Page 1

Instruction Manual

D100399X012

Fisherr EWD, EWS, and EWT Valves

through NPS 12x8

EW Valve

September 2014

Contents

Introduction 1...................................

Scope of Manual 1.............................

Description 3.................................

Specifications 3...............................

Educational Services 4.........................

Installation 4

Inverted Globe Valve Applications

(Actuator below valve) 6.....................

Maintenance 7

Packing Lubrication 8..........................

Packing Maintenance 10........................

Trim Maintenance 14..........................

Retrofit: Installing C-seal Trim 20................

Replacement of Installed C-seal Trim 24...........

ENVIRO-SEALt Bellows Seal Bonnet 27...........

Parts Ordering 32

Parts Kits 33.....................................

Parts List 36.....................................

....................................

..................................

Replacing Packing 11.......................

Trim Removal 15..........................

Lapping Metal Seats 16.....................

Valve Plug Maintenance 17..................

Trim Replacement 19......................

Trim Removal (C-seal Constructions) 24.......

Lapping Metal Seats (C-seal Constructions) 25..

Remachining Metal Seats

(C-seal Constructions) 25.................

Trim Replacement (C-seal Constructions) 26...

................................

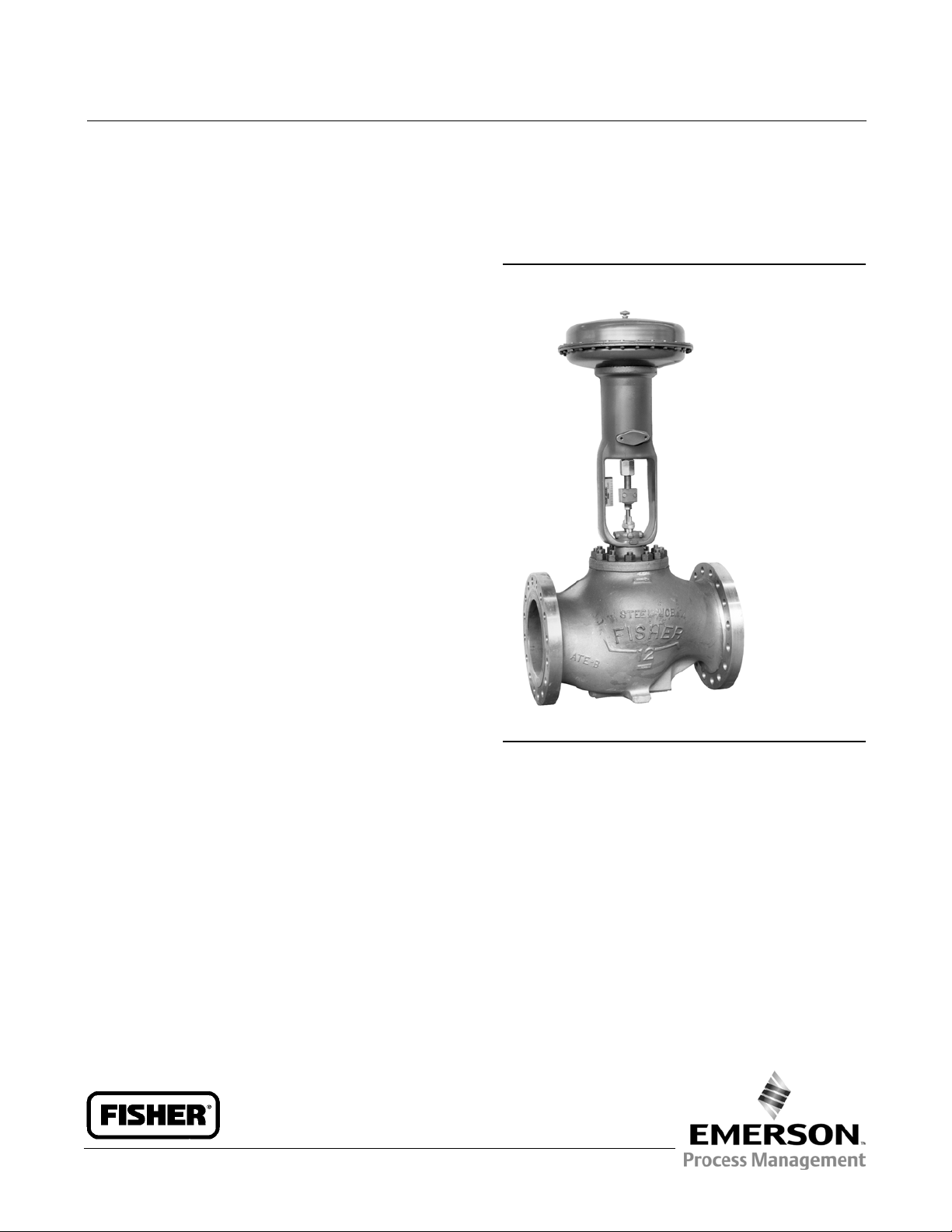

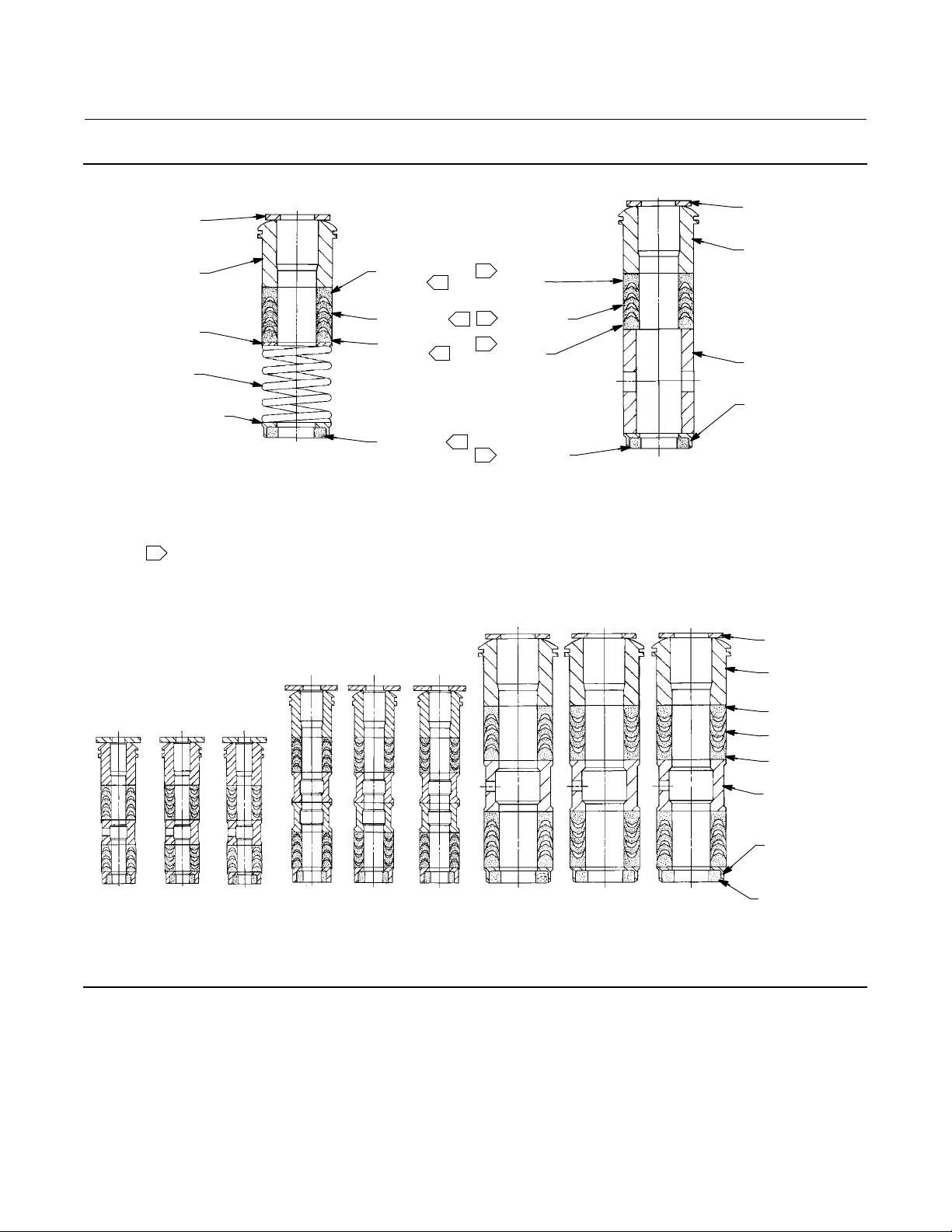

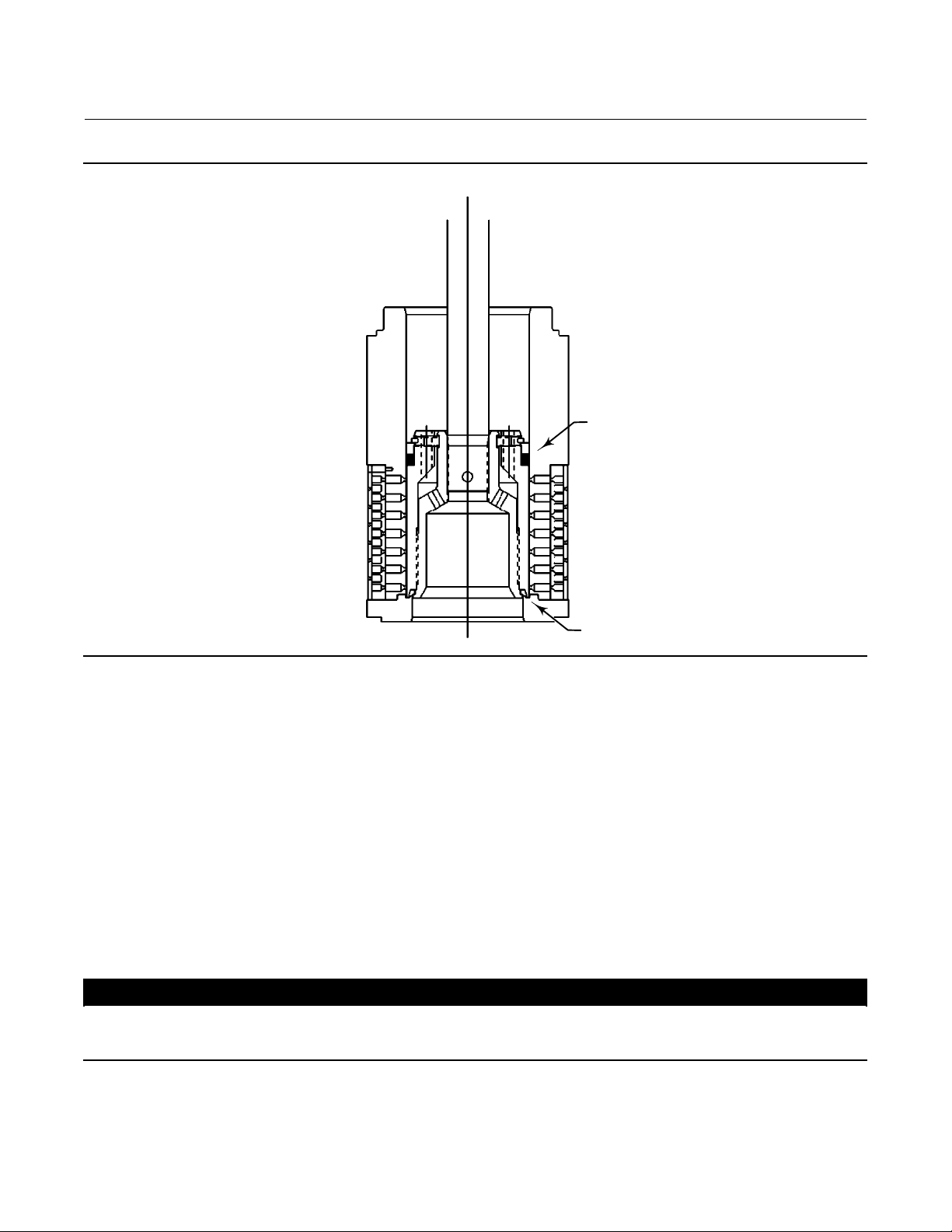

Figure 1. Fisher NPS 12x6 EW Series Valve With

667 Actuator

W2777-2*

Introduction

Scope of Manual

This instruction manual includes installation, maintenance, and parts information for Fisher NPS 4x2 through 12x8

EWD, EWS, and EWT valves (figure 1). Refer to separate manuals for instructions covering the actuator and

accessories.

Do not install, operate, or maintain an EW valve without being fully trained and qualified in valve, actuator, and

accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is important to

carefully read, understand, and follow all the contents of this manual, including all safety cautions and warnings. If you

have any questions about these instructions, contact your Emerson Process Management sales office before

proceeding.

www.Fisher.com

Page 2

EW Valve

September 2014

Table 1. Specifications

Instruction Manual

D100399X012

End Connection Styles

Flanged Ends: CL300, CL600, or CL900 Raised-face or

ring-type joint flanges per ASME B16.5

Whisper Trim Cages: Always up

Cavitrol Cages: Always down

WhisperFlo Trim: Flow up (standard)–through the

seat ring and out through the cage orifices

Buttwelding Ends: Styles per ASME B16.25 schedules

consistent with ASME B16.34 are: Schedules

J 80 for all CL300 and CL600 valves, Schedule J 80

or

J XXS for NPS 8x6 CL900 valves, or Schedule

J 80, J 100, or J 120 for NPS 12x8 CL900 valves.

Maximum Inlet Pressures, Temperatures, and

Pressure Drops

Consistent with applicable J CL300, J CL600

J CL900

(1)

(3)

pressure/temperature ratings per ASME

B16.34, but do not exceed the pressure,

temperature, and pressure drop conditions specified

when the valve was ordered. Also see the Installation

section.

Also see Bulletin 80.3:010 WhisperFlot Aerodynamic

Attenuation Trims, D102362X012

Shutoff Classifications

See table 2

C-seal trim: High-temperature, Class V per ANSI/FCI

70-2 and IEC 60534-4

See table 3

WhisperFlo Trim:

J 40 or

(2)

,or

Approximate Weights

See table 4

WhisperFlo Trim Material and Selection

J 410 Stainless Steel

J Others per application

See appropriate valve body bulletin

WhisperFlo Pressure/Temperature Capability

J -29 to 427_C(-20to800_F)

J Others per application

See appropriate valve body bulletin for

complementary information

WhisperFlo Aerodynamic Trim Pressure Ratings

Up to 1500 psi drop

WhisperFlo Velocity Limits

WhisperFlo trim is designed for 0.3 MACH as an

inherent outlet velocity limit. Variations higher and

lower may be applied per special applications

J Class IV per ANSI/FCI 70-2 and IEC 60534-4

J Others per application

Flow Characteristics

Standard Cages:

J equal percentage

J Linear, J quick opening, or

Whisper Trimt and Cavitrolt Cages: Linear

WhisperFlo Trim: Linear (restricted linear cages and

special, characterized cages are available--consult

WhisperFlo Rangeability

100:1

WhisperFlo Noise Attenuation

Approximately -40 dBA maximum depending on the

nP/P

ratio per IEC 534-8-3 calculation procedure

1

See Fisher Specification Manager

your Emerson Process Management sales office)

Additional Specifications

Flow Directions

EWS and Standard Cage: Normally up

EWD or EWT with Standard Cage: Normally down

1. The pressure or temperature limits in this manual and any applicable standard limitationsshould not be exceeded.

2. Certain bonnet bolting material selections may require a CL600 easy-e valve assembly to be derated. Contact your Emerson Process Management sales office.

3. There are two different CL900 NPS 8x6 valve bodies, one for use only with Cavitrol III cages and the other for use with all other constructions. ACL900 valve with Cavitrol III cage can takefull

CL900 pressure drops.For information on other NPS 8x6 constructions that can take full CL900 pressure drops, contact your Emerson Process Management sales office. All other trim construc

tions are limitedto CL600 pressure/temperature limits even though installed in a CL900 valve.

For specifications such as materials, port diameters,

valve plug travels, yoke boss diameters, and stem

diameters, refer to the Parts List

(1,2)

2

Page 3

Instruction Manual

D100399X012

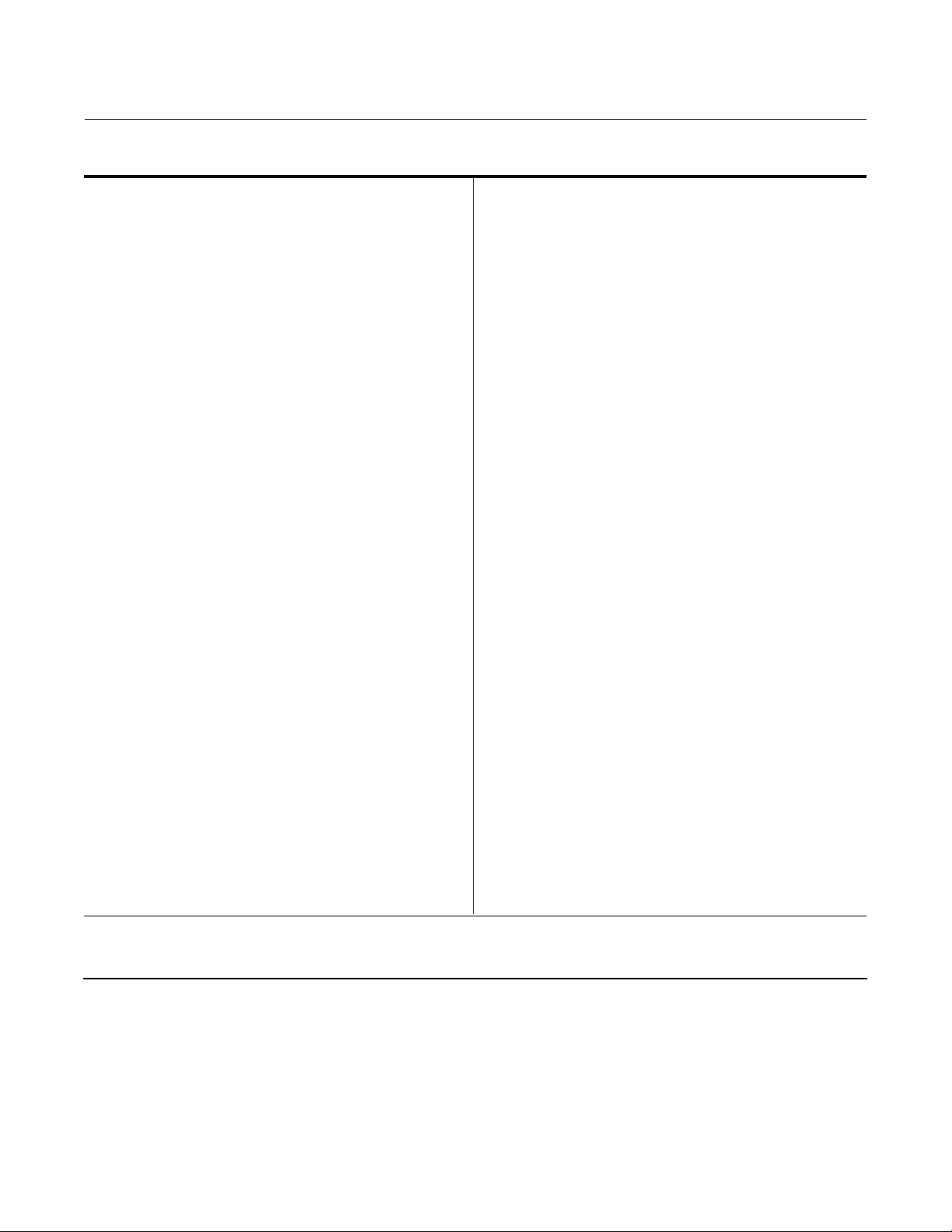

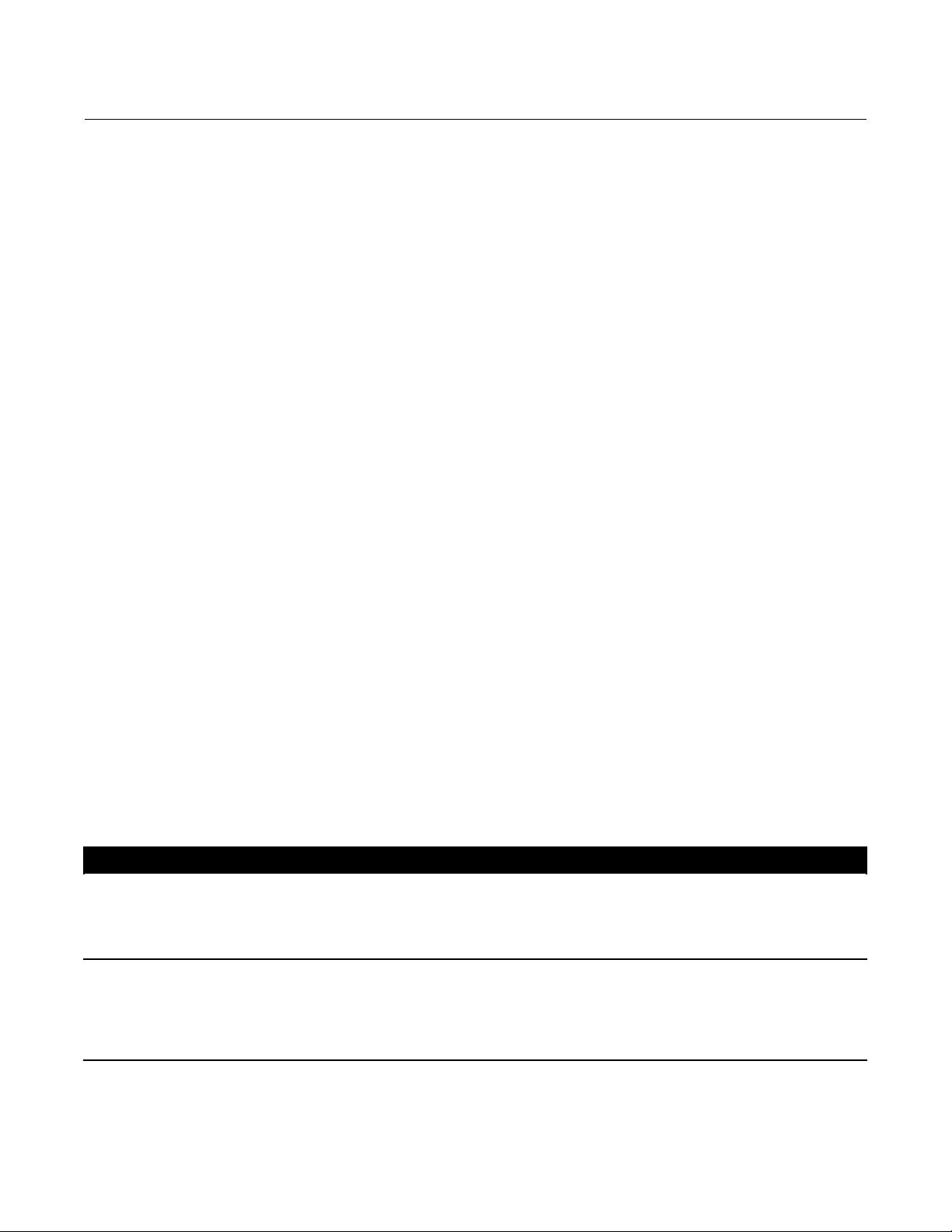

Figure 2. Cutaway Detail of the Fisher WhisperFlo Trim, Valve Body Typical

EW Valve

September 2014

W6825-1

Description

These single-port globe-style valves have cage guiding, clamped seat rings, and push-down-to-close valve plug action.

Valve configurations are as follows:

EWD: Balanced valve plug with metal-to-metal seating for all general applications over a wide range of pressure drops

and temperatures.

C-seal trim is available for EWD valves, CL300 and CL600, in sizes NPS 6x4x2-1/2, 6x4, 8x4, 8x6, 12x6, 10x8, and 12x8.

With C-seal trim, a balanced valve can achieve high-temperature, Class V shutoff. Because the C-seal plug seal is

formed from metal (N07718 nickel alloy) rather than an elastomer, a valve equipped with the C-seal trim can be

appliedinprocesseswithafluidtemperatureofupto593_C (1100_F), provided other material limits are not

exceeded.

EWS: Unbalanced valve plug with metal-to-metal or optional metal-to-PTFE seating for all general applications

requiring better shutoff capabilities than can be obtained with the EWD valve.

EWT: Balanced valve plug with either metal-to-PTFE seating (standard for all except Cavitrol III cages) for stringent

shutoff requirements or metal-to-metal seating (standard for Cavitrol III cages, optional for all others) for higher

temperatures.

Control valves with WhisperFlo cages (figure 2) provide additional attenuation for aerodynamic noise in very

demanding vapor or gas applications with high-pressure drops. A WhisperFlo cage with an appropriately sized valve

body is designed to reduce the noise level up to -40 dBA. For special applications, -50 dBA attenuation can be

achieved.

Specifications

Typical specifications for these valves are shown in table 1.

3

Page 4

EW Valve

September 2014

Instruction Manual

D100399X012

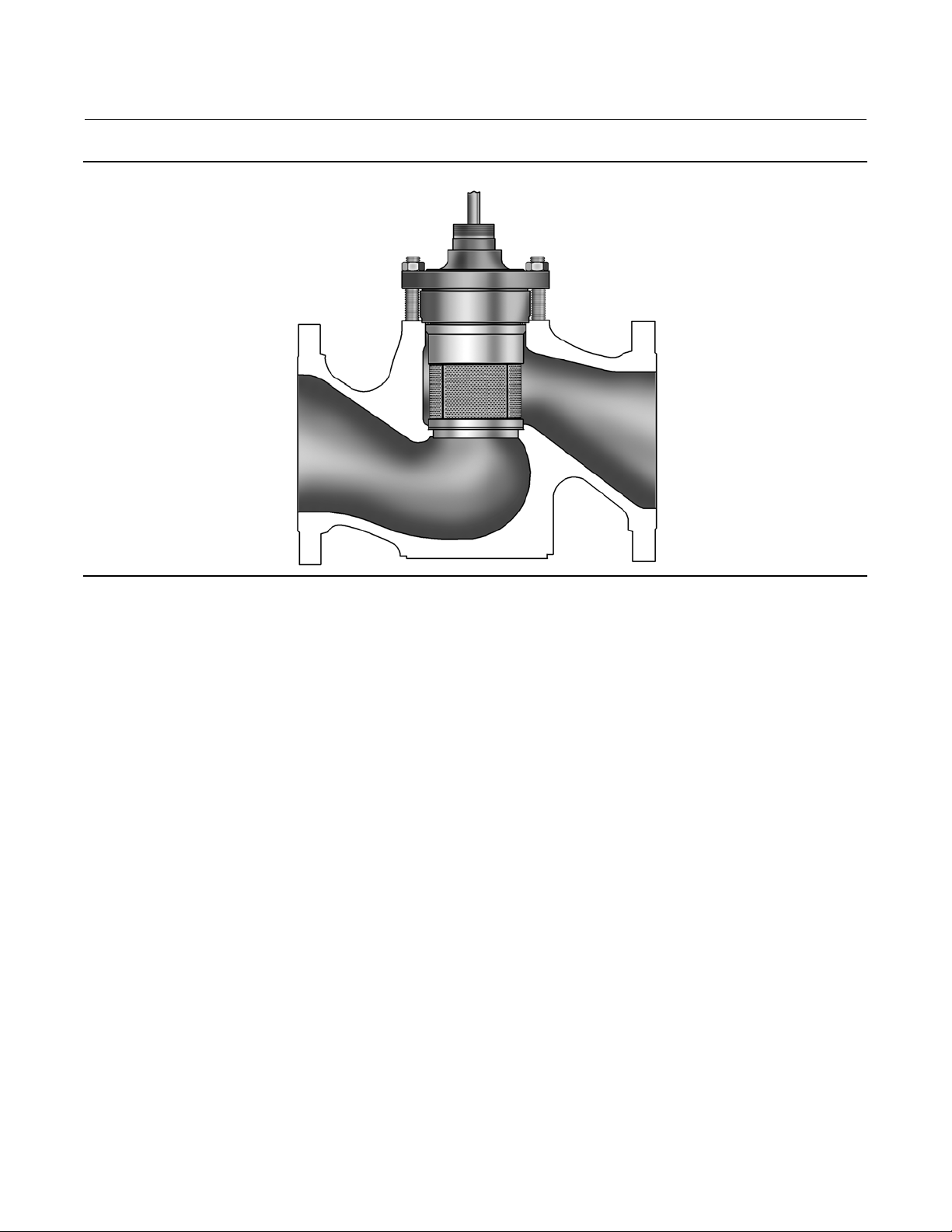

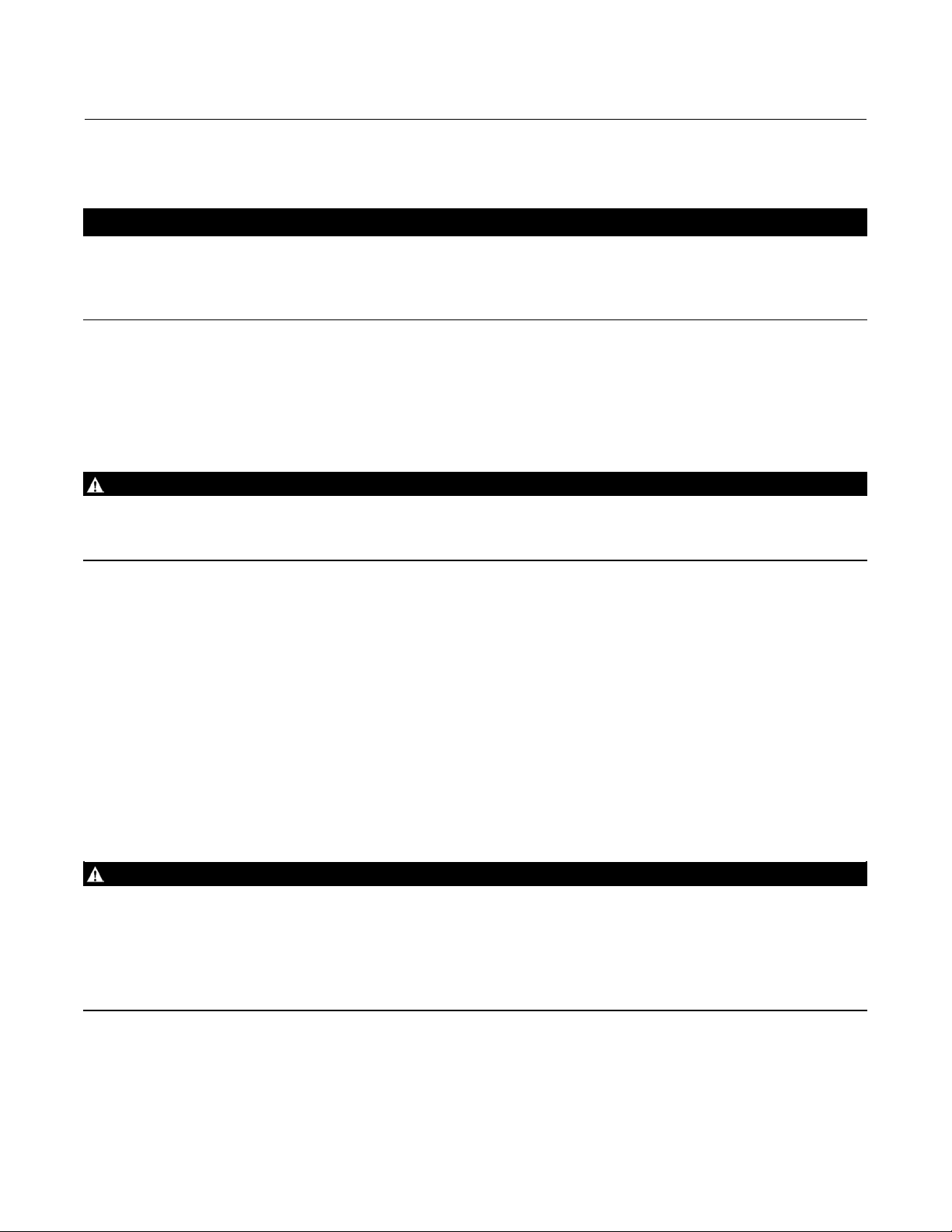

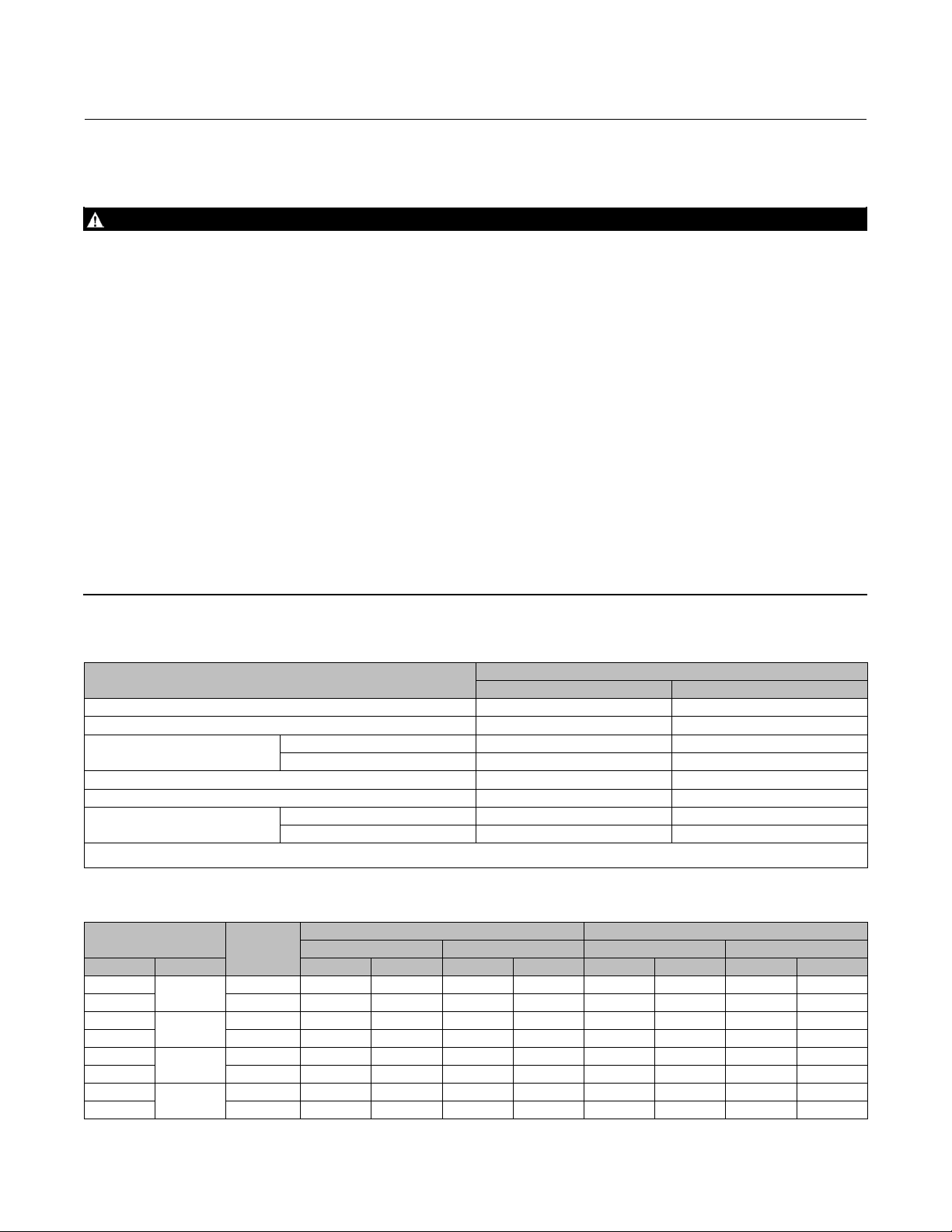

Table 2. Shutoff Classification Per ANSI/FCI 70-2 and IEC 60534-4

Valve Seating Shutoff Class

EWD Metal

EWS Metal

EWS PTFE VI

EWT with all except

Cavitrol III cages

EWT with

1-stage Cavitrol III cage

EWT with 2-stage Cavitrol III cage Metal V

1. Class V shutoff for EWT requires spring loadeds eal ring, radius-seat plug, wide-bevel seat ring, and seatlapping. Not availablewith 8-inch port, quick-opening cage. Not available with

S31600 (316 SST) valve plug and seat ring.

PTFE

Metal IV (standard)

Metal V (optional)

Metal

II (standard)

III (optional for NPS 6x4 through 12x6 valves with optional single graphite piston ring or for

NPS 10x8 and 12x8 valves with optional double piston rings)

IV (optional for NPS 6x4 through 12x8 valves with optional multiple graphite piston rings)

IV (standard)

V (optional,consult your Emerson Process Management sales office)

Standard Air Test (maximum leakage is 0.05 mL/min/psid/inch port diameter)

V (optional)

(1)

IV (standard)

V (optional)

Table 3. Additional Shutoff Classification for C-seal Trim Per ANSI/FCI 70-2 and IEC 60534-4

Valve Valve Size, NPS Port Diameter, Inches Cage Style Leakage Class

Equal Percentage, Linear, Whisper I,

Cavitrol III (2-stage)

Equal Percentage, Linear, Whisper I,

Cavitrol III (1-stage)

Equal Percentage, Linear, Whisper I,

Cavitrol III (1-stage)

Equal Percentage, Linear, Whisper I,

Cavitrol III (1-stage)

V(forport

diameters from 2.875

through 8-inch with

optional C-seal trim)

EWD

(CL300, CL600)

6x4x2-1/2 2.875

6x4

8x4

8x6 and 12x6 5.375 Whisper III (A3, B3, D3, D3), Cavitrol III (2-stage)

8x6

12x6

10x8

12x8

4.375

7

8

Educational Services

For information on available courses for the Fisher EW valve, as well as a variety of other products, contact:

Emerson Process Management

Educational Services - Registration

Phone: 1-641-754-3771 or 1-800-338-8158

E-mail: education@emerson.com

http://www.emersonprocess.com/education

Installation

WARNING

Always wear protective gloves, clothing, and eyewear when performing any installation operations to avoid personal

injury.

Personal injury or equipment damage caused by sudden release of pressure or bursting of parts may result if the valve

assembly is installed where service conditions could exceed the limits given in table 1 or on the appropriate nameplates. To

avoid such injury or damage, provide a relief valve for overpressure protection as required by government or accepted

industry codes and good engineering practices.

4

Page 5

Instruction Manual

D100399X012

EW Valve

September 2014

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

If installing into an existing application, also refer to the WARNING at the beginning of the Maintenance section in this

instruction manual.

CAUTION

When ordered, the valve configuration and construction materials were selected to meet particular pressure, temperature,

pressure drop and controlled fluid conditions. Responsibility for the safety of process media and compatibility of valve

materials with process media rests solely with the purchaser and end-user. Since some body/trim material combinations

are limited in their pressure drop and temperature ranges, do not apply any other conditions to the valve without first

contacting your Emerson Process Management sales office.

Before installing the valve, inspect the valve and pipelines for any damage and any foreign material which may cause

product damage.

Table 4. Approximate Weights

VALVE SIZE, NPS

END CONNECTION

CL300 (flanged only) 84 185 150 330 234 515 284 625 567 1250 500 1102 653 1440

CL600

CL900

Flanged 100 220 195 430 272 600 308 680 744 1640 721 1590 857 1890

Buttwelding 61 135 122 270 177 390 272 600 512 1130 526 1160 658 1450

Flanged --- --- --- --- --- --- 612 1350 --- --- --- --- 1361 3000

Buttwelding --- --- --- --- --- --- 454 1000 --- --- --- --- 1293 2850

4X2 6X4 8X4 8X6 10X8 12X6 12X8

Kg Lb Kg Lb Kg Lb Kg Lb Kg Lb Kg Lb Kg Lb

CAUTION

If hoisting the valve, use a nylon sling to protect the surfaces. Carefully position the sling to prevent damage to the actuator

tubing and any accessories. Also, take care to prevent people from being injured in case the hoist or rigging slips

unexpectedly. Refer to table 4 for valve assembly weights. Be sure to use adequately sized hoists and chains or slings to

handle the valve.

1. Before installing the valve, inspect the valve body cavity and associated equipment for any damage and any foreign

material.

2. Make certain the valve body interior is clean, that pipelines are free of foreign material, and that the valve is

orientedsothatpipelineflowisinthesamedirectionasthearrowonthesideofthevalve.

3. Install the control valve assembly in any orientation unless limited by seismic criteria. However, the normal method

is with the actuator vertical above the valve. Other positions may result in uneven valve plug and cage wear and in

improper operation. With some valves, the actuator may also need to be supported when it is not vertical. For more

information, consult your Emerson Process Management sales office.

Note

If installing a valve with small internal flow passages, such as with WhisperFlo, Whisper Trim, or Cavitrol cages, consider installing

an upstream strainer to prevent the lodging of particles in these passages. This is especially important if the pipeline cannot be

thoroughly cleaned or if the flowing medium is not clean.

5

Page 6

EW Valve

September 2014

4. Use accepted piping and welding practices when installing the valve in the line. For flanged valve bodies, use a

suitable gasket between the valve body and pipeline flanges.

Instruction Manual

D100399X012

CAUTION

Depending on valve body materials used, post weld heat treating may be required. If so, damage to internal elastomeric

and plastic parts, as well as internal metal parts is possible. Shrink-fit pieces and threaded connections may also loosen. In

general, if post weld heat treating is to be performed, remove all trim parts. Contact your Emerson Process Management

sales office for additional information.

5. With a leak-off bonnet construction, remove the pipe plugs (keys 14 and 16, figure 21) from the bonnet to hook up

the leak-off piping. If continuous operation is required during inspection or maintenance, install a three-valve

bypass around the control valve assembly.

6. If the actuator and valve are shipped separately, refer to the actuator mounting procedure in the appropriate

actuator instruction manual.

WARNING

Personal injury could result from packing leakage. Valve packing was tightened before shipment; however, the packing

might require some readjustment to meet specific service conditions. Check with your process or safety engineer for any

additional measures that must be taken to protect against process media.

Valves with ENVIRO-SEAL live-loaded packing or HIGH-SEAL live-loaded packing will not require this initial

re-adjustment. See Fisher instruction manuals, ENVIRO-SEAL Packing System for Sliding-Stem Valves, D101642X012,

or HIGH-SEAL Live-Loaded Packing System, D101453X012, (as appropriate), for packing instructions. If you wish to

convert your present packing arrangement to ENVIRO-SEAL packing, refer to the retrofit kits listed in the parts kit

sub-section near the end of this manual.

Inverted Globe Valve Applications (Actuator below valve)

Due to space restrictions in your application, you may be required to mount the valve/actuator assembly in an inverted

orientation, with the actuator positioned below the valve. If so, the following procedures will help you with

disassembly and assembly techniques.

WARNING

Avoid personal injury or property damage caused by components dropping.

With the valve/actuator upside down, components may drop during disassembly or assembly. Be careful not to position

yourself below the valve in the path of falling parts.

As the bonnet/plug/cage is lowered from the valve body, the center of gravity will be above the lifting points. Take care to

prevent the assembly from tipping over as it is lowered. Either leave the actuator attached to the plug and bonnet, attach

straps to the stem, or provide other means to prevent tipping.

Disassembly

1. Provideadequatesupporttotheactuatorwhileremovingitfromthebonnet.

6

Page 7

Instruction Manual

D100399X012

EW Valve

September 2014

2. Provideadequatesupporttothebonnetwhileremovingthebonnetnuts.

3. Be aware that the bonnet/plug/cage may tip over as they are lowered from the valve body. Make provision to

prevent tipping.

4. Be aware that the cage and seat ring may not come out with the bonnet and plug/stem assembly. If this occurs,

make provision to support these parts, as they may fall out unexpectedly.

Assembly

1. Start this assembly procedure with the plug/stem assembly already installed in the bonnet.

2. Put the gaskets and cage onto the bonnet and plug.

3. Place the seat ring with the seat ring gasket onto the cage, if applicable with the valve design.

4. Raise this bonnet/plug/cage assembly up into the valve body. Make provision to prevent tipping of these parts as

they are being raised into the valve body.

5. Torque the bonnet nuts.

6. Mount the actuator.

Maintenance

Valve parts are subject to normal wear and must be inspected and replaced as necessary. Inspection and maintenance

frequency depends on the severity of service conditions. This section includes instructions for packing lubrication,

packing maintenance, trim maintenance, lapping metal seats, and ENVIRO-SEAL bellows seal bonnet replacement. All

maintenance operations may be performed with the valve in the line.

WARNING

Avoid personal injury or property damage from sudden release of process pressure. Before performing any maintenance

operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both sides of the valve. Drain the process media from both sides of the valve.

D Vent the pneumatic actuator loading pressure and relieve any actuator spring precompression.

D Use lock-out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

CAUTION

Follow instructions carefully to avoid damaging the product surfaces, which could result in damage to the product.

7

Page 8

EW Valve

September 2014

Note

Whenever a gasket seal is disturbed by removing or shifting gasketed parts, install a new gasket upon reassembly. This is necessary

to ensure a good gasket seal because the used gasket may not seal properly.

Instruction Manual

D100399X012

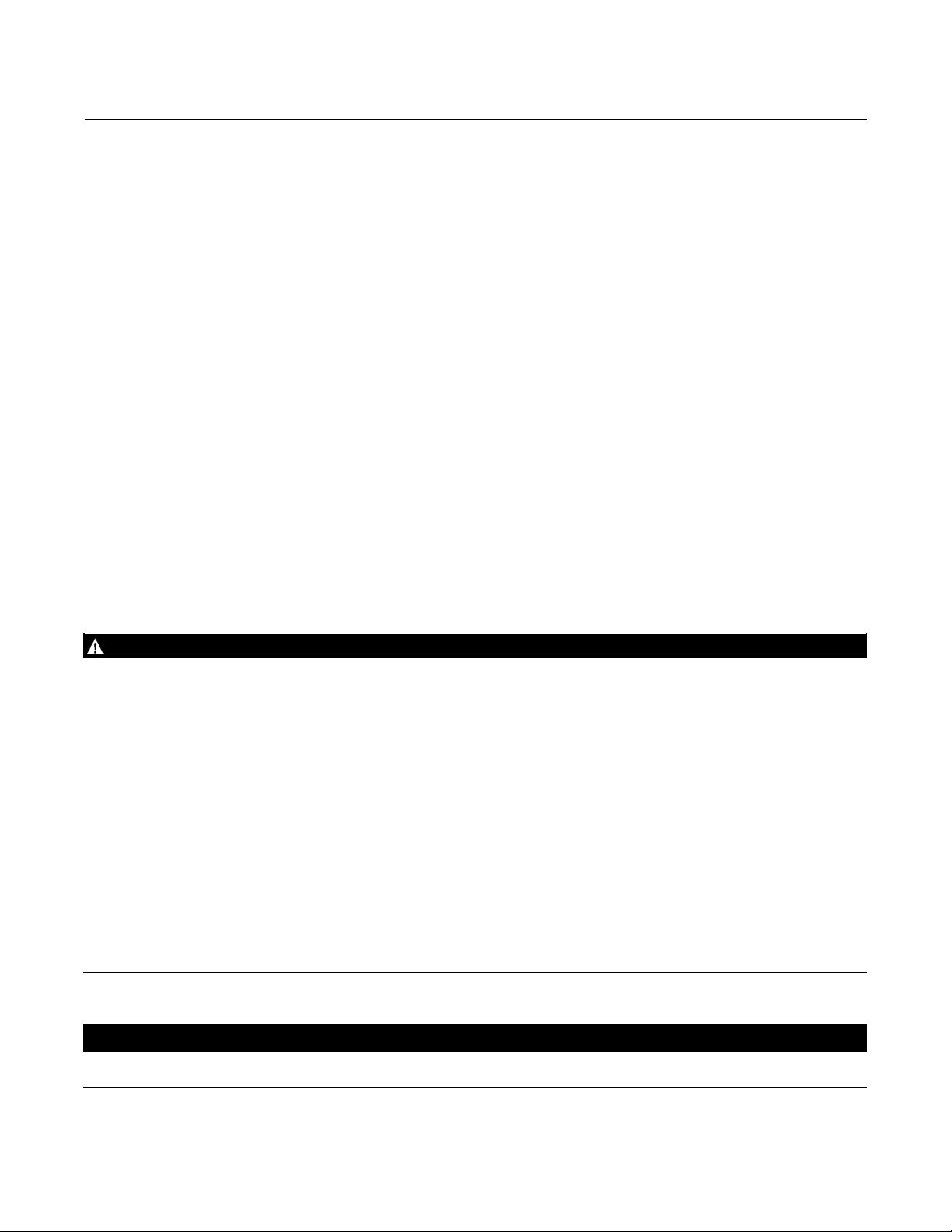

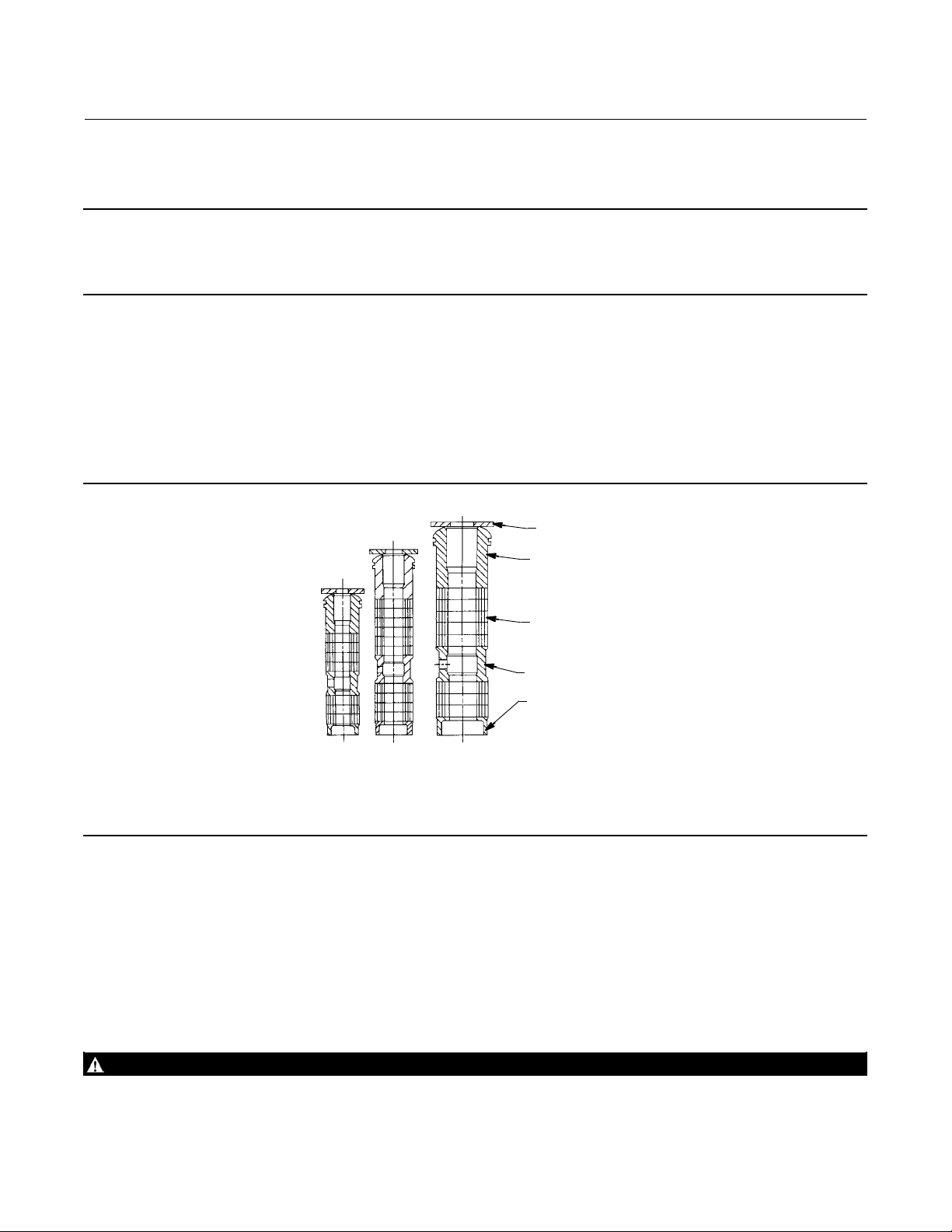

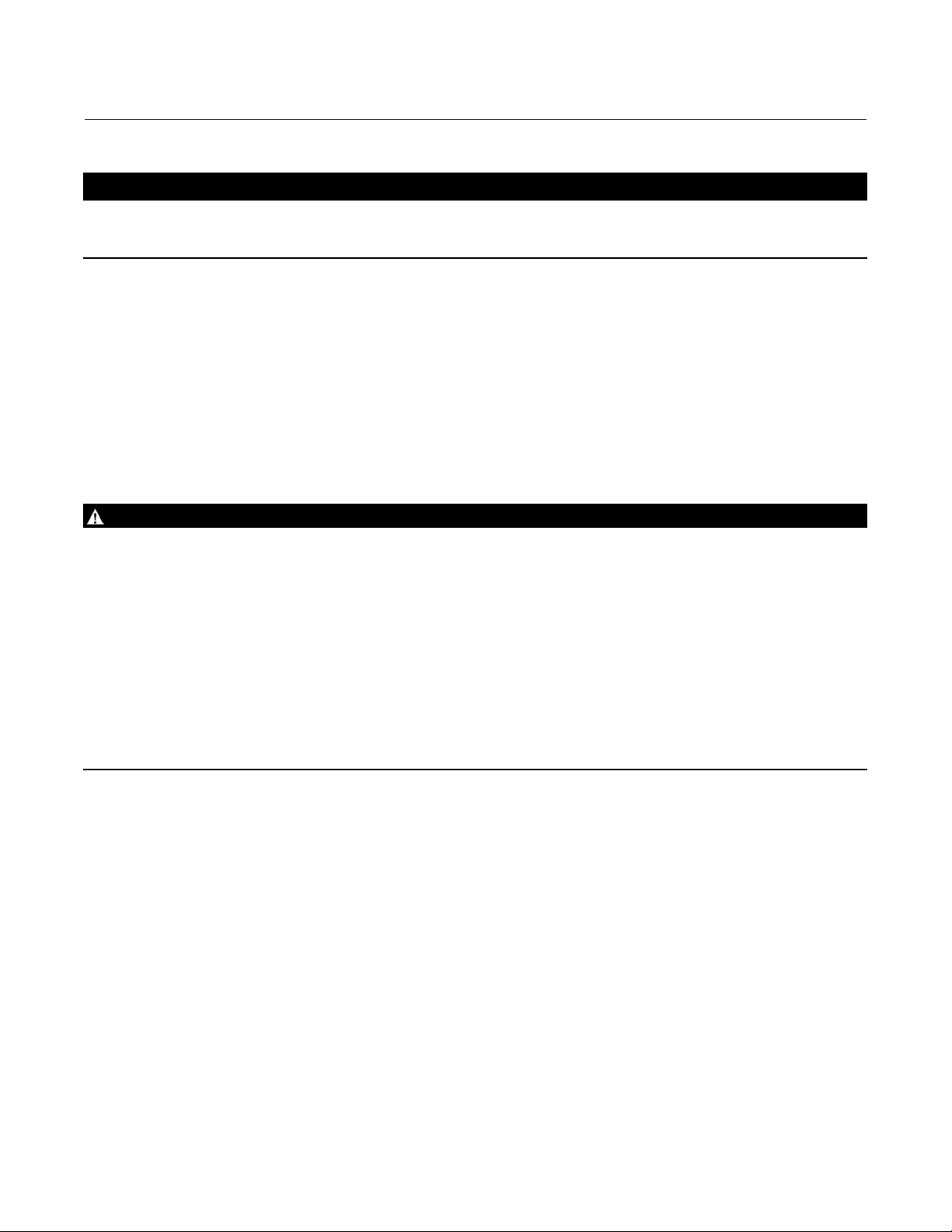

Figure 3. Lubricator and Lubricator/Isolating Valve (optional)

LUBRICATOR

10A9421-A

AJ5428-D

A0832-2

LUBRICATOR/ISOLATING VALVE

Packing Lubrication

CAUTION

Do not lubricate graphite packing. Graphite packing is self-lubricated. Additional lubrication may result in slip-stick

movement of the valve.

Note

ENVIRO-SEAL or HIGH-SEAL packing does not require lubrication.

WARNING

To avoid personal injury or property damage resulting from fire or explosion, do not lubricate packing used in oxygen

service or in processes with temperatures over 260_C (500_F).

If a lubricator or lubricator/isolating valve (figure 3) is provided for PTFE/composition or other packings that require

lubrication, it will be installed in place of the pipe plug (key 14, figure 21). Use a good quality silicon-base lubricant. Do

not lubricate packing used in oxygen service or in processes with temperatures over 260_C(500_F). To operate the

lubricator, simply turn the cap screw clockwise to force the lubricant into the packing box. The lubricator/isolating

valveoperatesthesameway,exceptopentheisolatingvalvebeforeturningthecapscrewandthenclosetheisolating

valve after lubrication is completed.

8

Page 9

Instruction Manual

D100399X012

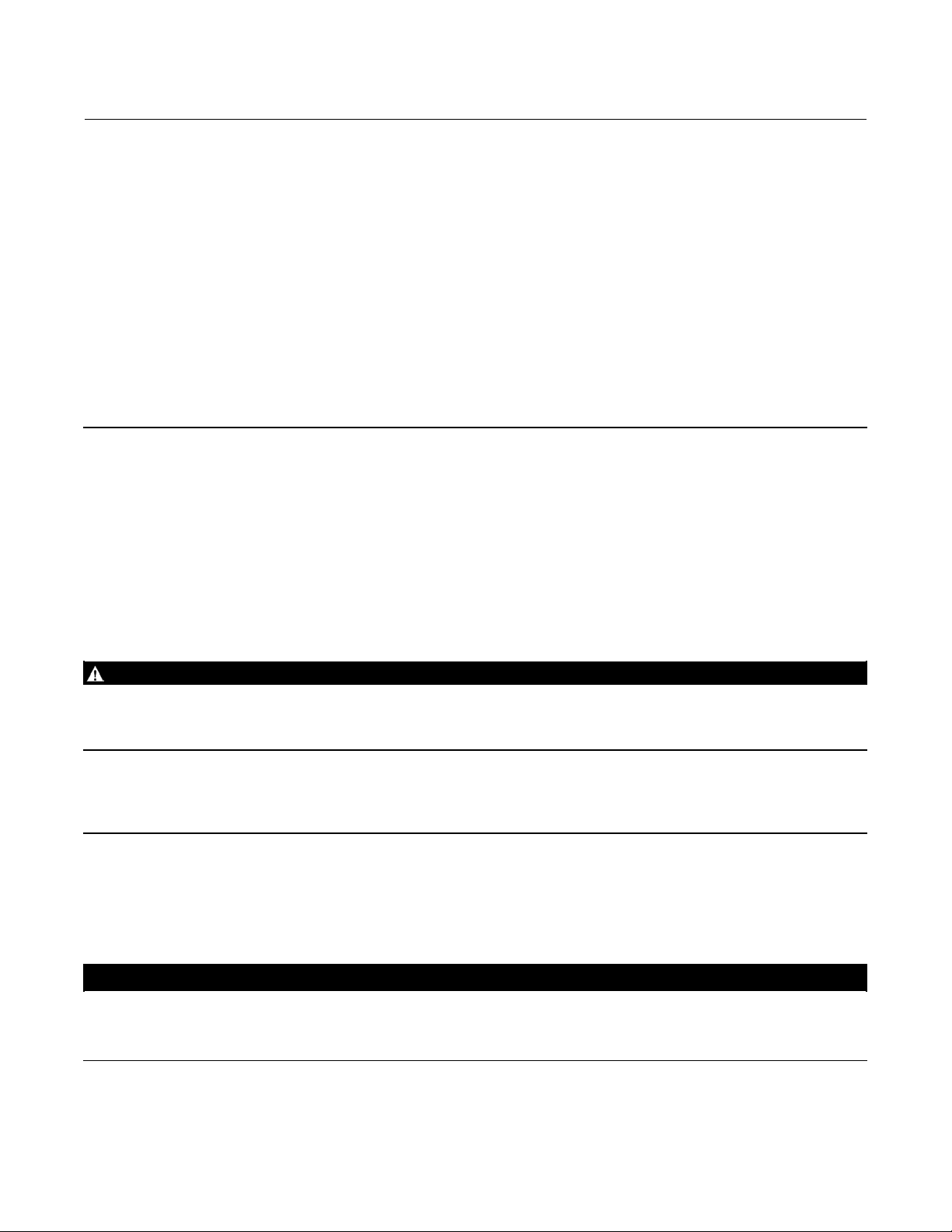

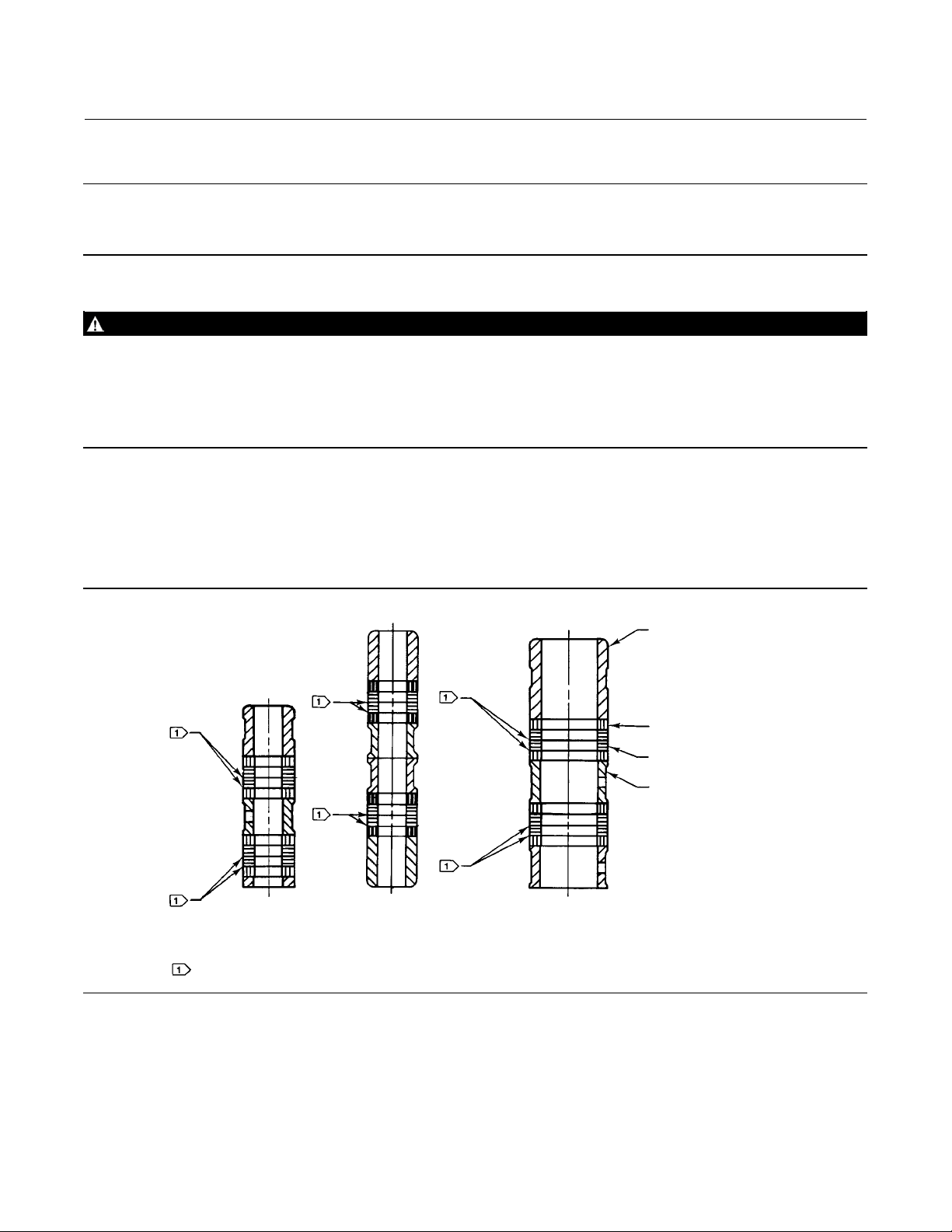

Figure 4. PTFE V-Ring Packing Arrangements

EW Valve

September 2014

UPPER WIPER

(KEY 12)

PACKING

FOLLOWER

(KEY 13)

WASHER

(KEY 10)

SPRING

(KEY 8)

PACKING BOX

RING (KEY 11)

12A7837- A/IL

FOR S31600 (316 SST) OR

S17400 (17-4PH SST)

METAL PACKING BOX PARTS

NOTE:

1

PACKING SET (KEY 6) (2 REQ'D FOR DOUBLE ARRANGEMENTS).

B2398

FEMALE

ADAPTOR

PACKING RING

MALE

ADAPTOR

LOWER WIPER

1

1

1

1

1

1

1

1

SINGLE ARRANGEMENTS

FEMALE

ADAPTOR

PACKING RING

MALE

ADAPTOR

LOWER WIPER

FORALLOTHERMETALPACKING

BOX PART MATERIALS

UPPER WIPER

(KEY 12)

PACKING

FOLLOWER

(KEY 13)

SPACER

(KEY 8)

PACKING BOX

RING (KEY 11)

UPPER WIPER

(KEY 12)

PACKING

FOLLOWER (KEY 13)

12A8187-C 12A7814-C 12A7839-A

ASSEMBLY 1

(POSITIVE

PRESSURES)

ASSEMBLY 2

(VACUUM)

ASSEMBLY 3

(POSITIVE

PRESSURES

& VACU UM)

ASSEMBLY 1

(POSITIVE

PRESSURES)

ASSEMBLY 2

(VACUUM)

ASSEMBLY 3

(POSITIVE

PRESSURES

& V ACUUM)

ASSEMBLY 1

(POSITIVE

PRESSURES)

ASSEMBLY 2

9.5 mm (3/8 INCH) STEM 12.7mm (1/2 INCH)STEM 19.1,25.4, OR 31.8 mm

(3/4, 1, OR 1-1/4 INCH) STEM

B1428-2

DOUBLE ARRANGEMENTS

(VACUUM)

ASSEMBLY 3

(POSITIVE

PRESSURES

& V ACUUM)

MALE ADAPTOR

PACKING RING

FEMALE ADAPTOR

LANTERN RING

(KEY 8)

PACKING BOX

RING (KEY 11)

LOWER WIPER

9

Page 10

EW Valve

September 2014

Instruction Manual

D100399X012

Packing Maintenance

Note

For valves with ENVIRO-SEAL live-loaded packing, see the Fisher instruction manual, ENVIRO-SEAL Packing System for Sliding-Stem

Valves, D101642X012, for packing instructions. For valves with HIGH-SEAL live-loaded packing, see the Fisher instruction manual,

HIGH-SEAL Live-Loaded Packing System, D101453X012, for packing instructions.

Key numbers refer to figure 4 for PTFE V-ring packing and to figure 5 for PTFE/composition packing, unless otherwise

indicated.

For spring-loaded single PTFE V-ring packing, the spring (key 8, figure 4) maintains a sealing force on the packing. If

leakage is noted around the packing follower (key 13, figure 4), check to be sure the shoulder on the packing follower

is touching the bonnet. If the shoulder is not touching the bonnet, tighten the packing flange nuts (key 5, figure 21)

until the shoulder is against the bonnet. If leakage cannot be stopped in this manner, go to the Replacing Packing

procedure.

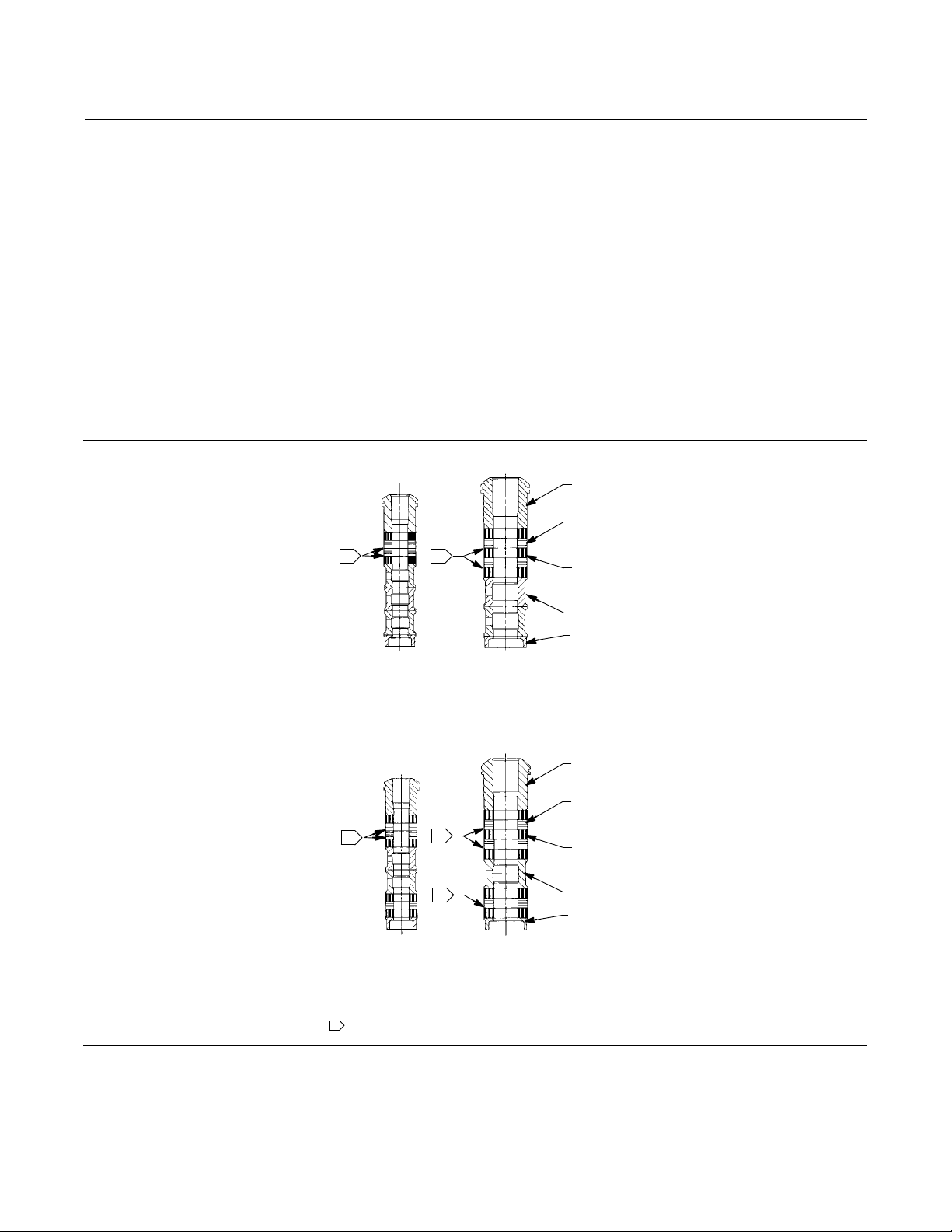

Figure 5. Detail of PTFE/Composition Packing Arrangements

UPPER WIPER

(KEY 12)

PACKING

FOLLOWER

(KEY 13)

PACKING RING

(KEY 7)

LANTERN RING

(KEY 8)

PACKING BOX

RING (KEY 11)

12A8188-A

12A7815-A

12A8173-A

A2619-1

9.5 mm

(3/8 INCH)

STEM

12.7 mm

(1/2 INCH)

STEM

19.1, 25.4, OR

31.8 mm

(3/4,1,OR

1-1/4 INCH) STEM

TYPICAL (DOUBLE) ARRANGEMENTS

If there is undesirable packing leakage with other than spring-loaded packing, first try to limit the leakage and

establish a stem seal by tightening the packing flange nuts.

If the packing is relatively new and tight on the stem and if tightening the packing flange nuts does not stop the

leakage, the valve stem may be worn or nicked so that a seal cannot be made. The surface finish of a new valve stem is

critical for making a good packing seal. If the leakage comes from the outside diameter of the packing, the leakage

may be caused by nicks or scratches around the packing box wall. If performing any of the following procedures,

inspect the valve stem and packing box wall for nicks and scratches.

Replacing Packing

WARNING

Avoid personal injury or property damage from sudden release of process pressure. Before performing any maintenance

operations:

10

Page 11

Instruction Manual

D100399X012

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both sides of the valve. Drain the process media from both sides of the valve.

D Vent the pneumatic actuator loading pressure and relieve any actuator spring precompression.

D Use lock-out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

EW Valve

September 2014

1. Isolatethecontrolvalvefromthelinepressure,releasepressure from both sides of the valve, and drain the process

media from both sides of the valve. If using a power actuator, also shut-off all pressure lines to the power actuator

andreleaseallpressurefromtheactuator.Uselock-outprocedurestobesurethattheabovemeasuresstayin

effect while you work on the equipment.

2. Disconnect the operating lines from the actuator and any leak-off piping from the bonnet. Disconnect the stem

connector, and then remove the actuator from the valve by unscrewing the yoke locknut (key 15, figure 21) or the

hex nuts (key 26, figure 21).

3. Loosen the packing flange nuts (key 5, figure 21) so that the packing is not tight on the valve stem. Remove any

travel indicator parts and stem locknuts from the valve stem threads.

WARNING

To avoid personal injury or property damage caused by uncontrolled movement of the bonnet, loosen the bonnet by

following the instructions in the next step. Do not remove a stuck bonnet by pulling on it with equipment that can stretch

or store energy in any other manner. The sudden release of stored energy can cause uncontrolled movement of the bonnet.

Note

The following step also helps to provide additional assurance that the valve body fluid pressure has been relieved.

4. Hex nuts (key 16, figure 22, 23 or 24) attach the bonnet (key 1, figure 21) to the valve body (key 1, figure 22, 23 or

24). Loosen these nuts approximately 3 mm (1/8 inch). Then loosen the body-to-bonnet gasketed joint by either

rocking the bonnet or prying between the bonnet and valve body. Work the prying tool around the bonnet until the

bonnet loosens. If no fluid leaks from the joint, proceed with bonnet removal as described in the following steps.

CAUTION

To avoid damage to the seating surface caused by the valve plug and stem assembly dropping from the bonnet after being

lifted part way out, temporarily install a valve stem locknut on the valve stem when lifting the bonnet. The locknut

prevents the valve plug and stem assembly from dropping out of the bonnet.

5. Completely remove the hex nuts (key 16) and carefully lift the bonnet off the valve body.

11

Page 12

EW Valve

September 2014

Instruction Manual

D100399X012

6. Remove the locknut and separate the valve plug and stem from the bonnet. Set the parts on a protective surface to

prevent damage to gasket or seating surfaces.

7. Remove the bonnet gasket (key 10, figure 22 through 24), and cover the opening in the valve body to protect the

gasket surface and prevent foreign material from getting into the valve body cavity.

8. Remove the packing flange nuts, packing flange, upper wiper, and packing follower (keys 5, 3, 12, and 13, figure

21). Carefully push out all the remaining packing parts from the valve side of the bonnet using a rounded rod or

other tool that will not scratch the packing box wall. Clean the packing box and the metal packing parts.

9. Inspect the valve stem threads and packing box surfaces for any sharp edges that might cut the packing. Scratches

or burrs could cause packing box leakage or damage to the new packing. If the surface condition cannot be

improved by light sanding, replace the damaged parts by following the appropriate steps in the Trim Maintenance

procedure.

10. Remove the covering protecting the valve cavity and install a new bonnet gasket (key 10, figure 22 through 24),

making sure the gasket seating surfaces are clean and smooth. Place the stem and valve plug into the valve body

and slide the bonnet over the stem and onto the stud bolts (key 15, figure 22, 23, or 24).

Figure 6. Detail of Graphite Ribbon/Filament Packing

PACKING

FOLLOWER

(KEY 13)

GRAPHITE

RIBBON

PACKING RING

1

13A9775-B

12.7 mm

(1/2 INCH)

STEM

1

13A9776-B

19.1, 25.4, & 31.8 mm

(3/4, 1 & 1-1/4 INCH)

STEM

SINGLE ARRANGEMENTS

(KEY 7)

GRAPHITE

FILAMENT

PACKING RING

(KEY 7)

LANTERN

RING (KEY 8)

PACKING BOX

RING (KEY 11)

12

A6067

1

14A1849-B

12.7 mm

(1/2 INCH)

STEM

NOTES:

1

USE ONLY ONE BELOW EACH GRAPHITE RIBBON RING.

0.102 mm (0.004 INCH) THICK SACRIFICIAL ZINC WASHERS;

1

1

14A1780-B

19.1, 25.4, & 31.8 mm

(3/4, 1 & 1-1/4 INCH)

STEM

DOUBLE ARRANGEMENTS

PACKING

FOLLOWER

(KEY 13)

GRAPHITE

GRAPHITE

RIBBON

RIBBON

PACKING RING

PACKING RING

(KEY 7)

(KEY 7)

GRAPHITE

FILAMENT

PACKING RING

(KEY 7)

LANTERN

RING (KEY 8)

PACKING BOX

RING (KEY 11)

Page 13

Instruction Manual

D100399X012

Note

Proper performance of the tightening procedures in step 11 compresses the spiral wound gasket (key 12, figure 22 through 23) or

load ring (key 26, figure 24) enough to both load and seal the seat ring gasket (key 13, figure 22, 23 or 24). It also compresses the

outer edge of the bonnet gasket (key 10, figure 22 through 24) enough to seal the body-to-bonnet joint.

The proper bolting procedures in step 11 include--but are not limited to--ensuring that bolting threads are clean, and evenly

tightening the nuts onto the studs in a criss-cross pattern. Because of the bolt-up characteristics of spiral wound gaskets,

tightening one nut may loosen an adjacent nut. Repeat the criss-cross tightening pattern several times until each nut is tight and

the body-to-bonnet seal is made. When the operating temperature has been reached, perform this torquing procedure once

again.

Note

Stud(s) and nut(s) should be installed such that the manufacturer's trademark and material grade marking is visible, allowing easy

comparison to the materials selected and documented in the Emerson/Fisher serial card provided with this product.

EW Valve

September 2014

WARNING

Personal injury or damage to equipment could occur if improper stud and nut materials or parts are used. Do not operate or

assemble this product with stud(s) and nut(s) that are not approved by Emerson/Fisher engineering and/or listed on the

serial card provided with this product. Use of unapproved materials and parts could lead to stresses exceeding the design

or code limits intended for this particular service. Install studs with the materialgrade and manufacturer's identification

mark visible. Contact your Emerson Process Management representative immediately if a discrepancy between actual

parts and approved parts is suspected.

11. Lubricate the bolting (not necessary if factory pre-lubricated stud bolt nuts are used) and install it, using proper

bolting procedures during tightening so that the body-to-bonnet joint will withstand test pressures and application

service conditions. Use the bolt torques in table 5 as guidelines.

12. Install new packing and the metal packing box parts according to the appropriate arrangement in figure 4, 5, or 6.

Place a smooth-edged pipe over the valve stem and gently tap each soft packing part into the packing box.

13. Slide the packing follower, upper wiper, and packing flange (keys 13, 12, and 3, figure 21) into position. Lubricate

the packing flange studs (key 4, figure 21) and the faces of the packing flange nuts (key 5, figure 21). Install the

packing flange nuts.

14. For spring-loaded PTFE V-ring packing, tighten the packing flange nuts until the shoulder on the packing follower

(key 13, figure 21) contacts the bonnet.

For graphite packing, tighten the packing flange nuts to the maximum recommended torque shown in table 6. Then,

loosen the packing flange nuts, and retighten them to the recommended minimumtorqueshownintable6.

For ENVIRO-SEAL or HIGH-SEAL live-loaded packing, refer to the note at the beginning of the Packing Maintenance

section.

For other packing types, tighten the packing flange nuts alternately in small equal increments until one of the nuts

reaches the minimum recommended torque shown in table. Then, tighten the remaining flange nuts until the packing

flange is level and at a 90-degree angle to the valve stem.

15. Mount the actuator on the valve assembly, and reconnect the actuator and valve stem according to the procedure

in the appropriate actuator instruction manual.

13

Page 14

EW Valve

September 2014

Instruction Manual

D100399X012

Trim Maintenance

WARNING

Avoid personal injury or property damage from sudden release of process pressure. Before performing any maintenance

operations:

D Do not remove the actuator from the valve while the valve is still pressurized.

D Always wear protective gloves, clothing, and eyewear when performing any maintenance operations to avoid personal

injury.

D Disconnect any operating lines providing air pressure, electric power, or a control signal to the actuator. Be sure the

actuator cannot suddenly open or close the valve.

D Use bypass valves or completely shut off the process to isolate the valve from process pressure. Relieve process pressure

on both sides of the valve. Drain the process media from both sides of the valve.

D Vent the pneumatic actuator loading pressure and relieve any actuator spring precompression.

D Use lock-out procedures to be sure that the above measures stay in effect while you work on the equipment.

D The valve packing box may contain process fluids that are pressurized, even when the valve has been removed from the

pipeline. Process fluids may spray out under pressure when removing the packing hardware or packing rings, or when

loosening the packing box pipe plug.

D Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

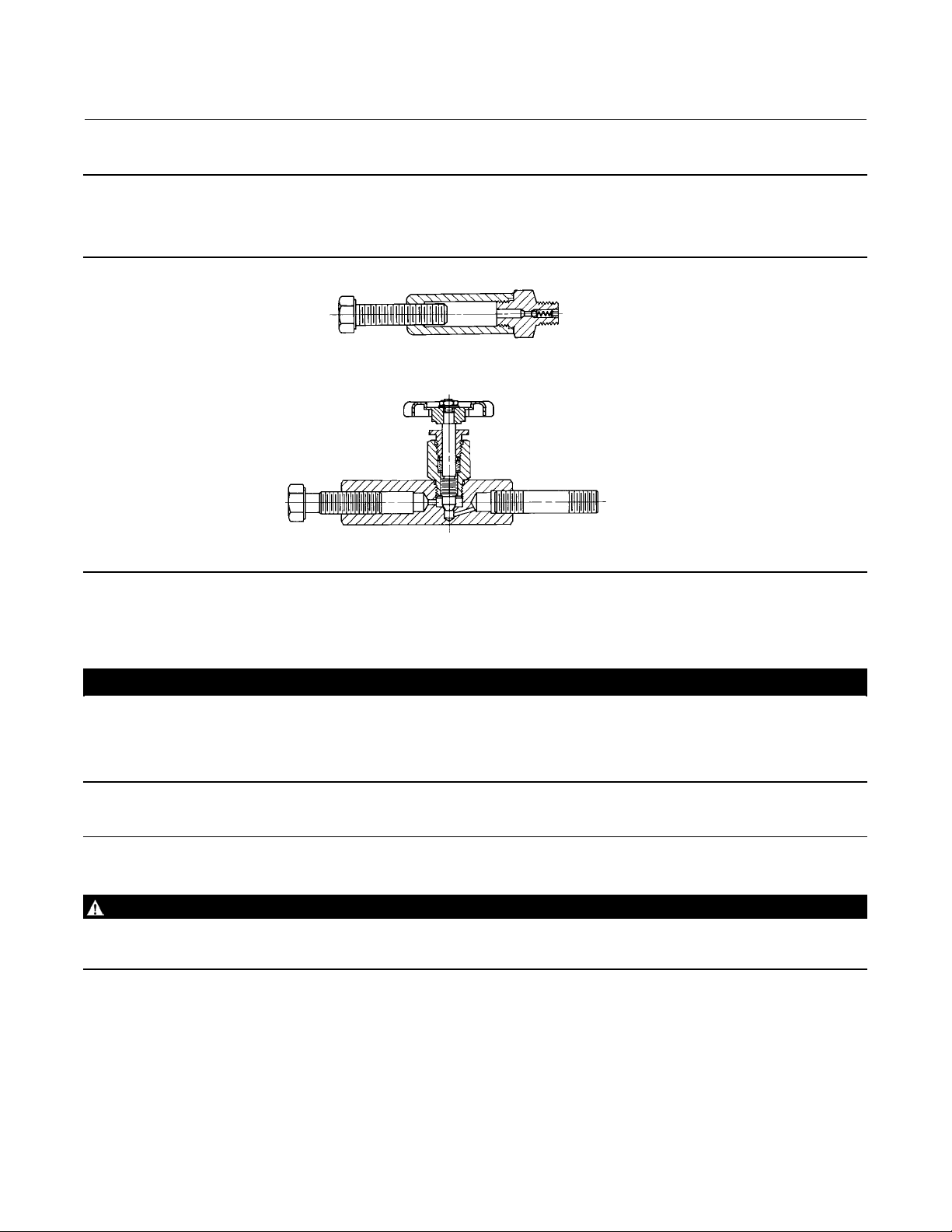

Table 5. Body-to-Bonnet Bolt Torque Guidelines

VALVE SIZE, NPS

4x2 102 75

6x4 or 8x4 259 191

8x6

10x8 745 550

12x6 548 404

12x8

1. Determined from laboratory tests.

2. For other materials, contact your Emerson Process Management sales office for torques.

CL300 or CL600 548 404

CL900 1315 970

CL300 or CL600 732 540

CL900 2712 2000

NSm LbfSft

BOLT TORQUES

(1, 2)

Table 6. Recommended Torque for Packing Flange Nuts

VALVE STEM

DIAMETER

mm Inches NSm LbfSIn NSm LbfSIn NSm LbfSIn NSm LbfSIn

12.7

12.7 CL600 9 81 14 122 4 39 7 58

19.1

19.1 CL600 21 182 31 274 10 87 15 131

25.4

25.4 CL600 35 310 53 466 17 149 25 223

31.8

31.8 CL600 49 437 74 655 24 209 36 314

1/2

3/4

1

1-1/4

PRESSURE

RATING

CL300 7 59 10 88 3 28 5 42

CL300 15 133 23 199 7 64 11 95

CL300 26 226 38 339 12 108 18 162

CL300 36 318 54 477 17 152 26 228

Minimum Torque Maximum Torque Minimum Torque Maximum Torque

GRAPHITE TYPE PACKING PTFETYPE PACKING

14

Page 15

Instruction Manual

D100399X012

EW Valve

September 2014

CAUTION

In the following applicable procedures, to avoid damaging parts, do not grip the bellows shroud or other parts of the

stem/bellows assembly. Grip only the flat areas on the stem where it extends out of the top of the bellows shroud.

For C-seal construction, see the appropriate C-seal sections in this instruction manual.

Except where indicated, key numbers in this section are referenced in figure 22 for EWD constructions, figure 22 for

restricted trim detail, figure 23 for EWS constructions, and figure 24 for EWT constructions. Refer to figures 26 and 27

for Cavitrol III, figure 27 for Whisper Trim III, and figure 29 for WhisperFlo construction.

Trim Removal

1. Remove the actuator and the bonnet according to steps 1 through 5 of the Replacing Packing procedure.

WARNING

Avoid personal injury or property damage from valve or packing leakage.

When lifting the valve plug stem (key 7) and attached valve plug (key 2) out of the valve, be certain that the cage (key 3)

remains in the valve (key 1). This will prevent cage damage that might be caused by the cage dropping back into the valve

after being lifted part way out.

Use care to avoid damaging gasket sealing surfaces.

Each graphite piston ring (key 6) in an EWD valve is brittle and in two pieces. Use care to avoid damage to the piston ring(s)

caused by dropping or rough handling.

Any damage to the gasket sealing surfaces could cause the valve to leak. The surface finish of the valve stem (key 7) is

criticalformakingagoodpackingseal.Theinsidesurfaceofthecageorcage/baffleassembly(key3)orcageretainer(key

31) is critical for smooth operation of the valve plug and for making a seal with the piston ring (key 6) or seal ring (key 28).

The seating surfaces of the valve plug (key 2) and the seat ring (key 9) on a metal-seat construction are critical for tight

shutoff. Protect these parts accordingly while disassembling the trim.

2. Remove the packing flange nuts, packing flange, upper wiper, and packing follower (keys 5, 3, 24, and 25, figure

21). Carefully push out all the remaining packing parts from the valve side of the bonnet using a rounded rod or

other tool that will not scratch the packing box wall. Clean the packing box and the metal packing parts.

3. Inspect the valve stem threads and packing box surfaces for any sharp edges which might cut the packing.

Scratches or burrs could cause packing box leakage or damage to the new packing. If the surface condition cannot

be improved by light sanding, replace the damaged parts.

4. Remove the load ring (key 26) from an NPS 10x8 or 12x8 valve or the cage adaptor (key 4) from any restricted-trim

valve through NPS 8x4, and wrap it for protection.

5. On a 102 mm (4-inch) travel valve with Whisper Trim I cage or on any NPS 8x6 or 12x6 valve with Whisper Trim III

cage, remove the bonnet spacer (key 32) and bonnet gasket (key 10) on top of the spacer. Then on any

construction with a cage retainer (key 31), remove the cage retainer and its associated gaskets. A Whisper Trim III

cage retainer has two 3/8-inch - 16 UNC tappings in which screws or bolts can be installed for lifting.

6. Remove the cage or cage/baffle assembly (key 3) and the associated gaskets (keys 10, 11, and 12). With

full-capacity constructions that have FGM gasket sets, a shim (key 53) is used instead of the cage gasket (key 11). If

thecageisstuckinthevalve,usearubbermallettostriketheexposedportionofthecageatseveralpointsaround

its circumference.

15

Page 16

EW Valve

September 2014

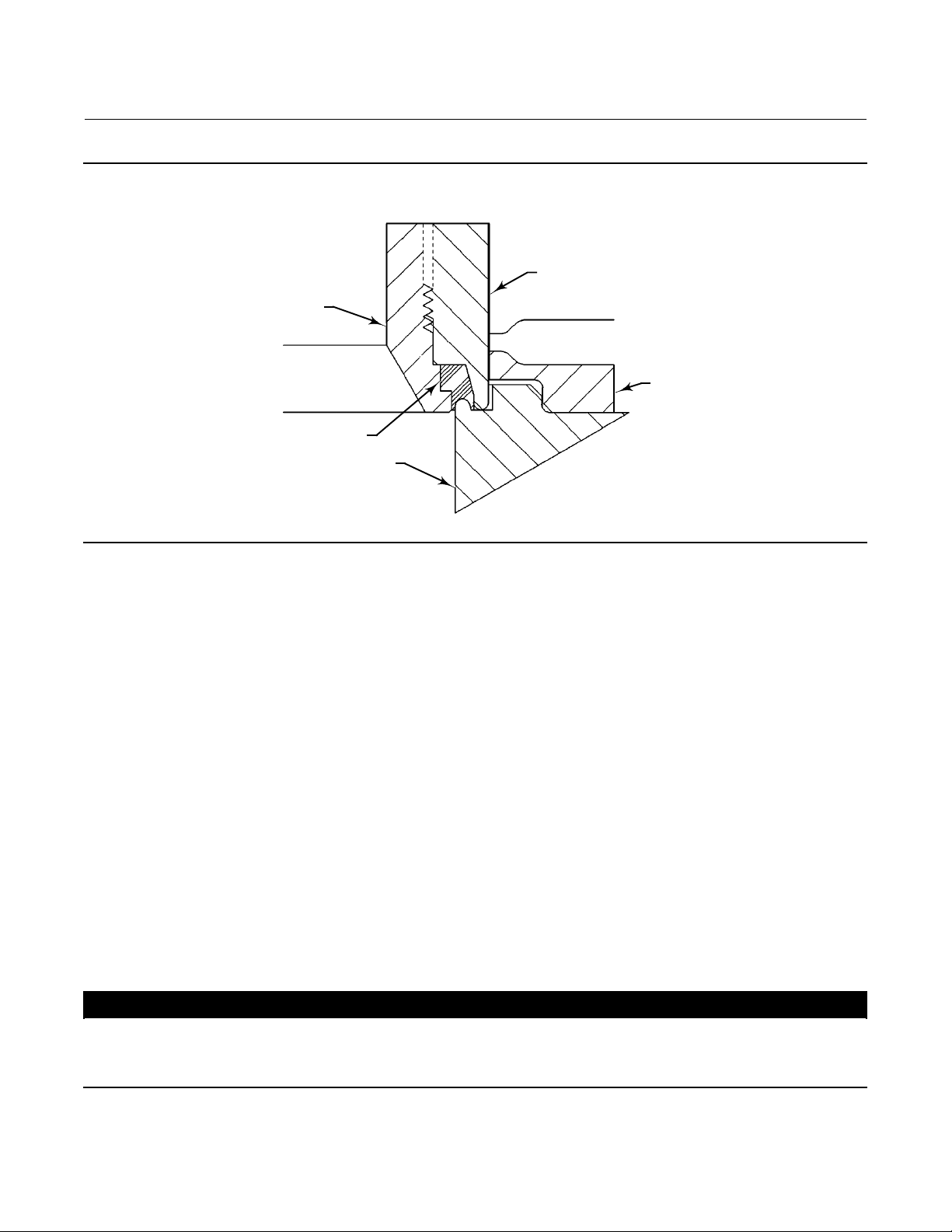

Figure 7. TSO (Tight Shutoff Trim), Detail of Protected Soft Seat

INNER PLUG

PROTECTED SOFT SEAT

SEAT RING

A7088

Instruction Manual

D100399X012

OUTER PLUG

CAGE

7. For constructions other thanTSO(tightshutofftrim), remove the seat ring (key 9) or disk seat (key 22), seat ring

gasket (key 13), and the seat ring adaptor (key 5) and adaptor gasket (key 14) where used in a restricted-capacity

construction. EWS and EWT PTFE-seat constructions use a disk (key 23) sandwiched between the disk seat and disk

retainer (key 21). A CL900 NPS 8x6 EWT construction with Cavitrol III cage has its spiral wound gasket (key 12) on

thesideoftheseatringoppositetheseatringgasket.

8. For TSO (tight shutoff trim) constructions, perform the following steps (refer to figures 7 and 8):

D Remove the piston ring, anti-extrusion rings, backup ring, and retainer.

D Remove the set screws that lock the outer plug to the inner plug.

D Using a strap wrench or similar tool, unscrew the outer plug from the inner plug. Do not damage the outer plug

guide surfaces.

D Remove the protected soft seat seal.

D Inspect the parts for damage and replace if needed.

9. For all constructions, inspect parts for wear or damage that would prevent proper operation of the valve. Replace or

repair trim parts according to the following procedures for lapping metal seats or other valve plug maintenance

procedures, as appropriate.

Lapping Metal Seats

CAUTION

To avoid damaging the ENVIRO-SEAL bellows seal bonnet assembly, do not attempt to lap the metal seating surfaces. The

design of the assembly prevents rotation of the stem and any forced rotation will damage internal components of the

ENVIRO-SEAL bellows seal bonnet.

16

Page 17

Instruction Manual

D100399X012

Figure 8. Typical Balanced TSO Trim

EW Valve

September 2014

VALVE PLUG

SEAL

A7096

PROTECTED

SOFT SEAT

Except with respect to the ENVIRO-SEAL Bellows Seal Bonnet assembly, with metal seat constructions, seating surfaces

of the valve plug and seat ring (keys 2 and 9, figures 24 through 26) can be lapped for improved shutoff. (Deep nicks

should be machined out rather than ground out.) Use a good quality lapping compound of a mixture of 280 to

600-grit. Apply the compound to the bottom of the valve plug.

Assemble the valve to the extent that the cage (and cage retainer and bonnet spacer, if used) is in place and the

bonnetisboltedtothevalve.Asimplehandlecanbemadefromapieceofstrapironlockedtothevalveplugstem

with nuts. Rotate the handle alternately in each direction to lap the seats. After lapping, remove the bonnet, and clean

the seat surfaces. Completely assemble the valve as described in the Trim Replacement portion of the Trim

Maintenance section, and test the valve for shutoff. Repeat the lapping procedure if leakage is still excessive.

Valve Plug Maintenance

Except where indicated, key numbers in this section are referenced in figure 22 for EWD valve plugs, figure 23 for EWS

valve plugs, and figure 24 for EWT valve plugs.

CAUTION

If replacing the piston ring (key 6) or seal ring (key 28), be careful not to scratch the surfaces of the ring groove in the valve

plug or any of the surfaces of the replacement ring, or the replacement ring may not seal properly.

1. With the valve plug (key 2) removed, according to the Trim Removal section, proceed as appropriate:

17

Page 18

EW Valve

September 2014

Instruction Manual

D100399X012

For the EWD carbon-filled PTFE piston ring, the ring is split in one place. If there is visible damage, spread the ring

slightly, and remove it from the groove in the valve plug. To install a carbon-filled PTFE piston ring, spread the ring

apart slightly at the split, and install it over the stem and into the groove in the valve plug. The open side must face

along the stem, depending on flow direction, as shown in figure 22.

For each EWD graphite piston ring, the ring can be easily removed since it is in two pieces. A new graphite piston ring is

furnished as a complete ring. Use a vise with smooth or taped jaws to break this replacement ring into halves. Place the

new ring in the vise so that the jaws will compress the ring into an oval. Slowly compress the ring until it snaps on both

sides. If one side snaps first, do not try to tear or cut the other side. Instead, keep compressing the ring until the other

side snaps. Be sure to match the broken ends when installing the ring in the valve plug groove.

For the EWT two-piece seal ring, the ring cannot be reused as it is a closed ring, which must be pried and/or cut from

the groove. Then the elastomeric backup ring (key 29) can be spread slightly and removed.

To install a new two-piece seal ring, apply a general purpose silicone-base lubricant to both the backup ring and seal

ring(keys29and28).Placethebackupringoverthestem(key7)andintothegroove.Placethesealringoverthetop

edge of the valve plug (key 2) so that it enters the groove on one side of the valve plug. Slowly and gently stretch the

sealring,andworkitoverthetopedgeofthevalveplug.ThePTFEmaterialinthesealringmustbepermittedtimeto

cold-flow during the stretching procedure; so avoid jerking sharply on this ring. Stretching the seal ring over the valve

plug may make it seem unduly loose when in the groove, but it will contract to its original size after insertion into the

cage.

For the EWT spring-loaded seal ring, the ring used on a valve plug having a 136.5 mm (5.375 inch) or less port

diameter may be removed undamaged by first working the retaining ring (key 27) off with a screwdriver. Then

carefully slide the metal backup ring (key 29) and seal ring (key 28) off the valve plug (key 2). The spring-loaded seal

ring used on a valve plug having a 178 mm (7-inch) or greater port diameter must be carefully pried and/or cut from its

groove. Therefore, it cannot be reused.

A spring-loaded seal ring must be installed so that its open side faces toward either the top or the bottom of the valve

plug, depending on flow direction, as shown in view A of figure 24. To install a spring-loaded seal ring on a valve plug

with a 136.5 mm (5.375 inch) or less port diameter, slide the seal ring (key 28) onto the valve plug followed by the

metal backup ring (key 29). Then install the retaining ring (key 27) by inserting one end in the groove and, while

turning the plug, press the ring into the groove. Again, be careful not to scratch any surfaces of the ring or plug.

To install the seal ring on a valve plug with 178 mm (7-inch) or greater port diameter, lubricate it with a general

purpose silicone-base lubricant. Then gently stretch the seal ring, and work it over the top edge of the valve plug. The

PTFE material in the seal ring must be permitted time to cold-flow during the stretching procedure; so avoid jerking

sharply on the ring. Stretching the seal ring over the valve plug may make it seem unduly loose when in the groove,

but it will contract to its original size after insertion into the cage.

CAUTION

Never reuse an old stem or adaptor with a new valve plug. Using an old stem or adaptor with a new plug requires drilling a

new pin hole in the stem (or adaptor in case an ENVIRO-SEAL bellows seal bonnet is being used). This drilling weakens the

stem or adaptor and may cause failure in service. However, a used valve plug may be reused with a new stem or a daptor

except with Cavitrol III trim.

Note

The valve plug and valve plug stem for Cavitrol III trim are a matched set and must be ordered together. If the Cavitrol III valve plug

or valve plug stem is damaged, replace the entire assembly (key 2, figure 26 and 27).

2. Toreplacethevalvestem(key7),driveoutthepin(key8).Unscrewthevalveplugfromthestemoradaptor.

18

Page 19

Instruction Manual

D100399X012

EW Valve

September 2014

3. To replace the adaptor (key 24, figure 21) on ENVIRO-SEAL bellows seal bonnets, place the plug stem assembly and

valve plug in a soft-jaw chuck or other type of vise so that the jaws grip a portion of the valve plug that is not a

seating surface. Drive out the pin (key 36, figure 21). Reverse the plug stem assembly and valve plug in the soft-jaw

chuck or vise. Grip the flat areas on the valve stem just below the threads for the actuator/stem connection.

Unscrew the valve plug/adaptor assembly (key 24, figure 21) from the valve stem assembly (key 20, figure 21).

4. Screw the new stem or adaptor into the valve plug. Tighten to the torque value given in table 7. Refer to table 7 to

select the proper drill size. Drill through the stem or adaptor, using the hole in the valve plug as a guide. Remove

anychipsorburrs,anddriveinanewpintolocktheassembly.

5. For ENVIRO-SEAL bellows seal bonnets, grip the flats of the stem extending out of the top of the bellows shroud

with a soft-jaw chuck or other type of vise. Screw the valve plug/adaptor assembly onto the valve stem. Tighten as

necessarytoalignthepinholeinthestemwithoneoftheholesintheadaptor.Securetheadaptortothestemwith

anewpin.

Trim Replacement

Except where indicated, key numbers in this section are referenced in figure 22 for EWD constructions, figure 22 for

restricted trim detail, figure 23 for EWS construction, and figure 24 for EWT constructions. Refer to figures 26 and 27

for Cavitrol III, figure 28 for Whisper Trim III, and figure 29 for WhisperFlo constructions.

1. With a restricted-trim seat ring construction, install the adaptor gasket (key 14) and seat ring adaptor (key 5).

2. Install the seat-ring gasket (key 13), seat ring (key 9), or disk seat (key 22). With a PTFE-seat construction install the

disk and disk retainer (keys 21 and 23). With an NPS 8x6 CL900 EWT valve with Cavitrol III cage, install the spiral

wound gasket (key 12) on the seat ring.

3. Install the cage or cage/baffle assembly (key 3). Any rotational orientation of the cage or assembly with respect to

the valve is acceptable. A Whisper Trim III cage designated by level A3, B3, or C3 may be installed with either end

up.ThelevelD3cage/baffleassemblyorCavitrolIIIcageassembly,however,mustbeinstalledwiththeholepattern

end next to the seat ring. If a cage retainer (key 31) is to be used, place it on top of the cage.

4. For constructions other thanTSO(tightshutofftrim), slide the valve plug (key 2) and stem assembly or valve plug

and ENVIRO-SEAL bellows seal assembly into the cage. Make sure the piston ring or seal ring (key 6 or 28) is evenly

engaged in the entrance chamfer at the top of the cage (key 3) or cage retainer (key 31) to avoid damaging the ring.

5. For TSO (tight shutoff) trim constructions, perform the following steps (refer to figures 7 and 8).

D Thread the outer plug onto the inner plug until the parts seat metal to metal, using a strap wrench or similar tool

that will not damage the outer plug guide surfaces.

D Mark the top of the inner plug and outer plug with alignment marks in the assembled position.

Table 7. Valve Stem to Plug Torque and Pin Replacement Data

VALVE STEM DIAMETER STEM TORQUE, MINIMUM TO MAXIMUM

mm Inch NSm LbfSft

12.7 1/2 81 to 115 60 to 85 1/8

19.1 3/4 237 to 339 175 to 250 3/16

25.4 1 420 to 481 310 to 355 1/4

31.8 1-1/4 827 to 908 610 to 670 1/4

DRILL SIZE, INCHES

D Disassemble the outer plug from the inner plug and install the seal over the inner plug, so that the seal rests below

the threaded area.

D Thread the outer plug onto the inner plug and tighten with a strap wrench or similar tool until the alignment marks

line up. This will ensure that the plug parts are metal to metal and the seal is compressed properly. Do not damage

the outer plug guide surfaces.

D Install set screws centering the inner plug in the outer plug and torque to 11 NSm(8lbfSft).

19

Page 20

EW Valve

September 2014

Instruction Manual

D100399X012

D Assemble the piston ring, anti-extrusion rings, backup ring, and retainer.

6. For all constructions, place the gaskets (keys 12, 11 or 14 if used, and 10) and the shim, if used (key 53), on top of

the cage or cage retainer. If there is a cage adaptor (key 4) or a bonnet spacer (key 32), set it on the cage or cage

retainer gaskets and place another flat sheet gasket (key 10) on top of the adapterorspacer.Ifthereisonlyacage

retainer or bonnet spacer, place another flat sheet gasket on the retainer or spacer.

7. With an NPS 10x8 or 12x8 valve, install the load ring (key 26).

8. Mount the bonnet on the valve, and complete assembly according to steps 11 through 15 of the Replacing Packing

section. Be sure to observe the note prior to step 11.

Retrofit: Installing C-seal Trim

Note

Additional actuator thrust is required for a valve with C-seal trim. When installing C-seal trim in an existing valve, contact your

Emerson Process Management sales office for assistance in determining new actuator thrust requirements.

Assemble the new valve plug/retainer assembly (with C-seal plug seal) using the following instructions:

CAUTION

To avoid leakage when the valve is returned to service, use appropriate methods and materials to protect all sealing

surfaces of the new trim parts while assembling the individual parts and during installation in the valve body.

1. Apply a suitable high-temperature lubricant to the inside diameter of the C-seal plugseal.Also,lubricatethe

outside diameter of the valve plug where the C-seal plug seal must be pressed into the proper sealing position

(figure 9).

2. Orient the C-seal plug seal for correct sealing action based on the process fluid flow direction through the valve.

D The open interior of the C-seal plug seal must face up in a valve with flow-up construction (figure 9).

D The open interior of the C-seal plug seal must face down in a valve with flow-down construction (figure 9).

Note

An installation tool must be used to properly position the C-seal plug seal on the valve plug. A tool is available as a spare part from

Emerson Process Management or a tool could be manufactured following the dimensions given in figure 10.

3. Place the C-seal plug seal over the t op of the valve plug and press the C-seal plug seal onto the plug using the C-seal

installation tool. Carefully press the C-seal plug seal onto the plug until the installation tool contacts the horizontal

referencesurfaceofthevalveplug(figure11).

4. Apply a suitable high-temperature lubricant to the threads on the plug. Then, place the C-seal retainer onto the

plug and tighten the retainer using an appropriate tool such as a strap wrench.

5. Using an appropriate tool such as a center punch, stake thethreadsontopofthepluginoneplace(figure12)to

secure the C-seal retainer.

20

Page 21

Instruction Manual

D100399X012

Figure 9. Fisher EWD with C-seal Trim

EW Valve

September 2014

64 64

FLOW DOWN

VIEW A

FLOW UP

7

8

65

64

A

2

A6790

6. Install the new plug/retainer assembly with C-seal plug seal on the new stem following the appropriate instructions

in the Trim Replacement section of this manual.

7. Install piston rings by following instructions in the Trim Replacement section of this manual.

8. Remove the existing valve actuator and bonnet following the appropriate instructions in the Replacing Packing

sectioninthismanual.

9

CAUTION

Do not remove the existing valve stem from the valve plug unless you are planning to replace the valve stem.

Never reuse an old valve stem with a new plug or reinstall a valve stem after it has been removed. Replacing a valve stem

requires drilling a new pin hole in the stem. This drilling weakens the stem and may cause failure in service. However, a

used valve plug may be reused with a new valve stem.

9. Remove the existing valve stem and plug, cage, and seat ring from the valve body following the appropriate

instructions in the Trim Removal section in this manual.

10. Replace all gaskets according to appropriate instructions in the Trim Replacement section in this manual.

11. Install the new seat ring, cage, valve plug/retainer assembly, and stem into the valve body and completely

reassemble the valve package following the appropriate instructions in the Trim Replacement section in this

manual.

21

Page 22

EW Valve

September 2014

Instruction Manual

D100399X012

FOR VALVE

PLUGS

FITTING

PORT SIZE

(Inches)

2.875 82.55

3.4375 101.6

3.625 104.394

4.375 125.984

5.375 142.748

7 184.15

8 209.55

FOR VALVE

PLUGS

FITTING

PORT SIZE

(Inches)

A B C D E F G H

52.324 -

52.578

58.674 -

58.928

65.024 -

65.278

83.439 -

83.693

100.076 -

100.33

141.376 -

141.630

166.776 -

167.030

4.978 - 5.029 3.708 - 3.759 41.148

4.978 - 5.029 3.708 - 3.759 50.8

4.978 - 5.029 3.708 - 3.759 50.8

4.978 - 5.029 3.708 - 3.759 50.8

4.978 - 5.029 3.708 - 3.759 45.974

4.978 - 5.029 3.708 - 3.759 60.198

4.978 - 5.029 3.708 - 3.759 55.88

A B C D E F G H

DIMENSIONS, mm

(See DrawingBelow)

DIMENSIONS, INCHES

(See DrawingBelow)

52.680 -

52.781

61.011 -

61.112

68.936 -

69.037

87.351 -

87.452

103.835 -

103.937

145.136 -

145.237

170.536 -

170.637

55.118 -

55.626

63.449 -

63.957

71.374 -

71.882

89.789 -

90.297

106.274 -

106.782

147.574 -

148.082

172.974 -

173.482

Part Number

(To Order

A Tool)

70.891 - 71.044 24B9816X012

85.166 - 85.319 24B5612X012

89.941 - 90.094 24B3630X012

108.991 - 109.144 24B3635X012

128.219 - 128.372 23B9193X012

169.520 - 169.672 23B9180X012

194.920 - 195.072 24B9856X012

Part Number

(To Order

A Tool)

2.875 3.25 2.060 - 2.070 0.196 - 0.198 0.146 - 0.148 1.62 2.074 - 2.078 2.170 - 2.190 2.791 - 2.797 24B9816X012

3.4375 4.00 2.310 - 2.320 0.196 - 0.198 0.146 - 0.148 2.00 2.402 - 2.406 2.498 - 2.518 3.353 - 3.359 24B5612X012

3.625 4.11 2.560 - 2.570 0.196 - 0.198 0.146 - 0.148 2.00 2.714 - 2.718 2.810 - 2.830 3.541 - 3.547 24B3630X012

4.375 4.96 3.285 - 3.295 0.196 - 0.198 0.146 - 0.148 2.00 3.439 - 3.443 3.535 - 3.555 4.291 - 4.297 24B3635X012

5.375 5.62 3.940 - 3.950 0.196 - 0.198 0.146 - 0.148 1.81 4.088 - 4.092 4.184 - 4.204 5.048 - 5.054 23B9193X012

7 7.25 5.566 - 5.576 0.196 - 0.198 0.146 - 0.148 2.37 5.714 - 5.718 5.810 - 5.830 6.67 4 - 6.680 23B9180X012

8 8.25 6.566 - 6.576 0.196 - 0.198 0.146 - 0.148 2.20 6.714 - 6.718 6.810 - 6.830 7.67 4 - 7.680 24B9856X012

Figure 10. C-seal Plug Seal Installation Tool

45 X0.06

8 -9

C

D

A6777

A

B

F

G

H

E

45 X0.02

BREAK SHARP

CORNER

45 X0.01MAX

22

Page 23

Instruction Manual

D100399X012

Figure 11. Installing the C-seal Plug Seal Using the Installation Tool

INSTALLATION

TOOL

C-SEAL

METAL

PLUG

SEAL

EW Valve

September 2014

VALVE

PLUG

HORIZONTAL

REFERENCE

SURFACE

NOTE:

PRESS INSTALLATION TOOL OVER VALVE PLUG UNTIL THE TOOL CONTACTS THE

A6778

HORIZONTAL REFERENCE SURFACE OF THE VALVE PLUG.

Figure 12. Stake the Threads of the C-seal Retainer

DEFORM THREAD TO

STAKE C-SEAL RETAINER

PISTON

RING

RETAINER

C-SEAL

METAL

PLUG

SEAL

FLOW DOWN

VALVE

PLUG

A6779

FLOW DOWN

23

Page 24

EW Valve

September 2014

Instruction Manual

D100399X012

CAUTION

To avoid excessive leakage and seat erosion, the valve plug must be initially seated with sufficient force to overcome the

resistance of the C-seal plug seal and contact the seat ring. You can c orrectly seat the valve plug by applying the full

actuator load. This force will adequately drive the valve plug to the seat ring, thus giving the C-seal plug seal a

predetermined permanent set. Once this is done, the plug/retainer assembly, the cage, and the seat ring become a

matched set.

With full actuator force applied and the valve plug fully seated, align the actuator travel indicator scale with the lower end

of valve travel. Refer to the appropriate actuator instruction manual for information on this procedure.

Replacement of Installed C-seal Trim

Trim Removal (C-seal Constructions)

1. Remove the valve actuator and bonnet following the appropriate instructions in the Replacing Packing section in

this manual.

CAUTION

To avoid leakage when the valve is returned to service, use appropriate methods and materials to protect all sealing

surfaces of the trim parts during maintenance.

Use caution when removing piston ring(s) and C-seal plug seal to avoid scratching any sealing surface.

CAUTION

Do not remove the valve stem from the plug/retainer assembly unless you are planning to replace the valve stem.

Never reuse an old valve stem with a new plug or reinstall a valve stem after it has been removed. Replacing a valve stem

requires drilling a new pin hole in the stem. This drilling weakens the stem and may cause failure in service. However, a

used valve plug may be reused with a new valve stem.

2. Remove the plug/retainer assembly (with C-seal plug seal), cage, and seat ring from the valve body following the

appropriate instructions in the Trim Removal section of this manual.

3. Locate the staked thread on top of the valve plug (figure 12). The staked thread secures the retainer. Use a drill with

a 1/8 inch bit to drill out the staked area of the thread. Drill approximately 1/8 inch into the metal to remove the

staking.

4. Locate the break between sections of the piston ring(s). Using an appropriate tool such as a flat-blade screwdriver,

carefully pry out the piston ring(s) fromthegroove(s)intheC-sealretainer.

5. After removing the piston ring(s), locate the 1/4-inch diameter hole in the groove. In a retainer with two piston ring

grooves,theholewillbefoundintheuppergroove.

6. Selectanappropriatetoolsuchasapunchandplacethetipofthetoolintotheholewiththebodyofthetoolheld

tangent to the outside diameter of the retainer. Strike the tool with a hammer to rotate the retainer and free it from

thevalveplug.Removetheretainerfromtheplug.

7. Use an appropriate tool such as a flat-blade screwdriver to pry the C-seal plug seal off the plug. Use caution to avoid

scratches or other damage to the sealing surfaces where the C-seal plug seal makes contact with the valve plug

(figure 13).

24

Page 25

Instruction Manual

D100399X012

Figure 13. Lower (Valve Plug to Seat Ring) and Upper (C-seal Plug Seal to Cage) S eating Surfaces

RETAINER

C-seal METAL

PLUG SEAL

1

VALVE PLUG

UPPER SEATING SURFACE

PLUG

CAGE

CAGE

EW Valve

September 2014

SEAT

NOTE:

UPPER SEATING SURFACE ISTHE AREAOF CONTACTBETWEEN

1

THE C-seal METAL PLUG SEAL AND THE CAGE.

A6780

LOWER SEATING SURFACE

RING

8. Inspect the lower seating surface where the valve plug contacts the seat ring for wear or damage which would

prevent proper operation of the valve. Also, inspect the upperseatingsurfaceinsidethecagewheretheC-sealplug

seal contacts the cage, and inspect the sealing surface where the C-seal plug seal makes contact with the plug

(figure 13).

9. Replace or repair trim parts according to the following procedure for lapping metal seats, remachining metal seats,

or other valve plug maintenance procedures as appropriate.

Lapping Metal Seats (C-seal Constructions)

Before installing a new C-seal plug seal, lap the lower seating surface (valve plug to seat ring,

figure 13) following appropriate procedures in the Lapping Metal Seats section of this manual.

Remachining Metal Seats (C-seal Constructions)

See figure 14. A valve plug with a C-seal metal plug seal features two seating surfaces. One seating surface is found

wherethevalveplugcontactstheseatring. The second seating surface is found where the C-seal plug seal contacts

the upper seating surface in the cage. If you machine the seats on the seat ring and/or plug, you must machine an

equal dimension from the seating area in the cage.

CAUTION

If metal is removed from the seat ring and plug and a corresponding amount is not removed from the cage seating area, the

C-seal plug seal will be crushed as the valve closes and the C-seal retainer will strike the seating area of the cage, preventing

the valve from closing.

25

Page 26

EW Valve

September 2014

Instruction Manual

D100399X012

Figure 14. Example of Machining the Lower (Valve Plug to Seat Ring) and Upper (C-seal Plug Seal to Cage) Seating

Surfaces

1

PLUG

0.254 (0.010)

C-seal

RETAINER

(4)

UPPER SEATING

SURFACE

(4)

0.508 (0.020)

MACHINING OF THE UPPER

SEATING SURFACE MUST

EQUALTHETOTALMACHININGOF

THE LOWER SEATING SURFACE

(PLUGPLUS SEAT RING). IF NOT, THE

RETAINER MAY STRIKE THE UPPER

SEATING SURFACE BEFORE THE

VALVE PLUG PROPERLY SEATS ON

THE LOWER SEATING SURFACE.

3

CAGE

SEAT

RING

(4)

0.254 (0.010)

2

LOWER SEATING SURFACE

NOTE:

PLUS

A6781 / IL

REMOVAL OF 0.254 mm (0.010 inch) FROM THE VALVE PLUG

1

REMOVAL OF 0.254mm (0.010 inch) FROM THE SEAT RING

2

3

REMOVAL OF 0.508 mm (0.020inch) FROM THEUPPER

SEATING SURFACE IN THE CAGE

4. THESE VALUES ARE FOR EXAMPLE ONLY. REMOVEONLY THEMINI

MUM AMOUNT OF MATERIAL REQUIRED TO REFURBISHTHE SEATS.

Trim Replacement (C-seal Constructions)

1. Apply a suitable high-temperature lubricant to the inside diameter of the C-seal plugseal.Also,lubricatethe

outside diameter of the valve plug where the C-seal plug seal must be pressed into the proper sealing position

(figure 9).

2. Orient the C-seal plug seal for correct sealing action based on the process fluid flow direction through the valve.

D The open interior of the C-seal plug seal must face up in a valve with flow-up construction (figure 9).

D The open interior of the C-seal plug seal must face down in a valve with flow-down construction (figure 9).

Note

An installation tool must be used to properly position the C-seal plug seal on the valve plug. A tool is available as a spare part from

Emerson Process Management or a tool could be manufactured following the dimensions given in figure 10.

26

Page 27

Instruction Manual

D100399X012

EW Valve

September 2014

3. PlacetheC-sealplugsealoverthetopofthevalveplugandpressitontotheplugusingtheinstallationtool.

Carefully press the C-seal plug seal onto the plug until the installation tool contacts the horizontal reference surface

of the valve plug (figure 11).

4. Apply a suitable high-temperature lubricant to the threads on the plug. Then, place the C-seal retainer onto the

plug and tighten the retainer using an appropriate tool such as a strap wrench.

5. Using an appropriate tool such as a center punch, stake thethreadsontopofthepluginoneplace(figure12)to

secure the C-seal retainer.

6. Replace the piston ring(s) following instructions in the Trim Replacement section of this manual.

7. Return the seat ring, cage, plug/retainer assembly, and stem to the valve body and completely reassemble the valve

package following the appropriate instructions in the Trim Replacement section of this manual.

CAUTION

To avoid excessive leakage and seat erosion, the valve plug must be initially seated with sufficient force to overcome the

resistance of the C-seal plug seal and contact the seat ring. You can c orrectly seat the valve plug by applying the full

actuator load. This force will adequately drive the valve plug to the seat ring, thus giving the C-seal plug seal a

predetermined permanent set. Once this is done, the plug/retainer assembly, the cage, and the seat ring become a

matched set.

With full actuator force applied and the valve plug fully seated, align the actuator travel indicator scale with the lower end

of valve travel. Refer to the appropriate actuator instruction manual for information on this procedure.

ENVIRO-SEAL Bellows Seal Bonnet

Replacing a Plain or Extension Bonnet with an ENVIRO-SEAL Bellows Seal Bonnet

(Stem/Bellows Assembly)

Except where indicated, key numbers in this section are referenced in figure 22 for EWD constructions, figure 22 for

restricted trim detail, figure 23 for EWS constructions, and figure 24 for EWT constructions. Refer to figures 26 and 27

for Cavitrol III, figure 27 for Whisper Trim III, and figure 29 for WhisperFlo constructions.

Table 8. Recommended Torque for ENVIRO-SEAL Bellows Seal Bonnet Packing Flange Nuts

VALVE SIZE,

NPS

4x2 1/2 2 22 4 33

6x4 to 12x8 1 5 44 8 67

VALVE STEM

DIAMETER THROUGH

PACKING

1. Remove the actuator and bonnet according to steps 1 through 6 of the Replacing Packing procedure in the

Maintenance section.

2. Lift out the cage.

3. Remove and discard the existing bonnet gasket. Cover the valve body opening to protect sealing surfaces and to

prevent foreign material from entering the v alve body cavity.

Note

The ENVIRO-SEAL stem/bellows assembly for easy-et valves is available only with a threaded and drilled plug/adaptor/stem

connection. The existing valve plug can be reused with the new s tem/bellows assembly or a new plug can be installed.

MINIMUM TORQUE MAXIMUM TORQUE

NSm LbfSin NSm LbfSin

27

Page 28

EW Valve

September 2014

Instruction Manual

D100399X012

4. Inspect the existing valve plug. If the plug is in good condition, it can be reused with the new ENVIRO-SEAL

stem/bellows assembly. To remove the existing valve plug from the stem, first, place the existing plug stem

assembly in a soft-jaw chuck or other type of vise so that the jaws grip a portion of the valve plug that is not a

seating surface. Drive out or drill out the pin (key 8).

5. Then,reversetheplugstemassemblyinthesoft-jawchuckorvise.Gripthevalvesteminanappropriateplaceand

unscrew the existing plug from the valve stem.

CAUTION

When installing a valve plug on the ENVIRO-SEAL stem/bellows assembly, the valve stem must not be rotated. Damage to

the bellows may result.

Do not grip the bellows shroud or other parts of the stem/bellows assembly. Grip only the flat areas on the stem where it

extends out of the top of the bellows shroud.

Note

The ENVIRO-SEAL stem/bellows assembly has a one-piece stem.

6. To attach the valve plug to the stem of the new ENVIRO-SEAL stem/bellows assembly, it is necessary to first attach

the plug to the adaptor (key 24, figure 21). Locate the adaptor. Notice that a hole has not been drilled in the threads

wheretheplugscrewsontotheadaptor.Securethevalvepluginasoft-jawchuckorothertypeofvise.Donotgrip

the plug on any seating surface. Position the plug in the chuck or vise for easy threading of the adaptor. Thread the

adaptor into the valve plug and tighten to the appropriate torque value.

7. Select the proper size of drill bit and drill through the adaptor using the hole in the valve plug as a guide. Remove

any metal chips or burrs and drive in a new pin (key 8) to lock the plug/adaptor assembly together.

8. Attach the plug/adaptor assembly to the ENVIRO-SEAL stem/bellows assembly by first securing the stem/bellows

assemblyinasoft-jawchuckorothertypeofvisesothatthejawsofthechuckorvisegriptheflatsofthestem

extendingoutofthetopofthebellowsshroud.Screwthevalveplug/adaptorassemblyontothevalvestem.

Tighten the plug/adaptor assembly until it is snug. Then turn the plug/adaptor assembly to the next pin hole in the

valve stem. Drive in new pin (key 36, figure 21) to lock the assembly.

9. Inspect the seat ring (key 9). Replace, if necessary.

10. Place a new gasket (key 10) into the valve body in place of the bonnet gasket. Install the new stem/bellows

assembly with valve plug/adaptor by placing it into the valve body on top of the new bellows gasket.

11. Place a new gasket (key 22, figure 21) over the stem/bellows assembly. Place the new ENVIRO-SEAL bonnet over

the stem/bellows assembly.

28

Page 29

Instruction Manual

D100399X012

Figure 15. PTFE Packing Arrangement for Use in Fisher ENVIRO-SEAL Bellows Seal Bonnets

UPPER WIPER

(KEY 12)

BUSHING

(KEY 13)

FEMALE ADAPTOR

PAC KI NG RI NG

MALE ADAPTOR

SPACER (KEY 8)

SPACER (KEY 8)

A5855/IL

THRUST

RING

(KEY 39)

SPRING

(KEY 8)

THRUST

RING

9.5 mm

(KEY 39)

(3/8 INCH)

STEM

FOR S31603 (316 SST) PACKING

BOX PARTS

12.7 mm

(1/2 INCH)

STEM

9.5 mm

(3/8 INCH)

STEM

FOR ALL PACKING BOX MATERIALS

SINGLE ARRANGEMENTS

SPACER

(KEY 8)

12B4185- A- SHT2/IL12B4182- A- SHT2/IL12B4185- A- SHT1/IL12B4182- A/ IL

12.7 mm

(1/2 INCH)

EXCEPT S31603

STEM

EW Valve

September 2014

PACKING SET

(KEY 6)

A5886-1

12B4183- A/IL

(3/8 INCH)

9.5 mm

STEM

BUSHING

(KEY 13)

THRUST

RING

(KEY 39)

BUSHING

(KEY 13)

SPACER

(KEY 8)

18A0906- D/IL

12.7 mm

(1/2 INCH)

STEM, NPS2

VALVES

DOUBLE ARRANGEMENTS

18A5338- B/IL

12.7 mm

(1/2 INCH)

STEM, NPS 3 AND

NPS 4 VALVES

UPPER WIPER

(KEY 12)

BUSHING

(KEY 13)

FEMALE

ADAPTOR

PACKING RING

MALE ADAPTOR

SPACER (KEY 8)

PACKING SET

(KEY 6)

29

Page 30

EW Valve

September 2014

Instruction Manual

D100399X012

Note

Stud(s) and nut(s) should be installed such that the manufacturer's trademark and material grade marking is visible, allowing easy