E-flite Cessna 150 Aerobat 250 ARF User Manual

Cessna 150 Aerobat 250 ARF

Assembly Manual

Notice

All instructions, warranties and other collateral

documents are subject to change at the sole

discretion of Horizon Hobby, Inc. For up-to-date

product literature, visit http://www.horizonhobby.

com and click on the support tab for this product.

Meaning of Special Language

The following terms are used throughout the product

literature to indicate various levels of potential harm

when operating this product:

This is a sophisticated hobby product and NOT a

toy. It must be operated with caution and common

sense and requires some basic mechanical

ability. Failure to operate this Product in a safe

and responsible manner could result in injury or

damage to the product or other property. This

product is not intended for use by children without

direct adult supervision. Do not attempt disassembly,

use with incompatible components or augment

product in any way without the approval of Horizon

Hobby, Inc. This manual contains instructions for

safety, operation and maintenance. It is essential to

read and follow all the instructions and warnings

in the manual, prior to assembly, setup or use, in

order to operate correctly and avoid damage or

serious injury.

PROPELLER

Keep loose items that can get entangled in the

propeller away from the prop, including loose clothing

or other objects such as pencils and screwdrivers.

Especially keep your hands away from the propeller as

injury can occur.

BATTERIES

Notes on Lithium Polymer Batteries

When misused, lithium polymer batteries are

significantly more volatile than alkaline or Ni-Cd/

Ni-MH batteries used in RC applications. Always

follow the manufacturer’s instructions when using and

disposing of any batteries. Mishandling of Li-Po batteries

can result in fire causing serious injury and damage.

NOTICE: Procedures, which if not properly followed,

create a possibility of physical property damage

AND a little or no possibility of injury.

CAUTION: Procedures, which if not properly followed,

create the probability of physical property damage

AND a possibility of serious injury.

WARNING: Procedures, which if not properly followed,

create the probability of property damage, collateral

damage, and serious injury OR create a high

probability of superficial injury.

WARNING: Read the ENTIRE instruction

manual to become familiar with the features of the

product before operating. Failure to operate the

product correctly can result in damage to the

product, personal property and cause serious injury.

Warnings

Read and follow all instructions and safety precautions

before use. Improper use can result in fire, serious

injury and damage to property.

Age Recommendation: Not for children under

14 years. This is not a toy.

COMPONENTS

Use only with compatible components. Should any

compatibility questions exist, please refer to the

product instructions, the component instructions or

contact Horizon Hobby, Inc.

FLIGHT

Fly only in open areas to ensure safety. It is

recommended flying be done at AMA (Academy of

Model Aeronautics) approved flying sites. Consult local

laws and ordinances before choosing a location to fly

your aircraft.

SMALL PARTS

This kit includes small parts and should not be left

unattended near children as choking and serious injury

could result.

SAFETY PRECAUTIONS

• Checkallcontrolsurfacespriortoeachtakeoff.

• Donotflyyourmodelnearspectators,parkingareas

or any other area that could result in injury to people

or damage of property.

• Donotflyduringadverseweatherconditions.

Poor visibility and/or strong winds can cause

disorientation and loss of control of your aircraft.

• Donottakechances.Ifatanytimeduringflightyou

observe any erratic or abnormal operation, land

immediately and do not resume flight until the cause

of the problem has been ascertained and corrected.

Safety can never be taken lightly.

• Donotflynearpowerlines.

2 E-flite Cessna 150 Aerobat 250 ARF Assembly Manual

Table of Contents

Notice ......................................................................2

Meaning of Special Language ...................................2

Warnings ................................................................. 2

Introduction .............................................................. 3

Important Information Regarding

Warranty Information ....................................... 3

Specifications ...........................................................3

Using the Manual .....................................................3

Contents of Kit/Parts Layout ......................................4

Covering Colors ........................................................ 4

Hardware/Accessory Sizes .......................................4

Recommended Radio Equipment ................................ 4

Park 250 Motor Setup ...............................................4

Park 280 Motor Setup ...............................................4

Optional Accessories ................................................4

Required Tools and Adhesives ...................................4

Before Starting Assembly ..........................................5

Aileron Servo Installation ..........................................5

Rudder and Elevator Servo Installation .......................8

Landing Gear Installation ........................................10

Motor and Speed Control Installation .......................14

Receiver Installation................................................. 15

Horizontal Stabilizer Installation .............................. 16

Vertical Stabilizer Installation ...................................19

Rudder, Elevator and Nose Gear

Linkage Installation .........................................21

Windscreen, Wing and Wing Strut Installation ......... 23

Motor Battery, Cowl, Propeller and

Spinner Installation .........................................25

Decal Installation ....................................................27

Center of Gravity .................................................... 27

Control Throws .......................................................28

Preflight ..................................................................28

Range Test Your Radio ............................................. 29

Flying Your Model ...................................................29

Daily Flight Checks ................................................. 29

Limited Warranty .................................................... 30

Warranty Services ..................................................30

Compliance Information for the European Union ...... 31

Academy of Model Aeronautics

National Model Aircraft Safety Code ..............32

Building and Flying Notes ................................. 33–34

Introduction

The Cessna 150, while designed over 50 years ago,

to this day has a personality and spirit all its own.

Considered still tame enough for training, the Aerobat

version appealed to casual pilots that needed a jolt

to become even more proficient. This 250-size ARF

version is for RC pilots wanting the thrill of basic

aerobatics in a small yet detailed package. This clever,

all-wood model remarkably maintains the subtle curves

and character of the original aircraft, yet is distinctively

detailed with a checker-scheme that honors the

character of the Aerobat. Despite its compact size, you

get these great features like an: authentic scale outline,

laser cut engineering, fiberglass cowl and wheel pants,

and a lightweight UltraCote® ParkLite™ trim scheme.

The magnetically secured wing panels and cowling

make for quick assembly and the oversized quickrelease accessory hatch allows easy access for radio

and battery installation. The steerable nose strut makes

ground handling a breeze and the optional aluminum

spinner (EFLSP100) adds the perfect finish to the

model.

Important Information

Regarding Warranty Information

Please read our Warranty and Liability Limitations

section before building this product. If you as the

Purchaser or user are not prepared to accept the

liability associated with the use of this Product, you are

advised to return this Product immediately in new and

unused condition to the place of purchase.

Specifications

Wingspan: 37.9 in (960mm)

Length: 27.2 in (690mm)

Wing Area: 196 sq in (12.6 sq dm)

Weight with battery: 12.0–13.7 oz

(340–388 g)

Weight w/o battery: 10.9–12.2 oz

(309–346 g)

Using the Manual

This manual is divided into sections to help make

assembly easier to understand and to provide breaks

between each major section. In addition, check boxes

have been placed next to each step to keep track

of its completion. Steps with a single circle () are

performed once, while steps with two or more circles

() indicate the step will require repeating, such as

for a right or left wing panel, two servos, etc.

Remember to take your time and follow the directions.

3E-flite Cessna 150 Aerobat 250 ARF Assembly Manual

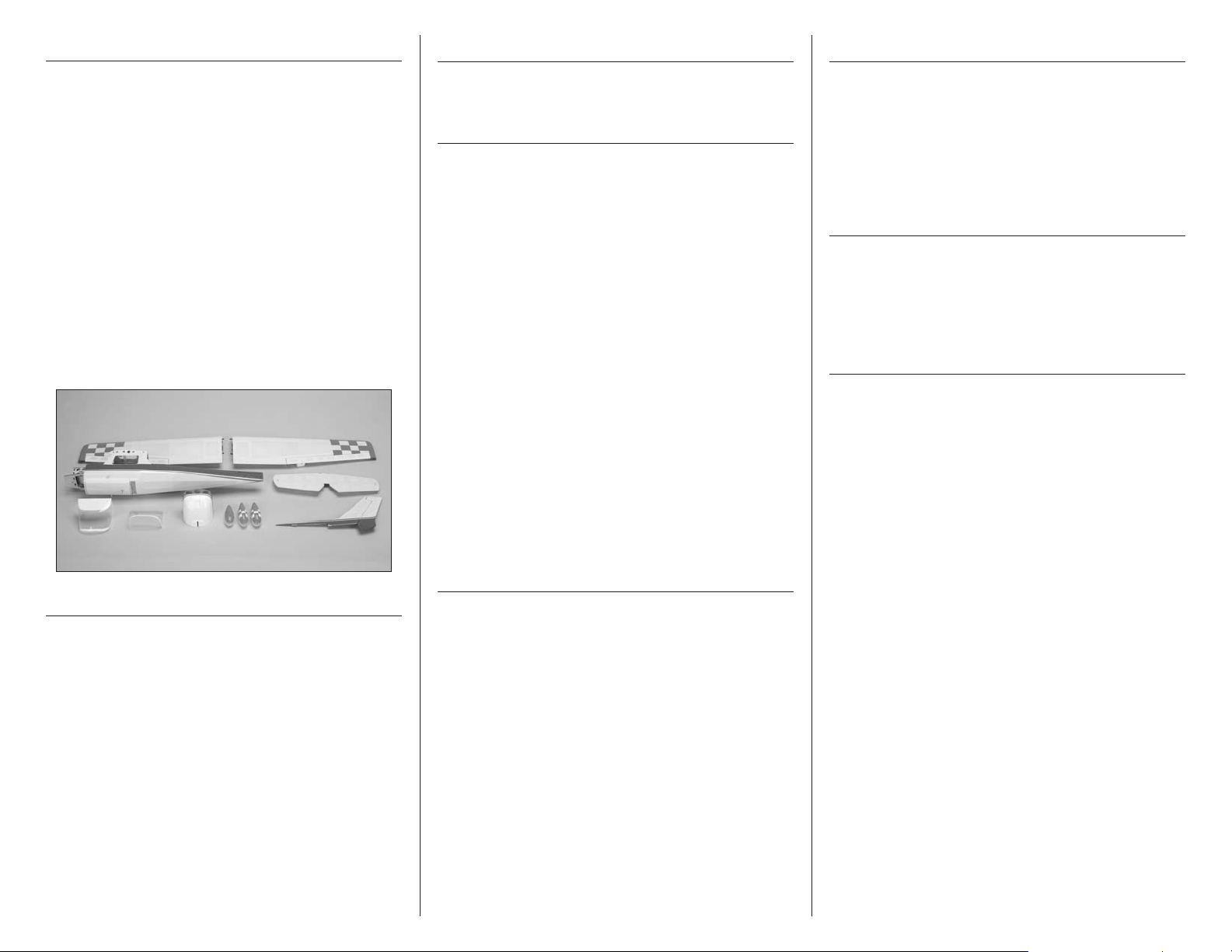

Contents of Kit/Parts Layout

Hardware/Accessory Sizes

Park 280 Motor Setup

Replacement Parts

EFL505001 Fuselage

EFL505002 Wing Panels left and right

EFL505003 Tail Set

EFL505004 Landing Gear Set

EFL505005 Cowling

EFL505006 Windshields

EFL505007 Hardware

EFL505008 Pushrods

EFL505009 Main Struts

EFL505010 Wing Tube

EFL505011 Wheel Pant Set

EFL505012 Decal Set

EFL505013 Wheel Set:

40mm (2), 35mm (1)

EFL505014 Main Hatch

Covering Colors

ParkLite, Orange HANU0814

ParkLite, True Red HANU0815

ParkLite, White HANU0801

Main wheel 1.57-inch (40mm)

Nose wheel 1.37-inch (35mm)

Recommended Radio Equipment

You will need a minimum 4-channel transmitter,

receiver and four servos.

Recommended Transmitter

SPMR5510 DX5e DSMX

Transmitter Only

Additional Items

SPMAR6300 AR6300 DSM2™ Nanolite

6-Channel Receiver

EFLRDS35 DS35 Digital Super

Sub-Micro Servo (4)

SPMEXJST3UL 3-inch (76mm) Ultralight JST

Servo Extension (2) (rudder

and elevator extensions)

SPMEXJST6UL 6-inch (152mm) Ultralight JST

Servo Extension (4) (aileron

wing extension (2) and aileron

to fuselage extension (2))

SPMYHJST3UL 3-inch (76mm) Ultralight JST

Y-Harness (aileron to fuselage

extension Y-harness)

®

5-Channel

Park 250 Motor Setup

EFLM1130 Park 250 Brushless Outrunner

Motor, 2200Kv

EFLA1010 10-Amp Pro Brushless ESC

EFLB4302SJ 430mAh 2S 7.4V 20C Li-Po,

20AWG

GWSEP7035B 7 x 3.5 Direct Drive Propeller

EFLM1140 Park 280 Brushless Outrunner

Motor, 1800Kv

EFLA1010 10-Amp Pro Switch-Mode BEC

Brushless ESC

EFLB4503SJ30 450mAh 3S 11.1V 30C LiPo,

18AWG JST

GWSEP7035B 7 x 3.5 Direct Drive Propeller

Optional Accessories

EFLSP100 1.00-inch Aluminum Spinner

with 2mm Collet

EFLA110 Power Meter

EFLC3025 Celectra™ 80W AC/DC Multi-

Chemistry Battery Charger

Required Tools and Adhesives

Tools & Equipment

Dental floss Paper towels

Felt-tipped pen Flat blade screwdriver: 1.5mm

Flat file Hemostat

Hex wrench: 1.5mm Hobby knife with #11 blade

Low-tack tape Open-end wrench: 6mm

Pencil Phillips screwdriver: #0, #1, #2

Pin vise Razor saw

Ruler Scissors

Square Toothpicks

Rubbing alcohol Side cutters

Drill bit: #56/.046 (1mm), 1/16-inch (1.5mm),

5/64-inch (2mm)

Optional Tools & Equipment

Balancing stand (optional)

Adhesives

Medium CA PAAPT02

Thin CA PAAPT08

Threadlock PAAPT42

Canopy Glue PAAPT56

4 E-flite Cessna 150 Aerobat 250 ARF Assembly Manual

Before Starting Assembly

Before beginning the assembly of your model, remove

each part from its bag for inspection. Closely inspect

the fuselage, wing panels, rudder and stabilizer for

damage. If you find any damaged or missing parts,

contact the place of purchase.

If you find any wrinkles in the covering, use a heat gun

(HAN100) and covering glove (HAN150) or covering

iron (HAN101) with a sealing iron sock (HAN141) to

remove them. Use caution while working around seams

or areas where the colors overlap to prevent pulling

the seams.

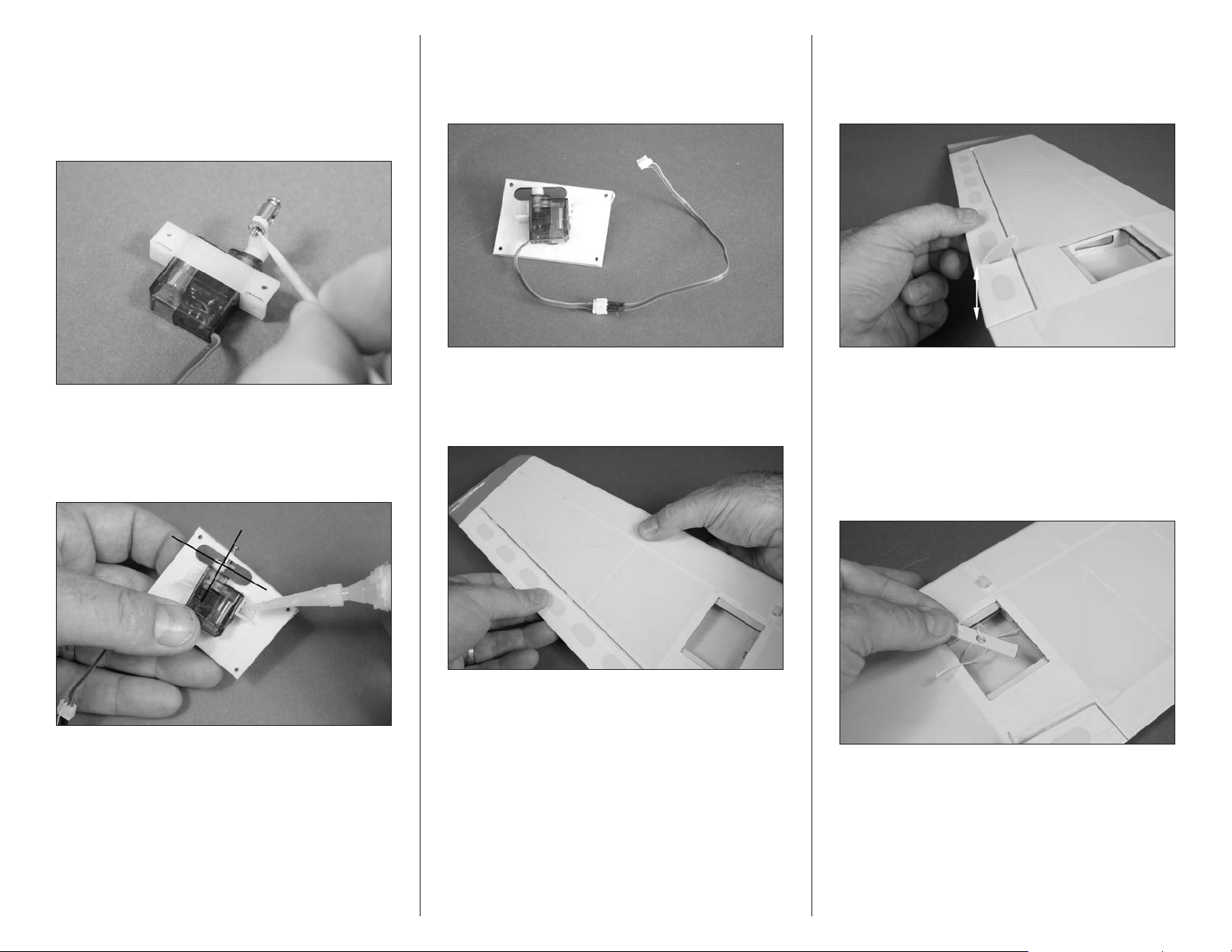

Aileron Servo Installation

Required Parts

Wing panel (right and left)

Transmitter Receiver

Receiver battery Servo with accessories (2)

2mm x 5mm self-tapping screw (8)

Aileron pushrod, 2.75-inch (78mm) (2)

6-inch (152mm) servo extension (2)

Pushrod connector with hardware (2)

Required Tools and Adhesives

Medium CA Phillips screwdriver: #0, #1

Pin vise Thin CA

Pencil Dental floss

Toothpicks Side cutters

Drill bit: 1/16-inch (1.5mm), 5/64-inch (2mm)

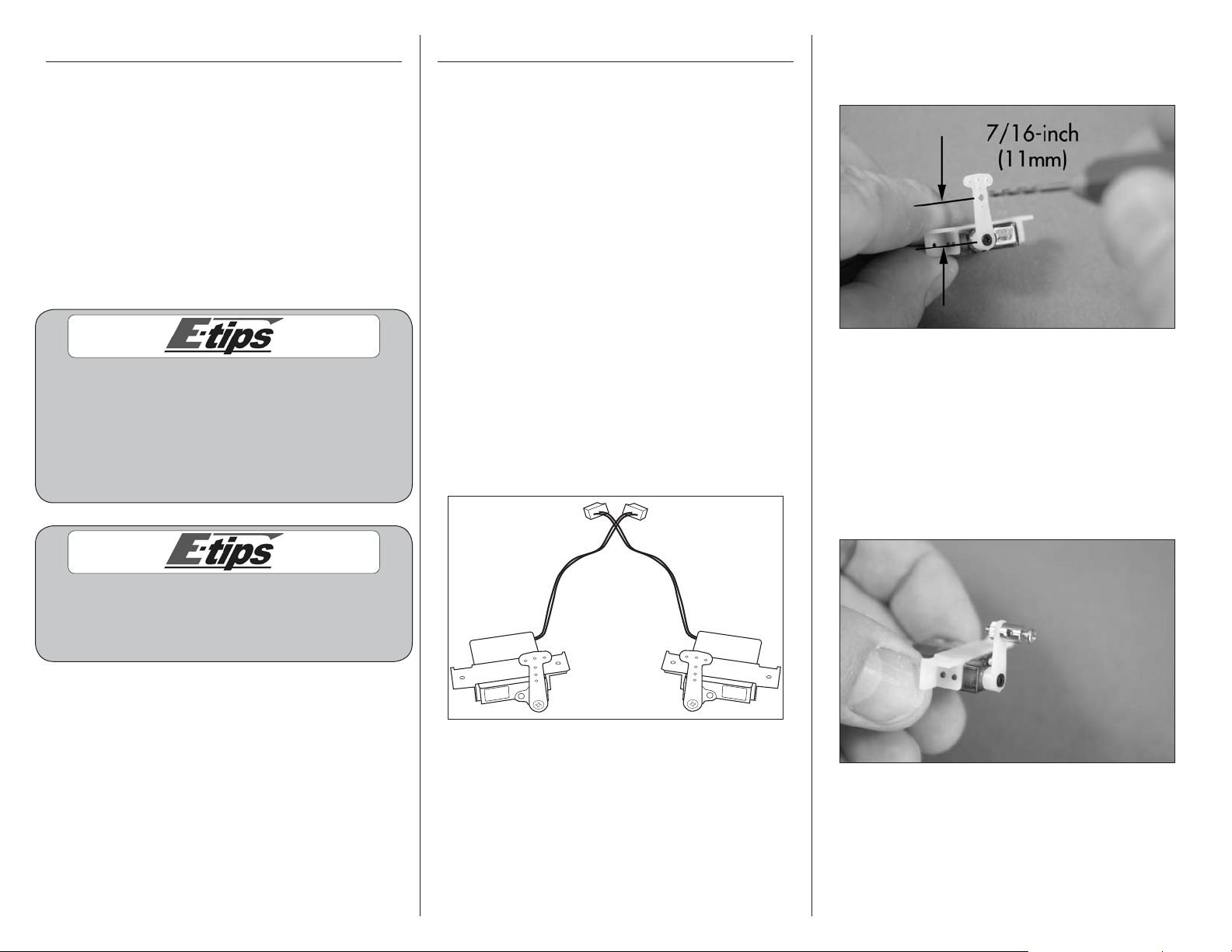

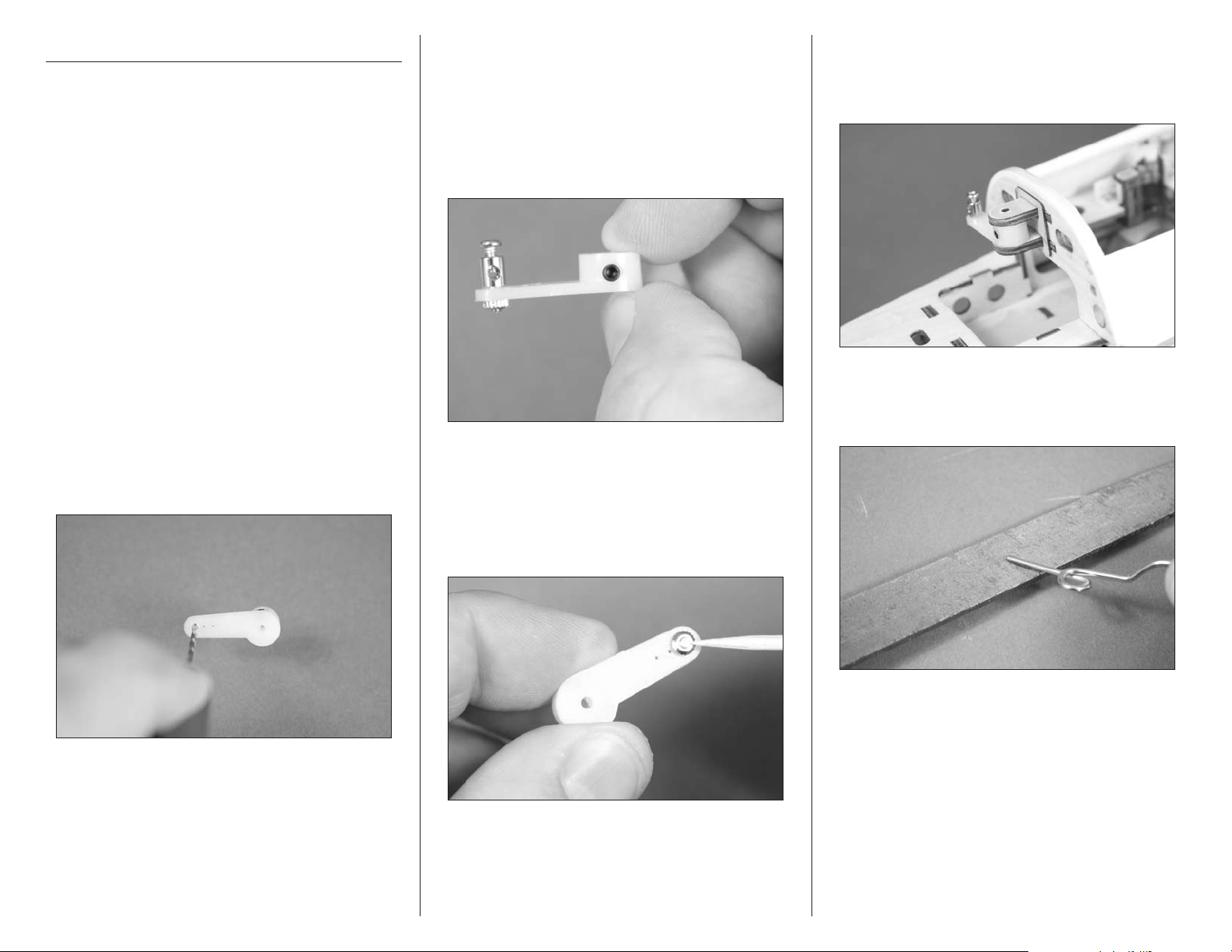

2. Use a pin vise and 5/64-inch (2mm) drill bit to

enlarge the hole that is second from the inside on

the servo arm.

During the course of building your model, we

suggest you use a soft base for the building surface.

Such things as a foam stand, large piece of

bedding foam or a thick bath towel will work well

and help protect the model from damage during

assembly. This is not shown in the instructions

to provide the greatest detail in the photos.

When referencing directions (up, down, left,

right, top and bottom), take note that these are

in relationship to the pilot sitting in the cockpit

of the aircraft unless noted otherwise.

1. Use the radio system to center the aileron servos.

Use a # 0 Phillips screwdriver to center both of the

stock arms so they are centered perpendicular to the

servo. Make one of each shown for the left and right

wing. Attach the mounting bracket to the servos as

shown.

3. Use side cutters to remove the excess servo arm

as shown. Attach the pushrod connector to the

servo horn using the hole enlarged in the previous

step. The washers that come on the connector are

not needed and can be removed. Tighten the nut

so that it is secure on the arm but is not tight. There

should be a small amount of play between the arm

and the connector and the connector should be able

to rotate freely on the arm.

5E-flite Cessna 150 Aerobat 250 ARF Assembly Manual

4. Use a very small amount of medium CA on a

toothpick to secure the nut to the bottom of the

connector threads. Do not use thin CA for this

step as it can wick through the nut and glue the

connector to the arm. Make sure the connector still

rotates freely in the arm after the glue is cured.

6. Connect a 6-inch (152mm) servo extension to

the servo lead. Use a piece of dental floss to secure

the leads so they do not accidentally disconnect

inside the wing.

8. Move the control surface through its range of

motion several times to break in the hinges. This

will reduce the initial load on the servo during

your first flights.

5. Place the servo on the aileron servo cover. Center

the servo arm in the opening, then use medium CA

to glue the mount to the cover. Use care not to get

glue under the servo.

7. Check that the hinges are secure by gently pulling

on the control surface. If not, apply thin CA to any

hinges that are not glued and recheck.

9. A string is located in the wing to pull the servo

lead through the wing. Remove the string from the

wood support and tie the string to the end of the

servo lead as shown. Pull the servo lead through

the wing using care not to damage the internal

structure. Once the lead is routed through the wing,

remove the string from the lead.

6 E-flite Cessna 150 Aerobat 250 ARF Assembly Manual

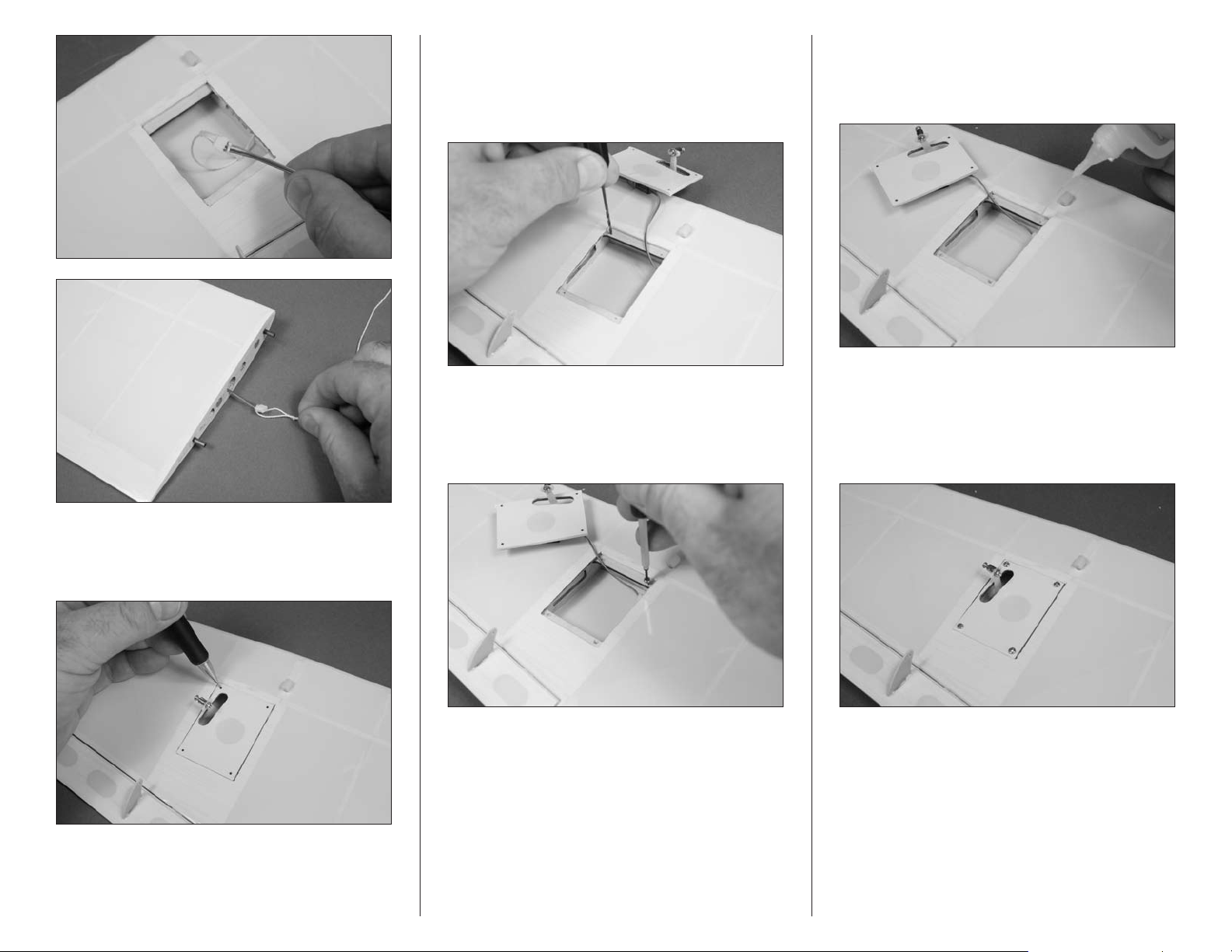

11. Use a pin vise and 1/16-inch (1.5mm) drill bit

to drill four holes for the mounting screws. Use care

not to accidentally puncture the covering on the top

of the wing or to push too hard on the mounting

rails, as this could break them.

12. Use a #1 Phillips screwdriver to thread a 2.5mm

x 8mm washer-head self-tapping screw into each

of the holes to cut threads in the surrounding wood.

Remove the screw before moving to the next step.

13. Apply 2–3 drops of thin CA in each of the holes

to harden the surrounding wood. This will harden

the threads so the screws do not easily strip the

surrounding wood.

14. Use a #1 Phillips screwdriver and four 2mm x

5mm self-tapping screws to secure the cover to the

wing. Note that the servo arm is aligned with the

aileron control horn and the hole in the mounting

plate is facing forward.

10. Place the servo cover in position on the wing.

Use a pencil to mark the locations for the four

mounting screws.

7E-flite Cessna 150 Aerobat 250 ARF Assembly Manual

15. With the aileron servo centered, attach the

Rudder Elevator

Z-bend of the pushrod to the control horn.

16. Pass the pushrod through the pushrod connector

and center the aileron. Use a #1 Phillips screwdriver

to tighten the screw in the pushrod connector to

secure the pushrod wire. Use side cutters to remove

the excess wire. Support the clevis and the wire

while doing this to not damage the model.

Rudder and Elevator Servo Installation

Required Parts

Fuselage Servo with hardware (2)

3-inch (76mm) servo extension (2)

Required Tools and Adhesives

Pencil Phillips screwdriver: #0

Pin vise Drill bit: #56.046-inch (1mm)

Thin CA Dental floss

1. Remove the battery hatch cover from the fuselage

by sliding the locking pin forward. The front of the

hatch is held in place by a tab at the front. Set the

cover aside until it is required later in the manual.

2. Prepare the rudder and elevator servos by using

a #0 Phillips screwdriver to remove the servo horns

from the servos. Attach the mounting bracket to the

servos as shown.

3. Position the rudder servo in the fuselage. Locate

the servo so the outer edge is against the outer

edge of the mounting rail and centered between the

front and rear. Use a pencil to mark the locations

for the two mounting screws.

17. Repeat steps 2 through 16 to install the

remaining aileron servo.

18. Check to make sure the radio system has been

turned off before proceeding.

8 E-flite Cessna 150 Aerobat 250 ARF Assembly Manual

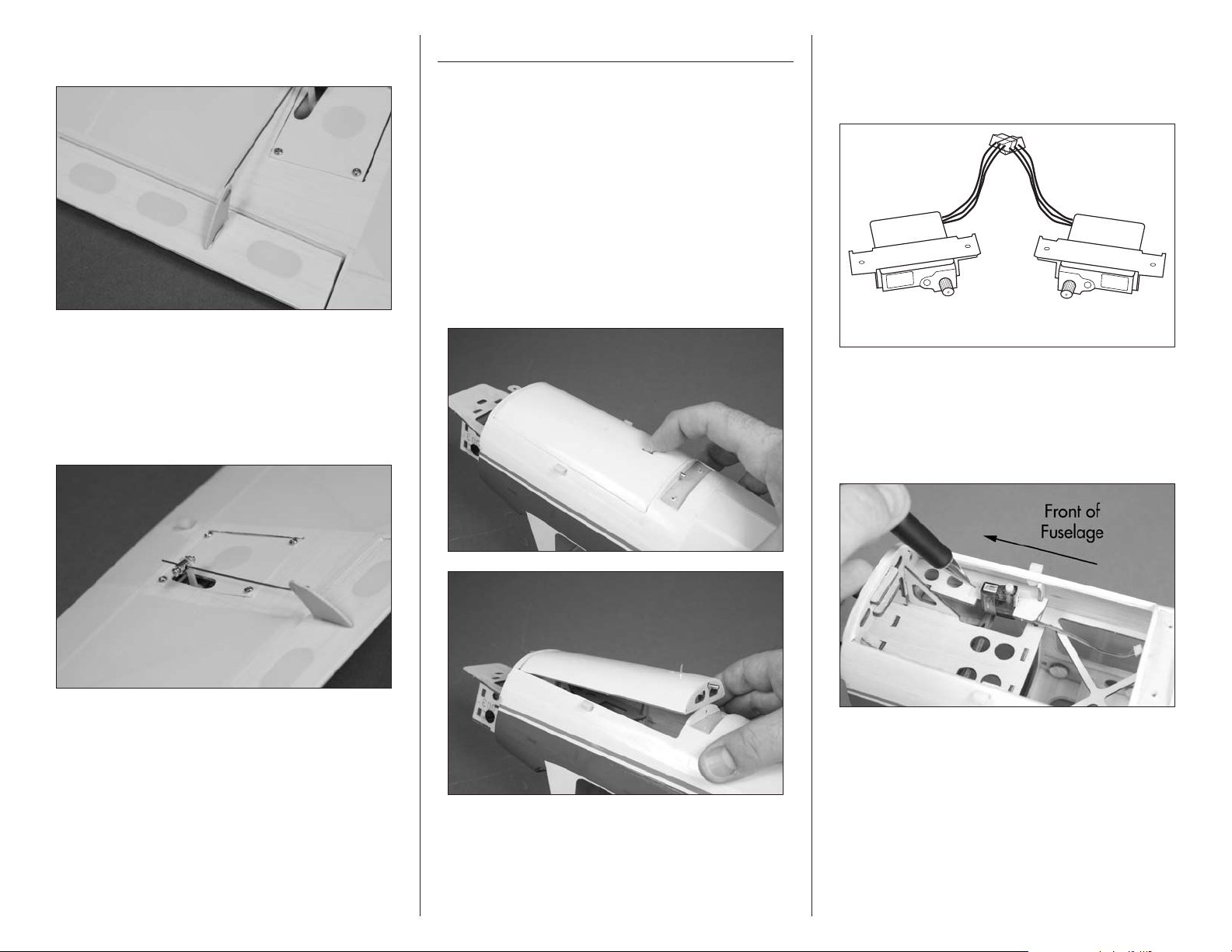

4. Use a pin vise and a #56/.046-inch (1mm) drill

bit to drill the holes for the mounting screws. Use

care not to push too hard on the mounting rails as

this could damage them.

6. Use the screws provided with the servo and a #0

Phillips screwdriver to secure the rudder servo in

the fuselage. Use care not to push too hard on the

mounting rails while tightening the screws.

8. Connect a 3-inch (76mm) servo extension to

each of the servo leads. Use a piece of dental floss

to secure the leads so they do not accidentally

disconnect inside the fuselage.

5. Apply 2–3 drops of thin CA in each of the holes

to harden the surrounding wood. This will harden

the threads so the screws do not easily strip the

surrounding wood.

7. Repeat steps 3 through 6 to install the elevator

servo in the fuselage.

9. Route the leads and extensions for the elevator

and rudder servos to the front of the fuselage,

exiting at the top hole in the motor box.

9E-flite Cessna 150 Aerobat 250 ARF Assembly Manual

Landing Gear Installation

Required Parts

Fuselage assembly Steering arm

Nose gear wire Main landing gear

2mm nut (2) 2mm washer (4)

Wood spacer (3) Nose wheel pant

3mm washer (2) Main wheel pant (2)

Wheel collar with setscrew(3)

2mm x 25mm machine screw (2)

Pushrod connector with hardware

Main wheel, 1.57-inch (40mm) (2)

Nose wheel, 1.37-inch (35mm)

3mm x 8mm self-tapping screw (2)

Required Tools and Adhesives

Flat file Phillips screwdriver: #1, #2

Hex wrench: 1.5mm Hemostat

Canopy glue Low-tack tape

Threadlock Medium CA

Toothpick Pin vise

Ruler Drill bit: 5/64-inch (2mm)

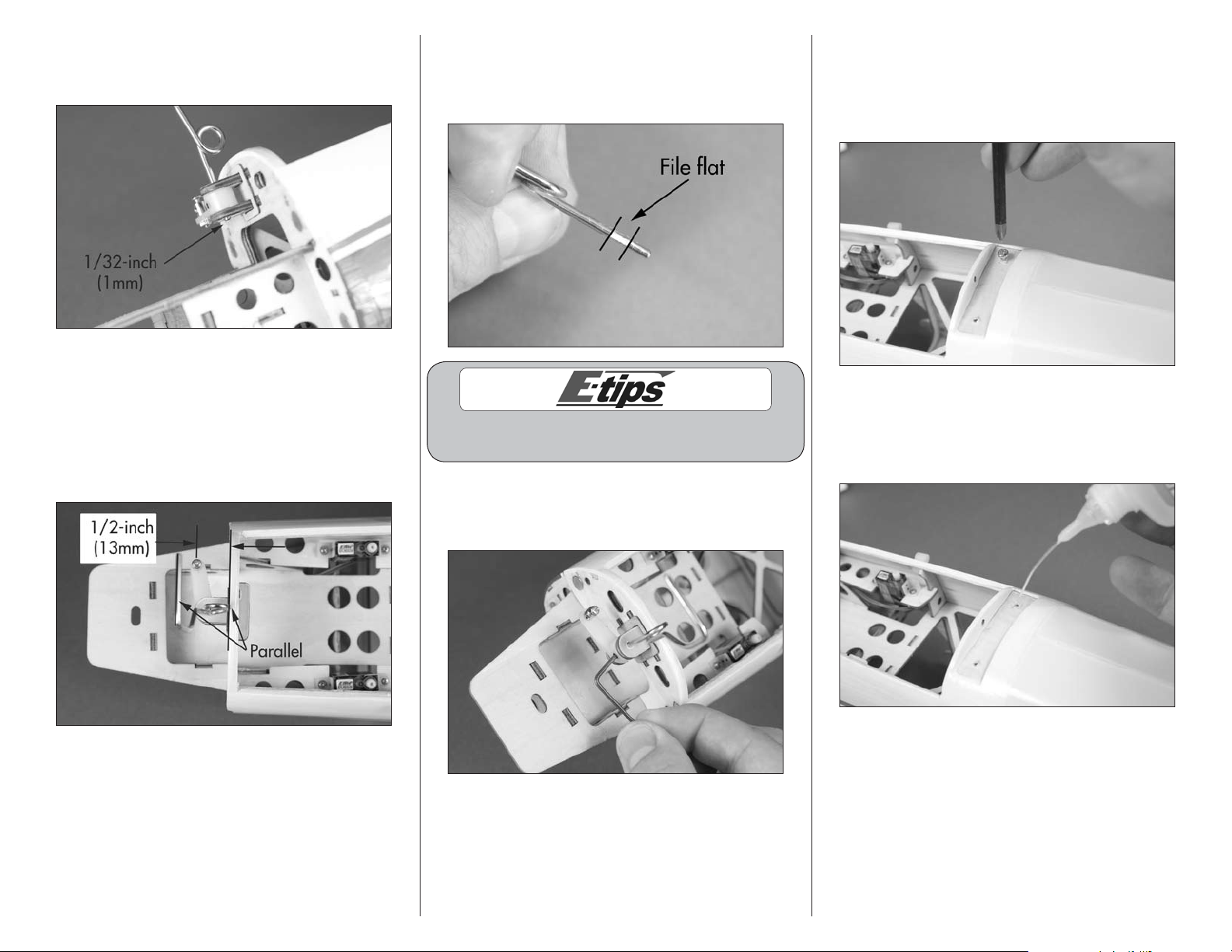

2. Attach the pushrod connector to the outside hole

of the steering arm as shown. The washers that

come on the connector are not needed and can

be removed. Tighten the nut so it is secure on the

steering arm but is not tight. There should be a small

amount of play between the arm and the connector

and the connector should be able to rotate freely on

the arm.

4. Install the steering arm into the bracket on the

lower section of the fire wall. The steering arm will fit

in the bracket as shown with the pushrod connector

facing the bottom of the fuselage.

5. The end of the nose gear wire may have to

be filed slightly to remove any burs or edges for

an easier fit.

1. Use a pin vise and 5/64-inch (2mm) drill bit to

enlarge the outer hole in the steering arm.

3. Use a very small amount of medium CA on a

toothpick to secure the nut to the bottom of the

connector threads. Do not use thin CA for this

step as it can wick through the nut and glue the

connector to the arm. Make sure that the connector

still rotates freely in the arm after the glue is cured.

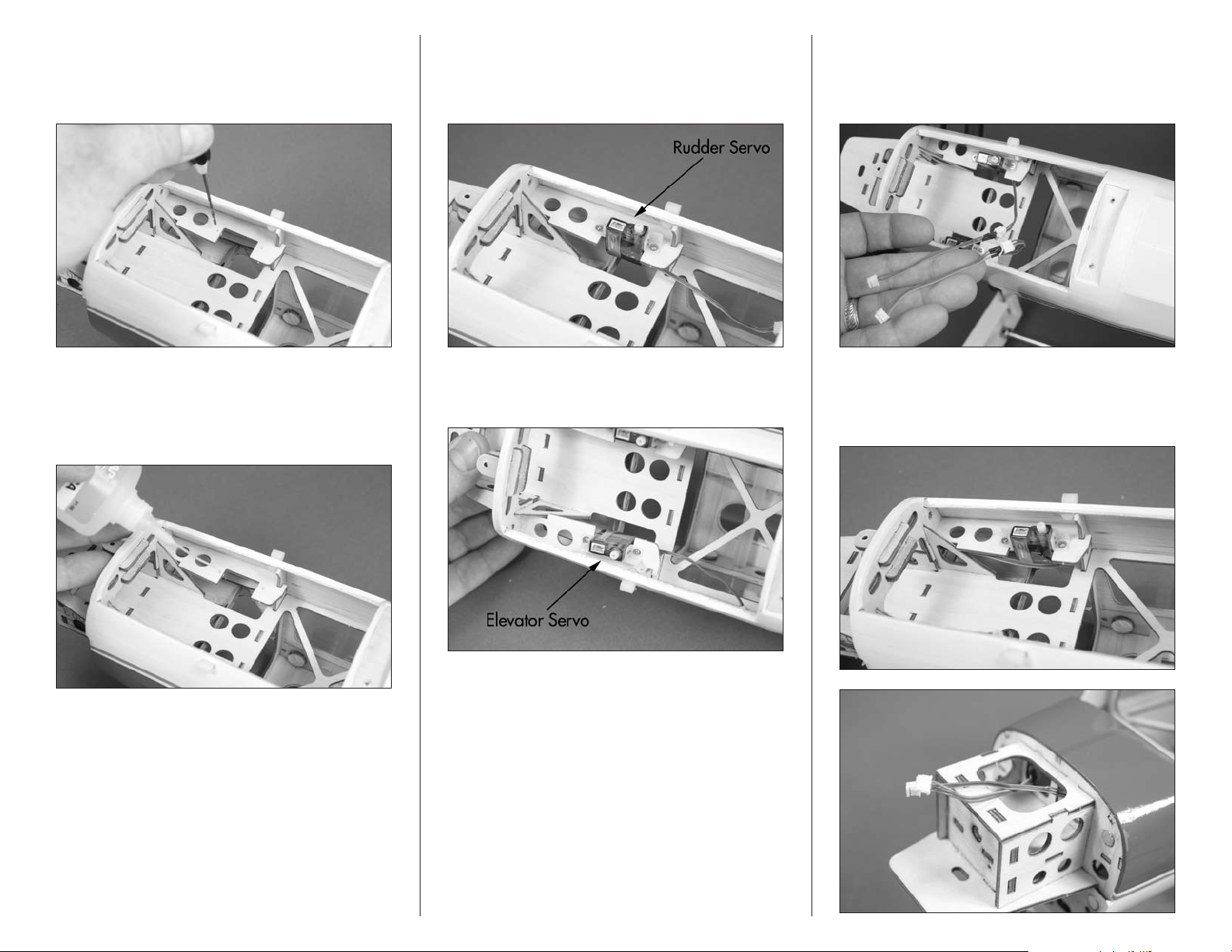

10 E-flite Cessna 150 Aerobat 250 ARF Assembly Manual

6. Slide the nose gear wire into the bracket and

steering arm. The top of the gear will protrude

through the bracket 1/32-inch (1mm).

7. Position the nose gear wire so it is parallel to the

former as shown. Position the steering arm so the

connector is 1/2-inch (13mm) from the former. Check

to make sure that 1/32-inch (1mm) of the wire is still

protruding through the top of the arm. Tighten the

screw on the steering arm so it will leave a mark on

the nose gear wire.

8. Remove the nose gear wire from the airframe.

Use a flat file to make a flat area for the screw in the

steering arm. This will help prevent the gear from

rotating when flown from rough surfaces.

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.

9. Place the nose gear back into position and

tighten the screw in the steering arm using a

1.5mm hex wrench.

10. Use a #2 Phillips screwdriver to thread a 3mm x

8mm self-tapping screw into each of the holes to cut

threads in the surrounding wood plate for mounting

the main gear. Remove the screw before moving to

the next step.

11. Apply 2–3 drops of thin CA in each of the holes

to harden the surrounding wood. This will harden

the threads so the screws do not easily strip the

surrounding wood.

11E-flite Cessna 150 Aerobat 250 ARF Assembly Manual

Loading...

Loading...