28 Endress+Hauser

Page 29

“Commuwin II” opera tin g ma trix

H4 H5 H6 H7...H9

VOLUME UNIT

2: l

4: m3

6: USgal

8: USgal*1000

DENSITY UNIT

1: kg/dm3

7: g/cc

TEMPERA TURE UNIT

0: C (Celsius)

1: K (Kelvin)

2: F (Fahrenheit)

3: R (Rankine)

SIMULATION CURR.

0: OFF

2: 2 mA

3: 4 mA

5: 12 mA

7: 22 mA

8: 25 mA

ACTUAL CURRENT

FULL SCALE FLOW SIMULATION FREQ.

0: OFF

1: 0 Hz

2: 2 Hz

3: 10 Hz

4: 1 kHz

PRESS. PULSE SUPPR

O. OPEN COLLECTOR

(Assign Status Output)

0: ERROR

1: FLOW DIRECTION

RESET DEVICE

0: CANCEL

7: REBOOT SYSTEM

SENSOR DATA VALUE SERIAL NUMBER SOFTWARE VERSION

Promass 60 5 Operation

Endress+Hauser 29

Page 30

5 Operation Promass 60

30 Endress+Hauser

Page 31

6 Function Description

6.1 DIP switch functions

Cut-in and cut-off points

DN On Off On Off On Off

[mm] in [kg/h] resp. [l/h] ** in [lb/min] in [USgal/min] **

1

2

4

8

15

15*/25

25*/40

40*/50

80

100

0.05655

0.22619

0.90478

3.61911

12.72345

35.34292

90.47787

141.37167

361.91147

565.48668

0.11310

0.45239

1.80956

7.23823

25.44690

70.68583

180.95574

282.74334

723.82295

1130.97336

0.00208

0.00831

0.03324

0.13298

0.46751

1.29863

3.32449

5.19452

13.29797

20.77773

0.00416

0.01662

0.06649

0.26596

0.93501

2.59726

6.64899

10.38904

26.59594

41.55546

0.00025

0.00100

0.00398

0.01593

0.05602

0.15561

0.39836

0.62244

1.59345

2.48977

0.00050

0.00199

0.00797

0.03187

0.11204

0.31122

0.79672

1.24488

3.18690

4.97954

* DN 15, 25, 40 “FB” = Full bore versions Promass I

** with ρ = 1.000 kg/dm

3

Function description (DIP switches)

Creep

suppression

Creep suppression prevents “false flow” in the lower part of the measuring

range from being detected (e.g. varying liquid at standstill). This enables flows

to be suppressed which should no be measured or totalised.

With flow variations in the lower measuring range, the hysteresis (–50% of the

creepage) prevents the creep suppression from continually turning on and off.

Cut-in point (1)

When the velocity of the fluid is less than 0.02 m/s creep suppression is

activated and all output signals (pulse and analog signals) are set to the fall

back value (0/4 mA logical “0”).

Cut-off point (2)

When the velocity of the fluid again exceeds 0.04 m/s, creep suppression is

deactivated.

Factory setting

creepage 100 %

1

Cut-in point for suppression

2

Cut-off point for suppression

Suppression

active

Time

Suppression

active

ba013y17

0.02

0.04

0.00

50 %

Promass 60 6 Function Description

Endress+Hauser 31

Page 32

open

open

closed

Function description (DIP switches)

Status output

The status output can optionally be configured for:

ON → Signalling the direction of flow

OFF → Error messages (System error) or power supply failure

Notes!

• The status output acts as a normally closed contact, i.e. in normal operation,

free from fault, the output is closed (transistor conducting, see above figure).

• The behaviour of the outputs in the event of a fault is described on page 59.

“Unidirectional” or “bidirectional” operating mode:

The Promass 60 measuring system can operate either bidirectionally or in one

direction only. Selecting the operating mode is, however, directly coupled with

the configuration of the status output:

Factory setti ng

Status output

configuration

Status Response

Open Collector

(transistor)

Indication of system

errors

system O.K.

Fault indication

Power supply failure

Flow direction

“closed” → Open Collector conductive

“open” → Open Collector non-conductive

closed

open

forwards

reverse

Status output Operating

mode

Current / pulse output

ON (flow direction) bidirectional always active (signal output

in both flow directions)

OFF (error messages) unidirectional active only with positive flow

direction (no signal output

with negative flow, reverse)

6 Function Description Promass 60

32 Endress+Hauser

Page 33

Function description (DIP switches)

System units

Select the desired unit system with this function:

ON → US unit

OFF → SI unit

1 lb = 0.4536 kg

1 ton = 907.1847 kg

1 USgal = 3.7854 l

Current range

The current at zero flow (Q = 0) can be set to 0 or 4 mA. The current for the

full scale value is always 20 mA. Scaling is possible up to 25 mA, i.e. up to

125% of the full scale value.

Example (operating mode = bidirectional)

At zero flow (Q = 0) and the DIP switch is:

ON → Zero scale = 0 mA

OFF → Zero scale = 4 mA

Factory setti ng

Factory setting

reverse forward

4...20 mA

0...20 mA

I [mA]

Scaled full scale

value

- Q

ba013y23

+Q

Scaled full scale

value

Promass 60 6 Function Description

Endress+Hauser 33

Page 34

Function description (DIP switches)

Pulse value

The pulse value indicates for which freely selectable mass an output pulse

is supplied. These pulses may be added up by an external totalizer to

determine the total mass flow since the start of the measurement.

The pulse-pause ratio is approx. 1:1. The pulse width is limited to a maximum

of 10 s (≤0.05 Hz). At f

max

= 500 Hz the maximum pulse width is 1 ms.

Eight pulse values are selectable using DIP switches No. 5–7

(see Ta bles on page 37).

Connection diagrams for mechanical and electron i c cou nters

Example for counters without an internal power supply

Unidirectional measurement (forward):

The Promass 60 measuring system can also be operated unidirectionally.

The selection of “bidirectional” or “unidirectional” operating mode is however

directly coupled with the configuration of the status output (see page 32).

Values for voltage and resistor for external counters can be found in the

technical data of instruments which are connected.

Full scale value

(Current output)

The current output supplies signals between 0/4...20 mA, corresponding to the

momentary value of the flow. By setting the full scale value, a maximum desired

flow is assigned to a current of 20 mA.

Any scaling always applies to both flow directions (bidirectional).

Given the respective configuration, the flow direction is displayed at the status

output.

Eight full scale values are selectable using DIP switches Nrs. 8–10

(see Tables on page 38).

Factory setting

Bidirectional measurement (forward and reverse):

ba013y47

External power supply (e .g. 24 V)

External resistor (e.g. 10 kΩ) for electronic counters

Factory setting

6 Function Description Promass 60

34 Endress+Hauser

Page 35

Function description (DIP switches)

Auxiliary input

By applying a voltage of 3...30 V DC to the auxiliary input, various functions may

be activated. The selection of these functions is made with DIP switch No. 11

and/or a jumper on the local display:

➊

Positive zero return (ON)

As long as the external voltage is applied, the current output is set to 0/4 mA;

the pulse output to the closed-circuit voltage (transistor non-conductive).

Eight dashes for the flow rate are shown on the display when positive zero return

is active.

Application: Interruption of the measuring process, e.g. during the time a piping

is cleaned.

➋

Setting the totalizer to zero

After applying an exernal voltage to the auxiliary input, the totalizer is

automatically reset to “zero”.

Note!

The totalizer can also be reset using the “Totalizer-Reset” key on the local

display (see page 24).

➌

Zero-point calibration (OFF)

1. First observe the requirements and conditions for a zero point adjustment

(see page 39).

2. Before the zero point adjustment, ensure that DIP switch No. 11 is in fact

in the “OFF” position (see page 22)

3. Start the zero point adjustment by applying an external voltage to the

auxiliary input. The time during which the external voltage is applied is to be

selected, from 110 ms...10 s. The zero point adjustment is also possible

by connecting a multimeter (set to “Diode test”) to the auxiliary input terminals.

Note!

The zero point adjustment can also be performed using the local display with

the “0.-AdJUSt” function (see page 39).

Factory setti ng

ba013y50

Jumper

left

Configuration

auxiliary input

Jumper

right

➋➌➊

Promass 60 6 Function Description

Endress+Hauser 35

Page 36

Function description (DIP switches)

Short-cycle

batching

By activating this function (ON), a better reproducibility for short batching cycles

can be achieved.

ON → for batching times <60 s

OFF → for batching times >60 s and for continuous measuring mode

Factory setti ng

6 Function Description Promass 60

36 Endress+Hauser

Page 37

Pulse values (DIP switches)

Eight preset pulse values can be selected for each nominal diameter by using

Switches No. 5, 6 and 7. Setting the max. pulse value(s) thus corresponds to a

frequency of f = 400 Hz. As a rule, the last of the switch settings shown is for

v = 10 m/s (ρ = 1000 kg/m

3

) at f = 400 Hz.

VOLUME – Pulse value

SI units [ml; l; m3]

DN

1

2

4

8

15

15*/25

25*/40

40*/50

80

100

0.0001 ml

0.01 ml

0.1 ml

1 ml

1 ml

10 ml

10 ml

10 ml

100 ml

1 l

0.001 ml

0.1 ml

1 ml

10 ml

10 ml

100 ml

100 ml

100 ml

1 l

10 l

0.01 ml

1 ml

10 ml

100 ml

100 ml

1 l

1 l

1 l

10 l

100 l

0.1 ml

10 ml

100 ml

1 l

1 l

10 l

10 l

10 l

100 l

1 m

3

1 ml

100 ml

1 l

10 l

10 l

100 l

100 l

100 l

1 m3

10 m

3

10 ml

1 l

10 l

100 l

100 l

1 m3

1 m

3

1 m

3

10 m

3

100 m

3

100 ml

10 l

100 l

1 m3

1 m

3

10 m

3

10 m

3

10 m

3

100 m

3

1000 m

3

0.000020 l

0.000079 l

0.000314 l

0.001257 l

0.004418 l

0.012272 l

0.031416 l

0.049087 l

0.125664 l

0.196350 l

US units [USgal]

DN

1

2

4

8

15

15*/25

25*/40

40*/50

80

100

0.0000001

0.00001

0.0001

0.001

0.001

0.01

0.01

0.01

0.1

1

0.000001

0.0001

0.001

0.01

0.01

0.1

0.1

0.1

1

10

0.00001

0.001

0.01

0.1

0.1

1

1

1

10

100

0.0001

0.01

0.1

1

1

10

10

10

100

1000

0.001

0.1

1

10

10

100

100

100

1000

10000

0.01

1

10

100

100

1000

1000

1000

10000

100000

0.1

10

100

1000

1000

10000

10000

10000

100000

1000000

0.000005

0.000021

0.000083

0.000334

0.001174

0.003261

0.008348

0.013043

0.033391

0.052173

Example:

A pulse frequency of f = 20 Hz

should not be exceeded (e.g.

input frequency of an electronic

totalizer). The nominal diameter

should be 25 mm; the flow rate

Q = 21.6 t/h.

Pulse value =

Q

f

max

=

21.6

t

⁄

h

20 s

−

1

=

6

kg

⁄

s

20 s

−

1

= 0.3 kg

Using the pulse value calculated

(for DN 25), select the next

highest switch setting → 1 kg per

pulse (OFF–ON–OFF).

(In the opposite way, the exact

pulse frequency can be determined using a known flow rate Q

and a selected pulse value)

* DN 15, 25, 40 “FB” =

Full bore versions Promass I

MASS – Pulse value

SI units [g; kg; t]

DN

1

2

4

8

15

15*/25

25*/40

40*/50

80

100

0.0001 g

0.01 g

0.1 g

1 g

1 g

10 g

10 g

10 g

100 g

1 kg

0.001 g

0.1 g

1 g

10 g

10 g

100 g

100 g

100 g

1 kg

10 kg

0.01 g

1 g

10 g

100 g

100 g

1 kg

1 kg

1 kg

10 kg

100 kg

0.1 g

10 g

100 g

1 kg

1 kg

10 kg

10 kg

10 kg

100 kg

1 t

1 g

100 g

1 kg

10 kg

10 kg

100 kg

100 kg

100 kg

1 t

10 t

10 g

1 kg

10 kg

100 kg

100 kg

1 t

1 t

1 t

10 t

100 t

100 g

10 kg

100 kg

1 t

1 t

10 t

10 t

10 t

100 t

1000 t

0.000020 kg

0.000079 kg

0.000314 kg

0.001257 kg

0.004418 kg

0.012272 kg

0.031416 kg

0.049087 kg

0.125664 kg

0.196350 kg

US units [lb]

DN

1

2

4

8

15

15*/25

25*/40

40*/50

80

100

0.0000001

0.00001

0.0001

0.001

0.001

0.01

0.01

0.01

0.1

1

0.000001

0.0001

0.001

0.01

0.01

0.1

0.1

0.1

1

10

0.00001

0.001

0.01

0.1

0.1

1

1

1

10

100

0.0001

0.01

0.1

1

1

10

10

10

100

1000

0.001

0.1

1

10

10

100

100

100

1000

10000

0.01

1

10

100

100

1000

1000

1000

10000

100000

0.1

10

100

1000

1000

10000

10000

10000

100000

1000000

0.000043

0.000174

0.000697

0.002787

0.009797

0.027213

0.069665

0.108851

0.278659

0.435397

Caution!

Before using these tables,

please note the following:

Mass or volume measurement

Access operating mode with local

display → see page 24.

SI units

Switch No. 3 → OFF

US units

Switch No. 3 → ON

* DN 15, 25, 40 “FB” =

Full bore versions Promass I

Factory

settings

ON

OFF

Factory

settings

ON

OFF

Promass 60 6 Function Description

Endress+Hauser 37

Page 38

Full scale values (DIP switches)

For every nominal diameter, eight preset flow rates (full scale values) can be

selected for a current of 20 mA using Switches No. 8, 9 and 10.

VOLUME – Full scale value (current output)

SI units [l/h]

DN

1

2

4

8

15

15*/25

25*/40

40*/50

80

100

1

5

20

100

300

1000

2000

4000

9000

14000

2

10

40

200

600

2000

4000

8000

18000

28000

3

15

60

300

900

3000

6000

12000

27000

42000

4

20

80

400

1200

4000

8000

16000

36000

56000

5

25

100

500

1500

5000

10000

20000

45000

70000

10

50

200

1000

3000

10000

20000

40000

90000

140000

16

80

320

1600

4800

16000

32000

64000

144000

224000

20

100

400

2000

6000

20000

40000

80000

180000

280000

US units [USgal/min]

DN

1

2

4

8

15

15*/25

25*/40

40*/50

80

100

0.005

0.025

0.100

0.500

1.500

4.000

10.000

15.000

40.000

50.000

0.010

0.050

0.200

1.000

3.000

8.000

20.000

30.000

80.000

100.000

0.015

0.075

0.300

1.500

4.500

12.000

30.000

45.000

120.000

150.000

0.020

0.100

0.400

2.000

6.000

16.000

40.000

60.000

160.000

200.000

0.025

0.125

0.500

2.500

7.500

20.000

50.000

75.000

200.000

250.000

0.050

0.250

1.000

5.000

15.000

40.000

100.000

150.000

400.000

500.000

0.080

0.400

1.600

8.000

24.000

64.000

160.000

240.000

640.000

800.000

0.100

0.500

2.000

10.000

30.000

80.000

200.000

300.000

800.000

1000.000

* DN 15, 25, 40 “FB” =

Full bore versions Promass I

MASS – Full scale value (current output)

SI units [kg/h]

DN

1

2

4

8

15

15*/25

25*/40

40*/50

80

100

1

5

20

100

300

1000

2000

4000

9000

14000

2

10

40

200

600

2000

4000

8000

18000

28000

3

15

60

300

900

3000

6000

12000

27000

42000

4

20

80

400

1200

4000

8000

16000

36000

56000

5

25

100

500

1500

5000

10000

20000

45000

70000

10

50

200

1000

3000

10000

20000

40000

90000

140000

16

80

320

1600

4800

16000

32000

64000

144000

224000

20

100

400

2000

6000

20000

40000

80000

180000

280000

US units [lb/min]

DN

1

2

4

8

15

15*/25

25*/40

40*/50

80

100

0.05

0.20

0.75

4.00

10.00

30.00

75.00

125.00

325.00

425.00

0.10

0.40

1.50

8.00

20.00

60.00

150.00

250.00

650.00

850.00

0.15

0.60

2.25

12.00

30.00

90.00

225.00

375.00

975.00

1275.00

0.20

0.80

3.00

16.00

40.00

120.00

300.00

500.00

1300.00

1700.00

0.25

1.00

3.75

20.00

50.00

150.00

375.00

625.00

1625.00

2125.00

0.50

2.00

7.50

40.00

100.00

300.00

750.00

1250.00

3250.00

4250.00

0.80

3.20

12.00

64.00

160.00

480.00

1200.00

2000.00

5200.00

6800.00

1.00

4.00

15.00

80.00

200.00

600.00

1500.00

2500.00

6500.00

8500.00

Caution!

Before using these tables,

please note the following:

Mass or volume measurement

Access operating mode with local

display → see page 24.

SI units

Switch No. 3 → OFF

US units

Switch No. 3 → ON

* DN 15, 25, 40 “FB” =

Full bore versions Promass I

Factory

settings

ON

OFF

Factory

settings

ON

OFF

6 Function Description Promass 60

38 Endress+Hauser

Page 39

6.2 Local display functions

Function description (Local display)

rAtE

Display of actual flow rate or totalizer amount. A negative flow direction is

indicated on the display by a minus sign.

Selection of engineering units

➔

Press “Set” key

Caution!

SI/US units are selected using the DIP switches on the communication board

(see page 22).

tot

dISP-OF

Display of the number of totalizer overruns with values >9999999.

rAtE-tot

Alternating displays (approx. every 10 s) of actual flow and totalizer value.

O.-AdJUSt

With this function, the zero point adjustment can be automatically started.

The new zero point determined by the system is taken over in the PIPO function.

The adjustment procedure is as described below:

Note!

Alternatively, the zero point adjustment can also be initiated using the auxiliary

input (see page 35).

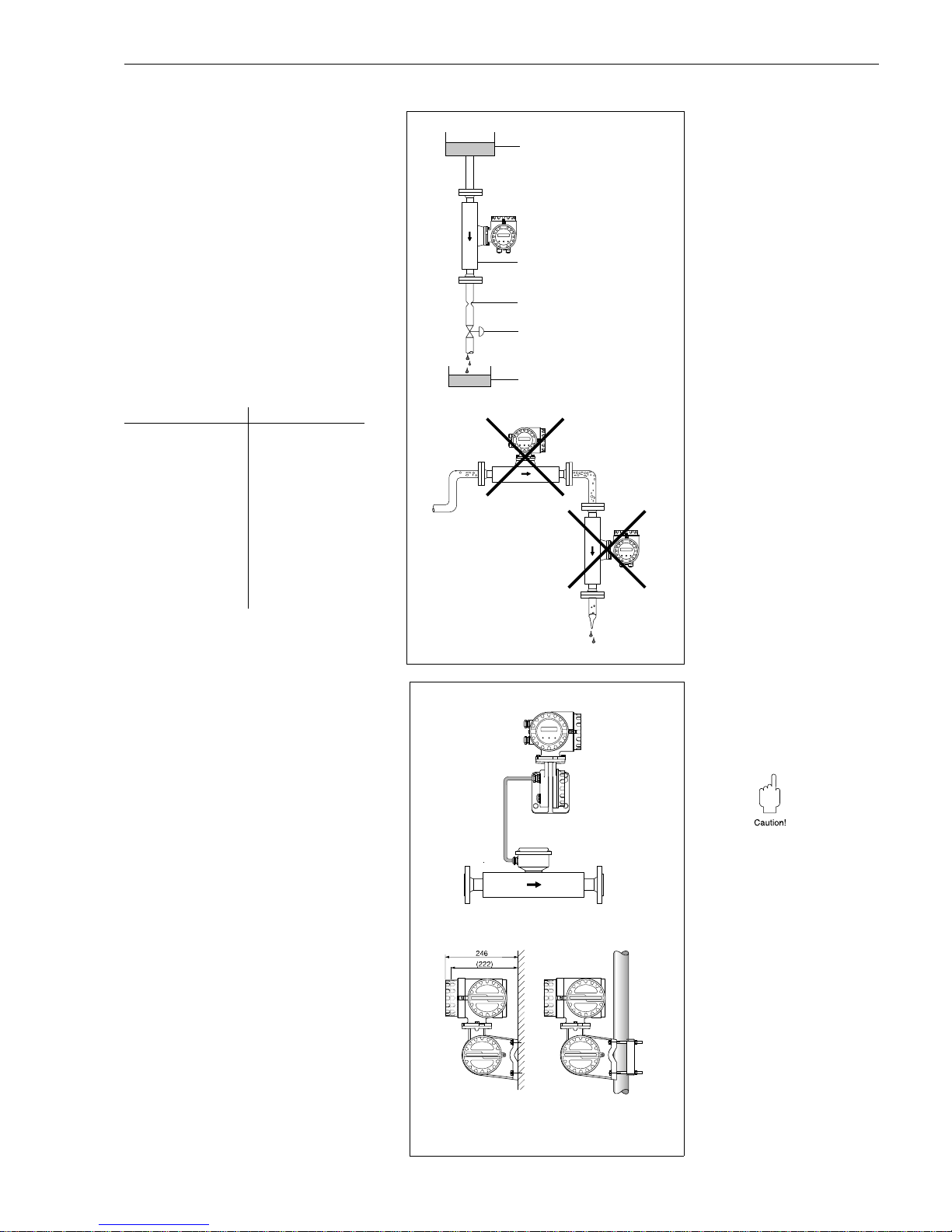

General information for zero point calibration

All Promass sensors are calibrated using the most up-to-date technology

available with the zero point stated on the nameplate. Calibration is carried

out according to reference conditions (see page 89). Therefore a zero point

calibration is generally not necessary!

Practical experience has shown that a zero point calibration is only required

in special cases:

• to achieve highest measuring accuracy

• with extreme process or operating conditions (e.g. with very high process

temperatures or high viscosity)

Requirements

– For fluids without gas or solids content

– Zero point calibration is carried out using completely filled measuring tubes

and at “no-flow” with e.g. shut-off valves both upstream and downstream

of the sensor or by using existing shut-off and sliding valves:

Normal operation

• Open valves A and B

Zero point calibration with pumping pressure

• Open valve A

• Close valve B

Zero point calibration without pumping pressure

• Close valve A

• Open valve B

Caution!

With difficult fluids (outgassing fluids or fluids

with solids content) it may be that no stable zero point

can be achieved despite carrying out a number

of zero point calibrations. In such cases,

please contact your E+H Service Centre.

(continued on next page)

ba013y74

Promass 60 6 Function Description

Endress+Hauser 39

Page 40

Function description (Local display)

O.-AdJUSt

(continued)

Carrying out a zero point calibration:

1. Run the plant for as long as necessary until it is operating normally.

2. Stop the flow (v = 0 m/s).

3. Check the shut-off valves (for leaks). Also check the operating pressure.

4. Carry out the zero point calibration as follows:

a) Select the function 0.-AdJUSt by pressing the “Display Function” key.

b) Begin the zero point calibration by pressing the “Set” key.

During calibration the message AdJ-bUSY is shown on the display

for approx. 30 seconds.

If a zero point calibration cannot be carried out, e.g. with v >0.1 m/s,

then an LED will flash on the communication board (see page 60).

Any local display present will give the error message “AdJ-Error”.

After a successful adjustment, the newly determined zero point value (PIPO)

appears on the display. The instrument will now work with the newly determined

zero point value.

PIPO

In this function, the zero point can be entered which is determined by a

“dynamic” zero point calibration.

Caution!

Dynamic zero point calibration is only required for very special applications!

Under normal circumstances, such a calibration is carried out only by the

E+H service technician or by an authorised person.

Entry

➔

Press

+

/ – keys

6 Function Description Promass 60

40 Endress+Hauser

Page 41

Function description (Local display)

density

With this function a one-point density calibration can be carried out on site.

The internal density calibration values are newly calculated and subsequently

stored in the Promass 60 measuring system.

For this purpose, the actual measured density is first displayed in kg/dm

3

.

General information for density calibration

With a density calibration, optimum measurement accuracy will be achieved in

the calculation of the flow volume. In addition, a calibration is required in the

following cases: