Emerson LR128 Instruction Manual

Instruction Manual

November 2014

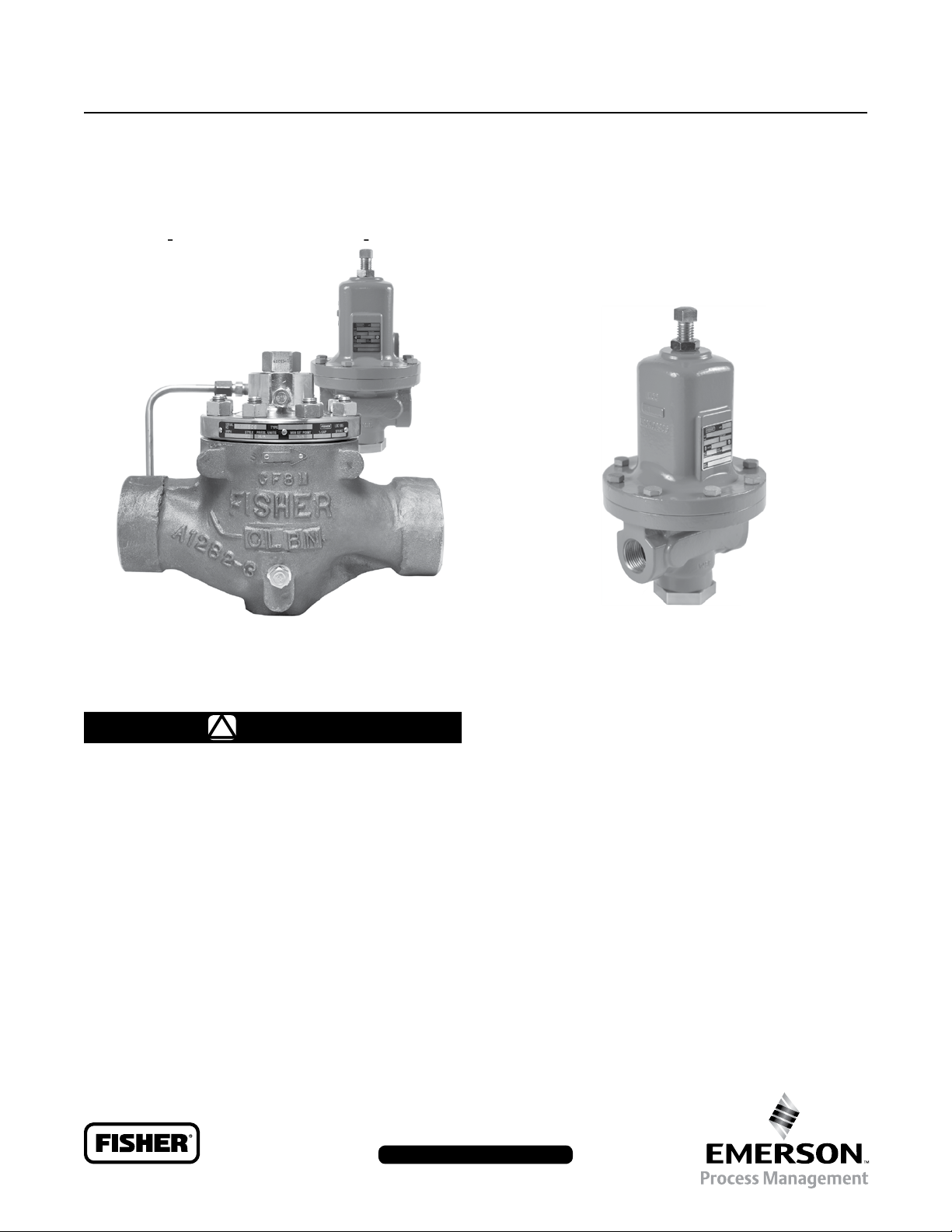

Type LR128 Relief Valve or

Backpressure Liquid Regulator

Type LR128

TYPE LR128 REGULATOR

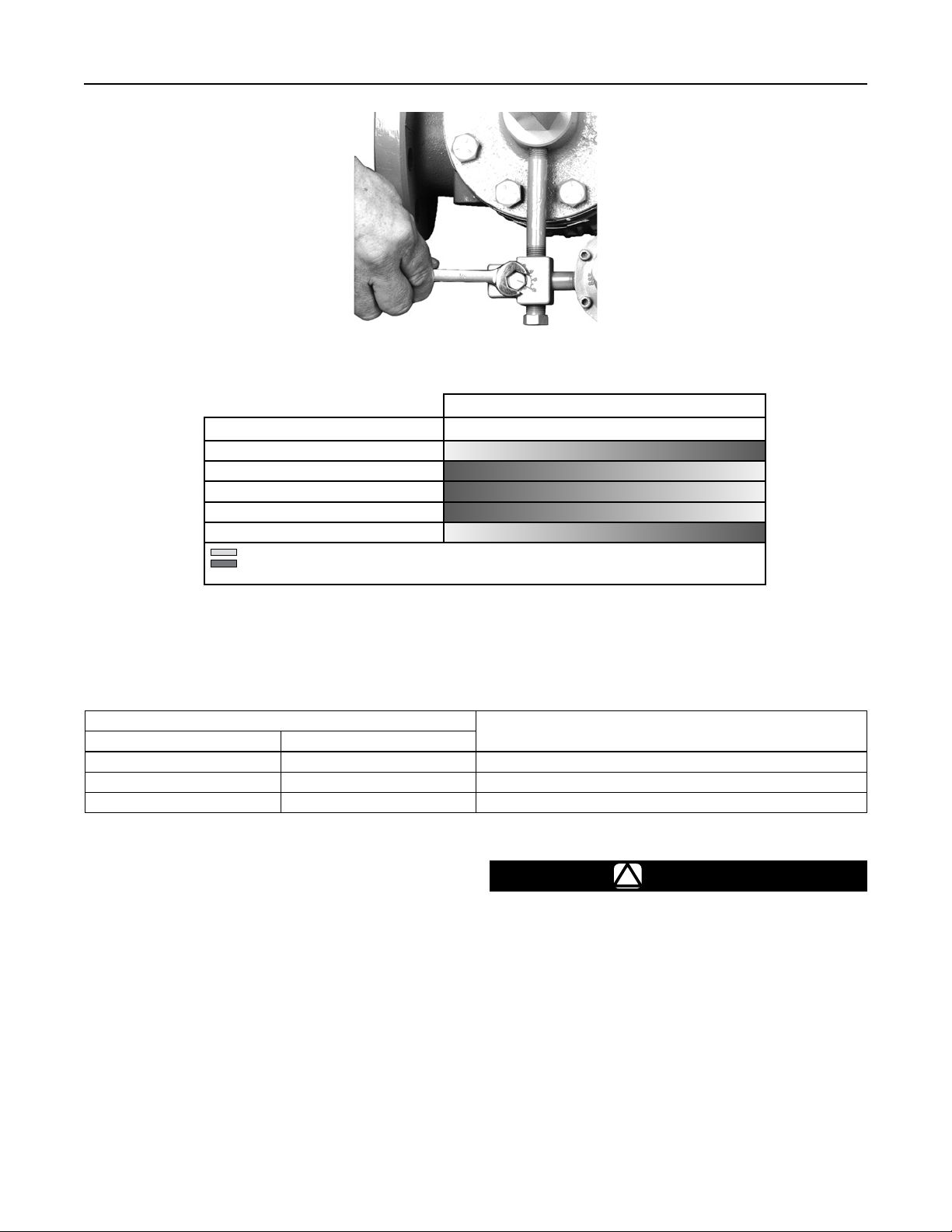

Figure 1. Type LR128 Relief Valve or Backpressure Regulator and Type MR98H Pilot

WARNING

!

Failure to follow these instructions or

to properly install and maintain this

equipment could result in bursting

of the equipment and/or chemical

contamination causing property damage

and personal injury or death.

Fisher® relief valves and backpressure

regulators must be installed, operated

and maintained in accordance with

federal, state and local codes, rules

and regulations and Emerson Process

Management Regulator Technologies, Inc.

(Emerson™) instructions.

If the relief valve or backpressure regulator

discharges process uid or a if leak

develops in the system, service to the unit

TYPE MR98H PILOT

may be required. Failure to correct trouble

could result in a hazardous condition.

Call a quali ed service person to service

the unit. Installation, operation and

maintenance procedures performed

by unquali ed personnel may result

in improper adjustment and unsafe

operation. Either condition may result

in equipment damage or personal

injury. Only a quali ed person must

install or service the relief valve or

backpressure regulator.

The Type LR128 is designed for liquid

service. Do not operate the regulator

in applications where temperatures are

below the process uid’s freezing point

or above its boiling point which are

dependent on the process uid and the

application pressures.

www.fisherregulators.com

D103578X012

Type LR128

Specications

Specications for the Type LR128 relief valve or backpressure regulator are shown below. Other information for the main

valve appears on the nameplate. The control spring range for the pilot is marked on the nameplate of Type MR98H pilot.

Main Valve Body Sizes, End Connection Styles

and Structural Design Ratings

(1)

See Table 1

Maximum Inlet Pressures

Type LR128 Main Valve: See Table 1

(1)

Type MR98H Pilot: See Table 2

Type 112 Restrictor: 1500 psig / 103 bar

Maximum Outlet Pressure

Type LR128 Main Valve: See Table 1

Type MR98H Pilot: 450 psig / 31.0 bar

Relief Set Pressure/Backpressure Control Ranges

See Table 3

Main Valve Plug Travel

1 in. / DN 25: 0.37 in. / 9.4 mm

2 in. / DN 50: 0.68 in. / 17 mm

3 in. / DN 80: 0.98 in. / 25 mm

4 in. / DN 100: 1.19 in. / 30 mm

Main Valve Minimum Differential Pressures

(1)

See Table 6

Main Valve Maximum Differential Pressures

(1)

See Table 7

Main Valve Internal Inlet Strainer Sizes

1 in. / DN 25:

12 Mesh (0.0661 in. / 1.68 mm)

(2)

2, 3 and 4 in. / DN 50, 80 and 100:

10 Mesh (0.0787 in. / 2.00 mm)

Temperature Capabilities

(1)

(2)

See Table 11

Pressure Registration

External: 1/8 NPT

Spring Case Vent

Type Y602-12

Construction Materials

Type LR128 Main Valve

Body: WCC Steel, CF8M or CF3M Stainless steel

Bonnet: LF2 Steel or 316/316L Stainless steel

Bonnet Bushing: 416 Hardened Stainless steel

Type LR128 Main Valve (continued)

Spring: 302 Stainless steel or 17-7 Stainless steel

Top Plug: 17-4 Stainless steel

Bottom Plug: 416 Stainless steel

Inlet Strainer: Stainless steel

Diaphragm: Nitrile (NBR) or Fluorocarbon (FKM)

O-Rings: Nitrile (NBR) or Fluorocarbon (FKM)

Flanged Locknut: 17-4 Stainless steel

Backup Rings: Polytetrauoroethylene (PTFE)

Upper Spring Seat: 416 Stainless steel

Indicator Protector and Cover: Plastic

Indicator Stem: 303 Stainless steel

Indicator Fitting: 416 Stainless steel

Travel Indicator Plug: 416 Stainless steel

Type MR98H Pilot

Body: WCC Steel or CF8M Stainless steel

Spring Case: WCC Steel or CF8M Stainless steel

Orice: 416 Stainless steel

Valve Plug: 416 Stainless steel

Guide and Pusher Post: 416 Stainless steel

Gasket: Nitrile (NBR) or Fluorocarbon (FKM)

O-rings: Nitrile (NBR) or Fluorocarbon (FKM)

Diaphragm: Neoprene (CR) or Fluorocarbon (FKM)

Mounting Parts

Pilot Mounting Pipe Nipple: Plated steel or

Stainless steel

Pipe Fittings: Plated steel or Stainless steel

Tubing: Stainless steel

Type 112 Restrictor

Body: 15-5 Stainless steel

Groove Valve: 416 Stainless steel

Retainer: 416 Stainless steel

Pipe Plug: 316 Stainless steel

O-rings: Nitrile (NBR) or Fluorocarbon (FKM)

Options

• Pre-piped Pilot Supply

• Travel Indicator

Cage: 15-5 Stainless steel

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

2. Nominal sieve opening.

Introduction

Scope of the Manual

This Instruction Manual provides installation, startup,

adjustment, maintenance and parts ordering information

for Type LR128 relief valve or backpressure regulator,

1/2 NPT Type MR98H pilot and Type 112 restrictor.

2

Product Description

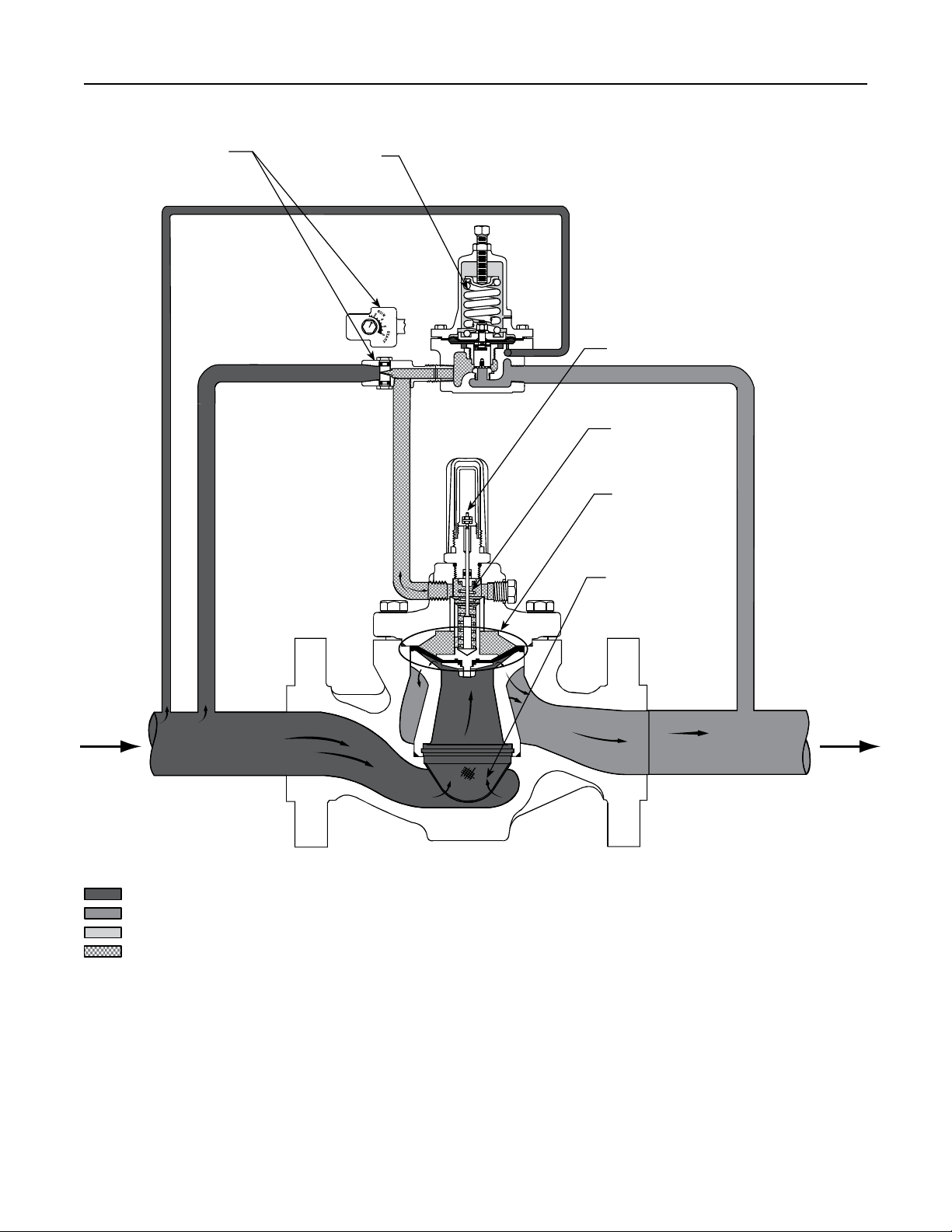

The Type LR128 pilot-operated, relief valve or

backpressure regulator is used for liquid applications

and include a Type 112 restrictor and a 1/2 NPT

Type MR98H pilot.

Type LR128

TYPE 112 RESTRICTOR

TYPE MR98H PILOT

O

MP

C

OPTIONAL TRAVEL INDICATOR

MAIN SPRING

DIAPHRAGM AND

PLUG ASSEMBLY

INTERNAL

STRAINER

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

LOADING PRESSURE

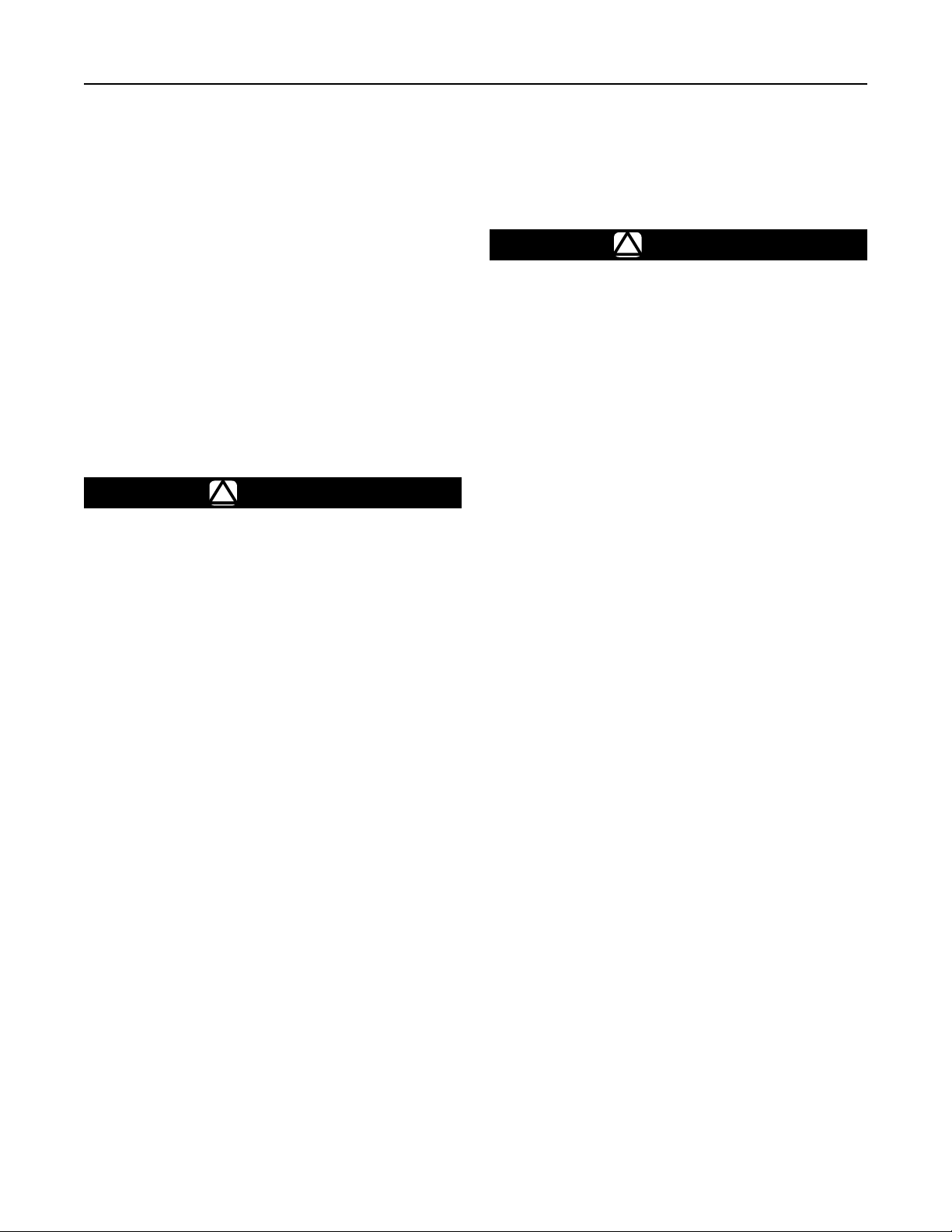

TYPE LR128 WITH TYPE MR98H PILOT AND TYPE 112 RESTRICTOR

Figure 2. Type LR128 Operational Schematic

3

Type LR128

Pilot Type Description

Type MR98H – High-pressure relief pilot for 25 to

375 psig / 1.7 to 25.9 bar set pressures. Designed to

handle inlet pressures up to 450 psig / 31.0 bar.

Principle of Operation (Figure 2)

A pressure relief valve is a throttling pressure control

device that limits pressure build-up, it opens to prevent

the rise of internal pressure in excess of a specied

value. Fisher® relief valves cannot be used as ASME

safety relief valves.

A backpressure regulator is a device that maintains

a desired upstream pressure by varying the ow

in response to changes in upstream pressure. It

functions the same as a relief valve, i.e., it opens on

increasing upstream pressure.

Relief Valve

As long as the inlet pressure is below the set pressure,

the Type MR98H pilot control spring keeps the pilot

valve plug closed. Inlet pressure passes through the

Type 112 restrictor and registers as loading pressure

on top of the Type LR128 diaphragm and plug

assembly. Force from the main spring, in addition

to inlet pressure bleeding through the Type 112

restrictor, provides a downward loading pressure to

keep the main valve diaphragm and plug assembly

tightly shutoff.

When the inlet pressure rises above the set pressure,

the pressure on the pilot diaphragm overcomes the

pilot control spring and opens the pilot valve plug. The

pilot then exhausts the loading pressure from the top

of the main valve diaphragm and plug assembly. The

inlet pressure unbalance overcomes the main spring

force and opens the diaphragm and plug assembly.

The pilot continuously exhausts process uid when the

inlet pressure is above the set pressure.

pilot valve plug closed. Force from the main spring,

in addition to inlet pressure bleeding through the

Type 112 restrictor, provides downward loading

pressure to keep the main valve diaphragm and plug

assembly tightly shutoff.

When inlet pressure rises above the set pressure,

pressure on the pilot diaphragm overcomes the control

spring to stroke the valve plug open. The pilot then

exhausts loading pressure from the top of the main

valve diaphragm. Inlet pressure unbalance overcomes

the main spring force to open the main valve

diaphragm and plug assembly.

As inlet pressure drops below set pressure, the pilot

control spring overcomes the diaphragm force to

stroke the valve plug down to close. Force from the

main spring, along with pilot loading pressure, pushes

the diaphragm and plug assembly onto the tapered

edge seat, producing tight shutoff.

Installation

WARNING

!

Personal injury, equipment damage or

leakage due to escaping process uid

or bursting of pressure-containing

parts may result if the Type LR128 is

overpressured or is installed where

service conditions could exceed

the limits given in Specications

section or where conditions exceed

any ratings of the adjacent piping or

piping connections.

To avoid such injury or damage,

Type LR128 relief valve or backpressure

regulator where:

• Service conditions are within unit

capabilities (including those in the

Specications section).

install a

As the inlet pressure drops below the set pressure,

the pilot control spring closes the pilot valve plug and

the exhaust to atmosphere stops. Force from the main

spring, along with pilot loading pressure, pushes the

diaphragm and plug assembly onto the tapered edge

seat, producing tight shutoff.

Backpressure Regulator

As long as inlet pressure remains below set pressure,

the Type MR98H pilot control spring keeps the

4

• Service conditions are within applicable

codes, regulations or standards.

Additionally, physical damage to the

relief valve or backpressure regulator

could break the pilot off the main valve,

causing personal injury and property

damage due to escaping process uid.

To avoid such injury and damage, install

the regulator in a safe location.

Type LR128

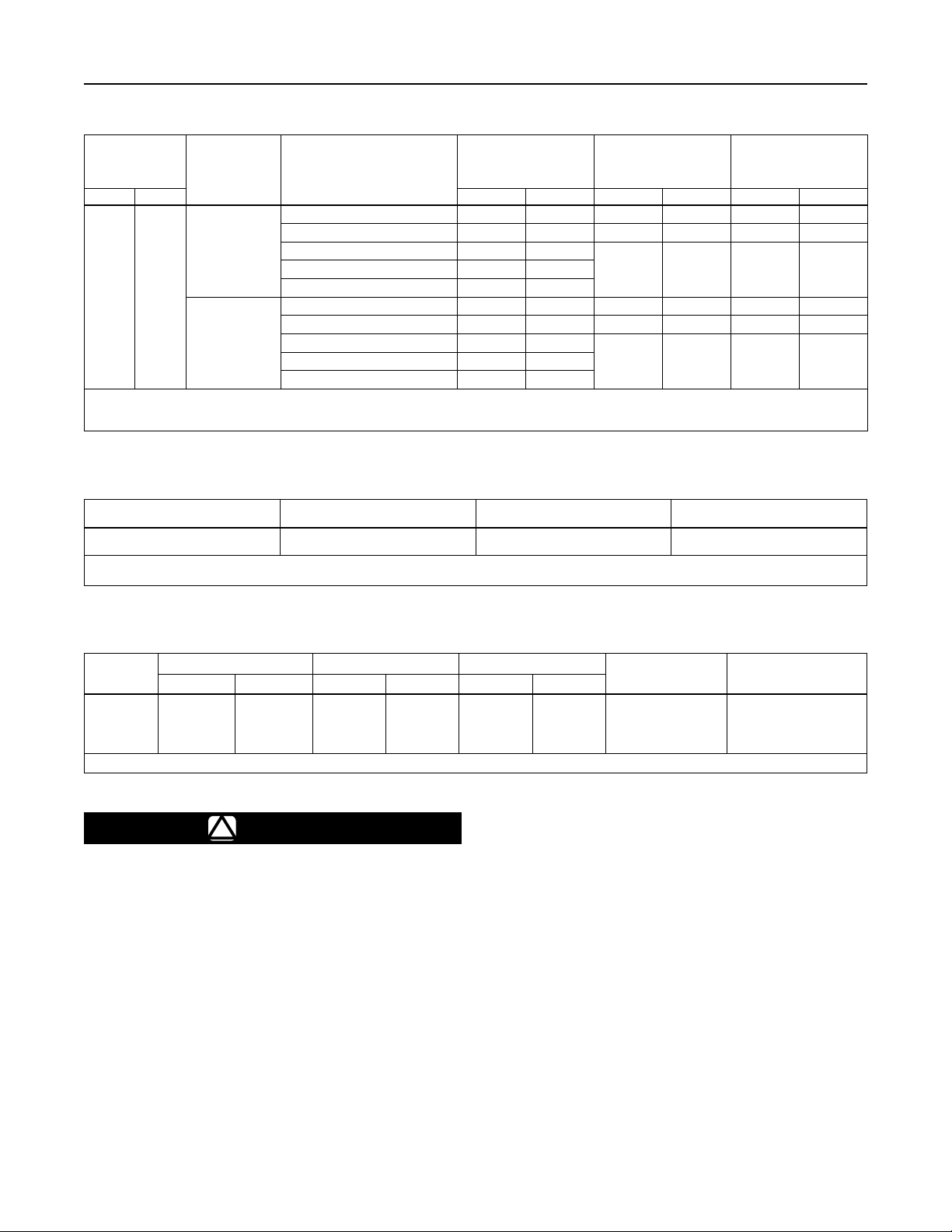

Table 1. Type LR128 Main Valve Body Sizes, End Connection Styles, Structural Design Ratings and Maximum Operating Inlet Pressures

MAIN VALVE

BODY SIZE

In. DN psig bar psig bar psig bar

1, 2,

3 and

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

2. Ratings and end connections for other than ASME standard can usually be provided. Contact your local Sales Ofce for assistance.

3. Maximum cold working pressure (CWP) per ASME B16.34 or product bulletin limit, whichever is lowest. Temperature may decrease these maximum pressures.

25, 50,

80 and

4

100

MAIN VALVE

BODY

MATERIAL

WCC Steel

CF8M

Stainless steel

END CONNECTION STYLE

NPT or SWE (1 and 2 in. only) 1500 103 450 31.0 450 31.0

CL150 RF 290 20.0 290 20.0 290 20.0

CL300 RF 750 51.7

PN 16/25/40 RF 580 40.0

NPT (1 and 2 in. only) 1440 99.2 450 31.0 450 31.0

CL150 RF 275 19.0 275 19.0 275 19.0

CL300 RF 720 49.6

PN 16/25/40 RF 580 40.0

STRUCTURAL DESIGN

(2)

RATING

(3)

Table 2. Type MR98H Pilot Maximum Cold Working Pressure

BODY SIZE

1/2 NPT

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation should not be exceeded.

2. Temperature and/or the body end connection may decrease these maximum pressures.

BODY AND SPRING

CASE MATERIAL

Steel

Stainless steel

MAXIMUM INLET PRESSURE MAXIMUM OUTLET PRESSURE

450 psig / 31.0 bar 450 psig / 31.0 bar

MAXIMUM OPERATING

RELIEF (INLET)

PRESSURE INCLUDING

BUILD-UP

450 31.0 450 31.0CL600 RF 1500 103

450 31.0 450 31.0CL600 RF 1440 99.2

(3)

(1)(2)

MAXIMUM OPERATING

OUTLET PRESSURE

(1)

Table 3. Relief Set Pressure or Backpressure Control Ranges

PILOT

Type

MR98H

1. 150 to 375 psig / 10.3 to 25.9 bar spring range is for the Type MR98HH pilot construction.

SET PRESSURE RANGE SPRING WIRE DIAMETER SPRING FREE LENGTH

psig bar In. mm In. mm

25 to 75

70 to 140

130 to 200

150 to 375

1.7 to 5.2

4.8 to 9.7

9.0 to 13.8

(1)

10.3 to 25.9

WARNING

!

0.234

0.283

0.331

(1)

0.394

5.94

7.19

8.41

10.0

Liquid pressure control systems should

be designed using engineering practices

to eliminate quick control starting or

stopping of the ow stream, which can

produce water hammer.

The robust design of the Type LR128 allows this relief

valve or backpressure regulator to be installed indoors

or outdoors. Type LR128 is designed to withstand the

elements. The powder paint coating protects against

minor impacts, abrasions and corrosion. When installed

outdoors, the Type LR128 does not require protective

housing. However, the Type MR98H pilot should be

SPRING PART NUMBER

AND COLOR

ERAA01910A0, Green

ERAA01911A0, Red

ERAA02889A0, Blue

1N943427142, Unpainted

2.595

2.44

2.250

5.063

65.9

62.0

57.2

129

SPRING MATERIAL

Powder-coated steel

Powder-coated steel

Powder-coated steel

Powder-coated steel

oriented so that the pilot spring case vent is pointed

down. Otherwise, make sure the vent is protected

so that rain, moisture, insects or any debris will not

accumulate inside or block the vent assembly.

When installed indoors, no remote venting is required

except on the pilot spring case. Refer to Step 8 of the

following procedure for the correct venting practices.

1. Only personnel qualied through training and

experience should install, operate and maintain

a relief valve or backpressure regulator. Before

installation, make sure that there is no damage

to or debris in the main valve body or pilot. Also,

make sure that all tubing and piping are clean

and unobstructed.

5

Type LR128

Note

The Type LR128 internal inlet strainer

is intended to prevent occasional

large particles from entering the main

valve. If the owing media contains

continuous particles, upstream ltration

is recommended before the main valve

and in the pilot supply piping (reference

Figure 3). See the Specications section

for the corresponding mesh size of the

internal inlet strainer.

2. A Type LR128 relief valve or backpressure regulator

may be installed in any orientation, as long as ow

through the unit matches the direction of the arrow

on the main valve body and the pilot vent is pointed

down. However, for easier maintenance, install the

regulator with the bonnet up.

CAUTION

Provide adequate support to the bonnet

when disassembling Type LR128

relief valve or backpressure regulator

installed in a vertical installation or

other application where the bonnet is

not oriented upward. Without adequate

support, the bonnet may fall and cause

physical injury when the cap screws

are loosened.

3. The standard pilot mounting position is as shown

in Figure 1. Rotate the bonnet (key 2, Figure 7) or

the pilot (Figure 14) for other mounting positions.

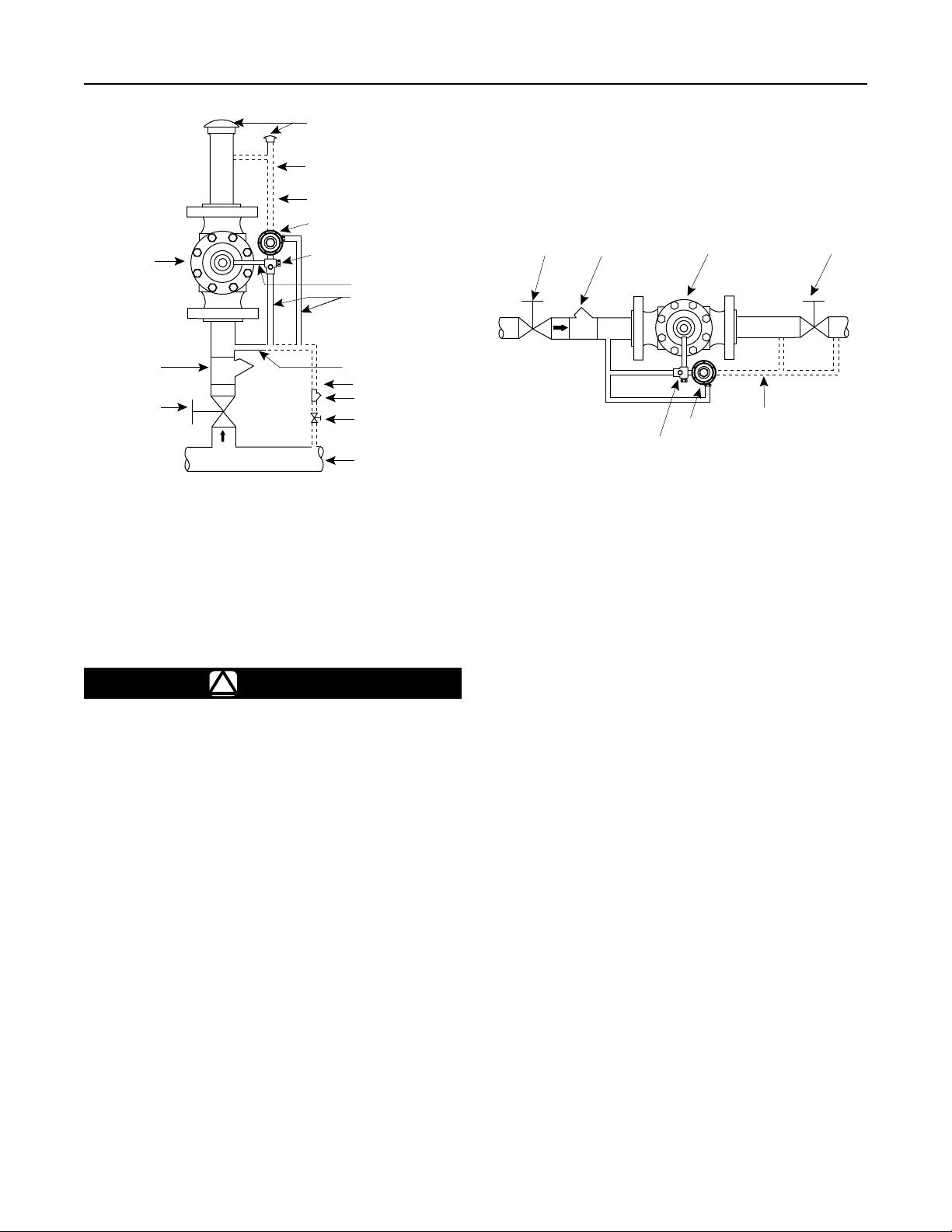

4. An upstream control line is required and must be

installed – as shown in Figure 3 – into the 1/8 NPT

connection in the pilot body assembly (Figure 14).

Do not make the upstream pipeline connection in

or directly downstream of a turbulent area such

as a swage or elbow. A lter or strainer may be

installed in the control line upstream of the pilot

to provide clean uid. Inspect and clean this lter

regularly to make sure it is not plugged, which can

prevent proper pilot operation.

5. Run a supply pressure line from the upstream

pipeline to the restrictor inlet (use 3/8 NPT outer

diameter tubing or larger). Install a lter or strainer

upstream of the restrictor, if needed, to keep the

supply source from clogging the restrictor or pilot.

Inspect and clean this lter regularly to make sure

it has not been plugged which can prevent proper

relief valve or backpressure operation.

6. Apply a good grade of pipe compound to the

external pipeline threads for a threaded body

or use suitable line gaskets for a anged body.

Use approved piping procedures when installing

the relief valve or backpressure regulator.

WARNING

!

When used in relief valve service, the

Type LR128

the environment. In toxic or hazardous

liquid service, leaked chemical may

accumulate and cause personal injury,

death or property damage due to

escaping uid.

To prevent such injury or damage,

provide piping or tubing to vent the

hazardous liquid to a remote, safe

location away from air intakes or any

hazard-prone location.

piping must be designed and installed to

guard against excessive ow restriction.

Protect the vent line or stack opening

against condensation or clogging.

For safety during shutdown, vent valves

are required immediately upstream

and downstream of the main valve on a

backpressure or bypass installation.

7. If system operation during maintenance is required,

install isolating and vent valves as needed.

8 The pilot spring case vent (key 54, Figure 14) must

be kept open to atmospheric pressure. A clogged

pilot spring case vent may cause the relief valve

or backpressure regulator to function improperly.

To prevent plugging (and to keep the spring case

from collecting moisture, corrosive chemicals or

other foreign material) point the vent down, orient

it to the lowest possible point on the spring case

or otherwise protect it. Protect the vent assembly

from icing, moisture or debris that may cause

blockage, as required. Inspect the vent regularly

to make sure it has not been plugged. To change

the vent orientation, twist the vent assembly in the

spring case.

9. To remotely vent a spring case, remove the vent

and install obstruction-free tubing or piping into

the 1/4 NPT vent tapping. Provide protection on a

remote vent by installing a screened vent cap onto

the remote end of the vent pipe.

may leak toxic chemical to

The exhaust

6

TYPE LR128

MAIN VALVE

NON-RESTRICTIVE

VENTS AND PIPING

ALTERNATE PILOT

EXHAUST PIPING

A

TYPE MR98H PILOT

TYPE 112 RESTRICTOR

C

D

Type LR128

BLOCK VALVE STRAINER BLOCK VALVE

TYPE LR128

MAIN VALVE

STRAINER

BLOCK VALVE

RELIEF PRESSURE CONTROL

A - VENT (TO DOWNSTREAM PIPING)

C - TO TYPE LR128 LOADING CHAMBER

D - PILOT SUPPLY (FROM UPSTREAM)

Figure 3. Typical Type LR128 Installation Schematic

Startup and Shutdown

CAUTION

If pressure is introduced rst to the

main valve before the pilot, the main

valve may go wide-open and subject the

downstream system to full inlet pressure.

Note

CONTROL LINE

ALTERNATE CONTROL LINE

STRAINER

HAND VALVE

MAIN PRESSURE LINE

D

TYPE 112 RESTRICTOR

BACKPRESSURE CONTROL

C

TYPE MR98H

A

ALTERNATE PILOT

EXHAUST PIPING

Shutdown

1. Close block valve and hand valve, if installed.

2. Slowly open upstream vent valve (not shown).

Backpressure Installation (Figure 3)

Startup

1. Close upstream and downstream vent valves

(not shown).

The maximum inlet pressure for specic

constructions are given in Tables 1 and

2. Use a pressure gauge to monitor inlet

pressure during startup.

Relief Installation (Figure 3)

Startup

1. Close upstream vent valve (not shown).

2. Slowly open block valve and hand valve, if installed.

3. Adjust the pilot as needed.

2. Slowly open upstream block valve rst and then

slowly open downstream block valve.

3. Adjust the pilot as needed. If the pilot is not piped

downstream, make sure the pilot exhaust is

pointed in the correct direction.

Shutdown

1. Close upstream block valve rst and then close the

downstream block valve.

2. Open downstream and upstream vent valves

(not shown).

7

Type LR128

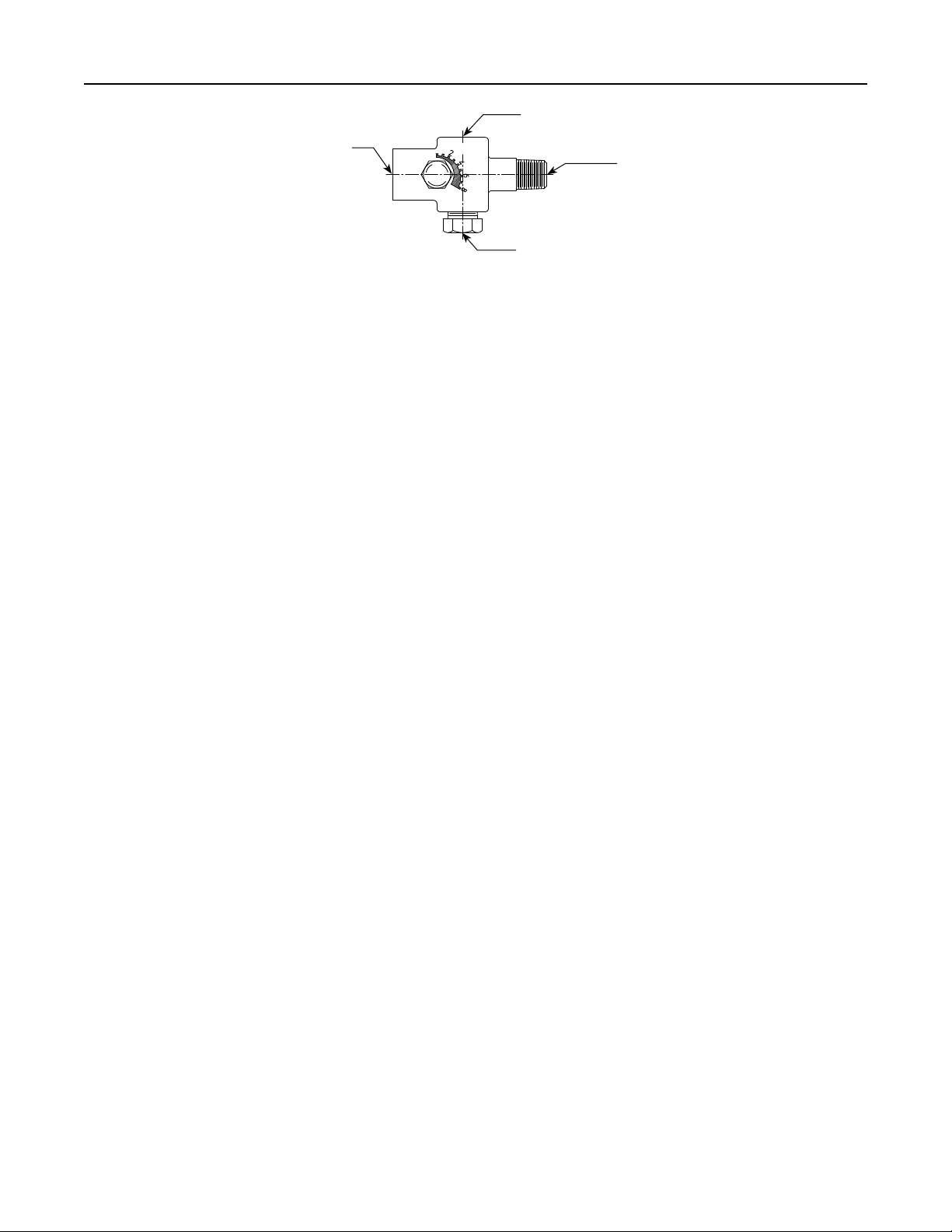

PILOT SUPPLY CONNECTION: 1/4 NPT PIPE

CONNECTS TO UPSTREAM PILOT SUPPLY TAP

LOADING CONNECTION: 1/4 NPT PIPE CONNECTS TO

TYPE LR128 DIAPHRAGM LOADING PORT

OUTLET CONNECTION: 1/4 NPT PIPE

CONNECTS TO PILOT INLET CONNECTION

11B5004-A

Figure 4. Type 112 Restrictor

Pilot Adjustment

The factory setting of the regulator can be varied

within the pressure range stamped on the nameplate.

To change the set (control) pressure, loosen the

jam nut (key 17, Figure 14) and turn the adjusting

screw (key 15) clockwise to increase set (control)

pressure or counterclockwise to decrease it. Monitor

the set (control) pressure with a test gauge during the

adjustment. Tighten the locknut to maintain the

desired setting.

Recommended set (control) pressure ranges available

and color codes of the respective springs are shown in

Table 3.

Type 112 Restrictor Adjustment (Figure 5)

OPTIONAL LOADING CONNECTION:

1/4 NPT NORMALLY PLUGGED

spaces of the restrictor. This may cause

the unit response to get slower and unit

performance to decrease. If clogging of

the restrictor is suspected, immediately

check and clean the restrictor.

Regular inspection of the restrictor

is recommended to ensure optimum

performance. Refer to the Type 112

Restrictor Maintenance section.

Likewise, debris in the process uid

may clog the restrictor. Install strainer

upstream of the regulator to prevent

debris from clogging the restrictor.

Regular inspection, maintenance and

cleaning of the strainer is recommended

to ensure optimum performance.

The Type 112 restrictor controls the relief valve or

backpressure regulator’s accuracy and speed of

response. A restrictor setting of “6” for the 1, 2 and

3 in. sizes and “8” for the 4 in. size are recommended

to optimize accuracy, speed of response and stability.

However, the restrictor can be used to ne tune the

relief valve or backpressure regulator for maximum

performance by decreasing the restrictor setting for

tighter control (increased opening speed, decreased

closing speed); or increasing the restrictor setting

for maximum stability (decreased opening speed,

increased closing speed). A lower setting also provides

a narrower proportional band for better accuracy. The

“8” position has the largest ow, is most stable and

easiest for startup. The “0” setting has the smallest

(minimum) ow passage; at no point of rotation will the

Type 112 restrictor be completely shut off.

Note

Mineral, dirt and sediments may

gradually deposit and build up inside the

Recommended Type 112 Restrictor

Settings and Restrictor Setting Guide

(Table 4 and Figure 5)

This guide can be used to adjust performance

according to application conditions. The recommended

initial setting is “6” for the 1, 2 and 3 in. sizes and “8”

for the 4 in. size (see Table 4).

Maintenance

Relief valve or backpressure regulator parts are

subject to normal wear and must be inspected

periodically and replaced as necessary. Due to the

care Emerson™ takes in meeting all manufacturing

requirements (heat treating, dimensional tolerances,

etc.), use only replacement parts manufactured or

furnished by Emerson. Also, when lubrication is

required, use a good quality lubricant and lightly coat

the recommended part.

8

W4559_1

Type LR128

RESTRICTOR ADJUSTMENT

TYPE 112 RESTRICTOR ADJUSTMENT GUIDE

Regulator Performance 2 4 6 8

Accuracy

Hysteresis

Stability

Speed of Response (Main Valve Closing)

Speed of Response (Main Valve Opening)

Increased performance

Decreased performance

1. See Table 4 for recommended restriction settings.

RESTRICTOR SETTING GUIDE

Figure 5. Restrictor Adjustment and Restrictor Setting Guide

Table 4. Recommended Setting for Type 112 Restrictor

BODY SIZE

In. DN

1 and 2 25 and 50 “6” (other restriction settings may be used)

3 80 “6” or “8” (lower settings are not recommended)

4 100 “8” (lower settings are not recommended)

RECOMMENDED RESTRICTION SETTING

(1)

The frequency of inspection and parts replacement

depends upon the severity of service conditions,

applicable codes and government regulations and

company inspection procedures. Table 8 lists possible

relief valve or backpressure regulator issues and

solutions for them.

Type LR128 Main Valve Trim

Parts Maintenance

Instructions are given for complete disassembly and

assembly. The main valve may remain in the pipeline

during maintenance procedures. Key numbers are

referenced in Figures 7 through 11.

WARNING

!

Avoid personal injury or damage

to property from sudden release of

pressure or uncontrolled process

uid. Before starting to disassemble,

carefully release all pressures

according to the Shutdown procedure.

Use gauges to monitor inlet, loading

and outlet pressures while releasing

these pressures.

9

Loading...

Loading...