Page 1

Product Bulletin

DLC3020f Digital Level Controller

D103433X012

11.2:DLC3020f

November 2014

Fisherr FIELDVUEt DLC3020f Digital Level

Controller for F

The FIELDVUE DLC3020f digital level controller is a

fieldbus communicating instrument used to measure

liquid level or the level of interface between two

liquids using displacement sensor technology.

In addition to the normal function of reporting process

level PV, the DLC3020f, using F

protocol, gives easy access to information critical to

process operation and will readily integrate into a new

or existing control system. AMS Suite: Intelligent

Device Manager or the 475 Field Communicator can

be used to configure, calibrate, or test the digital level

controller.

The DLC3020f is also designed to directly replace

pneumatic, analog, or HARTr transmitters/

controllers. It can be mounted on a wide variety of 249

cageless and caged level sensors as well as on other

displacer type level sensors through the use of

mounting adaptors.

OUNDATION fieldbus

OUNDATION

t

fieldbus

W9954-1_DLC3020f

n Dynamic Temperature Compensation Integration

of process fluid temperature, when needed, enables

density compensation to maintain PV accuracy.

Features

n Ease of Use The DLC3020f, a fieldbus level or

interface transmitter, features the latest in user

interface technology. In addition to reporting the

PV, the DLC3020f can act as a PID controller or level

switch.

n Guided Setup and Calibration Leads you through

instrument setup, process fluid selection, and

calibration in an easy‐to‐use format.

n Simple Process Fluid Configuration The capability to

easily select/define process fluids allows for fluid

changes without requiring re-calibration.

n Calibration/Setup Logs Saved in Instrument

Logs, including calibration, instrument setup, and

process fluid data, can be saved for future reference

or re‐use in batch or continuous applications. The

instrument stores up to 30 logs.

n Performance/Reliability State‐of‐the‐art Emerson

advanced electronics provide increased

performance and reliability.

www.Fisher.com

Page 2

Product Bulletin

11.2:DLC3020f

November 2014

Specifications

DLC3020f Digital Level Controller

D103433X012

Available Configurations

Mounts on 249 caged and cageless sensors. Refer to

Fisher Bulletin 11.2:Level

or 34.2:2500 for

information on 249 sensors.

Function: Transmitter, Controller, Switch

Communications Protocol: F

OUNDATION fieldbus

Digital Communication Protocol

OUNDATION fieldbus registered device (ITK 5)

F

Supply Requirements

9 to 32 volts DC, 17.7 mA DC;

instrument is not polarity sensative

Device Inputs

Level Sensor Input (required)

Rotary motion of torque tube shaft is proportional to

buoyant force of the displacer caused by changes in

liquid level or interface level

Process Temperature Compensation Input (optional)

RTD—interface for 2‐ or 3‐wire 100 ohm

platinum RTD

AO Block—F

OUNDATION fieldbus temperature

transmitter

Manual—compensation values manually entered in

the device

LCD Meter Indications

Process Variable in engineering units

Process Variable in percent (%) only

Alternating Process Variable in engineering units and

percent (%)

Optional: Alerts as configured

‐continued‐

Function Block Suite

AI, PID, DI (two), AO (three), ISEL, and an ARTH

function block

Block Execution Times

AI, PID, DI, AI, ISEL: 15 ms

ARTH: 25 ms

Fieldbus Device Capabilities

Backup Link Active Scheduler (BLAS)

Performance

Performance Criteria DLC3020f

Independent Linearity

Accuracy

Repeatability <0.1% of full scale output

Hysteresis <0.10% of output span

Deadband <0.05% of input span

Humidity

Note: At full design span, reference conditions.

1. To lever assembly rotation inputs.

$0.1% of output span

$0.15%

$0.10% (RH9.2% to 90%)

(1)

Minimum Differential Specific Gravity

0.1 SGU with standard volume displacers

Ambient Temperature Effect

The combined temperature effect on zero and span is

less than 0.01% of full scale per degree Celsius over

the operating range -40 to 80_C (-40 to 176_F)

Process Temperature Effect

Temperature compensation can be implemented to

correct for fluid density changes due to process

temperature variations

Electromagnetic Compatibility

Meets EN 61326-1 (First Edition)

Immunity—Industrial locations per Table 2 of

the EN 61326-1 standard.

Emissions—Class A

ISM equipment rating: Group 1, Class A

2

Page 3

DLC3020f Digital Level Controller

D103433X012

Specifications (continued)

Product Bulletin

11.2:DLC3020f

November 2014

Alerts and Diagnostics

Electronic Alerts advise when there is an electronic

error in memory

Operational Range Alerts notify when PV range and

sensor range changes might affect calibration

Rate Limit Alerts indicate rapid rise or fall in displacer,

which can signify abnormal operating conditions

RTD Alerts show health and condition of connected

RTD

Sensor Board Alerts indicate if the device is operating

above or below maximum recommended limits;

advises if the electronic sensor electronics cannot

communicate properly

Input Compensation Error Alerts advise of “Bad” or

“Uncertain” status of AO connection or setup.

Simulate Function

Simulate Active, when enabled, simulates an active

alert without making it visible.

Operating Limits

Process Temperature: See figure 1

(1)

Ambient Temperature

Conditions Normal Limits

Ambient

Temperature

Ambient

Relative

Humidity

-40 to 80_C

(-40 to 176_F)

0 to 95% (non-condensing) 40%

and Humidity

Transport and

Storage Limits

-40 to 85_C

(-40 to 185_F)

Nominal

Reference

25_C

(77_F)

Electrical Classification

Hazardous Area

CSA— Intrinsically Safe, Explosion‐proof,

Division 2, Dust Ignition‐proof

FM— Intrinsically Safe, Explosion‐proof,

Non‐Incendive, Dust Ignition‐proof

ATEX— Intrinsically Safe, Flameproof, Type n

IECEx— Intrinsically Safe, Flameproof, Type n

Electrical Housing

CSA— Type 4X

FM— NEMA 4X, IP66

ATEX— IP66

IECEx— IP66

Mounting Positions

Digital level controllers can be mounted right‐ or

left‐of‐displacer (the position of the instrument when

you are looking at the LCD relative to the displacer)

Construction Materials

Case and Cover: Low‐copper aluminum alloy

Internal: Plated steel, aluminum, and stainless steel;

encapsulated printed wiring boards; Neodymium Iron

Boron Magnets

Electrical Connections

Two 1/2‐14 NPT internal conduit connections; one on

bottom and one on back of terminal box. M20

adapters available.

Weight

Less than 2.7 Kg (6 lbs)

Dimensions

Refer to Fisher Bulletin 34.2:249

for sensor, level

controller, and transmitter dimensions

Options

J Heat insulator J Mountings for Masoneilant,

Yamatake, and Foxborot‐Eckhardt sensors available

1. The pressure/temperature limits in this manual and any applicable standard or code limitation for valve should not be exceeded.

3

Page 4

Product Bulletin

11.2:DLC3020f

November 2014

DLC3020f Digital Level Controller

D103433X012

Ordering Information

When ordering, specify:

1. Type of measurement

J Level or J Interface

2. Process fluid type

J Water, J Saline water, J Saturated water,

J Saturated steam,J Crude oil, J Refined

product,

specified fluid

Note

If Interface indicate both upper and lower fluid types.

3. Process operating conditions

Temperature ______________________________

Fluid density or SG __________________________

J Gas well condensate, or J Customer

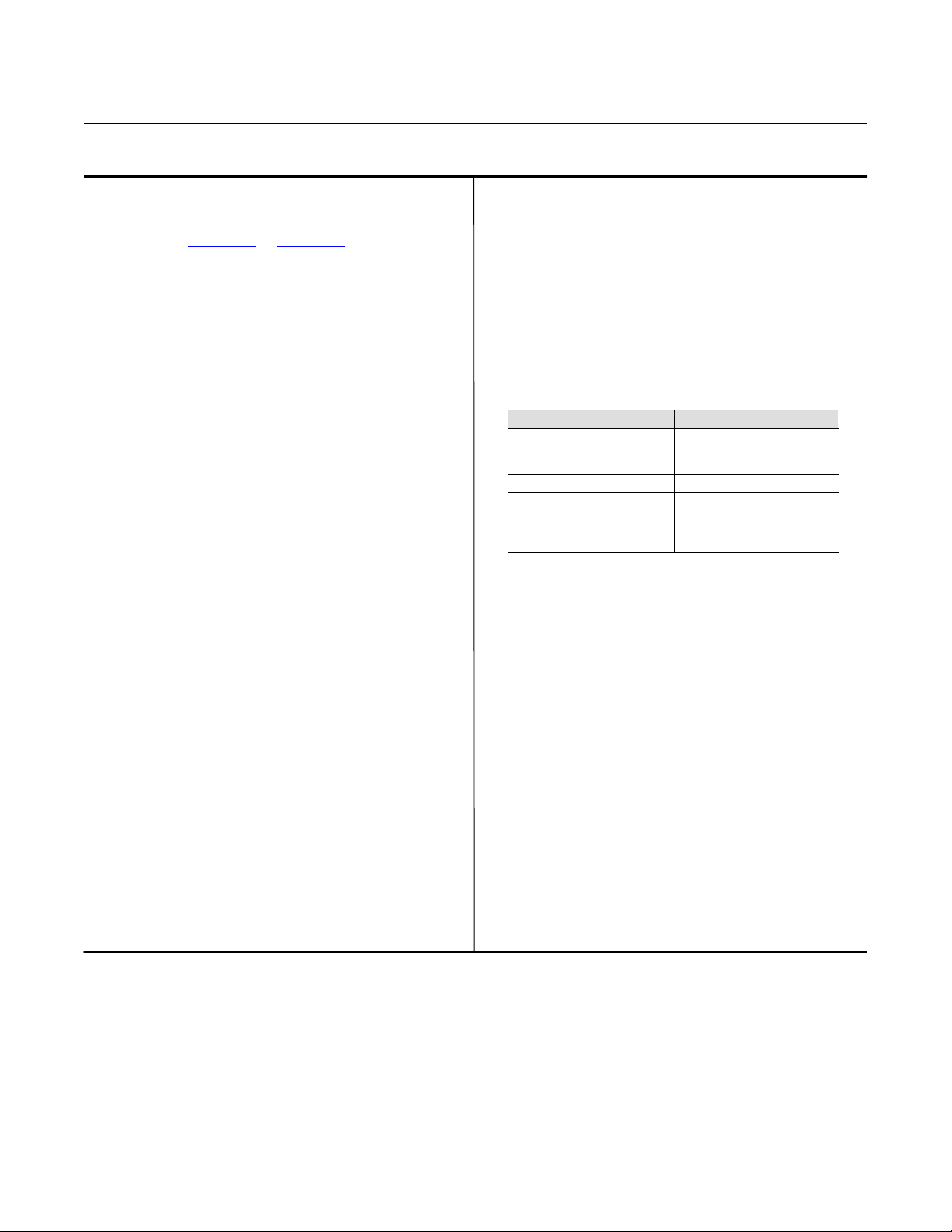

Figure 1. Guidelines for Use of Optional Heat

Insulator Assembly

AMBIENT TEMPERATURE (_C)

010 20

HEAT INSULATOR

REQUIRED

NO HEAT INSULATOR NECESSARY

HEAT INSULATOR

REQUIRED

0 20 40 60 80 100 120 140 160

AMBIENT TEMPERATURE (_F)

-325

PROCESS TEMPERATURE (_F)

400

-40 -30

800

0

1

TOO

COLD

-20 -10

-20-40

STANDARD TRANSMITTER

Notes:

1 For process temperatures below -29_C (-20_F) and above 204_C (400_F)

sensor materials must be appropriate for the process (refer to bulletin

34.2:2500)

2. If ambient dew point is above process temperature, ice formation might

cause instrument malfunction and reduce insulator effectiveness.

39A4070‐B

A5494‐1

30 40 50 60

TOO

HOT

70

80

425

400

300

200

100

0

-100

-200

176

PROCESS TEMPERATURE (_C)

Optional Heat Insulator

Note

If Interface indicate fluid density or SG for both upper and

lower fluids.

4. Tag number, as required _____________________

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher and FIELDVUE are marks owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process

Management, Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective

owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

If the DLC3020f and a 249 sensor are ordered as an

assembly, and a heat insulator is required for the

application, order the heat insulator as a 249 sensor

option. If the DLC3020f is ordered separately, the heat

insulator is available as a kit. Figure 1 contains

guidelines for use of the optional heat insulator.

E 2010, 2014 Fisher Controls International LLC. All rights reserved.

4

Loading...

Loading...