Page 1

Products Solutions Services

BA00236F/00/EN/14.14

71253004

Valid for software version:

V01.03.06

Operating Instructions

Gammapilot M FMG60

Radiometric Measurement

AUTHORIZED DISTRIBUTOR:

InstrumentsAndControl.com

Houston, Texas USA

sales@InstrumentsAndControl.com

281-609-7170

Page 2

Endress+Hauser

Short instructions

L00-FMG60xxx-05-00-00-en-050

Contents of the Operating Instructions

These Operating Instructions describe how to install and commission the radiometric

compact transmitter Gammapilot M (communication version 4-20 mA with HART).

All the functions that are required for standard measuring tasks have been included.

Also, the Gammapilot M provides additional functions for optimizing the measuring point

and for converting the measured value. These functions are not included in these Operating

Instructions.

You can find an overview of all the device functions in the Appendix.

A detailed description of all the instrument functions is given in Operating Instructions

BA00287F/00/EN "Gammapilot M - Description of Device Functions" which can be found on

the CD-ROM supplied.

E

+

-

+

E

+

-

-

……

……

100 (HART)

2457 (PA,FF)

333 (HART)

33333 (PA,FF)

…

……

E

E

E

E

52025626

KA242F/00/a2/02.07

*00

*0

*2

*C

*4

*5

*6

*A

*A0

*01

*02 *03 *04

*06 *09

*0A

*0B

*A1

*A4

*3

*9 *92

*A3

*C0

*05

*1 *10 *11 *12 *13

*14

*16*15 *11

*19

*17

*18*15 *11

*1B*11 *1C *1D *1E *1F

*1A

*15

*19

++

*07 *08

slave, end slave

safety settings

system

parameters

linearisation

gammagraphy

output (HART, FF)

profibus param.(PA)

diagnostics

present

error

previous

error

unlock

parameter

temp. compens.

display language

reset

tag

marking

density/concentration

density

calibr.

stop/edit

start

avg. pulse

rate

density

value

calibr.

point

absorp.

coeff.

ref. pulse

rate

calibr.

point

calibration

next point

no

yes

Contrast: or

*indicates the

meas.mode:

L: Level

S: Level limit

D: Density

C: Concentration

calibration backgr.

calib

start

avg. pulse

rate

bgr. pulse

rate

stop/edit

calibr. point

value

full

full

calibr.

stop/edit

calibration

start

avg. pulse

rate

next point

value

empty

empty

calibr.

stop/edit

calibration

start

avg. pulse

rate

no

yes

level/

limit

density

unit

pipe diam.

unit

pipe diam.

output

damping

min.

density

max.

density

measured value

Group

selection

basic setup

todays

date

beam type isotope operating

mode

meas.

mode

Gammapilot M - Quick Setup

Page 3

Gammapilot M FMG60 HART

Endress+Hauser 3

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . . . 4

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Installation, commissioning, operation . . . . . . . . . 4

1.3 Hazardous area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Radiation protection . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Identification . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Parts of the Gammapilot M . . . . . . . . . . . . . . . . . . . 8

2.2 Nameplates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Supplied documentation . . . . . . . . . . . . . . . . . . . . . 9

2.5 Certificates and approvals . . . . . . . . . . . . . . . . . . 10

2.6 Registered trademarks . . . . . . . . . . . . . . . . . . . . . 10

3 Installation . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Incoming acceptance, transport, storage . . . . . . 11

3.2 Installation conditions . . . . . . . . . . . . . . . . . . . . . 12

3.3 Water cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4 Installation check . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.1 Terminal compartments . . . . . . . . . . . . . . . . . . . . 20

4.2 Cable entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Terminal assignment . . . . . . . . . . . . . . . . . . . . . . 21

4.4 Fieldbus connectors . . . . . . . . . . . . . . . . . . . . . . . 23

4.5 Potential equalization . . . . . . . . . . . . . . . . . . . . . . 24

4.6 Wiring in terminal compartment 1 . . . . . . . . . . 25

4.7 Wiring in terminal compartment 2 . . . . . . . . . . 26

4.8 Connecting the

remote display and operation FHX40 . . . . . . . . . 27

4.9 Wiring in cascading mode . . . . . . . . . . . . . . . . . . 28

4.10 Wiring example for

level limit detection 200/400 mm . . . . . . . . . . . 29

4.11 Measuring solids flow . . . . . . . . . . . . . . . . . . . . . . 30

4.12 Post-connection check . . . . . . . . . . . . . . . . . . . . . 30

5 Operation. . . . . . . . . . . . . . . . . . . . . . . . . 31

5.1 Overview over the operating options . . . . . . . . . 31

5.2 Display operation . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.3 Alternative operation options . . . . . . . . . . . . . . . 36

5.4 Lock/unlock configuration . . . . . . . . . . . . . . . . . . 37

5.5 Reset to the default configuration . . . . . . . . . . . 37

6 Commissioning. . . . . . . . . . . . . . . . . . . . 38

6.1 Calibration: overview . . . . . . . . . . . . . . . . . . . . . . 38

6.2 Switching on the device . . . . . . . . . . . . . . . . . . . . 39

6.3 Basic setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.4 Calibration for

level measurement and limit detection . . . . . . . 46

6.5 Function group "Safety settings" (*2) . . . . . . . . . 55

6.6 SIL locking (for level limit detection

200/400 mm PVT scintillator) . . . . . . . . . . . . . . . 56

6.7 Calibration for density and concentration

measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.8 Density measurement/

temperature-compensated . . . . . . . . . . . . . . . . . . 69

6.9 Gammagraphy detection . . . . . . . . . . . . . . . . . . . . 69

7 Maintenance and repairs. . . . . . . . . . . 70

7.1 Exterior cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.2 Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.3 Repairs to Ex- or SIL-approved devices . . . . . . . . 70

7.4 Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.5 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.6 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.7 Contact addresses of Endress+Hauser . . . . . . . . . 71

8 Accessories. . . . . . . . . . . . . . . . . . . . . . . 72

8.1 Commubox FXA195 HART . . . . . . . . . . . . . . . . . . 72

8.2 Commubox FXA291 . . . . . . . . . . . . . . . . . . . . . . . . 72

8.3 ToF adapter FXA291 . . . . . . . . . . . . . . . . . . . . . . . 72

8.4 Field Xpert SFX100 . . . . . . . . . . . . . . . . . . . . . . . . . 72

8.5 Remote display FHX40 . . . . . . . . . . . . . . . . . . . . . . 73

8.6 Mounting device FHG60 (for level

measurement and level limit measurement) . . . 75

8.7 Clamping device for

density measurement FHG61 . . . . . . . . . . . . . . . . 77

8.8 Measurement section for

density measurement FHG62 . . . . . . . . . . . . . . . . 77

9 Troubleshooting . . . . . . . . . . . . . . . . . . 78

9.1 System error messages . . . . . . . . . . . . . . . . . . . . . 78

9.2 Possible calibration errors . . . . . . . . . . . . . . . . . . . 81

9.3 Software history . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10 Technical Data. . . . . . . . . . . . . . . . . . . . 83

10.1 Additional technical data . . . . . . . . . . . . . . . . . . . . 83

10.2 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

11 Appendix . . . . . . . . . . . . . . . . . . . . . . . . 88

11.1 Operating menu for level measurements . . . . . . 88

11.2 Operating menu for level limit detection . . . . . . . 90

11.3 Operating menu for density and concentration

measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Page 4

Safety instructions Gammapilot M FMG60 HART

4 Endress+Hauser

1 Safety instructions

1.1 Designated use

The Gammapilot M is a compact transmitter for non-contact level, level limit, density and

concentration measurement. The measuring range of a single Gammapilot M extends up to

2 m (6.6 ft). Large measuring ranges of any size can be implemented, however, by cascading

several Gammapilot M devices. When used for level limit detection, the Gammapilot M is

certified according to IEC 61508 for safety-related operation up to SIL 2/3.

1.2 Installation, commissioning, operation

The Gammapilot M is fail-safe and is constructed to the state-of-the-art. It meets the

appropriate standards and EC directives. However, if you use it improperly or other than for

its designated use, it may pose application-specific hazards, e.g. product overflow due to

incorrect installation or configuration. Installation, electrical connection, startup, operation

and maintenance of the measuring device must therefore be carried out exclusively by

trained specialists authorized by the system operator. Technical personnel must have read

and understood these Operating Instructions and must adhere to them. You may only

undertake modifications or repair work to the device when it is expressly permitted by the

Operating Instructions.

1.3 Hazardous area

Measuring systems for use in hazardous environments are accompanied by separate "Ex

documentation", which is an integral part of these Operating Instructions. Strict compliance

with the installation instructions and ratings as stated in this supplementary documentation

is mandatory.

• Ensure that all personnel are suitably qualified.

• Observe the specifications in the certificate as well as national and local standards and

regulations.

CAUTION

!

Detector or cooling jacket can be damaged if the cooling water freezes.

‣ Empty cooling jacket or protect against freezing.

WARNING

!

Depending on the certificate version observe the associated Safety Instructions

( ä 83).

WARNING

!

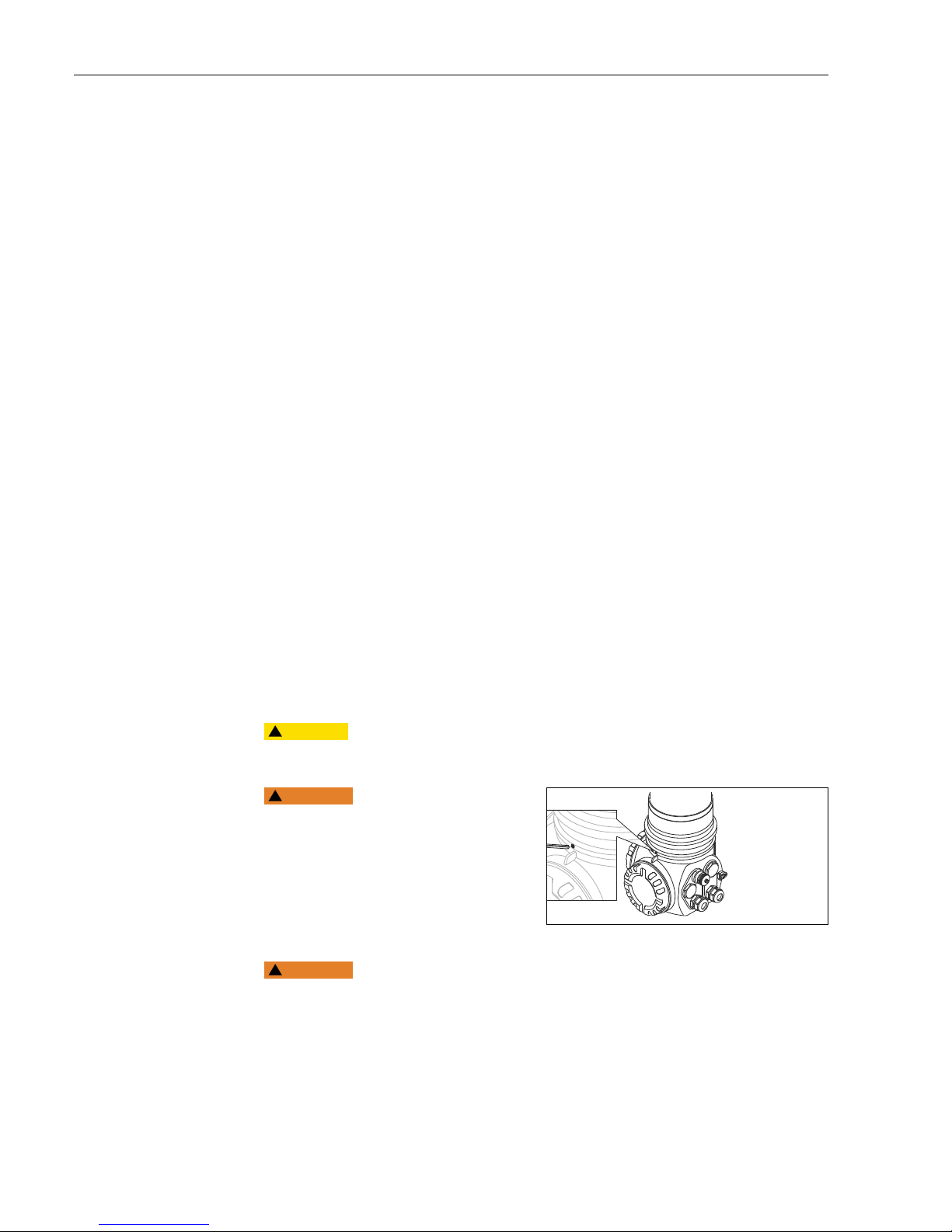

The three screws, connecting the pipe

housing to the compartment housing,

must not be opened.

A0018068

Page 5

Gammapilot M FMG60 HART Safety instructions

Endress+Hauser 5

1.4 Radiation protection

The Gammapilot M is used in conjunction with a radioactive source, contained in a source

container. When handling radioactive sources, the following instructions have to be

observed:

1.4.1 Basic regulations on radiation protection

WARNING

!

When handling radioactive sources, all unnecessary radiation exposure should be

avoided. All unavoidable radiation exposure should be kept as low as possible. Three

measures are used for this:

A0016373

A Screening

BTime

CDistance

Shielding

Ensure the best possible shielding between the radiation source and yourself as well as all

other individuals. Effective shielding is provided by source containers (FQG60, FQG61/

FQG62, FQG63, QG2000) and all high-density materials (lead, iron, concrete).

CAUTION

!

When working with source containers, all the instructions for mounting and usage

outlined in the following documents must be observed:

Time

Stay as short as possible in the area exposed to radiation.

Distance

Keep as far away as possible from the radiation source. The local radiation intensity

decreases as the square-root of the distance from the radiation source.

A

B

C

Source Container Document

FQG60 TI00445F/00/EN

FQG61, FQG62 TI00435F/00/EN

FQG63 TI00446F/00/EN

QG2000 TI00346F/00/EN

BA00223F/00/EN

Page 6

Safety instructions Gammapilot M FMG60 HART

6 Endress+Hauser

1.5 Symbols

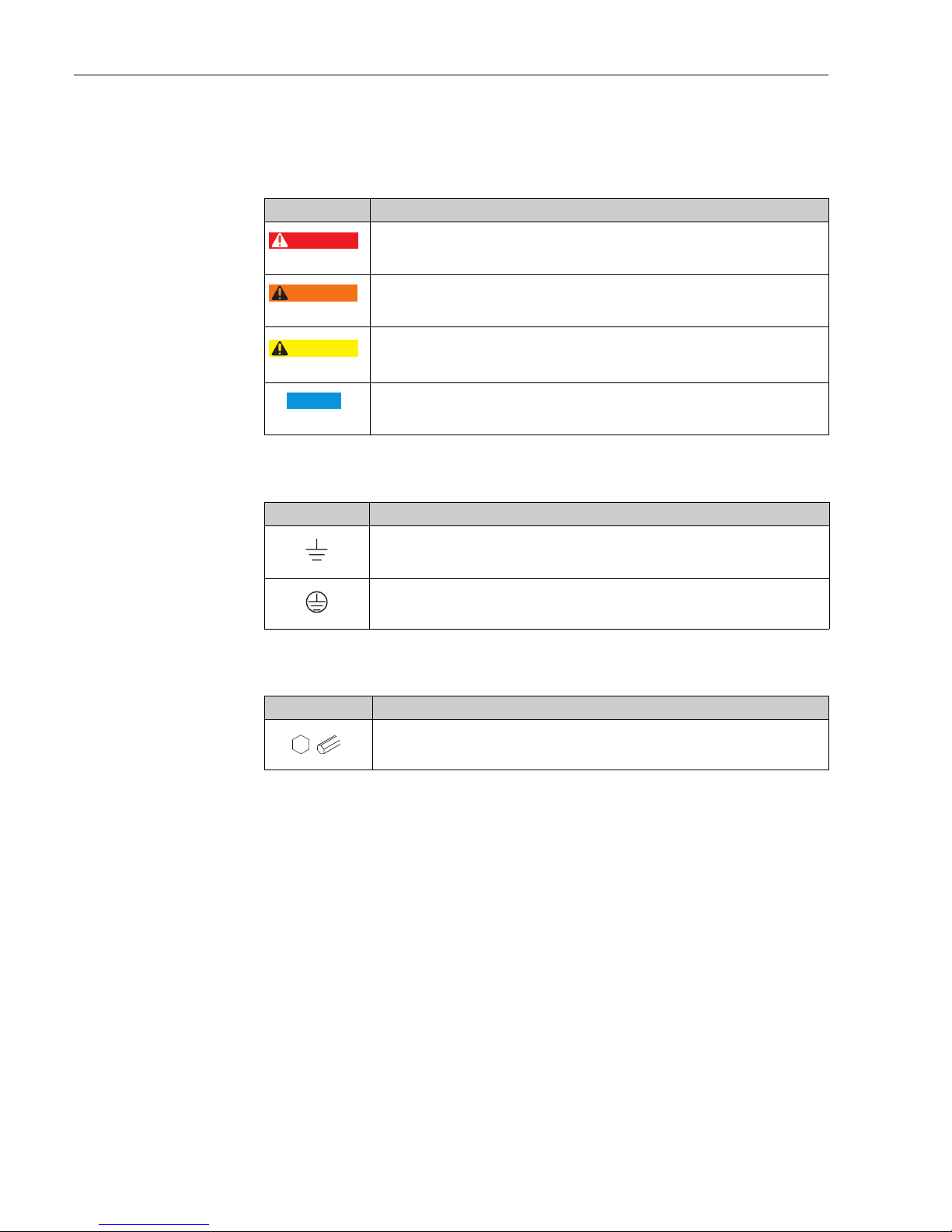

1.5.1 Safety symbols

1.5.2 Electrical symbols

1.5.3 Tool symbols

Symbol Meaning

A0011189-DE

DANGER!

This symbol alerts you to a dangerous situation. Failure to avoid this situation will result in

serious or fatal injury.

A0011190-DE

WARNING!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

serious or fatal injury.

A0011191-DE

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation can result in

minor or medium injury.

A0011192-DE

NOTICE!

This symbol contains information on procedures and other facts which do not result in

personal injury.

Symbol Meaning

A0018338

Ground connection

A grounded terminal which, as far as the operator is concerned, is grounded via a

grounding system..

A0018339

Protective ground connection

A terminal which must be connected to ground prior to establishing any other connections.

Symbol Meaning

A0011221

Allen key

DANGER

WARNING

CAUTION

NOTICE

Page 7

Gammapilot M FMG60 HART Safety instructions

Endress+Hauser 7

1.5.4 Symbols for certain types of information

1.5.5 Symbols in graphics

Symbol Meaning

A0011182

Allowed

Indicates procedures, processes or actions that are allowed.

A0011183

Preferred

Indicates procedures, processes or actions thar are preferred.

A0011184

Forbidden

Indicates procedures, processes or actions that are forbidden.

A0011193

Tip

Indicates additional information.

A0015484

Reference to page

Refers to the corresponding page number.

, , ... Series of steps

Symbol Meaning

1, 2, 3, 4, ... Item numbers

, , ... Series of steps

A, B, C, D, ... Views

A0011187

Hazardous area

Indicates a hazardous area.

A0011188

Safe area (non-hazardous area)

Indicates a non-hazardous location.

-

.

Page 8

Identification Gammapilot M FMG60 HART

8 Endress+Hauser

2 Identification

2.1 Parts of the Gammapilot M

1. Terminal head

2. Mounting collar

3. Detector pipe

4. Measuring range marks

5. Terminal compartment 2

6. Terminal compartment 1

7. Supplementary nameplate

8. Centering knob

9. Instrument nameplate

10. Cooling water connections

11. Marking of the radiation

window (only for versions

with collimator)

12. Potential equalization

terminal of the water

cooling jacket

A0018069

A Gammapilot M without water cooling jacket

B Gammapilot M with water cooling jacket

C Gammapilot M with collimator

1

2

3

6

5

8

4

4

9

7

4

4

10

10

AB/C

12

11

C

Page 9

Gammapilot M FMG60 HART Identification

Endress+Hauser 9

2.2 Nameplates

2.3 Scope of delivery

• Ordered version of the device (including Operating Instructions)

• Endress+Hauser operating program (on the CD-ROM supplied)

• Accessories as ordered

2.4 Supplied documentation

2.4.1 Operating Instructions (BA00236F/00/EN)

Describe how to install and commission the Gammapilot M (communication version

4-20 mA HART). Those functions of the operating menu are included, which are required

for standard measuring tasks. Any additional functions are contained in the "Description of

Device Functions" (BA00287F/00/EN).

2.4.2 Description of Device Functions (BA00287F/00/EN)

Contains a detailed description of all the functions of the Gammapilot M and applies for all

communication versions. This document can be found as a PDF file on the CD-ROM supplied

and can be downloaded from the Internet under "www.de.endress.com" ( download).

2.4.3 Safety instructions

Additional safety instructions (XA, ZE, ZD) are supplied with certified device versions. Refer

to the nameplate for the names of the safety instructions that apply to your device variant.

An overview of the certificates and approvals can be found in TI00363F/00/EN, chapter

"Certificates and approvals".

Device nameplate

A0018070

1 Order code (as defined by the Ordering information)

2 Serial number

3 Measuring range

4Power supply

5Output signal

6 Max. ambient temperature

Supplementary nameplate (Examples)

A0018070

7 No. of certificate

8Equipment group and category

9 Type of protection

10 Reference to additional safety-relevant information

11 Reference to additional certificates (e.g. WHG, SIL)

12 Specification of required temperature resistance of

the connected cables (only for instrument versions

with water cooling jacket)

Ser.-No.:

Order Code:

IP 66/67

Gammapilot M

Made in Germany, D-79689 Maulburg

L=

mm

Dat. xx.xx

250001828- -

TYPE 4X / 6 Encl.

Ta

-40°C

°C

1

2

3

4

5

6

000000- -

KEMA 04 ATEX

11

10

7

8

9

000000- -

11

10

T Ta + 20 K

T Ta + 20 K

0044

Page 10

Identification Gammapilot M FMG60 HART

10 Endress+Hauser

2.5 Certificates and approvals

CE mark, declaration of conformity

The device is designed to meet state-of-the-art safety requirements, has been tested and left

the factory in a condition in which it is safe to operate. The device takes into account

applicable standards and regulations which are listed in the EC declaration of conformity

and thus meets the legal requirements of the EC Directives. Endress+Hauser confirms the

successful testing of the instrument by affixing to it the CE mark.

2.6 Registered trademarks

HART

®

Registered trademark of the HART Communication Foundation, Austin, USA

ToF

®

Registered trademark of Endress+Hauser GmbH+Co. KG, Maulburg, Germany

Page 11

Gammapilot M FMG60 HART Installation

Endress+Hauser 11

3Installation

3.1 Incoming acceptance, transport, storage

3.1.1 Incoming acceptance

Check the packing and contents for any signs of damage.

Check the shipment, make sure nothing is missing and that the scope of supply matches your

order.

3.1.2 Transport

CAUTION

!

Follow the safety instructions and transport conditions for devices of more than

18 kg (39.69 lbs).

3.1.3 Storage

Pack the measuring instrument so that it is protected against impacts for storage and

transport. The original packing material provides the optimum protection for this.

The permissible storage temperature is:

• -40 to +50 °C (-40 to +122 °F) for devices with PVT scintillator

• -40 to +60 °C (-40 to +140 °F) for devices with NaI crystal

Page 12

Installation Gammapilot M FMG60 HART

12 Endress+Hauser

3.2 Installation conditions

3.2.1 Dimensions, weight

Gammapilot M (without water cooling jacket)

A0018072

Gammapilot M with water cooling jacket or collimator

A0018073

Type

Measuring

length A

[mm (in)]

Without water cooling

jacket

With water cooling jacket

Overall

length

B [mm (in)]

Weight

[kg (lbs)]

1)

1) The given weight data are for 316L version. The weight of the aluminium version is reduced by 5,3 kg

(11.69 lbs).

Overall

length

B [mm (in)]

Weight

without water

[kg (lbs)]

)

Weight

including

water

[kg (lbs)]

)

NaI 50 (1.97) 621 (24.4) 14 (30.87) 631 (24.8) 18 (39.69) 20 (44.10)

NaI with collimator 50 (1.97) 663 (26.1) 35 (77.18)

PVT 200 (7.87) 780 (30.7) 15 (33.08) 790 (31.1) 20 (44.10) 24 (52.92)

PVT 400 (15.7) 980 (38.6) 16 (35.28) 990 (39) 23 (50.72) 29 (63.95)

PVT 800 (31.5) 1380 (54.3) 20 (44.10) 1390 (54.7) 31 (68.36) 40 (88.20)

PVT 1200 (47.5) 1780 (70.1) 24 (52.92) 1790 (70.5) 37 (81.59) 50 (110.25)

PVT 1600 (63) 2180 (85.8) 28 (61.74) 2190 (86.2) 45 (99.23) 61 (134.51)

PVT 2000 (7.87) 2580 (102) 31 (68.36) 2590 (102) 51 (112.46) 72 (158.76)

160x190

(6.3x7.48)

ø120

(4.72)

ø80

(3.15)

537 (22.6)

mm (in)

A

B

160x190

(6.3x7.48)

537 (22.6)

A

B

164 (6.46)

mm (in)

12 (0.47)

ø140

(5.51)

Page 13

Gammapilot M FMG60 HART Installation

Endress+Hauser 13

3.2.2 Installation conditions for level measurement

Conditions

• For level measurements the Gammapilot M is mounted vertically; if possible the detector

head should point downwards.

• The exit angle of the source container must be exactly aligned to the measuring range of

the Gammapilot M. Observe the measuring range marks of the Gammapilot M.

• In cascading mode no gap should occur between the measuring ranges of the different

Gammapilot M.

• The source container and the Gammapilot M must be mounted as close to the vessel as

possible. Any access to the beam must be blocked so that no persons or part of their body

(hand, arm, head) may come into the area of the beam.

• In order to enlarge the lifetime, the Gammapilot M should be protected against direct sun.

If necessary, a protective cover should be applied.

• The mounting device FHG60 ( ä 72, "Accessories") or an equivalent mounting device

should be used for fastening the Gammapilot M.

The mounting device must be installed in a way such that it can withstand the weight of

the Gammapilot M

1)

under all operating conditions (e.g. vibrations).

NOTICE

The Gammapilot M should be given additional support to prevent damage to the

connecting cable or to the unit if it falls off.

Examples

A0018074

A Vertical cylinder; the Gammapilot M is mounted vertically with the detector head pointing downwards;

the gamma ray is aligned to the measuring range.

B Cascading of multiple Gammapilot M; there is no gap between the measuring ranges

C Wrong: Gammapilot M mounted inside the tank insulation

D Conical tank outlet (here with sun protection cover)

E Horizontal cylinder (here with sun protection cover)

F Right: Tank insulation removed for Gammapilot M

1Support

1) The weights of the various versions of the Gammapilot M are summarized in the section "Dimensions, weight".

A

D

B C

EF

1

Page 14

Installation Gammapilot M FMG60 HART

14 Endress+Hauser

3.2.3 Installation conditions for level limit detection

Conditions

• For level limit detection, the Gammapilot M should be mounted horizontally at the height

of the desired level limit.

• The exit angle of the source container must be exactly aligned to the measuring range of

the Gammapilot M. Observe the measuring range marks of the Gammapilot M.

• The source container and the Gammapilot M must be mounted as close to the vessel as

possible. Any access to the beam must be blocked so that no persons or part of their body

(hand, arm, head) may come into the area of the beam.

• In order to enlarge the lifetime, the Gammapilot M should be protected against direct sun.

If necessary, a protective cover should be applied.

• The mounting device FHG60 ( ä 72, "Accessories") or an equivalent mounting device

should be used for fastening the Gammapilot M.

The mounting device itself must be fitted in a way such that it can withstand the weight of

the Gammapilot M

2)

under all operating conditions to be expected.

More information with regard to the safety-related deployment of Gammapilot M can

be found in Functional Safety Manual SD00230F/00/EN and SD00324F/00/EN.

Examples

A0018075

A Maximum fail-safe mode

B Minimum point level detection

2) The weights of the various versions of the Gammapilot M are summarized in the section "Dimensions, weight".

A

B

Page 15

Gammapilot M FMG60 HART Installation

Endress+Hauser 15

3.2.4 Installation conditions for density and concentration

measurement

Conditions

• If possible, density and concentration should be measured at vertical pipes with a feed

direction from bottom to top.

• If only horizontal pipes are accessible, the path of the ray should also be arranged

horizontally to reduce the influence of air bubbles and sediments.

• The Endress+Hauser clamping device ( ä 72, "Accessories") or an equivalent clamping

device should be used for fastening the radiation source container and the Gammapilot M

to the measuring tube.The clamping device itself must be installed in a way such that it can

withstand the weight of the source container

3)

and the Gammapilot M4) under all

operating conditions.

• The sample point may not be further than 20 m (66 ft) from the measuring point.

• The distance of the density measurement to pipe bends is 3 x pipe diameter and 10 x

pipe diameter for pumps.

Configuration of the measuring system

The configuration of the source container and the Gammapilot M depends on the pipe

diameter (or the length of the irradiated measuring path respectively) and the measuring

range. These two parameters determine the measuring effect (relative change of the pulse

rate). The measuring effect increases with the length of the radiation path through the

medium. Therefore, diagonal irradiation or the use of a measurement section is necessary

for small pipe diameters.

For the configuration of the measuring system please contact your Endress+Hauser sales

organization or use the "Applicator"

5)

configuration software.

A0018076

A Vertical beam (90°)

B Diagonal beam (30°)

C Measurement section

1Sample point

NOTICE

General

‣ To increase the accuracy for density measurements, the use of a collimator is

recommended. The collimator screens the detector against environmental radiation.

‣ When planning, the total weight of the measuring system must be taken into

consideration.

‣ The Gammapilot M should be given additional support to secure it against falling or

prevent damage to the connecting cable.

‣ A clamping device and a measurement section are available as accessories ( ä 72,

"Accessories").

3) The weights of the source containers are specified in TI00445F/00/EN (FQG60), TI00435F/00/EN (FQG61, FQG62), TI00446F/00/EN (FQG63)

or TI00346F/00/EN (QG2000).

4) The weights of the various versions of the Gammapilot M are summarized in the section "Dimensions, weight".

5) The "Applicator"

is available from your Endress+Hauser sales organization.

ABC

1

Page 16

Installation Gammapilot M FMG60 HART

16 Endress+Hauser

3.2.5 Empty pipe detection

A0018077

1 Gammapilot M

2 Monitoring detector FTG20 or FMG60

3SPS

Mounting the FTG20 or FMG60 on the FMG60 for empty pipe detection

If the pipe becomes empty as a result of operational processes, the radiation on the detector

side can hit dangerous levels.

• In such instances, the irradiation channel must be closed immediately for reasons of

radiation protection.

• A high local dose rate also causes the detector unit (scintillator and photomultiplier) to age

quickly.

The best way of avoiding such a situation is to mount a second radiometric measuring

system that monitors the radiation intensity. If high radiation levels occur, an alarm is

output and/or the source container is automatically switched off through pneumatic action

for example.

1

2

3

Page 17

Gammapilot M FMG60 HART Installation

Endress+Hauser 17

3.3 Water cooling

For the versions of the Gammapilot with water cooling jacket, the following applies:

• Material: 316L

• Water connection: 2 x G 1/4"A, DIN ISO 228

• Inlet temperature: max. 40 °C (104 °F)

• Outlet temperature: max. 50 °C (122 °F) (temperature monitoring recommended)

• Water pressure: 4 to 6 bar (60 to 90 psi)

A0018078

A T <75 °C (167 °F)

B T <120 °C (248 °F)

CAUTION

!

Detector or cooling jacket can be damaged if the cooling water freezes.

‣ Empty cooling jacket or protect against freezing.

WARNING

!

Pressurized water cooling system!

‣ Do not open the cylinder screws (see figure below) when pressurized.

A0023205

1 Cylinder screws

AB

G1/4"A

G1/4"A

*

1

CAUTION

!

To consider when using the water cooling

jacket

‣ It is recommended to ground the water

cooling jacket separately at the provided

earth terminal (see picture above)

‣ The ambient temperature of the

compartment housing must not exceed

75 °C (167 °F). This is also valid, if water

cooling is applied.

‣ The three screws, connecting the pipe

housing to the compartment housing, must

not be opened.

A0018068

Page 18

Installation Gammapilot M FMG60 HART

18 Endress+Hauser

3.3.1 Mounting versions

A0018079

A Recommended mounting position for level measurement: compartment housing at the bottom

B In exceptional cases (e.g. shortage of space) the compartment housing may be located at the top

C Mounting position for point level detection and density measurement

CAUTION

!

The water inlet must always be at the bottom to ensure that the water cooling jacket is

completely filled.

A

B C

Page 19

Gammapilot M FMG60 HART Installation

Endress+Hauser 19

3.3.2 Required flow rate

The required flow rate depends on

• the ambient temperature at the water cooling jacket

• the inlet temperature

• the measuring range of the Gammapilot M

Typical values are given in the following tables:

Ambient temperature T

A

=75°C (167°F)

Ambient temperature T

A

= 100 °C (212 °F)

Ambient temperature T

A

= 120 °C (248 °F)

3.4 Installation check

After installing the device, carry out the following checks:

• Is the device damaged (visual inspection)?

• Does the device correspond to the measuring point specifications for ambient

temperature, measuring range etc.?

• If available: Are the measuring point number and labeling correct (visual inspection)?

• Is the measuring device sufficiently protected against direct sunlight?

• Are the cable glands tightened correctly?

Inlet temperature

°C (°F)

Measuring range in mm (in)

50 (1.97) 200 (7.87) 400 (15.7) 800 (31.5) 1200 (47.2)1600 (63) 2000 (78.7)

20 (68) 30 l/h 30 l/h 30 l/h 41 l/h 55 l/h 70 l/h 84 l/h

25 (77) 30 l/h 30 l/h 30 l/h 45 l/h 61 l/h 77 l/h 93 l/h

30 (86) 30 l/h 30 l/h 33 l/h 50 l/h 68 l/h 86 l/h 104 l/h

35 (95) 30 l/h 30 l/h 38 l/h 59 l/h 80 l/h 101 l/h 122 l/h

40 (104) 30 l/h 30 l/h 47 l/h 72 l/h 98 l/h 124 l/h 149 l/h

Inlet temperature

°C (°F)

Measuring range in mm (in)

50 (1.97) 200 (7.87) 400 (15.7) 800 (31.5) 1200 (47.2)1600 (63) 2000 (78.7)

20 (68) 30 l/h 30 l/h 38 l/h 59 l/h 80 l/h 101 l/h 122 l/h

25 (77) 30 l/h 30 l/h 42 l/h 64 l/h 87 l/h 110 l/h 133 l/h

30 (86) 30 l/h 30 l/h 47 l/h 73 l/h 98 l/h 124 l/h 150 l/h

35 (95) 30 l/h 30 l/h 54 l/h 84 l/h 113 l/h 143 l/h 173 l/h

40 (104) 33 l/h 33 l/h 66 l/h 101 l/h 137 l/h 173 l/h 210 l/h

Inlet temperature

°C (°F)

Measuring range in mm (in)

50 (1.97) 200 (7.87) 400 (15.7) 800 (31.5) 1200 (47.2) 1600 (63) 2000 (78.7)

20 (68) 30 l/h 30 l/h 45 l/h 70 l/h 94 l/h 119 l/h 144 l/h

25 (77) 30 l/h 30 l/h 50 l/h 77 l/h 104 l/h 131 l/h 158 l/h

30 (86) 30 l/h 30 l/h 55 l/h 85 l/h 115 l/h 146 l/h 176 l/h

35 (95) 32 l/h 32 l/h 64 l/h 98 l/h 133 l/h 168 l/h 203 l/h

40 (104) 38 l/h 38 l/h 75 l/h 116 l/h 157 l/h 199 l/h 240 l/h

Page 20

Wiring Gammapilot M FMG60 HART

20 Endress+Hauser

4 Wiring

4.1 Terminal compartments

4.2 Cable entries

NOTICE

Cable entries

‣ On delivery, not more than one cable gland is present for each of the terminal

compartments. If further cable glands are required (e.g. for cascading mode), they must

be supplied by the user.

‣ Connecting cables should be routed away from the housing from below to prevent

moisture from penetrating the connection compartment. Otherwise, a drain loop should

be provided or the Gammapilot M should be fitted with a weather protection cover.

The Gammapilot M has got two terminal

compartments:

• Terminal compartment 1, for

– Power supply

– Signal output (depending on the instrument

version)

• Terminal compartment 2, for

– Signal output (depending on the instrument

version)

– PT-100 input (4-wire)

– Pulse input for cascading mode

– Pulse output for cascading mode

– Display and operating module FHX40

(or VU331)

NOTICE

Depending on the instrument version, the

signal output is located in the terminal

compartment 1 or 2.

Maximum cable length:

• For cascade, 20 m (66 ft) each

• For PT-100 2 m (6.6 ft) (temperature should be

measured as close as possible to density

measurement)

A0018082

1

2

The number and type of cable entries depend on

the instrument version ordered. The following

types may occur:

• Gland M20x1.5

tightening diameter (clamping range):

7.0 to 10.5 mm

• Cable entry M20x1.5

• Cable entry G1/2

• Cable entry NPT1/2

• M12 connector (see "Fieldbus connectors")

• 7/8" connector (see "Fieldbus connectors")

In addition, Gammapilot M has a socket to

connect the separate display and operating unit

FHX40. The housing of the Gammapilot M does

not have to be opened to connect the FHX40.

A0018083

1 Cable entries for terminal compartment 2

2 Socket for FHX40

3 Cable entries for terminal compartment 1

1 2

3

Page 21

Gammapilot M FMG60 HART Wiring

Endress+Hauser 21

4.3 Terminal assignment

Terminal compartment 1

A0018084

1 90 to 253VAC, 18 to 36 VDC

Terminal compartment 2

A0018085

1

14

15

2

(3)

L1L+N

L-

+-

(4)

1

0

9

3

++

+

5

7

10

4

--

-

6

11

12

13

SIM WP

PT100

IN CASCADE OUT

OFF

ON

8

)

Page 22

Wiring Gammapilot M FMG60 HART

22 Endress+Hauser

Terminal(s) Meaning

0 Grounding of the cable screen

1)

1) Rated cross section > 1 mm2 (17 AWG)

1, 2 Power supply

2)

2) Rated cross section max. 2.5 mm2 (14 AWG)

Compartment 2:

3, 4

Compartment 1:

(3)

1

,(4)

1

Signal output, depending on communication version:

• 4-20mA with HART

•PROFIBUS PA

• Foundation Fieldbus

(Depending on the device version ordered, the signal output is in connection compartment 1

or 2, see below)

NOTICE

For the versions of the Gammapilot M with fieldbus plug connectors (M12 or 7/8"), the

signal output is wired in compartment 2 on delivery and connected to the fieldbus plug

connector (see below, section "Fieldbus connectors"). In this case, the housing needs

not to be opened for connecting the signal line.

5, 6 Pulse input (for cascading mode; is used for master and slave)

7, 8 Pulse output (for cascading mode; is used for slave and end slave)

9, 10, 11, 12 PT-100 input (4-wire)

13 Plug for display and operating module VU331 (normally in FHX40);

is wired on delivery and connected to the FHX40 plug

14 Protective earth

)

15 Protective earth or grounding of the cable screen

)

The cables used at terminals 14 or 15 must at least have the same cross section as the

cables at terminals 1 and 2.

Page 23

Gammapilot M FMG60 HART Wiring

Endress+Hauser 23

4.4 Fieldbus connectors

For the versions with a connector M12 or 7/8", the housing does not have to be opened for

connecting the signal line.

4.4.1 Pin assignment for M12 connector

4.4.2 Pin assignment for 7/8" connector

Feature 30 of the ordering information:

Power supply wiring/output wiring

Terminal compartment for

Supply voltage Signal output

ANon-Ex; Non-Ex 1 2

A0018082

BEx e; Ex ia 1 2

CEx e; Ex e 1 1

D Ex d (XP); Ex d (XP) 1 1

E Ex d (XP); Ex ia (IS) 1 2

F Dust-Ex; Dust-Ex 1 1

G Ex e, Dust-Ex; Ex e, Dust-Ex 1 1

H Ex d, Dust-Ex; Ex d, Dust-Ex 1 1

J Ex e, Dust-Ex; Ex ia, Dust-Ex 1 2

K Ex d, Dust-Ex; Ex ia, Dust-Ex 1 2

L Dust-Ex; Ex ia 1 2

A0011175

PIN Meaning

1Signal +

2Not assigned

3Signal –

4Earth

A0011176

PIN Meaning

1Signal –

2Signal +

3Shield

4Not assigned

1

2

21

3

4

2

1

4

3

Page 24

Wiring Gammapilot M FMG60 HART

24 Endress+Hauser

4.5 Potential equalization

Before wiring, connect the potential

matching line to the external ground

terminal of the transmitter. If a water

cooling jacket is present, it must be

separately connected to the potential

matching line.

CAUTION

!

In Ex applications, the instrument must

only be grounded on the sensor side.

Further safety instructions are given in

the separate documentation for

applications in explosion hazardous

areas.

NOTICE

For optimum electromagnetic

compatibility the potential matching line

should be as short as possible and at least

2.5 mm

2

(14 AWG) in cross-section.

A0018086

*

Page 25

Gammapilot M FMG60 HART Wiring

Endress+Hauser 25

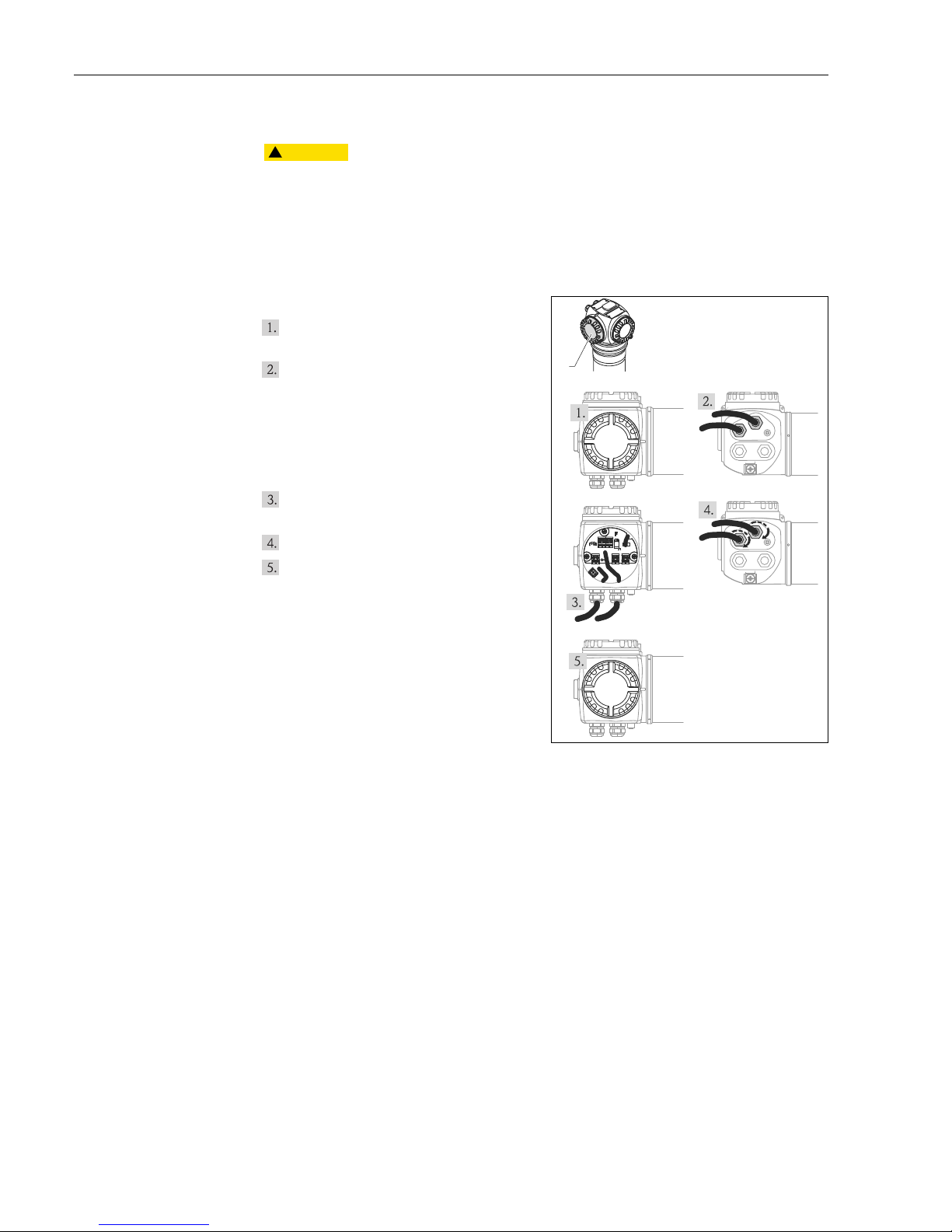

4.6 Wiring in terminal compartment 1

CAUTION

!

Before connection please note the following:

‣ When using the instrument in hazardous areas, make sure to comply with national

standards and the specifications in the Safety Instructions (XAs). Make sure you use the

specified cable gland.

‣ The supply voltage must comply to the data on the nameplate.

‣ Switch off power supply before connecting the instrument.

‣ Connect potential matching line to the outer transmitter ground terminal and to the

ground terminal of the water cooling jacket (if present) before connecting up the

instrument (see "Potential equalization", ä 24).

‣ Connect protective earth to the protective earth terminal (see "Terminal compartments",

ä 20).

‣ According to IEC/EN 61010 a suitable power switch has to be provided for the

instrument.

‣ The cable isolations must comply with the supply voltage and the overvoltage category.

‣ The temperature resistance of the connecting cable must comply with the ambient

temperature.

The procedure

Using a 3 mm Allen key, loosen the

cover clamp for the connection

compartment cover.

Unscrew the cover of the terminal

compartment.

Push the power cable and (if required)

the signal cable) through the

appropriate cable glands or cable

threads.

Wire up according to the terminal

assignment diagram.

Tighten the cable glands or threads.

Screw the cover securely back onto the

terminal compartment..

Adjust the cover clamp so it is set over

the cover and tighten.

A0019826

1

L1

L+

N

L-

+

-

Page 26

Wiring Gammapilot M FMG60 HART

26 Endress+Hauser

4.7 Wiring in terminal compartment 2

CAUTION

!

Before connection please note the following:

‣ Connect potential matching line to transmitter ground terminal and to the ground

terminal of the water cooling jacket (if present) before connecting up the instrument

("Potential equalization", ä 24).

‣ The cable isolations must comply with the supply voltage and the overvoltage category.

‣ The temperature resistance of the connecting cable must comply with the ambient

temperature.

The procedure

Unscrew the cover of the terminal

compartment.

Push the following cables through the

appropriate cable glands or threads:

- signal cable (if the signal output is

located in terminal compartment 2)

- PT-100 cable (if present)

- cascading cables (input and/or output,

if required)

Wire up according to the terminal

assignment diagram.

Tighten the cable glands or threads.

Screw the cover securely back onto the

terminal compartment.

A0018927

+

-

PT100

IN CASCADE OUT

SIM WP

OFF

ON

3

4

5

6

7

8

9

10

11

12

+ - - +

0

13

2

Page 27

Gammapilot M FMG60 HART Wiring

Endress+Hauser 27

4.8 Connecting the remote display and operation FHX40

For some Dust-Ex versions of the Gammapilot M, the FHX40 connector is protected by a

metal sleeve.

Loosen and remove the sleeve with an Allen wrench.

Connect the display and operating unit FHX40

Attach the sleeve and fasten the Allen screw.

A0018090

The remote display and operating unit

FHX40 is available as accessory. It is

connected to the FHX40-connector of the

Gammapilot M via the supplied cable. To do

this, the housing of the Gammapilot M

needs not to be opened.

A0018089

1 Gammapilot M FMG60

2 Cable of the display and operating unit FHX40

2

1

Page 28

Wiring Gammapilot M FMG60 HART

28 Endress+Hauser

4.9 Wiring in cascading mode

A0018091

A Power supply (90 to 253VAC or 18 to 36VDC )

BJunction box

M Master

SSlave

EEnd-Slave

NOTICE

For the positioning of the power switch according to IEC/EN 61010, there are two

options:

‣ At the side of the power supply (one switch for all transmitters)

‣ At the side of the transmitters (an individual switch for every transmitter)

WARNING

!

For applications in hazardous areas it is not allowed to interconnect the HART signal

circuits for multidrop operation.

L1

L+

N

L-

+

-

L1

L+

N

L-

+

-

L1

L+

N

L-

+

-

L1/L+

N/L-

AC/DC

A

B

M

S

E

+

-

PT100

IN CASCADE OUT

SIM WP

OFF

ON

3

4

9

10

11

12

+ - - +

13

+

-

PT100

IN CASCADE OUT

SIM WP

OFF

ON

3

4

9

10

11

12

+ - - +

13

+

-

PT100

IN CASCADE OUT

SIM WP

OFF

ON

3

4

9

10

11

12

+ - - +

13

+ -

+ - - +

- +

Page 29

Gammapilot M FMG60 HART Wiring

Endress+Hauser 29

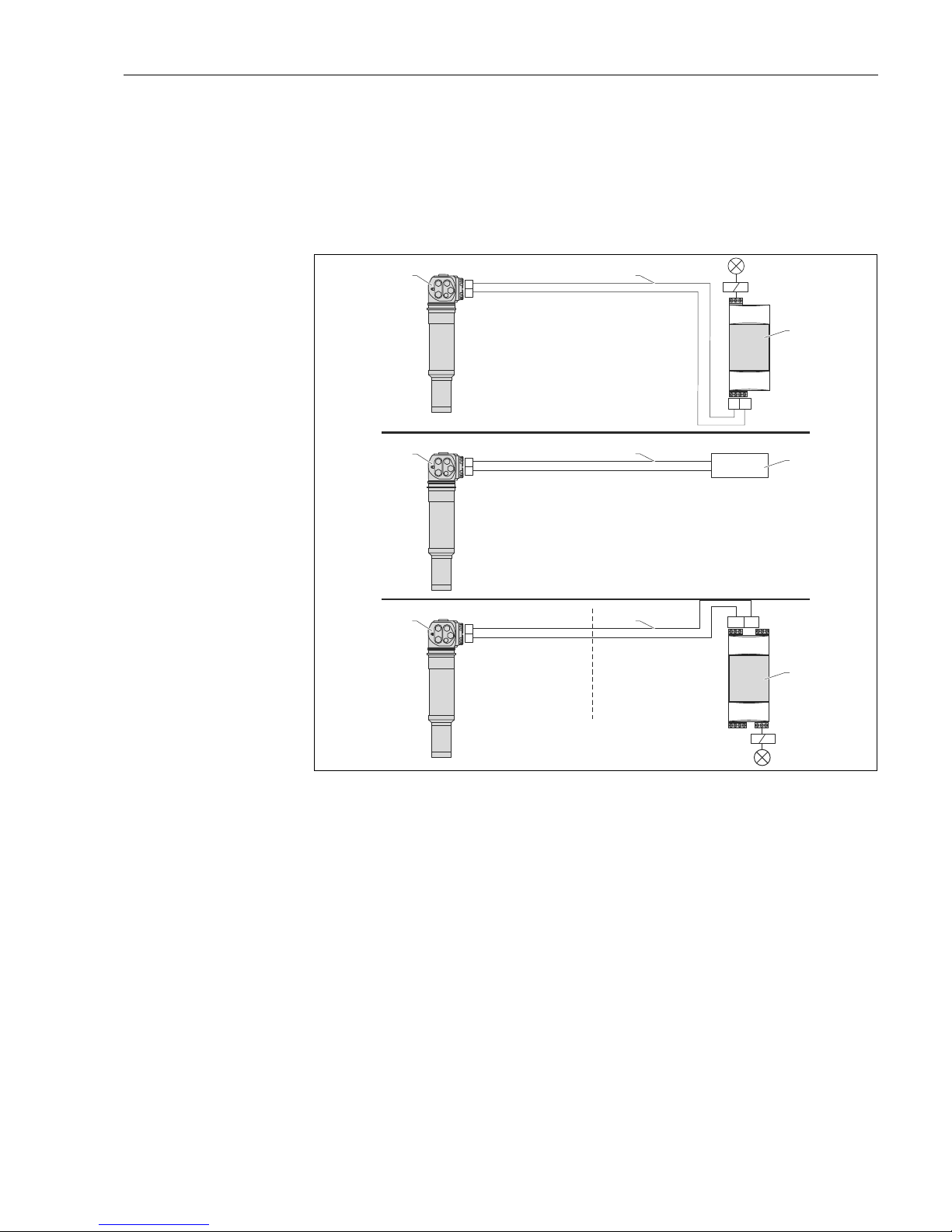

4.10 Wiring example for level limit detection 200/400 mm

The output signal is linear between the free and covered calibration (e.g. 4 to 20 mA) and

can be evaluated in the control system. If a relay output is needed, the following

Endress+Hauser process transmitters can be used:

• RTA421: for non-Ex applications, without WHG, without SIL

• RMA42: for Ex-applications; with WHG and SIL certificates

A0018092

A Wiring with RTA421 switching unit 1 Gammapilot M

B Wiring with process control system 2 4 to 20 mA

C Wiring with RMA42 switching unit 3 RTA421

D When installing in hazardous areas, please 4 SPS

observe the corresponding safety instructions 5 RMA42

4.10.1 Ex applications in connection with RMA42

Observe the following Safety Instructions:

• XA00303F/00/A3: ATEX II 2 (1) G for Gammapilot M

• XA00304F/00/A3: ATEX II 2 (1) D for Gammapilot M

• XA00095R/09/A3: ATEX II (1) G [Ex ia] IIC, ATEX II (1) D [Ex ia] IIIC for RMA42

4.10.2

SIL applications for Gammapilot M FMG60 in conjunction with

RMA42 (for point level detection 200/400 mm PVT scintillator)

• The Gammapilot M meets SIL2/3 as per IEC 61508, see:

– Functional safety manual SD00230F/00/EN (Maximum point level detection)

– Functional safety manual SD00324F/00/EN (Minimum point level detection)

• The RMA42 meets SIL2 as per IEC 61508:2010 (Edition 2.0), see functional safety

manual SD00025R/09/EN.

4

D

5

-

.

X8

X4

-

+

1

1

1

A

B

C

3

2

2

2

.

.

16

11

+

-

+

+

+

-

-

-

Page 30

Wiring Gammapilot M FMG60 HART

30 Endress+Hauser

4.11 Measuring solids flow

In conjunction with a density measuring device, such as Endress+Hauser's "Gammapilot M",

Promag 55S also determines the rate of solids with regard to the mass, volume or percentage

content. The following order information is required for this purpose for Promag 55S:

Order option for software function "Solids flow" (F-CHIP) and order option for a current input.

A0018093

Solids flow measurement (m) with the aid of a density and flow measuring device. If the density of the solids (

S

) and the density of

the transporting liquid (

C

) are also known, the solids flow rate can be calculated.

1 Flow measuring device (Promag 55S)

Volume flow (V). The solids density (

S

) and the density of the transporting liquid

(

C

) also have to be entered in the transmitter

2 Density measuring device (e.g. "Gammapilot M")

Total density

M

(transporting liquid and solids)

4.12 Post-connection check

After wiring the device, carry out the following checks:

• Is the protective earth connected?

• Is the Potential Equalization Line connected?

• Are the terminals correctly assigned?

• Are the cable glands and dummy plugs tight?

• Are the fieldbus connectors and the FHX40 connector fixed securely?

• Are the lids screwed tightly onto the terminal compartments?

• For dust ignition-proof devices: Is the protective sleeve for the FHX40 socket correctly

attached?

• Is the cover of the terminal compartment 1 secured by the cover clamp?

WARNING

!

The Gammapilot M may only be operated, if the cover of the terminal compartment 1

is tightly closed.

r

C

r

S

1

2

r

M

m

V

Page 31

Gammapilot M FMG60 HART Operation

Endress+Hauser 31

5Operation

5.1 Overview over the operating options

5.1.1 4 to 20mA with HART protocol

A0018095

1 PLC (programmable logic controller) 5 Gammapilot M

2 Computer with operating tool (e.g. FieldCare) 6 Field Xpert SFX100

3 Commubox FXA291 with ToF Adapter FXA291 7 VIATOR Bluetooth modem with connection cable

4 FHX40 8 Commubox FXA195 (USB)

If the HART communication resistor is not built into the supply unit, it is necessary to insert

a communication resistor of 250 into the 2-wire line.

Operation via the service interface

• With the display and operating unit FHX40

• With a personal computer, Commubox FXA291 with ToF Adapter FXA291 (USB) and the

operating program "FieldCare". FieldCare is a graphical operating software for devices from

Endress+Hauser. It assists with commissioning, securing data, signal analysis and

documentation of the measuring point.

Operation via HART

• With Fiel Xpert SFX100

• With the Commubox FXA195 and the operating program "FieldCare"

4

5

8

22

3

7

6

1

Page 32

Operation Gammapilot M FMG60 HART

32 Endress+Hauser

5.2 Display operation

5.2.1 Display and operating elements

The LCD module VU331 for displaying and operating is inside the remote display and

operating unit FHX40. The measured value can be read off through the FHX40 sight glass.

In order to operate the instrument, the FHX40 must be opened by removing the four screws.

A0018096

1 Gammapilot M

2 FHX40

3Operating module VU331

Display and operating module VU331

A0018097

1 Operating keys 4 Function name

2 Bargraph 5 Parameter Identification number

3Symbols

Display symbols

The following table describes the symbols that appear on the liquid crystal display:

1

2

3

ENDRESS + HAUSER

E

+–

1

2

3

4

5

Symbol Meaning

ALARM_SYMBOL

This alarm symbol appears when the instrument is in an alarm state. If the symbol flashes, this

indicates a warning.

LOCK_SYMBOL

This lock symbol appears when the instrument is locked, i.e. if no input is possible.

COM_SYMBOL

This communication symbol appears when data transmission via HART, PROFIBUS PA or

FOUNDATION Fieldbus, for example, is in progress.

SIMULATION_SWITCH_ENABLE

This communication symbol appears when simulation in FOUNDATION Fieldbus is enabled via the

DIP switch.

Page 33

Gammapilot M FMG60 HART Operation

Endress+Hauser 33

Function of the keys

Key(s) Meaning

O

or

V

Navigate upwards in the selection list.

Edit numeric value within a function.

S

or

W

Navigate downwards in the selection list.

Edit numeric value within a function.

X

or

Z

Navigate to the left within a function group.

F

Navigate to the right within a function group, confirmation.

O

and

F

or

S

and

F

Contrast settings of the LCD.

O

and S and

F

Hardware lock / unlock

After a hardware lock, an operation of the instrument via display or communication

is not possible! The hardware can only be unlocked via the display.

An unlock parameter must be entered to do so.

Page 34

Operation Gammapilot M FMG60 HART

34 Endress+Hauser

5.2.2 The operating menu

Function code

The functions of the Gammapilot M are arranged in an operating menu. To ensure easy

orientation within the menu, a unique position code is indicated on the display for each

function. This code consists of one alphabetic and two numeric characters.

A0019876-EN

1Measuring mode

2Function group

3Function

• The alphabetic character specifies the current measuring mode of the Gammapilot M:

– L: level

– S: limit (switch)

– D: density

– C: concentration

– *: no measuring mode selected yet

• The first numeric character identifies the function group:

– basic setup *0

– calibration *1

– Safety settings *2

– ...

• The second numeric character numbers the individual functions within the function group:

basic setup *0

– today's date *01

– beam type *02

– isotope *03

– operating mode *04

– ...

Hereafter, the position is always given in brackets after the function name. "*" (not yet

selected) is always indicated as the measurement method, e.g. "present date" (*01).

1 2

3

Page 35

Gammapilot M FMG60 HART Operation

Endress+Hauser 35

Operation using the onsite display VU331

Selection and configuration in Operation menu:

1. Change from Measured Value Display to Group Selection by pressing F.

2. Press S or O to select the required Function Group and confirm by pressing F.

The active selection is marked by a

in front of the menu text.

3. Activate Edit mode with O or S.

Selection menus

a. Select the required parameter in the function selected with S or O.

b. F confirms selection;

appears in front of the selected parameter.

c. F confirms the edited value; system quits edit mode.

d. Simultaneous pressing of O and S interrupts selection; system quits edit mode.

Typing in numerals and text

a. Press O or S to edit the first character of the numeral / text.

b. F positions the cursor at the next character; continue with a. until you have

completed your input.

c. If a symbol appears at the cursor, press F to accept the value entered; system quits

edit mode.

d. If a symbol appears at the cursor, press F to return to the previous character (e.g.

for correction of entries).

e. Simultaneous pressing of O and S interrupts selection; system quits edit mode.

4. Press F to select the next function.

5. Press O and S simultaneously once; return to previous function.

Press O and S simultaneously twice; return to Group Selection.

6. Press O and S simultaneously to return to Measured value display.

Basic setup Todays date Isotop Return to

group selection

Calibration 3 137 Cs

Safety setting 60Co

Temp. Comp. no comp.

Linearisation

...

>3 s

ESC ESC

S S

2 x

ESC

S

ESC

S

F

ENDRESS + HAUSER

E

+

–

S

F

F

S

Page 36

Operation Gammapilot M FMG60 HART

36 Endress+Hauser

5.3 Alternative operation options

Apart from local operation, you can also parameterise the measuring instrument and view

measured values by means of a HART protocol. There are two options available for

operation:

• Operation via the universal handheld operating unit Field Xpert SFX100

• Operation via the Personal Computer (PC) using the operating program FieldCare

NOTICE

The device can also be operated locally using the keys. If operation is prevented by the

keys being locked locally, parameter entry via communication is not possible either.

5.3.1 Operation via Field Xpert SFX100

Compact, flexible and robust industry handheld terminal for remote parametrization and

measured value inspection via the HART current output or FOUNDATION Fieldbus. For

details refer to BA00060S/04/EN.

5.3.2 FieldCare operating program

FieldCare is an Endress+Hauser asset management tool based on FDT technology. With

FieldCare, you can configure all Endress+Hauser devices as well as devices from other

manufacturers that support the FDT standard. Hardware and software requirements you can

find on the internet:

www.endress.com

select your country search: FieldCare FieldCare Technical Data.

FieldCare supports the following functions:

• Configuration of transmitters in online operation

• Loading and saving device data (upload/download)

• Documentation of the measuring point

Connection options:

• HART via Commubox FXA195 and the USB port on a computer

• Commubox FXA291 with ToF Adapter FXA291 via service interface

Page 37

Gammapilot M FMG60 HART Operation

Endress+Hauser 37

5.4 Lock/unlock configuration

5.4.1 Software security locking

Enter a number 100 into the "unlock parameter" (*A4) function in the "diagnostics"

(*A) function group. The symbol appears on the display. Inputs are no longer possible.

If you try to change a parameter, the device jumps to the "unlock parameter" (*A4)

function. Enter "100". Now change the parameters.

5.4.2 Hardware security locking

Press S, O and F simultaneously. Inputs are no longer possible.

If you try to change a parameter, the following appears:

Press S, O and F simultaneously. The "unlock parameter" (*A4) function appears.

Enter "100". Now change the parameters.

NOTICE

A hardware locking can only be unlocked again via the display by pressing the O, S and

F keys at the same time again. It is not possible to unlock the hardware by

communication.

5.5 Reset to the default configuration

It is advisable to reset the customer parameters if you want to use a device with an unknown

history. Effects of resetting:

• All customer parameters are reset to their default values.

• Linearization is switched to "linear", but the table values are kept. The table can be

switched back on in the "linearization" (*4) function group in the "linearization" (*40/

*46) function.

In order to carry out the reset, enter "333" in the "reset" (*A3) function in the "diagnostics"

(*A) function group.

CAUTION

!

A reset may lead to impairment of the measurement. As a rule, a basic calibration is

required after a reset. All the calibration data are deleted after a reset. A complete

calibration is needed to put the measurement back into operation.

NOTICE

The default values of each parameter are shown in bold in the menu overview in the

appendix.

On-site display

unlock parameter 0A4

Hardware locked

Page 38

Commissioning Gammapilot M FMG60 HART

38 Endress+Hauser

6 Commissioning

NOTICE

This chapter describes the commissioning of the Gammapilot M using the operating

module VU331 (which is located in the remote display and operating unit FHX40).

Commissioning using the "FieldCare" or the "Field Xpert SFX100" is similar. For further

instructions to the operating program "FieldCare" see BA00027S/04/EN or the

BA00060S/04/EN supplied together with the Field Xpert SFX100.

6.1 Calibration: overview

A detailed description of the functions used can be found in the following sections:

ä 40, "Basic setup"

ä 46, "Calibration for level measurement and limit detection"

ä 61, "Calibration for density and concentration measurements"

ä 69, "Density measurement/temperature-compensated"

Power up instrument

see ä 39,

"Switching on the device"

Basic setup

see ä 40, "Basic setup"

Calibration for level measurement and level limit detection

Calibration for density and concentration measurements

Calibration for density measurements/ temperature compensated

see ä 46, "Calibration for level

measurement and limit detection"

see ä 61, "Calibration for density and concentration measurements"

see ä 69, "Density measurement/temperature-compensated"

Additional settings

see "Description of Instrument

Functions" BA00287F/00/EN

Page 39

Gammapilot M FMG60 HART Commissioning

Endress+Hauser 39

6.2 Switching on the device

NOTICE

Error messages A165 "electronics defect" and A635 "present date not defined"

The Gammapilot M contains 2 real-time clocks for the decay compensation, which are

permanently compared to each other for safety reasons. In order to bridge voltage

interruptions, the clocks are buffered with a capacitor. To ensure that the clocks work

correctly and retain the date in the event of a voltage interruption, this capacitor must have

a minimum charge. If the A165 "Electronics defect" or A635 "Present date not defined" error

message appears after switching on the Gammapilot M, then the capacitor may possibly

not yet be charged sufficiently. In this case, the Gammapilot M must be operated at the

operating voltage for at least 20 to 30 minutes, in order to charge the capacitor. After this,

the date must be entered correctly. If the error message still persists subsequent to this, it

can be deleted by switching the Gammapilot M off and on.

After switching on the supply voltage, the instrument is first initialized. Due to internal

memory tests, this takes approx. 2 minutes.

On-site display Meaning

FMG60

Then, the following appear for approximately five seconds:

•Device type

•Software version

• Type of the communication signal

V01.03.06 HART

On first power up you are requested to select the language for

the display texts.

Language 092

Select the language with the O and S keys.

Confirm your choice by pressing F twice.

Englisch

Français

Español

After that the measured value display appears. Now you can

perform the basic setup and the calibration.

Press F to switch to the group selection.

Group selection

Press F again to enter the first function of the "basic setup"

function group.

Basic setup

Calibration

Safety settings

Page 40

Commissioning Gammapilot M FMG60 HART

40 Endress+Hauser

6.3 Basic setup

6.3.1 "Present date" (*01)

6.3.2 "Beam type" (*02)

6.3.3 "Isotope" (*03)

On-site display Meaning

Present date *01 Date and time of the basic setup are specified in this function.

Each of these values must be confirmed by "E" after it has been

entered.

17.11.04 10:30

dd.mm.yy hh:mm

On-site display Meaning

Beam type *02

This function is used to specify whether the radiation source

used emits radiation continuously or whether it is modulated

(for grammagraphy suppression).

• Standard/continuous (permanent, continuous radiation)

• Modulated (modulated radiation source)

Standard/cont.

Modulated

On-site display Meaning

Isotope *03

This function is used to specify which isotope is used for the

measurement. The Gammapilot M needs this information for

the decay compensation.

137 Cs

60 Co

no compens.

Page 41

Gammapilot M FMG60 HART Commissioning

Endress+Hauser 41

6.3.4 "Operating mode" (*04)

NOTICE

The selection can be performed only once and the function is automatically locked after

that. It can only be unlocked again by a reset of the Gammapilot M ("Reset" (*A3)

function).

A0018107

A One Gammapilot M is sufficient for measuring ranges up to 2 m (6.6 ft ); For larger measuring ranges as many

Gammapilot M as required can be connected (cascading mode). By Software settings they are defined as

B Master

CSlave(s) or

DEnd-Slave

1 4 to 20 mA HART; PROFIBUS PA; FOUNDATION Fieldbus

Options/display:

• Stand alone: This option is selected if the Gammapilot M is used as a single instrument.

• Master: This option is selected if the Gammapilot is located at the beginning of a

cascading chain. It receives pulses from a connected slave, adds its own pulses and

calculates the measuring value from this total.

• Slave: This option is selected if the Gammapilot M is located in the middle of a cascading

chain. It receives the pulses from an additional connected slave or end-slave, adds its own

pulses and transmits this total to the next device (master or slave). After selecting this

option, the basic setup is finished. When cascading several transmitters the further

calibration is performed on the master only.

• End slave: This option is selected if the Gammapilot M is located at the end of a cascading

chain. It does not receive pulses from another device but transmits its own pulses to the

next device (master or slave). After selecting this option, the basic setup is finished. When

cascading several transmitters the further calibration is performed on the master only.

• Not defined: Is displayed if no operating mode has been selected yet. In order to continue

the basic setup, a selection is necessary.

NOTICE

If a "Slave" or an "End-slave" are connected to the "FieldCare", the pulse rate of this

device is displayed in the header instead of the measured value.

On-site display Meaning

Operating mode *04

This function is used to specify in which operating mode the

Gammapilot M will be used.

Stand alone

Master

Slave

A

B

1

C

D

Page 42

Commissioning Gammapilot M FMG60 HART

42 Endress+Hauser

6.3.5 "Measuring mode" (*05)

Further options:

• Level measurement (continuous)

• Level limit detection

• Density measurement (with temperature compensation if required)

• Concentration measurement (density measurement followed by linearization)

NOTICE

The selection can be performed only once and the function is automatically locked after

that. It can only be unlocked again by a reset of the Gammapilot M ("Reset" (*A3)

function).

A0018108

A Level measurement (continuous)

Density

B Level limit detection E Concentration

C Density measurement (with temperature compensation if required)

D Concentration measurement (density measurement followed by linearization)

On-site display Meaning

Meas. mode *05

This function is used to select the desired measuring mode.

Level

Limit

Density

A

B

C

D

r

E

Page 43

Gammapilot M FMG60 HART Commissioning

Endress+Hauser 43

6.3.6 "Density unit" (*06)

Further options:

•g/cm

3

•g/l

• lb/gal; [1g/cm

3

= 8,345 lb/gal]

•lb/ft

3

; [1g/cm3 = 62,428 lb/ft3]

• 1°Brix = [270 (1 - 1/x)]

• °Baumé; [1°Baumé = 144.3 (1 - 1/x)]

• °API; [1°API = 131.5 (1.076/x - 1)]

• °Twaddell; [1°Twaddell = 200 (x-1)]

"x" refers to the density in g/cm

3

. The formula indicates how many degrees this density

corresponds to.

6.3.7 "Min. density" (*07)

6.3.8 "Max. density" (*08)

6.3.9 "Pipe diameter unit" (*09)

On-site display Meaning

Density unit *06

This function is needed for density and concentration measurements only. It is used to select the density unit.

g/cm3

g/l

lb/gal

On-site display Meaning

Min. density *07

This function is needed for density and concentration measurements only. It is used to specify the lower limit of the density

range.

The output current for this density is 4 mA.

0,9500 g/cm³

On-site display Meaning

Max. density *08

This function is needed for density and concentration measurements only. It is used to specify the upper limit of the density

range.

The output current for this density is 20 mA.

1,2500 g/cm³

On-site display Meaning

Pipe diam. unit *09

This function is needed for density and concentration measurements only. It is used to select the unit for the pipe diameter.

1 inch = 25,4 mm

mm

inch

Page 44

Commissioning Gammapilot M FMG60 HART

44 Endress+Hauser

6.3.10 "Pipe diameter" (*0A)

A0018109

Always specify the complete irradiated measuring path L in the "pipe diameter" (*0A) function. Depending on the installation, this

value may be larger than the actual pipe diameter.

On-site display Meaning

Pipe diam. *0A

This function is needed for density and concentration measurements only. It is used to specify the irradiated measuring path

L. With standard installation, this value is identical to the inner

pipe diameter D

I

. For other installations (in order to enlarge

the irradiated measuring path) it may be larger (see figure).

The pipe walls are not to be considered a part of the measuring

path.

200 mm

1

1

1

L

L

L

a

D

I

a

L

30°

2.0 x D

I

Page 45

Gammapilot M FMG60 HART Commissioning

Endress+Hauser 45

6.3.11 "Output damping" (*0B)

A0018110

1 Level change (or density change)

2Measured value

Range of values

1 to 999 s

Default

The default depends on the selected "measuring mode" (*05):

•Level: 6 s

• Limit: 6 s

• Density: 60 s

• Concentration: 60 s

Selecting the output damping

The best value of the output damping depends on the process conditions. By enlarging the

output damping, the measured value becomes considerably steadier but also slower.

In order to dampen the influence of strongly fluctuating surfaces or stirrers, it is advisable to

enlarge the output damping. On the other hand, if rapid changes of the measured value have

to be detected accurately, the output damping may not be selected to large.

On-site display Meaning

Output damping *0B

This function is used to specify the output damping (in

seconds) by which changes of the measured value are attenuated.

After a surge in the level or density it takes 5 x until the new

measured value is reached.

60 s

5 x t

t

L

1

2

Page 46

Commissioning Gammapilot M FMG60 HART

46 Endress+Hauser

6.4 Calibration for level measurement and limit detection

6.4.1 Basic principles

The calibration points for the measurement are entered in the "calibration" (*1) function

group. Each calibration point consists of a level and the associated pulse rate.

Calibration points for level measurement

A0018111

A Background calibration

B Full calibration

C Empty calibration

Background calibration

Refers to the following situation:

• The radiation is switched off.

• Within the measuring range, the vessel is filled as far as possible (ideally: 100%).

The background calibration is necessary, in order to register the natural background

radiation at the mounting position of the Gammapilot M. The pulse rate of this background

radiation is automatically subtracted from any other measured pulse rate. That means: only

the part of the pulse rate which originates from the applied radiation source is taken into

account and is displayed.

As opposed to the radiation of the applied source, the background radiation remains nearly

constant during the complete measurement. Therefore, it is not submitted to the automatic

decay compensation of the Gammapilot M.

Full calibration

Refers to the following situation:

• The radiation is switched on.

• Within the measuring range, the vessel is filled as far as possible (ideally: 100%,

minimum 60%).

If the vessel cannot be filled to at least 60% during the calibration, the full calibration can

alternatively performed with the radiation being switched off, which is a way of simulating

a filling of 100%. In this case, the full calibration is identical to the background calibration.

As the pulse rate of the background radiation is automatically subtracted, the displayed

pulse rate is about 0 cps.

NOTICE

This type of simulated calibration is not possible with self-radiating media. In this case

it is always necessary to perform the background and full calibration with the vessel

filled to 100%.

C

B

A

OFF

ON ON

Page 47

Gammapilot M FMG60 HART Commissioning

Endress+Hauser 47

Empty calibration

Refers to the following situation:

• The radiation is switched on.

• Within the measuring range, the vessel is emptied as far as possible (ideally: 0%,

maximum 40%).

Calibration points for limit detection

A0018112

A Background calibration

B Covered calibration

C Free calibration

Background calibration

Refers to the following situation:

• The radiation is switched off.

• If possible, the radiation path is completely covered.

The background calibration is necessary, in order to register the natural background

radiation at the mounting position of the Gammapilot M. The pulse rate of this background

radiation is automatically subtracted from any other measured pulse rate. That means: only

the part of the pulse rate which originates from the applied radiation source is taken into

account and is displayed.

As opposed to the radiation of the applied source, the background radiation remains nearly

constant during the complete measurement. Therefore, it is not submitted to the automatic

decay compensation of the Gammapilot M.

Covered calibration

Refers to the following situation:

• The radiation is switched on.

• If possible, the radiation path is completely covered.

If the radiation path cannot be completely covered during the calibration, the covered

calibration can alternatively be performed with the radiation being switched off, which is a

way of simulating complete covering. In this case, the covered calibration is identical to the

background calibration. As the pulse rate of the background radiation is automatically

subtracted, the displayed pulse rate is about 0 c/s.

NOTICE

This type of simulated calibration is not possible with self-radiating media. In this case

it is always necessary to perform the background calibration and the covered

calibration with the radiation path completely covered.

Free calibration

Refers to the following situation:

• The radiation is switched on.

• The radiation path is completely free.

AB

C

OFF ON ON

Page 48

Commissioning Gammapilot M FMG60 HART

48 Endress+Hauser

Methods for entering the calibration points

Automatic calibration

For an automatic calibration, the vessel is filled to the required value. For the background

calibration the radiation remains switched off, for the other calibration points the radiation

is switched on.

The Gammapilot M automatically records the pulse rate. The associated level is entered by

the user.

Manual calibration

If during the commissioning of the Gammapilot M one or more calibration points cannot be

realized (e.g. because the vessel cannot be sufficiently filled or emptied), the calibration

point must be entered manually.

That is, not only the level but also the associated pulse rate must be entered by the user.

For details concerning the calculation of the count rate please refer to your Endress+Hauser

sales organization.

NOTICE

Calibration date and calibration

‣ When calibrating manually, the calibration date is not set automatically. Instead, it must

be entered manually into the "calibration date" (*C7) function.

‣ A manually entered calibration point should be replaced by an automatic calibration as

soon as the associated level occurs during the operation of the plant. This recalibration is

advisable because calibration points entered automatically result in more precise

measurement results than calculated ones.

Page 49

Gammapilot M FMG60 HART Commissioning

Endress+Hauser 49

6.4.2 Background calibration

Excerpt from the operating menu

The following excerpt from the operating menu shows how the background calibration is