Emerson Fisher 4200 Series, Fisher 4211, Fisher 4212, Fisher 4215, Fisher 4220 Instruction Manual

...Page 1

Instruction Manual

Form 5596

July 2005

4200 Series Transmitters

4200 Series Electronic Position

Transmitters

Contents

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scope of Manual 1. . . . . . . . . . . . . . . . . . . . . . . . .

Description 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Educational Services 4. . . . . . . . . . . . . . . . . . . . . .

Installation 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Connections 7. . . . . . . . . . . . . . . . . . .

Sliding-Stem Actuator Mounting 7. . . . . . . . . . .

Rotary-Shaft Actuator Mounting 7. . . . . . . . . . .

Long Stroke Sliding-Stem Actuator

Mounting Type 585C and 470-16 8. . . . . . . .

Long Stroke Sliding-Stem Actuator

Mounting Type 585CLS and 490 9. . . . . . . .

Electrical Connections 9. . . . . . . . . . . . . . . . . . . . .

Conduit 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field Wiring 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Potentiometer Alignment 12. . . . . . . . . . . . . . . . .

Direct or Reverse Action 14. . . . . . . . . . . . . . . . . .

Operating Information 16. . . . . . . . . . . . . . . . . . . . .

Initial Considerations 16. . . . . . . . . . . . . . . . . . . . .

Transmitter and Position Switch

Conditions 16. . . . . . . . . . . . . . . . . . . . . . . . . .

Normal Operation 16. . . . . . . . . . . . . . . . . . . . . . . .

Calibration 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment Required 17. . . . . . . . . . . . . . . . .

Test Connections to the Field Wiring

Compartment 17. . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter Circuit Zero and Span

Adjustment 17. . . . . . . . . . . . . . . . . . . . . . . . . . .

High and Low Position Switch Adjustment 19. .

Setting the High Position Switch 19. . . . . . . . . .

Setting the High Position Switch

Deadband 19. . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Low Position Switch 19. . . . . . . . . .

Setting the Low Position Switch

Deadband 20. . . . . . . . . . . . . . . . . . . . . . . . . . .

Position Switch Circuit Shutoff 20. . . . . . . . . . . . .

Principle of Operation 21. . . . . . . . . . . . . . . . . . . . .

Transmitter Circuit 21. . . . . . . . . . . . . . . . . . . . . . .

Position Switch Circuit 21. . . . . . . . . . . . . . . . . . . .

Maintenance 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Procedures 23. . . . . . . . . . . . . .

Transmitter Circuit 23. . . . . . . . . . . . . . . . . . . . . .

Position Switch Circuit 23. . . . . . . . . . . . . . . . . .

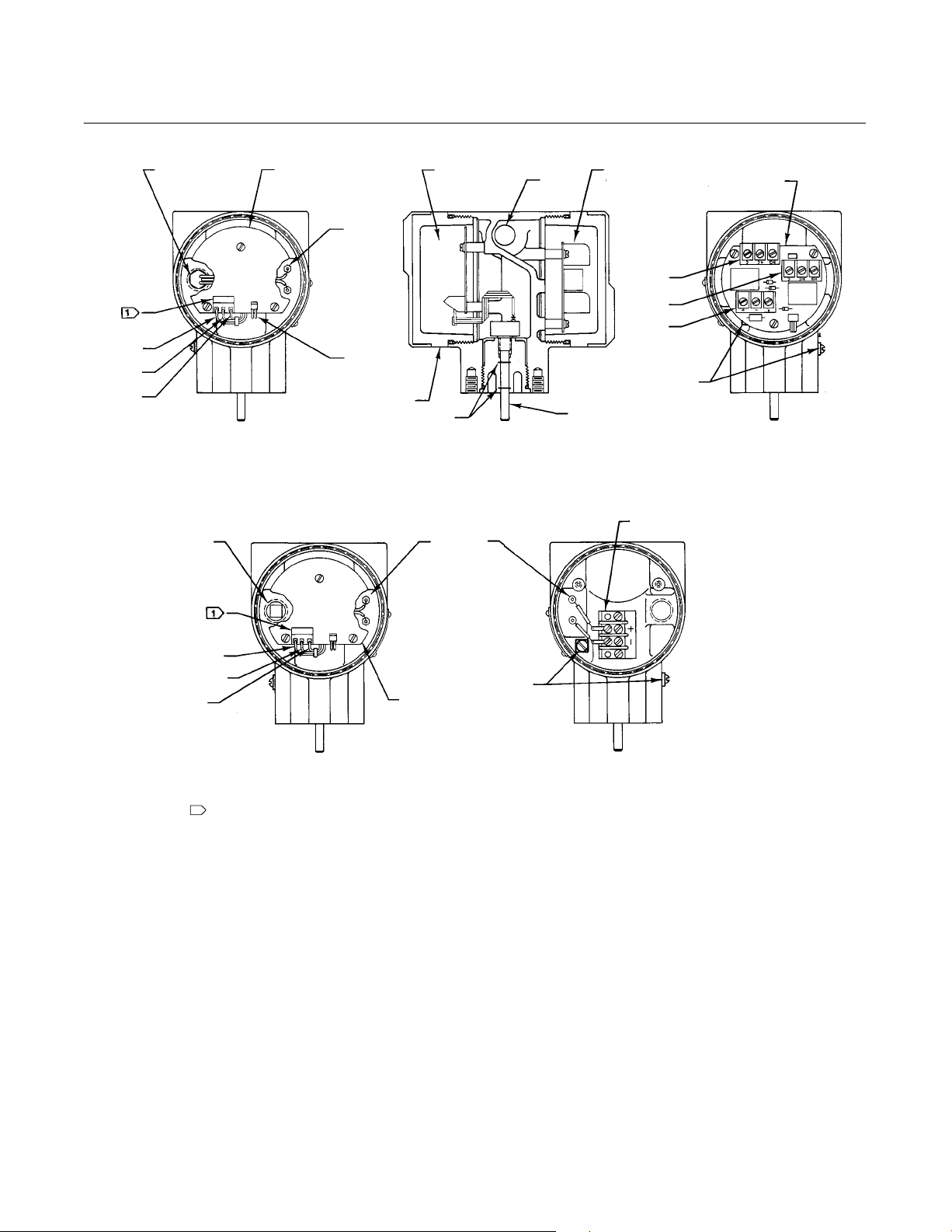

W4273-1

SLIDING-STEM

ACTUATOR MOUNTING

Figure 1. Typical 4200 Series Position Transmitters

Parts Ordering 26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loop Schematics and Nameplates 40. . . . . . . . . .

Introduction

Scope of Manual

This instruction manual provides installation,

operating, calibration, maintenance, and parts

ordering information for the 4200 Series electronic

position transmitters (figure 1). Refer to separate

instruction manuals for information on the actuator

and valve.

W4274-1

ROTARY

ACTUATOR MOUNTING

www.Fisher.com

D200354X012

Page 2

4200 Series Transmitters

Instruction Manual

Form 5596

July 2005

No person may install, operate or maintain a 4200

Series electronic position transmitter without first D

being fully trained and qualified in valve, actuator

and accessory installation, operation and

maintenance, and D carefully reading and

understanding the contents of this manual. If you

have any questions about these instructions, contact

your FisherR sales office.

Note

Neither Emerson

R

, Emerson Process

Management, Fisher, nor any of their

affiliated entities assumes

responsibility for the selection, use

and maintenance of any product.

Responsibility for the selection, use

and maintenance of any product

remains with the purchaser and

end-user.

Description

The 4200 Series electronic position transmitters

combine Fisher’s field-proven electronic and

mechanical expertise in a versatile, accurate

instrument. It senses the position of a sliding stem

actuator, rotary actuator, vent, damper, or other

device and sends a standard (4 to 20 milliampere)

output signal to an indicating device, a process

control system or programmable logic controller. The

4200 Series transmitters are available as a

transmitter only, as a transmitter with integral high

and low position switches, or with high and low

position switches only. Refer to the nameplate to

determine the type of transmitter. Use the Type

number and table 2 to determine the output and

travel ranges available from the transmitter.

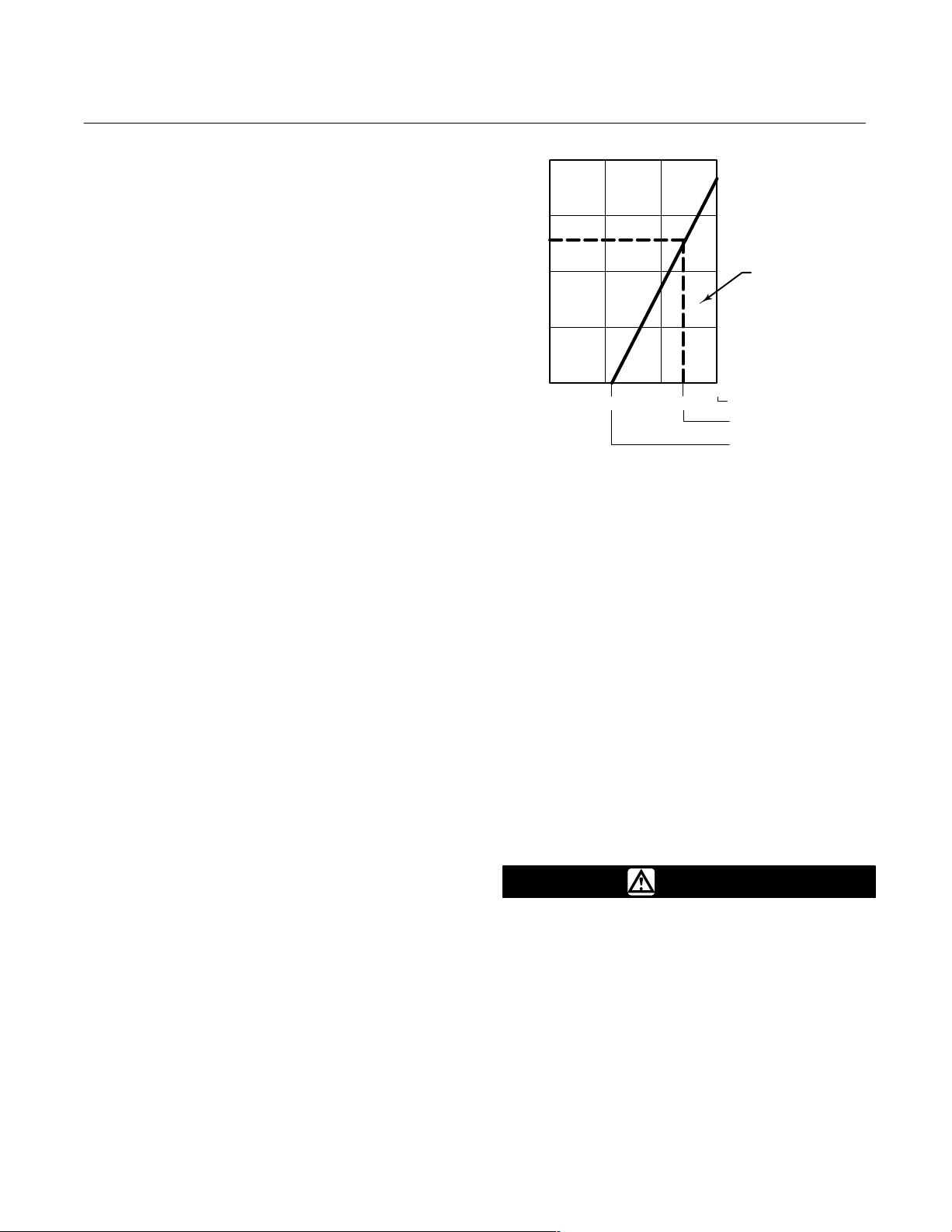

1000

750

650

500

250

LOAD IMPEDANCE (OHMS)

0

0

POWER SUPPLY VOLTAGE (VOLTS dc)

A6765/IL

10

11

Figure 2. Power Supply Requirements

24

OPERATING

REGION

3020

MAXIMUM TRANSMITTER

TERMINAL VOLTAGE

NOMINAL SUPPLY

VOLTAGE

MINIMUM TRANSMITTER

TERMINAL VOLTAGE

For instruments equipped with position switches, the

high relay position switch can be set at any point of

travel. The low relay position switch can be offset

from the high relay position switch trip point by as

little as 1/20 of the travel. In the event of a power

loss both position switch relays de-energize,

indicating loss of transmitter power.

Specifications

Specifications for the 4200 Series transmitters are

listed in table 1.

When the instrument is mounted, the potentiometer

shaft (figure 3) is mechanically connected to the

device to sense mechanical motion. Except for the

Type 4215 transmitter, all types of transmitters use a

single potentiometer for position input. The Type

4215 transmitter uses dual potentiometers mounted

on the same shaft. This permits using individual

potentiometers for the transmitter and the position

switch circuits, providing additional electrical

isolation. For long stroke applications, a multi-turn

potentiometer attached to a cable/pulley assembly

senses linear motion of the actuator stem or other

device.

2

WARNING

This product is intended for a specific

current range, temperature range and

other application specifications.

Applying different current, temperature

and other service conditions could

result in malfunction of the product,

property damage or personal injury.

Page 3

Instruction Manual

(mA)

Form 5596

July 2005

4200 Series Transmitters

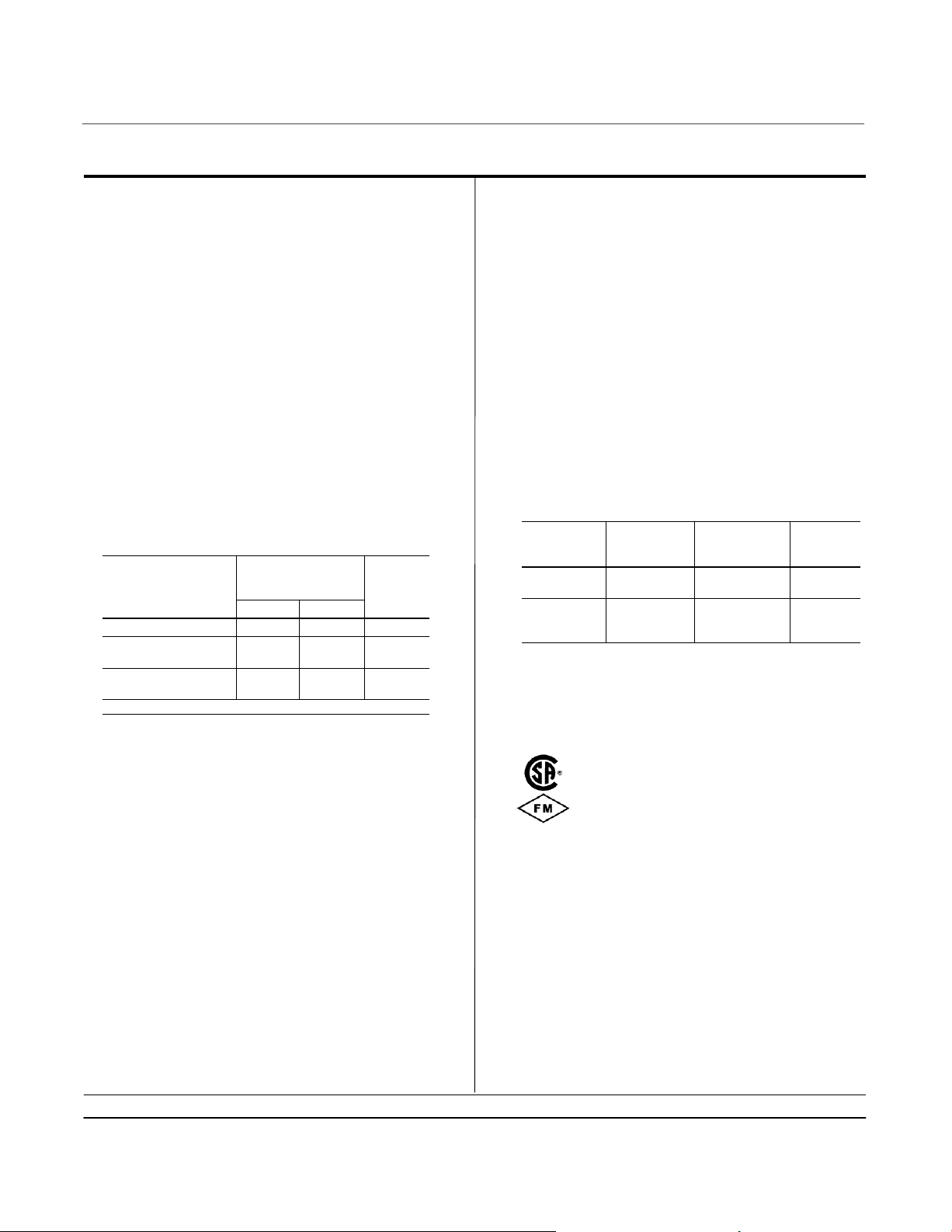

Table 1. Specifications

Available Configurations

See table 2

Input Signal

(1)

Source: Single potentiometer is standard or a

dual potentiometer is available for the Type 4215

only. Refer to table 3 for zero and span limits

Output Signal

Range

(1)

(1)

: 4 to 20 milliampere dc transmitter

output (Type 4210, 4211, 4215, 4220, and 4221

transmitters)

Load Impedance (transmitter only)

(1)

: See

figure 2.

Output Current Limit: 30 milliamperes dc

maximum

Switches: ON/OFF condition of high and low

position switch relay (SPDT)

Power Supply Requirements

Transmitter

Terminal Voltage

(Vdc)

Min Max

Transmitter Only 11 30 20 max.

Position Switch with

Transmitter

Position Switch without

Transmitter

1. Values indicate minimum power supply capabilities.

20 30 80 max.

20 30 50 max.

Current

Required

Operating Influences

Ambient Temperature

(1)

(1)

: For a 56_C (100_F)

change in normal operating conditions, maximum

zero shift is ±0.5%; maximum span shift is

±0.75% of span

Power Supply: Output signal changes less than

±0.1% when operating terminal voltage varies

between 11 and 30 volts dc

Electromagnetic Interference (EMI)

(1)

: Tested

per IEC 61326-1 (Edition 1.1). Conforms to the

European EMC Directive. Meets emission limits

for class A equipment (industrial locations) and

class B equipment (domestic locations). Meets

immunity requirements for industrial locations

(Table A.1 in the IEC specification document).

Immunity performance shown in table 4.

Operating Conditions

Condition

1

Ambient

Temperature

Ambient

Relative

Humidity

(−40 to 160_F)

(1)

Normal and

Operative

Limits

−40 to 71_C

10 to 95% 10 to 95% 40%

Transportation

and Storage

Limits

−50 to 71_C

(−60 to 160_F)

Normal

Reference

25_C

(77_F)

Mounting

The instrument can be mounted on the actuator of

sliding stem or rotary valves or on other devices

Recommended Power Supply

24 volts dc nominal

Position Switch Relays

Type: Two single-pole, double-throw relays

(SPDT)

Service Rating: The relay contact rating is 5

amperes at either 30 volts dc or 120 volts ac

(resistive load)

Life Expectancy: 100,000 operations at rated

load, or 50,000 operations at a typical inrush

current of 10 amperes with 120 volts ac lamp or

motor load

Reference Accuracy

±1% of output span. Includes combined effects of

hysteresis, linearity, and deadband

Repeatability

(1)

±0.25% of span

1. These terms are defined in ISA Standard S51.1.

Electrical Classification

Explosion proof, Dust-Ignition proof,

Intrinsically Safe

Explosion proof, Dust-Ignition proof,

Intrinsically Safe

APPROVED

ATEX

Intrinsically Safe and Type n

Refer to tables 5 and 6, figures 24, 25, 26, 27,

and 28, and the Hazardous Area Classification

bulletins 9.2:001 series and 9.2:002 for

additional information and/or approvals.

Housing

NEMA 4X; CSA Enclosure 4; IP66

Approximate Weight

Transmitter Without Mounting Bracket: 1.8 kg

(4 pounds)

3

Page 4

4200 Series Transmitters

ELECTRICAL

POTENTIOMETER

CONNECTION

TYPE

CONNECTION

(1)

Zero

Zero

Zero

4211

0 to 90

15

90

4221

0 to 884

150

884

Enclosure

l

I/O signal/control

Table 2. Available Configurations

TYPE

NUMBER

4210

4211

4212

4215

4220

4221

4222

1. See table 3 for zero and span limits.

TRANSMITTER

X

X

− − −

X

X

X

− − −

POSITION

SWITCHES

X

− − −

X

X

X

− − −

X

Standard Stroke

Up to 105 mm

(Up to 4.125 Inches)

(1)

X

X

X

X

− − −

− − −

− − −

TRAVEL

Long Stroke

Up to 610 mm

(Up to 24 Inches)

(1)

− − −

− − −

− − −

− − −

X

X

X

Instruction Manual

Form 5596

July 2005

DUAL

POTENTIOMETER

− − −

− − −

− − −

X

− − −

− − −

− − −

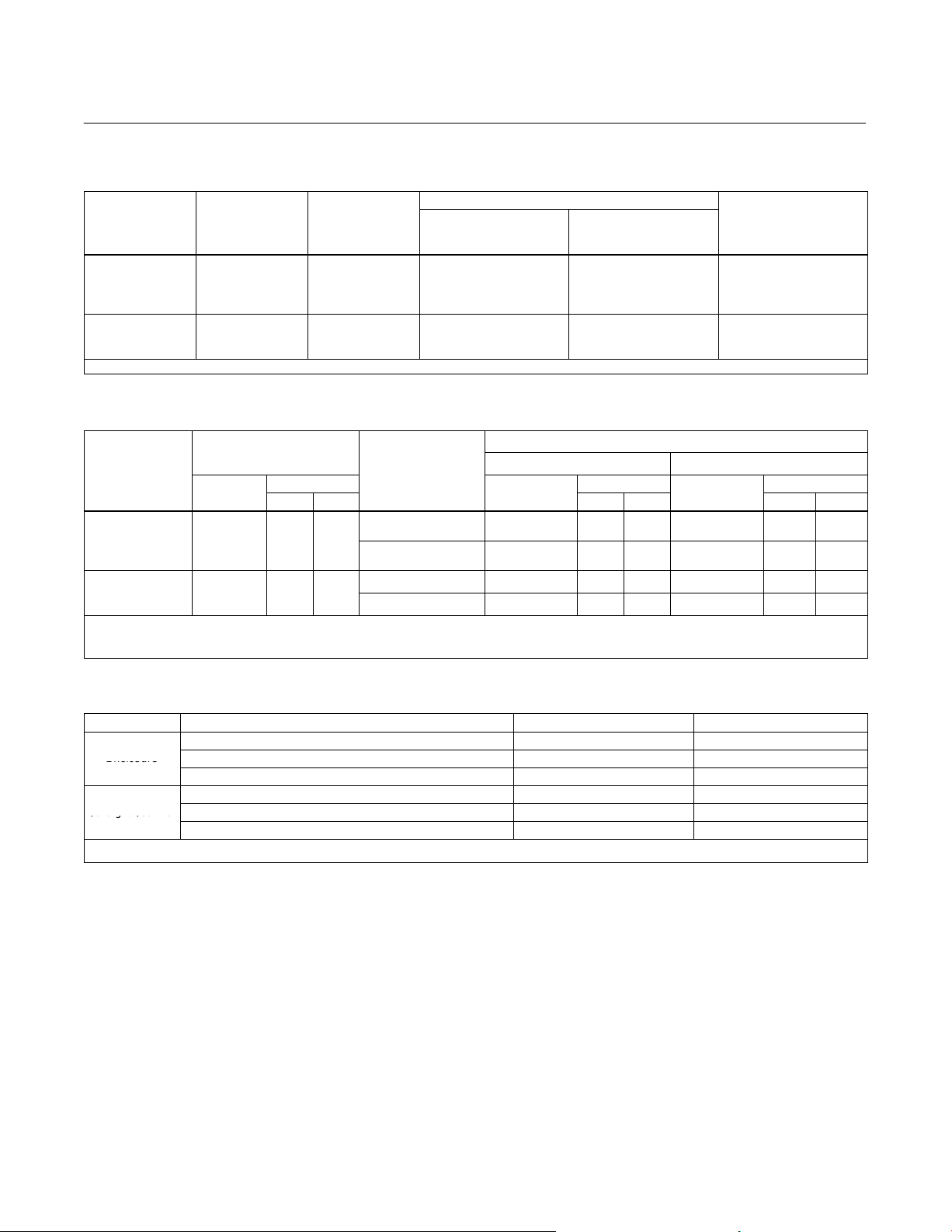

Zero

(2)

SLIDING STEM ACTUATOR TRAVEL

mm INCHES

Span

Min. Max.

Zero

Position

Span

Min. Max.

Table 3. Zero and Span Limits

DEGREES OF

TYPE

NUMBER

4210

4211

4212

4215

4220

4222

1. Refer to figures 15, 22, and 23 for locations of connections.

2. Zero position is the range of values over which the transmitter zero can be adjusted. Span is the range of shaft rotation or stem travel the transmitter span can be adjusted. For

example, a zero position of 45 degrees and a span of 15 degrees means the transmitter output is 4 mAdc after 45 degrees of shaft rotation. The output then increases from 4 mAdc to

20 mAdc as the shaft rotates from 45 to 60 degrees.

Zero

Position

ROTATION

Min. Max.

Span

(1)

Position

1 0 to 51 8 51 0 to 2 0.315 2

2 0 to 105 17 105 0 to 4.125 0.670 4.125

12-Inch Transducer 0 to 305 105 305 0 to 12 4.125 12

24-Inch Transducer 0 to 610 305 610 0 to 24 12 24

Table 4. Immunity Performance

Port Phenomenon Basic Standard Performance Criteria

Electrostatic discharge (ESD) IEC 61000-4-2 A

Enclosure

I/O signal/contro

Specification limit = ±1% of span

1. A = No degradation during testing. B = Temporary degradation during testing, but is self-recovering.

Radiated EM field IEC 61000-4-3 A

Rated power frequency magnetic field IEC 61000-4-8 A

Burst (fast transients) IEC 61000-4-4 A

Surge IEC 61000-4-5 B

Conducted RF IEC 61000-4-6 A

(1)

Educational Services

For information on available courses for 4200 Series

electronic position transmitters, as well as a variety

of other products, contact:

Emerson Process Management

Educational Services, Registration

P.O. Box 190; 301 S. 1st Ave.

Marshalltown, IA 50158−2823

Phone: 800−338−8158 or

Phone: 641−754−3771

FAX: 641−754−3431

e-mail: education@emersonprocess.com

4

Page 5

Instruction Manual

ATEX

Form 5596

July 2005

CERTIFICATION

BODY

CSA

FM

MODEL/

TYPE

4211, 4221

4210, 421 1,

4212, 4215,

4220, 4221,

4222

4210, 421 1,

4212, 4215,

4220, 4221,

4222

4211, 4221

4210, 421 1,

4212, 4215,

4220, 4221,

4222

4211, 4221 Class I Division 2 GP A,B,C,D − − −

4210, 421 1,

4212, 4215,

4220, 4221,

4222

4200 Series Transmitters

Table 5. Hazardous Area Classifications for North America

CERTIFICATION OBTAINED ENTITY RATING

(Intrinsic Safety)

Class/Division

SClass I,II,III Division 1 GP A,B,C,D,E,F,G

per drawing 20B6503

(Explosion Proof)

Class/Division

SClass I, Division 1 GP C,D

Class II Division 1 GP E,F,G

(Intrinsic Safety)

Class/Division

SClass I,II,III Division 1 GP A,B,C,D,E,F,G

per drawing 20B6408

(Explosion Proof)

Class/Division

SClass I, Division 1 GP C,D

Class II Division 1 GP E,F,G − − −

V

= 40 Vdc

max

= 200 mA

I

max

= 5 nF

C

i

= 0 mH

L

i

− − −

− − −

− − −

TEMPERATURE

CODE

TC3 (T

T5 (T

T5 (T

T4A (T

T5 (T

T5 (T

T5 (T

amb

amb

amb

amb

amb

amb

amb

71°C)

71°C)

71°C)

71°C)

71°C)

71°C)

71°C)

ENCLOSURE

RATING

4X

4X

4X

4X

4X

4X

4X

CERTIFICATE

(AGENCY)

ATEX

(LCIE)

MODEL/

TYPE

4211, 4221

4211, 4221

Table 6. Hazardous Area Classifications for Europe and Asia-Pacific

CERTIFICATION OBTAINED ENTITY RATING

(Intrinsic Safety)

II 1 G

Gas

SEEx ia IIC T4/T5

Dust

ST81C (T

71°C)

amb

Ui = 30 Vdc

I

= 150 mA

i

P

= 1.0 W

i

= 5 nF

C

i

L

= 0 mH

i

(Type n)

II 3 G

Gas

SEEx nL IIC T4

Dust

ST81C (T

71°C)

amb

− − −

TEMPERATURE

T4 (T

amb

T5 (T

amb

T4 (T

amb

CODE

71°C)

40°C)

71°C)

ENCLOSURE

RATING

IP66

IP66

5

Page 6

4200 Series Transmitters

Instruction Manual

Form 5596

July 2005

PORT

1/2-INCH NPT

(2 PLACES)

51

51

(2.00)

19A7968−E

B1910−4 / IL

(2.00)

BOTTOM VIEW

5/16-18UNC

13 DEEP

(0.53)

CAP

(2 PLACES)

6 (0.25)

DIA.

END VIEW

Figure 3. Transmitter Dimensions

Installation

WARNING

Always wear protective clothing and

eyewear when performing any

installation operations to avoid

personal injury.

Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

If installing into an existing

application, also refer to the WARNING

at the beginning of the Maintenance

section in this instruction manual.

When the 4200 Series transmitters are ordered with

an actuator, the factory mounts the transmitter and

adjusts the zero and span for the travel specified on

the order. Make field wiring connections as

described in the electrical connections procedure

and fine tune the transmitter to the application. Refer

to the appropriate actuator and valve instruction

manuals to install the attached assemblies.

If the transmitter has been ordered separately, or

removed for maintenance, perform the appropriate

portion of the Mechanical Connections, Electrical

Connections, Potentiometer Alignment, and

Calibration procedures.

The transmitter can be mounted in any of four

positions. Mount the transmitter vertically or

102

(4.00)

67

(2.62)

TRANSMITTER

COMPARTMENT

102

(4.00)

35

(1.38)

75

21

(0.81)

ALLOW 254 mm (10 INCHES)

FOR MAINTENANCE (2 PLACES)

(3.00)

159

(6.25)

67

(2.62)

SIDE VIEW

FIELD WIRING

COMPARTMENT

POTENTIOMETER

SHAFT

mm

(INCH)

horizontally depending on the application

requirements. Refer to figures 15 through 23 for

examples of typical actuator mounting assemblies.

As an aid to installation, and to understand the

transmitter design in general, refer to figure 3 which

shows the location of the transmitter compartment

and the field wiring compartment. The transmitter

compartment contains the transmitter and/or the

position switch circuit on the printed wiring board,

associated wiring assemblies, adjustment

potentiometers, and the potentiometer that senses

position. Remove the cover on the transmitter

compartment to gain access to this compartment.

The transmitter compartment is adjacent to the

symbol on the housing.

Except for a Type 4211 or 4221 transmitter, the field

wiring compartment contains a printed wiring board

with the terminal blocks (figure 4) for connecting field

wiring and associated cable assemblies. It also

contains the position switch relays which are

mounted on the printed wiring board. Remove the

cap adjacent to the + and − symbols on the housing

to access this compartment.

For a Type 4211 or 4221 transmitter without position

switch circuits, the field wiring compartment contains

a barrier strip for installation of the transmitter field

wiring (figure 4).

Figure 3 shows the location of the ports into the field

wiring compartment. Two ports are available for

routing the transmitter and/or position switch wiring

into the transmitter housing. After transmitter

installation, install a plug in the unused port. When

installing the transmitter, allow sufficient space for

6

Page 7

Instruction Manual

Form 5596

July 2005

4200 Series Transmitters

removing the covers to perform maintenance and to

make the wiring connections. Figure 3 also shows

the basic transmitter outline dimensions.

Mechanical Connections

Sliding-Stem Actuator Mounting,

Types 4210, 4211, 4212, and 4215

Use the following general procedures and figures 15,

16, 17, and 18 to mount the transmitter on

sliding-stem actuators, standard stroke up to 105

mm (4.125 inches) travel.

Refer to figure 15 for key number locations for this

example.

1. Install the transmitter on the mounting plate

(key 21) with two cap screws (key 32).

2. Bolt the stem mounting bracket and spacer (keys

34 and 39) to the stem connector on the actuator

stem. Replace the stem connector cap screws with

the two cap screws (key 35) furnished with the stem

mounting bracket.

3. If necessary, refer to the appropriate procedures

in the actuator instruction manual to reconnect the

actuator stem to the valve stem.

4. Fasten the stem bracket (key 33) to the stem

mounting bracket (key 34) with two cap screws

(key 37) centered in the slots of the stem bracket.

Tighten the cap screws slightly.

5. On the transmitter, install the pickup pin into the

lever assembly (key 30) in the position to match the

application. Refer to table 3 and figure 15.

6. Temporarily connect the 24 volt dc power supply

to the instrument as indicated in figure 4.

7. Perform the potentiometer alignment procedures

before mounting the transmitter on the actuator. To

simulate mid-stroke position in step 4 of the

procedure, move the lever assembly (key 30) until its

center line is parallel with the center line of the

operating arm (key 25). After completing step 9 of

the potentiometer alignment procedure, remove the

24 volts dc, and continue the actuator mounting

procedure as described in the following steps.

8. Stroke the actuator to the mid position of the

valve travel.

9. Fit the pickup pin, located in the lever assembly

(key 30), into the horizontal slot in the stem bracket

(key 33). Bolt the mounting plate (key 21) to the

actuator with cap screws, washers, and spacers

(keys 23, 24, and 22) using the two tapped holes in

the side of the actuator yoke.

10. Use the mounting plate slots, which allow the

lever assembly (key 30) and the operating arm

(key 25) to be nearly parallel, and position the long

edge of the mounting plate parallel with the actuator

stem. Tighten the bolts securely.

11. Loosen the two cap screws (key 37) connecting

the stem bracket (key 33) to the stem mounting

bracket (key 34). Manually move the lever assembly

(key 30) until its center line is parallel with the center

line of the operating arm (key 25).

12. Tighten the two cap screws (key 37) in the

slotted holes.

13. Stroke the actuator to ensure that full travel is

allowed.

14. Perform the electrical connection and direct and

reverse action procedures.

15. Verify potentiometer alignment by performing

the potentiometer alignment procedure.

Rotary-Shaft Actuator Mounting,

Types 4210, 4211, 4212, and 4215

Use the following general procedures and figures 19,

20, and 21 to mount the transmitter on rotary-shaft

actuators.

Refer to figure 19 for key number locations for this

example.

1. Install the transmitter on the mounting plate

(key 21) with two cap screws (key 32). The

transmitter can be mounted in any of four positions

on the bracket. Tighten the cap screws slightly.

2. On the actuator, attach the coupler plate

assembly (key 57) and travel indicator to the

actuator shaft. This is accomplished by removing

two self-tapping screws and travel indicator and

replacing them with the self-tapping screws and

coupler plate assembly furnished with the transmitter

for the mounting application.

3. Install the mounting plate (key 21) on the actuator

using the four cap screws and washers (keys 23

and 24). The transmitter and bracket can be

mounted in any of four positions by using the cap

screws (key 23) on the face of the actuator hub.

4. Tighten the cap screws (key 23) slightly while

aligning the potentiometer shaft on the transmitter

with the coupler plate assembly pin (key 57). When

aligned, tighten the four cap screws (key 23).

Maintain this alignment while tightening the two cap

7

Page 8

4200 Series Transmitters

Instruction Manual

Form 5596

July 2005

screws (key 32) holding the transmitter to the

mounting plate (key 21).

5. Slide the coupler (key 52) over the potentiometer

shaft and into the hole in the mounting plate

(key 21). Slide the coupling (key 54) onto the plate

assembly pin and attach the coupling to the plate

assembly pin using the set screw.

6. Slide the coupler (key 52) into the coupling

(key 54). The coupling should not be deflected in

any direction when installed. Do not tighten the

coupling set screw (key 53) as it will be tightened

during the potentiometer alignment procedure.

7. Perform the electrical connections and

potentiometer alignment procedures.

Long Stroke Sliding-Stem Type 585C

and 470-16 Actuator Mounting, Types

4220, 4221, and 4222

Use the following general procedures and figure 22

to mount the transmitter on long stroke sliding-stem

Type 585C and 470-16 actuators with 105 to 206

mm (4.125 to 8.125 inches) travel.

4. Attach the cable transducer housing (key 100A)

to the mounting plate (key 63) using cap screws

(key 103) and hex nuts (key 104).

5. Attach the mounting plate (key 63) to the actuator

using hex head cap screws (key 32). Note: Some

actuators may require spacers (key 101) between

the mounting plate (key 63) and the actuator.

CAUTION

Free release of the cable (key 100B)

will damage the transducer. Whenever

the cable (key 100B) is extended, take

steps to ensure that free release does

not happen.

6. Carefully pull the cable (key 100B) down to the

cable bracket (key 60) and attach it with the socket

head cap screw (key 102), the lock washer (key 83)

and the nut (key 72).

7. Remove the four cap screws (key 100D) and the

mounting plate (key 100C) from the cable

transducer.

8. Mount the mounting plate (key 100C) to the

transmitter using cap screws (key 105).

CAUTION

To avoid damaging the potentiometer

after the transmitter is mounted, do

not stroke the actuator without first

loosening the socket screw set

(key 100F) that fastens the coupling

(key 100E) to the potentiometer shaft

(key 5).

1. Stroke the actuator to mid-stroke.

2. Bolt the cable bracket (key 60) to the stem

connector on the actuator stem. To do this, first

replace the existing stem connector cap screws with

studs (key 78). Slide the cable bracket (key 60) over

the studs (key 78) before installing the nuts (key 71).

Tighten the nuts (key 71).

3. If necessary, refer to the appropriate actuator

instruction manual for the procedure to reconnect

the actuator stem to the valve stem.

9. Verify that the actuator is still in the mid-stroke

position. Loosen the socket cap screws (key 100F)

and rotate the coupling until the socket cap screws

(key 100F) can be accessed with a hex wrench

through one of the openings in the cable transducer

housing (key 100A). Lock the coupling in place by

tightening the inboard socket cap screw (key 100F).

10. Turn the potentiometer shaft (key 5) to the

midpoint of it’s range.

11. Carefully install the transmitter to the cable

transducer housing (key 100A) making sure that the

potentiometer shaft (key 5) slides freely into the

coupling (key 100E) and remains in the midpoint

position. Reinstall the four cap screws (key 100D).

12. Lock the coupling (key 100E) to the

potentiometer shaft (key 5) by tightening the outer

socket cap screw (key 100F).

13. Install the cable cover assembly (key 64) on to

the mounting plate (key 63) with the two machine

screws (key 81). Attach the lower end of the cable

cover assembly (key 64) to the actuator yoke with

the cap screw (key 82). Note: Some actuators may

require additional pieces to fully cover the yoke.

14. Perform the electrical connections.

8

Page 9

Instruction Manual

Form 5596

July 2005

4200 Series Transmitters

Long Stroke Sliding-Stem Type 585CLS

and 490 Actuator Mounting, Types 4220,

4221, and 4222

Use the following general procedures and figure 23

to mount the transmitter on long stroke sliding-stem

Type 585CLS and 491 actuators with 229 to 610 mm

(9 to 24 inches) travel.

CAUTION

To avoid damaging the potentiometer

after the transmitter is mounted, do

not stroke the actuator without first

loosening the socket screw set

(key 100F) that fastens the coupling

(key 100E) to the potentiometer shaft

(key 5).

1. Stroke the actuator to mid-stroke.

2. Bolt the cable clip (key 61) to the stem connector

on the actuator stem. To do this, first replace the

existing stem connector cap screws with a stud (key

35). Slide the cable clip (key 61) over the stud

(key 35) before installing the nuts (key 73). Tighten

the nuts.

3. If necessary, refer to the appropriate actuator

instruction manual for the procedure to reconnect

the actuator stem to the valve stem.

4. Attach the cable transducer housing (key 100A)

to the mounting plate (key 63) using cap screws

(key 103) and hex nuts (key 104).

5. Attach the mounting plate to the actuator using

hex head cap screws (key 75). Note: Some

actuators may require spacers (key 101) between

the mounting plate (key 63) and the actuator.

8. Mount the mounting plate (key 100C) to the

transmitter using cap screws (key 105).

9. Verify that the actuator is still in the mid-stroke

position. Loosen the socket cap screws (key 100F)

and rotate the coupling until the socket cap screws

(key 100F) can be accessed with a hex wrench

through one of the openings in the cable transducer

housing (key 100A). Lock the coupling in place by

tightening the inboard socket cap screw (key 100F).

10. Turn the potentiometer shaft (key 5) to the

midpoint of it’s range.

11. Carefully install the transmitter to the cable

transducer housing (key 100A) making sure that the

potentiometer shaft (key 5) slides freely into the

coupling (key 100E) and remains in the midpoint

position. Reinstall the four cap screws (key 100D).

12. Lock the coupling (key 100E) to the

potentiometer shaft (key 5) by tightening the outer

socket cap screw (key 100F).

13. Install the lower yoke cover (key 69) on to

actuator yoke with pan head machine screws (key

77) and washers (key 86).

14. Perform the electrical connections.

Electrical Connections

Note

For intrinsically safe installations, refer

to loop schematics or to instructions

supplied by the barrier manufacturer

for proper wiring and installation.

Conduit

Install conduit using local and national electrical

codes which apply to the application.

CAUTION

Free release of the cable (key 100B)

will damage the transducer. Whenever

the cable (key 100B) is extended, take

steps to ensure that free release does

not happen.

6. Carefully pull the cable (key 100B) down to the

cable clip (key 61) and attach it with the socket head

cap screw (key 102), the lock washer (key 83) and

the nut (key 72).

7. Remove the four cap screws (key 100D) and the

mounting plate (key 100C) from the cable

transducer.

WARNING

For explosion-proof applications,

install a suitable conduit seal no more

than 460 mm (18 inches) from the

transmitter. Personal injury or property

damage may result from fire and

explosion if the seal is not installed.

Field Wiring

Figure 4 shows typical field wiring connections into

the field wiring compartment. The transmitter is

powered by 24 volts dc. Refer to table 1 to

9

Page 10

4200 Series Transmitters

Instruction Manual

Form 5596

July 2005

determine the power supply requirements. For units

without position switches, the 24 volts dc can be

provided by the receiving device or an external

supply.

For units with position switches, the power supply

provides 24 volt dc power to the position switch

circuit in units without the transmitter, or to both the

position switch circuits and transmitter in units with

the transmitter. A 24 volt dc power supply

independent of the receiving device is

recommended. A separate return is required for the

relays. This prevents relay return currents from

flowing in the transmitter 4 to 20 ma dc current loop.

For the position switch relay wiring, during normal

operating conditions relays K1 and K2 are

energized, which connects the common (C) terminal

to the normally open (NO) terminal (TB1 and TB2,

figure 4). During a tripped (or alarm) condition the

relay is de-energized, which connects the C terminal

to the normally closed (NC) terminal. If power is

removed or lost from the power supply both relays

are de-energized which connects the common (C)

terminals to the normally closed terminals (NC).

CAUTION

Connect the transmitter grounding

terminal (key 58) to an earth ground.

Improper grounding of the position

transmitter can cause erratic

operation.

Before making transmitter or position switch

connections, ensure that the power supply is turned

off. Refer to figure 4 for location of connections.

1. Remove the cover from the field wiring

compartment.

2. Bring the transmitter field wiring and/or position

switch wiring into the housing through one or both of

the ports.

3. Field wiring connections:

(−) terminal of the power supply to the (R)

terminal on TB3. Also connect a wire from the (−)

terminal on the power supply to the negative (−)

terminal of the receiving device. Connect a wire

from the receiving device positive (+) terminal to

the (−) terminal on TB3. Connect a wire from the

(+) terminal on the power supply to the (+)

terminal on TB3. Provide wiring for the position

switch indicating device to match the application.

b. For Type 4212 and 4222 position switches

without a transmitter, connect a wire from the (+)

terminal of the power supply to the (+) terminal

on TB3. Connect a wire from the (−) terminal of

the power supply to the (R) terminal on TB3.

Provide wiring for the position switch indicating

device to match the application.

c. For a Type 4211 or 4221 transmitter without

position switches. Connect a wire from the (+)

terminal of the power supply to the (+) terminal

on the barrier strip (key 11). Connect a wire from

the (−) terminal of the power supply to the

negative (−) terminal of the receiving device.

Connect a wire from the receiving device positive

(+) terminal to the (−) terminal on the barrier strip.

4. Connect the grounding terminal (key 58) to an

earth ground.

5. For a Type 4210, 4212, 4215, 4220, or 4222

instrument with position switches, perform the

following steps to connect the position switch wiring:

a. Connect the high position switch field wiring

from the high indicating device to TB1 on the field

circuit printed wiring board.

Note

On transmitters with position

switches, always make the connection

between the power supply negative (−)

terminal and the (R) terminal on TB3,

even if the position switch outputs are

not used.

a. For a Type 4210, 4215, or 4220 transmitter

with position switches, connect a wire from the

10

b. Connect the low position switch field wiring

from the low indicating device to TB2 on the field

circuit printed wiring board.

6. If only one output port is used, screw the pipe

plug (supplied with the transmitter) into the unused

port.

7. Perform the potentiometer alignment and

direct/reverse action procedures for all applications.

Page 11

Instruction Manual

Form 5596

July 2005

4200 Series Transmitters

FIELD CIRCUIT PRINTED

WIRING BOARD

TB1

GROUNDING

TERMINAL

UNDER PRINTED

WIRING BOARD

TB2

TRANSMITTER

FIELD WIRING

POSITION SWITCH

FIELD WIRING

RELAY RETURN

1

FIELD WIRING

COMPARTMENT

R

3

3

TB3

FOR TYPE 4210, 4215, OR 4220 TRANSMITTER WITH POSITION SWITCHES AND

FOR TYPE 4212 OR 4222 POSITION SWITCHES WITHOUT THE TRANSMITTER

4

EARTH

GROUND

+

POWER

SUPPLY

−

+

DEVICE

RECEIVING

4 TO 20 MA

DC SIGNAL

−

12

DEVICE

RECEIVING LO

POSITION

SWITCH OUTPUT (CONTACT

CLOSURE)

DEVICE

RECEIVING HI

POSITION

SWITCH OUTPUT (CONTACT

CLOSURE)

FIELD WIRING

COMPARTMENT

TRANSMITTER

FIELD WIRING

EARTH

GROUND

GROUNDING

TERMINAL

BARRIER STRIP

(KEY 11)

SAFETY GROUND

FOR TYPE 4211 OR 4221 TRANSMITTER WITHOUT POSITION SWITCHES

NOTES:

1

TYPE 4212 AND 4222 POSITION SWITCHES WITHOUT THE TRANSMITTER CIRCUIT DO NOT REQUIRE A RECEIVING DEVICE OR

THE ASSOCIATED WIRING.

2

RECEIVING DEVICE MAY BE ANALOG CURRENT INPUT TO DISTRIBUTED CONTROL SYSTEM, PROGRAMMABLE LOGIC

CONTROLLER OR INDICATING DEVICE. INDICATING DEVICE CAN BE A VOLTMETER ACROSS A 250 OHM RESISTOR OR A CURRENT

METER.

3

DURING NORMAL CONDITIONS, RELAYS K1 AND K2 ARE ENERGIZED, WHICH CONNECTS THE COMMON (C) TERMINAL TO THE

NORMALLY OPEN (NO) TERMINAL. A TRIPPED (OR ALARM) CONDITION IS WITH THE RELAY(S) DE-ENERGIZED, WHICH CONNECTS

THE COMMON (C) TERMINAL TO THE NORMALLY CLOSED (NC) TERMINAL.

4

SEPARATE RETURN REQUIRED FOR RELAYS. RETURN WIRE MUST BE CONNECTED EVEN IF RELAY OUTPUTS ARE NOT USED.

49A7894-D

49A7892-D

C0601-4/IL

+

POWER

SUPPLY

−

DEVICE

+

RECEIVING

4 TO 20 MA

DC SIGNAL

−

2

Figure 4. Wiring Connections

11

Page 12

4200 Series Transmitters

Instruction Manual

Form 5596

July 2005

Potentiometer Alignment

CAUTION

The following procedure must be

performed prior to calibrating the

transmitter or position switches.

Failure to perform this procedure may

result in erratic performance or unit

failure.

This procedure adjusts the potentiometer to the

center of its electrical travel when the control valve

actuator or other device is at the center of its

mechanical travel.

Refer to the Calibration section for the test

equipment required in this section.

WARNING

3. Loosen the appropriate set screw connecting the

potentiometer shaft to the linkage:

a. For sliding stem applications, loosen the set

screw (key 26, figure 15) in the operating arm

(key 30) on the potentiometer shaft.

b. For rotary actuator applications, loosen the set

screw in the coupling (key 50, figure 19) on the

potentiometer shaft.

c. For long stroke applications, leave the coupler

(key 100E) rigidly attached to the potentiometer

shaft. Loosen only the coupling screw (key 100F,

figures 22 and 23) in the coupler (key 100E) on

the transducer shaft.

4. Stroke the actuator or other device to the

mid-stroke position.

Note

On units with position switches, the

(R) terminal on TB3 must be connected

to the power supply negative (−)

terminal as shown in figure 9 to attain

correct potentiometer alignment.

On an explosion-proof instrument,

remove electrical power before

removing the covers in a hazardous

area. Personal injury or property

damage may result from fire or

explosion if power is applied to the

instrument with the covers removed, in

a hazardous area.

On an intrinsically safe instrument,

current monitoring during operation

must be with a meter approved for

hazardous areas.

Refer to figure 5 for component locations.

1. Remove power from the instrument.

2. Connect the digital voltmeter (DVM) leads as

follows:

a. For all transmitters (except a Type 4212 or

4222) connect between TP3 (+) and TP4 (−) on

the printed wiring board.

b. For a Type 4212 or 4222 transmitter, connect

the DVM between TP5 (+) and TP6 (−).

5. Apply power to the instrument.

6. While the device is in mid-stroke position, insert a

screwdriver blade into the slot in the end of the

potentiometer shaft (see figure 15), or turn the

coupler (key 52, figure 19 or key 100E, figures 22

and 23) to turn the potentiometer shaft until the DVM

reads 1.25 ±0.05 volts dc. This establishes the

electrical center of the potentiometer.

7. Tighten the appropriate set screw. Check that the

DVM reading has remained at 1.25 ±0.05 volts dc.

Note

For sliding stem applications, tighten

the set screw (key 26, figure 15) in the

operating arm (key 30) to a torque of

3.39 to 3.95 NSm (30 to 35 lbfSin).

8. Remove the power from the transmitter power

supply.

9. Remove the DVM leads from TP3 and TP4

(transmitter signal) or TP5 and TP6 (position switch

signal).

10. Refer to the direct or reverse action procedures.

12

Page 13

Instruction Manual

Form 5596

July 2005

4200 Series Transmitters

SPAN

ADJUSTMENT

(R2)

ZERO

ADJUSTMENT

(R1)

TP1

TP4

TP2

HIGH POSITION

SWITCH

ADJUSTMENT (R3)

JUMPER W1

JUMPER W2

TP3

FOR TYPE 4210, 4215, OR 4220 TRANSMITTERS WITH POSITION SWITCHES

SPAN

ADJUSTMENT

(R16)

ZERO

ADJUSTMENT

(R15)

LOW POSITION

SWITCH

ADJUSTMENT (R6)

HIGH POSITION

SWITCH DEADBAND

ADJUSTMENT (R4)

JUMPER W3

LOW POSITION

SWITCH DEADBAND

ADJUSTMENT (R5)

TP6

TP5

39A6156-F

39A7238-E

B1957-3 / IL

TP4

TP2TP3

FOR TYPE 4211 OR 4221 TRANSMITTER WITHOUT POSITION SWITCHES

HIGH POSITION

SWITCH

ADJUSTMENT (R3)

FOR TYPE 4212 OR 4222 POSITION SWITCHES WITHOUT TRANSMITTER

TP1

LOW POSITION

SWITCH

ADJUSTMENT (R6)

HIGH POSITION

SWITCH DEADBAND

ADJUSTMENT (R4)

JUMPER W3

LOW POSITION

SWITCH DEADBAND

ADJUSTMENT (R5)

TP6

TP5

Figure 5. Transmitter Printed Wiring Board Assemblies

13

Page 14

4200 Series Transmitters

Instruction Manual

Form 5596

July 2005

TB1

BROWN

ORANGE

RED

FEEDTHROUGH TRANSMITTER

END VIEW CUTAWAY SIDE VIEW END VIEW

PRINTED WIRING

BOARD

FOR TYPE 4210, 4215, OR 4220 TRANSMITTER WITH POSITION SWITCHES

AND FOR TYPE 4212 OR 4222 POSITION SWITCHES WITHOUT THE TRANSMITTER

PLUG

TB1

RFI

FILTER

WIRES

FROM

RFI FILTER

CAP

O-RINGS

TRANSMITTER

COMPARTMENT

RFI FILTER

PORT

POTENTIOMETER

SHAFT

FIELD WIRING

COMPARTMENT

TB2

TB1

TB3

GROUNDING

TERMINALS

BARRIER STRIP

(KEY 11)

FIELD CIRCUIT PRINTED

WIRING BOARD

BROWN

ORANGE

RED

TRANSMITTER

PRINTED WIRING

BOARD

FOR TYPE 4211 OR 4221 TRANSMITTER WITHOUT POSITION SWITCHES

NOTES:

1

49A7894-C

49A7892-D

C0602−4 / IL

WIRES CONNECTED TO TB1 ARE SHOWN IN THE COLOR SEQUENCE FOR DIRECT

ACTION. FOR REVERSE ACTION, THE COLOR SEQUENCE IS RED, ORANGE, AND BROWN

(FROM LEFT TO RIGHT).

Figure 6. Instrument Assembly Details

Direct or Reverse Action

Direct action means, when looking at the slotted end

of the potentiometer shaft, a clockwise rotation of the

shaft produces an increasing output signal from the

transmitter.

Reverse action means, when looking at the slotted

end of the potentiometer shaft, a clockwise rotation

of the shaft produces a decreasing output signal

from the transmitter.

GROUNDING

TERMINALS

The transmitter produces a direct or reverse action

output signal depending on the location of the

potentiometer wires inserted in terminal block

number 1 (TB1) mounted on the transmitter printed

wiring board. Refer to figure 6 for the location of the

wires and the wire color sequence for direct action.

For reverse action, exchange the positions of the

brown and red wires.

14

Page 15

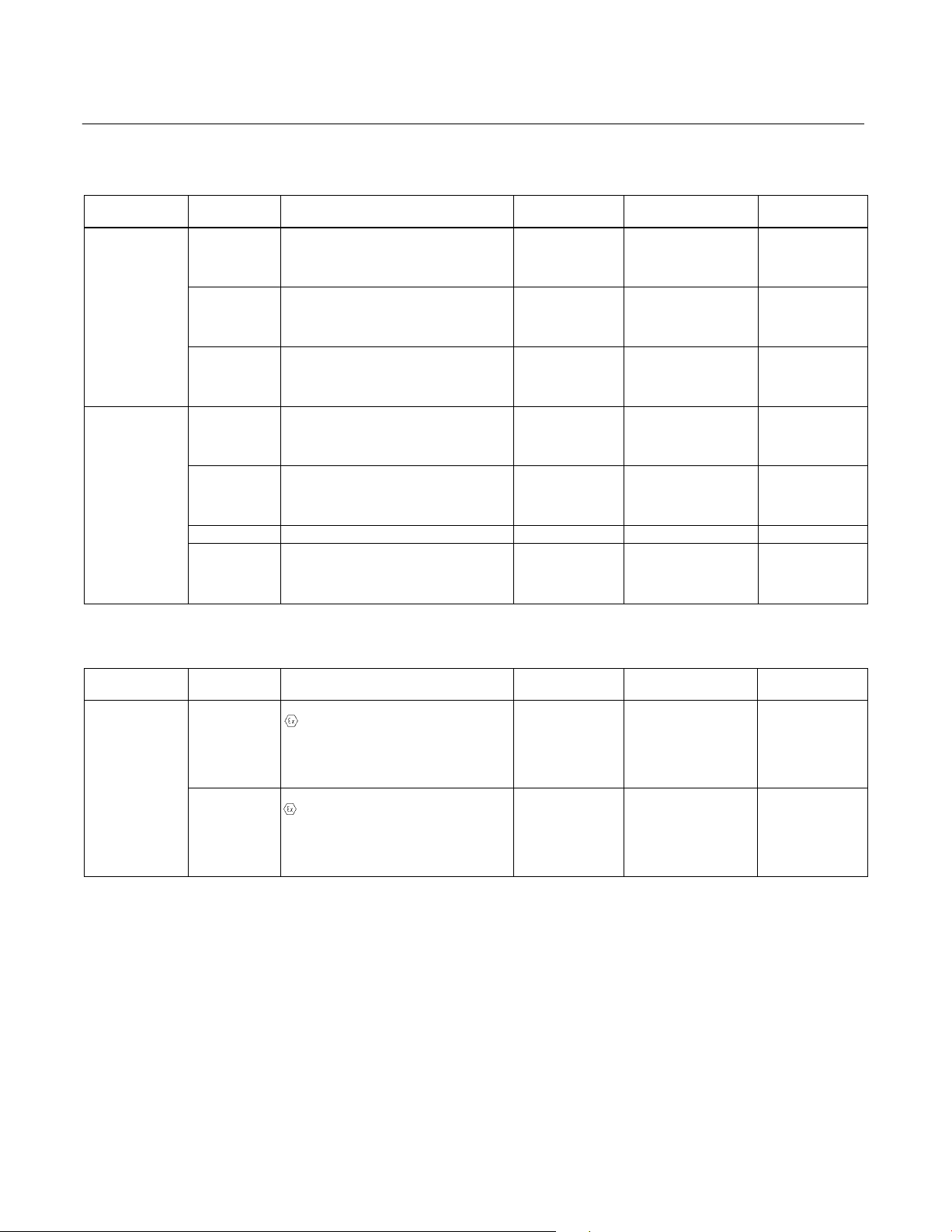

Instruction Manual

A,D

Direct

B,C

4210

A,D

Reverse

B,C

A,D

Direct

N/A

4212

B,C

A,D

Direct

B,C

4215

A,D

Reverse

B,C

Direct

− − −

4210

4220

Reverse

− − −

Direct

− − −

4222

Direct

− − −

4215

Reverse

− − −

Form 5596

July 2005

FOR ROTARY ACTUATORS

Type

Transmitter

Action

Actuator Style

4212

Reverse Not available for position switches without transmitter

4211 Not required for transmitter without position switches

4210

4220

4212

Reverse Not available for position switches without transmitter

4211,4221 Not required for transmitter without position switches

1. Viewed from the potentiometer shaft end.

Actuator Stem

Travel

Down CW 20 Hi

Up CCW 4 Lo

Up CW 20 Hi

Down CCW 4 Lo

Up CCW 20 Hi

Down CW 4 Lo

Down CCW 20 Hi

Up CW 4 Lo

Down CW Hi

Up CCW

Up CW

Down CCW Lo

Down CW 20 Hi

Up CCW 4 Lo

Up CW 20 Hi

Down CCW 4 Lo

Down CS 4 Hi

Up CCW 20 Lo

Up CW 4 Hi

Down CCW 20 Lo

FOR SLIDING STEM ACTUATORS

Down CW 20 Hi

Up CCW 4 Lo

Up CCW 20 Hi

Down CW 4 Lo

Down CW N/A Hi

Up CCW N/A Lo

Down CW 20 Hi

Up CCW 4 Lo

Down CW 20 Hi

Up CCW 4 Lo

4200 Series Transmitters

Input Potentiometer

Rotation

(1)

Transmitter

Current Output,

Milliampere

Set Position Switch

Lo

Hi

NOTES:

1

WHEN USING THE COMMON (C) AND THE

NORMALLY CLOSED (NC) TERMINAL

CONNECTIONS, THE CONTACTS WILL BE CLOSED

WHEN THE RELAY COIL IS DE-ENERGIZED.

A3787 / IL

Figure 7. Transmitter and Position Switch Conditions

ACTUATOR TRAVEL

UP OR DOWN

REFER TO TABLES

ABOVE FOR

CONDITIONS

ACTUATOR TRAVEL

UP OR DOWN

HIGH

ALARM

RANGE

LOW

ALARM

RANGE

TERMINAL CONNECTIONS

HIGH ALARM SETPOINT (TRIPS ON)

0−10% FULL SPAN

(TRIPS OFF)

(TRIPS OFF)

0−10% FULL SPAN

LOW ALARM SETPOINT (TRIPS ON)

CONTACT

CLOSED

DESIRED

DEADBAND

CONTACT

OPEN

DESIRED

DEADBAND

CONTACT

CLOSED

15

Page 16

4200 Series Transmitters

Instruction Manual

Form 5596

July 2005

Arrange wires on the terminal block (TB1) for either

direct or reverse action to match the application

requirements; then repeat the potentiometer

alignment procedures.

Refer to the Calibration section to adjust the zero

and span of the transmitter and/or position switch

circuits.

Operating Information

Initial Considerations

If the transmitter is ordered with an actuator, the

transmitter is factory calibrated to the length of travel

specified on the order. If the transmitter is ordered

separately, adjust the zero and span as described in

the Calibration section so that the transmitter

operates properly in your specific application.

If the transmitter is calibrated for a specific control

valve actuator travel, perform the procedures in the

Calibration section to fine tune the zero and span

adjustments to the specific application.

from relays K1 and K2 (figures 4 and 9). The high

position switch circuit output controls relay K1

mounted on the field circuit printed wiring board and,

the relay contacts connect to TB1. The low position

switch circuit output controls relay K2 and, the relay

contacts connect to TB2. Deadband is the difference

between trip and reset points of a relay.

D A Type 4215 transmitter obtains position

information from a dual potentiometer on the same

shaft, which allows for individual potentiometers for

the transmitter circuit and the position switch circuits.

The transmitter input is from one of the

potentiometers and its output connects to TB3

(figure 6) mounted on the field circuit printed wiring

board. The position switch input is obtained from the

other potentiometer.

The high position switch circuit output controls relay

K1 mounted on the field circuit printed wiring board

and the relay contacts connect to TB1. The low

position switch circuit output controls relay K2 and

the relay contacts connect to TB2. The relationship

between the transmitter output, relay position switch

outputs, and deadband is shown in figure 7.

Deadband is the difference between the trip and

reset points of a relay.

Transmitter and Position Switch

Conditions

D A Type 4210 or 4220 transmitter (with position

switches) obtains stem position from the input

potentiometer and circuit electronics to provide a 4

to 20 milliampere output. The transmitter output

connects to a terminal block mounted in the field

wiring compartment. The high position switch circuit

output controls relay K1 mounted on the field circuit

printed wiring board, and the relay contacts connect

to TB1. The low position switch circuit output

controls relay K2, and the relay contacts connect to

TB2. The relationship between the transmitter

output, relay position switch outputs, and deadband

is shown in figure 7. Deadband is the difference

between trip and reset points of a relay.

D A Type 4211 or 4221 transmitter (without

position switches) obtains input information from the

potentiometer and provides a 4 to 20 milliampere

output. The transmitter output connects to the barrier

strip (key 11, figure 4) mounted in the field wiring

compartment.

D A Type 4212 or 4222 position switch (without

the transmitter) obtains stem position from the input

potentiometer and provides position switch outputs

Normal Operation

WARNING

On an explosion-proof instrument,

remove electrical power before

removing the instrument covers in a

hazardous area. Personal injury or

property damage may result from fire

or explosion if power is applied to the

instrument with the covers removed, in

a hazardous area.

Once the instrument has been calibrated and placed

in operation, further adjustments should not be

necessary. The 4 to 20 milliampere output can be

monitored during operation (in a non-hazardous

environment) by removing the cover and connecting

a milliammeter between TP1 (+) and TP2 (−) on the

printed wiring board (figure 5) on Type 4210, 4211,

4215, 4220, or 4221 transmitter. On Type 4212 or

4222 connect a voltmeter between TP5 (+) and TP6

(−) to measure potentiometer position.

For position switch circuits, the switching condition

can be monitored by observing the indicating device

or using an ohmmeter connected to the terminal

16

Page 17

Instruction Manual

Form 5596

July 2005

4200 Series Transmitters

blocks (TB1 and TB2) in the field wiring

compartment. Refer to the Calibration section for the

test setup.

Calibration

Note

The potentiometer alignment

procedures, in the Installation section,

must be completed before performing

instrument calibration. Also, be sure

the direct or reverse action is correct

for the application.

Calibration of the instrument consists of adjusting

the zero and span of the transmitter and/or adjusting

the high and low position switches for a specific

travel. The high and low position switches also have

deadband adjustments that are made during the

calibration procedures. Refer to figure 7 for

transmitter and position switch conditions.

For a Type 4212 or 4222 instrument with position

switch circuits only, refer to the high and low position

switch adjustment procedures in this section. For a

transmitter with or without position switch circuits,

refer to the transmitter circuit zero and span

adjustment procedures in this section.

Test Connections to the Field Wiring

Compartment

During calibration setup the transmitter as shown in

figure 8. Except for Type 4211 and 4221

transmitters, the field circuit printed wiring board is

used. A Type 4211 or 4221 transmitter uses a

barrier strip (key 11, figure 4) mounted in the field

wiring compartment for field wiring connections. For

calibration and bench check of the 4211 or 4221

transmitter, make connections to the barrier strip

(key 11).

For a Type 4210, 4215, or 4220 transmitter with

position switches, the transmitter can be calibrated

with or without the position switch outputs being

connected.

Note

On units with position switches, the

(R) terminal on TB3 must be connected

to the power supply negative (−)

terminal for proper instrument

operation, even if the position switch

outputs are not used.

For a Type 4211 or 4221 transmitter without position

switches, use a two wire system with the indicating

device installed as shown in figure 8.

If satisfactory results cannot be obtained during

calibration, refer to the appropriate procedures in the

Maintenance section.

Test Equipment Required

The following test equipment is used in the

calibration and maintenance of the instrument:

D Digital voltmeter (DVM) that measures voltages

in the range of 0 to 30 volts dc with an accuracy of

±0.25 percent.

D Power supply capable of supplying 20 to 30 volts

dc at 100 milliamperes.

D Resistor, 250 ohms, 0.1%, 0.5 watt or greater.

Transmitter Circuit Zero and Span

Adjustment

WARNING

On an intrinsically safe instrument, the

current monitoring across TP1 and

TP2 during operation must be with an

approved meter. Personal injury or

property damage may result from fire

or explosion if an approved meter is

not used in a hazardous area.

Calibration of the transmitter consists of adjusting

the zero and span for a 1 to 5 volt dc output across a

250 ohm resistor, or a 4 to 20 milliampere output

17

Page 18

4200 Series Transmitters

Instruction Manual

Form 5596

July 2005

J3

TO RFI

FILTERS

J1 FROM

RFI FILTERS

TRANSMITTER COMPARTMENT

NOTES:

1

CONNECT DVM TO TEST POINTS AS DIRECTED BY CALIBRATION AND

MAINTENANCE PROCEDURES.

2

INSURE THAT THE CONNECTOR ATTACHED TO J1 (VIEW A) IS NOT

REVERSED WHEN INSTALLING IT ON THE PRINTED WIRING BOARD.

3

THE INDICATING DEVICE CAN BE A VOLTMETER ACROSS A 250 OHM

49A7894-B

39A6156-F

B1948-4 / IL

RESISTOR OR A CURRENT METER.

SEPARATE RETURN LEAD REQUIRED FOR RELAYS. RETURN WIRE

4

MUST BE CONNECTED EVEN IF RELAY OUTPUTS ARE NOT USED.

Figure 8. Calibration and Bench Check Test Setup

current for a specific travel. If necessary refer to the

type number on the nameplate to determine the

configuration of the transmitter.

1. Remove power from the instrument.

2. Connect the transmitter as shown in figure 8.

3. Remove the transmitter covers.

4. Stroke the valve or device to the mid-stroke

position

5. Check the potentiometer alignment by connecting

a digital voltmeter (DVM) as follows:

FIELD WIRING

COMPARTMENT

J1

(SEE VIEW A)

VIEW A

+ 24 VOLT

DC POWER

SUPPLY

8. Stroke the valve or device to the point of travel

where the transmitter output is to be 4 milliamperes

dc.

9. Adjust the zero potentiometer (R1 or R15,

figure 5) until the output is 4 milliamperes dc (1.00

volt across 250 ohms).

10. Stroke the valve or device to the point of travel

where the transmitter output is to be 20 milliamperes

dc.

11. Adjust the span potentiometer (R2 or R16,

figure 5) until the output is 20 milliamperes dc (5.00

volts across 250 ohms).

a. For all transmitters (except a Type 4212 or

4222) connect between TP3 (+) and TP4 (−) on

the printed wiring board.

b. For a Type 4212 or 4222 transmitter, connect

the DVM between TP5 (+) and TP6 (−).

6. Apply power to the instrument.

7. The DVM should read 1.25 ±0.05 volts dc. If not,

perform the potentiometer alignment procedures in

the Installation section.

18

12. Some small interaction between the two

adjustments may occur. Repeat steps 8 through 11

until the error is within the application requirements.

13. For a Type 4211 or 4221 transmitter without

position switches, calibration is complete. Refer to

the installation and/or operating information to place

the transmitter in service.

14. If calibration is complete, replace the transmitter

covers. For transmitters with position switches, refer

to the high and low position switch adjustment

procedure below.

Page 19

Instruction Manual

Form 5596

July 2005

4200 Series Transmitters

High and Low Position Switch

Adjustment

Note

The “high” and “low” designations

refer to the voltage output of the

position potentiometer. See figure 7

for relationship to valve or actuator

travel.

The high position switch must be

adjusted before the low position

switch. If the deadband of either the

high or low position switches exceeds

the difference between the set points

of the high and low position switches,

both position switches may be on at

the same time.

The following procedure sets the high and low

position switches, and the deadband for each of

them. The high position switch must be adjusted

before the low position switch. Use an ohmmeter

connected between the normally closed (NC) and

common (C) connections on terminal block TB1

(high switch) or TB2 (low switch) to observe relay

switching action as directed by the procedures.

The potentiometer alignment procedures must be

performed before calibrating the position switch

circuits. For transmitter and position switch switch

conditions, refer to figure 7 while performing the

following calibration:

1. If necessary, perform the potentiometer

alignment procedure.

2. Remove power from the instrument.

3. Remove the transmitter covers.

Note

The potentiometers are 25 turn

trimpots with a slip clutch. To set

these potentiometers at their

maximum counterclockwise position,

turn them 25 or more turns in the

counterclockwise direction.

Setting the High Position Switch

For Type 4210, 4220, 4212, 4222, and 4215 direct

acting transmitters, refer to figure 5 for location of

adjustments.

1. Turn the high position switch potentiometer

(HIGH, R3) fully clockwise.

2. Stroke the valve or device to the point of travel

where the high position switch is to operate (see

figure 7).

3. Apply power to the instrument.

4. Turn the high position switch potentiometer (R3)

slowly counterclockwise until the high position switch

trips, the ohmmeter changes from a high resistance

to a low resistance reading.

5. The high position switch is now set.

Setting the High Position Switch

Deadband

1. Slowly stroke the actuator or device between the

tripped and reset point of the high position switch.

Observe this by the changing readings of the

ohmmeter. Note the differences in travel between

the trip point and reset points. This is the deadband

of the switch.

2. If necessary, increase the deadband by turning

the potentiometer (DBH, R4), clockwise.

3. Repeat steps 1 and 2 until the desired deadband

setting is obtained.

Setting the Low Position Switch

4. To provide an indication of switch conditions,

remove power from the instrument. Disconnect the

position switch field wiring from TB1 and TB2, and

connect an ohmmeter to TB1 between the (NC) and

(C) terminals (figure 4).

Turn both the high and low deadband

potentiometers (DBH, R4, and DBL, R5) fully

counterclockwise to set the deadbands to minimum

and set the low position switch potentiometer (LOW,

R6) fully counterclockwise.

Note

Perform the high position switch

adjustment procedures before

adjusting the low position switch.

1. To provide an indication of switch condition,

remove power from the instrument. Connect an

ohmmeter to TB2 between the (NC) and (C)

terminals (figure 4).

2. Stroke the device to the point of travel where the

low position switch is to operate (See figure 7).

19

Page 20

4200 Series Transmitters

Instruction Manual

Form 5596

July 2005

MECHANICAL

CONNECTION

TO DEVICE

B1946-4/IL

TRANSMITTER

TRANSMITTER

PRINTED WIRING

BOARD

TRANSMITTER

CIRCUIT

SWITCHING

CIRCUIT

NOTES:

1

THIS EQUIVALENT CIRCUIT IS TYPICAL FOR ALL TYPES OF TRANSMITTERS.

GENERALLY, IF A PORTION OF THE CIRCUIT IS NOT USED, IT IS OMITTED.

2

RECEIVING DEVICE MAY BE ANALOG CURRENT INPUT TO DISTRIBUTED CONTROL SYSTEM,

PROGRAMMABLE LOGIC CONTROLLER OR INDICATING DEVICE. INDICATING DEVICE CAN BE A

VOLTMETER ACROSS 250 OHM RESISTOR OR A CURRENT METER.

3

FIELD WIRING FOR POSITION SWITCHING CIRCUITS CAN BE A TWO OR THREE WIRE SYSTEM

DEPENDING ON THE APPLICATION REQUIREMENTS.

4

SEPARATE RETURN REQUIRED FOR RELAYS. RETURN WIRE MUST BE CONNECTED EVEN IF

RELAY OUTPUTS ARE NOT USED.

FIELD CIRCUIT

PRINTED WIRING

BOARD

K1

RELAY

K2

RELAY

+

24 VOLT

DC POWER

SUPPLY

−

4

+

DEVICE

RECEIVING

4 TO 20 MA

DC SIGNAL

−

2

DEVICE

RECEIVING

HI POSITION

SWITCH OUTPUT

(CONTACT

CLOSURE)

DEVICE

RECEIVING LO

POSITION

SWITCH OUTPUT

(CONTACT

CLOSURE)

Figure 9. Transmitter Operation

3. Apply power to the instrument.

4. Ensure that the low position switch potentiometer

(LOW, R6, figure 5) is fully counterclockwise as

previously instructed.

5. Turn the low position switch potentiometer (R6)

slowly clockwise until the low position switch trips,

the ohmmeter changes from a high to a low

resistance reading.

6. The low position switch is now set.

Setting the Low Position Switch

Deadband

1. Slowly stroke the actuator or device between the

tripped and reset point of the low position switch.

Observe this by the changing readings on the

20

ohmmeter. Note the differences in travel between

the trip point and reset points. This is the deadband

of the low position switch.

2. If necessary, increase the deadband, by turning

potentiometer (DBL, R5, figure 5) clockwise.

3. Repeat steps 1 and 2 until the desired deadband

setting is obtained.

4. If adjustments are complete, remove power from

the instrument and disconnect the ohmmeter.

5. Perform the installation and/or operating

procedures to place the transmitter in service and

replace the transmitter covers.

Position Switch Circuit Shutoff

Refer to figure 5 for location of adjustments.

Certain conditions may require the position switch

circuit capabilities to be shut off. To shut off the

Page 21

Instruction Manual

Form 5596

July 2005

4200 Series Transmitters

position switches, turn the high position switch

potentiometer (HIGH, R3) fully clockwise, and turn

the low position switch potentiometer (LOW, R6)

fully counterclockwise. To restore the position switch

circuits to operation, follow the high and low position

switch adjustment procedures described in this

section.

Note

Both position switch relays are

energized in this condition. The trip

points cannot be adjusted to prevent

the relays from energizing.

Principle of Operation

The basic concept of the electronic position

transmitter can be understood by visualizing the

entire transmitter as a variable resistor in series with

a load and connected to a power supply as shown in

figure 9. A linkage or cable/pulley assembly

transmits linear motion of the device into rotary

motion of the potentiometer. The potentiometer is

connected to the input of the transmitter circuit. The

voltage present at the wiper of the potentiometer

supplies input voltage to the electronic circuitry in the

transmitter to produce a current output.

The position switch circuit is driven by the same

input system as the transmitter (except for the Type

4215 transmitter). The position switch circuit acts as

an electronic switch that controls two relays. The

voltage present at the wiper of the potentiometer is

compared to the settings of the high and low position

switch set points and provides an on or off condition

for the relays. Instruments that use a single element

potentiometer use the same element for both the

transmitter input and the input to the position switch

circuits. A Type 4215 transmitter with dual element

potentiometers uses one element of the

potentiometer for the transmitter input and the other

element for the position switch circuit input. On an

instrument with position switches only, the single

element potentiometer is used for the position switch

circuit input. Each of the position switch circuit

outputs is connected to a relay on the field circuit

printed wiring board, and depending on the

potentiometer position, the relays are energized or

de-energized.

Transmitter Circuit

At all times, the current flow into the transmitter

equals the current flow out of the transmitter. The

current flowing into the transmitter divides between a

regulator circuit and transistor Q1.The regulator

circuit establishes two voltages one of which is

(VREF). This voltage is applied across the input

potentiometer. The other voltage, (VREG) powers

the hybrid circuit.

On units with position switches, the transmitter

voltage regulator, 4 to 20 mA signal, and relay coil

currents flow in the wire between the power supply

(+) terminal and the (+) terminal on TB3. The

transmitter voltage regulator, switching, and relay

coil currents are returned to the power supply

common from the (R) terminal on TB3. The 4 to 20

mA output signal flows between the (−) terminal on

TB3 and the power supply common. This prevents

the relay coil switching currents from appearing on

the 4 to 20 mA output.

Position Switch Circuit

A regulated voltage is setup to power the position

switch circuit. The position switch circuit senses the

position of the potentiometer and triggers the

appropriate position switch relay (K1 or K2, figure

10) when travel reaches the trip points established

by the adjustments. The Type 4215 transmitter uses

dual potentiometers which allows individual

potentiometers for the transmitter circuit and the

position switch circuit.

21

Page 22

4200 Series Transmitters

29A6206-C / DOC

Figure 10. Schematic Diagram for the Field Printed Wiring Board

Instruction Manual

NOTES:

1

RELAYS K1 AND K2 ARE SHOWN IN THE DE-ENERGIZED POSITION.

(TRIPPED POSITION)

Form 5596

July 2005

Maintenance

WARNING

To avoid personal injury or property

damage from the sudden release of

pressure:

D Always wear protective clothing

and eyewear when performing any

maintenance operations.

D Disconnect any operating lines

providing air pressure, electric power,

or a control signal to the actuator. Be

sure the actuator cannot suddenly

open or close the valve.

D Use bypass valves or completely

shut off the process to isolate the

valve from process pressure. Relieve

process pressure on both sides of the

valve.

D Use lock-out procedures to be

sure that the above measures stay in

effect while you work on the

equipment.

D Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

WARNING

On an explosion-proof instrument,

remove the electrical power before

removing the instrument covers in a

hazardous area. Personal injury or

property damage may result from fire

and explosion if power is applied to

the instrument with the covers

removed, in a hazardous area.

Test equipment for the following procedure is listed

in the Calibration section. Voltage references in this

procedure may vary depending on the temperature

of the instrument. The voltages below are taken at

approximately 22_C (72_F) ambient temperature.

CAUTION

Electrostatic voltages present in the

environment may be transferred to the

transmitter printed wiring board which

may cause failure or degraded

performance. Use appropriate

antistatic procedures when working

with the printed wiring board to protect

the electronic circuits.

The following procedures consider the instrument

assembled with all components installed according

to the type number description. The following

procedures can be used in the field or for a bench

check. Connect the instrument as shown in figure 8

for bench check.

22

Page 23

Instruction Manual

Form 5596

July 2005

4200 Series Transmitters

Troubleshooting Procedures

Transmitter Circuit

Note

On transmitters with position

switches, the (R) terminal on the field

circuit printed wiring board must be

connected to the power supply

negative (−) terminal for proper

transmitter operation, even though the

position switch outputs are not used.

1. Verify that the instrument is receiving power, and

verify that the receiving device(s) are operating

correctly.

2. If the transmitter is the problem, maintenance can

be performed by either sending the entire instrument

to the factory for repair, by replacing the printed

wiring board(s), or by replacing the pot/bushing

assembly (key 3, figures 13 and 14) depending on

which is defective.

3. Troubleshoot the transmitter circuit by measuring

the voltages.

4. Locations of test voltages designated by V1 and

V2 (table 7) are shown on the printed wiring board

assembly (figure 11).

5. Check the voltages V1 and V2 as described in

table 7.

6. If either or both of the voltages are not present,

field repair of the instrument is not recommended.

Either replace the printed wiring board or return the

instrument to the factory for repair.

7. If these voltages are present, the potentiometer

may be the source of trouble.

c. If the potentiometer voltage is present but the

transmitter output current does not change

linearly as the position of the potentiometer

changes, replace the transmitter printed wiring

board, or return the transmitter to the factory for

repair.

Position Switch Circuit

1. Ensure that the position switch circuit is

connected correctly, and that the terminal marked

(R) on the field circuit printed wiring board is

returned to the negative terminal of the supply. Refer

to figure 4 for wiring connections.

2. Ensure that the power supply voltage is between

20 and 30 volts dc.

3. Check the voltages V3 and V4 as described in

table 7:

a. If either or both of the voltages are not

present, field repair of the instrument is not

recommended. Return the instrument to the

factory for repair.

b. If V3 and V4 are correct, continue with the

following steps:

4. Perform the high and low position switch

calibration procedures in the Calibration section.

5. If the position switches cannot be set, replace the

field circuit printed wiring board (figure 13) or return

the instrument to the factory for repair.

Printed Wiring Board Removal and

Replacement

8. Check the voltage between TP3 (+) and TP4 (−)

as the position of the potentiometer is varied. For

Type 4212 and 4222 transmitters, check the voltage

between TP5 and TP6 as the position of the

potentiometer is varied.

a. If the voltage does not vary with position,

perform the potentiometer alignment. If the

problem remains, replace the pot/bushing

assembly (key 3, figure 13 or 14).

b. If the potentiometer wiper voltage checks

good, but the transmitter output is constant or

non-linear, the problem may be due to improper

potentiometer alignment. Perform the

potentiometer alignment procedures; then repeat

step 8 above.

WARNING

Refer to the Maintenance WARNING at

the beginning of this section.

CAUTION

Electrostatic voltages present in the

environment may be transferred to the

transmitter printed wiring board which

may cause failure or degraded

performance. Use appropriate

antistatic procedures when working

with the printed wiring board to protect

the electronic circuits.

23

Page 24

4200 Series Transmitters

STEP

DVM READS

Instruction Manual

Form 5596

July 2005

V2

V1

39A6156-F

A3497-2 / IL

45

V1

V2

FOR TYPE 4210, 4215, OR 4220 TRANSMITTER

WITH POSITION SWITCHES

8

V3

V4

39A7236-E

39A6156-F

A3504-2 / IL

Figure 11. Transmitter Printed Wiring Boards

FOR TYPE 4211 OR 4221 TRANSMITTER

WITHOUT POSITION SWITCHES

V3

V4

FOR TYPE 4212 OR 4222 POSITION SWITCHES

WITHOUT TRANSMITTER