Page 1

4660 Pressure Pilot

D200051X012

Fisherr 4660 High-Low Pressure Pilot

The Fisher 4660 pneumatic high-low pressure pilot

activates safety shutdown systems for flowlines,

production vessels, and compressors. This pilot is

available with either single or dual set point capability,

using switch points to maintain full output pressure

when the process pressure is within the set point

range. If the process pressure is outside this range, the

pilot switches from full output pressure to zero output

pressure.

The primary switching mechanism in this pilot is a

block-and-bleed relay assembly. This construction can

be used in both block-and-bleed and bleed-only

systems.

Unless otherwise noted, all NACE references are to

NACE MR0175-2002.

X0231

Product Bulletin

34.5:4660

January 2014

Features

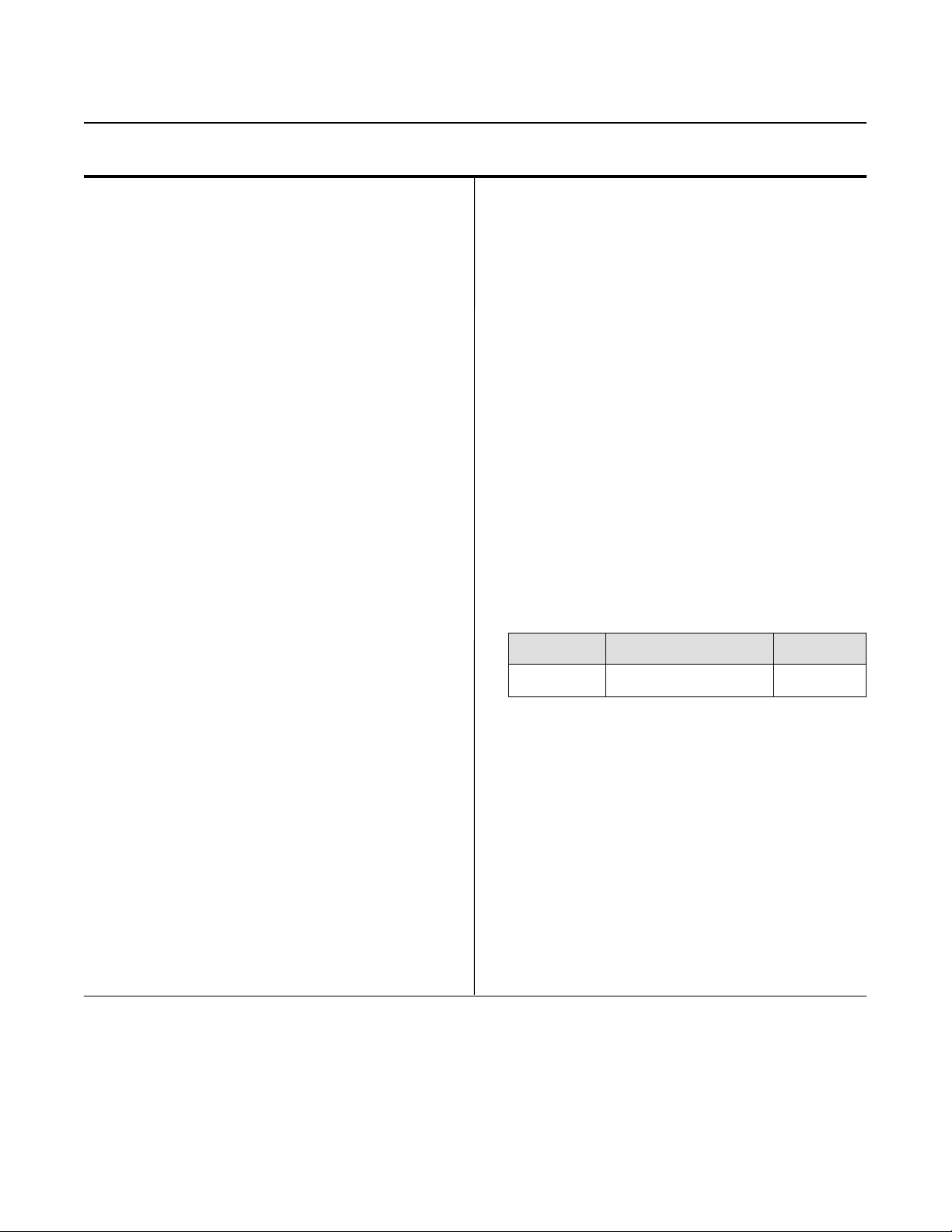

n Safety Certification—The 4660 is certified for use in

Safety Instrumented System (SIS) applications.

Certification is by exida Consulting LLC, a global

provider of functional safety and control system

security (see figure 1). SIS certification is identified

on the product by a label affixed to the case.

The functional safety assessment was performed to

the requirements of IEC 61508: ed2, 2010, SIL3 for

mechanical components.

n Superior Performance—Repeatability meets the U.S.

Minerals Management Service test tolerances

referenced in Outer Continental Shelf (OCS) Order

No. 5 and defined in the American Petroleum

Institute (API) RP14C standard.

n Cost-Effective Design—One pilot provides either a

high-low function or a single switch point,

whichever the application requires.

FISHER 4660 HIGH-LOW PRESSURE PILOT

WITH BLOCK AND BLEED RELAY

Figure 1. exida Certificate

www.Fisher.com

Page 2

Product Bulletin

34.5:4660

January 2014

4660 Pressure Pilot

D200051X012

n NACE Conformance—A NACE compliant Bourdon

tube is available for those applications where the

pilot must meet the requirements of NACE

MR0175-2002.

n Environmental Packaging—Construction materials

have been selected to protect the pilot from

corrosive environments such as the salt spray

atmosphere of offshore platforms.

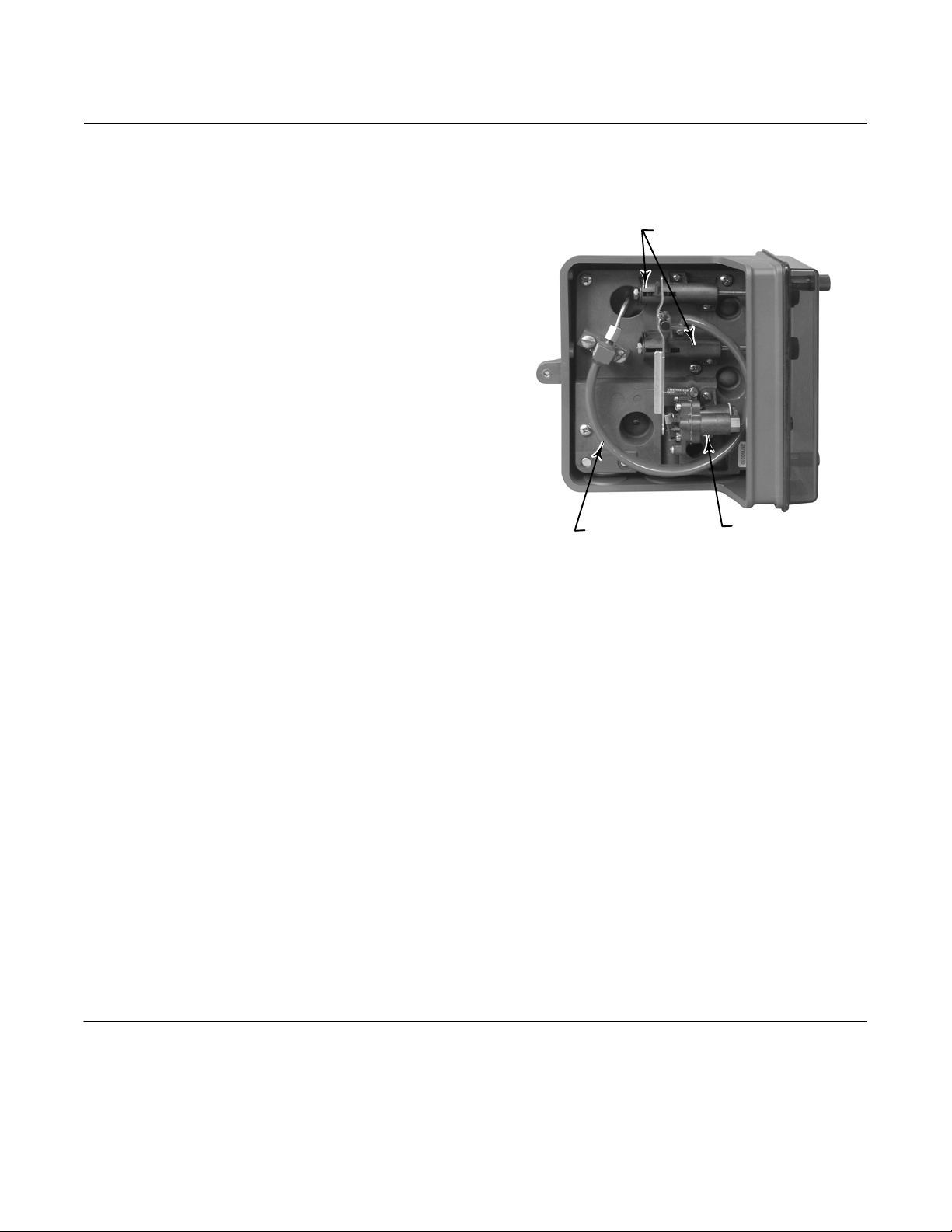

n Reliable Operation—The pilot uses a field-proven

Bourdon tube process pressure sensing element,

shown in figure 2, that reduces maintenance by

eliminating the need for wetted dynamic O-rings.

n Reduced Air/Gas Consumption—The 4660

pneumatic high-low pressure pilot is an energy

efficient choice. The low bleed relay provides a

steady state consumption rate that is less than the

6 SCFH requirement set for the oil and gas industry

by the US Environmental Protection Agency (New

Source Performance Standards Subpart OOOO,

EPA-HQ-QAR-2010-0505).

n Vibration Resistance—The rugged Bourdon tube

sensing element and shock-absorbing switch points

dampen the effects of vibration while maintaining

performance.

n Set Point Accuracy—Standard high-resolution set

point adjustments are easy to set, non-interactive,

and can be locked in place to maintain the desired

set point. The optional set point indication

assemblies on the front panel are easy to read and

let you simply dial in the desired set point.

Figure 2. Fisher 4660 High-Low Pressure Pilot with

Block and Bleed Relay; Left Side with Case Cover Off

SET POINT ADJUSTMENTS

X0232

n Easy Maintenance—Simple modular construction

BOURDON TUBE

BLOCK AND

BLEED RELAY

plus a line of prepackaged parts kits makes pilot

maintenance fast and easy.

n Installation Versatility—Panel, rack, pipestand, or

actuator mounting is available to meet field

requirements.

n Operational Indications—A supply pressure test

function is provided. The optional output indicator

lets you check at a glance whether the pilot output

pressure is at full output or zero output pressure.

Table of Contents

Features 1.....................................

Principle of Operation 6.........................

Performance 6.................................

Applications 7.................................

2

Installation 7..................................

Ordering Information 11.........................

Application 11................................

Construction 11...............................

Page 3

4660 Pressure Pilot

D200051X012

Specifications

Product Bulletin

34.5:4660

January 2014

Available Configurations

J High-low, J low-only, or J high-only set point

capability

Input Signal

Type: Process pressure sensed with a Bourdon tube

Bourdon Tube Ratings: See table 1 or 2

Overpressure Protection: Maximum allowable

emergency process pressures and maximum

allowable process pressures to ensure set point

readjustability are shown in table 3

Output Signal

J Zero pressure or J full supply pressure

(automatically resets)

Supply Pressure

(1)

Normal Operating Pressure: 1.4 to 4.4 bar

(20 to 65 psig)

Medium: Air or natural gas

(2)

Quality: Should be dry with solid particles removed

Steady-State Air Consumption

(3)

Output Signal at 0 psig: ≤0.134 normal m3/hr

(≤5 scfh)

Output Signal at Full Supply Pressure:

≤0.00134 normal m3/hr (≤0.05 scfh)

Exhaust Capacity

≥15

C

g

Construction Materials

Case and Cover: Polyester

Front Cover: Tinted polycarbonate with

scratch-resistant coating

Base: Hard-anodized nickel-sealed aluminum alloy

Bourdon Tube:

J S31600 SST or J NACE compliant

material

Relay Body, Relay Flange, Nozzle/Flapper Assembly

Orifice Block, and Switch Point. Housings: Glass-filled

polyphenylene sulfide

Relay Diaphragm: Fluorosilicone/Polyester

Relay Discs: Fluorosilicone

Process Pressure Block, Tubing, Front Plate, Flapper,

Linkages, and Other Major Metal Parts: Stainless steel

Gaskets: Chloroprene and nitrile

O-Rings.

Relay: Nitrile

Switchpoint Assembly: Nitrile impregnated with

molybdenum disulphide

Base/Case: Nitrile

Operating Conditions

Condition Normal Operating Limits

Ambient

Temperature

(1)

Nominal

Reference

-59 to 71_C (-75 to 160_F) 21_C (70_F)

Set Point Adjustments

Continuously adjustable between 3% and 97% of

Bourdon tube rating; see table 1 or 2 for ranges

Performance in Percentage of Bourdon Tube Rating

Repeatability:

Set Point ΔP

≤0.25%

.

min

(See table 1 or 2)

Single High-Low Unit: 10% for up to 170 bar (2500

psig) Bourdon tubes; 15% for 350, 500, and 700

(NACE) bar (5000, 7500, and 10,000 (NACE) psig)

Bourdon tubes

Low-Only and High-Only Pair: 3%

Trip-to-Reset Zone: ≤1.5% (see table 1 or 2)

Operating Influences on Switch Point Sensitivity

Supply Pressure: ≤0.05% of Bourdon tube rating for a

10% change in supply pressure

Ambient Temperature: ≤2% of Bourdon tube rating

throughout normal operating limits with nominal

reference

Time: ≤1% of Bourdon tube rating over 30 days at

ambient temperature nominal reference

Process Pressure: Range shift or set point drift can

occur if process pressure exceeds the Bourdon tube

rating

Pressure Connections

1/4 NPT internal

-continued-

3

Page 4

Product Bulletin

34.5:4660

January 2014

Specifications (continued)

4660 Pressure Pilot

D200051X012

Mounting

J Panel, J rack, J pipestand, or J actuator

Safety Instrumented System Classification

SIL3 capable certified by exida Consulting LLC

Approximate Weight

Hazardous Area Classification

Complies with the requirements of ATEX Group II

Category 2 Gas and Dust

2.3 kg (5 pounds)

Options

J Visual output indication J stainless steel panel

mounting flange,

J tamper-resistant front cover

NOTE: Specialized instrument terms are defined in ANSI/ISA Standard 51.1 - Process Instrument Terminology.

1. The pressure/temperature limits in this document and any applicable standard or code limitation for valve should not be exceeded.

2. Natural gas to contain no more than 20 ppm of H

3. Normal m

3

/h--Normal cubic meters per hour at 0_C and 1.01325 bar, absolute. Scfh--Standard cubic feet per hour at 60_F and 14.7 psia.

S.

2

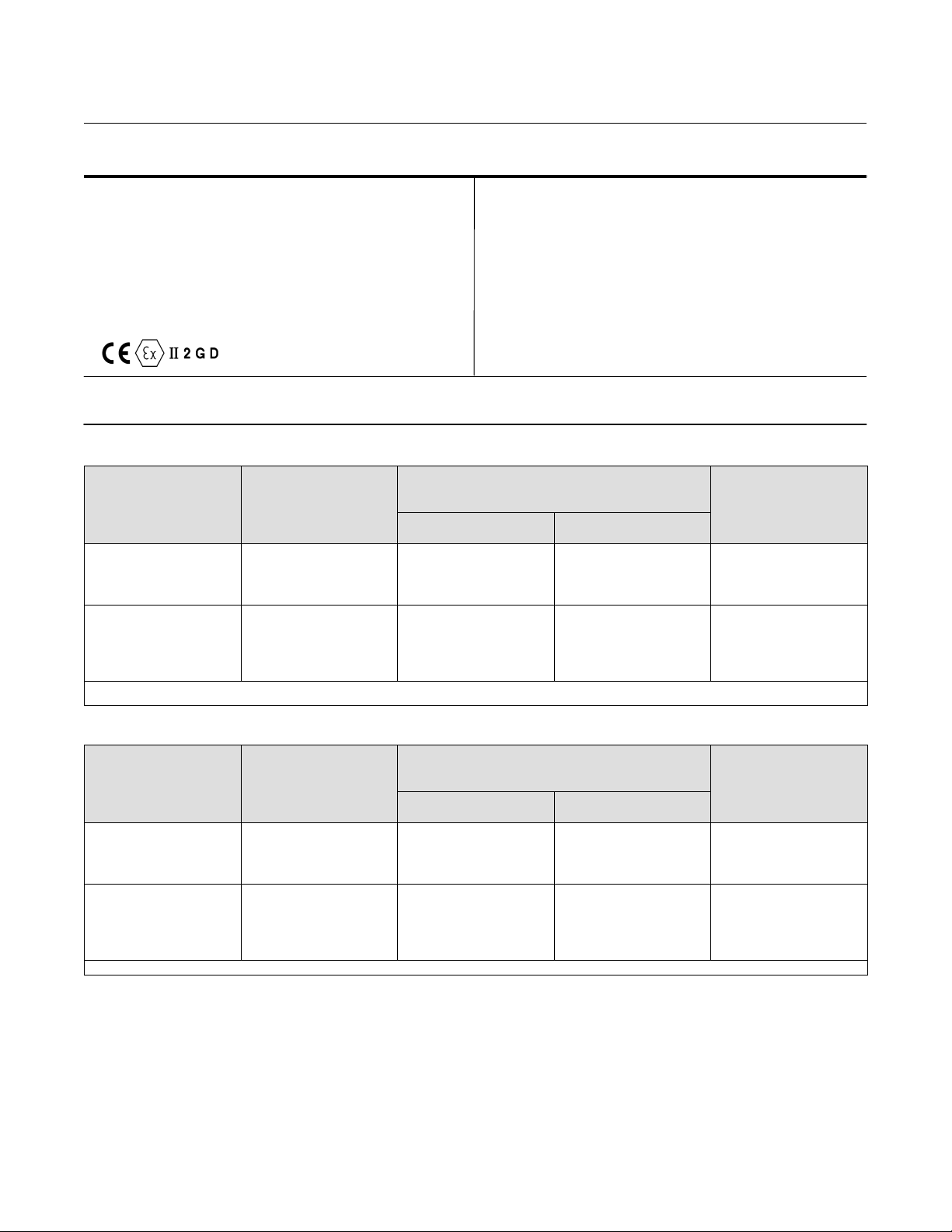

Table 1. Additional Specifications, Bar

BOURDON TUBE

7

17

35

70

100

170

350

500

700

1. Rating indicated on Bourdon tube and set range on front panel are in kPa (1 bar = 100 kPa).

2. Available in NACE compliant material only.

RATING

(2)

(1)

SET RANGE

0.6 to 16.6

1.1 to 33.4

2.1 to 67.9

3.2 to 100.2

5.2 to 167.2

10.4 to 334.4

15.6 to 501.5

20.7 to 668.8

(1)

Single High-Low Unit

0.3 to 6.6

SET POINT ΔP

ALLOWABLE DIFFERENCE

BETWEEN HIGH AND LOW SETTINGS)

0.7

1.7

3.5

6.9

10.3

17.2

51.7

70.7

103.4

(MINIMUM

MIN

J set point indication, and

High-Only/

Low-Only Pair

0.2

0.5

1.0

2.1

3.1

5.2

10.3

15.5

20.7

TRIP-TO-RESET ZONE

≤0.1

0.3

0.5

1.0

1.6

2.6

5.2

7.8

10.3

Table 2. Additional Specifications, Psig

BOURDON TUBE

RATING

100

250

500

1000

1500

2500

5000

7500

(1)

10,000

1. Available in NACE compliant material only.

4

SET RANGE

3 to 97

8 to 242

5 to 485

30 to 970

45 to 1455

75 to 2425

150 to 4850

225 to 7275

300 to 9700

SET POINT ΔP

ALLOWABLE DIFFERENCE

BETWEEN HIGH AND LOW SETTINGS)

Single

High-Low Unit

10

25

50

100

150

250

750

1025

1500

(MINIMUM

MIN

Low-Only Pair

High-Only/

3.0

7.5

15

30

45

75

150

225

300

TRIP-TO-RESET ZONE

≤1.5

3.8

7.5

15

23

38

75

113

150

Page 5

4660 Pressure Pilot

D200051X012

Product Bulletin

34.5:4660

January 2014

Table 3. Maximum Allowable Process Pressure

BOURDON TUBE RATING MAXIMUM ALLOWABLE EMERGENCY PROCESS PRESSURE

(2)

Bar

6.9

17.2

34.5

69.0

103.4

172.4

344.8

517.2

689.5

6.9

17.2

34.5

69.0

103.4

172.4

344.8

517.2

689.5

1. Normal operating process pressures should not exceed the Bourdon tube rating.

2. Ratings indicated on Bourdon tube are in psig and kPa (1 bar = 100 kPa).

3. Values listed for the NACE compliant Bourdon tubes are for a 2% deviation from set point due to overpressure.

Psig

100

250

500

1000

1500

2500

5000

7500

10,000

Maximum Allowable Process Pressure to Ensure Set Point Readjustability

100

250

500

1000

1500

2500

5000

7500

10,000

(1)

Stainless Steel Bourdon Tubes NACE Compliant Bourdon Tubes

(2)

Bar

13.8

34.2

69.0

138.0

206.8

344.8

517.2

646.3

N/A

13.8

34.8

51.7

103.5

155.1

172.4

517.2

646.3

N/A

Psig Bar

200

500

1000

2000

3000

5000

7500

9375

N/A

200

500

750

1500

2250

2500

7500

9375

N/A

13.8

34.2

69.0

138.0

206.8

258.6

430.9

568.8

758.5

(3)

13.8

22.3

53.4

89.7

124.0

227.5

344.8

517.2

689.5

(2)

Psig

200

500

1000

2000

3000

3750

6250

8250

11,000

200

325

775

1300

1800

3300

5000

7500

10,000

5

Page 6

Product Bulletin

34.5:4660

January 2014

Figure 3. Principle of Operation Schematic

4660 Pressure Pilot

D200051X012

LOW SETPOINT

PIVOT

HIGH SETPOINT

PIVOT

BOURDON TUBE

PROCESS PRESSURE

LOW SETPOINT ADJUSTMENT

HIGH SETPOINT

ADJUSTMENT

SPRING

FLAPPER

NOZZLE

BEAM

BLOCK AND BLEED

RELAY ASSEMBLY

SUPPLY PRESSURE

38A3803-A

A2898-2

Principle of Operation

Refer to figure 3.

Process pressure is connected to the Bourdon tube

sensing element. While the process pressure remains

in the adjusted set ranges (between the low set point

and the high set point), the flapper does not contact

either set point pivot. This keeps the nozzle capped

and maintains full output pressure.

As the process pressure decreases below the low set

point value, the radius of arc of the Bourdon tube

contracts. This causes the flapper to contact the low

set point pivot and uncap the nozzle, which blocks

supply pressure and vents (bleeds) output pressure. As

the process pressure increases above the high set

OUTPUT PRESSURE

point value, the radius of arc of the Bourdon tube

extends. This causes the flapper to contact the high set

point pivot, also uncapping the nozzle and providing

block-and-bleed action. When the process pressure

returns to the set range, the nozzle is again capped,

switching the relay back to maintain full output

pressure.

Performance

The performance characteristics discussed in the

Performance in Percentage of Bourdon Tube Rating

specification on page 3 and shown in figure 4

illustrate several important functional parameters.

6

Page 7

4660 Pressure Pilot

D200051X012

Product Bulletin

34.5:4660

January 2014

SL represents the low set point and SH represents the

high set point. The set range capability is 3 to 97

percent of the Bourdon tube rating. However, with a

single high-low unit or a high-only/low-only pair, there

is a limit on how close to each other the set points can

ΔP

be adjusted. This limit is defined as set point

is shown as S

′ and SH′.

L

MIN

and

Trip-to-reset is the combined effect of pilot deadband

and hysteresis. After the pilot has tripped, it

automatically resets when the process pressure

returns to the set range. However, full output pressure

is not instantaneous. The difference between the set

point and reset to full output pressure is the

trip-to-reset zone. This parameter is also a function of

the Bourdon tube rating as shown in figure 4 and

discussed in the Performance in Percentage of

Bourdon Tube Rating specification on page 3.

Repeatability is the switch point deviation around the

set point as a percentage of the Bourdon tube rating.

Applications

Figure 4. Performance Characteristics

TRIP-TORESET ZONE

SET POINT

ΔP

100%

OUTPUT

PRESSURE

A2897-2

PROCESS PRESSURE

MIN

Figure 5 shows some of the many ways in which the

4660 high-low pressure pilot may be connected to

accommodate requirements for single and dual

outputs as well as single and dual process pressure

lines. Examples A and D in figure 5 show how a pair of

high-only and low-only pilots are connected to obtain

closer set points as specified by the set point

ΔP

MIN

values in tables 1 and 2. Example B or C shows

connections for a two-segment flow line configuration

that adheres to API Specification RP14C. Example E

shows a typical connection to an electrical pressure

switch.

Installation

Normal installation is with the pilot mounted vertically

and the connections for process pressure, supply

pressure, and output pressure facing down. The supply

medium should be regulated dry air or natural gas with

solid particles removed.

Figures 6 and 7 illustrate the mounting dimensions

and the location of the pressure connections.

7

Page 8

Product Bulletin

34.5:4660

January 2014

Figure 5. Typical Connection Schematics

PROCESS

SUPPLY

PROCESS

NO. 1

SUPPLY

4660 Pressure Pilot

D200051X012

PROCESS

NO. 2

OUTPUT

38A6085-B

A. HIGH-ONLY AND LOW-ONLY PILOTS

SENSING A SINGLE PROCESS POINT

AND HAVING A SINGLE OUTPUT

OUTPUT TO SUPPLY

SUPPLY

PROCESS NO. 1

C. LOW-ONLY AND HIGH/LOW PILOTS

WITH SINGLE OUTPUT AND

DIFFERENT PROCESS PRESSURES

38A6087-B

OUTPUT

OUTPUT

PROCESS

NO. 2

OUTPUT

OUTPUT

B. LOW-ONLY AND HIGH/LOW PILOTS

WITH DUAL OUTPUTS AND DIFFERENT

38A6084-B

PROCESS PRESSURES

PROCESS

SUPPLY

D. LOW-ONLY AND HIGH-ONLY PILOTS

WITH DUAL OUTPUTS AND

COMMON PROCESS PRESSURE

38A6086-B

OUTPUT

OUTPUT

8

C0584-1

ELECTRICAL

PRESSURE

SWITCH

39A1578-A

OUTPUT

E. HIGH/LOW PILOT INTERFACED

WITH A PRESSURE SWITCH

SUPPLY

PROCESS

Page 9

4660 Pressure Pilot

D200051X012

Figure 6. Panel Mounting Dimensions

Product Bulletin

34.5:4660

January 2014

107

(4.22)

183

(7.22)

FIELD MOUNTING

Note:

All connection are 1/4 NPT.

39A1578-A

18A3804-G

B1589-3

208

(8.19)

130

(5.12)

PANEL MOUNTING

57

(2.25)

28

(1.12)

57

(2.25)

70

(2.75)

RIGHT SIDE VIEW

5/16-UNC-2B

62

(2.44)

212

(8.34)

(7.31)

18A3804-F

A3299-1

186

4

(0.16)

109

(4.29)

117

(4.62)

REAR REMOVAL

98

(3.84)

(0.16)

195

(7.69)

4

5.2

(0.20)

DIAMETER

HOLES

205

(8.06)

(0.16)

4

FRONT REMOVAL

109

(4.29)

117

(4.62)

5.2

(0.20)

DIAMETER

HOLES

195

(7.69)

98

(3.84)

4

(0.16)

mm

(INCH)

9

Page 10

Product Bulletin

34.5:4660

January 2014

Figure 7. Pipestand Mounting Dimensions

OPTIONAL

4660 Pressure Pilot

D200051X012

233.4

(9.19)

184.2

(7.25)

212.9

(8.38)

10B2287-B

B1965

168.1

(6.62)

VERTICAL PIPESTAND

MOUNTING

BOTTOM VIEW

108

(4.25)

SUPPLY CONNECTION

OUTPUT CONNECTION

PROCESS CONNECTION

HORIZONTAL

PIPESTAND MOUNTING

mm

(INCH)

10

Page 11

4660 Pressure Pilot

D200051X012

Product Bulletin

34.5:4660

January 2014

Ordering Information

When ordering, specify:

Application

n Bourdon tube rating and material

n Composition, pressure, and temperature of the

process fluid

n Ambient temperature range

n Description of application

Construction

Refer to the Specifications table. Review the

information under each specification and in the

referenced tables; specify the desired selection

whenever there is a choice to be made.

11

Page 12

Product Bulletin

34.5:4660

January 2014

4660 Pressure Pilot

D200051X012

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process Management,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 1982, 2014 Fisher Controls International LLC. All rights reserved.

12

Loading...

Loading...