Page 1

KA01289D/06/EN/01.17

71350539

Products Solutions Services

Brief Operating Instructions

Proline Promag H

Electromagnetic sensor

These instructions are Brief Operating Instructions; they are

not a substitute for the Operating Instructions pertaining to

the device.

Sensor Brief Operating Instructions

Contain information about the sensor.

Transmitter Brief Operating Instructions → 3.

Page 2

Proline Promag H

Order code:

Ext. ord. cd.:

Ser. no.:

www.endress.com/deviceviewer

Endress+Hauser

Operations App

XXXXXXXXXXXX

XXXXX-XXXXXX

XXX.XXXX.XX

Serial number

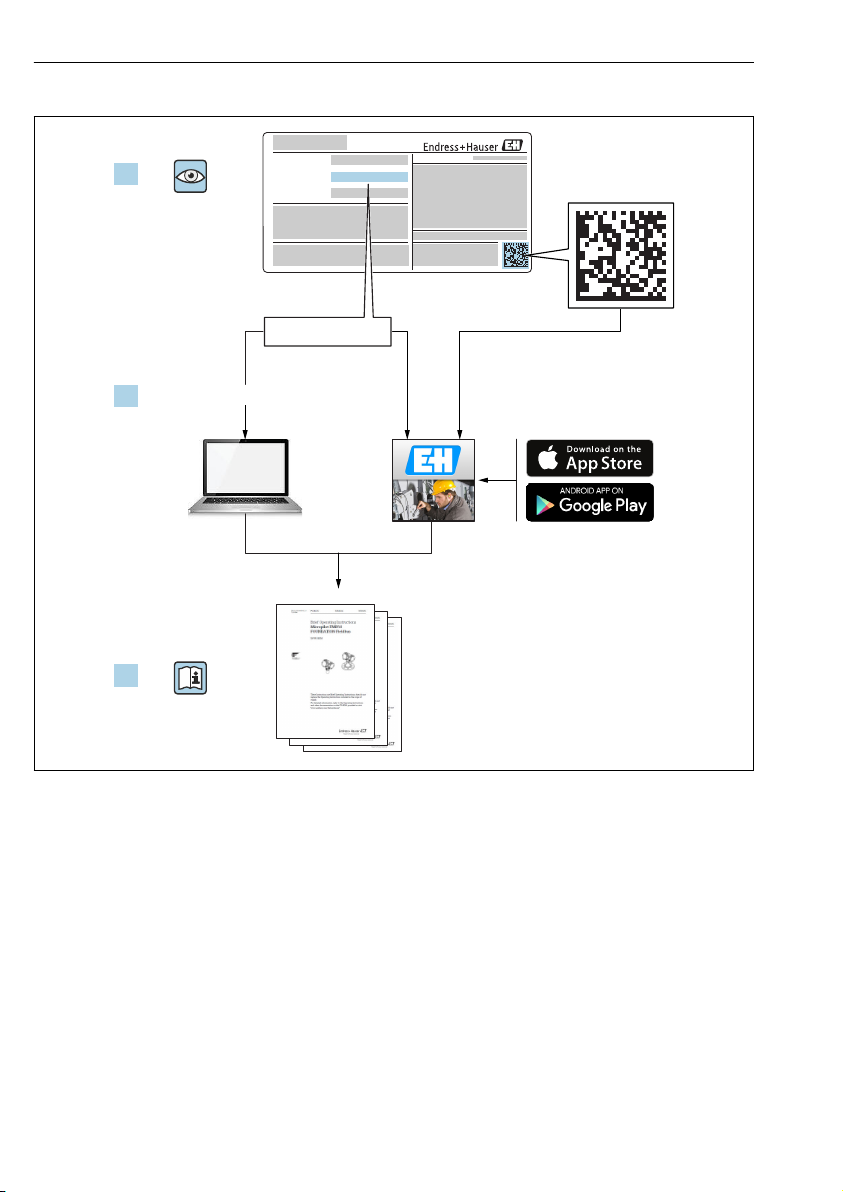

1.

3.

2.

2 Endress+Hauser

A0023555

Page 3

Proline Promag H Brief Operating Instructions for the device

Brief Operating Instructions for the device

The device consists of a transmitter and a sensor.

The process of commissioning these two components is described in two separate manuals:

• Sensor Brief Operating Instructions

• Transmitter Brief Operating Instructions

Please refer to both Brief Operating Instructions when commissioning the device as the

contents of the manuals complement one another:

Sensor Brief Operating Instructions

The Sensor Brief Operating Instructions are aimed at specialists with responsibility for

installing the measuring device.

• Incoming acceptance and product identification

• Storage and transport

• Installation

Transmitter Brief Operating Instructions

The Transmitter Brief Operating Instructions are aimed at specialists with responsibility for

commissioning, configuring and parameterizing the measuring device (until the first

measured value).

• Product description

• Installation

• Electrical connection

• Operation options

• System integration

• Commissioning

• Diagnostic information

Additional device documentation

These Brief Operating Instructions are the Sensor Brief Operating Instructions.

The "Transmitter Brief Operating Instructions" are available via:

• Internet: www.endress.com/deviceviewer

• Smart phone/tablet: Endress+Hauser Operations App

Detailed information about the device can be found in the Operating Instructions and the

other documentation:

• Internet: www.endress.com/deviceviewer

• Smart phone/tablet: Endress+Hauser Operations App

Endress+Hauser 3

Page 4

Table of contents Proline Promag H

Table of contents

1 Document information ............................................................ 5

1.1 Symbols used ......................................................................... 5

2 Basic safety instructions .......................................................... 7

2.1 Requirements for the personnel ............................................................7

2.2 Designated use ........................................................................ 7

2.3 Workplace safety ...................................................................... 8

2.4 Operational safety ......................................................................8

2.5 Product safety .........................................................................8

2.6 IT security ............................................................................9

3 Incoming acceptance and product identification ................................. 10

3.1 Incoming acceptance ................................................................... 10

3.2 Product identification .................................................................. 11

4 Storage and transport ........................................................... 12

4.1 Storage conditions .................................................................... 12

4.2 Transporting the product ................................................................12

5 Installation ...................................................................... 14

5.1 Installation conditions ..................................................................14

5.2 Mounting the measuring device ...........................................................21

5.3 Post-installation check ................................................................. 30

6 Disposal ......................................................................... 31

6.1 Removing the measuring device .......................................................... 31

6.2 Disposing of the measuring device ......................................................... 31

4 Endress+Hauser

Page 5

Proline Promag H Document information

DANGER

WARNING

CAUTION

NOTICE

A

1.

1 Document information

1.1 Symbols used

1.1.1 Safety symbols

Symbol Meaning

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

NOTE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

1.1.2 Symbols for certain types of information

Symbol Meaning Symbol Meaning

Permitted

Procedures, processes or actions that

are permitted.

Forbidden

Procedures, processes or actions that

are forbidden.

Reference to documentation

Preferred

Procedures, processes or actions that

are preferred.

Tip

Indicates additional information.

Reference to page

Reference to graphic

Result of a step Visual inspection

, 2., 3.… Series of steps

1.1.3 Electrical symbols

Symbol Meaning Symbol Meaning

Direct current Alternating current

Direct current and alternating current Ground connection

Endress+Hauser 5

A grounded terminal which, as far as

the operator is concerned, is grounded

via a grounding system.

Page 6

Document information Proline Promag H

1.

-

.

Symbol Meaning

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

Equipotential connection

A connection that has to be connected to the plant grounding system: This may be a potential

equalization line or a star grounding system depending on national or company codes of practice.

1.1.4 Communication symbols

Symbol Meaning Symbol Meaning

Wireless Local Area Network

(WLAN)

Communication via a wireless, local

network.

LED

Light emitting diode is off.

LED

Light emitting diode is flashing.

Bluetooth

Wireless data transmission between

devices over a short distance.

LED

Light emitting diode is on.

1.1.5 Tool symbols

Symbol Meaning Symbol Meaning

Torx screwdriver Flat blade screwdriver

Cross-head screwdriver Allen key

Open-ended wrench

1.1.6 Symbols in graphics

Symbol Meaning Symbol Meaning

1, 2, 3,... Item numbers

A, B, C, ... Views A-A, B-B, C-C, ... Sections

Hazardous area

Flow direction

6 Endress+Hauser

, 2., 3.… Series of steps

Safe area (non-hazardous area)

Page 7

Proline Promag H Basic safety instructions

2 Basic safety instructions

2.1 Requirements for the personnel

The personnel must fulfill the following requirements for its tasks:

Trained, qualified specialists must have a relevant qualification for this specific function

‣

and task.

Are authorized by the plant owner/operator.

‣

Are familiar with federal/national regulations.

‣

Before starting work, read and understand the instructions in the manual and

‣

supplementary documentation as well as the certificates (depending on the application).

Follow instructions and comply with basic conditions.

‣

2.2 Designated use

Application and media

The measuring device is only suitable for flow measurement of liquids with a minimum

conductivity of 5 μS/cm(Promag 100, 300, 500) or 20 μS/cm (Promag 200).

Depending on the version ordered, the measuring device can also measure potentially

explosive, flammable, poisonous and oxidizing media.

Measuring devices for use in hazardous areas, in hygienic applications or where there is an

increased risk due to process pressure, are labeled accordingly on the nameplate.

To ensure that the measuring device remains in proper condition for the operation time:

Only use the measuring device in full compliance with the data on the nameplate and the

‣

general conditions listed in the Operating Instructions and supplementary documentation.

Based on the nameplate, check whether the ordered device is permitted for the intended

‣

use in the hazardous area (e.g. explosion protection, pressure vessel safety).

Use the measuring device only for media to which the process-wetted materials are

‣

sufficiently resistant.

If the measuring device is not operated at atmospheric temperature, compliance with the

‣

relevant basic conditions specified in the associated device documentation is absolutely

essential: "Documentation" section..

Protect the measuring device permanently against corrosion from environmental

‣

influences.

Incorrect use

Non-designated use can compromise safety. The manufacturer is not liable for damage caused

by improper or non-designated use.

WARNING

L

Danger of breakage due to corrosive or abrasive fluids!

Verify the compatibility of the process fluid with the sensor material.

‣

Ensure the resistance of all fluid-wetted materials in the process.

‣

Keep within the specified pressure and temperature range.

‣

Endress+Hauser 7

Page 8

Basic safety instructions Proline Promag H

NOTICE

Verification for borderline cases:

For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance in

‣

verifying the corrosion resistance of fluid-wetted materials, but does not accept any

warranty or liability as minute changes in the temperature, concentration or level of

contamination in the process can alter the corrosion resistance properties.

Residual risks

WARNING

L

The electronics and the medium may cause the surfaces to heat up. This presents a burn

hazard!

For elevated fluid temperatures, ensure protection against contact to prevent burns.

‣

2.3 Workplace safety

For work on and with the device:

Wear the required personal protective equipment according to federal/national

‣

regulations.

For welding work on the piping:

Do not ground the welding unit via the measuring device.

‣

If working on and with the device with wet hands:

Due to the increased risk of electric shock, gloves must be worn.

‣

2.4 Operational safety

Risk of injury!

Operate the device in proper technical condition and fail-safe condition only.

‣

The operator is responsible for interference-free operation of the device.

‣

Environmental requirements

If a plastic transmitter housing is permanently exposed to certain steam and air mixtures, this

can damage the housing.

If you are unsure, please contact your Endress+Hauser Sales Center for clarification.

‣

If used in an approval-related area, observe the information on the nameplate.

‣

2.5 Product safety

This measuring device is designed in accordance with good engineering practice to meet stateof-the-art safety requirements, has been tested, and left the factory in a condition in which it

is safe to operate.

It meets general safety standards and legal requirements. It also complies with the EU

directives listed in the device-specific EU Declaration of Conformity. Endress+Hauser confirms

this by affixing the CE mark to the device.

8 Endress+Hauser

Page 9

Proline Promag H Basic safety instructions

2.6 IT security

We only provide a warranty if the device is installed and used as described in the Operating

Instructions. The device is equipped with security mechanisms to protect it against any

inadvertent changes to the device settings.

IT security measures in line with operators' security standards and designed to provide

additional protection for the device and device data transfer must be implemented by the

operators themselves.

Endress+Hauser 9

Page 10

Incoming acceptance and product identification Proline Promag H

1

2

1

2

Order code:

Ser. no.:

Ext. ord. cd.:

i

i

Date:

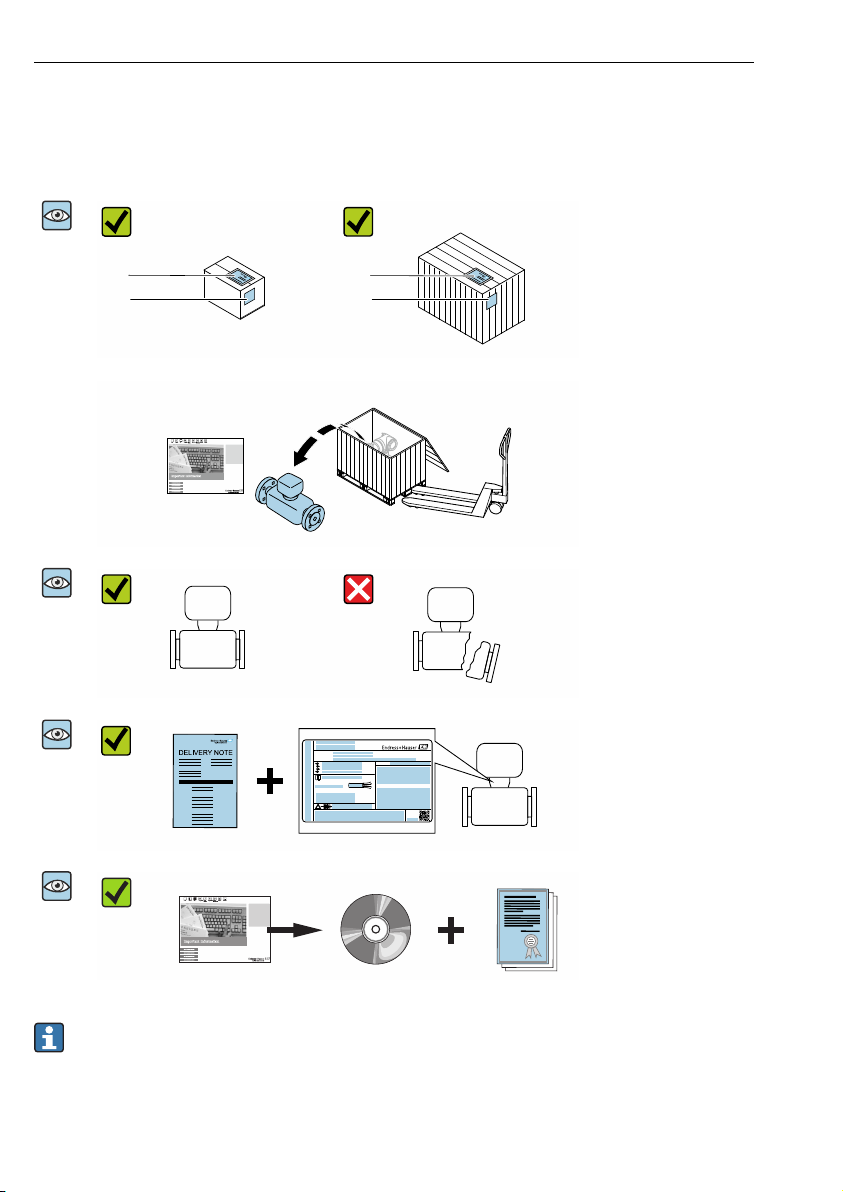

3 Incoming acceptance and product identification

3.1 Incoming acceptance

Are the order codes on

the delivery note (1)

A0028673

A0028673

and the product sticker

(2) identical?

Are the goods

undamaged?

Do the nameplate data

match the ordering

A0028673

information on the

delivery note?

Is the CD-ROM with the

Technical

A0028673

Documentation

(depends on device

version) and documents

present?

• If one of the conditions is not satisfied, contact your Endress+Hauser Sales Center.

• Depending on the device version, the CD-ROM might not be part of the delivery! The

Technical Documentation is available via the Internet or via the Endress+Hauser

Operations App.

10 Endress+Hauser

Page 11

Proline Promag H Incoming acceptance and product identification

Order code:

Ext. ord. cd.:

Ser. no.:

Order code:

Ext. ord. cd.:

Ser. no.:

1

2

3

4

3.2 Product identification

The following options are available for identification of the measuring device:

• Nameplate specifications

• Order code with breakdown of the device features on the delivery note

• Enter serial numbers from nameplates in W@M Device Viewer

(www.endress.com/deviceviewer): All information about the measuring device is displayed.

• Enter the serial number from the nameplates into the Endress+Hauser Operations App or

scan the 2-D matrix code (QR code) on the nameplate with the Endress+Hauser Operations

App: all the information for the measuring device is displayed.

A0030196

1 Example of a nameplate

1 Order code

2 Serial number (Ser. no.)

3 Extended order code (Ext. ord. cd.)

4 2-D matrix code (QR code)

For detailed information on the breakdown of the specifications on the nameplate, see

the Operating Instructions for the device .

Endress+Hauser 11

Page 12

Storage and transport Proline Promag H

4 Storage and transport

4.1 Storage conditions

Observe the following notes for storage:

• Store in original packaging.

• Do not remove protective covers or protective caps installed on process connections.

• Protect from direct sunlight.

• Select a storage location where moisture cannot collect in the measuring device.

• Store in a dry and dust-free place.

• Do not store outdoors.

4.2 Transporting the product

Transport the measuring device to the measuring point in the original packaging.

A0029252

Do not remove protective covers or caps installed on process connections. They prevent

mechanical damage to the sealing surfaces and contamination in the measuring tube.

4.2.1 Measuring devices without lifting lugs

WARNING

L

Center of gravity of the measuring device is higher than the suspension points of the

webbing slings.

Risk of injury if the measuring device slips.

Secure the measuring device against slipping or turning.

‣

Observe the weight specified on the packaging (stick-on label).

‣

12 Endress+Hauser

Page 13

Proline Promag H Storage and transport

A0029214

4.2.2 Measuring devices with lifting lugs

CAUTION

L

Special transportation instructions for devices with lifting lugs

Only use the lifting lugs fitted on the device or flanges to transport the device.

‣

The device must always be secured at two lifting lugs at least.

‣

4.2.3 Transporting with a fork lift

If transporting in wood crates, the floor structure enables the crates to be lifted lengthwise or

at both sides using a forklift.

CAUTION

L

Risk of damaging the magnetic coil

If transporting by forklift, do not lift the sensor by the metal casing.

‣

This would buckle the casing and damage the internal magnetic coils.

‣

A0029319

Endress+Hauser 13

Page 14

Installation Proline Promag H

h

1 1

5 Installation

5.1 Installation conditions

5.1.1 Mounting position

Mounting location

A0029343

h ≥ 2 × DN

A0033017

2 Installation of the sensor after a control valve is not recommended

1 Control valve

Installation in down pipes

Install a siphon with a vent valve downstream of the sensor in down pipes whose length h ≥

5 m (16.4 ft). This precaution is to avoid low pressure and the consequent risk of damage to

the measuring tube. This measure also prevents the system losing prime.

14 Endress+Hauser

Page 15

Proline Promag H Installation

h

2

1

2 x DN³

5 x DN³

A0028981

3 Installation in a down pipe

1 Vent valve

2 Pipe siphon

h Length of down pipe

Installation in partially filled pipes

A partially filled pipe with a gradient necessitates a drain-type configuration.

A0029257

Orientation

The direction of the arrow on the sensor nameplate helps you to install the sensor according

to the flow direction.

An optimum orientation position helps avoid gas and air accumulations and deposits in the

measuring tube.

Vertical

A0015591

Endress+Hauser 15

Page 16

Installation Proline Promag H

1

22

≥ 5 × DN

≥ 2 × DN

Optimum for self-emptying pipe systems and for use in conjunction with empty pipe

detection.

Horizontal

A0028998

1 EPD electrode for empty pipe detection

2 Measuring electrodes for signal detection

• Ideally, the measuring electrode plane should be horizontal. This prevents brief

insulation of the two measuring electrodes by entrained air bubbles.

• Empty pipe detection only works if the transmitter housing is pointing upwards as

otherwise there is no guarantee that the empty pipe detection function will actually

respond to a partially filled or empty measuring tube.

Inlet and outlet runs

A0028997

4 Order code for "Design", option A "Insertion length short, ISO/DVGW until DN400, DN450-2000

1:1" and order code for "Design", option B "Insertion length long, ISO/DVGW until DN400,

DN450-2000 1:1.3"

16 Endress+Hauser

Page 17

Proline Promag H Installation

≥ 0 × DN

A0032859

5 Order code for "Design", option C "Insertion length short ISO/DVGW until DN300, w/o inlet and

outlet runs, constricted meas.tube"

For the dimensions and installation lengths of the device, see the "Technical Information"

document, "Mechanical construction" section.

5.1.2 Requirements from environment and process

Ambient temperature range

For detailed information on the ambient temperature range, see the Operating

Instructions for the device.

If operating outdoors:

• Install the measuring device in a shady location.

• Avoid direct sunlight, particularly in warm climatic regions.

• Avoid direct exposure to weather conditions.

Temperature tables

For detailed information on the temperature tables, see the separate document entitled

"Safety Instructions" (XA) for the device.

System pressure

A0028777

Furthermore, install pulse dampers if reciprocating, diaphragm or peristaltic pumps are

used.

Endress+Hauser 17

Page 18

Installation Proline Promag H

L

100

10

0.5

d / D

[mbar]

0.6 0.7 0.8 0.9

1 m/s

2 m/s

3 m/s

4 m/s

5 m/s

6 m/s

7 m/s

8 m/s

1

D

d

max. 8°

Vibrations

A0029004

6 Measures to avoid device vibrations (L > 10 m (33 ft))

Adapters

18 Endress+Hauser

A0029002

Page 19

Proline Promag H Installation

146 (5.75)

48 (1.9)

12 (0.47)

280 (11.0) 255 (10.0)

134 (5.3)

30 (1.18)

213 (8.4)

39 (1.5)

243 (9.6)

203 (8.0)

5.1.3 Special mounting instructions

Weather protection cover: Proline 300

A0029553

Weather protection cover: Proline 500

7 Weather protection cover for Proline 500 – digital

Endress+Hauser 19

A0029552

Page 20

Installation Proline Promag H

146 (5.75)

48 (1.9)

12 (0.47)

280 (11.0) 255 (10.0)

134 (5.3)

30 (1.18)

1

1

2

2

1

1

5 (0.2) min. 15 (0.6)

SW 2.5

M3

A0029553

8 Weather protection cover for Proline 500

Cover locking

NOTICE

Order code "Housing" "Transmitter housing", option L "Cast, stainless": The covers of the

transmitter housing are provided with a borehole to lock the cover.

The cover can be locked using screws and a chain or cable provided by the customer.

It is recommended to use stainless steel cables or chains.

‣

If a protective coating is applied, it is recommended to use a heat shrink tube to protect the

‣

housing paint.

1 Cover borehole for the securing screw

2 Securing screw to lock the cover

20 Endress+Hauser

A0029799

Page 21

Proline Promag H Installation

5.2 Mounting the measuring device

5.2.1 Required tools

For transmitter

• Torque wrench

• For wall mounting:

Open-ended wrench for hexagonal screw max. M5

• For pipe mounting:

– Open-ended wrench AF 8

– Phillips head screwdriver PH 2

For transmitter Proline 500

For mounting on a post:

• Proline 500 – digital transmitter

– Open-ended wrench AF 10

– Torx screwdriver TX 25

• Proline 500 transmitter

Open-ended wrench AF 13

For wall mounting:

Drill with drill bit ⌀ 6.0 mm

For sensor

For flanges and other process connections: Corresponding mounting tools

5.2.2 Preparing the measuring device

1. Remove all remaining transport packaging.

2. Remove any protective covers or protective caps present from the sensor.

3. Remove stick-on label on the electronics compartment cover.

5.2.3 Mounting the sensor

WARNING

L

An electrically conductive layer could form on the inside of the measuring tube!

Risk of measuring signal short circuit.

Ensure that the inside diameters of the gaskets are greater than or equal to that of the

‣

process connections and piping.

Ensure that the gaskets are clean and undamaged.

‣

Install the gaskets correctly.

‣

Do not use electrically conductive sealing compounds such as graphite.

‣

Endress+Hauser 21

Page 22

Installation Proline Promag H

WARNING

L

Danger due to improper process sealing!

Ensure that the inside diameters of the gaskets are greater than or equal to that of the

‣

process connections and piping.

Ensure that the gaskets are clean and undamaged.

‣

Install the gaskets correctly.

‣

1. Ensure that the direction of the arrow on the sensor matches the flow direction of the

medium.

2. To ensure compliance with device specifications, install the measuring device between

the pipe flanges in a way that it is centered in the measurement section.

3. Install the measuring device or turn the transmitter housing so that the cable entries do

not point upwards.

A0029263

Process connections

The sensor is supplied to order, with or without pre-installed process connections. Preinstalled process connections are firmly secured to the sensor by 4 or 6 hexagonal-headed

bolts.

The sensor may need to be supported or additionally secured depending on the

application and pipe length. In particular, it is absolutely essential to secure the sensor

additionally if plastic process connections are used. An appropriate wall mounting kit can

be ordered separately as an accessory from Endress+Hauser.

Seals

• In the case of metal process connections, the screws must be tightened securely. The

process connection forms a metal connection with the sensor, which ensures a defined

compression of the seal.

• In the case of plastic process connections, observe the maximum torques for lubricated

threads: 7 Nm (5.2 lbf ft); always insert a seal between the connection and the

counterflange.

• Depending on the application the seals should be replaced periodically, particularly if

molded seals are used (aseptic version)! The interval between changes depends on the

frequency of the cleaning cycles, the cleaning temperature and the medium temperature.

Replacement seals can be ordered as an accessory.

• For "PFA" lining: additional seals are always required (Promag 200).

22 Endress+Hauser

Page 23

Proline Promag H Installation

A

B

C

DN 2…25

( 1")1/12…

DN 40…1 05

(1 ½… ")6

A

B

DN 2…25

( 1")1/12…

A0019804

9 Seals of process connections Promag H 100

A Process connections with O-ring seal

B Process connections with aseptic molded seal, DN 2 to 25 (1/12 to 1")

C Process connections with aseptic molded seal, DN 40 to 150 (1 ½ to 6")

A0018782

10 Seals of process connections Promag H 200

A Process connections with O-ring seal

B Process connections with aseptic gasket seal

Mounting grounding rings, DN 2 to 25 (1/12 to 1")

For information on potential equalization, see the Transmitter Brief Operating

Instructions.

In the case of plastic process connections (e.g. flange connections or adhesive fittings),

additional ground rings must be used to ensure potential matching between the sensor and

the fluid. If grounding rings are not installed, this can affect the measuring accuracy or cause

Endress+Hauser 23

Page 24

Installation Proline Promag H

1

3

2

4

2

the destruction of the sensor as a result of the electrochemical decomposition of the

electrodes.

• Depending on the option ordered, plastic disks are used instead of grounding rings on

some process connections. These plastic disks only act as "spacers" and do not have any

potential matching function. Furthermore, they also perform a significant sealing

function at the sensor/process connection interface. Therefore, in the case of process

connections without metal grounding rings, these plastic disks/seals should never be

removed and should always be installed!

• Grounding rings can be ordered separately as an accessory from Endress+Hauser .

When ordering make sure that the grounding rings are compatible with the material

used for the electrodes, as otherwise there is the danger that the electrodes could be

destroyed by electrochemical corrosion!

• Grounding rings, including seals, are mounted inside the process connections.

Therefore the installation length is not affected.

A0028971

11 Installing grounding rings

1 Hexagonal-headed bolts of process connection

2 O-ring seals

3 Grounding ring or plastic disk (spacer)

4 Sensor

1. Release the 4 or 6 hexagonal-headed bolts (1) and remove the process connection from

the sensor (4).

2. Remove the plastic disk (3), along with the two O-ring seals (2), from the process

connection.

3. Place the first O-ring seal (2) back into the groove of the process connection.

4. Fit the metal grounding ring (3) in the process connection as illustrated.

5. Place the second O-ring seal (2) into the groove of the grounding ring.

24 Endress+Hauser

Page 25

Proline Promag H Installation

6. Mount the process connection back on the sensor. When doing so, make sure to observe

the maximum screw tightening torques for lubricated threads: 7 Nm (5.2 lbf ft)

Welding the sensor into the pipe (welding connections)

WARNING

L

Risk of destroying the electronics!

Make sure that the welding system is not grounded via the sensor or transmitter.

‣

1. Tack-weld the sensor to secure it in the pipe. A suitable welding aid can be ordered

separately as an accessory.

2. Release the screws on the process connection flange and remove the sensor, along with

the seal, from the pipe.

3. Weld the process connection into the pipe.

4. Reinstall the sensor in the pipe, and in doing so make sure that the seal is clean and in

the right position.

• If thin-walled pipes carrying food are welded correctly, the seal is not damaged by the

heat even when mounted. However, it is recommended to disassemble the sensor and

seal.

• It must be possible to open the pipe by approx. 8 mm (0.31 in) for disassembly.

Cleaning with pigs

It is essential to take the internal diameters of the measuring tube and process connection

into account when cleaning with pigs. All the dimensions and lengths of the sensor and

transmitter are provided in the separate "Technical Information" document.

5.2.4 Mounting the transmitter of the remote version: , Proline 500 – digital

CAUTION

L

Ambient temperature too high!

Danger of electronics overheating and housing deformation.

Do not exceed the permitted maximum ambient temperature .

‣

If operating outdoors: Avoid direct sunlight and exposure to weathering, particularly in

‣

warm climatic regions.

CAUTION

L

Excessive force can damage the housing!

Avoid excessive mechanical stress.

‣

Endress+Hauser 25

Page 26

Installation Proline Promag H

149 (5.85)

211 (8.31)

=

5.8 (0.23)

17 (0.67) =

L

5.8 (0.23)

Wall mounting

A0029054

12 Engineering unit mm (in)

L Depends on order code for "Transmitter housing"

Order code for "Transmitter housing"

• Option A, aluminum coated: L =14 mm (0.55 in)

• Option D, polycarbonate: L = 13 mm (0.51 in)

26 Endress+Hauser

Page 27

Proline Promag H Installation

ø 20…70

( 0.79…2.75)ø

~102 (~ 4.0)

4 x

SW 10

3 x

TX 25

Post mounting

WARNING

L

Excessive tightening torque applied to the fixing screws on plastic housing!

Risk of damaging the plastic transmitter.

Tighten the fixing screws as per the tightening torque: 2 Nm (1.5 lbf ft)

‣

13 Engineering unit mm (in)

Endress+Hauser 27

A0029051

Page 28

Installation Proline Promag H

20 (0.79)

100 (3.94)

100 (3.94)

! 8.6 (0.39)

! 18 (0.71)

! 10 (0.39)

5.2.5 Mounting the transmitter housing: Proline 500

CAUTION

L

Ambient temperature too high!

Danger of electronics overheating and housing deformation.

Do not exceed the permitted maximum ambient temperature .

‣

If operating outdoors: Avoid direct sunlight and exposure to weathering, particularly in

‣

warm climatic regions.

CAUTION

L

Excessive force can damage the housing!

Avoid excessive mechanical stress.

‣

The transmitter can be mounted in the following ways:

• Post mounting

• Wall mounting

Wall mounting

14 Engineering unit mm (in)

A0029068

28 Endress+Hauser

Page 29

Proline Promag H Installation

1

4 x

SW 13

! … (! 0.79 to 2.75)20 70

Post mounting

A0029057

15 Engineering unit mm (in)

Endress+Hauser 29

Page 30

Installation Proline Promag H

5.3 Post-installation check

Is the device undamaged (visual inspection)?

Does the measuring device conform to the measuring point specifications?

For example:

• Process temperature

• Process pressure (refer to the section on "Pressure-temperature ratings" in the "Technical Information"

document)

• Ambient temperature

• Measuring range

Has the correct orientation for the sensor been selected ?

• According to sensor type

• According to medium temperature

• According to medium properties (outgassing, with entrained solids)

Does the arrow on the sensor nameplate match the direction of flow of the fluid through the piping ?

Are the measuring point identification and labeling correct (visual inspection)?

Is the device adequately protected from precipitation and direct sunlight?

Have the fixing screws been tightened with the correct tightening torque?

30 Endress+Hauser

Page 31

Proline Promag H Disposal

6 Disposal

6.1 Removing the measuring device

1. Switch off the device.

WARNING

L

Danger to persons from process conditions.

Beware of hazardous process conditions such as pressure in the measuring device, high

‣

temperatures or aggressive fluids.

2. Carry out the mounting and connection steps from the "Mounting the measuring device"

and "Connecting the measuring device" sections in reverse order. Observe the safety

instructions.

6.2 Disposing of the measuring device

WARNING

L

Danger to personnel and environment from fluids that are hazardous to health.

Ensure that the measuring device and all cavities are free of fluid residues that are

‣

hazardous to health or the environment, e.g. substances that have permeated into crevices

or diffused through plastic.

Observe the following notes during disposal:

Observe valid federal/national regulations.

‣

Ensure proper separation and reuse of the device components.

‣

Endress+Hauser 31

Page 32

www.addresses.endress.com

Loading...

Loading...