Page 1

Product Bulletin

4320 Position Monitor

D103286X012

Fisherr 4320 Wireless Position Monitor

The Fisher 4320 wireless position monitor eliminates

the need for wiring to an on/off pneumatically

actuated valve. It provides a precise wireless feedback

signal to indicate equipment position with a percent

(%) of span plus on/off indication. The 4320 can be

used to control and/or monitor valves, slidingstem

regulators, displacement and float level sensors, and

relief valves. It is designed to be simple to use,

compact, and easily mounted.

The control portion of the 4320 accepts commands

through the wireless network from a control system

and provides a pneumatic on/off signal to an actuator.

The feedback portion of the instrument periodically

reads the position of a measured device and transmits

that data over the wireless network. Transmitted data

includes the percent of span value, limit switch status

indications, valve set point, internal device

temperatures, and power module voltage. It also

checks for service and configuration instructions from

host systems such as distributed control systems

(DCS), asset management systems (AMS), and

supervisory control and data acquisition (SCADA)

systems.

X0535

ON/OFF CONTROL OPTION

62.3:4320

July 2014

The 4320 can be powered by a battery sourced power

module, eliminating the need to install wires. This

makes it easier to design new applications or

implement into retrofit locations. An external power

option is also available. The elimination of levers and

linkages reduces the number of mounting parts and

installation complexity. The autocalibration feature

allows consistent valve feedback.

The 4320 uses a linkage-less feedback design that

eliminates direct contact with the measured device

(e.g., valve, regulator, level, louver, or other devices)

eliminating physical contact and wear. IEC 62591/

WirelessHARTr communication protocol, operating at

2.4 Ghz, is utilized and is approved for use globally.

Instrument calibration and commissioning is

performed with a push button and liquid crystal

display (LCD) interface. This simplicity eliminates the

need for tools or the setting of cams during setup,

saving you time.

Designed to meet intrinsically safe and nonincendive

requirements, this instrument delivers scalable

functionality in a small package. Due to the

energylimiting nature of the design, this intrinsically

safe device is suitable for use in all zone locations. The

battery sourced power module option has no cable

conduits.

www.Fisher.com

Page 2

Product Bulletin

62.3:4320

July 2014

Specifications

4320 Position Monitor

D103286X012

Available Mountings

J Quarter-turn rotary-shaft,

J Sliding-stem, or

J Linear applications

Can also be mounted on other actuators that comply

with IEC 60534-6-1, IEC 60534-6-2, VDI/VDE 3845 and

NAMUR mounting standards.

Input Measurement

Stem Travel (linear movement)

Minimum: 2.5 mm (0.10 inch)

Maximum: 210 mm (8.25 inches)

Shaft Rotation (rotary movement)

Minimum: 45_

Maximum: 90_

Shaft Rotation (rotary movement, arced array)

Minimum: 13_

Maximum: 30_

Measurement Output

Analog: 0-100%

Discrete: on/off switches (2)

Reference Accuracy

1% of span

On/Off Control

Output Signal

Pneumatic signal as required by the actuator, up to

95% of supply pressure

Minimum Span: 3.1 bar (45 psig)

Maximum Span: 7 bar (101 psig)

Action: Single or Double Acting

Supply Pressure

Minimum: 3.1 bar (45 psig)

Maximum: 7 bar (101 psig)

Supply Medium

Air or Natural Gas

Air: Supply pressure must be clean, dry air that

meets the requirements of ISA Standard 7.0.01. The

supply air at the device should have a dew point less

than -20_C (-4_F).

Natural Gas: Natural gas must be clean, dry, oil-free

and noncorrosive. H2s content should not exceed

20 ppm.

-continued-

A maximum 40 micrometer particle size in the air

system is acceptable. Further filtration down to 5

micrometer particle size is recommended.

Lubricant content is not to exceed 1 ppm weight

(w/w) or volume (v/v) basis. Condensation in the air

supply should be minimized.

Air Consumption

(1)

4320

At 5.5 bar (80 psig) supply pressure:

0.036 m

3

/hr (1.27 scfh)

Pilot Valve Leakage

Maximum at 20_C: 8 ml/min (0.0003 scfm/min)

Maximum at -20_C: 800 ml/min (0.028 scfm/min)

Air Capacity / Flow Rate

Supply Pressure: 1.2 Cv

Connections (Optional)

Supply, Output Pressure, and Vent: 1/4 NPT

Wireless Set Point Command

IEC 62591 (WirelessHART) 2.4 GHz DSSS

Local User Interface

Liquid Crystal Display (LCD)

Two pushbuttons for navigation, setup, and

calibration

Communication Protocol

HART 7 and IEC 62591 (WirelessHART)

Maintenance Port Communication Signal

Bell 202 Voltage Signaling: 1200 bps binary

phase-continuous Frequency-Shift-Keying (1220 Hz

mark, 2400 Hz space) superimposed on voltage level

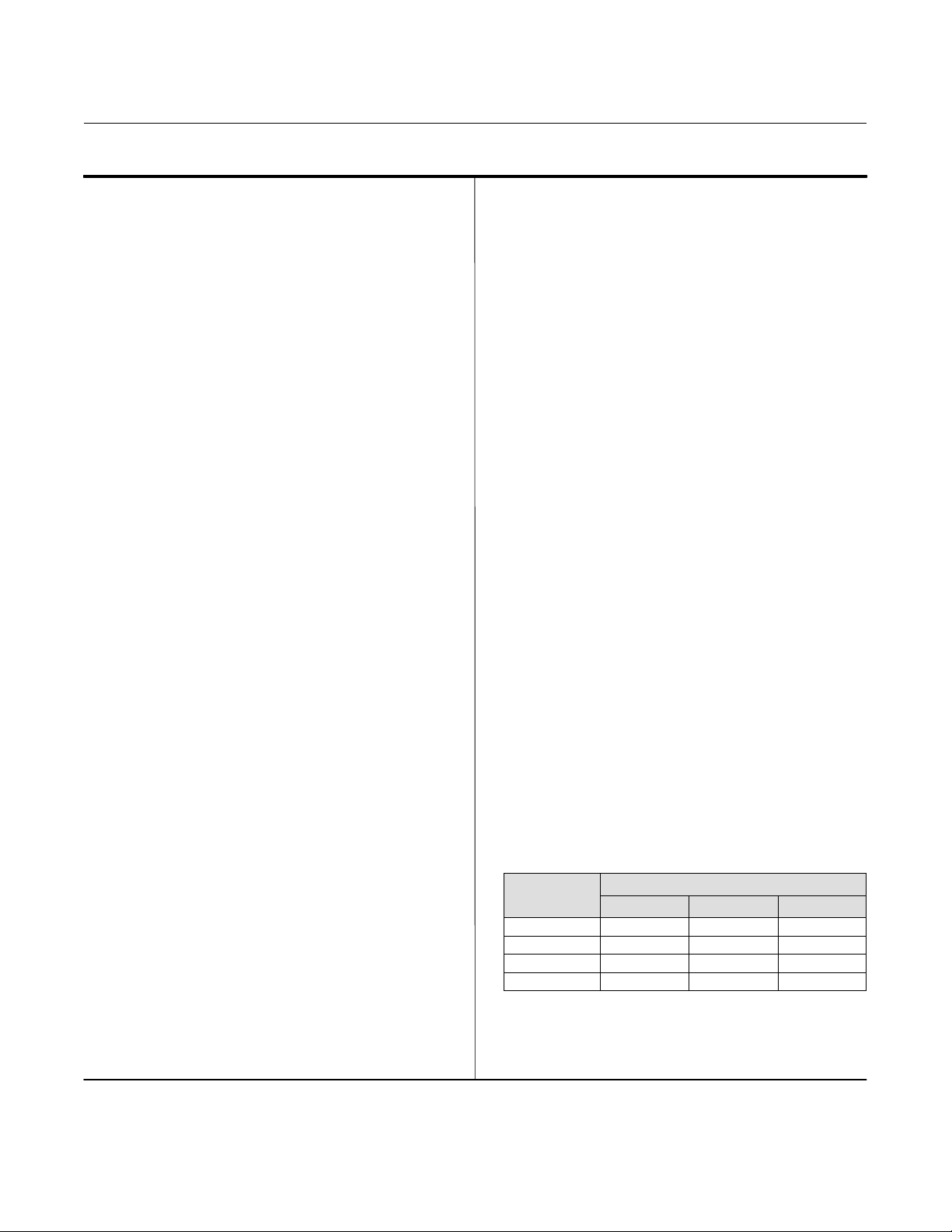

Initial Dynamic Variable Assignments (Default)

Dynamic

Variable

Assignment

Primary (PV) Position Position Position

Secondary (SV) Set Point Set Point Switch States

Tertiary (TV) Switch States Switch States Cycle Counter

Quaternary (QV) Supply Voltage Supply Voltage Supply Voltage

Control Snap Control Monitor

DEVICE STRUCTURE

Wireless Communication Signal

2.4 Ghz, DSSS, IEC 62591 (WirelessHART)

Maximum 10 dBm (10 mW) EIRP at 2.46 GHz

2

Page 3

4320 Position Monitor

D103286X012

Specifications (continued)

Product Bulletin

62.3:4320

July 2014

Wireless Classifications

Class A digital device, complies with part 15 of the

FCC Rules

Contains FCC ID: LW2RM2510

Contains IC: 2731A-RM2510

Electromagnetic Compatibility

Meets EN 61326‐1 (First Edition)

Immunity—Industrial locations per Table 2 of

the EN 61326‐1 standard

Emissions—Class A & B

ISM equipment rating:

Group 1, Class A & B

Vibration Testing

Meets or exceeds vibration levels specified in

ANSI/ISA 75.13.01 1996 (2007):

4 mm peak to peak at 5 Hz,

2 g from 15150 Hz, and

1 g from 150 2000 Hz

European Directive Information

This product complies with the following directives:

ATEX Directive (94/9/EC)

Electro Magnetic Compatibility (EMC) (2004/108/EC)

Radio and Telecommunications Terminal Equipment

Directive (R&TTE) (1999/5/EC)

Refer to the Safety Instructions (D103022X012) for

the Declaration of Conformity

Electrical Classification

CSA (C/US)— Intrinsically Safe

ATEX— Intrinsically Safe

IECEx— Intrinsically Safe

Contact your Emerson Process Management sales

office for classification specific information

Electrical Housing

Type 4X, IP66 & IP67

Other Classifications/Certifications

Customs Union—Russia, Belarus & Kazakhstan

INMETRO—National Institute of Metrology,

Quality and Technology (Brazil)

NEPSI—National Supervision and Inspection Centre

for Explosion Protection and Safety of

Instrumentation (China)

PESO CCOE—Petroleum and Explosives Safety

Organisation - Chief Controller of Explosives (India)

Contact your Emerson Process Management sales

office for classification/certification specific

information

IEC 61010 Compliance

Operating Temperature Limits

(2)

Monitoring

Battery Power: -40 to 85_C (-40 to 185_F)

External Power: -40 to 80_C (-40 to 176_F)

LCD may not be readable below -20_C (-4_F)

With Pnuematic Output (On/Off Control Option):

-20 to 50_C (-4 to 122_F)

Temperature Sensitivity

0.06% change per degree C

Storage Temperature Limits

(2)

-40 to 70_C (-40 to 158_F)

Humidity Limits

10-95% Non‐Condensing Relative Humidity

Meets Pollution Degree 2

Adjustments

Zero and Maximum Span through local interface

Dimensions

See figure 1, 2, and 3

Weight

Monitoring: 0.57 kg (1.25 lbs)

On/Off Control: 1.6 kg (3.4 lbs)

Power Module

Standard —Lithium (non-rechargeable)

-continued-

3

Page 4

Product Bulletin

62.3:4320

July 2014

Specifications (continued)

4320 Position Monitor

D103286X012

Power Module Limits

Standard— 5 years at update rate of 16 seconds or

longer with 3 additional devices communicating

through it

Extended‐Life— 10 years at update rate of 8 seconds

Update Rates

For position feedback, temperature, and power

module voltage—selectable from 1 second to 1 hour;

1s, 2s, 4s, 8s, 16s, 32s, 1 to 60 minutes

or longer with 3 additional devices communicating

through it

Shelf life —10 years (radio off)

Note: Sample rate for position feedback is normally

the same as the update rate.

External Power (Optional)

12 - 28 volts DC

Construction Material

100 mA maximum operating current

Polarity Insensitive

Wire Size— 14-20 gauge

1. Normal m3/hour - Normal cubic meters per hour at 0_C and 1.01325 bar, absolute. Scfh - Standard cubic feet per hour at 60_F and 14.7 psia.

2. The temperature limits in this document and any applicable standard or code limitation for valve should not be exceeded.

Housing: A03600 low copper aluminum alloy

Elastomers: nitrile, fluorosilicone

4

Page 5

4320 Position Monitor

D103286X012

Product Bulletin

62.3:4320

July 2014

Features

n Simplicity— The 4320 is easy to use. The linkageless

feedback system is easy to install with a magnet

array assembled to the valve stem. The 4320 has a

local user interface that will allow you to calibrate

the instrument. The full text display in the local

interface is easy to navigate, in part due to the

selection of languages.

n Quick Installation—Simply attach the 4320, calibrate

and commission to any control system. With the

pneumatic output option, only air is needed to

automate an on/off valve. No conduit easements or

permits are required with the standard or extended

life power modules, thus saving time, costs, and

effort in documenting cable runs and associated

design reviews. Because there is no wiring,

implementation times are shortened for device

installation, setup, and commissioning.

n Energy Efficiency—The optional pneumatic output

has zero steady state air consumption. Air

generation costs can be reduced.

n Reliability—The WirelessHART selforganizing mesh

network provides the high level of communication

reliability required in process control.

n Power Options—More than 5 years operation is

typical using standard life and extended life power

modules. Optional ability to use local 1228 V

power in the field.

n Minimized Maintenance—The feedback design

provides more accurate monitoring and eliminates

physical wearout common in traditional valve

instruments. This results in less frequent

maintenance, repair, and recalibration. Power

modules can be easily replaced without losing

power to the device, using the “hot swap” feature

to maintain network reliability.

n Diagnostics—Predefined device, network, and

system diagnostics provide details on the health of

the device and its ability to communicate. Device

diagnostics include whether the device calibration

has been completed and power module health. The

number of completed cycles is measured for the

monitored equipment.

Note

A cycle is the change from open to closed position or vice

versa. This is determined by moving past the trigger point in

each direction.

n Security—The WirelessHART self-organizing mesh

network includes encryption, authentication, and

authorization mechanisms to provide the level of

security required in process locations and by the

Information Technology (IT) industry.

5

Page 6

Product Bulletin

62.3:4320

July 2014

4320 Position Monitor

D103286X012

Integration

Because the 4320 wireless position monitor operates

with WirelessHART communications it can be used for

incremental monitoring applications. This replaces

manual efforts to audit or verify equipment position

during normal operations, such as startup and

shutdown situations, product changeover, product

isolation, and sampling activities.

One implementation method can be accomplished

using an overlay approach; adding wireless

instrumentation on top of existing instrumentation.

This preserves the existing infrastructure and enables

improved information for operation, reactiveness,

maintenance, and safety.

A second approach is to replace older limit switches

and position transmitters, either because of increased

maintenance requirements or dated wiring

infrastructure that has become or is believed to

become an operational concern.

A third approach is to use the 4320 where feedback is

not possible with standard wired options. For example,

on rotating equipment, where the elimination of wires

makes feedback possible.

and provides a pneumatic on/off signal to an actuator.

The internal electronics periodically reads the position

of travel and transmits that data over the wireless

network. The device also checks for instructions from

host systems like DCS, SCADA and asset management

systems. The device “sleeps” until the next reading,

enabling longer power module life. The device is still

powered up in the sleep mode but operating at

ultra-low power consumption levels.

Setup/Installation

Device setup is typically performed prior to installation

and includes setting two network parameters. These

parameters are entered using a handheld such as the

475 or 375 Field Communicator. Calibration is

performed after installation and requires using the

local interface to place the device at the end points of

travel range. The device is then ready for

commissioning and service.

The wireless nature of this device leads to its

implementation in a wide range of systems, from

programmable logic controllers (PLC), to DCS, AMS,

and SCADA systems.

System integration for typical in-plant operations is

available through the Smart Wireless 1420 Gateway.

Principle of Operation

The control portion of the 4320 accepts commands

through the wireless network from a control system

Battery Sourced Power

Module Life

The 4320 position monitor uses power efficient

measures to keep energy consumption to a minimum.

However, there is a finite amount of energy within the

power module. The life expectancy of the module is

affected by two things; 1) the reporting rate, and 2)

the number of devices in the network that must

communicate through the 4320 position monitor.

Typical on/off applications will operate effectively at

one minute reporting periods.

6

Page 7

4320 Position Monitor

D103286X012

Product Bulletin

62.3:4320

July 2014

Ordering Information

When ordering, specify:

1. Position monitor control

n Monitoring

n On/off control option

2. Power source

n Battery sourced power module

n External power option

3. Mounting requirements

Feedback sensor and mounting brackets are part of

the mounting.

For rotary movement indicate if mounting

requirements are:

n 90_ NAMUR,

n 90_ ISO mounting, or

For linear movement, indicate travel length:

n 7 mm (1/4 inch),

n 19 mm (3/4 inch),

n 25 mm (1 inch),

n 38 mm (1-1/2 inch),

n 50 mm (2 inch),

n 100 mm (4 inch), or

n 210 mm (8-1/4 inch) strokes

Note

As a general rule, do not use less than 50% of the magnet

assembly for full travel measurement. Performance will

decrease as the assembly is increasingly subranged.

Contact your Emerson Process Management sales

office if longer travel lengths are required.

Note

Contact your Emerson Process Management sales office if

mounting on non-Emerson valves is required.

n 30_ for special applications

7

Page 8

Product Bulletin

62.3:4320

July 2014

Figure 1. Dimensions

18.8

(0.74)

172

(6.79)

136.7

(5.38)

17

(0.67)

4320 Position Monitor

D103286X012

89.8

(3.54)

39.9

(1.57)

50

(1.97)

51.1

(2.01)

6X M6 - 1

13 mm MAXIMUM

ALLOWABLE THREAD

ENGAGEMENT

17.68

(0.70)

69.4

(2.73)

19.9

(0.78)

67

(2.64)

19.9

(0.78)

11

(0.44)

11

(0.44)

128.9

(5.08)

91.7

(3.61)

ANTENNA SHOWN

VERTICAL

50

(1.97)

GE41356-C

8

17.68

(0.70)

46.72

(1.84)

35.36

(1.39)

46.72

(1.84)

35.7

(1.40)

35.36

(1.39)

35.7

(1.40)

ANTENNA SHOWN

HORIZONTAL

mm

(INCH)

Page 9

4320 Position Monitor

D103286X012

Figure 2. Dimensions with On/Off Control Option

Product Bulletin

62.3:4320

July 2014

18.8

(0.74)

6.6

(0.26)

51.1

(2.01)

6X M6 - 1

13 mm MAXIMUM

ALLOWABLE THREAD

ENGAGEMENT

197.3

(7.77)

136.7

(5.38)

97.6

(3.84)

1/4-18 NPT

SUPPLY

97.6

(3.84)

17.68

(0.70)

41.8

(1.65)

69.4

(2.73)

19.9

(0.78)

67

(2.64)

19.9

(0.78)

11

(0.44)

11

(0.44)

128.9

(5.08)

91.7

(3.61)

89.8

(3.54)

39.9

(1.57)

ANTENNA SHOWN

VERTICAL

50

(1.97)

50

(1.97)

17.68

(0.70)

10.8

(0.43)

2X 1/4-18 NPT

TO ACTUATOR

GE59669

10.7

(0.42)

46.72

(1.84)

35.36

(1.39)

46.72

(1.84)

35.7

(1.40)

35.36

(1.39)

35.7

(1.40)

ANTENNA SHOWN

HORIZONTAL

mm

(INCH)

9

Page 10

Product Bulletin

62.3:4320

July 2014

Figure 3. Dimensions—External Power Option

4320 Position Monitor

D103286X012

ON/OFF CONTROL OPTION

GE59678

42

(1.66)

M20 X 1.5 OR 1/2-14 NPT

CONDUIT CONNECTION

20

(0.79)

60

(2.36)

mm

(INCH)

10

Page 11

4320 Position Monitor

D103286X012

Product Bulletin

62.3:4320

July 2014

11

Page 12

Product Bulletin

62.3:4320

July 2014

4320 Position Monitor

D103286X012

For additional information on the

4320 wireless position monitor,

scan or click the QR code

Neither Emerson, Emerson Process Management, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance

of any product. Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Fisher is a mark owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co. Emerson Process Management,

Emerson, and the Emerson logo are trademarks and service marks of Emerson Electric Co. HART and WirelessHART are marks owned by the HART

Communication Foundation. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not

to be construed as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such

products at any time without notice.

Emerson Process Management

Marshalltown, Iowa 50158 USA

Sorocaba, 18087 Brazil

Chatham, Kent ME4 4QZ UK

Dubai, United Arab Emirates

Singapore 128461 Singapore

www.Fisher.com

E 2009, 2014 Fisher Controls International LLC. All rights reserved.

12

Loading...

Loading...