Page 1

easy-e Cryogenic Valves

D102189X012

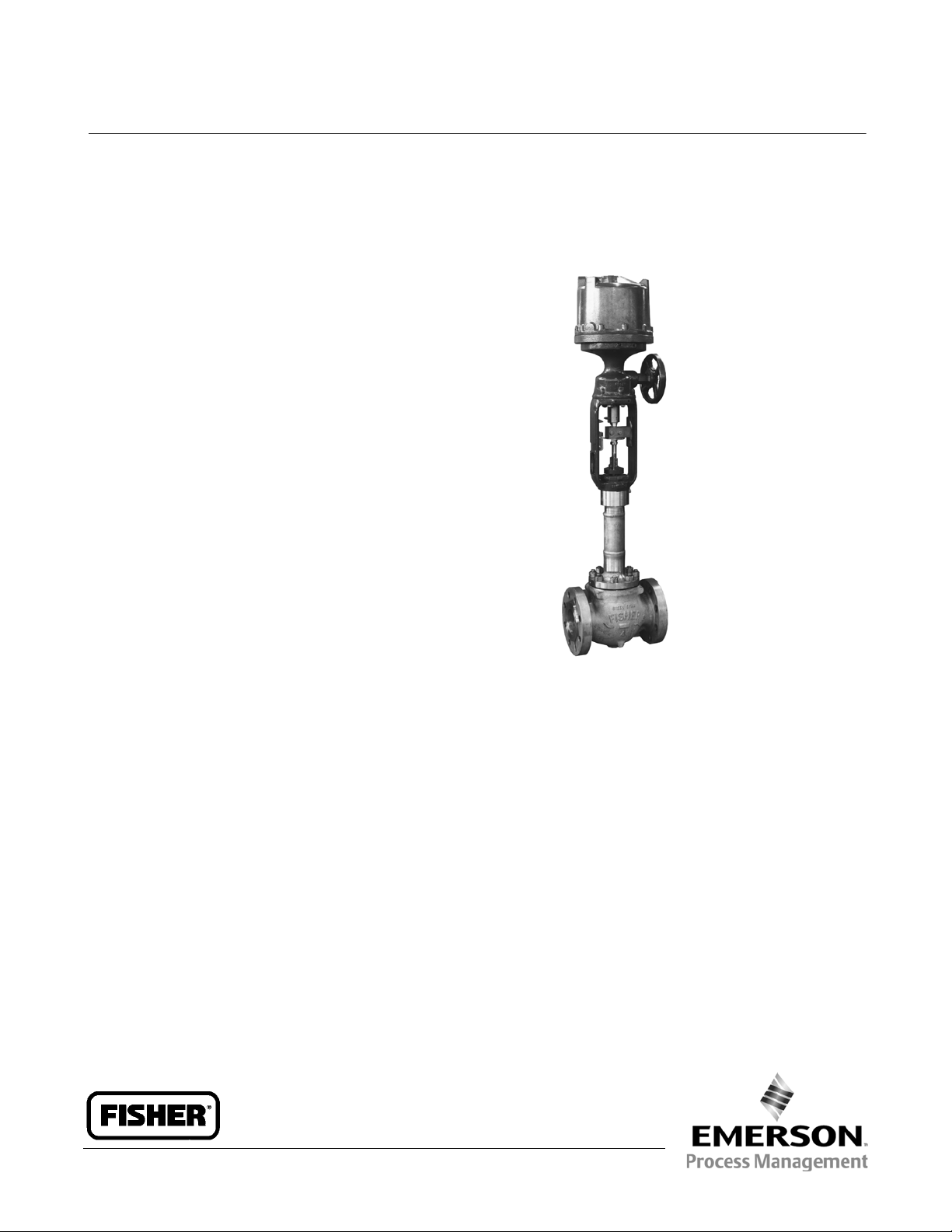

Fisherr easy-et Cryogenic

Sliding-Stem Control Valves

Fisher easy-e cryogenic valves are globe-style,

single-port, valves featuring stainless steel

construction materials and fabricated extension

bonnets. Fisher ET-C and EWT-C valves are

pressure-balanced, whereastheFisherEZ-Cvalveisan

unbalanced design. These cryogenic valves are

designed to provide throttling or on-off control of

liquids and gases at cryogenic temperatures as low as

-198_C(-325_F).

When required, these rugged valves can reliably

provide tight shutoff for special applications within the

chemical and hydrocarbon processing industries, such

as certain liquefied natural gas services.

Product Bulletin

51.1:easy-e Cryogenic

August 2012

The high-capacity ET-C and EWT-C valves with

pressure-balanced trim allow the use of smaller,

lower-cost actuators, reducing installed costs in

high-pressure and high-flow-rate applications.

The easy-e Valve Family

Thesevalvesarepartoftheversatile easy-e family of

industrial control valves. Special features include:

ET-C and EWT-C: Different cage/plug styles provide

particular flow characteristics for highly-specialized

applications. The standard cage comes in two

different flow characteristics:

J linear.

and

J equal percentage

W6370--1

Typical Fisher easy-e Cryogenic Valve with Extension

EZ-C: Interchangeable, restricted-capacity trims and

full-sized trims match a variety of process flow

demands for highly-specialized applications. The

standard plug is designed with three different flow

characteristics:

J quick-opening.

Bonnet and 585C Actuator

J equal percentage, J linear, and

www.Fisher.com

Page 2

Product Bulletin

51.1:easy-e Cryogenic

August 2012

easy-e Cryogenic Valves

D102189X012

Features

Cryogenic Spring-Loaded Seal Ring–The seal ring

and associated valve parts in the ET-C and EWT-C

valves are specifically designed and manufactured

for excellent performance at low temperatures.

Stable Control–Rugged cage guiding in the ET-C

and EWT-C valves stabilizes the valve plug at all

points in its travel to reduce vibration, mechanical

noise, and the need for hydraulic snubbers.

Cost Effective Operation and Economical

Maintenance–Increased wear resistance of

hardened stainless steel trim means long-lasting

service. Balanced valve plug construction in the

ET-C and EWT-C valves permits use of smaller,

lower-cost Fisher actuators.

Piping Economy–Expanded end connections of EW

Series valves may reduce the need for line swages

while accommodating oversized piping

arrangements used to limit fluid flow velocities.

Cryogenic Design Features–The stainless steel valve

body and bonnet with fabricated extension are

designed to meet low temperature requirements.

Theuniquemetal-to-metal seat design provides

repeatable tight shutoff, reducing maintenance

costs.

Rugged Metal Seat–The metal-to-metal seat is

designed and manufactured to provide long-lasting,

reliable, tight shutoff at both ambient and

cryogenic temperatures without the need for

periodic lapping. This reduces the need for soft

seats, even in applications with stringent shutoff

requirements.

Fugitive Emission Protection–The optional

ENVIRO-SEALt packing systems provide an

improved stem seal to help prevent the loss of

valuable or hazardous process fluids, and keep

emissions below the EPA limit of 100 ppm.

Additionally, these live-loaded packing systems can

provide long life and reliability at low temperatures

to help reduce maintenance costs and downtime.

Thoroughly Tested–Extensive cryogenic testing

during the development of the valve design reduces

the need for expensive cold testing for most

applications, which results in quicker delivery and

greater value.

Easy Maintenance–Quick-change trim, with a

clamped-in seat ring, reduces the disassembly/

assembly time. The valve body can stay in the

pipeline during removal of trim parts for inspection

or maintenance.

Sour Service Capability–For NACE applications,

consult your Emerson Process Management sales

office.

Contents

Features 2.....................................

Specifications 3................................

Tables

ET-C and EWT-C Typical Trim Materials 5..........

EZ-C Typical Combinations of Metal Trim Parts 5...

Maximum Allowable Actuator Thrust 5...........

2

ET-C and EWT-C Port Diameters,

Valve Plug Travel, Stem and Yoke Diameters 8...

EZ-C Port Diameters, Travel, Valve Plug and Stem

and Yoke Diameters 8.......................

Bolting Materials 8............................

EZ-C Maximum Allowable Pressure Drop 9.........

Dimensions 10.................................

Page 3

easy-e Cryogenic Valves

D102189X012

Specifications

Product Bulletin

51.1:easy-e Cryogenic

August 2012

Available Configurations

ET-C: Single-port, globe-style control valve with cage

guiding, balanced valve plug, and

push-down-to-close valve plug action (figure 1)

EWT-C: Single-port, globe-style control valve with

cage guiding, balanced valve plug,

push-down-to-close valve plug action, and with

expanded end connections (figure 1)

EZ-C: Single-port, globe-style control valve with

post-guiding, unbalanced valve plug, and

push-down-to-close valve plug action (figure 2)

Valve Sizes

ET-C:

J NPS 3, J 4, J 6, and J 8

EWT-C:

J NPS 6X4

(1)

, J 8X4, J 8X6, J 12X6, and

J 10X8

EZ-C:

J NPS 1, J 1-1/2, J 2, J 3, and J 4

End Connection Styles

(2)

CL150, 300, or 600 raised-face flanges per J ASME

B16.5,

J EN 1092-1/B

Maximum Inlet Pressure

(2)

Consistent with J CL150 and J CL300

pressure-temperature ratings per ASME B16.34

J CL600 valves with B8M Class 2 bolting are

consistent with CL600 pressure-temperature ratings

per ASME B16.34 except as shown below:

MAXIMUM INLET

VALVE

EZ-C

ET-C and EWT-C

VALVE SIZE,

NPS

1 77 1110

2 83 1200

3 94 1370

3 94 1370

6, 8 x 6,

12 x6

8, 10 x 8 96 1390

PRESSURE

at 38_C (100_F)

Bar Psig

75 1085

J CL600 valves with optional S20910 (XM-19)

bolting are consistent with CL600

pressure-temperature ratings per ASME B16.34

Trim Material

See tables 1 and 2

Shutoff Classifications Per ANSI/FCI 70-2 and IEC

60534-4

ET-C and EWT-C.

Metal Seat:.

J ClassIVisstandard

J ClassVAirTestisoptional

(Test will be 50 psid air)

(6)

.

J Class VI (Consult your Emerson Process

Management sales office)

Composition Seat:.

J Standard air test is standard

J ClassVIisoptional

EZ-C.

Metal Seat:.

J ClassIVisstandard

J ClassVIisoptional

Maximum Actuator Thrust

See table 3

Conformance to Customer Specifications

ET-C with metal seats and EZ-C valves successfully

passed type approval testing per SIPM (Shell)

specification T-2.253.730

Flow Characteristics

ET-C, EWT-C, and EZ-C.

J Equal percentage

J Linear

EZ-C Only.

J Quick-opening

Flow Direction

(5)

Maximum Pressure Drops

(2)

Same as maximum inlet pressure, except where

limited by spiral wound gasket for EZ-C

(see tables 7 and 8)

ET-C and EWT-C.

Normallydownforlinearandequal percentage trims.

Flow up for Whisper Trimt.Seefigure1.

EZ-C.

Up through the seat ring only. See figure 2

(Continued)

3

Page 4

Product Bulletin

51.1:easy-e Cryogenic

August 2012

Specifications (Continued)

easy-e Cryogenic Valves

D102189X012

Standard Construction Materials

Valve Body and Bonnet: CF8M (316 SST)

Body-Bonnet Bolting: SA-193-B8M Class 2 studs

Optional Materials.

J Double PTFE V-ring and

J Graphite ribbon/filament

with SA-194-8M nuts (see table 6)

Bonnet Bushing: S31600/filled PTFE

Flat Sheet Gaskets: S31600/graphite

Spiral Wound Gasket: N06600/graphite

PackingStudsandNuts:S31600 SST

Seal Ring (ET-C and EWT-C): UHMWPE

(3)

with R30003

spring

Back-UpRing(ET-CandEWT-C):S31600 (316 SST)

Retaining Ring (ET-C and EWT-C): S30200 (302 SST)

Load Ring (for ET-C, NPS 8 and for EWT-C, NPS 10 x 8

only): N07718

Packing Follower, Lantern Ring, Packing Spring

(4)

Packing Box Ring: S31600 SST

Material Temperature Capabilities

(2)

ET-C and EWT-C

-198 to 66_C(-325to150_F)

EZ-C

-198 to 149_C (-325 to 300_F)

and

ENVIRO-SEAL Packing Systems: See figure 5

Packing Material:

J PTFE V-ring and J Graphite ULF

See Bulletin 59.1:061, ENVIRO-SEAL Packing Systems

for Sliding-Stem Valves, for more information

Approximate Weights (CL600 Valves)

ET-C:.

NPS 3: 51 kg (135 lb)

NPS 4: 95 kg (210 lb)

NPS 6: 211 kg (465 lb)

NPS 8: 372 kg (820 lb)

EWT-C:.

NPS 6X4: 200 kg (440 lb)

NPS 8X4: 277 kg (610 lb)

NPS 8X6: 318 kg (700 lb)

NPS 12X6: 730 kg (1610 lb)

NPS 10X8: 753 kg (1660 lb)

Bonnet Extension Length

See figures 3 and 4 for standard valve dimensions

EZ-C:.

NPS 1: 15 kg (33 lb)

NPS 1-1/2: 23 kg (48 lb)

Flow Coefficients and Noise Level Prediction

See Catalog 12

NPS 2: 41 kg (90 lb)

NPS 3: 60 kg (130 lb)

NPS 4: 95 kg (210 lb)

Port Diameters, Plug Travel, Yoke Boss, and Stem

Diameter

See tables 4 and 5

Options

ET-C and EWT-C:

J Whisper Trim III and WhisperFlot

trim for aerodynamic noise attenuation, and

Packing Arrangements

Standard Material.

J Single PTFE V-ring. See figures 1 and 2

1. Valve size number is end connection sizeby normal trim s ize. For example, anNPS 6X4 EWT-C valvehas NPS 6 endc onnections with NPS 4trim (see table 4).

2. Do not exceed the pressure or temperature limits in thisbulletin, and any applicable code limitations.

3. UHMWPE stands for ultra high molecular weight polyethylene.

4. A spring is used only with PTFE V-ring packing. Alantern rings replace the spring in other packing arrangements.

5. Down is in through the cage and out the seatring (see figure 1).

6. Class V shutoff cannot be performed with water. The residual trapped moisture from testingwith water can cause valve and trim damage fromthe ice crystals formed at belowfreezing

service temperatures.

J Cavitrolt III cages for liquid cavitation protection

are available. Contact your Emerson Process

Management sales office for information

EZ-C:

J Micro-Flute and J Micro-Flow trim

4

Page 5

easy-e Cryogenic Valves

D102189X012

Product Bulletin

51.1:easy-e Cryogenic

August 2012

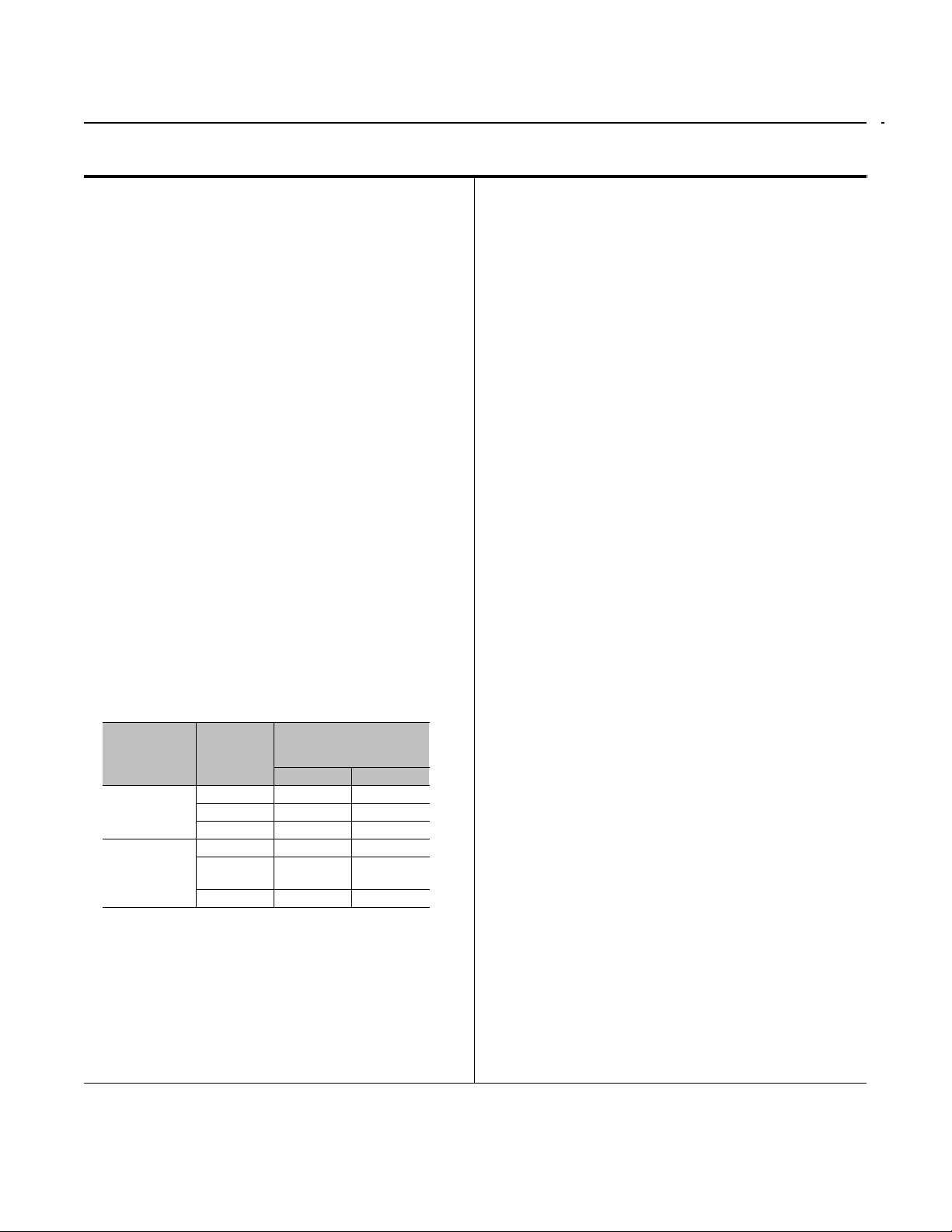

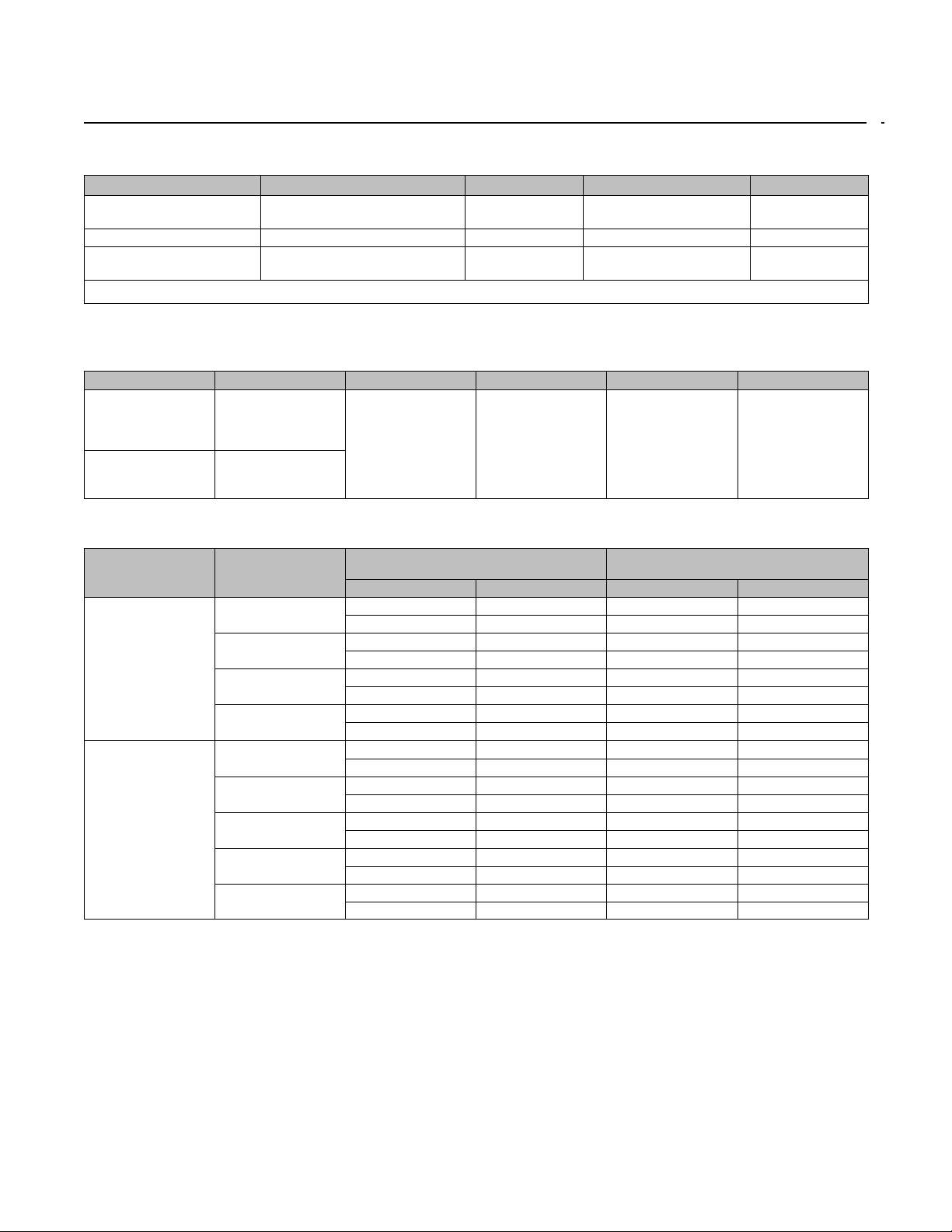

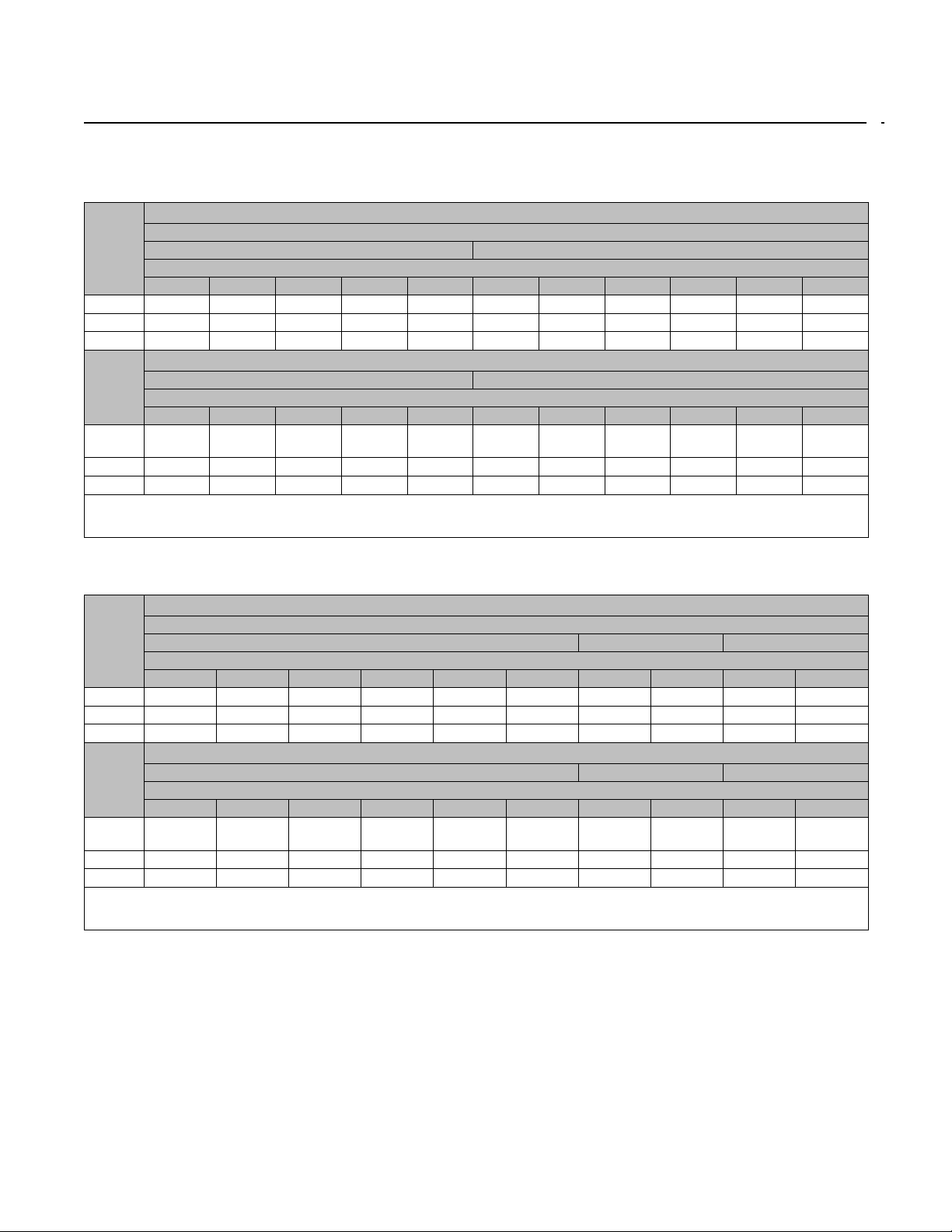

Table 1. Fisher ET-C and EWT-C Typical Trim Material

Trim Designation Valve Plug

429

(2)

430

431

1. Whisper Trim III requires use of Trim431.

2. Soft seatconstruction.

S31600 SSTwith CoCr-A (Alloy 6)

hard-faced seat

S31600 SST S20910 Chrome-plated S31600 SST S31600 SST/CTFE

S31600 SSTwith CoCr-A (Alloy 6)

hard-faced seat and guide

(1)

Valve Stem

S20910 Chrome-plated S31600 SST S31600 SST

S20910 Chrome-plated S31600 SST S31600 SST

Cage Seat Ring

Table 2. Fisher EZ-C Typical Combinations of Metal Trim Parts for Equal Percentage (Including Micro-Form), Linear,

and Quick-Opening Valve Plugs

Trim Designation Valve Plug Valve Stem Seat Ring Seat RingRetainer Guide Bushing

S31600 SST with

327

328

CoCr-A (Alloy 6)

hard-faced Seat and

Guide

S31600 SST with

CoCr-A (Alloy 6)

hard-faced Seat

S20910

(XM-19)

S31600 CF8M R30006

Table 3. Maximum Allowable Actuator Thrust for Standard Bonnet Extension Length

MAXIMUM ALLOWABLE STEM LOAD

FOR S20910(XM-19) STEM MATERIAL

VALVE VALVE SIZE, NPS

4, 6X4,8X4

ET-C and EWT-C

6, 8X6,12X6

8, 10X8

EZ-C

3

1

1-1/2

2

3

4

STEM DIAMETER

mm Inches N Lb

12.7 1/2 15,301 3440

19.1 3/4 45,459 10,220

12.7 1/2 16,458 3700

19.1 3/4 46,971 10,560

19.1 3/4 36,385 8180

25.4 1 81,487 18,320

19.1 3/4 41,366 9300

25.4 1 87,003 19,560

9.5 3/8 5382 1210

12.7 1/2 13,166 2960

9.5 3/8 5338 1200

12.7 1/2 13,166 2960

12.7 1/2 14,367 3230

19.1 3/4 44,169 9930

12.7 1/2 15,301 3440

19.1 3/4 45,459 10,220

12.7 1/2 16,458 3700

19.1 3/4 46,971 10,560

5

Page 6

Product Bulletin

51.1:easy-e Cryogenic

August 2012

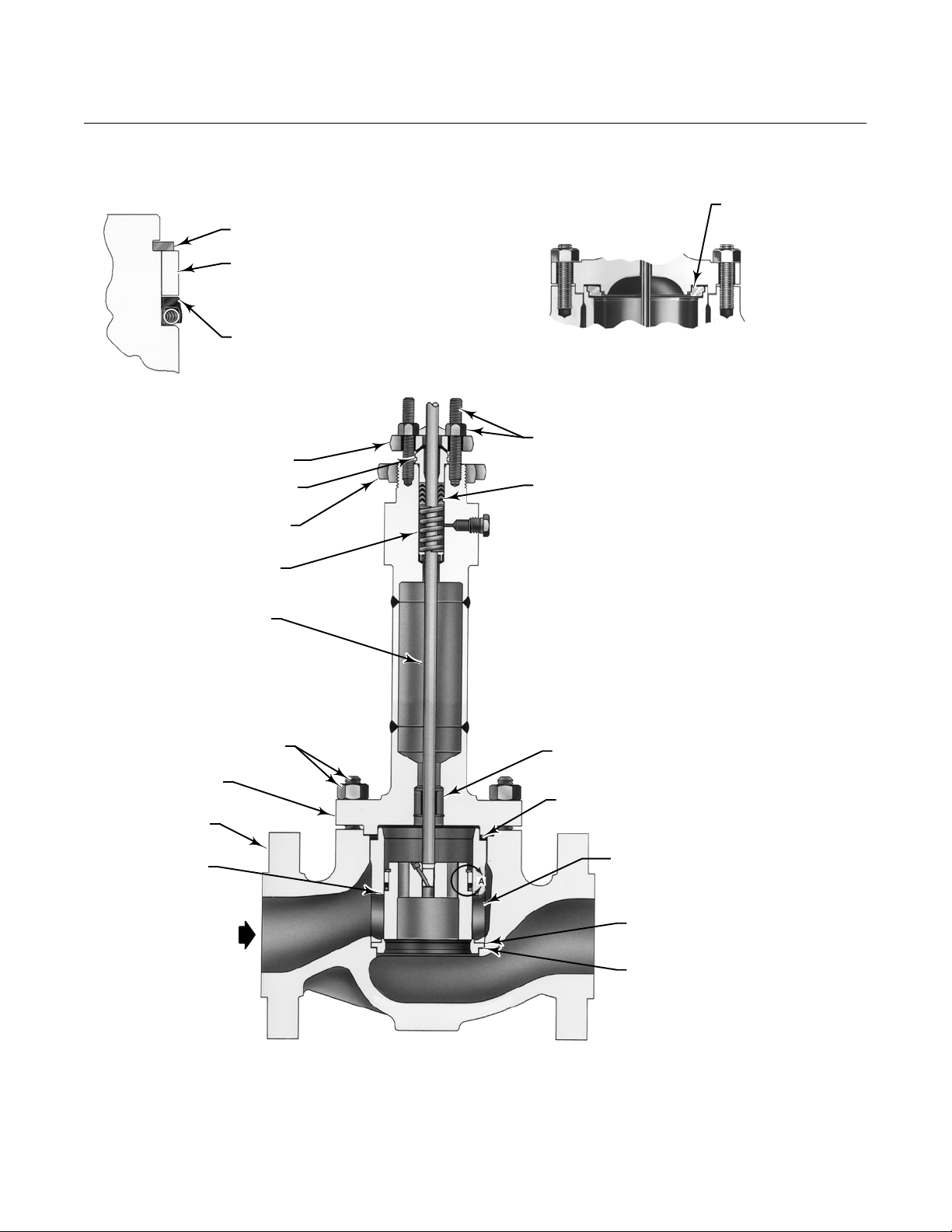

Figure 1. Fisher ET-C and EWT-C Valve Detail

RETAINING RING

BACK-UP RING

SEAL RING

easy-e Cryogenic Valves

D102189X012

LOAD

RING

W6398-1*

VIEW A

EXTENSION

BONNET

VALVE

BODY

PACKING

FLANGE

PACKING

FOLLOWER

ACTUATOR

LOCKNUT

PACKING

SPRING

STEM

BODY-BONNET

BOLTING

W1214-2*

STANDARD NPS 8 AND 10x8

PACKING STUDS

AND NUTS

PTFE V-RING PACKING

(STANDARDARRANGEMENT)

BUSHING

SPIRAL WOUND GASKET,

BONNET GASKET, AND SHIM

CONSTRUCTION DETAIL

VALVE

PLUG

FLOW

W6397-1*

6

CAGE

SEAT RING

SEAT RING

GASKET

Page 7

easy-e Cryogenic Valves

D102189X012

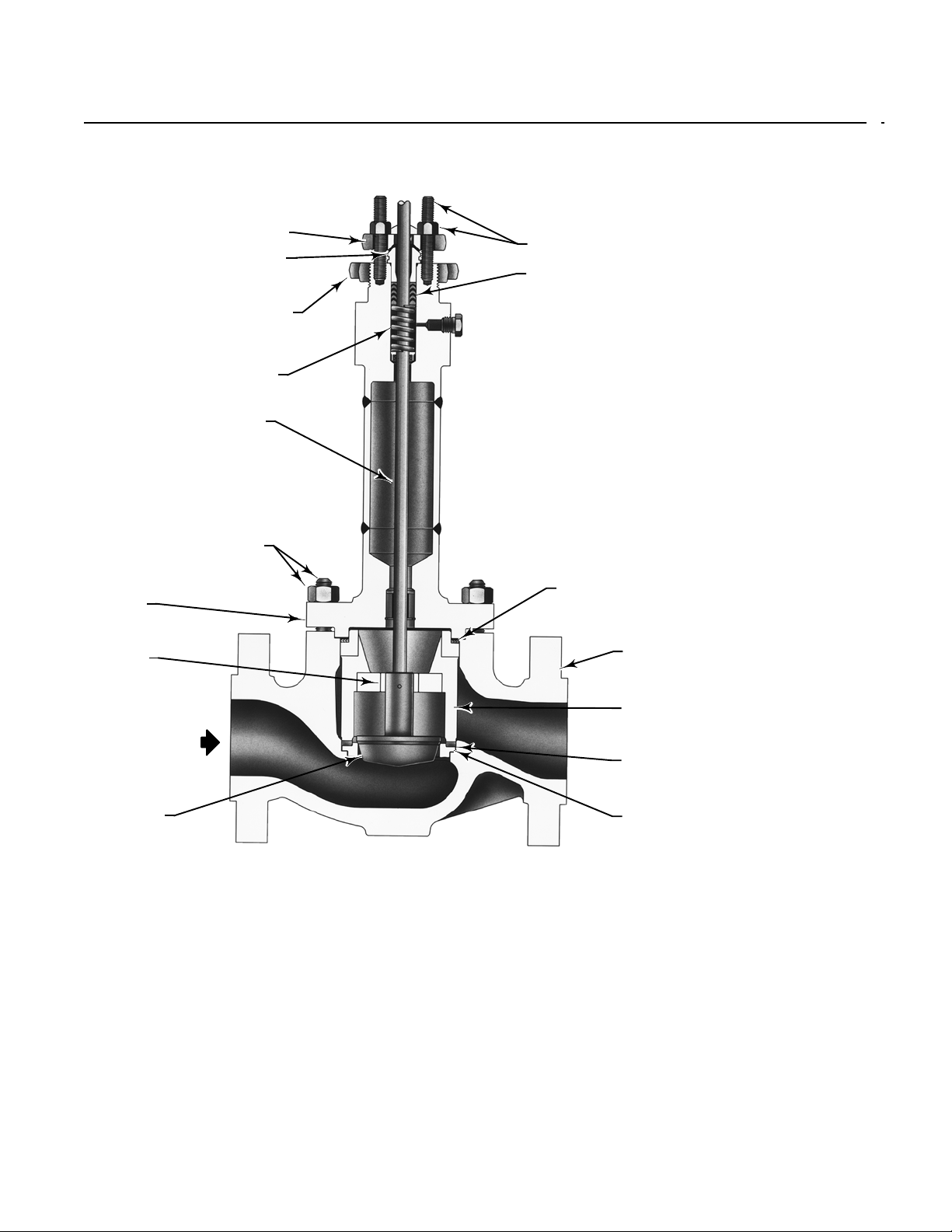

Figure 2. Fisher EZ-C Valve Assembly Detail

PACKING

FLANGE

PACKING

FOLLOWER

ACTUATOR

LOCKNUT

PACKING

SPRING

STEM

Product Bulletin

51.1:easy-e Cryogenic

August 2012

PACKING STUDS

AND NUTS

V-RING PACKING

(STANDARDARRANGEMENT)

EXTENSION

BONNET

GUIDE

BUSHING

VALVE PLUG

W6396-1

BODY-BONNET

BOLTING

SPIRAL WOUND GASKET,

BONNET GASKET, AND SHIM

VALVE BODY

SEAT RING

RETAINER

FLOW

SEAT RING

SEAT RING

GASKET

7

Page 8

Product Bulletin

51.1:easy-e Cryogenic

August 2012

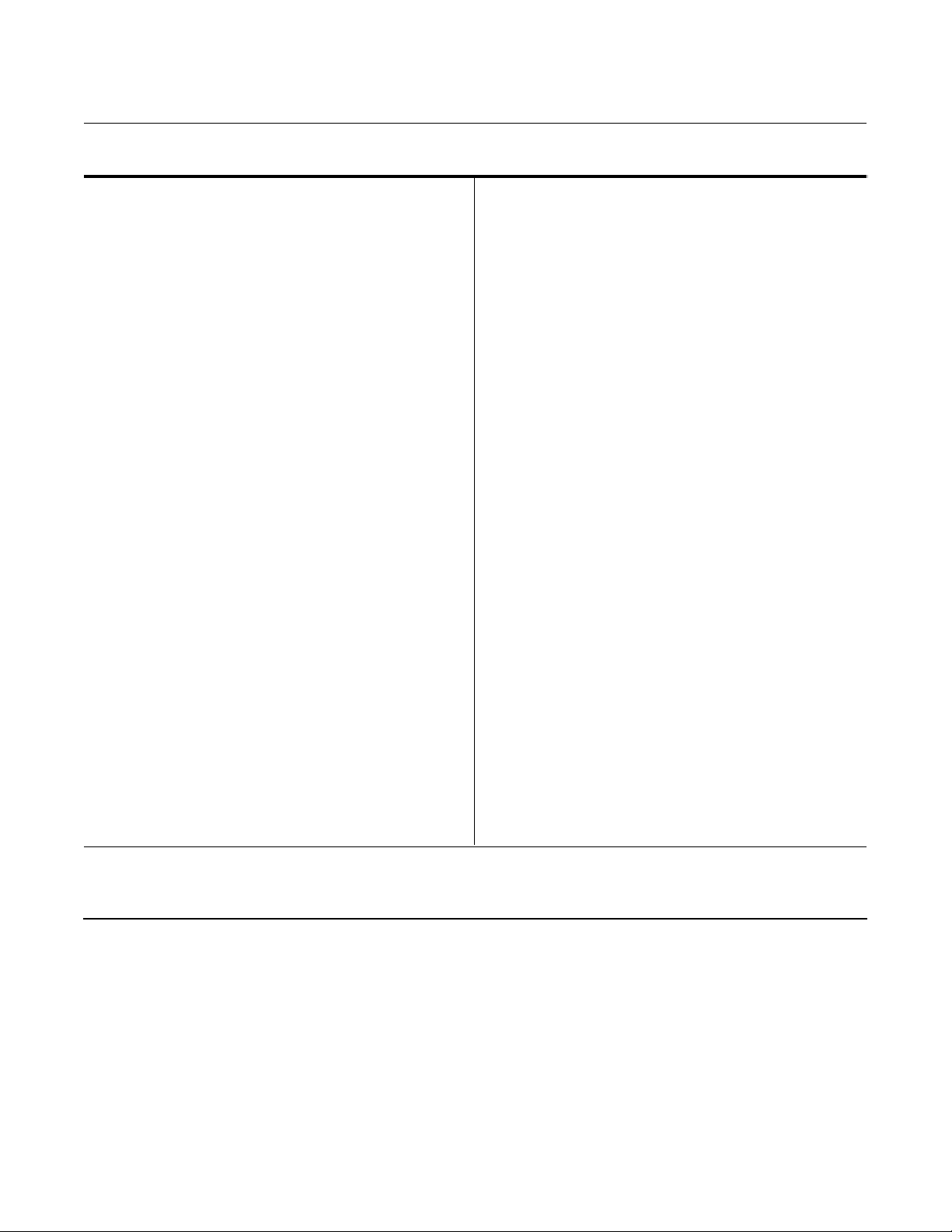

Table 4. Fisher ET-C and EWT-C Port Diameters, Valve Plug Travel, Stem and Yoke Diameters

VALVE SIZE, NPS

ET-C EWT-C Stem Yoke Boss Stem Yoke Boss

3 --- 87.3 38.1

4 6X4, 8X4 111.1 50.8

6 8X6, 12X6 177.8 50.2

8 10X8 203.2 76.2

3 --- 3.4375 1.5

4 6X4, 8X4 4.375 2

6 8X6, 12X6 7 2

8 10X8 8 3

PORT

DIAMETER

MAXIMUM

VALVE PLUG

TRAVEL

Standard Optional

mm

12.7 71 19.1 90

19.1 90.5 25.4 127.0

Inches

1/2 2-13/16 3/4 3-9/16

3/4 3-9/16 1 5

VALVE STEM AND YOKE BOSS

Table 5. Fisher EZ-C Port Diameters, Valve Plug Travel, and Stem and Yoke Diameters

VALVE

SIZE, NPS

EZ-C Equal Percentage

1 6.4, 9.5, 12.7,19.1, and 25.4 25.4 25.4

1-1/2 6.4, 9.5,12.7, 19.1, 25.4, and 38.1 38.1 38.1

2 6.4, 9.5,12.7, 19.1, 25.4, and 50.8 50.8 50.8 29

3 50.8 and 76.2 76.2 76.2 38

4 50.8 and 101.6 101.6 101.6 51

1 0.25, 0.375, 0.5, 0.75, and 1 1 1

1-1/2 0.25, 0.375,0.5, 0.75, 1, and 1.5 1.5 1.5

2 0.25, 0.375, 0.5, 0.75, 1, and 2 2 2 1.125

3 2and3 3 3 1.5

4 2and4 4 4 2

1. 6.4 through19.1 mm (0.25 through 0.75 inch) port diameters use Micro-Form valve plugs.

PORT DIAMETER,INCHES

(1)

Quick Opening Linear Stem Yoke Boss Stem Yoke Boss

mm

Inches

MAXIMUM

PLUG

TRAVEL

19 9.5 54 12.7 71

12.7 71 19.1 90

0.75 3/8 2-1/8 1/2 2-13/16

easy-e Cryogenic Valves

D102189X012

DIAMETERS

VALVE STEM AND YOKE BOSS

DIAMETERS

Standard Optional

1/2 2-13/16 3/4 3-9/16

Table 6. Bolting Materials

VALVE

ET-C,EWT-C,andEZ-C

1. Standard studand nut combination.

8

SA-193-B8M

S20910 (XM-19)

BODY-BONNET BOLTING

Studs Nuts

(1)

Strain Hardened SA-194-8M

SA-194-8M

SA-194-8MA

(1)

Page 9

easy-e Cryogenic Valves

D102189X012

Product Bulletin

51.1:easy-e Cryogenic

August 2012

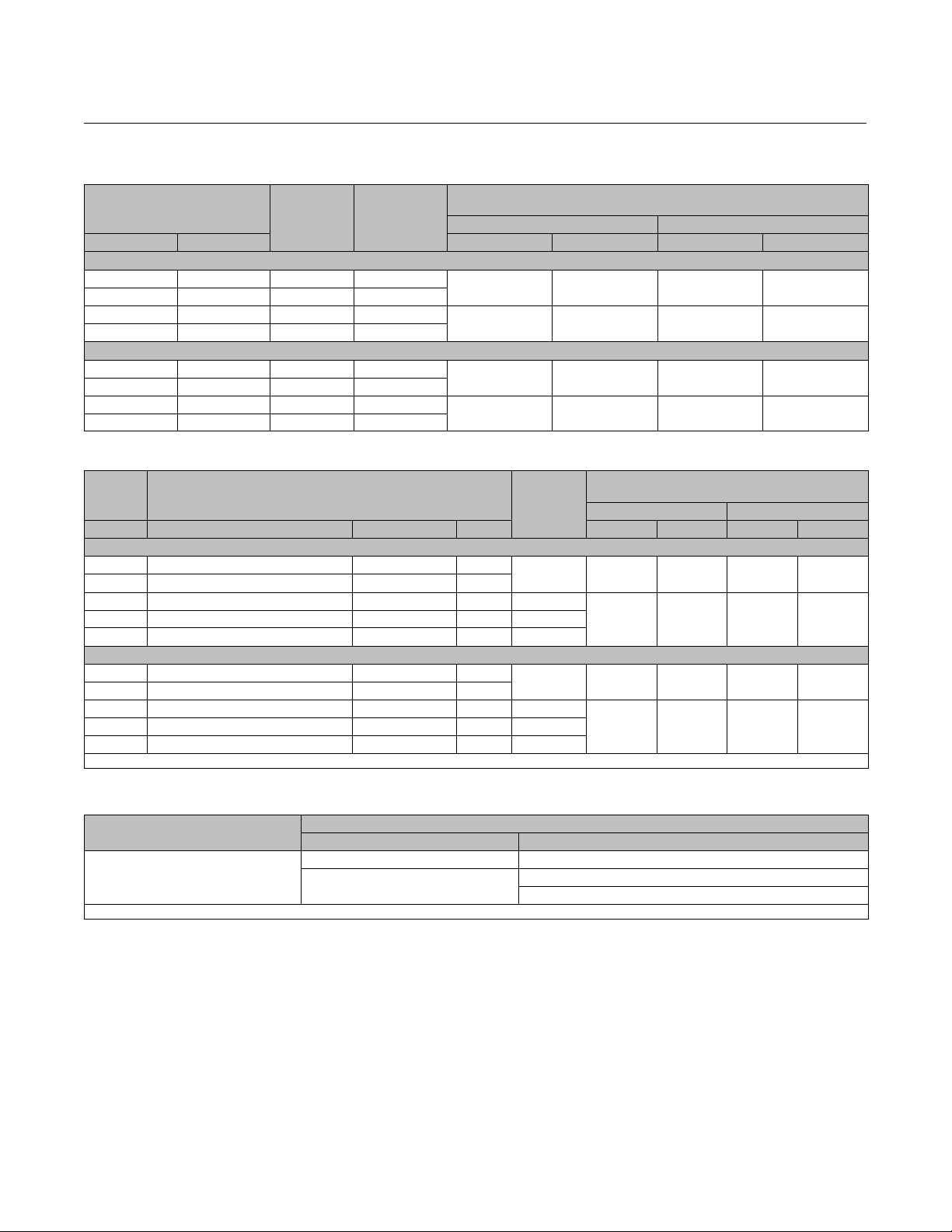

Table 7. Fisher EZ-C Maximum Allowable Pressure Drop for N06600/Graphite Spiral Wound Gasket (NPS 1 and 1-1/2

Valve Size) (Flow Up Only)

TEMPER-

ATURE,

(3)

_C

6.4 9.5 12.7 19.1 25.4 6.4 9.5 12.7 19.1 25.4 38.1

-198 to93 94.5 96.2 97.9 104.1* 114* 77.9 79.0 80.0 82.7 87.6 105*

93 89.6* 91.4* 93.1* 98.6* 108* 73.8 74.5 75.2 78.6 82.7 99.3*

149 85.5* 87.2* 88.9* 94.5* 103* 70.3 71.4 72.4 75.2 79.3* 94.5*

TEMPER-

ATURE,

(3)

_F

-325 to

100

200 1300* 1325* 1350* 1430* 1570* 1070 1080 1090 1140 1200 1440*

300 1240* 1265* 1290* 1370* 1500* 1020 1035 1050 1090 1150* 1370*

1. EZ-C should not be used in flow down service including on-off applications.

2. Pressure drop cannot exceedmaximum inlet pressure asindicated in the specificationtable on page 2.

3. Pressure dropsat intermediate temperaturesmay be interpolated.

* Pressure drops are in excess of CL600pressure ratings per ASME B16.34 for CF8Mbody material.

0.25 0.375 0.5 0.75 1 0.25 0.375 0.5 0.75 1 1.5

1370 1395 1420 1510* 1660* 1130 1145 1160 1200 1270 1520*

(1)

(2)

BAR

EZ-C Valve Size, NPS

1 1-1/2

Port Diameter, mm

(2)

PSI

1 1-1/2

Port Diameter, Inches

Table 8. Fisher EZ-C Maximum Allowable Pressure Drop for N06600/Graphite Spiral Wound Gasket (NPS 2 through 4

Valve Size) (Flow Up Only)

TEMPER-

ATURE,

(3)

_C

6.4 9.5 12.7 19.1 25.4 50.8 50.8 75.2 50.8 101.6

-198 to93 67.6 68.2 68.7 70.3 73.1 101* 69.6 97.2 65.5 114*

93 63.4 64.1 64.8 66.9 69.6 95.8* 66.2 92.4* 62.1 108*

149 60.7 61.4 62.1 63.4 66.2 91.7* 62.7 88.3* 58.6 103*

TEMPER-

ATURE,

(3)

_F

-325 to

100

200 920 930 940 970 1010 1390* 960 1340* 900 1560*

300 880 890 900 920 960 1330* 910 1280* 850 1490*

1. EZ-C should not be used in flow down service including on-off applications.

2. Pressure drop cannot exceedmaximum inlet pressure asindicated in the specificationtable on page 2.

3. Pressure dropsat intermediate temperaturesmay be interpolated.

* Pressure drops are in excess of CL600pressure ratings per ASME B16.34 for CF8Mbody material.

0.25 0.375 0.5 0.75 1 2 2 3 2 4

980 985 990 1020 1060 1470* 1010 1410 950 1650*

(1)

(2)

BAR

EZ-C Valve Size, NPS

2 3 4

Port Diameter, mm

(2)

PSI

2 3 4

Port Diameter, Inches

9

Page 10

Product Bulletin

51.1:easy-e Cryogenic

August 2012

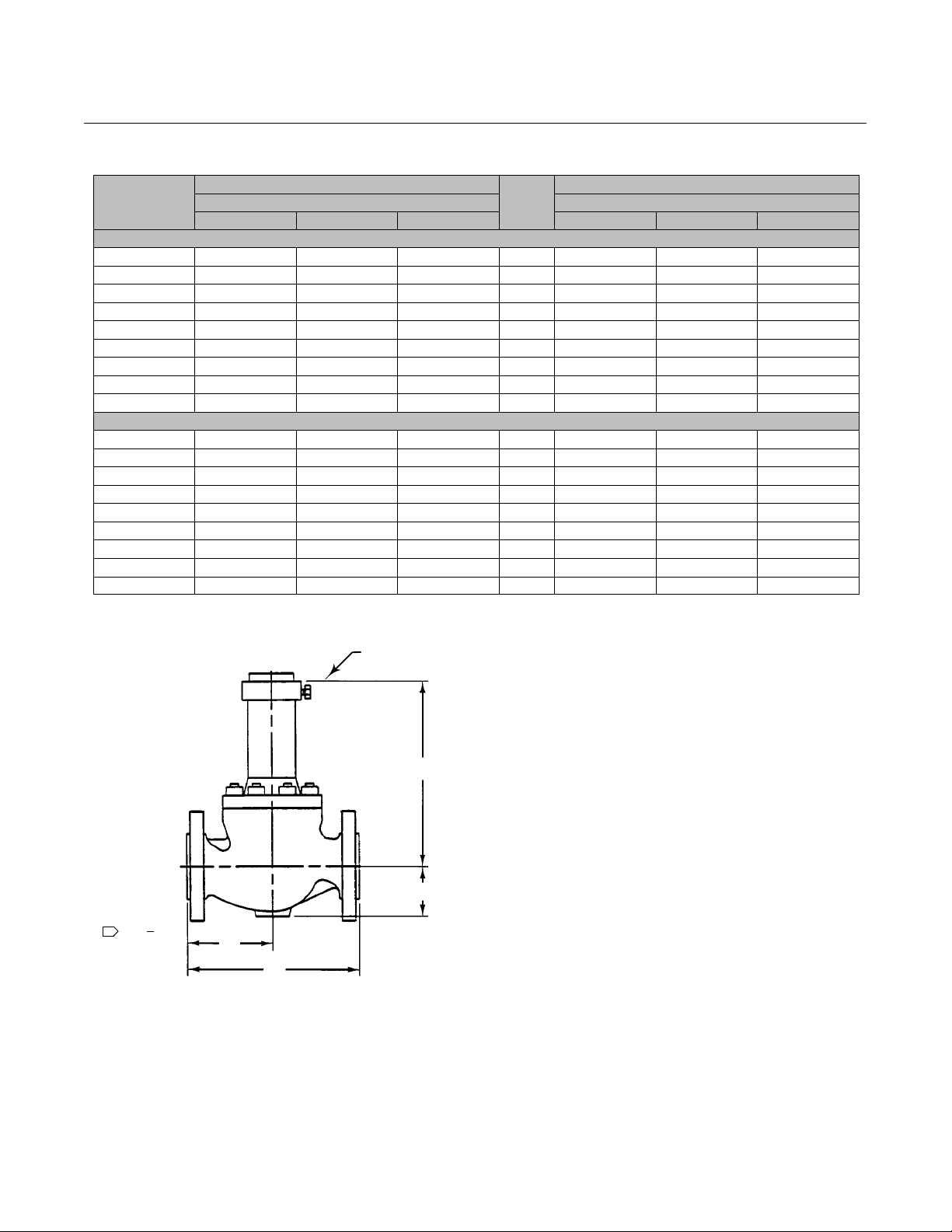

Table 9. Fisher ET-C and EWT-C Valve Dimensions

RAISED-FACE FLANGE

VALVE SIZE, NPS

CL150 CL300 CL600 12.7 (1/2) 19.1 (3/4) 25.4 (1)

3 298 318 337 97 533 533 ---

4 353 368 394 129 533 533 ---

6X4 451 473 508 135 568 568 ---

8X4 543 568 610 176 570 570 ---

6 451 473 508 140 --- 762 762

8X6 543 568 610 183 --- 797 797

12X6 737 775 819 254 --- 865 865

8 543 568 610 191 --- 762 762

10X8 673 708 752 273 --- 762 762

3 11.75 12.50 13.25 3.81 21.00 21.00 ---

4 13.88 14.50 15.50 5.06 21.00 21.00 ---

6X4 17.75 18.62 20.00 5.31 22.38 22.38 ---

8X4 21.38 22.38 24.00 6.94 22.44 22.44 ---

6 17.75 18.62 20.00 5.50 --- 30.00 30.00

8X6 21.38 22.38 24.00 7.19 --- 31.38 31.38

12X6 29.00 30.50 32.25 10.00 --- 34.06 34.06

8 21.38 22.38 24.00 7.50 --- 30.00 30.00

10X8 26.50 27.88 29.62 10.75 --- 30.00 30.00

A Stem Diameter, mm (Inches)

mm

Inches

G

easy-e Cryogenic Valves

D

D102189X012

Figure 3. Fisher ET-C and EWT-C Valve Dimensions (also see table 9)

MATCH LINE

FOR ACTUATOR

D

G

NOTE:

A

B =

1

54B8575-A

A6667

2

B

A

10

Page 11

Product Bulletin

easy-e Cryogenic Valves

D102189X012

Table10.FisherEZ-CValveDimensions

VALVE SIZE,

NPS

1 184 197 210 61 535 549 ---

1-1/2 222 235 251 71 535 548 ---

2 254 267 286 78 --- 533 533

3 299 318 337 97 --- 535 535

4 353 368 394 129 --- 535 535

1 7.25 7.75 8.25 2.38 21.06 21.62 ---

1-1/2 8.75 9.25 9.88 2.81 21.06 21.56 ---

2 10.00 10.50 11.25 3.06 --- 21.00 21.00

3 11.75 12.50 13.25 3.81 --- 21.06 21.06

4 13.88 14.50 15.50 5.06 --- 21.06 21.06

CL150 CL300 CL600 9.5 (3/8) 12.7 (1/2) 19.1 (3/4)

Figure 4. Fisher EZ-C Valve Dimensions (also see table 10)

RAISED-FACE FLANGE

A Stem Diameter, mm (Inches)

MATCH LINE

FOR ACTUATOR

G

mm

Inches

51.1:easy-e Cryogenic

D

August 2012

NOTE:

1

A6667

B =

D

G

A

2

B

A

11

Page 12

Product Bulletin

51.1:easy-e Cryogenic

August 2012

Figure 5. ENVIRO-SEAL Packing Systems

PACKING

BOX

STUDS

easy-e Cryogenic Valves

D102189X012

PACKING

BOX

STUD

SPRINGS

ANTIEXTRUSION

RING

LANTERN

RING

W5803-3

SPRINGS

PACKING

RING

VALVE

BONNET

PACKING

W8532-1

PTFE PACKING GRAPHITE ULF PACKING

FOLLOWER

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumesresponsibility for the selection, use or maintenance

of anyproduct. Responsibility for proper selection, use, and maintenance of any product remains solely withthe purchaserand end user.

Fisher, easy-e, ENVIRO-SEAL, Whisper Trim,WhisperFlo, and Cavitrol are marks owned by one of the companies in the Emerson Process Management

business unit of Emerson Electric Co. Emerson Process Management, Emerson, and the Emerson logo aretrademarks and service marks of Emerson Electric

Co. Allother marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they arenot

to be construed as warranties orguarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are availableupon request. Wereserve the right tomodify or improve thedesigns orspecifications of such

products at any time without notice.

Emerson ProcessManagement

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1995, 2012 Fisher ControlsInternational LLC. All rights reserved.

12

Loading...

Loading...