Page 1

Instruction Manual

D103434X012

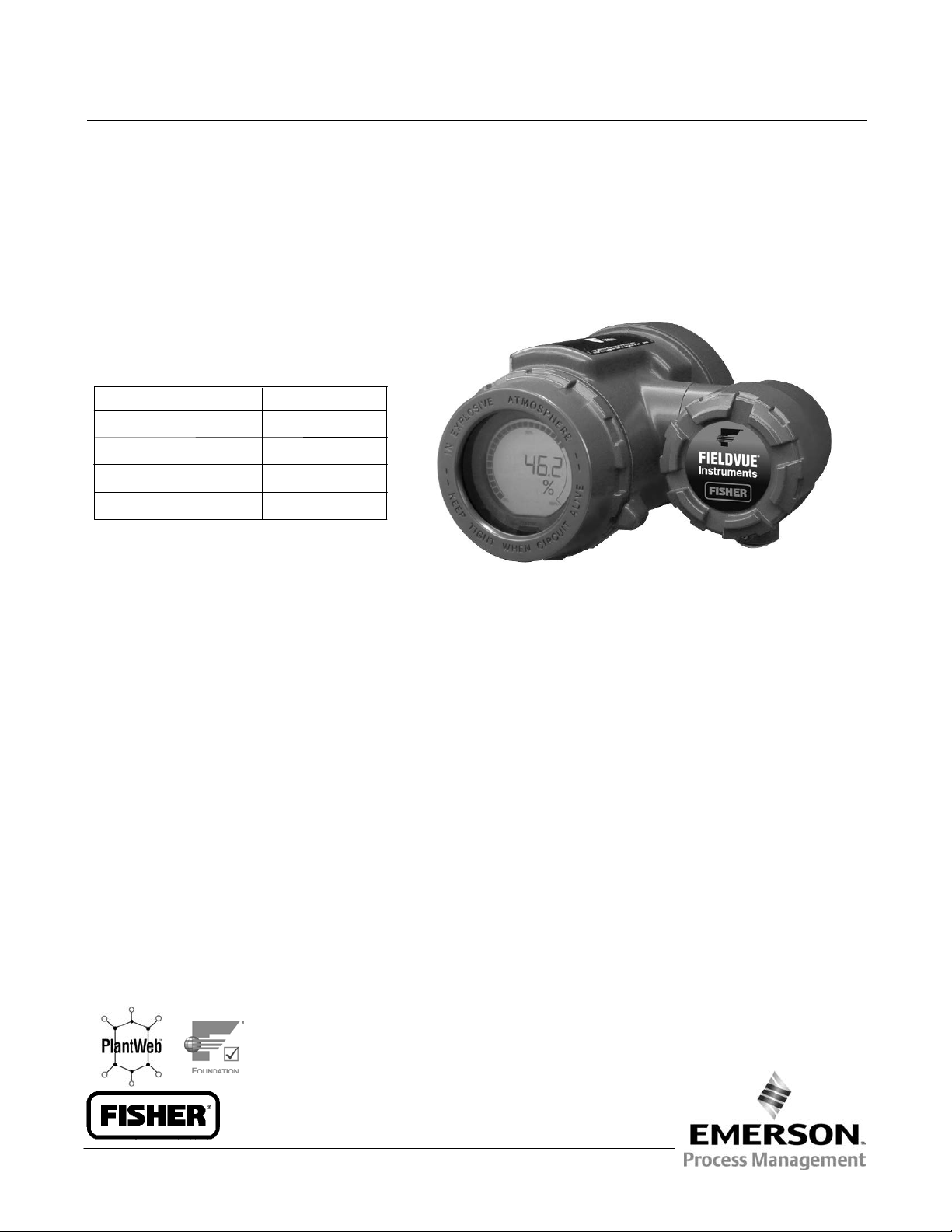

DLC3020f Digital Level Controller

Fisherr FIELDVUE™ DLC3020f Digital Level

November 2014

Controller for F

This manual applies to:

Device Type

Device Revision

Hardware Revision

Firmware Revision

DD Revision

3020

1

1.0

1.0

0x03

OUNDATION

™

fieldbus

www.Fisher.com

Page 2

Page 3

Instruction Manual

D103434X012

DLC3020f Digital Level Controller

November 2014

Contents

Section 1 Introduction and Specifications 3.

Scope of Manual 3..............................

Instrument Description 3........................

Blocks 3.......................................

Instrument Blocks 3...........................

Function Blocks 4.............................

Using this Manual 4.............................

Specifications 5................................

Related Information 5...........................

Educational Services 5...........................

Section 2 Installation 11.................

Configuration: On the Bench or in the Field 11.......

Protecting the Coupling and Flexures 12...........

Hazardous Area Classifications and Special

Instructions for “Safe Use” and Installation

in Hazardous Locations 13.....................

Mounting 13...................................

Mounting the 249 Sensor 13....................

DLC3020f Orientation 14.......................

Mounting the Digital Level Controller

on a 249 Sensor 15..........................

Mounting the Digital Level Controller

for High Temperature Applications 16..........

Electrical Connections 17........................

Fieldbus Connections 18.......................

Communication Connections 19.................

Simulate Enable Jumper 19.....................

Commissioning Tag 20.........................

Section 3 Overview 21...................

Overview 21...................................

Status 21....................................

Primary Purpose Variables 22....................

Shortcuts 22.................................

Section 4 Configuration 25...............

Guided Setup 25...............................

Manual Setup 26...............................

Device 27.....................................

Process Fluid 31................................

Instrument Display 32...........................

Snap Acting Control 33..........................

Options 34....................................

Alert Setup 38.................................

Section 5 Calibration 41.................

Calibrate 41...................................

Guided Calibration 41..........................

Expert User Calibration 42......................

Calibration Descriptions 43.....................

Full Calibration 43.........................

Trim Current Calibration 44.................

Section 6 Service Tools 45...............

Service Tools 45................................

Alerts 45.....................................

Alerts 45.....................................

Variables 46..................................

Variables 47..............................

Run Time Extremes 47......................

Simulate 48..................................

Maintenance 49...............................

Calibration/Setup Logs 49...................

Instrument Display Test 49..................

Restart Device 49..........................

Trends 50....................................

Section 7 Maintenance &

Troubleshooting 51...................

Removing the Digital Level Controller from

the Sensor 51..................................

Removing the DLC3020f Digital Level Controller

from a 249 Sensor 52........................

Standard Temperature Application 52.........

High Temperature Application 53............

LCD Meter Assembly 53.........................

Removing the LCD Meter Assembly 54............

Replacing the LCD Meter Assembly 54............

Electronics Module 55...........................

Removing the Electronics Module 55.............

Replacing the Electronics Module 55.............

Terminal Box 56................................

Removing the Terminal Box 56..................

Replacing the Terminal Box 56...................

Removing and Replacing the Inner Guide

and Access Handle Assembly 57..................

Lever Assembly 58..............................

Removing the Lever Assembly 58................

Replacing the Lever Assembly 59................

Packing for Shipment 59.........................

Instrument Troubleshooting 60...................

1

Page 4

DLC3020f Digital Level Controller

November 2014

Instruction Manual

D103434X012

Section 8 Parts 63......................

Parts Ordering 63...............................

Mounting Kits 63...............................

Repair Kits 64..................................

Parts List 64...................................

DLC3020f Digital Level Controllers 64............

Transducer Assembly 66........................

Terminal Box Assembly 67......................

Terminal Box Cover Assembly 67.................

Mounting Parts 68.............................

249 Sensor with Heat Insulator 68............

Masoneilan Sensors 68.....................

Yamatake Sensors 70.......................

Foxboro‐Eckardt Sensors 70.................

Appendix A Principle of Operation 71......

Digital Level Controller Operation 71..............

Appendix B Blocks 73...................

Analog Input (AI) Function Block 73...............

Proportional+Integral+Derivative (PID)

Function Block 85..............................

Discrete Input (DI) Function Block 104.............

Analog Output (AO) Function Block 113............

Input Selector (ISEL) Function Block 126............

Arithmetic (ARTH) Function Block 141.............

Resource Block 150.............................

Transducer Block (Primary) 157...................

Transducer Block (LCD) 172......................

Field Communicator Menu Tree 174...............

Appendix C Foundation Fieldbus

Communication 179..................

FOUNDATION Fieldbus Communication 179...........

Function Block Overview 179.....................

Function Blocks 179...........................

Instrument Specific Blocks 180..................

Resource Blocks 180.......................

Transducer Blocks 180......................

Block Modes 181...............................

Explanation of Modes 182......................

Examples of Modes for Various

Operation Statuses 183......................

Device Descriptions 183.........................

Transducer Block Status and Limit Propagation 183..

Status Propagation 184........................

Limit Propagation 185..........................

Network Communication 185....................

Device Addressing 185.........................

Link Active Scheduler 185.......................

Device Communications 186....................

Scheduled Transfers 186....................

Unscheduled Transfers 187..................

Function Block Scheduling 188..................

Network Management 188.......................

Glossary 189...........................

Index 193.............................

2

Page 5

Instruction Manual

D103434X012

Introduction and Specifications

November 2014

Section 1 Introduction and Specifications1‐1‐1

Scope of Manual

This instruction manual includes specifications, installation, operating, and maintenance information for the FIELDVUE

DLC3020f digital level controller.

This manual describes device setup using AMS Suite: Intelligent Device Manager version 10.5 and later. You can also

use the 475 or the 375 Field Communicator to setup the DLC3020f.

Note

This manual documents procedures in AMS Device Manager 10.5 and later. Earlier versions of AMS Device Manager contain the

same procedures and methods, but access is through the block in which they reside.

Do not install, operate, or maintain a DLC3020f digital level controller without being fully trained and qualified in field

instrument and accessory installation, operation, and maintenance. To avoid personal injury or property damage, it is

important to carefully read, understand, and follow all of the contents of this manual, including all safety cautions and

warnings. If you have any questions regarding these instructions contact your Emerson Process Management sales

office before proceeding.

Instrument Description

The FIELDVUE DLC3020f digital level controller is a fieldbus communicating instrument used to measure liquid level or

the level of interface between two liquids using displacement sensor technology.

In addition to the normal function of reporting process level PV, the DLC3020f, using F

gives easy access to information critical to process operation and will readily integrate into a new or existing control

system. AMS Suite: Intelligent Device Manager or the 475 Field Communicator can be used to configure, calibrate, or

test the digital level controller.

The DLC3020f is also designed to directly replace pneumatic, analog, or HARTr transmitters/ controllers. It can be

mounted on a wide variety of 249 cageless and caged level sensors as well as on other displacer type level sensors

through the use of mounting adaptors.

249 Caged Sensors (see table 1‐7)

D 249, 249B, 249BF, 249C, 249K, and 249L sensors side‐mount on the vessel with the displacer mounted inside a cage

outside the vessel. (The 249BF caged sensor is available only in Europe, Middle East, and Africa.)

249 Cageless Sensors (see table 1‐8)

D 249BP, 249CP, and 249P sensors top‐mount on the vessel with the displacer hanging down into the vessel.

D 249VS sensor side‐mounts on the vessel with the displacer hanging out into the vessel.

D 249W wafer‐style sensor mounts on top of a vessel or on a customer‐supplied cage.

OUNDATION fieldbus protocol,

Foundation Fieldbus Blocks

Instrument Blocks

The digital level controller is a block‐based device. For detailed information on the blocks within the digital level

controller, see the Parameter section.

3

Page 6

Introduction and Specifications

November 2014

D Resource Block—The resource block contains the hardware specific characteristics associated with a device; it has

no input or output parameters. The resource block monitors and controls the general operation of other blocks

within the device. For example, when the mode of the resource block is Out of Service, it impacts all function

blocks.

D Transducer Blocks—The transducer block takes an analog signal and converts it to a level or interface reading. The

DLC3020f has two transducer blocks, one for the device, and one for the display.

Instruction Manual

D103434X012

Function Blocks

In addition to the resource and transducer block, the digital level controller contains the following function blocks. For

additional information on function blocks, refer to the Parameter section.

D Analog Input (AI) Function Block—The analog input function block monitors the signal from a DLC3020f sensor and

makes the level or interface available to another block.

D Proportional‐Integral‐Derivative (PID) Function Block—The PID function block performs

proportional‐plus‐integral‐plus‐derivative control.

D Discrete Input (DI) Function Block (2) —The discrete input function block processes a single discrete input from a

DLC3020f and makes it available to other function blocks. In the digital level controller, the DI function block can

provide a user defined on/off switch indication.

D Analog Output (AO) Function Block (3) —The analog output function block accepts the output from another

function block and transfers it to the transducer block to use, for example, for process temperature compensation

or direct density readings.

D Input Selector (ISEL) Function block—The input selector function block selects from up to four inputs and may

provide the selected signal as input to the PID block. The input selection can be configured to select the first good

input signal; a maximum, minimum or average value; or a hot spare.

D Arithmetic (ARTH) Function Block—The arithmetic function block is used to calculate an output value that is based

on the value of IN and the auxiliary inputs, if used. IN_LO is used if an extended range flow measurement is required

from a differential pressure flow meter, like an orifice plate or venturi. Each of IN_1, IN_2 and IN_3 may be adjusted

by a bias and a gain, and then used as terms in an equation selected by the parameter ARITH_TYPE.

Using This Manual

This manual describes using AMS Device Manager to calibrate and configure the DLC3020f as well as information on

using the Field Communicator.

Navigation paths for Configuration and Calibration procedures are included for both AMS Device Manager and the

Field Communicator.

For example, to access Guided Calibrations:

AMS Device Manager Configure > Calibrate > Guided Calibrations

Field Communicator Configure > Calibrate > Full Calibration (Bench) or Full Calibration (Field)

Field Communicator menu structures for the function blocks and the resource and transducer blocks are included in

the Blocks section.

Throughout this document, parameters are typically referred to by their common name or label, followed by the

parameter name and index number; for example, Write Priority (WRITE_PRI [39]). However, not all interface systems

support the use of the parameter label and instead use only the Parameter Name, followed by the index number, when

referring to the block parameters.

4

Page 7

Instruction Manual

D103434X012

Introduction and Specifications

November 2014

Specifications

Specifications for DLC3020f are shown in table 1‐2. Specifications for 249 sensors are shown in table 1‐5.

Related Information

Fieldbus Installation and Wiring Guidelines

This manual describes how to connect the fieldbus to the digital level controller. For a technical description, planning,

and installation information for a F

from the Fieldbus Foundation.

Related Documents

Other documents containing information related to the DLC3020f digital level controllers and 249 sensors include:

D Bulletin 11.2:DLC3020f - FIELDVUE DLC3020f Digital Level Controllers (D103433X012)

OUNDATION fieldbus, refer to the FOUNDATION fieldbus Technical Overview available

D FIELDVUE DLC3020f Quick Start Guide (D103470X012)

D Bulletin 34.2:249 - Fisher 249 Sensor, Level Controller, and Transmitter Dimensions (D200039X012)

D Fisher 249 Caged Displacer Sensors Instruction Manual (D200099X012)

D Fisher 249 Cageless Displacer Sensors Instruction Manual (D200100X012)

D Fisher 249VS Cageless Displacer Sensor Instruction Manual (D103288X012)

D Fisher 249W Cageless Wafer Style Level Sensor Instruction Manual (D102803X012)

D Simulation of Process Conditions for Calibration of Fisher Level Controllers and Transmitters (D103066X012)

D Bolt Torque Information (D103220X012)

D Technical Monograph 7: The Dynamics of Level and Pressure Control

D Technical Monograph 26: Guidelines for Selection of Liquid Level Control Equipment

These documents are available from your Emerson Process Management sales office. Also visit our website at

www.Fisher.com.

Educational Services

For information on available courses for the DLC3020f digital level controller, as well as a variety of other products,

contact:

Emerson Process Management

Educational Services, Registration

Phone: +1-641-754-3771 or +1-800-338-8158

e‐mail: education@emerson.com

http://www.emersonprocess.com/education

5

Page 8

Introduction and Specifications

November 2014

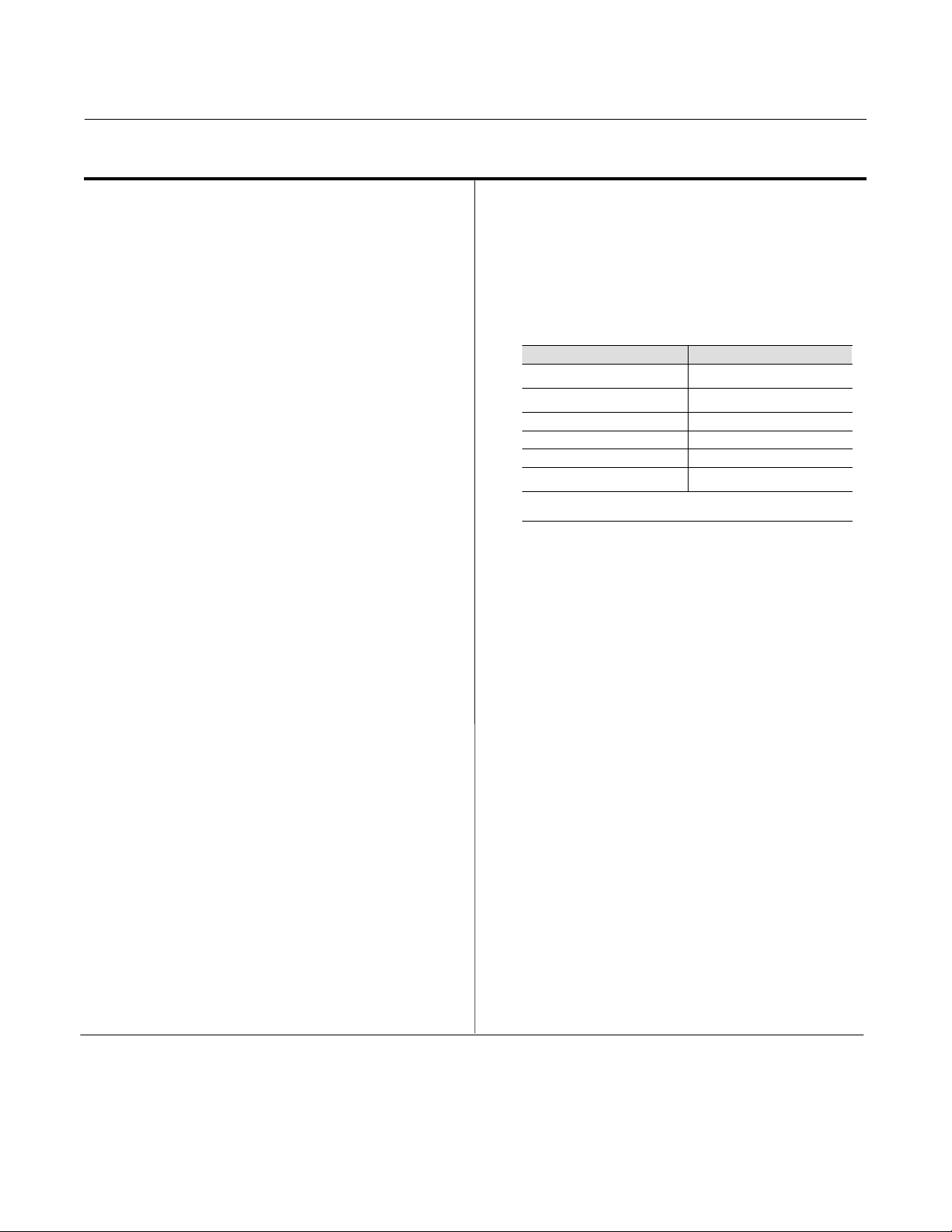

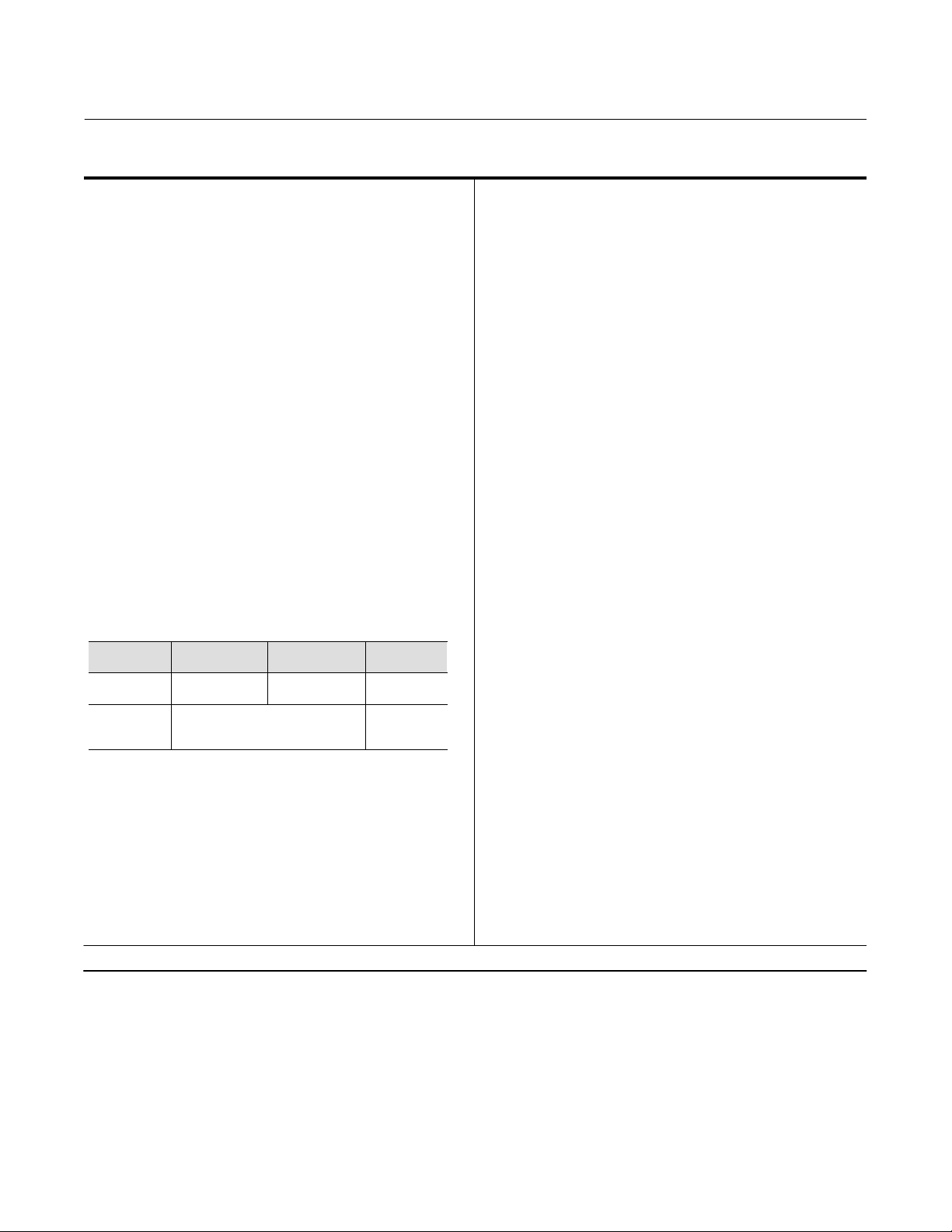

Table 1‐2. Specifications

Instruction Manual

D103434X012

Available Configurations

Mounts on 249 caged and cageless sensors.

Function: Transmitter, Controller, Switch

Communications Protocol: F

OUNDATION fieldbus

Digital Communication Protocol

OUNDATION fieldbus registered device (ITK 5)

F

Supply Requirements

9 to 32 volts DC, 17.7 mA DC;

instrument is not polarity sensitive

Device Inputs

Level Sensor Input (required)

Rotary motion of torque tube shaft is proportional to

buoyant force of the displacer caused by changes in

liquid level or interface level

Process Temperature Compensation Input (optional)

RTD—interface for 2‐ or 3‐wire 100 ohm platinum RTD

AO Block—F

OUNDATION fieldbus temperature

transmitter

Manual—compensation values manually entered in

the device

Block Execution Times

AI, PID, DI, AO, ISEL: 15 ms

ARTH: 25 ms

Fieldbus Device Capabilities

Backup Link Active Scheduler (BLAS)

Performance

Criteria DLC3020f

Independent Linearity

Accuracy

Repeatability <0.1% of full scale output

Hysteresis <0.10% of output span

Deadband <0.05% of input span

Humidity

Note: At full design span, reference conditions.

1. To lever assembly rotation inputs.

$0.1% of output span

$0.15%

$0.10% (RH9.2% to 90%)

(1)

Minimum Differential Specific Gravity

0.1 SGU with standard volume displacers

Ambient Temperature Effect

The combined temperature effect on zero and span is

less than 0.01% of full scale per degree Celsius over

the operating range -40 to 80_C (-40 to 176_F)

Process Temperature Effect

Temperature compensation can be implemented to

correct for fluid density changes due to process

temperature variations. See page 31 for information

on how to correct with temperature compensation.

LCD Meter Indications

Process Variable in engineering units

Process Variable in percent (%) only

Alternating Process Variable in engineering units and

percent (%)

Optional: Alerts as configured

Function Block Suite

AI, PID, DI (two), AO (three), ISEL, and an ARTH

function block

6

Electromagnetic Compatibility

Meets EN 61326-1 (First Edition)

Immunity—Industrial locations per Table 2 of

the EN 61326-1 standard. Performance is

shown in table 1‐3 below.

Emissions—Class A

ISM equipment rating: Group 1, Class A

Lightning and Surge Protection—The degree of

immunity to lightning is specified as Surge immunity

in table 1‐3. For additional surge protection

commercially available transient protection can be

used.

-continued-

Page 9

Instruction Manual

D103434X012

Table 1‐2. Specifications (continued)

Introduction and Specifications

November 2014

Alerts and Diagnostics

Electronic Alerts advise when there is an electronic

error in memory

Operational Range Alerts notify when PV range and

sensor range changes might affect calibration

Rate Limit Alerts indicate rapid rise or fall in displacer,

which can signify abnormal operating conditions

RTD Alerts show health and condition of connected

RTD

Sensor Board Alerts indicate if the device is operating

above or below maximum recommended limits;

advises if the electronic sensor electronics cannot

communicate properly

Input Compensation Error Alerts advise of “Bad” or

“Uncertain” status of AO connection or setup.

Simulate Function

Simulate Active, when enabled, simulates an active

alert without making it visible.

Electrical Housing:

CSA— Type 4X

FM— NEMA 4X, IP66

ATEX— IP66

IECEx— IP66

Mounting Positions

Digital level controllers can be mounted right‐ or

left‐of‐displacer, as shown in figure 2‐5

Construction Materials

Case and Cover: Low‐copper aluminum alloy

Internal: Plated steel, aluminum, and stainless steel;

encapsulated printed wiring boards; Neodymium Iron

Boron Magnets

Electrical Connections

Two 1/2‐14 NPT internal conduit connections; one on

bottom and one on back of terminal box. M20

Operating Limits

Process Temperature: See table 1‐4 and figure 2‐8

Ambient Temperature

Conditions Normal Limits

Ambient

Temperature

Ambient

Relative

Humidity

-40 to 80_C

(-40 to 176_F)

(1)

and Humidity

Transport and

Storage Limits

-40 to 85_C

(-40 to 185_F)

0 to 95% (non‐condensing) 40%

Nominal

Reference

25_C

(77_F)

adapters available.

Weight

Less than 2.7 Kg (6 lbs)

Options

J Heat insulator J Mountings for Masoneilant,

Yamatake, and Foxborot‐Eckhardt displacers

available

Declaration of SEP

Electrical Classification

Hazardous Area:

CSA— Intrinsically Safe, Explosion‐proof, Division 2,

Dust Ignition‐proof

FM— Intrinsically Safe, Explosion‐proof,

Non‐Incendive, Dust Ignition‐proof

ATEX— Intrinsically Safe, Flameproof, Type n

IECEx— Intrinsically Safe, Flameproof, Type n

1. The pressure/temperature limits in this manual and any applicable standard or code limitation for valve should not be exceeded.

Fisher Controls International LLC declares this

product to be in compliance with Article 3 paragraph

3 of the Pressure Equipment Directive (PED) 97 / 23 /

EC. It was designed and manufactured in accordance

with Sound Engineering Practice (SEP) and cannot

bear the CE marking related to PED compliance.

However, the product may bear the CE marking to

indicate compliance with other applicable European

Community Directives.

7

Page 10

Introduction and Specifications

November 2014

Instruction Manual

Table 1‐3. FIELDVUE DLC3020f EMC Summary Results—Immunity

Port Phenomenon Basic Standard Test Level

Electrostatic discharge (ESD) IEC 61000‐4‐2

Enclosure

I/O signal/control

1. Performance criteria: +/- 1% effect. A = No degradation during testing. B = Temporary degradation during testing, but is self‐recovering.

Radiated EM field IEC 61000‐4‐3

Rated power frequency

magnetic field

Burst IEC 61000‐4‐4

Surge IEC 61000‐4‐5

Conducted RF IEC 61000‐4‐6

IEC 61000‐4‐8

4 kV contact

8 kV air

80 to 1000 MHz @ 10V/m with 1 kHz AM at 80%

1400 to 2000 MHz @ 3V/m with 1 kHz AM at 80%

2000 to 2700 MHz @ 1V/m with 1 kHz AM at 80%

30 A/m at 50/60 Hz

1 kV

1 kV (line to ground only, each)

150 kHz to 80 MHz at 3 Vrms

Table 1‐4. Allowable Process Temperatures for Common Fisher 249 Sensor Pressure Boundary Materials

MATERIAL

Cast Iron -29_C (-20_F) 232_C (450_F)

Steel -29_C (-20_F) 427_C (800_F)

Stainless Steel -198_C (-325_F) 427_C (800_F)

N04400 -198_C (-325_F) 427_C (800_F)

Graphite Laminate/SST Gaskets -198_C (-325_F) 427_C (800_F)

N04400/PTFE Gaskets -73_C (-100_F) 204_C (400_F)

Minimum Maximum

PROCESS TEMPERATURE

D103434X012

Performance

Criteria

A

A

A

A

A

A

(1)

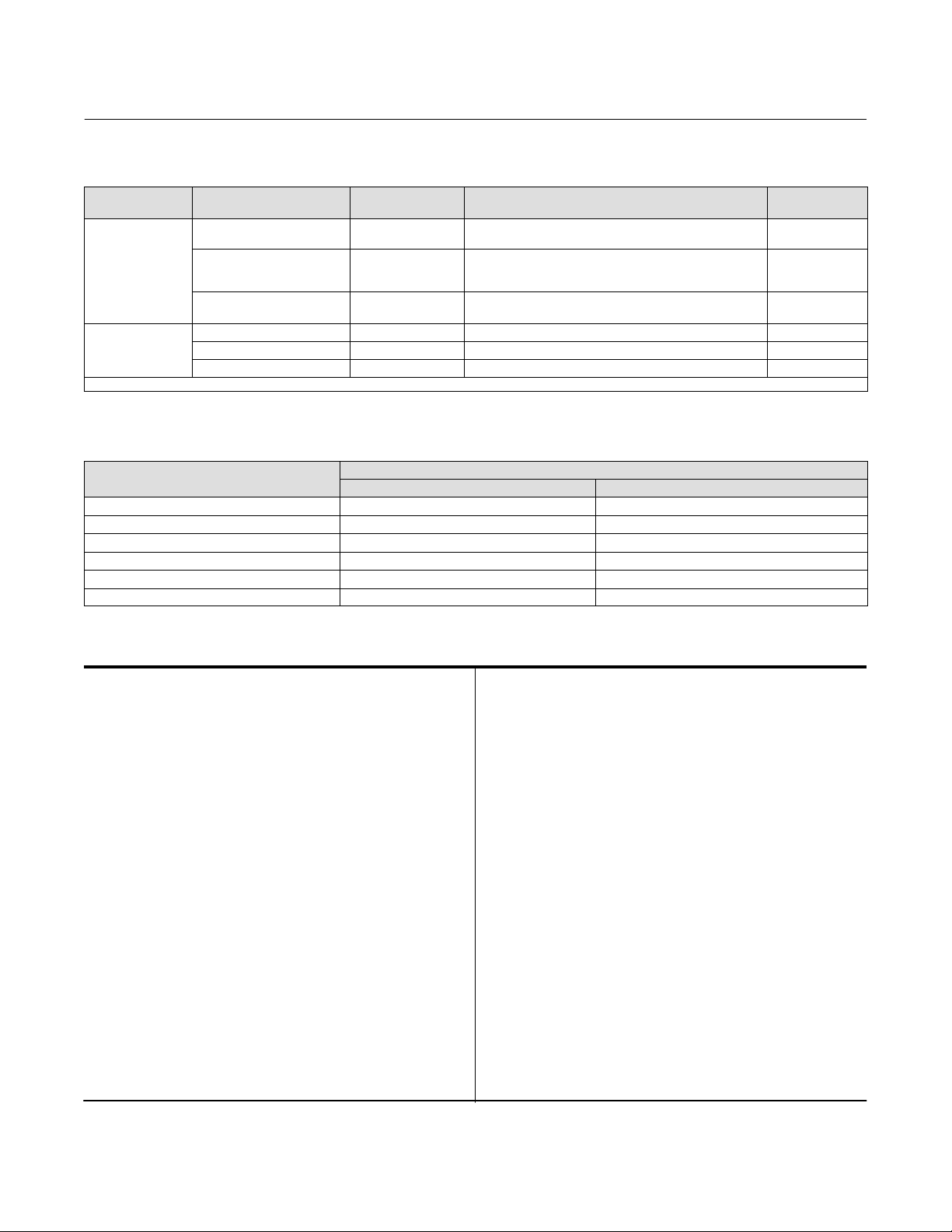

Table 1‐5. Fisher 249 Sensor Specifications

Input Signal

Liquid Level or Liquid‐to‐Liquid Interface Level:From 0

to 100 percent of displacer length

Liquid Density: From 0 to 100 percent of

displacement force change obtained with given

displacer volume—standard volumes are

J 980 cm

(60 inches3) for 249C and 249CP sensors or J 640

3

(100 inches3) for most other sensors; other

cm

volumes available depending upon sensor

construction

Sensor Displacer Lengths

See tables 1‐7 and 1‐8 footnotes

Sensor Working Pressures

Consistent with applicable ANSI

pressure/temperature ratings for the specific sensor

constructions shown in tables 1‐7 and 1‐8

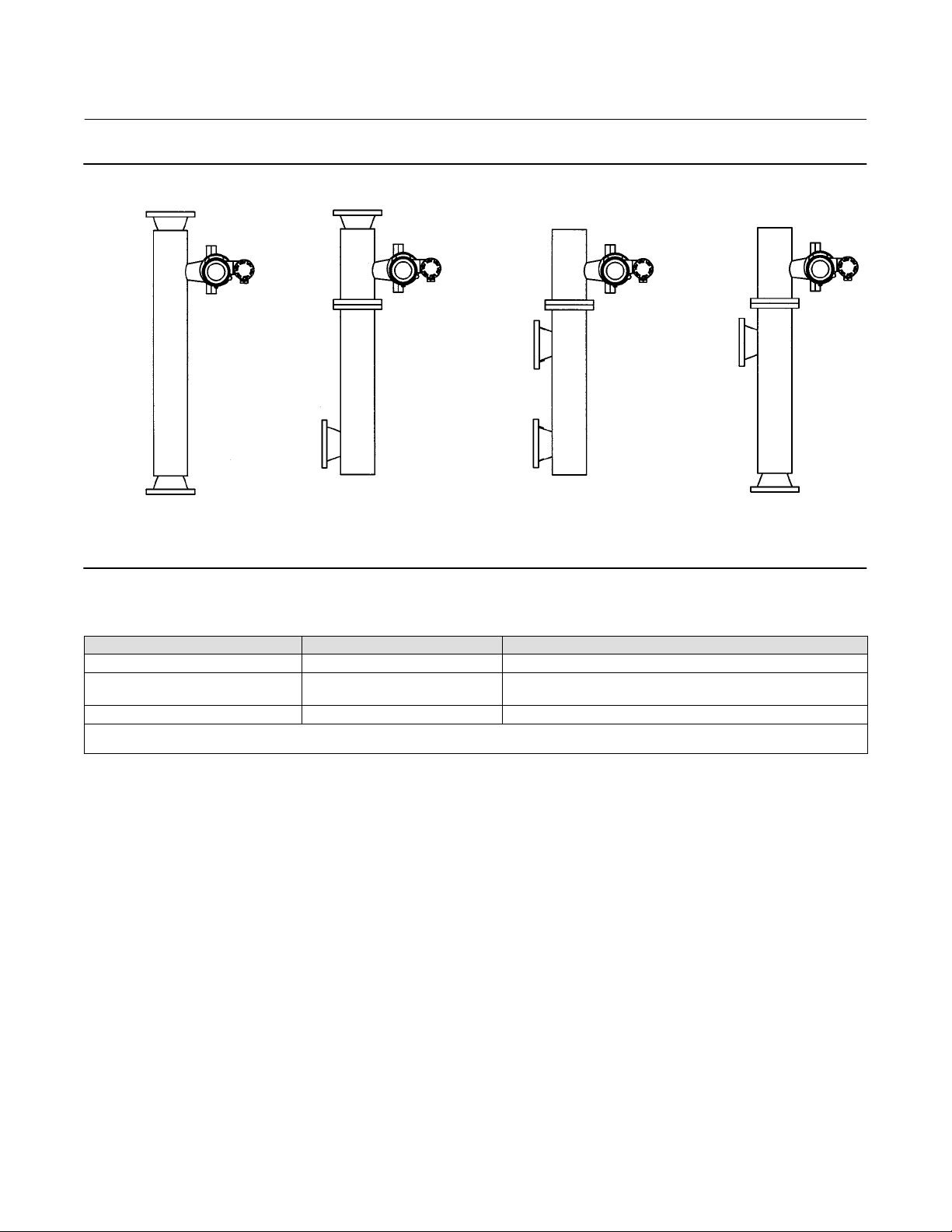

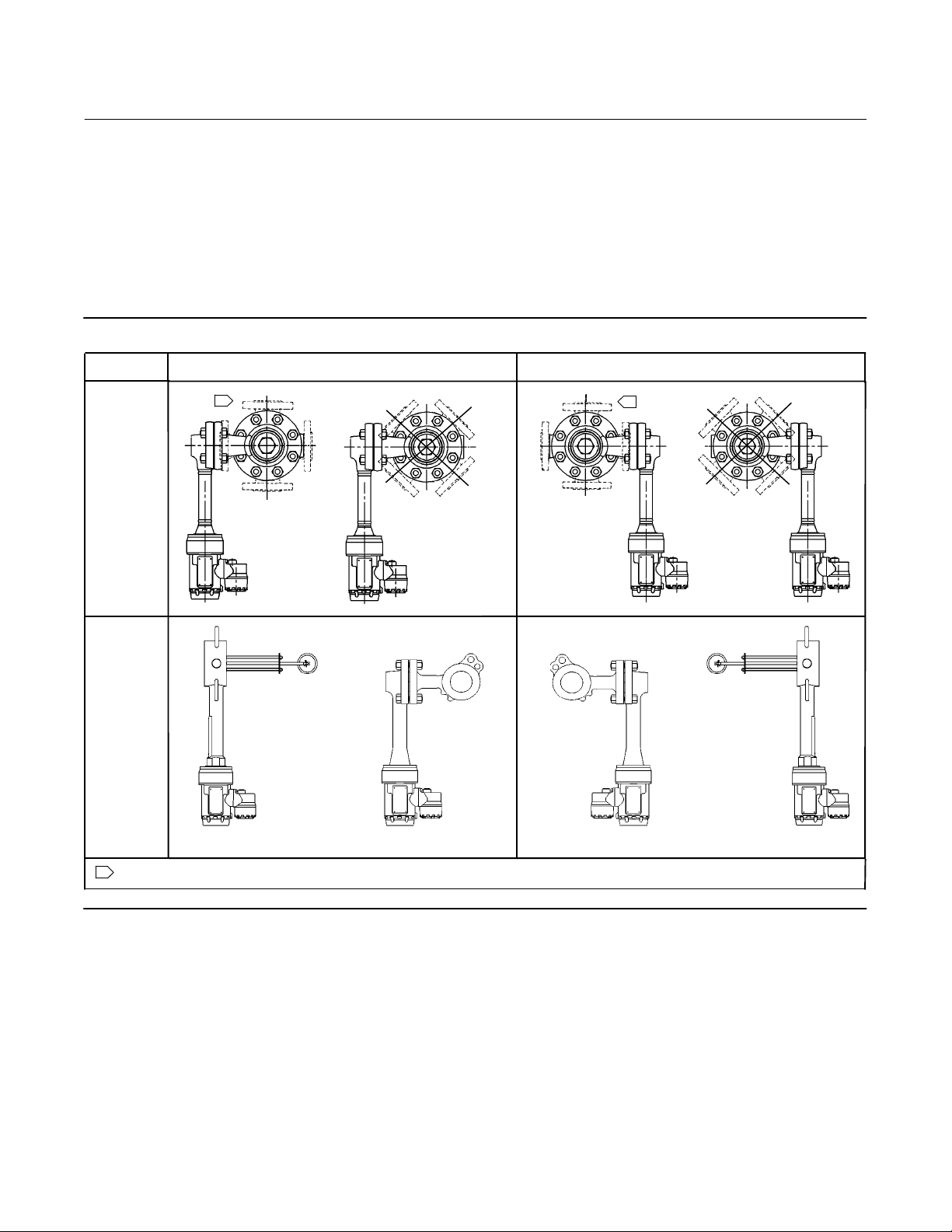

Caged Sensor Connection Styles

Cages can be furnished in a variety of end connection

styles to facilitate mounting on vessels; the

equalizing connection styles are numbered and are

shown in figure 1‐1.

Mounting Positions

3

Most level sensors with cage displacers have a

rotatable head. The head may be rotated through

360 degrees to any of eight different positions, as

shown in figure 2‐5.

Construction Materials

See tables 1‐6, 1‐7, and 1‐8

Operative Ambient Temperature

See table 1‐4

For ambient temperature ranges, guidelines, and use

of optional heat insulator, see figure 2‐8.

Options

J Heat insulator, see description under Ordering

Information

232_C (420 psig at 450_F), and

J Gauge glass for pressures to 29 bar at

J Reflex gauges for

high temperature and pressure applications

8

Page 11

Instruction Manual

S

D103434X012

Figure 1‐1. Style Number of Equalizing Connections

Introduction and Specifications

November 2014

TOP AND BOTTOM CONNECTIONS

SCREWED (S‐1) OR FLANGED (F‐1)

28B5536‐1

B1820‐2

STYLE 1

TOP AND LOWER SIDE CONNECTIONS

SCREWED (S‐2) OR FLANGED (F‐2)

STYLE 2

UPPER AND LOWER SIDE CONNECTIONS

SCREWED (S‐3) OR FLANGED (F‐3)

STYLE 3

UPPER SIDE AND BOTTOM CONNECTION

SCREWED (S‐4) OR FLANGED (F‐4)

STYLE 4

Table 1‐6. Displacer and Torque Tube Materials

Part Standard Material Other Materials

Displacer 304 Stainless Steel 316 Stainless Steel, N10276, N04400, Plastic, and Special Alloys

Displacer Stem, Driver Bearing,

Displacer Rod and Driver

Torque Tube N05500

1. N05500 is not recommended for spring applications above 232_C (450_F). Contact your Emerson Process Management sales office or application engineer if

temperatures exceeding this limit are required.

316 Stainless Steel N10276, N04400, other Austenitic Stainless Steels, and Special Alloys

(1)

316 Stainless Steel, N06600, N10276

9

Page 12

Introduction and Specifications

)

November 2014

Instruction Manual

D103434X012

Table 1‐7. Caged Displacer Sensors

TORQUE TUBE

ORIENTATION

249

SENSOR

(3)

(1)

STANDARD CAGE, HEAD,

AND TORQUE TUBE ARM

MATERIAL

Cast iron

EQUALIZING CONNECTION

Style Size (NPS)

Screwed 1‐1/2 or 2

Flanged 2

Screwed or optional socket weld 1‐1/2 or 2 CL600

1‐1/2

2

1‐1/2

Torque tube

arm rotatable

with respect to

equalizing

connections

249B, 249BF

(3)

249C

(4)

Steel

316 stainless steel

Raised face or optional ring‐type joint

flanged

Screwed 1‐1/2 or 2 CL600

Raised face flanged

2

249K Steel

249L Steel Ring‐type joint flanged 2

1. Standard displacer lengths for all styles (except 249) are 14, 32, 48, 60, 72, 84, 96, 108 and 120 inches. The 249 uses a displacer with a length of either 14 or 32 inches.

2. EN flange connections available in EMA (Europe, Middle East and Africa).

3. Not available in EMA.

4. The 249BF available in EMA only. Also available in EN size DN 40 with PN 10 to PN 100 flanges and size DN 50 with PN 10 to PN 63 flanges.

5. Top connection is NPS 1 ring‐type joint flanged for connection styles F1 and F2.

Table 1‐8. Cageless Displacer Sensors

Mounting Sensor

(1)

Standard Head

(6)

Body

and Torque Tube

(2)

, Wafer

Raised face or optional ring‐type joint

flanged

1‐1/2 or 2 CL900 or CL1500

(5)

Flange Connection (Size) Pressure Rating

Arm Material

NPS 4 raised face or optional ring‐type joint CL150, CL300, or CL600

NPS 6 or 8 raised face CL150 or CL300

NPS 4 raised face or optional ring‐type joint

NPS 6 or 8 raised face

CL900 or 1CL500

(EN PN 10 to DIN PN 250)

CL150, CL300, CL600, CL900,

CL1500, or CL2500

Mounts on

top of vessel

(4)

249BP

Steel

249CP 316 Stainless Steel NPS 3 raised face CL150, CL300, or CL600

(5)

249P

Steel or stainless steel

CL125, 150, 250, 300, 600,

Mounts on

side of vessel

249VS LCC, WCC (steel), CF8M

For NPS 4 raised face or flat face

900, or 1500 (EN PN 10 to DIN

PN 160)

For NPS 4 butt weld end, XXS CL2500

Mounts on top of

vessel or on

customer

249W

supplied cage

1. Standard displacer lengths are 14, 32, 48, 60, 72, 84, 96, 108, and 120 inches.

2. Not used with side‐mounted sensors.

3. EN flange connections available in EMA (Europe, Middle East and Africa).

4. Not available in EMA.

5. 249P available in EMA only.

6. Wafer Body only applicable to the 249W.

WCC (steel) or CF8M For NPS 3 raised face CL150, CL300, or CL600

LCC (steel) or CF8M For NPS 4 raised face CL150, CL300, or CL600

PRESSURE RATING

CL125 or CL250

CL150, CL300, or

CL600

CL150, CL300, or

CL600

CL150, CL300, or

CL600

CL150, CL300, or

CL600

CL2500

(3)

(2

10

Page 13

Instruction Manual

D103434X012

Installation

November 2014

Section 2 Installation2‐2‐

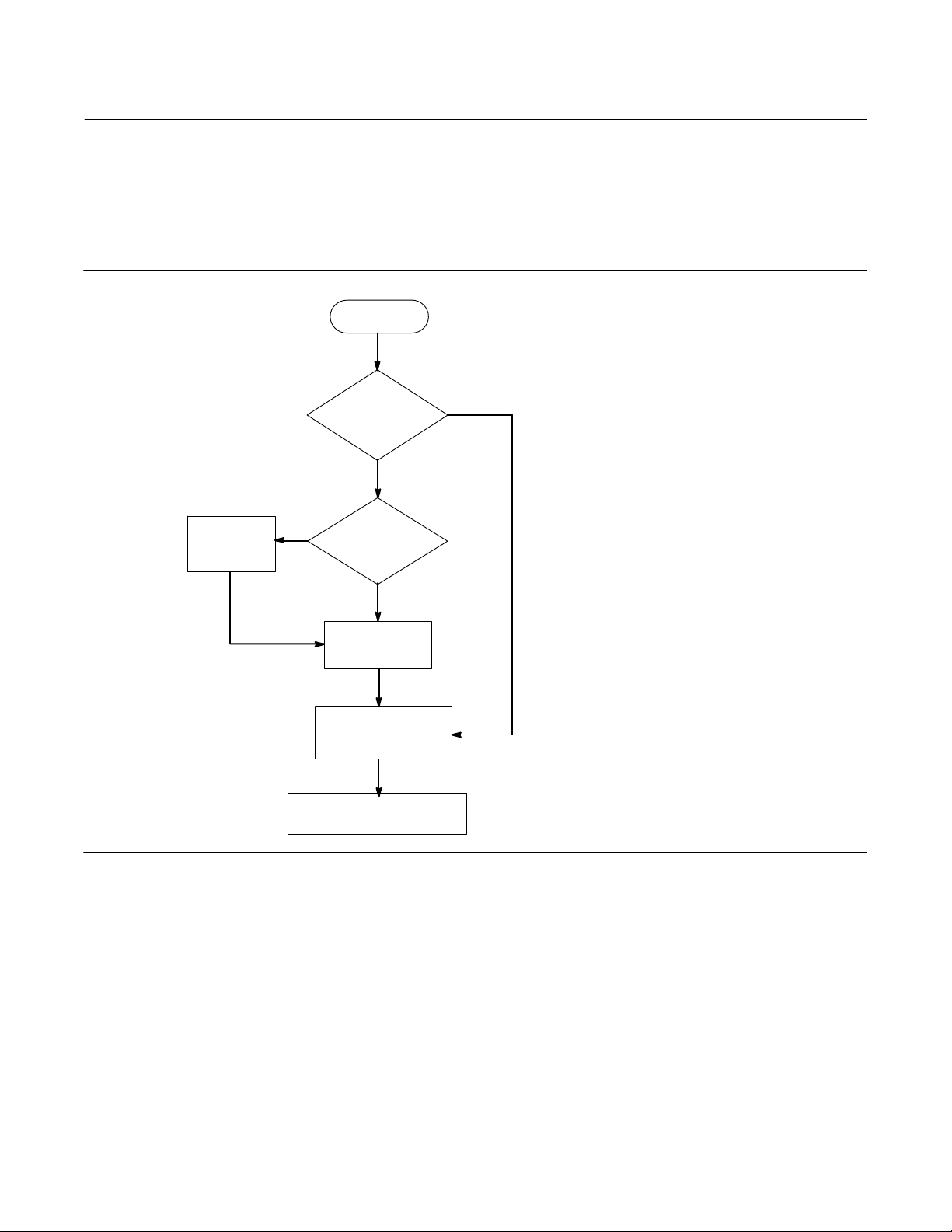

This section contains digital level controller installation information including an installation flowchart (figure 2‐1),

mounting and electrical installation information.

Figure 2‐1. Installation Flowchart

START

Install Heat

Insulator

mounted on

Yes

temperature

application?

Mount DLC3020f

Make Electrical

Set Up and Calibration

Factory

249 sensor

No

High

No

to Sensor

Connections

Power Device

Proceed to

Yes

Configuration: On the Bench or in the Field

Configure the digital level controller before or after installation in the field.

It may be useful to configure the instrument on the bench before installation to ensure proper operation, and to

familiarize yourself with its functionality.

11

Page 14

Installation

November 2014

Instruction Manual

D103434X012

Protecting the Coupling and Flexures

CAUTION

Damage to flexures and other parts can cause measurement errors. Observe the following steps before moving the sensor

and controller.

Lever Lock

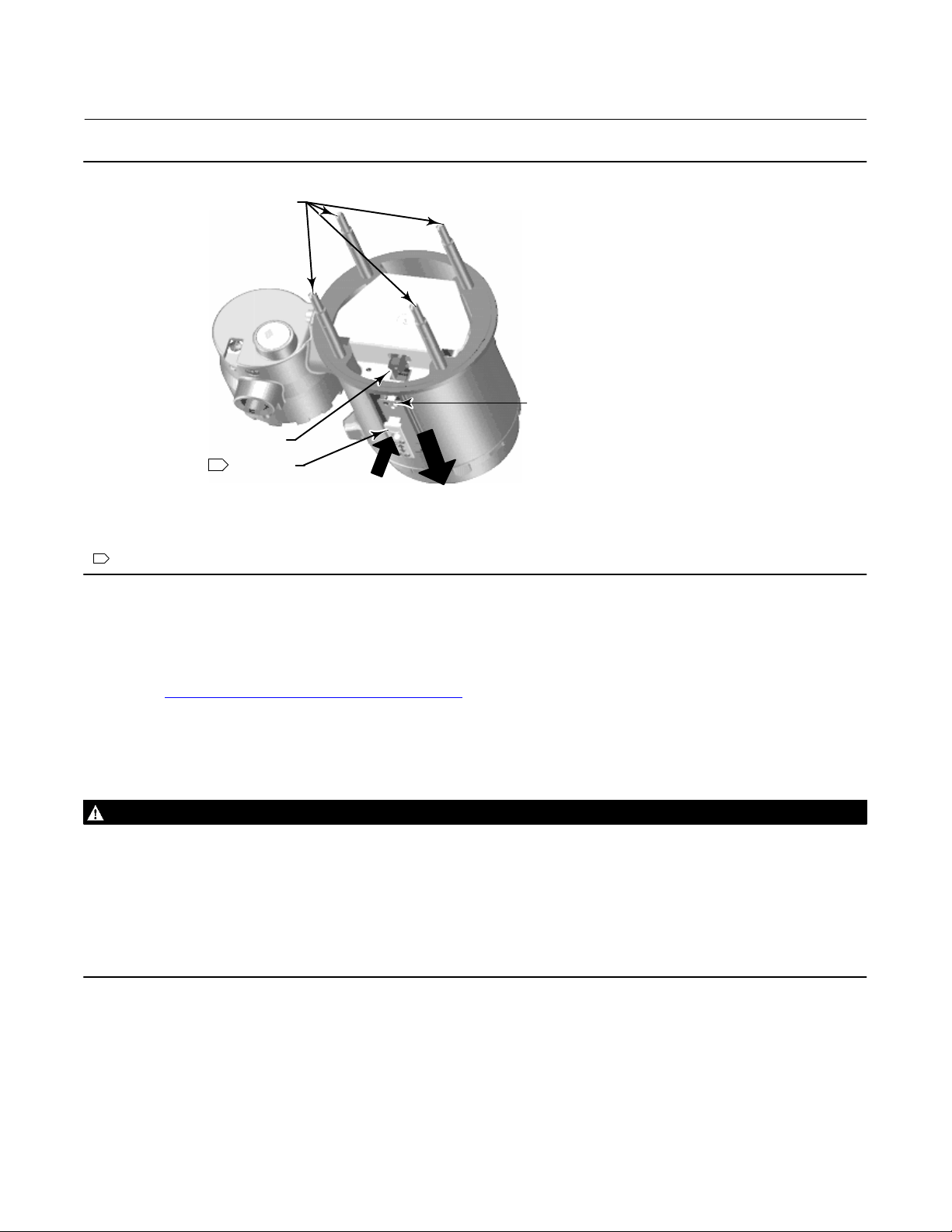

The lever lock is built in to the coupling access handle. When the handle is open, it positions the lever in the neutral

travel position for coupling. In some cases, this function is used to protect the lever assembly from violent motion

during shipment.

A DLC3020f digital level controller will have one of the following mechanical configurations when received:

1. A fully assembled and coupled caged‐displacer system shipped with the displacer or driver rod blocked within the

operating range by mechanical means. In this case, the access handle (figure 2‐2) will be in the unlocked position.

Remove the displacer blocking hardware before calibration. (See the appropriate sensor instruction manual). The

coupling should be intact.

CAUTION

When shipping an instrument mounted on a sensor, if the lever assembly is coupled to the linkage, and the linkage is

constrained by the displacer blocks, use of the lever lock may result in damage to bellows joints or flexure.

2. If the displacer cannot be blocked because of cage configuration or other concerns, the transmitter is uncoupled

from the torque tube by loosening the coupling nut, and the access handle will be in the locked position. Before

placing such a configuration into service, couple the instrument to the sensor as follows:

To couple the instrument to the sensor:

a. Slide the access handle to the open position to lock the lever assembly in place and expose the access hole. Press

on the back of the handle as shown in figure 2‐2 then slide the handle toward the front of the unit. Be sure the

locking handle drops into the detent.

b. If in process, ensure that the level or interface is in the lowest position on the displacer.

If on the bench, ensure that the displacer is dry and the displacer rod lever arm is not hitting a travel stop.

c. Insert a 10 mm deep well socket through the access hole and onto the torque tube shaft clamp nut. Tighten the

clamp nut to a maximum torque of 2.1 NSm(18 lbfSin).

d. Slide the access handle to the closed position. for operation or calibration (Press on the back of the handle as

shown in figure 2‐2 then slide the handle toward the rear of the unit.) Be sure the locking handle drops into the

detent.

12

Page 15

Instruction Manual

D103434X012

Figure 2‐2. Sensor Connection Compartment (Adapter Ring Removed for Clarity)

MOUNTING STUDS

ACCESS HOLE

SHAFT CLAMP

SET SCREW

1

Installation

November 2014

PRESS HERE TO

MOVE ACCESS HANDLE

NOTE:

1

SET SCREW IS USED TO LOCK THE LEVER IN PLACE FOR OPERATION

SLIDE ACCESS HANDLE

TOWARD FRONT OF UNIT TO

EXPOSE ACCESS HOLE

Hazardous Area Classifications and Special Instructions for “Safe

Use” and Installation in Hazardous Locations

Refer to the DLC3020f Quick Start Guide (D103470X012) that ships with the instrument for Hazardous Area

Classifications and Special Instructions for “Safe Use” and Installations in Hazardous Locations. If a copy of this quick

start guide is needed contact your Emerson Process Management sales office or visit our website at www.Fisher.com.

Mounting

WARNING

To avoid personal injury or property damage, always wear protective gloves, clothing, and eyewear when performing any

installation operations.

Personal injury or property damage due to sudden release of pressure, contact with hazardous fluid, fire, or explosion can

be caused by puncturing, heating, or repairing a displacer that is retaining process pressure or fluid. This danger may not

be readily apparent when disassembling the sensor or removing the displacer. Before disassembling the sensor or

removing the displacer, observe the appropriate warnings provided in the sensor instruction manual.

Check with your process or safety engineer for any additional measures that must be taken to protect against process

media.

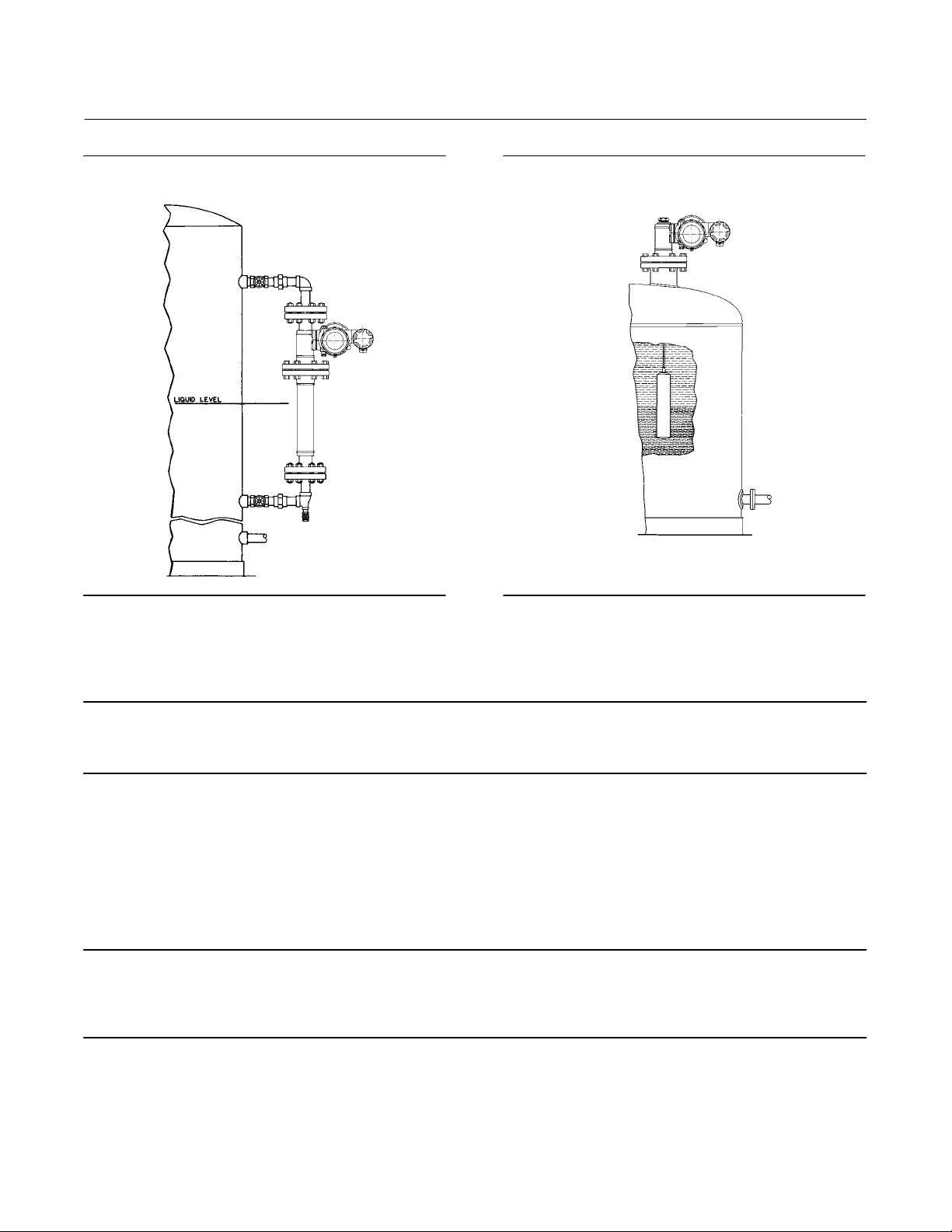

Mounting the 249 Sensor

The 249 sensor is mounted using one of two methods, depending on the specific type of sensor. If the sensor has a

caged displacer, it typically mounts on the side of the vessel as shown in figure 2‐3. If the sensor has a cageless

displacer, the sensor mounts on the side or top of the vessel as shown in figure 2‐4.

13

Page 16

Installation

November 2014

Instruction Manual

D103434X012

Figure 2‐3. Typical Caged Sensor Mounting

A3789‐1

Figure 2‐4. Typical Cageless Sensor Mounting

A3788‐1

The DLC3020f digital level controller is typically shipped attached to the sensor. If ordered separately, it may be

convenient to mount the digital level controller to the sensor and perform the initial setup and calibration before

installing the sensor on the vessel.

Note

Caged sensors have a rod and block installed on each end of the displacer to protect the displacer in shipping. Remove these parts

before installing the sensor to allow the displacer to function properly.

DLC3020f Orientation

Mount the DLC3020f with the torque tube shaft clamp access hole (see figure 2‐2) pointing downward to allow

accumulated moisture drainage.

Note

If alternate drainage is provided by the user, and a small performance loss is acceptable, the instrument could be mounted in 90

degree rotational increments around the pilot shaft axis. The LCD meter may be rotated in 90 degree increments to accommodate

this.

The digital level controller and torque tube arm are attached to the sensor either to the left or right of the displacer, as

shown in figure 2‐5. This can be changed in the field on the 249 sensors (refer to the appropriate sensor instruction

14

Page 17

Instruction Manual

D103434X012

Installation

November 2014

manual). Changing the mounting also changes the effective action, because the torque tube rotation for increasing

level, (looking at the protruding shaft), is clockwise when the unit is mounted to the right of the displacer and counter‐

clockwise when the unit is mounted to the left of the displacer.

All 249 caged sensors have a rotatable head. That is, the digital level controller can be positioned at any of eight

alternate positions around the cage as indicated by the position numbers 1 through 8 in figure 2‐5. To rotate the head,

remove the head flange bolts and nuts and position the head as desired.

Figure 2‐5. Typical Mounting Positions for the FIELDVUE DLC3020f Digital Level Controller on a Fisher 249 Sensor

SENSOR

CAGED

CAGELESS

LEFT‐OF‐DISPLACER

7

1

5

3

RIGHT‐OF‐DISPLACER

6

1

4

8

2

3

1

7

1

5

2

8

4

6

249VS

NOT AVAILABLE FOR SIZE NPS 2 CL300 AND CL600 249C SENSOR.

1

249W

249W

249VS

Mounting the DLC3020f on a 249 Sensor

Refer to figure 2‐2 unless otherwise indicated.

1. If the set‐screw in the access handle, (see figure 2‐6) is driven against the spring plate, back it out until the head is

flush with the outer surface of the handle, using a 2 mm hex key. Slide the access handle to the open position to

lock the lever assembly in place and to expose the access hole. Press on the back of the handle as shown in figure

2‐2 then slide the handle toward the front of the unit. Be sure the locking handle drops into the detent.

15

Page 18

Installation

November 2014

Instruction Manual

Figure 2‐6. Close‐up of Set‐Screw

SET‐SCREW

(2mm)

2. Using a 10 mm deep well socket inserted through the access hole, loosen the shaft clamp (figure 2‐2).

3. Remove the hex nuts from the mounting studs. Do not remove the adapter ring.

CAUTION

Measurement errors can occur if the torque tube assembly is bent or misaligned during installation.

D103434X012

4. Position the digital level controller so the access hole is on the bottom of the instrument.

5. Carefully slide the mounting studs into the sensor mounting holes until the digital level controller is snug against

the sensor mounting flange.

6. Reinstall the hex nuts on the mounting studs and tighten the hex nuts to 10 NSm (88.5 lbfSin).

Mounting the DLC3020f for High Temperature Applications

Refer to figure 2‐7 for parts identification except where otherwise indicated.

Figure 2‐7. Digital Level Controller Mounting on Sensor in High Temperature Applications

INSULATOR

(KEY 57)

SHAFT

EXTENSION

(KEY 58)

DIGITAL LEVEL CONTROLLER

MN28800

20A7423‐C

B2707

SENSOR

CAP SCREWS

(KEY 63)

SET

SCREWS

(KEY 60)

SHAFT

COUPLING

(KEY 59)

WASHER

(KEY 78)

HEX NUTS

(KEY 34)

MOUNTING STUDS

(KEY 33)

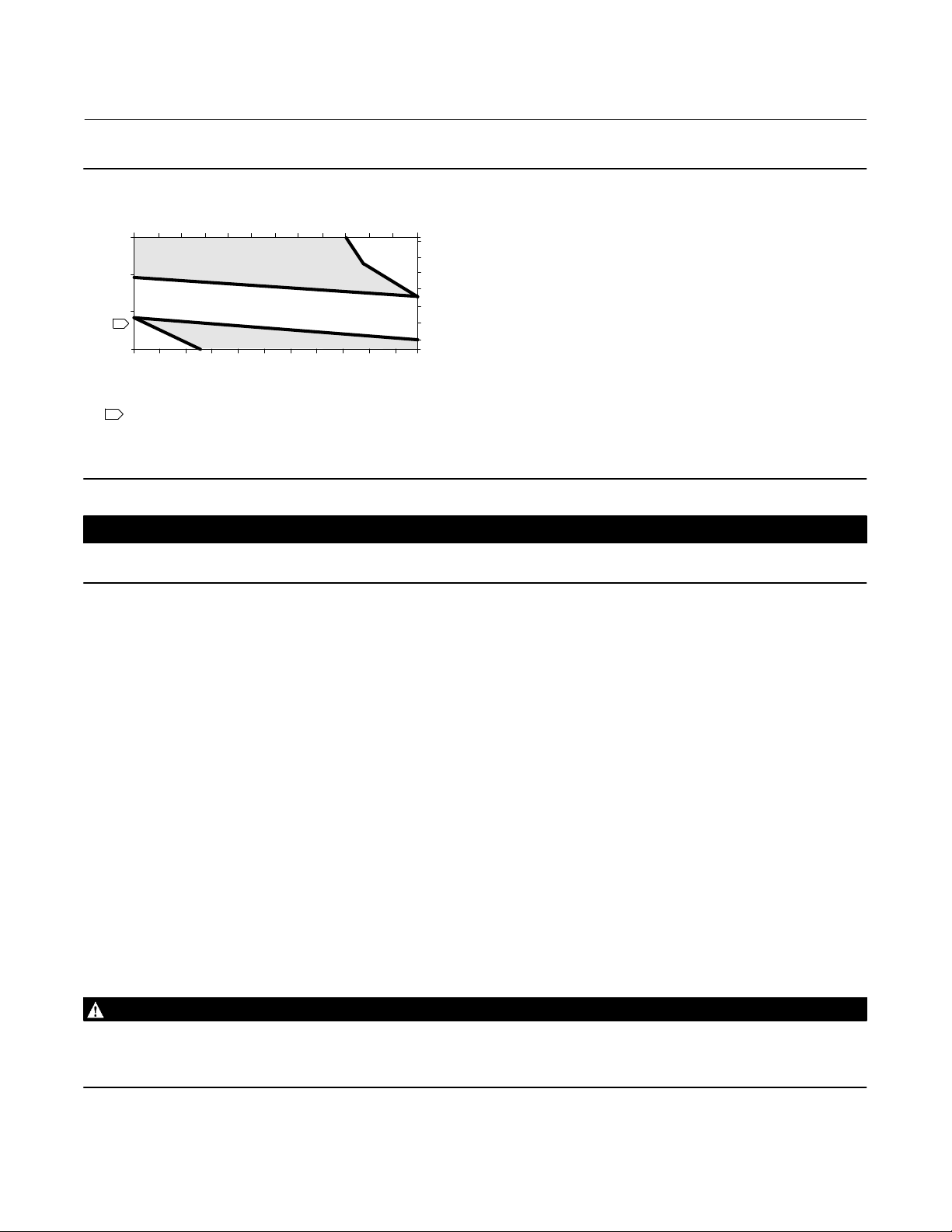

The digital level controller requires an insulator assembly when temperatures exceed the limits shown in figure 2‐8.

A torque tube shaft extension is required for a 249 sensor when using an insulator assembly.

16

Page 19

Instruction Manual

D103434X012

Figure 2‐8. Guidelines for Use of Optional Heat Insulator Assembly

AMBIENT TEMPERATURE (_C)

010 20

HEAT INSULATOR

REQUIRED

NO HEAT INSULATOR NECESSARY

HEAT INSULATOR

REQUIRED

0 20 40 60 80 100 120 140 160

AMBIENT TEMPERATURE (_F)

PROCESS TEMPERATURE (_F)

800

400

1

-325

-40 -30

0

TOO

COLD

-20 -10

-20-40

STANDARD TRANSMITTER

NOTES:

FOR PROCESS TEMPERATURES BELOW -29_C (-20_F) AND ABOVE 204_C (400_F) SENSOR

1

MATERIALS MUST BE APPROPRIATE FOR THE PROCESS - SEE TABLE 1‐4.

2. IF AMBIENT DEW POINT IS ABOVE PROCESS TEMPERATURE, ICE FORMATION MIGHT CAUSE

INSTRUMENT MALFUNCTION AND REDUCE INSULATOR EFFECTIVENESS.

39A4070‐B

A5494‐1

30 40 50 60

TOO

HOT

70

80

425

400

300

200

100

0

-100

-200

176

PROCESS TEMPERATURE (_C)

CAUTION

Installation

November 2014

Measurement errors can occur if the torque tube assembly is bent or misaligned during installation.

1. When mounting a DLC3020f on a 249 sensor, secure the shaft extension to the sensor torque tube shaft via the

shaft coupling and set screws, with the coupling centered as shown in figure 2‐7.

2. Slide the access handle to the locked position to expose the access hole. Press on the back of the handle as shown in

figure 2‐2 then slide the handle toward the front of the unit. Be sure the locking handle drops into the detent.

3. Remove the hex nuts from the mounting studs.

4. Position the insulator on the digital level controller, sliding the insulator straight over the mounting studs.

5. Install 4 washers (key 78) over the studs. Install the four hex nuts and tighten.

6. Carefully slide the digital level controller with the attached insulator over the shaft coupling so that the access hole

is on the bottom of the digital level controller.

7. Secure the digital level controller and insulator to the torque tube arm with four cap screws.

8. Tighten the cap screws to 10 NSm (88.5 lbfSin).

Electrical Connections

The following describes how to make fieldbus connections to the digital level controller. For information on

connecting a simulate jumper, refer to page 19.

WARNING

To avoid personal injury resulting from electrical shock, do not exceed the maximum input voltage specified in table 1‐2 or

on the product nameplate. If the input voltage specified differs, do not exceed the lowest specified maximum input

voltage.

17

Page 20

Installation

November 2014

Instruction Manual

D103434X012

WARNING

Select wiring and/or cable glands that are rated for the environment of use (such as hazardous area, ingress protection and

temperature). Failure to use properly rated wiring and/or cable glands can result in personal injury or property damage

from fire or explosion.

Wiring connections must be in accordance with local, regional, and national codes for any given hazardous area approval.

Failure to follow the local, regional, and national codes could result in personal injury or property damage from fire or

explosion.

Personal injury or property damage caused by fire or explosion may occur if this connection is attempted in a potentially

explosive atmosphere or in an area that has been classified as hazardous. Confirm that area classification and atmosphere

conditions permit the safe removal of the terminal box cover before proceeding

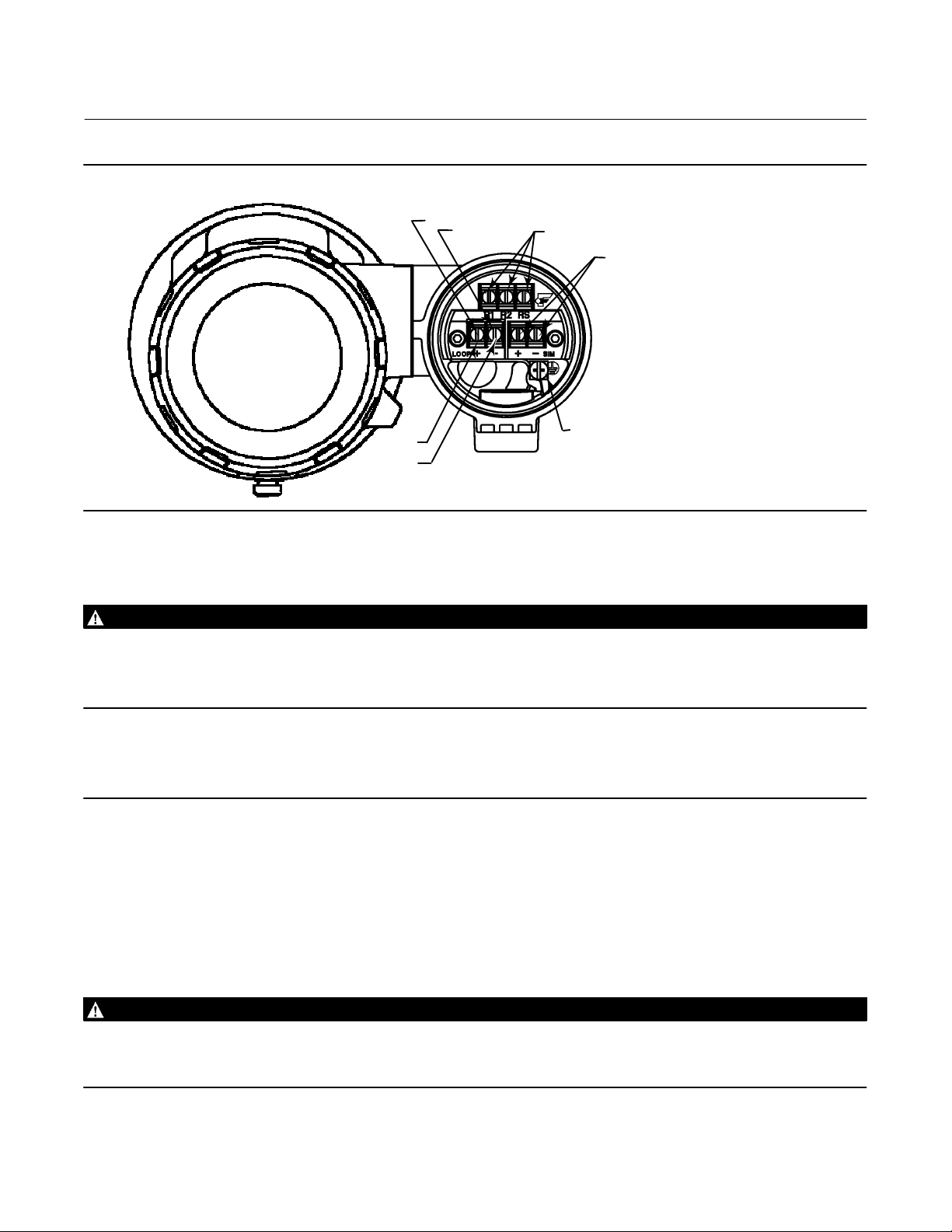

Fieldbus Connections

The digital level controller is normally powered over the bus from a fieldbus 9 to 32 volt power supply and can be

connected to the segment using field wiring. Refer to the site preparation guide for proper wire types, termination,

length, etc. for a fieldbus segment.

Note

As shipped from the factory, the DLC3020f will have the transducer block mode set Out of Service. See the Configuration Section

for information on setup and calibration and placing the instrument in service. The initial value for all blocks are shown in the

parameter list for each block in the Blocks section.

Refer to figure 8‐1 for identification of parts.

1. Remove the terminal box cover (key 6) from the terminal box (key 5).

2. Bring the field wiring into the terminal box. When applicable, install conduit using local and national electrical codes

which apply to the application.

3. Connect one wire from the control system output card to the LOOP + terminal in the terminal box as shown in

figure 2‐9. Connect the other wire from the control system output card to the LOOP - terminal. The instrument is

not polarity sensitive.

WARNING

Personal injury or property damage, caused by fire or explosion, can result from the discharge of static electricity. Connect

a 14 AWG (2.08 mm

gases are present. Refer to national and local codes and standards for grounding requirements.

4. As shown in figure 2‐9, ground terminals are available for connecting a safety ground, earth ground, or drain wire.

The safety ground terminal is electrically identical to the earth ground. Make connections to these terminals

following national and local codes and plant standards.

5. Replace and tighten the terminal box cover, ensuring that it is weather‐tight; engage the optional set‐screw lock if

required.

2

) ground strap between the digital level controller and earth ground when flammable or hazardous

18

Page 21

Instruction Manual

D103434X012

Figure 2‐9. Terminal Box Assembly

Installation

November 2014

LOOP+

LOOP-

CLIP‐ON +

CLIP‐ON -

RTD

SIMULATE ENABLE

SAFETY GROUND

Communication Connections

WARNING

Personal injury or property damage caused by fire or explosion may occur if this connection is attempted in a potentially

explosive atmosphere or in an area that has been classified as hazardous. Confirm that area classification and atmosphere

conditions permit the safe removal of the terminal box cap before proceeding.

Note

Host system device manager interfaces, such as Emerson's AMS Device Manager or the Field Communicator, communicate

directly with the device.

A FOUNDATION fieldbus communicating device, such as a Field Communicator, interfaces with the DLC3020f from any

wiring termination point in the segment. If you choose to connect the fieldbus communicating device directly to the

instrument, attach the device to the LOOP + / - clip‐on connections inside the terminal box to provide local

communications with the instrument.

Simulate Enable Jumper

WARNING

Personal injury or property damage caused by fire or explosion may occur if this connection is attempted in a potentially

explosive atmosphere or in an area that has been classified as hazardous. Confirm that area classification and atmosphere

conditions permit the safe removal of the terminal box cap before proceeding.

19

Page 22

Installation

November 2014

Instruction Manual

D103434X012

Install a jumper across the SIMULATE ENABLE terminals to enable the instrument to accept a simulate command.

(These terminals are marked SIM + / - in the terminal box, as shown in figure 2‐9). With the jumper in place and the

simulate software parameter set to enabled, various alerts can be simulated as required.

Note

Removing the jumper will disable the simulate, which may change the status of PV.

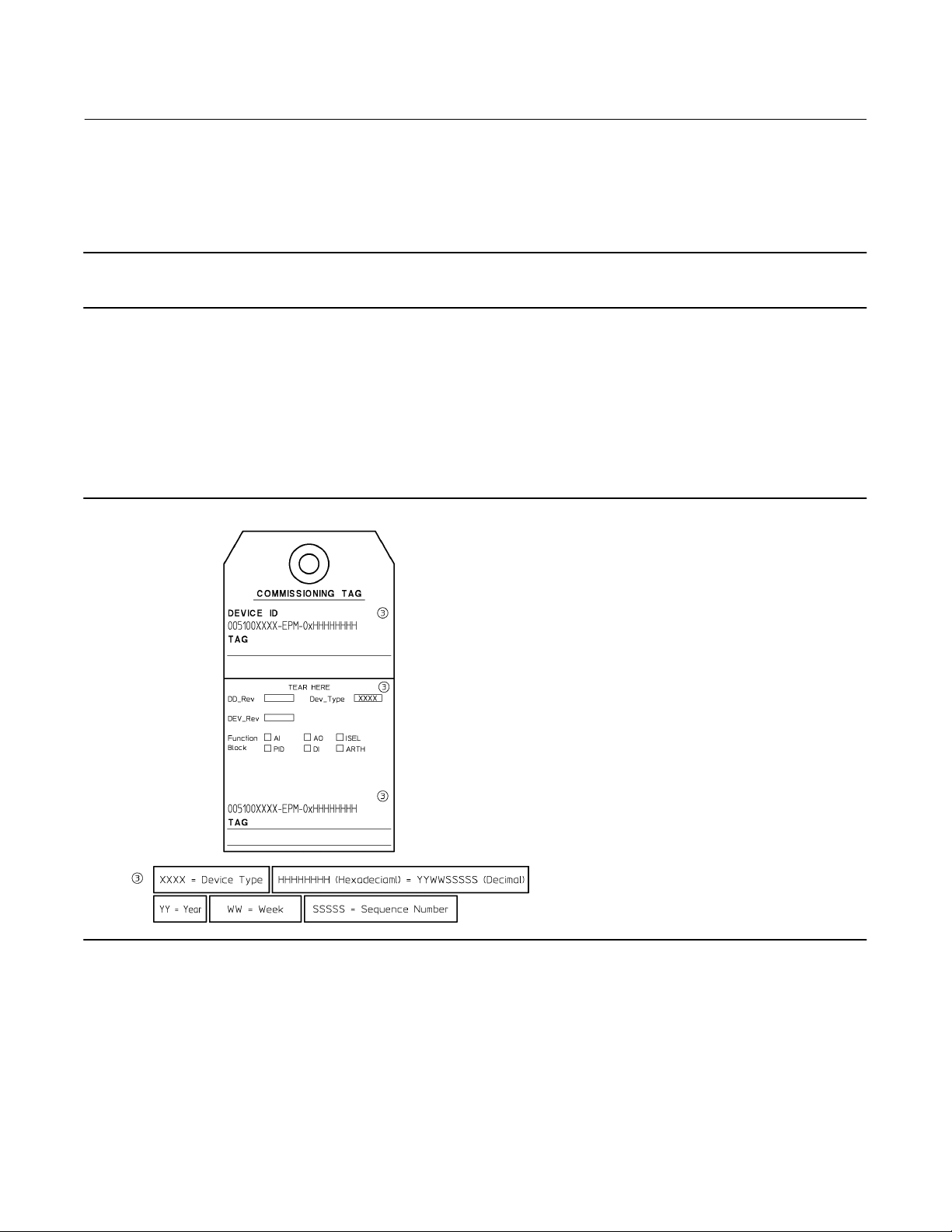

Commissioning Tag

The DLC3020f is supplied with a removable paper commissioning tag, shown in figure 2‐10. This tag contains both the

device ID and a space to record the device's tag number. The device ID is a unique code that identifies a particular

device in the absence of a device tag. The device tag is used as an operational identification for the device and is

usually defined by the piping and instrumentation diagram (P&ID).

Figure 2‐10. Paper Commissioning Tag

GE46500‐B

When commissioning more than one device on a fieldbus segment, identifying which device is at a particular location

can be tedious without tags. The removable tag provided with the digital level controller can be used to link the device

ID and the physical installation location. The installer should note the physical location in both places on the

removable commissioning tag and tear off the bottom portion. This should be done for each device on the segment.

The bottom portion of the tags can be used for commissioning the segment in the control system.

Prior to commissioning, the device ID is displayed by the host system if no device tag is configured in the digital level

controller electronics. Typically the placeholder displays the device tag. The information on the paper tag enables the

engineer to match the device ID to the correct placeholder.

20

Page 23

Instruction Manual

D103434X012

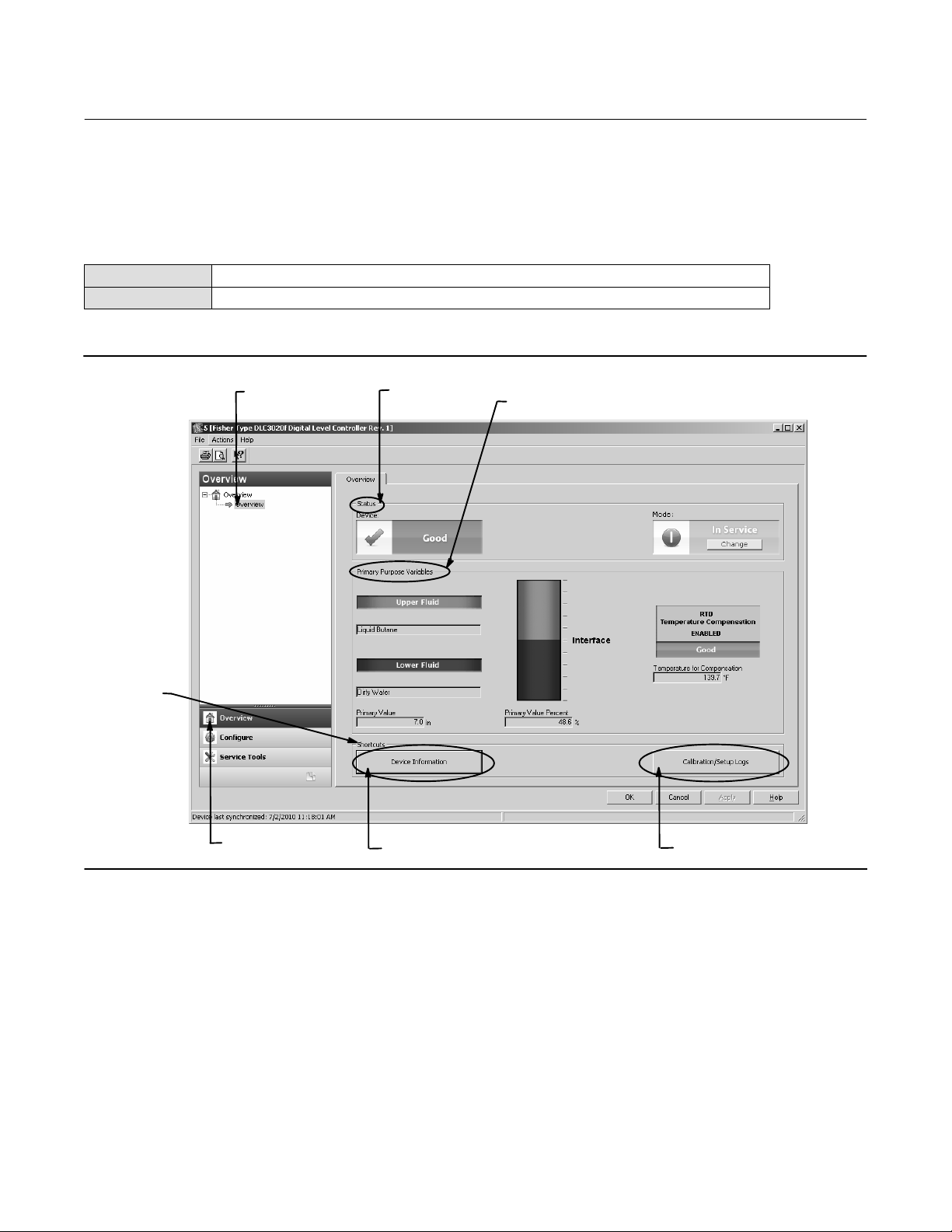

Section 3 Overview3‐3‐

Overview

AMS Device Manager Overview > Overview

Field Communicator Overview > Overview

Select the Overview tab (figure 3‐1) to access Overview and Shortcuts.

Figure 3‐1. Overview

OVERVIEW

STATUS

PRIMARY PURPOSE VARIABLES

Overview

November 2014

SHORTCUTS

OVERVIEW

DEVICE INFORMATION

CALIBRATION / SETUP LOGS

Overview

Status

Device

Good there are no active alerts and instrument is In Service

Failed a configured failed alert is active

Maintenance a configured maintenance alert is active and a configured failed alert is turned on

21

Page 24

Overview

November 2014

Advisory a configured advisory alert is active and configured failed or a maintenance alert is turned on

Instruction Manual

D103434X012

Mode

In Service the instrument is in service

Not in Service the instrument is not in service

Primary Purpose Variables

Depending on your application, the primary purpose variables found on Overview may include the following:

Fluid (Fluid for Level measurement, Upper Fluid and Lower Fluid or Interface measurement, when enabled).

Primary Value

Primary Value Percent

Temperature for Compensation (when enabled)

Type of Measurement (Level or Interface)

Shortcuts

Device Information

Device Overview

D Instrument Model Number

D Instrument Serial Number

Version Information

Version information contains information that is stored within the instrument.

D Device Revision

D Firmware Revision

D Hardware Revision

D Major Sensor Revision

D Minor Sensor Revision

D DD Information

22

Page 25

Instruction Manual

D103434X012

Overview

November 2014

Manufacturing Identification

Each instrument has a unique Device Identifier. The device identification provides in depth manufacturing data to help

ensure reliability.

D Lever Assembly ID

D Communication Module ID

D Sensor Module ID

D Shop Order Number

D Terminal Box Date Code

Calibration/Setup Logs

Logs including calibration, instrument setup, and process fluid data can be saved for future reference or re‐use. The

instrument can store up to 30 logs.

D Calibration in Use

Name

Date

Calibration Method

Calibrator

D Calibration/Setup Logs

View—select View to access stored logs.

Restore—select Restore to access stored logs; select the desired log to revert back to.

Save Current—select Save Current and enter a new name.

Rename—select Rename to change the name of an existing log.

Delete—select Delete to delete to delete an existing log.

D Mode—indicates whether the instrument is In Service or Not In Service.

23

Page 26

Overview

November 2014

Instruction Manual

D103434X012

24

Page 27

Instruction Manual

D103434X012

Configuration

November 2014

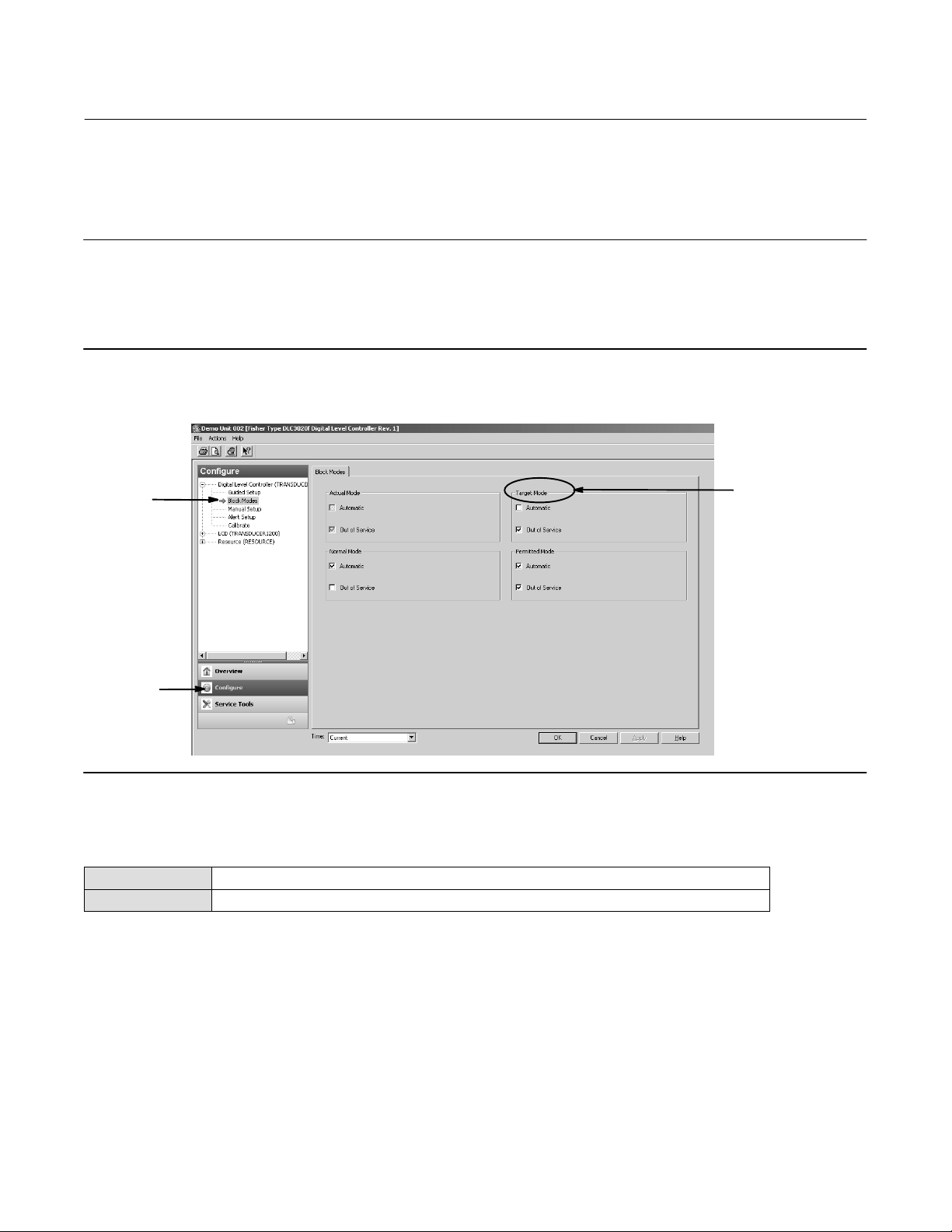

Section 4 Configuration4‐4‐

Note

The primary transducer block must be set to out of service before the device can be configured.

When using AMS Device Manager 10.1 and earlier go to Target Mode in Block Modes tab to set the primary transducer block in and

out of service. Refer to figure 4‐1.

Figure 4‐1. Block Modes Tab (AMS Device Manager 10.1 and earlier)

BLOCK

MODES

CONFIGURE

SET THE TARGET MODE

TO OUT OF SERVICE

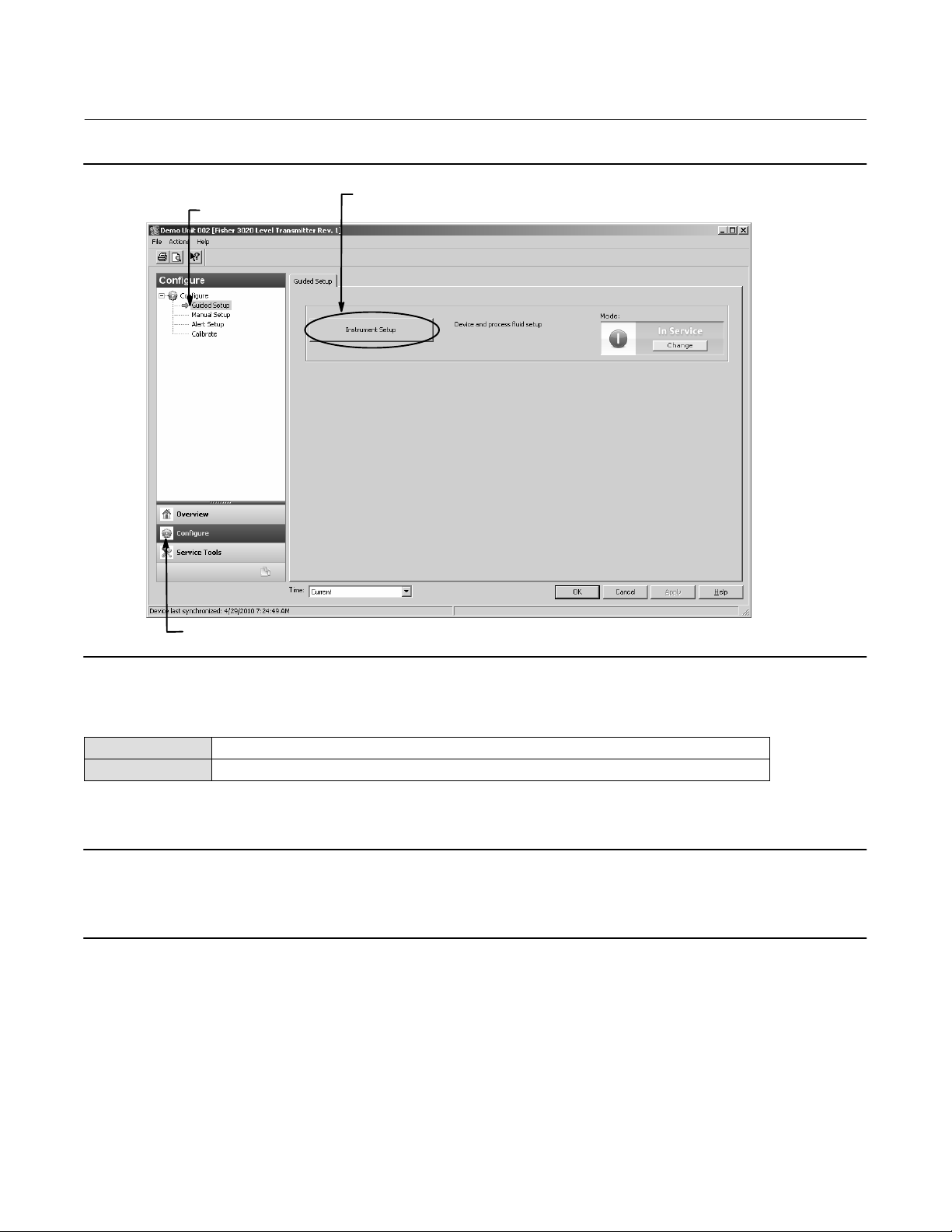

Guided Setup

AMS Device Manager Configure > Guided Setup

Field Communicator Configure > Instrument Setup

Access Instrument Setup from the Guided Setup tab, as shown in figure 4‐2, for sensor, device and process fluid setup.

Follow the prompts to setup the DLC3020f.

25

Page 28

Configuration

November 2014

Figure 4‐2. Guided Setup

GUIDED SETUP

Instruction Manual

D103434X012

INSTRUMENT SETUP

CONFIGURE

Manual Setup

AMS Device Manager Configure > Manual Setup

Field Communicator Configure > Manual Setup

The Device, Process Fluid, Instrument Display, Snap Acting Control, and Options tabs are accessible through Manual Setup.

Note

An error will be generated if the instrument is put back in service without applying device configuration changes; you must apply

changes before putting the instrument back In Service. To clear an error, set the Mode to Out of Service, select Apply, then put

back In Service.

26

Page 29

Instruction Manual

D103434X012

Configuration

November 2014

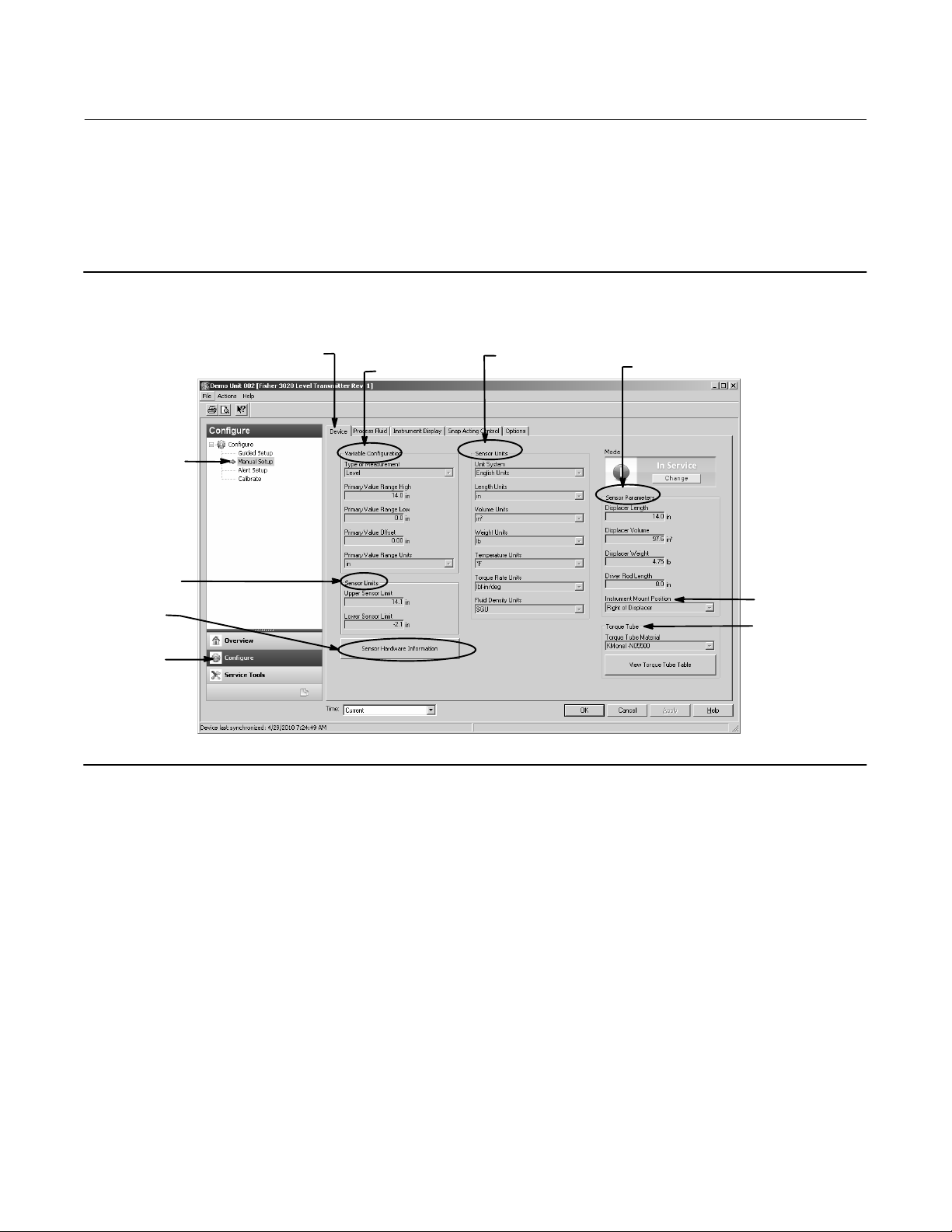

Device

Select the Device tab (figure 4‐3) to access Variable Configuration, Sensor Limits, Sensor Hardware Information, Sensor

Units, Mode, Sensor Parameters, Instrument Mount Position, and Torque Tube.

Figure 4‐3. Configure > Manual Setup > Device

MANUAL SETUP

SENSOR LIMITS

SENSOR

HARDWARE

INFORMATION

CONFIGURE

DEVICE TAB

VARIABLE

CONFIGURATION

SELECT UNIT SYSTEM

SENSOR PARAMETERS

INSTRUMENT

MOUNT POSITION

TORQUE TUBE

Variable Configuration

Type of Measurement— Level or Interface

Primary Value Range High— defines the maximum operational end point for reported PV.

Primary Value Range Low— defines the minimum operational end point for reported PV. Default is above zero.

Primary Value Offset— the constant offset applied to the level/interface measurement.

Primary Value Range Units— units for PV, PV Range, and Sensor Limits.

Sensor Limits

Upper Sensor Limit— Indicates the maximum usable value for the Primary Value Range High.

Lower Sensor Limit— Indicates the minimum usable value for the Primary Value Range Low.

27

Page 30

Configuration

November 2014

Instruction Manual

D103434X012

The Upper and Lower Sensor Limit limit what the DLC3020ft can read; values above and below these limits will not be

detected by the instrument. This is a dynamic reading based on temperature used when Temperature Compensation

is enabled.

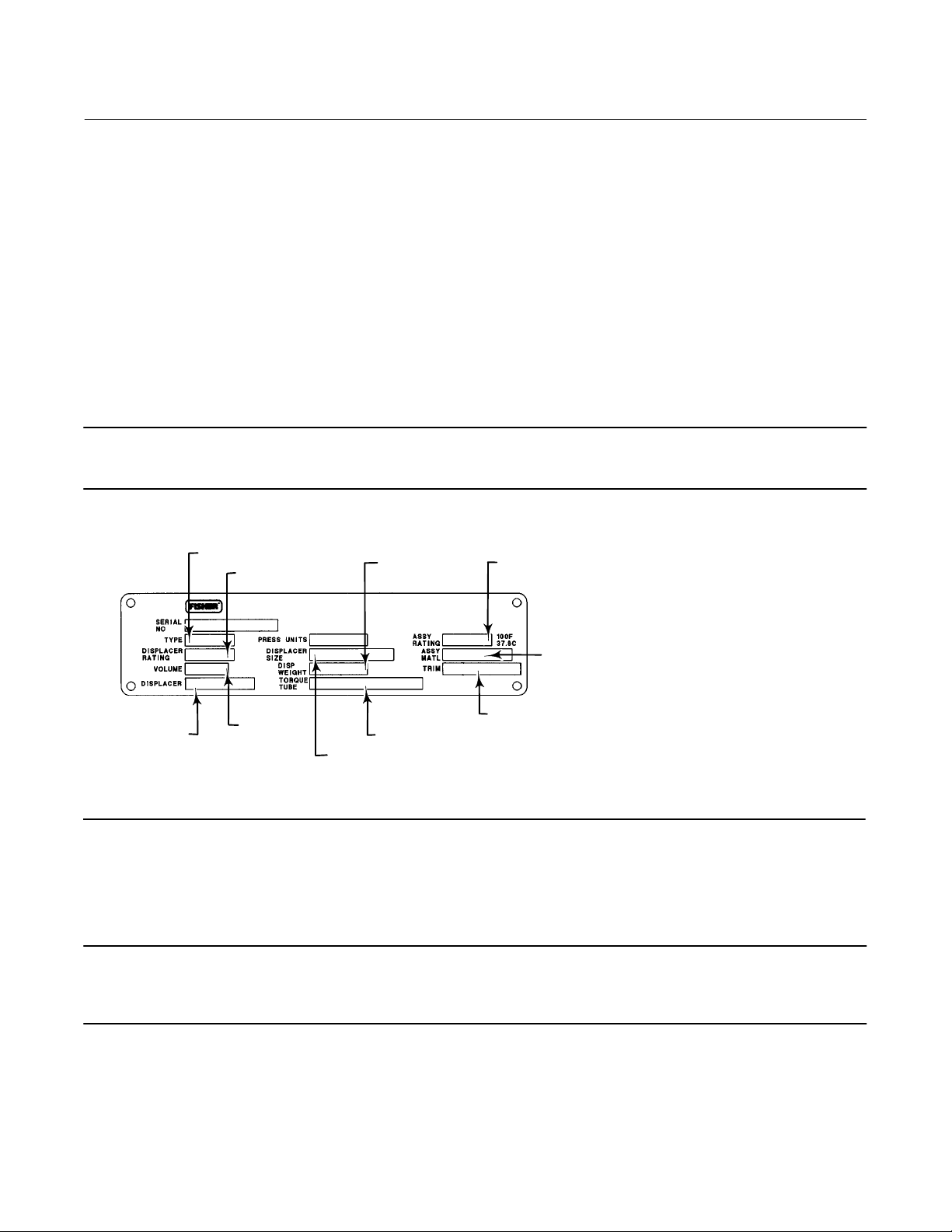

Sensor Hardware Information

Enter the following information by selecting Sensor Hardware Information.

Model Type, End Connection Style, End Connection Type, Body Material, Pressure Rating, Mechanical Sensor Serial

Number, Displacer Size Displacer Material, Displacer Rating, G Dimension, Torque Tube Material, Torque Tube Wall,

Heat Insulator.

Sensor information is typically found on the sensor nameplate, as shown in figure 4‐4.

Note

This data is informational only and is not used in calibration or PV calculations.

Figure 4‐4. Typical Sensor Nameplate

DISPLACER

MATERIAL

23A1725‐E sht 1

E0366

SENSOR TYPE

76543210

249B

1500 PSI

103 CU‐IN

316 SST

DISPLACER

PRESSURE RATING

PSI

2 x 32 INCHES

4 3/4 LBS

K MONEL/STD

DISPLACER

VOLUME

DISPLACER

WEIGHT

285/100 F

WCB STL

MONEL

TORQUE TUBE MATERIAL

DISPLACER SIZE

(DIAMETER X LENGTH)

ASSEMBLY

PRESSURE RATING

TRIM MATERIAL

Sensor Units

Select the appropriate sensor units for your application.

Note

Default units from factory are SI (Metric).

If you choose Mixed Units you must select the units for each sensor parameter.

ASSEMBLY MATERIAL

Unit System—English Units, Metric/SI Units, Mixed Units

Length Units—mm, cm, m, in, or ft

28

Page 31

Instruction Manual

D103434X012

Configuration

November 2014

Volume Units—mm3, ml, L, in

3

Weight Units—oz, lb, g, or kg

Temperature Units—_F, _R, _C, or K

Torque Rate Units—NSm/deg, dyneScm/deg, lbfSin/deg

Fluid Density Units—degAPI, SGU (Specific Gravity) lb/in

3

, lb/ft3, lb/gal, degBaum hv, degBaum lt, kg/m3, g/cm3, kg/L,

g/ml, or g/L

Sensor Parameters

Enter the sensor parameters. Selections shown in the drop down are based on the sensor units chosen.

Displacer Length

Displacer Volume

Displacer Weight

Driver Rod Length

Note

Table 4‐1 provides the driver rod length of 249 sensors with vertical displacers. If your sensor isn't included in table 4‐1 refer to

figure 4‐5 to determine the driver rod length.

Instrument Mount Position

(2)

(1)(3)

(3)

(1)

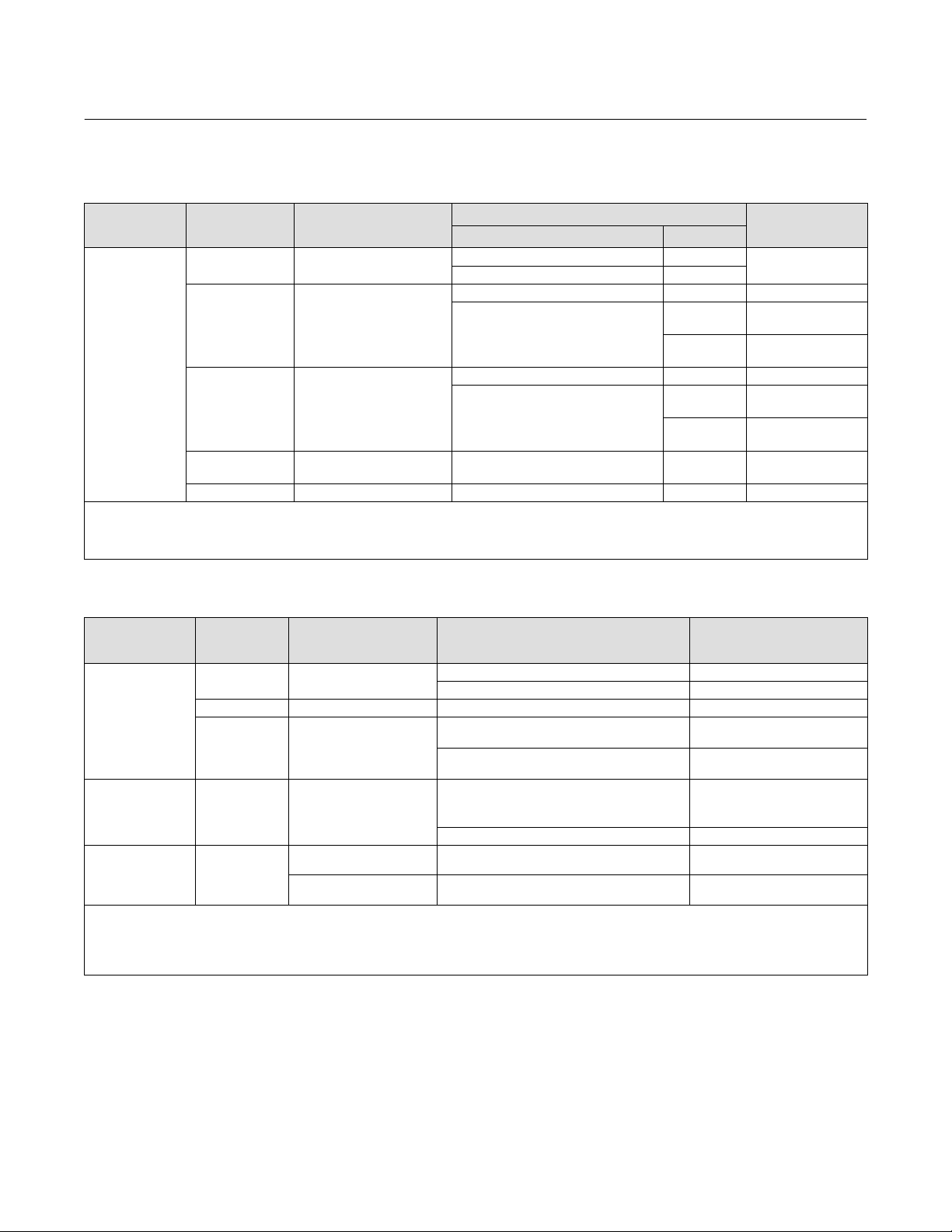

DRIVER ROD

mm INCH

See serial card See serial card

343 13.5

Table 4‐1. Driver Rod Length

SENSOR TYPE

249 203 8.01

249B 203 8.01

249BF 203 8.01

249BP 203 8.01

249C 169 6.64

249CP 169 6.64

249K 267 10.5

249L 229 9.01

249N 267 10.5

249P (CL125-CL600) 203 8.01

249P (CL900-CL2500) 229 9.01

249V (Special)

249V (Std)

249VS 343 13.5

249W 203 8.01

1. Driver rod length is the perpendicular distance between the vertical centerline of the displacer and the horizontal centerline of the torque tube. See figure 4‐5. If you cannot determine the

driver rod length, contact your Emerson Process Management sales office and provide the serial number of the sensor.

2. This table applies to sensors with vertical displacers only. For sensor types not listed, or sensors with horizontal displacers, contact your Emerson Process Management sales office for the

driver rod length. For other manufacturers' sensors, see the installation instructions for that mounting.

3. The 249V is only available in Europe.

29

Page 32

Configuration

November 2014

Figure 4‐5. Method of Determining Driver Rod Length from External Measurements

VERTICAL C

OF DISPLACER

HORIZONTAL CL OF

TORQUE TUBE

L

DISPLACER ROD LENGTH

VESSEL

Instruction Manual

D103434X012

Torque Tube

Torque Tube Material—select the material of the torque tube being used. See the sensor nameplate.

View Torque Tube Table—select View Torque Tube Table to see the torque tube gain over the entire temperature range

and the compensated torque rate.

30

Page 33

Instruction Manual

D103434X012

Process Fluid

Select the Process Fluid tab (figure 4‐6) to access Process Fluid, Temperature Compensation, and Mode.

Figure 4‐6. Configure > Manual Setup > Process Fluid

PROCESS FLUIDS TAB

PROCESS FLUID

MANUAL

SETUP

TEMPERATURE

COMPENSATION

MODE

Configuration

November 2014

CONFIGURE

Note

The instrument software contains density tables for common categories of fluids. Custom tables can be built if needed.

Some fluid categories have wide variations within fluid types. Select the fluid category and then the fluid type.

Input the operating process temperature and the density. The DLC3020f will load the density table that best matches the fluid

type at operating conditions.

CHANGE PROCESS FLUID

VIEW DENSITY PARAMETERS

Process Fluid

Fluid Name

Density In Use

Change Process Fluid —Select Change Process Fluid to begin the process to properly select the corrections for density

of the fluid that occur at operational temperature.

If Temperature Compensation is selected, the proper density table for use in temperature compensation is selected. If

Temperature Compensation is not needed, enter the operating conditions and name the fluid.

Temperature Compensation

If Temperature Compensation is selected, provide the following information:

31

Page 34

Configuration

November 2014

Instruction Manual

D103434X012

Temperature Input—select None, Manual, AO Block, or RTD.

Temperature compensation, when enabled, can come from a manually entered temperature, a temperature from a

fieldbus transmitter (AO block) or a temperature from an RTD.

Temperature for Compensation—the temperature in use for fluid density and torque tube material compensation.

View Fluid Density Table

Select View Fluid Density Table to see information concerning the temperature effect on process fluid density.

Instrument Display

Select the Instrument Display tab (figure 4‐7) to access Display Option, Device Display Primary Value Units, Decimal

Places, Display Primary Value Offset, and Scrolling Message Control.

Figure 4‐7. Configure > Manual Setup > Instrument Display

DEVICE DISPLAY PRIMARY VALUE UNITS

DISPLAY OPTION

DECIMAL PLACES

DISPLAY PRIMARY VALUE OFFSET

CONFIGURE

MANUAL

SETUP

INSTRUMENT

DISPLAY TAB

SCROLLING

MESSAGE CONTROL

MODE

Display Option

Select Primary Value Only, % Range, or Primary Value / % Range to be displayed on the DLC3020f LCD.

Device Display Primary Value Units

Select the units for the device display Primary Value.

Decimal Places

Enter the number of desired decimal places for the device display.

32

Page 35

Instruction Manual

D103434X012

Configuration

November 2014

Display Primary Value Offset

Enter the PV Offset to apply it to the LCD readout.

Scrolling Message Control

Messages that can be scrolled on the LCD screen. Choose from; Primary Value Bad, Primary Value Uncertain, Failed

Alert, Maintenance Alert, or Advisory Alert.

Snap Acting Control

Select the Snap Acting Control tab (figure 4‐8) to access Snap Acting Control, Primary Value, Primary Value Percent, DI1

Trip Point Settings, DI2 Trip Point Settings, and Mode.

Figure 4‐8. Configure > Manual Setup > Snap Acting Control

PRIMARY VALUE

PRIMARY VALUE PERCENT

CONFIGURE

MANUAL

SETUP

SNAP ACTING

CONTROL

SNAP ACTING

CONTROL TAB

DI1 TRIP POINT

SETTINGS

MODE

DI2 TRIP

POINT SETTINGS

Snap Acting Control

The DLC3020f can act as a snap acting controller while simultaneously reporting PV. When Snap Acting Control is

enabled, either one or both of the DI blocks will act as controllers and output a 0 (inactive) or 1 (active), depending on

if the level has gone past (either rising or falling) a user specified level value.

Snap Acting Control—enable or disable Snap Acting Control.

Snap Units—select the desired snap unit in engineering units; length units or percent (%).

Primary Value

PV in engineering units

33

Page 36

Configuration

November 2014

Instruction Manual

D103434X012

Primary Value Percent

PV in %

DI1 Trip Point Settings

Set Channel 1 or 2 of the DI for snap acting control.

DI1 Action—indicate whether the trip point is active on rising or falling level.

DI1 Trip Point—enter the point where DI1 is active.

DI1 Deadband—enter the desired deadband. This is the distance away from the trip point that DI1 clears.

DI1 Readback—indicates the status of the trip point. 0 indicates that DI1 Trip is inactive. 1 indicates DI1 Trip is active.

DI2 Trip Point Settings

DI2 Action—indicate whether the trip point is active on rising or falling level.

DI2 Trip Point—enter the point where DI2 is active.

DI2 Deadband—enter the desired deadband. This is the distance away from the trip point that DI2 clears.

DI2 Readback—indicates the status of the trip point. 0 indicates that DI2 Trip is inactive. 1 indicates DI2 Trip is active.

Options

Select the Options tab (figure 4‐9) to access Write Alarm, Block Alarm, Write Lock, Confirm Time, Communication

Timeout, Function Block Available, Features Selected, Alert Key, Maximum Alerts Allowed, Maximum Alerts Possible, Resource

Block, Transducer Block, and Mode.

34

Page 37

Instruction Manual

D103434X012

Figure 4‐9. Configure > Manual Setup > Options

MANUAL

SETUP

BOCK ALARM

WRITE ALARM

COMMUNICATION TIMEOUT

CONFIRM TIME

OPTIONS TAB

Configuration

November 2014

MODE

FUNCTION BLOCK

AVAILABLE

ALERT KEY

MAXIMUM ALERTS ALLOWED

MAXIMUM ALERTS POSSIBLE

RESOURCE BLOCK

TRANSDUCER BLOCK

CONFIGURE

WRITE LOCK

FEATURES SELECTED

Write Alarm

The Write Alarm (WRITE_ALM [40]) is used to alert when parameters are writable to the device.

Write Alarm Disabled—select to disable the Write Alarm

Alarm State—indicates the state of the Write Alarm. Five states are possible; Undefined, Clear‐Reported, Clear-Not

Reported, Active‐Reported, Active‐Not Reported.

Unacknowledged—select Undefined, Acknowledged, or Unacknowledged

Block Alarm

The block alarm is used for all configuration, hardware, connection failure, or system problems in the block. Alarm

Summary (ALARM_SUM [37]) determines if the Write Alarm and Block Alarm are disabled.

Block Alarm Disabled—select to disable the Block Alarm

Alarm State—indicates the state of the Block Alarm. Five states are possible; Undefined, Clear‐Reported, Clear-Not

Reported, Active‐Reported, Active‐Not Reported.

Unacknowledged—select Undefined, Acknowledged, or Unacknowledged

Write Lock

Write Lock determines if writes are permissible to other device parameters.

35

Page 38

Configuration

November 2014

Instruction Manual

D103434X012

Write Lock— When Write Lock is set to Locked, no writes are permitted to any parameters within the device except to

set Write Lock to Not Locked. When locked, the device functions normally, updating inputs and outputs and executing

algorithms. When Write Lock is set to Not Locked, the Write Alarm alert is active.

Write Priority—Write Priority sets the priority for Write Alarm. The lowest priority is 0. The highest is 15.

Confirm Time

Confirm Time determines the time in 1/32 of a millisecond, the instrument waits for confirmation of receipt of a report

before trying again. If Confirm Time is 0, the instrument does not try to resend the report. Enter 0 or a value between

320000 (10 seconds) and 640000 (20 seconds).

Communication Timeout

Note

Typically this parameter does not need to be changed. The unit will be operational using the default values assigned by the factory.

Perform this procedure only if a remote computer is sending setpoints from your “advanced” control.

Default value for RCas Timeout is 20 seconds.

Rcas Time‐Out—Rcas Timeout determines how long function blocks in the DLC3020f should wait before giving up on

remote computer writes to RCas parameters. When the timeout is exceeded, the block sheds to the next mode as

defined by the block shed options. If RCas Timeout is set to 0, the block will not shed from RCas. Enter a positive value

in the RCas Timeout Timeout field. Time duration is in 1/32 milliseconds (640000 = 20 secs).

Note

Typically this parameter does not need to be changed. The unit will be operational using the default values assigned by the factory.

Perform this procedure only if a remote computer is sending setpoints from your “advanced” control.

Default value for ROut Timeout is 20 seconds.

Rout Time-Out—ROut Timeout (SHED_ROUT [27]) determine how long function blocks in the DLC3020f should wait

before giving up on computer writes to ROut parameters. When the timeout is exceeded, the block sheds to the next

mode as defined by the block shed options. If ROut Timeout is set to 0, the block will not shed from ROut. Enter a

positive value in the ROut Timeout field. Time duration is in 1/32 milliseconds (640000 = 20 secs).

Write Lock—permits using Write Lock to prevent any external change to parameter values. Block connections and

calculation results will proceed normally, but the configuration is locked.

Reannunciation—permits the instrument to support Reannunciation of alarms.

Function Block Available

CasIn to Transducer Block

36

Page 39

Instruction Manual

D103434X012

Configuration

November 2014

Features Selected

Note

Typically this parameter does not need to be changed. The unit will be operational using the default values assigned by the factory.

Features Selected indicates which Resource Block Options features have been selected and is used to select the

desired features.

Reports—Selecting reports enables alert and event reporting. Reporting of specific alerts may be suppressed.

Fault State—Selecting Fault State enables the ability of the output block to react to various abnormal conditions by

shedding mode.

Write Lock—When selected, permits using Write Lock to prevent any external change to parameter values. Block

connections and calculation results will proceed normally, but the configuration is locked.

Reannunciation— When selected, the instrument will support Reannunciation of alarms.

Alert Key

Alert Key is a number that permits grouping alerts. This number may be used to indicate to the operator the source of

the alert, such as the instrument, plant unit, etc. Enter a value between 1 and 255.

Maximum Alerts Allowed

The number of alert reports that the device can send without getting a confirmation up to the maximum permitted

Resource Block

Tag Description— The Tag Description is used to assign a unique 32 character description to each block within the

digital level controller to describe the intended application of the block.

Strategy— Strategy permits strategic grouping of blocks so the operator can identify where the block is located. The

blocks may be grouped by plant area, plant equipment, etc. Enter a value between 0 and 65535 in the Strategy field.

Transducer Block

Tag Description— The Tag Description is a 32 character description used to assign a unique description to each block

within the digital level controller to describe the intended application for the block.

Strategy— Strategy permits strategic grouping of blocks so the operator can identify where the block is located. The

blocks may be grouped by plant area, plant equipment, etc. Enter a value between 0 and 65535 in the Strategy field.

37

Page 40

Configuration

November 2014

Alert Setup

AMS Device Manager Configure > Alert Setup

Field Communicator Configure > Alert Setup

Alert Setup is accessible through the Alert Setup tab (figure 4‐10).

Figure 4‐10. Alert Setup

Instruction Manual

D103434X012

OPERATIONAL

RATE LIMIT

CONFIGURE

ALERT SETUP

ALERT SETUP TAB

ELECTRONICS

SCROLL DOWN TO VIEW:

SENSOR BOARD

TEMPERATURE LIMIT INPUT

COMPENSATION ERROR

Alerts

The DLC3020f provides two levels of alerts; Instrument alerts and PlantWeb alerts.

Instrument Alert Conditions

Instrument Alert Conditions, when enabled, detect many operational and performance issues that may be of interest.

To view these alerts, the user must open the appropriate status screen on a host such as AMS Device Manager or a

Field Communicator.

38

Page 41

Instruction Manual

D103434X012

Configuration

November 2014

PlantWeb Alerts

Instrument alert conditions can be used to trigger PlantWeb alerts that will be reported in Failed, Maintenance or

Advisory categories, as configured by the user. PlantWeb alerts, when enabled, can participate in the DeltaVt alarm

interface tools such as the alarm banner, alarm list and alarm summary.

When a PlantWeb alert occurs, the DLC3020f sends an event notification and waits a specified period of time for an

acknowledgment to be received. This occurs even if the condition that caused the alert no longer exists. If the

acknowledgment is not received within the pre‐specified time‐out period, the event notification is retransmitted. This

reduces the possibility of alert messages getting lost.

DLC3020f alerts can be reported in the following categories.

Failed— indicates a problem with the DLC3020f that affects its operation. Immediate action is required for a Failed

condition.

Maintenance— indicates a problem with the DLC3020f that, if ignored, could eventually lead to its failure. Maintenance

conditions require prompt action.

Advisory— indicates a minor problem with the DLC3020f. An advisory condition does not have an impact on the

process or device.

No Category— the alert has not been categorized.

Suppress PlantWeb Alert—- the alert is still evaluated by the DLC3020f, but, it does not report the status condition

through an instrument alert.

Electronics

D Pending Memory Fail— when selected indicates if a pending memory error has been detected in the main board.

D Static Memory Fail— when selected indicates if a memory error has been detected in the main board.

Operational

D PV Exceeds Sensor Range— when selected indicates if the Primary Variable (PV) has reached or exceeded the Sensor

Range and is no longer correct.

D PV Range Exceeds Sensor Range— when selected indicates if the Primary Variable (PV) Range has exceeded the

range of the sensor's current calibration. The PV is still accurate but could move out of sensor range.

D PV Exceeds Primary Range— when selected indicates if the the Primary Variable (PV) has exceeded the PV Range.

D Calibration Validity— when selected indicates if a vital calibration parameter has been changed.

Rate Limit

D Displacer Rise Rate Exceeded— when selected indicates if the device detected a rise rate that exceeded the Rapid

Rate Limit.

D Displacer Fall Rate Exceeded Alert— when selected indicates if the device detected a fall rate that exceeded the

Rapid Rate Limit.

Rapid Rate Limit—when selected, triggers an alarm when the configured set point has been exceeded. Rapid rate limit

is user‐configured based on application.

Select Clear Rate Limit Alert to clear the alert.

39

Page 42

Configuration

November 2014

Instruction Manual

D103434X012

RTD Sensor

D RTD Sensor—when selected indicates if the RTD readings are out of range or the RTD is incorrectly connected.

D RTD Open—when selected indicates if the RTD is not connected.

Sensor Board

D Instrument Temperature Sensor— when selected indicates if the electronic sensor readings are out of range.

D Sensor Board Processor— when selected indicates if the device cannot communicate properly or other electronic

problem is effecting the processor.

D Hall Sensor— when selected indicates if the Hall Sensor readings are out of range.

Temperature Limit

D Instrument Temperature High— when selected indicates if the device has exceeded the Instrument Temperature

High Limit.

D Instrument Temperature Low— when selected indicates if the device has exceeded the Instrument Temperature

Low Limit.

Input Compensation Error

D Temperature Input Error— when selected indicates if the AO temperature status or RTD status has become “Bad" or

“Uncertain" or the device is not set up correctly to receive AO temperature.

D Upper Fluid Input Error— when selected indicates if the Upper Fluid AO status has become “Bad" or “Uncertain" or

the device is not setup correctly to receive AO density for the Upper Fluid.