Endress+Hauser H 200 Specifications

TI01061D/06/EN/05.17

71372370

Products Solutions Services

Technical Information

Proline Promag H 200

Electromagnetic flowmeter

The measuring device for smallest flow rates with genuine two-wire

technology

Application

• The measuring principle is virtually independent of pressure,

density, temperature and viscosity

• For the smallest flow quantities and demanding hygienic

applications

Device properties

• Liner made of PFA

• Sensor housing made of stainless steel (3A, EHEDG)

• Wetted materials CIP, SIP cleanable

• Loop-powered technology

• Robust two-chamber housing

• Plant safety: worldwide approvals (SIL, Haz. area)

Your benefits

• Flexible installation concept – numerous hygienic process

connections

• Energy-saving flow measurement – no pressure loss due to

cross-section constriction

• Maintenance-free – no moving parts

• Convenient device wiring – separate connection

compartment

• Safe operation – no need to open the device due to display

with touch control, background lighting

• Integrated verification – Heartbeat Technology™

Table of contents

Proline Promag H 200

Document information ....................... 3

Symbols used ................................ 3

Function and system design ................... 3

Measuring principle ............................ 3

Measuring system ............................. 5

Safety ..................................... 5

Input ..................................... 5

Measured variable ............................. 5

Measuring range .............................. 5

Operable flow range ........................... 6

Output ................................... 6

Output signal ................................ 6

Signal on alarm ............................... 7

Load ...................................... 9

Ex connection data ............................ 9

Low flow cut off ............................. 13

Galvanic isolation ............................ 13

Protocol-specific data .......................... 13

Power supply ............................. 17

Terminal assignment .......................... 17

Pin assignment, device plug ...................... 18

Supply voltage .............................. 18

Power consumption ........................... 18

Current consumption .......................... 19

Power supply failure .......................... 19

Electrical connection .......................... 19

Potential equalization ......................... 23

Terminals ................................. 24

Cable entries ............................... 24

Cable specification ............................ 24

Overvoltage protection ......................... 25

Process .................................. 30

Medium temperature range ...................... 30

Conductivity ................................ 31

Pressure-temperature ratings .................... 31

Pressure tightness ............................ 34

Flow limit ................................. 34

Pressure loss ............................... 34

System pressure ............................. 35

Vibrations ................................. 35

Mechanical construction .................... 35

Dimensions in SI units ......................... 35

Dimensions in US units ......................... 48

Weight ................................... 57

Measuring tube specification ..................... 57

Materials .................................. 58

Fitted electrodes ............................. 59

Process connections ........................... 59

Surface roughness ............................ 59

Operability ............................... 60

Operating concept ............................ 60

Local operation .............................. 60

Remote operation ............................ 61

Service interface ............................. 63

Certificates and approvals ................... 64

CE mark ................................... 64

C-Tick symbol ............................... 64

Ex approval ................................ 64

Sanitary compatibility ......................... 65

Functional safety ............................. 65

HART certification ............................ 65

FOUNDATION Fieldbus certification ................ 65

Certification PROFIBUS ......................... 65

Other standards and guidelines ................... 65

Performance characteristics .................. 25

Reference operating conditions ................... 25

Maximum measured error ....................... 25

Repeatability ............................... 26

Influence of ambient temperature ................. 26

Ordering information ....................... 66

Application packages ....................... 66

Diagnostics functions .......................... 66

Heartbeat Technology ......................... 66

Installation ............................... 26

Mounting location ............................ 27

Orientation ................................ 27

Inlet and outlet runs .......................... 28

Adapters .................................. 28

Special mounting instructions .................... 29

Environment .............................. 29

Ambient temperature range ..................... 29

Storage temperature .......................... 30

Degree of protection .......................... 30

Shock resistance ............................. 30

Vibration resistance ........................... 30

Mechanical load ............................. 30

Electromagnetic compatibility (EMC) ............... 30

Accessories ............................... 67

Device-specific accessories ...................... 67

Communication-specific accessories ................ 68

Service-specific accessories ...................... 68

System components ........................... 69

Documentation ............................ 69

Standard documentation ........................ 69

Supplementary device-dependent documentation ....... 70

Registered trademarks ...................... 70

2 Endress+Hauser

Proline Promag H 200

,…,

-

.

Document information

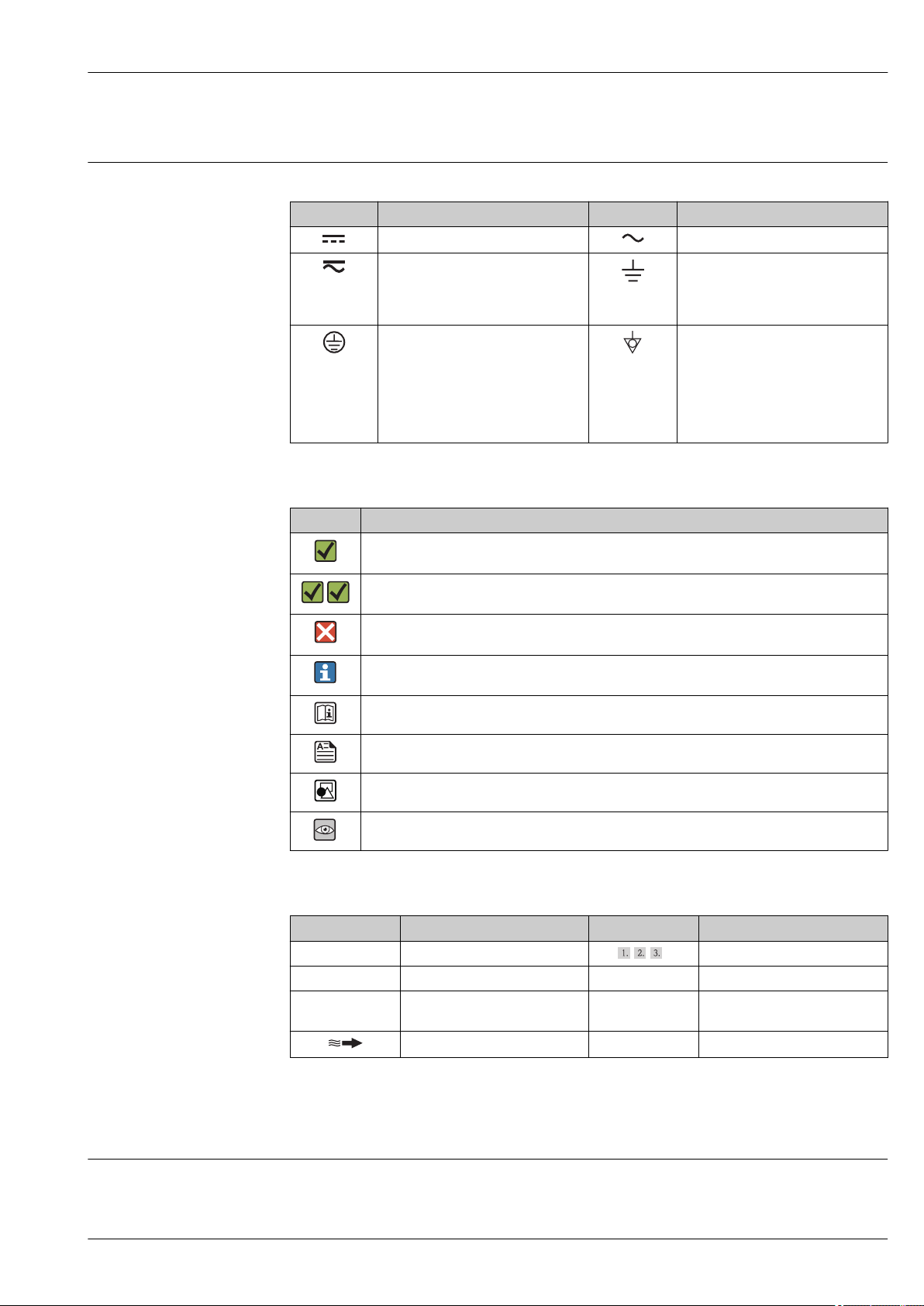

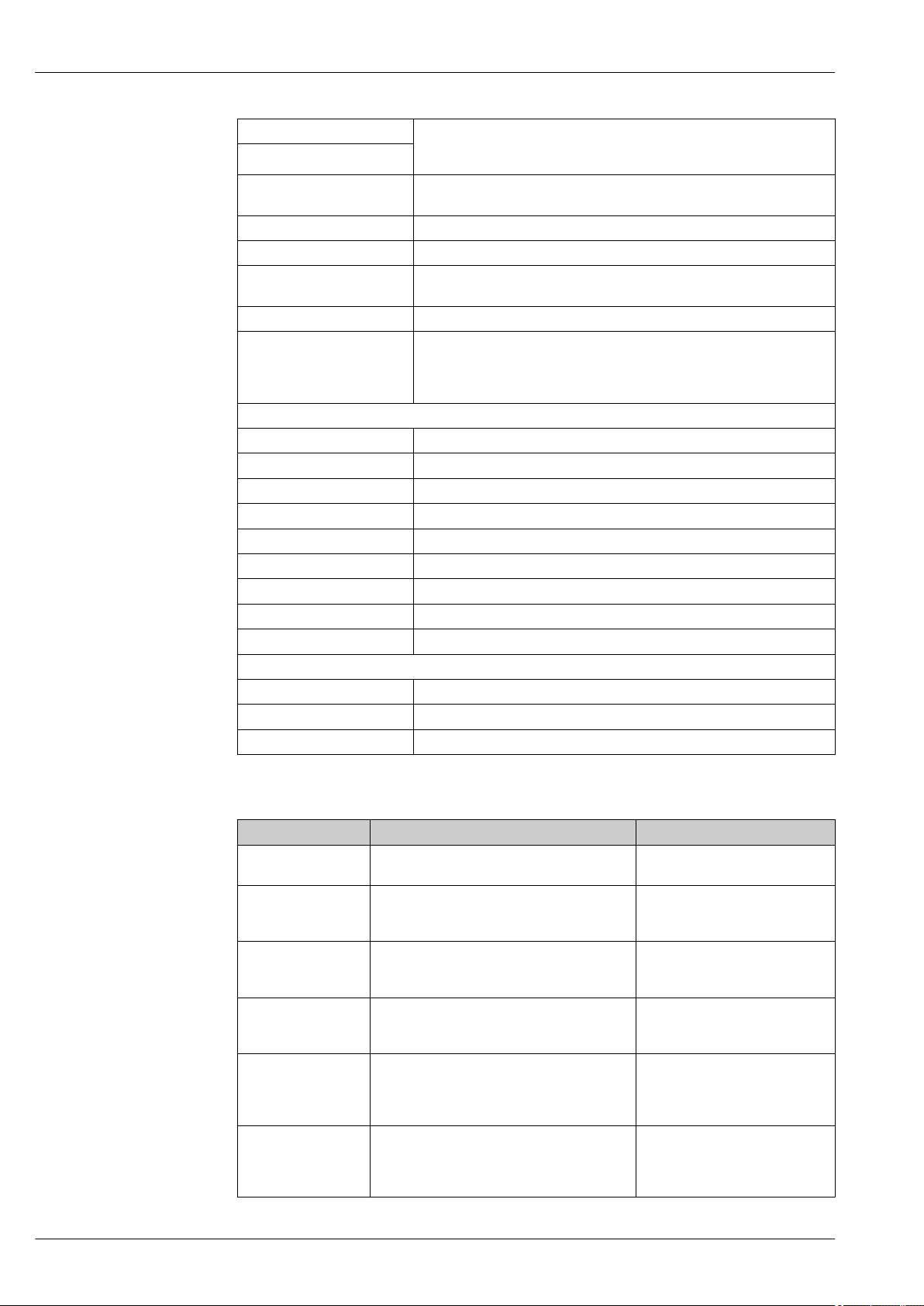

Symbols used Electrical symbols

Symbol Meaning Symbol Meaning

Direct current Alternating current

Direct current and alternating current Ground connection

Protective ground connection

A terminal which must be connected

to ground prior to establishing any

other connections.

Symbols for certain types of information

A grounded terminal which, as far as

the operator is concerned, is

grounded via a grounding system.

Equipotential connection

A connection that has to be connected

to the plant grounding system: This

may be a potential equalization line

or a star grounding system depending

on national or company codes of

practice.

Symbol Meaning

Permitted

Procedures, processes or actions that are permitted.

Preferred

Procedures, processes or actions that are preferred.

Forbidden

Procedures, processes or actions that are forbidden.

Tip

Indicates additional information.

Reference to documentation

Reference to page

Reference to graphic

Visual inspection

Symbols in graphics

Symbol Meaning Symbol Meaning

1, 2, 3,... Item numbers

A, B, C, ... Views A-A, B-B, C-C, ... Sections

Hazardous area

Series of steps

Safe area (non-hazardous area)

Flow direction

Function and system design

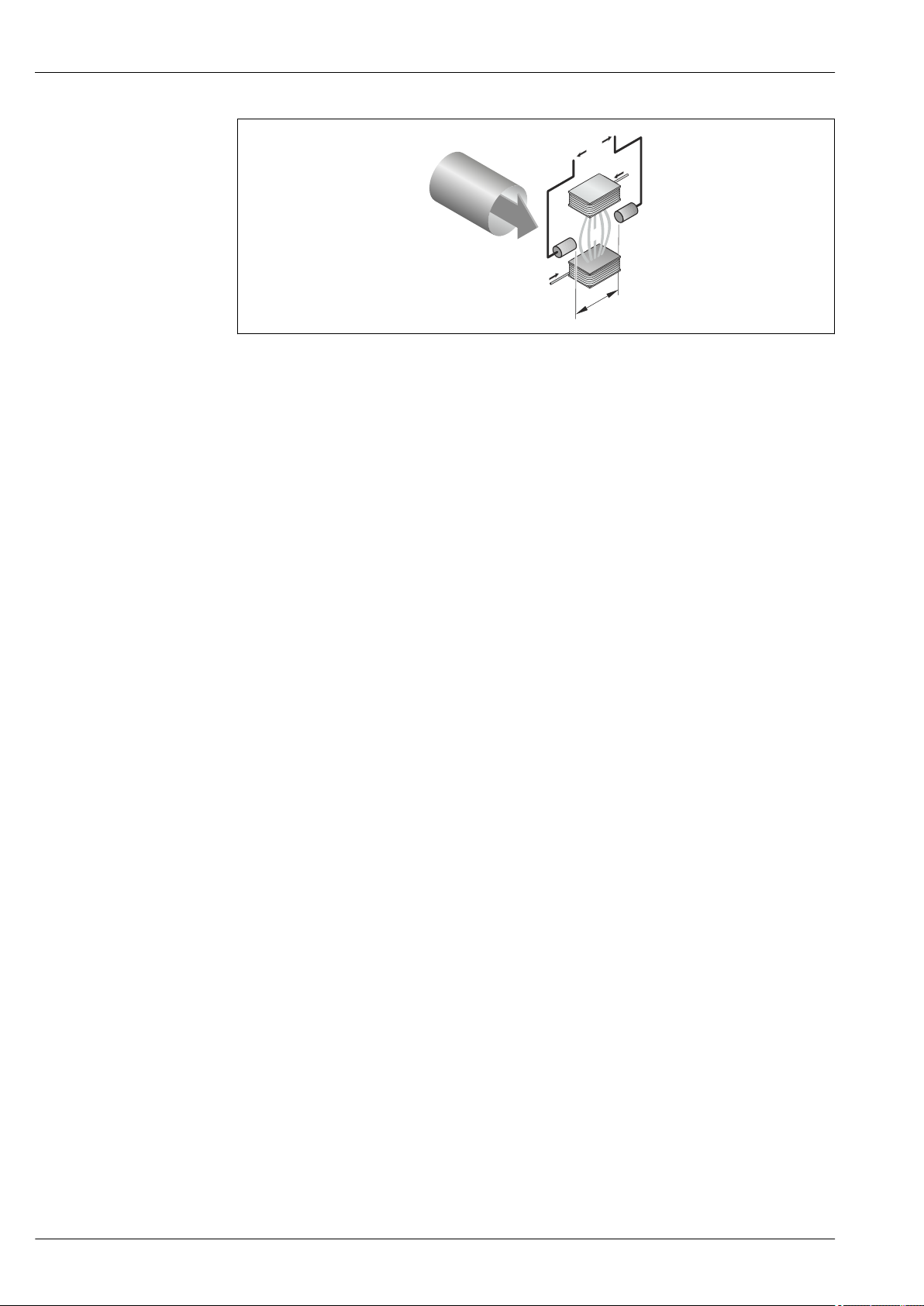

Measuring principle

Endress+Hauser 3

Following Faraday's law of magnetic induction, a voltage is induced in a conductor moving through a

magnetic field.

Proline Promag H 200

I

L

B

I

U

e

v

A0017035

Ue Induced voltage

B Magnetic induction (magnetic field)

L Electrode spacing

I Current

v Flow velocity

In the electromagnetic measuring principle, the flowing medium is the moving conductor. The

voltage induced (Ue) is proportional to the flow velocity (v) and is supplied to the amplifier by means

of two measuring electrodes. The flow volume (Q) is calculated via the pipe cross-section (A). The DC

magnetic field is created through a switched direct current of alternating polarity.

Formulae for calculation

• Induced voltage Ue = B · L · v

• Volume flow Q = A · v

4 Endress+Hauser

Proline Promag H 200

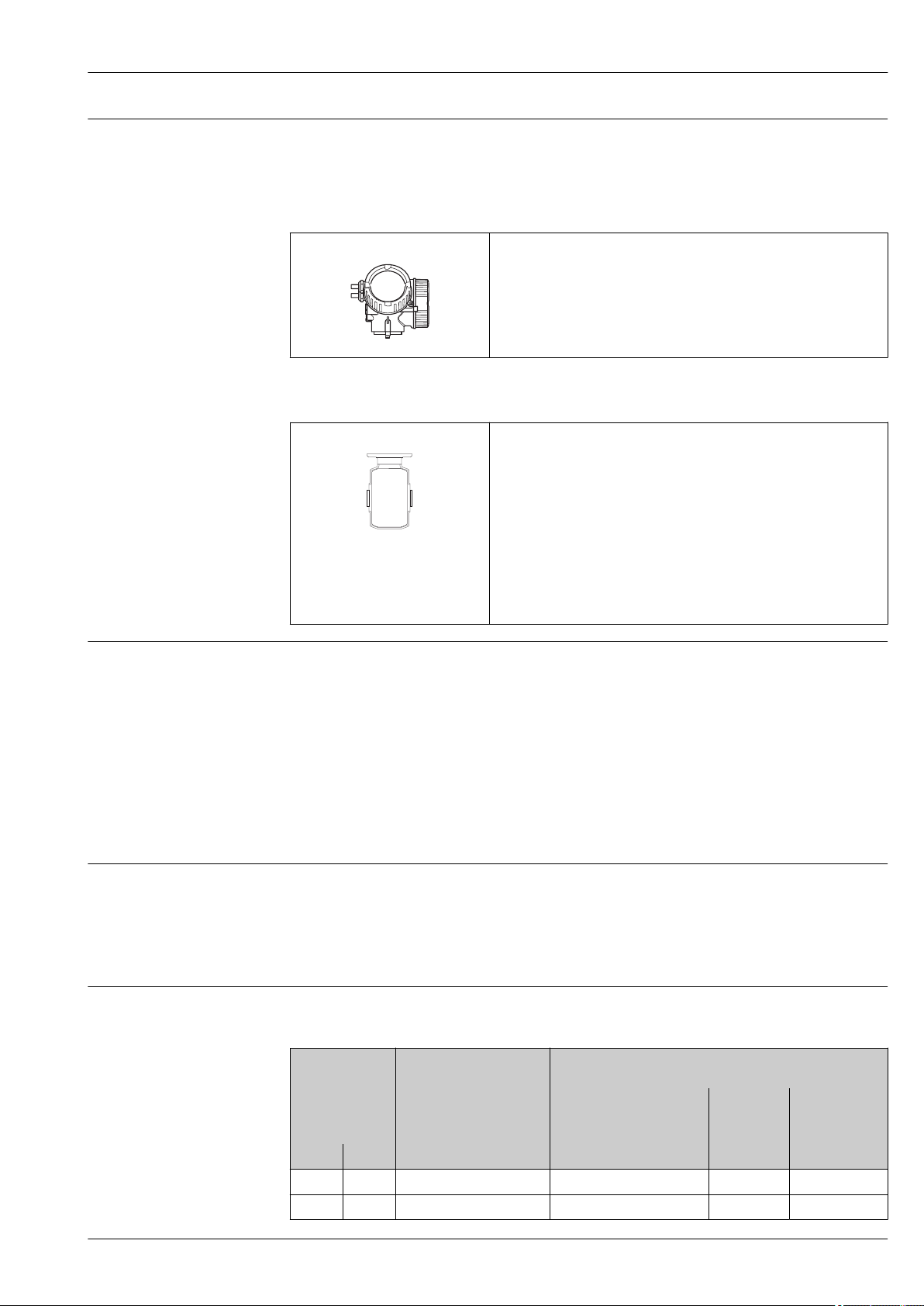

Measuring system

The device consists of a transmitter and a sensor.

The device is available as a compact version:

The transmitter and sensor form a mechanical unit.

Transmitter

Promag 200 Materials:

Aluminum, AlSi10Mg, coated

Configuration:

• External operation via four-line, illuminated local display with touch

control and guided menus ("Make-it-run" wizards) for applications

• Via operating tools (e.g. FieldCare)

A0013471

Sensor

Promag H Nominal diameter range: DN 2 to 25 (1/12 to 1")

Materials:

• Sensor housing: stainless steel 1.4301 (304)

• Measuring tubes: stainless steel, 1.4301 (304)

• Liner: PFA (USP Class VI; FDA 21 CFR 177.1550; 3A)

• Electrodes: stainless steel 1.4435 (F316L); Alloy C22, 2.4602 (UNS

A0017702

N06022); tantalum; platinum

• Process connections: stainless steel, 1.4404 (F316L); PVDF; PVC

adhesive sleeve

• Seals: EPDM, FKM, Kalrez

• Grounding rings (only for DN 02 to 25 (1/12 to 1")): stainless steel,

1.4435 (F316L); Alloy C22, 2.4602 (UNS N06022); tantalum

Safety IT security

We only provide a warranty if the device is installed and used as described in the Operating

Instructions. The device is equipped with security mechanisms to protect it against any inadvertent

changes to the device settings.

IT security measures in line with operators' security standards and designed to provide additional

protection for the device and device data transfer must be implemented by the operators themselves.

Input

Measured variable Direct measured variables

Volume flow (proportional to induced voltage)

Calculated measured variables

Mass flow

Measuring range

Typically v = 0.01 to 10 m/s (0.03 to 33 ft/s) with the specified accuracy

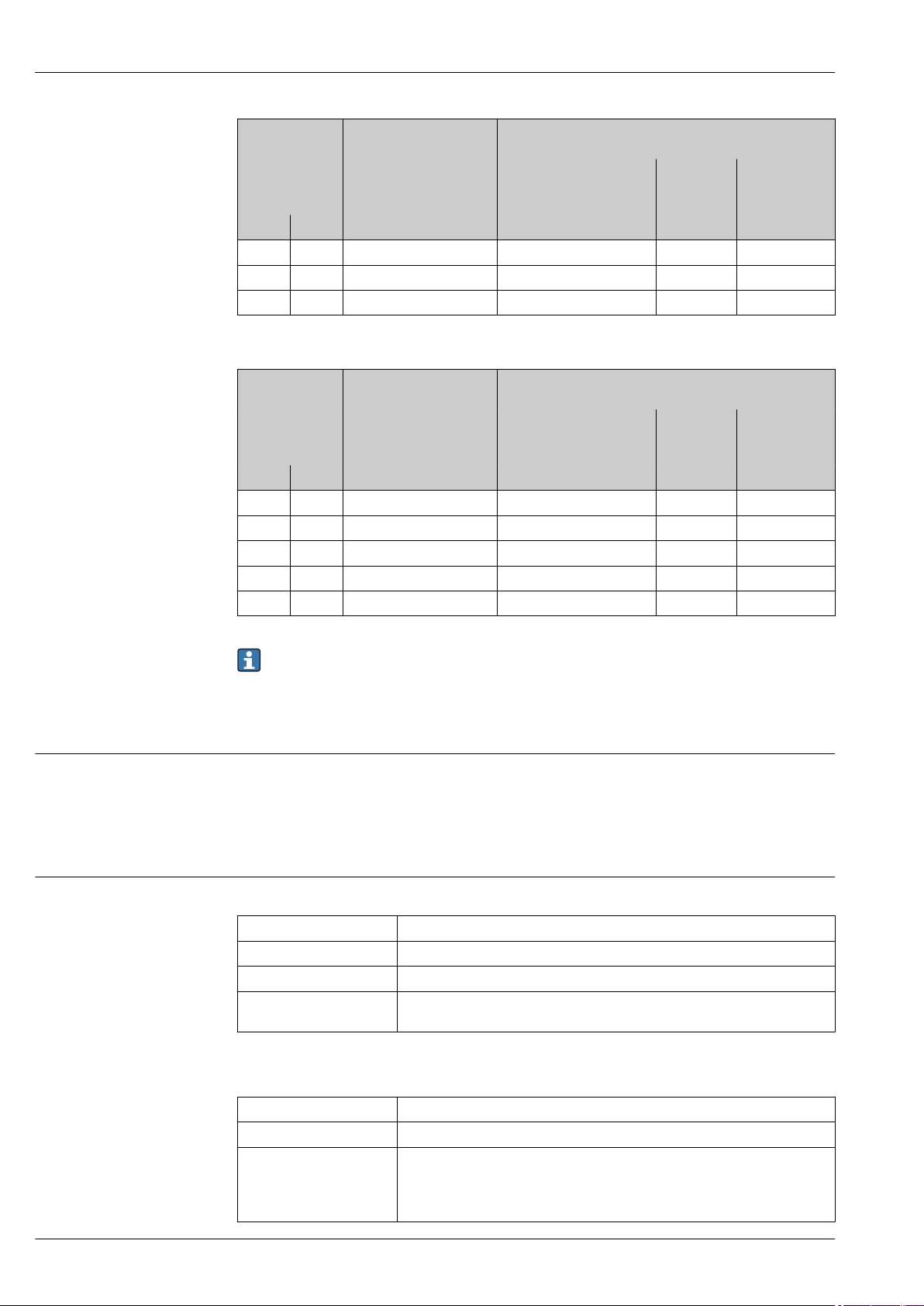

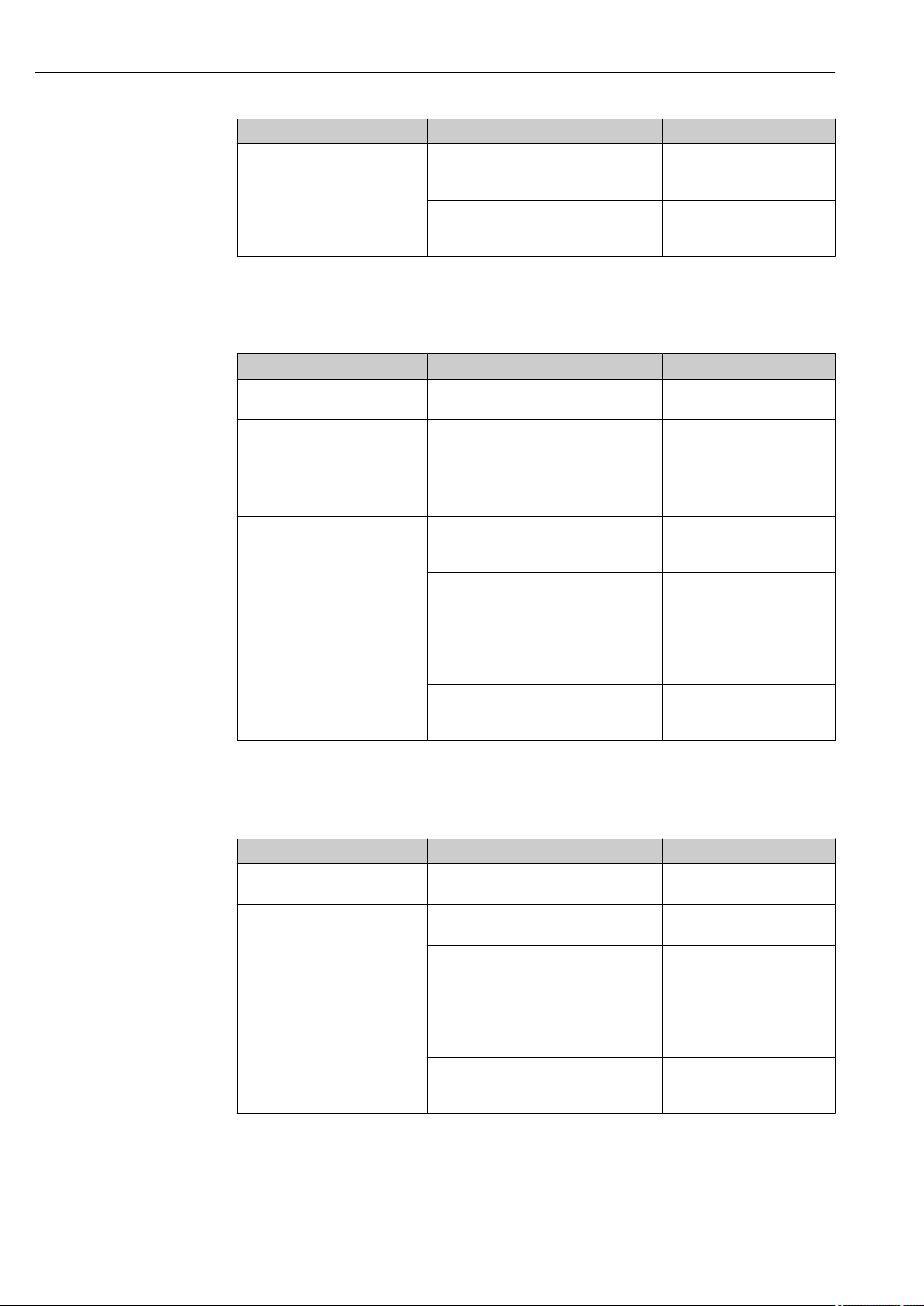

Flow characteristic values in SI units

Nominal

diameter

[mm] [in] [dm3/min] [dm3/min] [dm3] [dm3/min]

2 1/12 0.06 to 1.8 0,5 0.005 0,01

4 1/8 0.25 to 7 2 0.025 0,05

Recommended

Min./max. full scale value

(v ~ 0.3/10 m/s)

flow

Factory settings

Full scale value current

output

(v ~ 2.5 m/s)

Pulse value

(~ 2 pulse/s)

Low flow cut off

(v ~ 0.04 m/s)

Endress+Hauser 5

Proline Promag H 200

Nominal

diameter

[mm] [in] [dm3/min] [dm3/min] [dm3] [dm3/min]

8 3/8 1 to 30 8 0.1 0,1

15 ½ 4 to 100 25 0.2 0,5

25 1 9 to 300 75 0.5 1

Recommended

flow

Min./max. full scale value

(v ~ 0.3/10 m/s)

Factory settings

Full scale value current

output

(v ~ 2.5 m/s)

Pulse value

(~ 2 pulse/s)

Low flow cut off

(v ~ 0.04 m/s)

Flow characteristic values in US units

Nominal

diameter

[in] [mm] [gal/min] [gal/min] [gal] [gal/min]

1/12 2 0.015 to 0.5 0,1 0,001 0,002

1/8 4 0.07 to 2 0,5 0,005 0,008

3/8 8 0.25 to 8 2 0,02 0,025

½ 15 1 to 27 6 0,05 0,1

1 25 2.5 to 80 18 0,2 0,25

Recommended

flow

Min./max. full scale value

(v ~ 0.3/10 m/s)

Factory settings

Full scale value current

output

(v ~ 2.5 m/s)

Pulse value

(~ 2 pulse/s)

Low flow cut off

(v ~ 0.04 m/s)

To calculate the measuring range, use the Applicator sizing tool → 68

Recommended measuring range

"Flow limit" section → 34

Operable flow range

Over 1000 : 1

Output

Output signal Current output

Current output 4-20 mA HART (passive)

Resolution < 1 µA

Damping Adjustable: 0.0 to 999.9 s

Assignable measured

variables

Pulse/frequency/switch output

• Volume flow

• Mass flow

Function Can be set to pulse, frequency or switch output

Version Passive, open collector

Maximum input values • DC 35 V

• 50 mA

For information on the Ex connection values → 9

6 Endress+Hauser

Proline Promag H 200

Voltage drop • For ≤ 2 mA: 2 V

• For 10 mA: 8 V

Residual current ≤ 0.05 mA

Pulse output

Pulse width Adjustable: 5 to 2 000 ms

Maximum pulse rate 100 Impulse/s

Pulse value Adjustable

Assignable measured

variables

Frequency output

Output frequency Adjustable: 0 to 1 000 Hz

Damping Adjustable: 0 to 999 s

Pulse/pause ratio 1:1

Assignable measured

variables

Switch output

Switching behavior Binary, conductive or non-conductive

Switching delay Adjustable: 0 to 100 s

Number of switching

cycles

Assignable functions • Off

• Volume flow

• Mass flow

• Volume flow

• Mass flow

Unlimited

• On

• Diagnostic behavior

• Limit value

– Volume flow

– Mass flow

• Flow direction monitoring

• Status

– Empty pipe detection

– Low flow cut off

Signal on alarm

FOUNDATION Fieldbus

Signal encoding Manchester Bus Powered (MBP)

Data transfer 31.25 KBit/s, Voltage mode

PROFIBUS PA

Signal encoding Manchester Bus Powered (MBP)

Data transfer 31.25 KBit/s, Voltage mode

Depending on the interface, failure information is displayed as follows:

Current output

HART

Device diagnostics Device condition can be read out via HART Command 48

Endress+Hauser 7

Pulse/frequency/switch output

Pulse output

Failure mode Choose from:

• Actual value

• No pulses

Frequency output

Failure mode Choose from:

• Actual value

• 0 Hz

• Defined value: 0 to 1 250 Hz

Switch output

Failure mode Choose from:

• Current status

• Open

• Closed

Proline Promag H 200

FOUNDATION Fieldbus

Status and alarm

messages

Error current FDE (Fault

Disconnection Electronic)

Diagnostics in accordance with FF-912

0 mA

PROFIBUS PA

Status and alarm

messages

Error current FDE (Fault

Disconnection Electronic)

Diagnostics in accordance with PROFIBUS PA Profile 3.02

0 mA

Local display

Plain text display With information on cause and remedial measures

Backlight Additionally for device version with SD03 local display: red lighting indicates a

device error.

Status signal as per NAMUR recommendation NE 107

Operating tool

• Via digital communication:

– HART protocol

– FOUNDATION Fieldbus

– PROFIBUS PA

• Via service interface

Plain text display With information on cause and remedial measures

Additional information on remote operation → 61

8 Endress+Hauser

Proline Promag H 200

0

100

200

300

400

500

14

16 18 20

22 24

26 28 30 32

U [V]

s

R [ ]bW

1.1 1.21

34 36

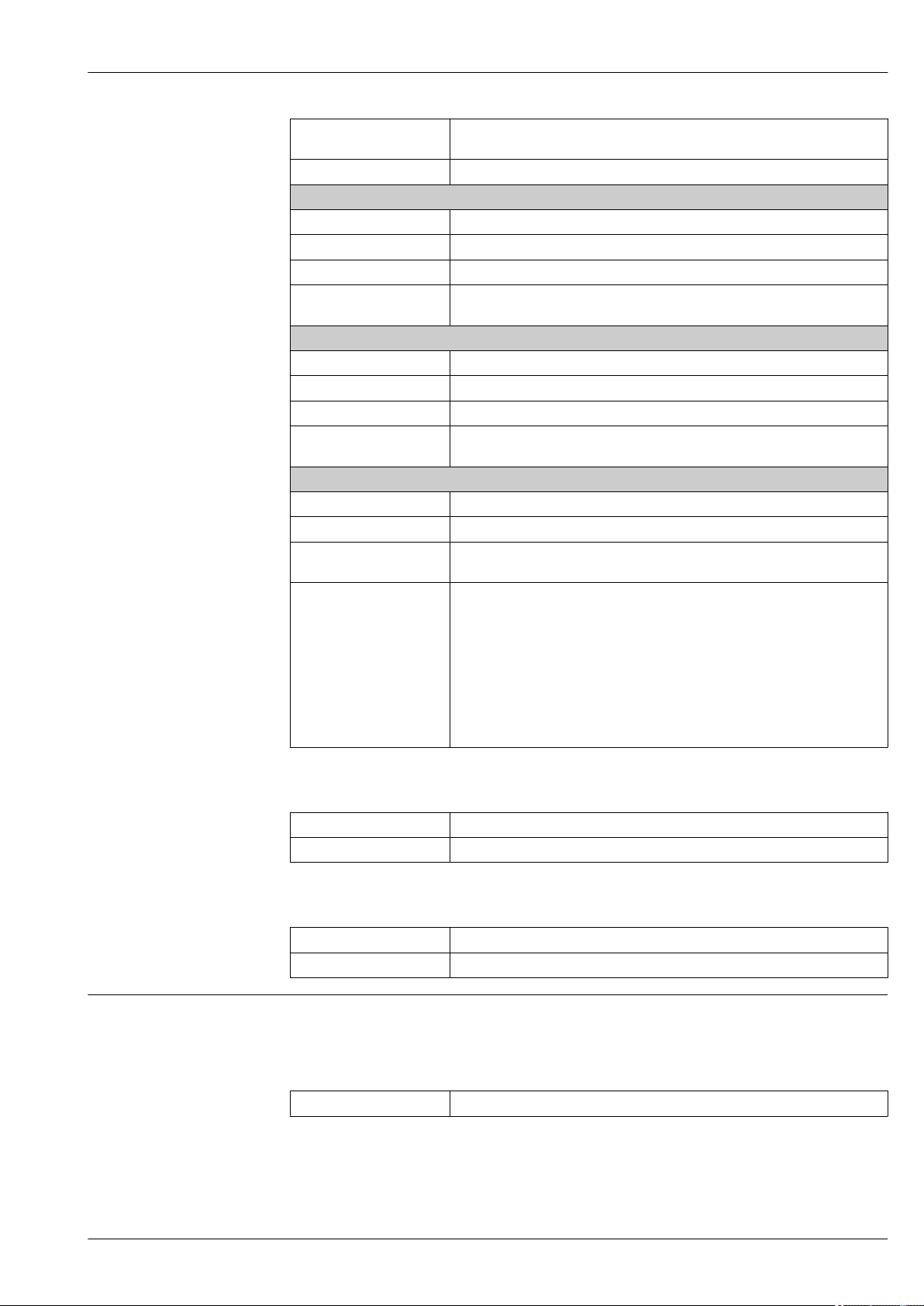

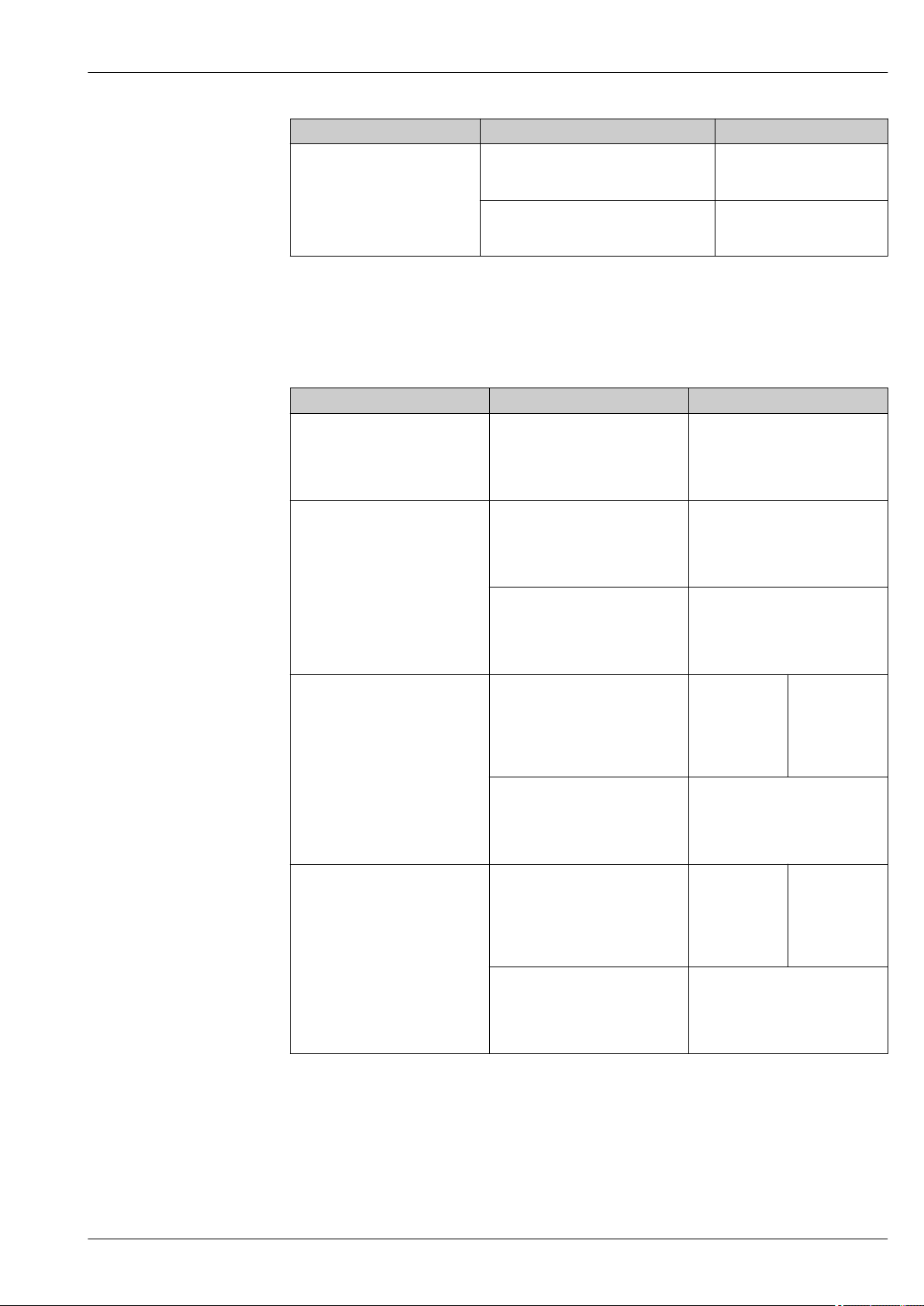

Load

Load for current output: 0 to 500 Ω, depending on the external supply voltage of the power supply

unit

Calculation of the maximum load

Depending on the supply voltage of the power supply unit (US), the maximum load (RB) including

line resistance must be observed to ensure adequate terminal voltage at the device. In doing so,

observe the minimum terminal voltage

• For US = 18 to 18.9 V: RB ≤ (US - 18 V): 0.0036 A

• For US = 18.9 to 24.5 V: RB ≤ (US - 13.5 V): 0.022 A

• For US = 24.5 to 30 V: RB ≤ 500 Ω

A0013563

1 Operating range

1.1 For order code for "Output", option A "4-20 mA HART"/option B "4-20 mA HART, pulse/frequency/switch

output" with Ex i

1.2 For order code for "Output", option A "4-20 mA HART"/option B "4-20 mA HART, pulse/frequency/switch

output" with non-Ex and Ex d

Sample calculation

Supply voltage of the power supply unit: US = 19 V

Maximum load: RB ≤ (19 V - 13.5 V): 0.022 A = 250 Ω

Ex connection data Safety-related values

Type of protection Ex d

Order code for "Output" Output type Safety-related values

Option A 4-20mA HART U

Option B 4-20mA HART U

Option E FOUNDATION Fieldbus U

Pulse/frequency/switch output U

Pulse/frequency/switch output U

nom

U

max

nom

U

max

nom

U

max

P

max

nom

U

max

P

max

nom

U

max

P

max

= DC 35 V

= 250 V

= DC 35 V

= 250 V

= DC 35 V

= 250 V

1)

= 1 W

= DC 32 V

= 250 V

= 0.88 W

= DC 35 V

= 250 V

1)

= 1 W

Endress+Hauser 9

Proline Promag H 200

Order code for "Output" Output type Safety-related values

Option G PROFIBUS PA U

Pulse/frequency/switch output U

1) Internal circuit limited by Ri = 760.5 Ω

Ex nA type of protection

Order code for "Output" Output type Safety-related values

Option A 4-20mA HART U

Option B 4-20mA HART U

Pulse/frequency/switch output U

Option E FOUNDATION Fieldbus U

Pulse/frequency/switch output U

Option G PROFIBUS PA U

Pulse/frequency/switch output U

nom

U

max

P

max

nom

U

max

P

max

nom

U

max

nom

U

max

nom

U

max

P

max

nom

U

max

P

max

nom

U

max

P

max

nom

U

max

P

max

nom

U

max

P

max

= DC 32 V

= 250 V

= 0.88 W

= DC 35 V

= 250 V

1)

= 1 W

= DC 35 V

= 250 V

= DC 35 V

= 250 V

= DC 35 V

= 250 V

1)

= 1 W

= DC 32 V

= 250 V

= 0.88 W

= DC 35 V

= 250 V

1)

= 1 W

= DC 32 V

= 250 V

= 0.88 W

= DC 35 V

= 250 V

1)

= 1 W

1) Internal circuit limited by Ri = 760.5 Ω

Type of protection XP

Order code for "Output" Output type Safety-related values

Option A 4-20mA HART U

Option B 4-20mA HART U

Pulse/frequency/switch output U

Option E FOUNDATION Fieldbus U

Pulse/frequency/switch output U

nom

U

max

nom

U

max

nom

U

max

P

max

nom

U

max

P

max

nom

U

max

P

max

= DC 35 V

= 250 V

= DC 35 V

= 250 V

= DC 35 V

= 250 V

1)

= 1 W

= DC 32 V

= 250 V

= 0.88 W

= DC 35 V

= 250 V

1)

= 1 W

10 Endress+Hauser

Proline Promag H 200

Order code for "Output" Output type Safety-related values

Option G PROFIBUS PA U

Pulse/frequency/switch output U

nom

U

max

P

max

nom

U

max

P

max

= DC 32 V

= 250 V

= 0.88 W

= DC 35 V

= 250 V

1)

= 1 W

1) Internal circuit limited by Ri = 760.5 Ω

Intrinsically safe values

Type of protection Ex ia

Order code for "Output" Output type Intrinsically safe values

Option A 4-20mA HART Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Option B 4-20mA HART Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Pulse/frequency/switch output Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 6 nF

Option E FOUNDATION Fieldbus STANDARD

Ui = 30 V

li = 300 mA

Pi = 1.2 W

Li = 10 µH

Ci = 5 nF

Pulse/frequency/switch output Ui = 30 V

li = 300 mA

Pi = 1 W

Li = 0 µH

Ci = 6 nF

Option G PROFIBUS PA STANDARD

Ui = 30 V

li = 300 mA

Pi = 1.2 W

Li = 10 µH

Ci = 5 nF

Pulse/frequency/switch output Ui = 30 V

li = 300 mA

Pi = 1 W

Li = 0 µH

Ci = 6 nF

FISCO

Ui = 17.5 V

li = 550 mA

Pi = 5.5 W

Li = 10 µH

Ci = 5 nF

FISCO

Ui = 17.5 V

li = 550 mA

Pi = 5.5 W

Li = 10 µH

Ci = 5 nF

Endress+Hauser 11

Proline Promag H 200

Type of protection Ex ic

Order code for "Output" Output type Intrinsically safe values

Option A 4-20mA HART Ui = DC 35 V

Ii = n.a.

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Option B 4-20mA HART Ui = DC 35 V

Ii = n.a.

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Pulse/frequency/switch output Ui = DC 35 V

Ii = n.a.

Pi = 1 W

Li = 0 μH

Ci = 6 nF

Option E FOUNDATION Fieldbus STANDARD

Ui = 32 V

li = 300 mA

Pi = n.a.

Li = 10 µH

Ci = 5 nF

Pulse/frequency/switch output Ui = 35 V

li = 300 mA

Pi = 1 W

Li = 0 µH

Ci = 6 nF

Option G PROFIBUS PA STANDARD

Ui = 32 V

li = 300 mA

Pi = n.a.

Li = 10 µH

Ci = 5 nF

Pulse/frequency/switch output Ui = 35 V

li = 300 mA

Pi = 1 W

Li = 0 µH

Ci = 6 nF

FISCO

Ui = 17.5 V

li = n.a.

Pi = n.a.

Li = 10 µH

Ci = 5 nF

FISCO

Ui = 17.5 V

li = n.a.

Pi = n.a.

Li = 10 µH

Ci = 5 nF

Type of protection IS

Order code for "Output" Output type Intrinsically safe values

Option A 4-20mA HART Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Option B 4-20mA HART Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 5 nF

Pulse/frequency/switch output Ui = DC 30 V

Ii = 300 mA

Pi = 1 W

Li = 0 μH

Ci = 6 nF

12 Endress+Hauser

Proline Promag H 200

Order code for "Output" Output type Intrinsically safe values

Option E FOUNDATION Fieldbus STANDARD

Ui = 30 V

li = 300 mA

Pi = 1.2 W

Li = 10 µH

Ci = 5 nF

Pulse/frequency/switch output Ui = 30 V

li = 300 mA

Pi = 1 W

Li = 0 µH

Ci = 6 nF

Option G PROFIBUS PA STANDARD

Ui = 30 V

li = 300 mA

Pi = 1.2 W

Li = 10 µH

Ci = 5 nF

Pulse/frequency/switch output Ui = 30 V

li = 300 mA

Pi = 1 W

Li = 0 µH

Ci = 6 nF

FISCO

Ui = 17.5 V

li = 550 mA

Pi = 5.5 W

Li = 10 µH

Ci = 5 nF

FISCO

Ui = 17.5 V

li = 550 mA

Pi = 5.5 W

Li = 10 µH

Ci = 5 nF

Low flow cut off

Galvanic isolation

The switch points for low flow cut off are user-selectable.

All outputs are galvanically isolated from one another.

Protocol-specific data HART

Manufacturer ID 0x11

Device type ID 0x48

HART protocol revision 7

Device description files

(DTM, DD)

HART load • Min. 250 Ω

Dynamic variables Read out the dynamic variables: HART command 3

Device variables Read out the device variables: HART command 9

Information and files under:

www.endress.com

• Max. 500 Ω

The measured variables can be freely assigned to the dynamic variables.

Measured variables for PV (primary dynamic variable)

• Off

• Volume flow

• Mass flow

Measured variables for SV, TV, QV (secondary, tertiary and quaternary

dynamic variable)

• Volume flow

• Mass flow

• Totalizer 1

• Totalizer 2

• Totalizer 3

The device variables are permanently assigned.

FOUNDATION Fieldbus

Manufacturer ID 0x452B48

Ident number 0x1048

Device revision 1

Endress+Hauser 13

DD revision Information and files under:

CFF revision

Device Tester Version (ITK

version)

ITK Test Campaign Number IT094200

Link Master capability (LAS) Yes

Choice of "Link Master" and

"Basic Device"

Node address Factory setting: 247 (0xF7)

Supported functions The following methods are supported:

Virtual Communication Relationships (VCRs)

Number of VCRs 44

Number of link objects in VFD 50

Permanent entries 1

Client VCRs 0

Server VCRs 10

Source VCRs 43

Sink VCRs 0

Subscriber VCRs 43

Publisher VCRs 43

Device Link Capabilities

Slot time 4

Min. delay between PDU 8

Max. response delay Min. 5

• www.endress.com

• www.fieldbus.org

6.1.1

Yes

Factory setting: Basic Device

• Restart

• ENP Restart

• Diagnostic

Proline Promag H 200

Transducer Blocks

Block Contents Output values

Setup Transducer Block

(TRDSUP)

Advanced Setup

Transducer Block

(TRDASUP)

Display Transducer

Block

(TRDDISP)

HistoROM Transducer

Block

(TRDHROM)

Diagnostic Transducer

Block

(TRDDIAG)

Expert Configuration

Transducer Block

(TRDEXP)

All parameters for standard commissioning. No output values

All parameters for more accurate measurement

configuration.

Parameters for configuring the local display. No output values

Parameters for using the HistoROM function. No output values

Diagnostics information. Process variables (AI Channel)

Parameters that require the user to have indepth knowledge of the operation of the device

in order to configure the parameters

appropriately.

No output values

• Temperature (7)

• Volume flow (9)

• Mass flow (11)

No output values

14 Endress+Hauser

Proline Promag H 200

Block Contents Output values

Expert Information

Transducer Block

(TRDEXPIN)

Service Sensor

Transducer Block

(TRDSRVS)

Service Information

Transducer Block

(TRDSRVIF)

Total Inventory

Counter Transducer

Block

(TRDTIC)

Heartbeat Technology

Transducer Block

(TRDHBT)

Heartbeat Results 1

Transducer Block

(TRDHBTR1)

Heartbeat Results 2

Transducer Block

(TRDHBTR2)

Heartbeat Results 3

Transducer Block

(TRDHBTR3)

Heartbeat Results 4

Transducer Block

(TRDHBTR4)

Parameters that provide information about the

state of the device.

Parameters that can only be accessed by Endress

+Hauser Service.

Parameters that provide Endress+Hauser Service

with information about the state of the device.

Parameters for configuring all the totalizers and

the inventory counter.

Parameters for the configuration and

comprehensive information about the results of

the verification.

Information about the results of the verification. No output values

Information about the results of the verification. No output values

Information about the results of the verification. No output values

Information about the results of the verification. No output values

No output values

No output values

No output values

Process variables (AI Channel)

• Totalizer 1 (16)

• Totalizer 2 (17)

• Totalizer 3 (18)

No output values

Function blocks

Block Number

of

blocks

Resource Block

(RB)

Analog Input

Block

(AI)

Discrete Input

Block

(DI)

PID Block

(PID)

1 This Block (extended functionality) contains

4 This Block (extended functionality) receives

2 This Block (standard functionality) receives a

1 This Block (standard functionality) acts as a

Contents Process variables (Channel)

–

all the data that uniquely identify the device; it

is the equivalent of an electronic nameplate

for the device.

Process variables (AI Channel)

the measurement data provided by the Sensor

Block (can be selected via a channel number)

and makes the data available for other blocks

at the output.

Execution time: 25 ms

discrete value (e.g. indicator that measuring

range has been exceeded) and makes the

value available for other blocks at the output.

Execution time: 19 ms

proportional-integral-differential controller

and can be used universally for control in the

field. It enables cascading and feedforward

control.

Execution time: 25 ms

• Temperature (7)

• Volume flow (9)

• Mass flow (11)

• Switch output state (101)

• Empty pipe detection (102)

• Low flow cut off (103)

• Status verification (105)

–

Endress+Hauser 15

Proline Promag H 200

Block Number

of

blocks

Multiple Digital

Output Block

(MDO)

Integrator Block

(IT)

1 This Block (standard functionality) receives

1 This Block (standard functionality) integrates

PROFIBUS PA

Contents Process variables (Channel)

Channel_DO (122)

several discrete values and makes them

available for other blocks at the output.

Execution time: 19 ms

a measured variable over time or totalizes the

pulses from a Pulse Input Block. The Block can

be used as a totalizer that totalizes until a

reset, or as a batch totalizer whereby the

integrated value is compared against a target

value generated before or during the control

routine and generates a binary signal when

the target value is reached.

Execution time: 21 ms

• Value 1: Reset totalizer 1

• Value 2: Reset totalizer 2

• Value 3: Reset totalizer 3

• Value 4: Flow override

• Value 5: Start heartbeat

verification

• Value 6: Status switch output

• Value 7: Not assigned

• Value 8: Not assigned

–

Manufacturer ID 0x11

Ident number 0x1563

Profile version 3.02

Device description files (GSD,

DTM, DD)

Output values

(from measuring device to

automation system)

Input values

(from automation system to

measuring device)

Information and files under:

• www.endress.com

• www.profibus.org

Analog input 1 to 2

• Mass flow

• Volume flow

Digital input 1 to 2

• Empty pipe detection

• Low flow cut off

• Status switch output

• Status verification

Totalizer 1 to 3

• Mass flow

• Volume flow

• Corrected volume flow

Digital output 1 to 3 (fixed assignment)

• Digital output 1: switch positive zero return on/off

• Digital output 2: switch switch output on/off

• Digital output 3: start verification

Totalizer 1 to 3

• Totalize

• Reset and hold

• Preset and hold

• Operating mode configuration:

– Net flow total

– Forward flow total

– Reverse flow total

16 Endress+Hauser

Proline Promag H 200

–

4

+

1

–

2

+

3

1

2

3

+

1

–

2

–

4

+

3

1

2

3

Supported functions • Identification & Maintenance

Configuration of the device

address

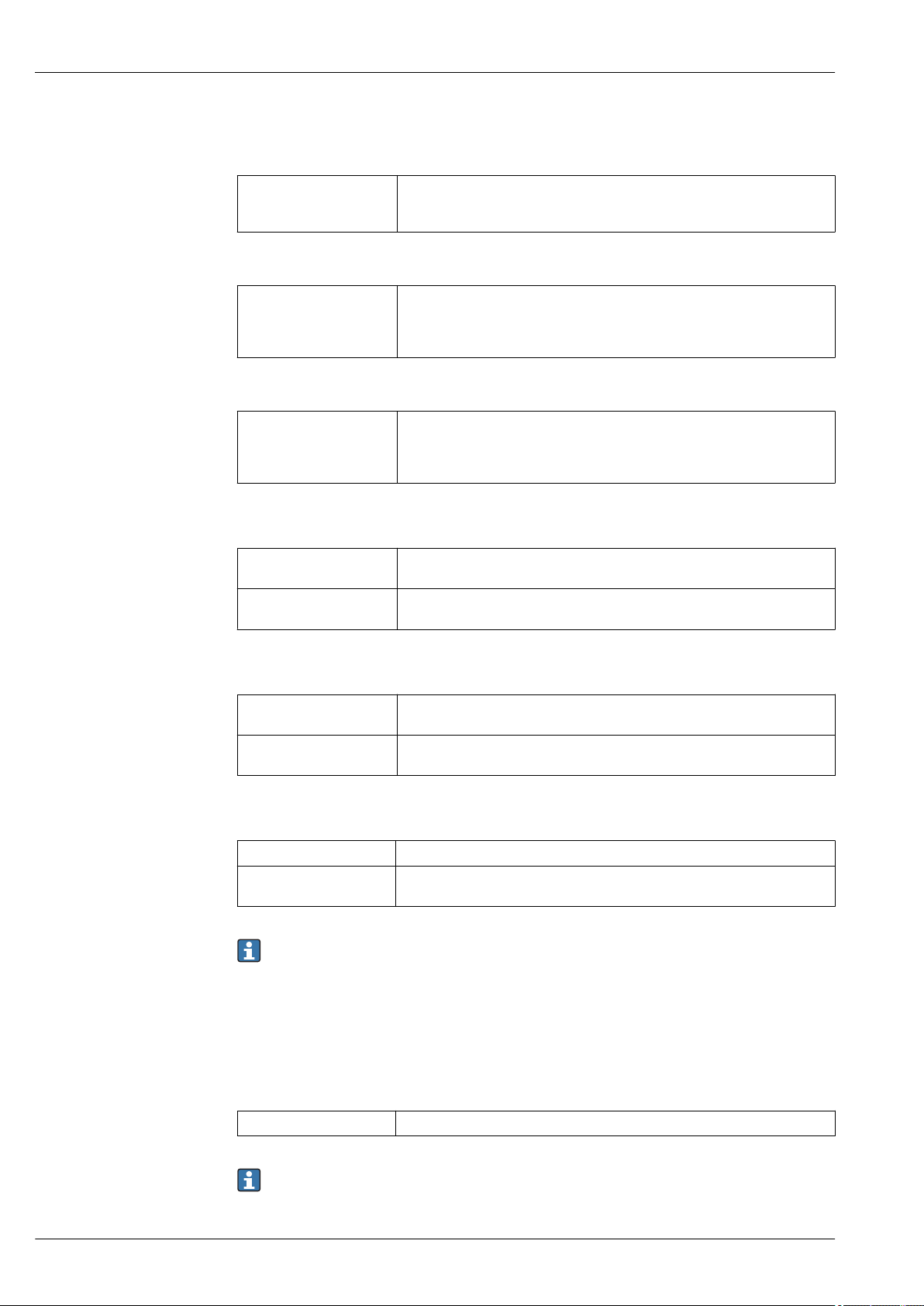

Power supply

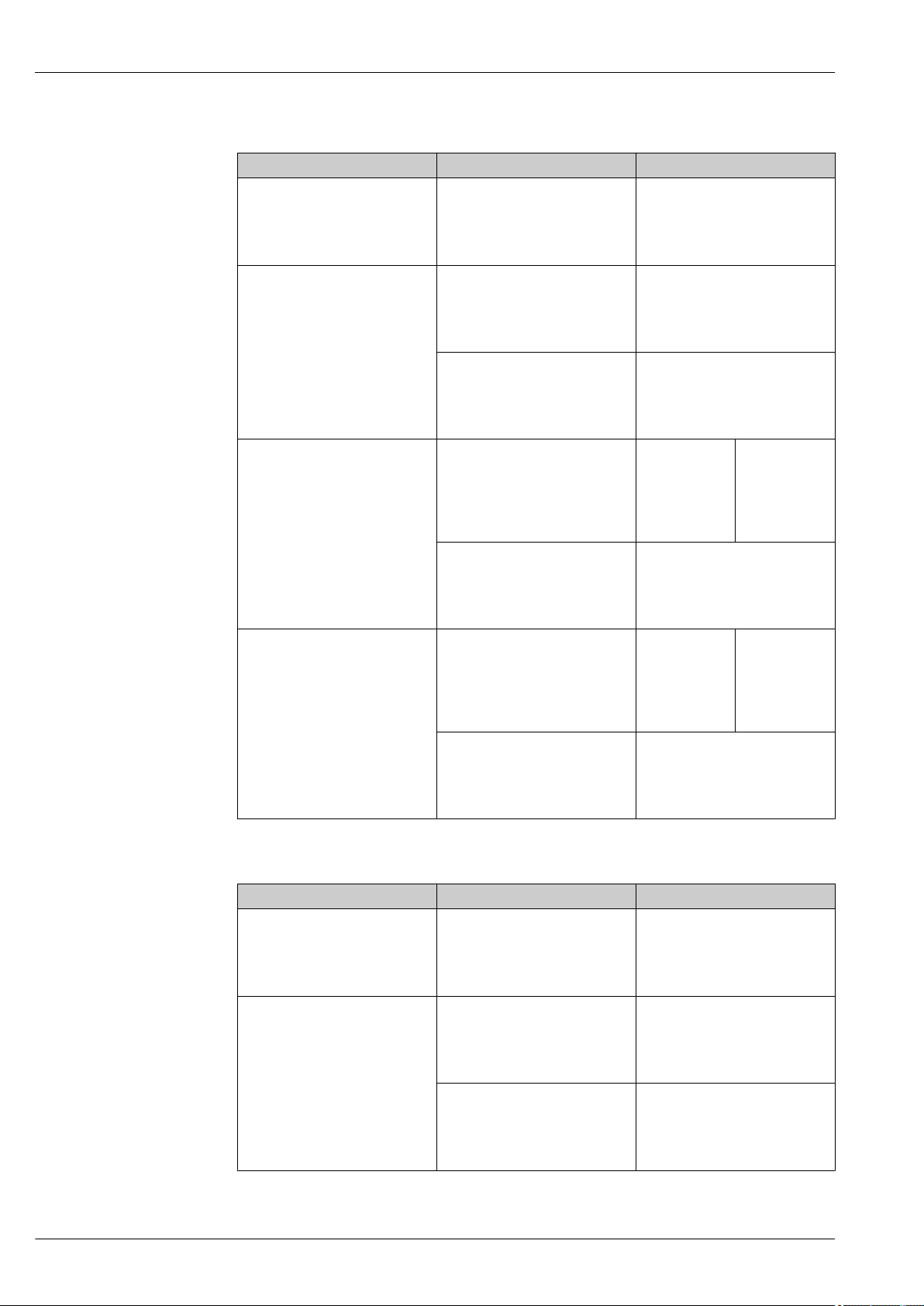

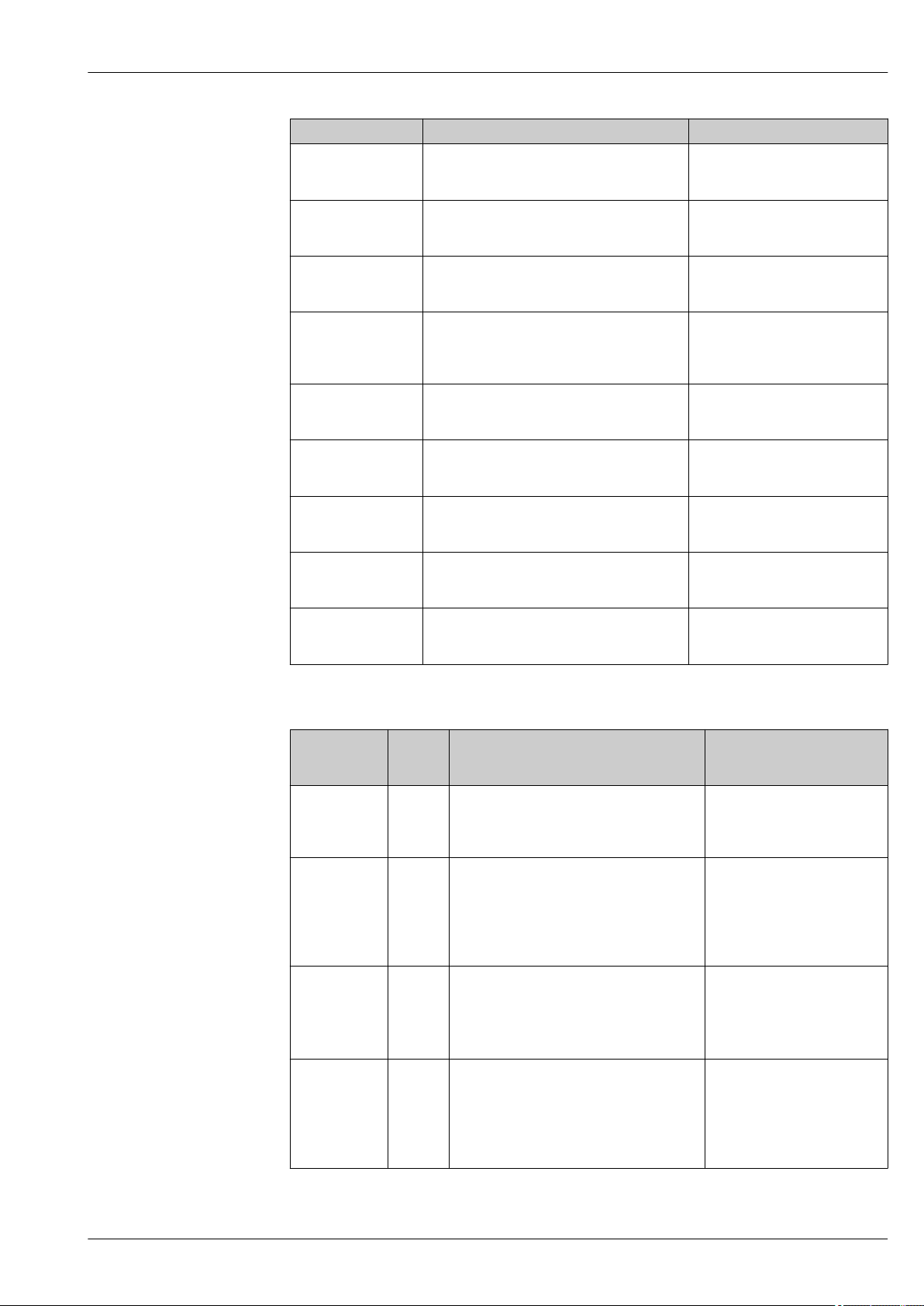

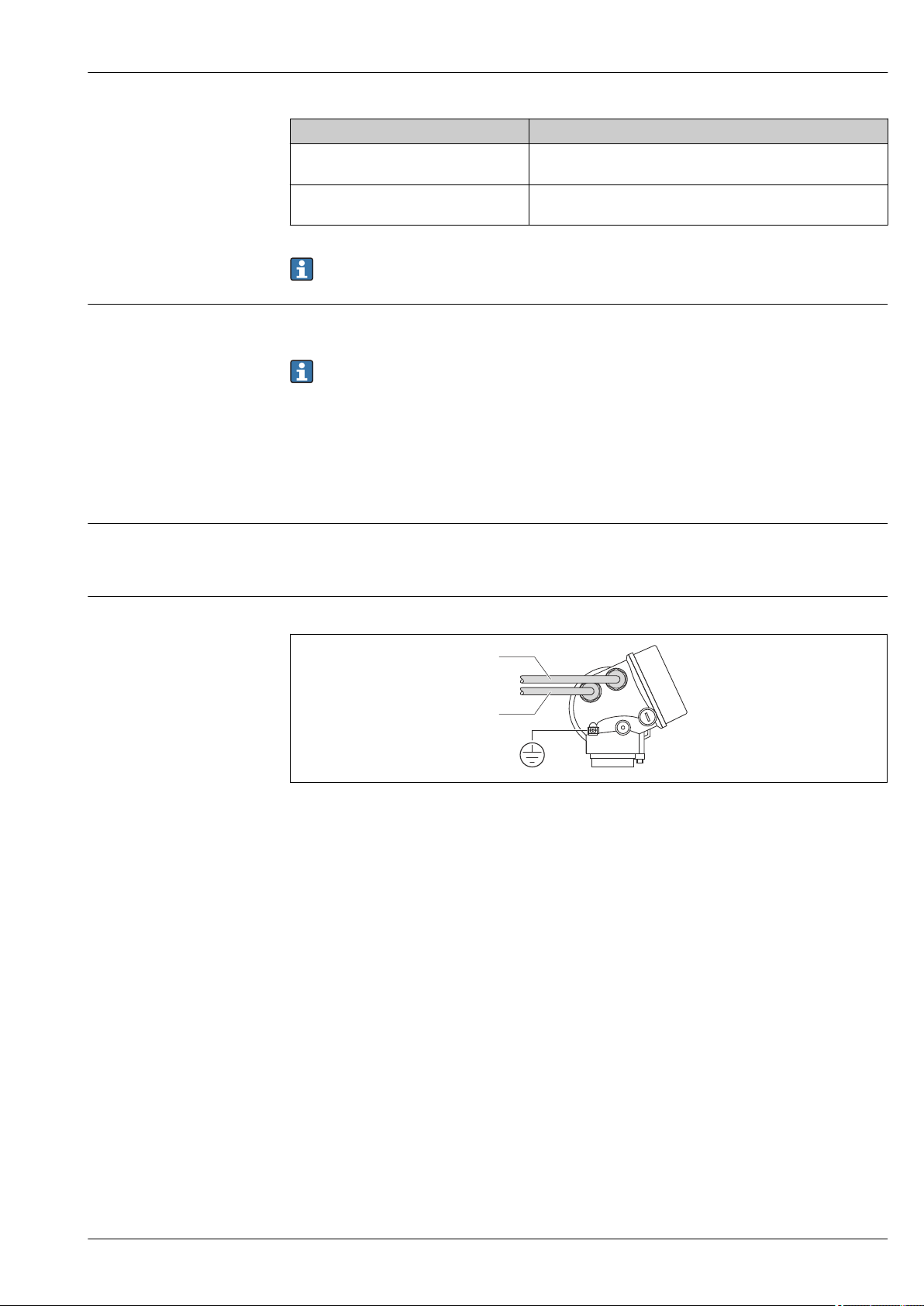

Terminal assignment Transmitter

Connection versions

Simplest device identification on the part of the control system and

nameplate

• PROFIBUS upload/download

Reading and writing parameters is up to ten times faster with PROFIBUS

upload/download

• Condensed status

Simplest and self-explanatory diagnostic information by categorizing

diagnostic messages that occur

• DIP switches on the I/O electronics module

• Local display

• via operating tools (e.g. FieldCare)

A0013570

Maximum number of terminals, without integrated

overvoltage protection

1

Output 1 (passive): supply voltage and signal transmission

2

Output 2 (passive): supply voltage and signal transmission

3

Ground terminal for cable shield

Order code for "Output" Terminal numbers

Output 1 Output 2

1 (+) 2 (-) 3 (+) 4 (-)

Option A 4-20 mA HART (passive) -

Option B

Option E

Option G

1) Output 1 must always be used; output 2 is optional.

2) FOUNDATION Fieldbus with integrated reverse polarity protection.

3) PROFIBUS PA with integrated reverse polarity protection.

1)

1) 2)

1) 3)

4-20 mA HART (passive) Pulse/frequency/switch output

FOUNDATION Fieldbus

PROFIBUS PA

Maximum number of terminals, with integrated

overvoltage protection

A0018161

(passive)

Pulse/frequency/switch output

(passive)

Pulse/frequency/switch output

(passive)

Endress+Hauser 17

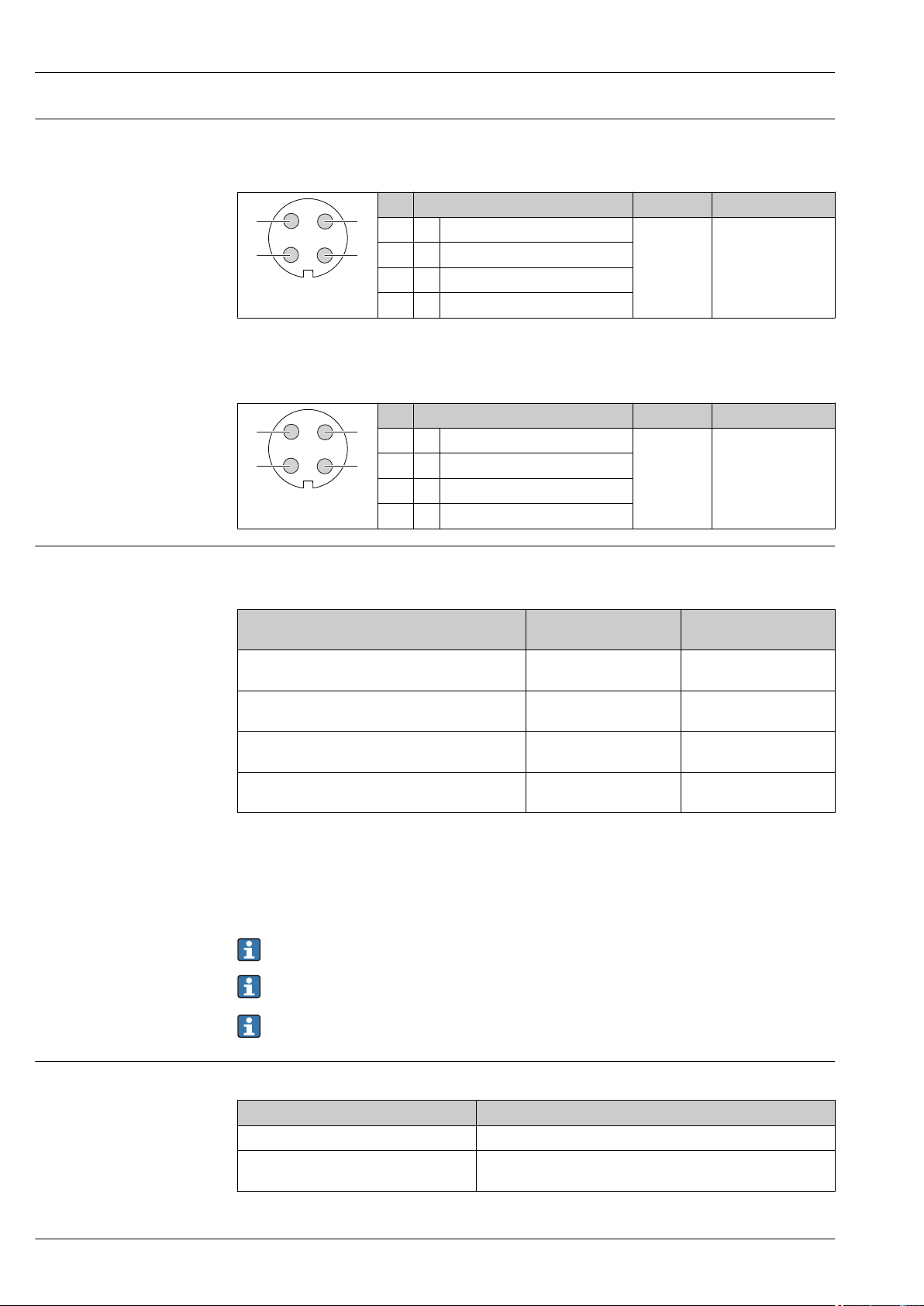

Pin assignment, device plug PROFIBUS PA

1

2

4

3

1

2

4

3

Device plug for signal transmission (device side)

FOUNDATION Fieldbus

Device plug for signal transmission (device side)

Proline Promag H 200

Pin Assignment Coding Plug/socket

1 + PROFIBUS PA + A Plug

2 Grounding

A0019021

A0019021

3 - PROFIBUS PA –

4 Not assigned

Pin Assignment Coding Plug/socket

1 + Signal + A Plug

2 - Signal –

3 Not assigned

4 Grounding

Supply voltage Transmitter

An external power supply is required for each output.

Order code for "Output"

Option A

Option B

switch output

Option E

frequency/switch output

Option G

output

1) External supply voltage of the power supply unit with load.

2) For device versions with SD03 local display: The terminal voltage must be increased by DC 2 V if

3) For device version with SD03 local display: The terminal voltage must be increased by DC 0.5 V if

1) 2)

1) 2)

3)

: FOUNDATION Fieldbus, pulse/

3)

: PROFIBUS PA, pulse/frequency/switch

backlighting is used.

backlighting is used.

For information about the load see → 9

Various power supply units can be ordered from Endress+Hauser: see "Accessories" section

→ 69

For information on the Ex connection values → 9

Minimum

terminal voltage

: 4-20 mA HART • For 4 mA: ≥ DC 18 V

• For 20 mA: ≥ DC 14 V

: 4-20 mA HART, pulse/frequency/

• For 4 mA: ≥ DC 18 V

• For 20 mA: ≥ DC 14 V

≥ DC 9 V

≥ DC 9 V

Maximum

terminal voltage

DC 35 V

DC 35 V

DC 32 V

DC 32 V

Power consumption Transmitter

Order code for "Output" Maximum power consumption

Option A: 4-20 mA HART 770 mW

Option B: 4-20 mA HART, pulse/

frequency/switch output

18 Endress+Hauser

• Operation with output 1: 770 mW

• Operation with output 1 and 2: 2 770 mW

Proline Promag H 200

1

2

Order code for "Output" Maximum power consumption

Option E: FOUNDATION Fieldbus, pulse/

frequency/switch output

Option G: PROFIBUS PA, pulse/frequency/

switch output

For information on the Ex connection values → 9

Current consumption Current output

For every 4-20 mA or 4-20 mA HART current output: 3.6 to 22.5 mA

If the option Defined value is selected in the Failure mode parameter : 3.59 to 22.5 mA

PROFIBUS PA

16 mA

FOUNDATION Fieldbus

16 mA

• Operation with output 1: 576 mW

• Operation with output 1 and 2: 2 576 mW

• Operation with output 1: 512 mW

• Operation with output 1 and 2: 2 512 mW

Power supply failure

• Totalizers stop at the last value measured.

• Configuration is retained in the device memory (HistoROM).

• Error messages (incl. total operated hours) are stored.

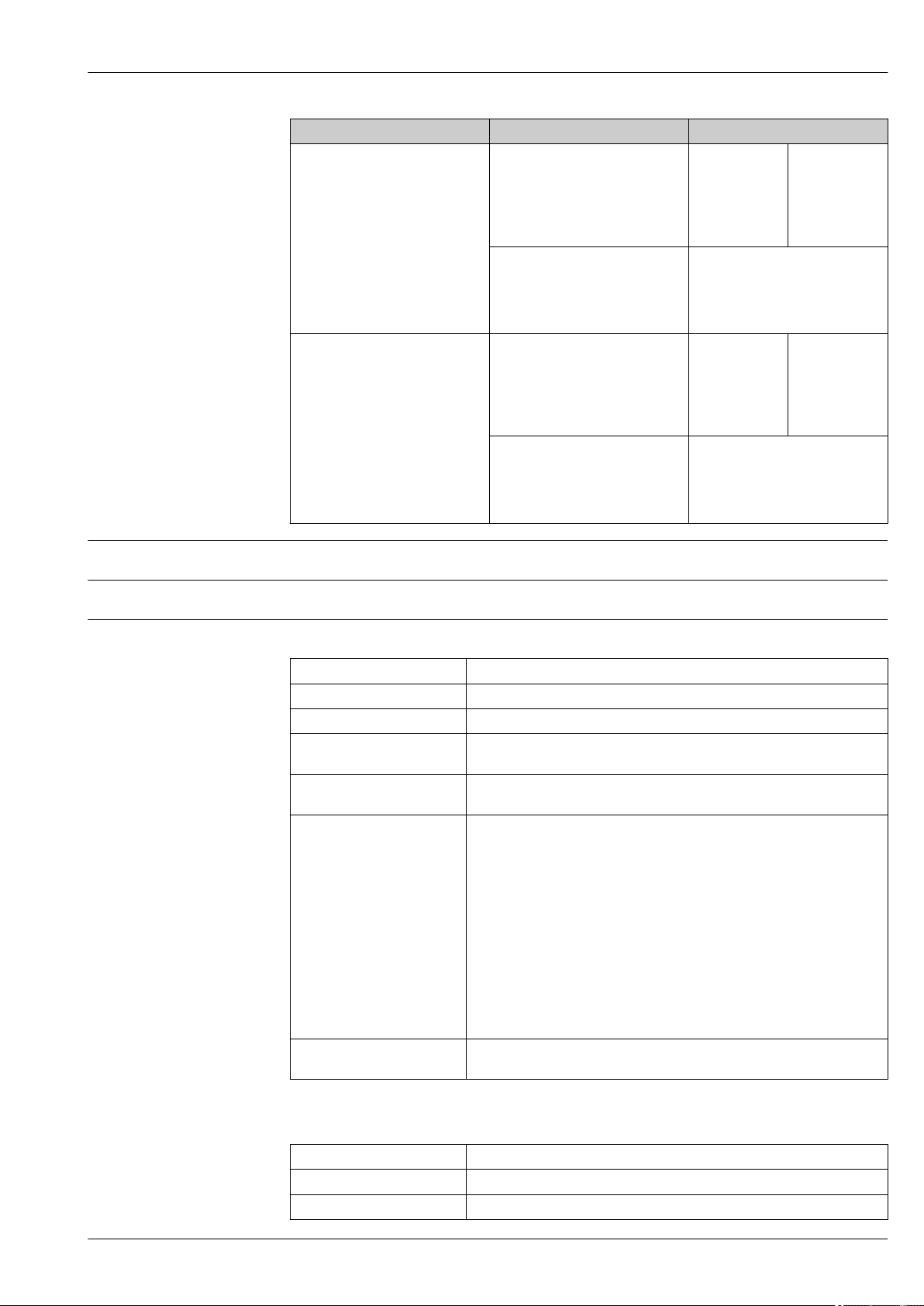

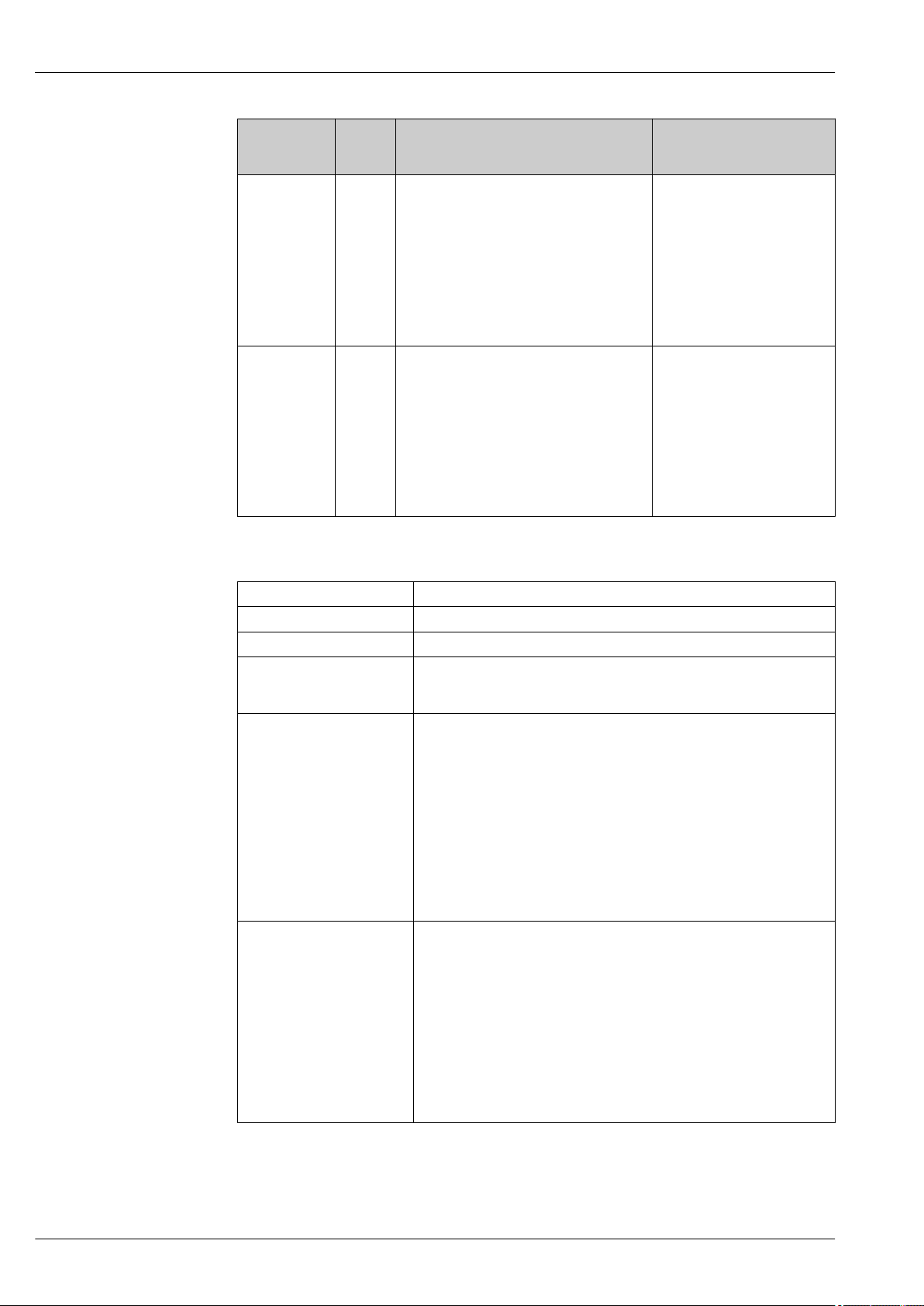

Electrical connection Connecting the transmitter

1 Cable entry for output 1

2 Cable entry for output 2

A0015510

Endress+Hauser 19

Proline Promag H 200

2

3

4...20 mA

41

+

-

5

+

-

1

+

_

12345

2

+

–

+

–

3

1

+

_

+

_

2

+

_

3

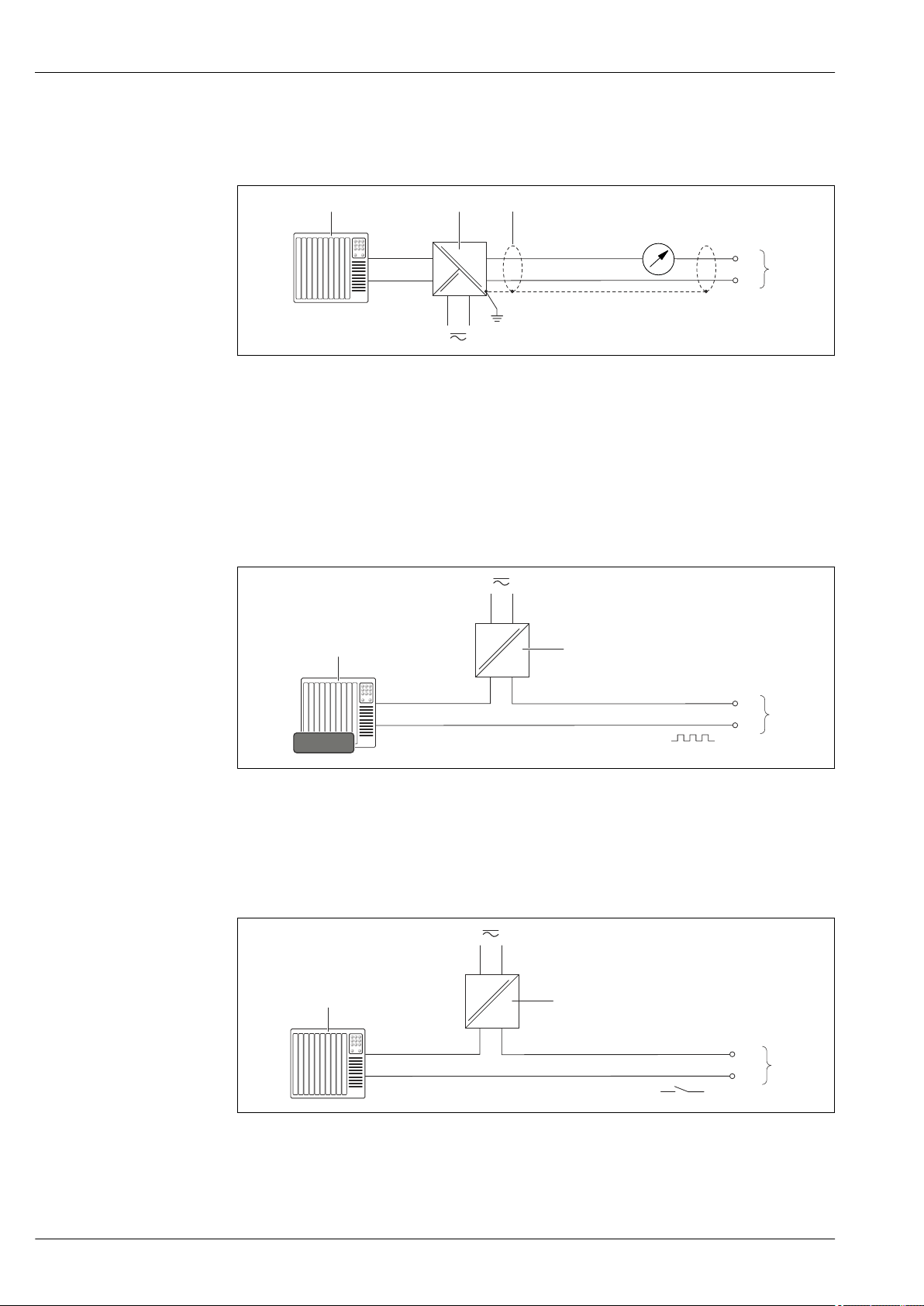

Connection examples

Current output 4-20 mA HART

A0015511

1 Connection example for 4-20 mA HART current output (passive)

1 Automation system with current input (e.g. PLC)

2 Active barrier for power supply with integrated resistor for HART communication (≥ 250 Ω)(e.g. RN221N)

Connection for HART operating devices → 61

Observe the maximum load → 9

3 Cable shield, observe cable specifications

4 Analog display unit: observe maximum load → 9

5 Transmitter

Pulse/frequency output

2 Connection example for pulse/frequency output (passive)

1 Automation system with pulse/frequency input (e.g. PLC)

2 Power supply

3 Transmitter: observe input values → 6

Switch output

A0016801

3 Connection example for switch output (passive)

1 Automation system with switch input (e.g. PLC)

20 Endress+Hauser

2 Power supply

3 Transmitter: observe input values

A0016802

Proline Promag H 200

21 3

+

-

+

-

+

-

4

5

5

78

6

6

6

6

6

6

.

-

PROFIBUS-PA

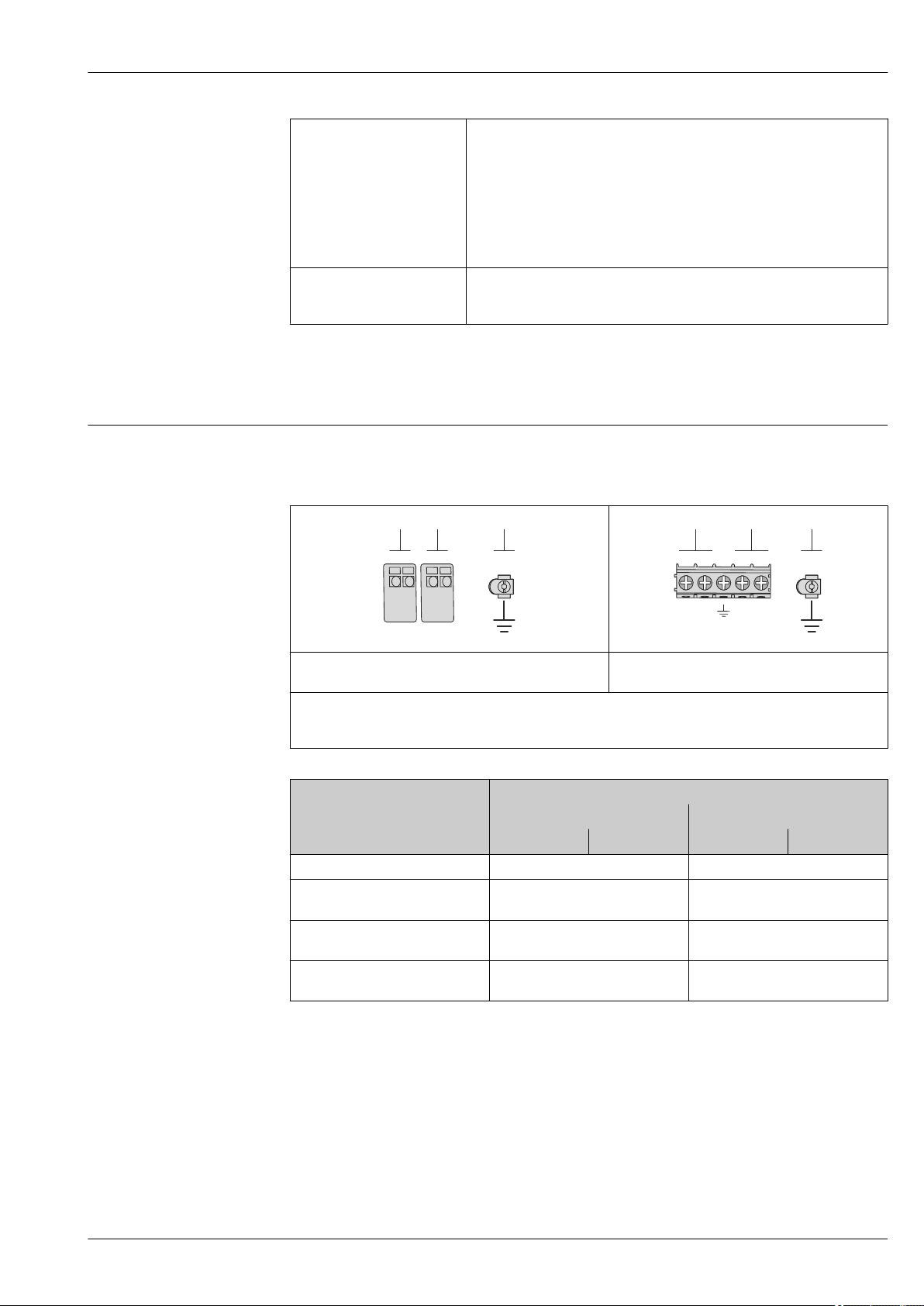

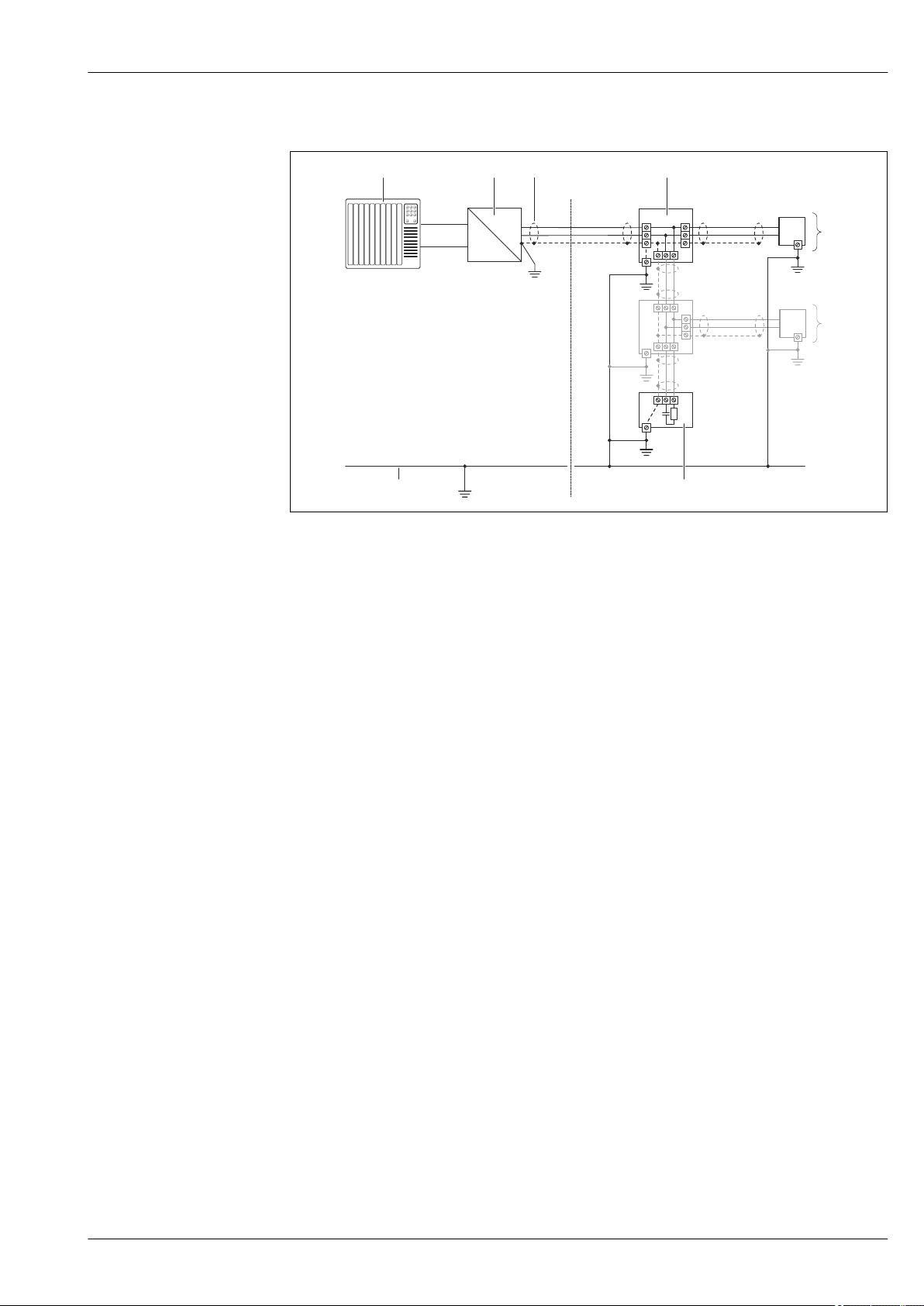

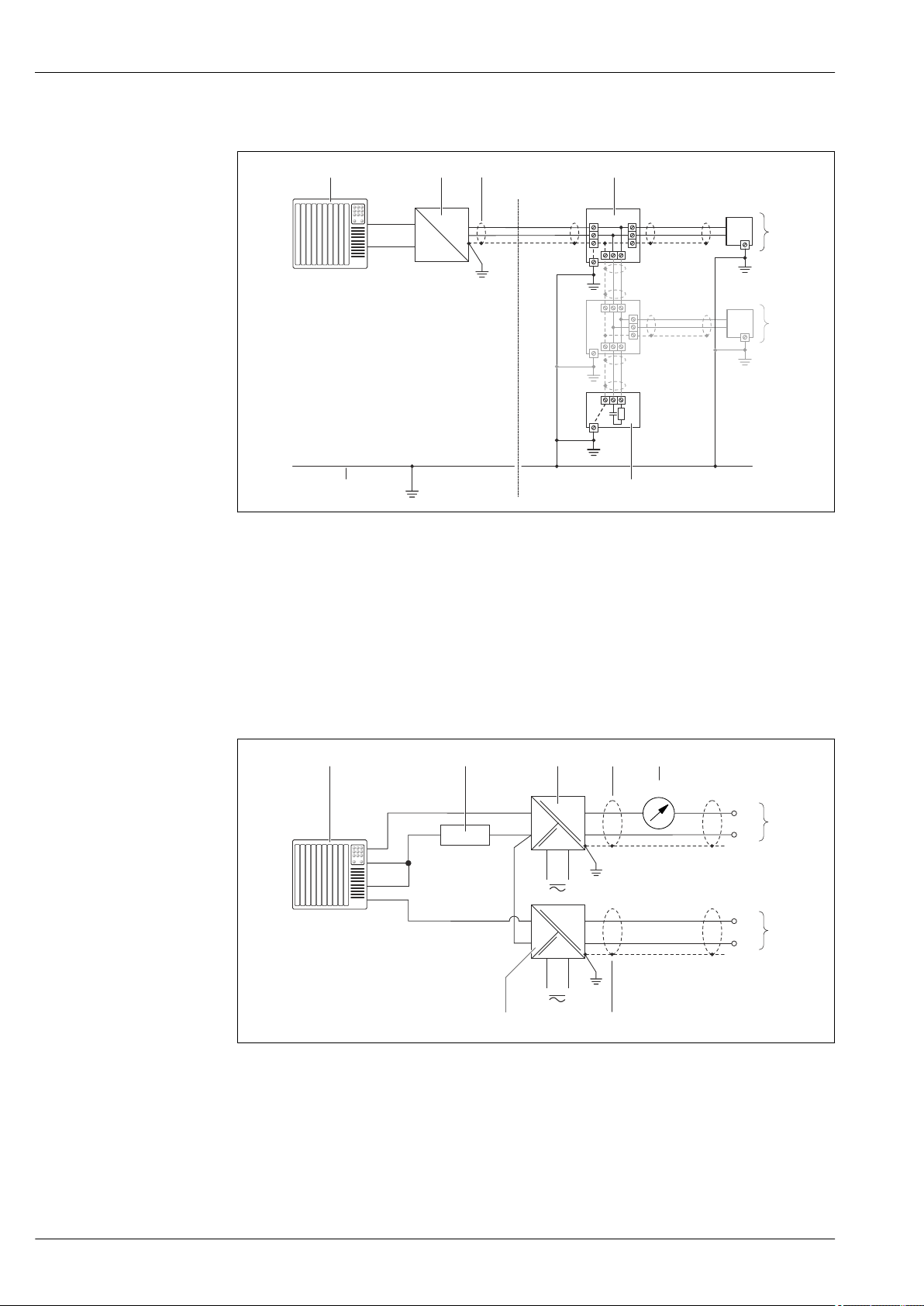

4 Connection example for PROFIBUS-PA

1 Control system (e.g. PLC)

2 Segment coupler PROFIBUS DP/PA

3 Cable shield

4 T-box

5 Measuring device

6 Local grounding

7 Bus terminator

8 Potential matching line

A0019004

Endress+Hauser 21

FOUNDATION Fieldbus

21 3

+

-

+

-

+

-

4

5

5

78

6

6

6

6

6

6

.

-

3

4...20 mA

5

1

+

-

3

6

+

–

+

+

–

+

–

+

–

+

–

–

2

4

4

7

+

-

Proline Promag H 200

5 Connection example for FOUNDATION Fieldbus

1 Control system (e.g. PLC)

2 Power Conditioner (FOUNDATION Fieldbus)

3 Cable shield

4 T-box

5 Measuring device

6 Local grounding

7 Bus terminator

8 Potential matching line

HART input

A0019004

6 Connection example for HART input with a common negative

1 Automation system with HART output (e.g. PLC)

2 Resistor for HART communication (≥ 250 Ω): observe maximum load → 9

3 Active barrier for power supply (e.g. RN221N)

4 Cable shield, observe cable specifications

5 Analog display unit: observe maximum load → 9

6 Pressure transmitter (e.g. Cerabar M, Cerabar S): see requirements

7 Transmitter

22 Endress+Hauser

A0016029

Loading...

Loading...