Page 1

Ultra®325 TT Automation Series

Ultra

®

525 TT Automation Series

Valve/Dispensing Device Configuration

EFD Valve Model Air Connections Air Connections Fluid Pressure Connection

(actuating) (atomizing)

752V-UHSS P1 N/A P2 or Auxiliary Air

725DA-SS P1 N/A P2 or Auxiliary Air

725HF-SS P1 N/A P2 or Auxiliary Air

740V-SS P1 N/A P2 or Auxiliary Air

736HPA P1 N/A P2, Auxiliary Air or customer supplied

780S-SS P1 P2 Auxiliary Air

790 Terminal 1+ Terminal 2 - N/A P2 Selectable between pulsed or

constant pressure

Syringe Barrel 0~100 psi P1 N/A Same as actuating

Syringe Barrel 0~30 psi P2 N/A Same as actuating

5800MP P1 N/A Same as actuating

HP4X

™

P1 N/A Same as actuating

HP7X

™

P1 N/A Same as actuating

2800 N/A N/A N/A

®

A NORDSON COMPANY

1

I/O Dispense Head

HS

P1 P2 AUX AIR

P1 = 0~100 psi

P2 = 0~30 psi

Quick Start Installation Guide

Z-head Electrical /

Air Connections

Power Button

EMO Button

Pressure Gauges

Pressure Regulators

Vacuum Control

Interactive LCD

PDA/Serial Connector

T Slots

Dispense Valves

Mounting

Bracket

Palm

™

handheld

Universal Fixture

Discrete I/O

General

Purpose

Outputs

General

Purpose

Inputs

Ethernet

Socket

™

adapter

attached

to RS232

Safety

Interlock

Main Power Input

Main Air

Entry

Exhaust

Fan

Main

Power

Circuit

Breaker

Electronic pdf files of EFD®manuals are also available at www.efd-inc.com/manuals.html

Page 2

1

7 Step Easy Setup

Use the power cord provided and plug the machine into the 100 ~ 240VAC, single-phase power source. This

machine uses a self-regulating power supply and will work on any voltage in the stated range. The electrical

connection is located on the back left-hand side of the machine.

2

3

6

4

Remove the bolt at the top right-hand corner of the Z-plate. This bolt was used to prevent

any movement of the Z-carriage during shipping.

Download the Software Installation CD that was included with the PDA to the PC. Once that is

done download the EFD PDA software to the PC. Copy the EFD PDA software to the palmOne

Quick Install and then HotSync to install the EFD PDA software to the palm.

Connect the Socket Bluetooth

®

adapter to the RS232 connector at the back of the Ultra TT.

Turn the main power circuit breaker at the back of the machine ON. Reset the EMO switch on

the front panel and press the green power button to power up the machine. Check that the Socket adapter LED is blinking.

Start the EFD software on your PDA handheld. Go to Tools and open the Bluetooth window. Tap Discover and wait for Socket #1

to appear in the Device list. Highlight this device and tap Connect. When the Security screen opens, type “1234” and press OK.

(Do not check “Add to trusted device list”.) Wait for the message “Connection established to selected device”. Tap Done. Return

to the Main screen, select Setup and the message “Dispenser is about to Home” will display. Tap OK to home the machine.

Adjust the height sensor probe so it is located approximately 25.0mm above the dispense tip when the probe is not actuated.

The height sensor is attached to the backside of the Z-plate. This will allow enough room for the dispense tip to reach the

parts without obstruction from the probe. To make the required adjustment, loosen the probe hold-down screw and slide

probe either downwards or upwards. Hand tighten only; do not overtighten probe hold down screw or it will deform the probe.

This should give you an approximate 22mm offset between tip and probe. You must still teach the offset as described in

the setup section in the manual to complete configuring your machine.

Electrical

Mounting

Height Sensor

Start-up

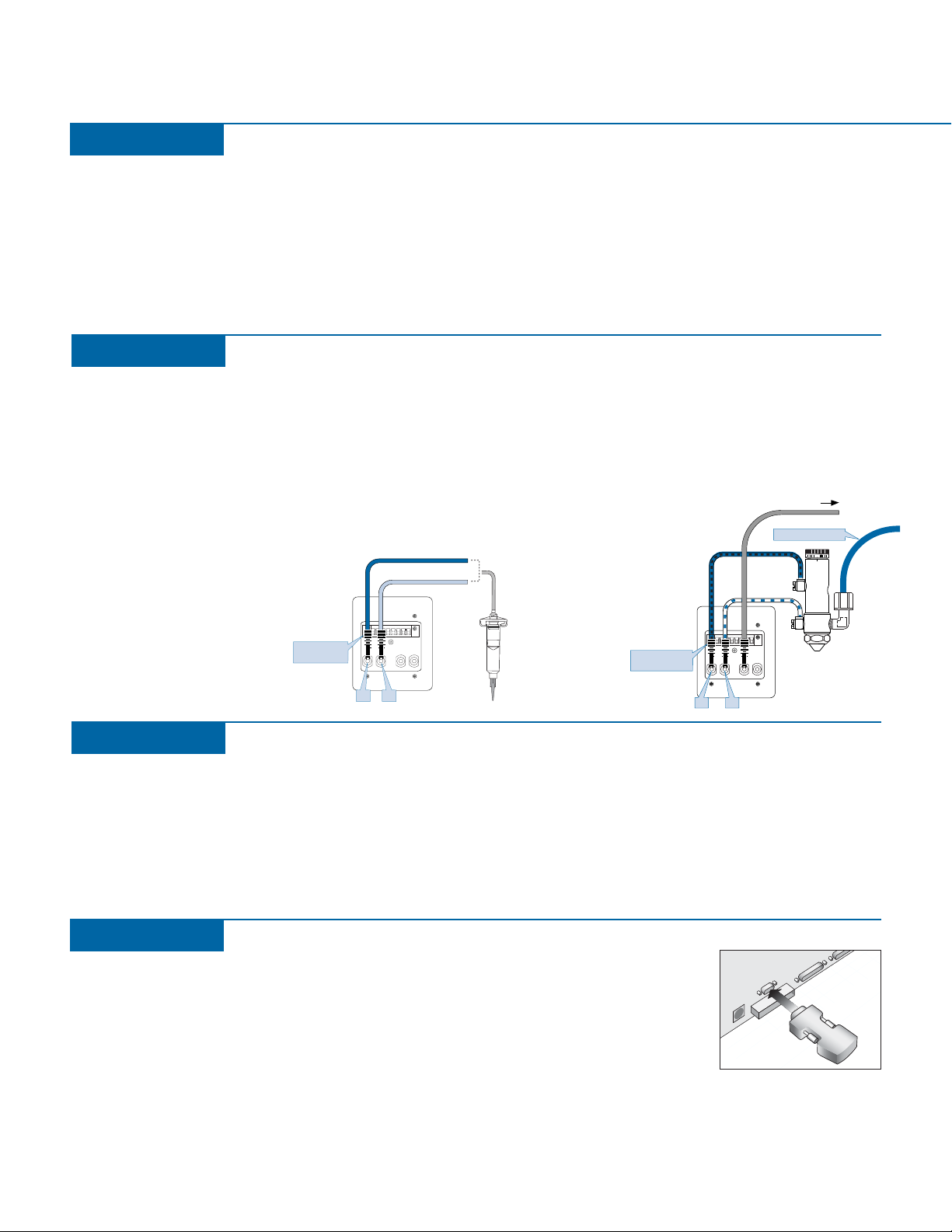

Step 3: Multi Air Input Valve

Attach the valve to the appropriate valve bracket. Install the

valve bracket onto the machine. Attach pulsed-air line to the

P1 connector and then attach the pulsed nozzle air to the P2

connector on top of the Z-head. Fluid reservoir air is connected

to the auxiliary air connector on top of the Z-head.

Step 3: Syringe Barrel

Locate and install the universal syringe barrel bracket (#700814).

Insert the holding pins into the holes on the back plate to fit the

size barrel you are using. Insert the luer end of the barrel into the

barrel stop and twist the barrel onto the captive luer extender.

Attach the barrel adapter to barrel and plug the male quick connect

into the P1 connector (0~100 psi) for dispensing high-viscosity

fluid or P2 (0~30 psi) for dispensing low-viscosity fluid. Attach your

dispensing tip to the bottom of the luer extender

I/O Dispense Head

HS

P1 P2 AUX AIR

0-100 psi

0-30 psi

Black (male)

quick-connect

P1 P2

I/O Dispense Head

HS

P1 P2 AUX AIR

Black (male)

quick-connect

P2P1

LVLP spray valve

2

0

0

5

Fluid feed hose

To pressurized reservoir or cartridge

Page 3

2

Use 6mm OD tubing to connect the air to the main air input on

the back of the machine. It is important that dry, clean, filtered

air is used.

It is recommended that either the 2000F755TT (5 micron filter

regulator) or 2000F756TT (includes coalescing filter) be incorporated between the factory air supply and the Ultra TT System.

TT

SERIES

®

A

N

O

R

D

S

O

N

C

O

M

P

A

N

Y

3

5

7

Install the EFD universal fixture plate (#7007-300 or

#7007-500) or your own tooling plate.

Ensure that it is level.

Note: Dimensional drawings for the Y-carriage can be found

on the CD-ROM included with this machine.

Caution: Failure to level your work-holding fixture may result

in difficulties when programming.

Step 3: Auger Valve

Attach the 790 auger valve to the auger valve bracket (#700806). Install

the valve bracket onto the machine. Barrel reservoir air is connected to

the P2 connector on top of the Z-head. The brown (+) lead is connected

into Terminal 1 and the white (-) lead is connected to terminal 2 of the

(4) position connector on top of the Z-head.

Step 3: Single Air Input Valve

Attach the valve to the appropriate valve bracket. Install the valve bracket

onto the machine. Attach pulsed-air line to the P1 connector on top of the

Z-head. Fluid reservoir air is connected to P2 or to auxiliary air connector

on top of the Z-head. The fluid reservoir tank should be placed to the side

of the machine or if using cartridges, attached to the T-slots on the Z-plate.

Follow the tutorial in the manual on the operations CD-ROM. This will teach you how to program all

the essential elements of a fluid-dispensing program. Read the manual before attempting to teach

your first program. If you have any questions regarding your new Ultra TT Automation Series system,

please contact EFD or their authorized representative.

Air

Tooling Plate

Programming

I/O Dispense Head

HS

P1 P2 AUX AIR

Fluid feed hose

Pulsed air line

752V-UHSS Valve

2

0

0

5

White (female)

quick-connect

P2P1

To pressurized reservoir or cartridge

I/O Dispense Head

HS

P1 P2 AUX AIR

P2

Terminal 1

Terminal 2

Black (male)

quick-connect

2000F755TT

or

2000F756TT

Air input hose

Page 4

Helpful Hints

– Pressure, Speed, Time and Tip Size control deposit size.

Experiment with all four variables to determine ideal application.

– Always use largest possible gauge tip to achieve your deposit size.

– Taper tips drastically reduce the amount of fluid pressure required to

dispense thicker materials.

– As a rule of thumb, the tip should be the diameter of your deposit

size from the substrate. This may change depending upon fluid

pressures and viscosity of the material being dispensed.

– Never dispense a two-part material through an EFD valve. Always

premix your material and load and dispense directly from EFD

syringe barrels.

– When making small dots, try using different retract heights and

speeds. This can often yield much better results.

– When adjusting pressure with regulators, always reduce the pres-

sure below the desired range before turning the pressure back up.

– Change tips as often as possible; material can cure inside the tips

and reduce flow. Changing pressure to compensate for reduced

flow is the least reliable method to compensate for flow reduction.

– Locate a point or mark on your part that you can use to orient the tip

to when creating a new tip offset.

– Always consider safety when working around automated equipment.

– Remove the shipping bolt on top right-hand corner of Z-plate.

Palm is a trademark of Palm, Inc. Socket is a trademark of Socket Communications, Inc.

Bluetooth is a trademark of Bluetooth SIG, Inc. ULTRATTGUIDE-01 ©2006 Nordson Corporation. v022306

For application assistance

in the USA, call 800-556-3484.

For EFD sales and service in over 30 countries,

contact EFD USA or go to www.efd-inc.com/contact

EFD Inc., a Nordson Company

977 Waterman Avenue

East Providence, RI 02914-1342 USA

telephone +1 401-434-1680 fax +1 401-431-0237

automation@efd-inc.com www.efd-inc.com/xyz

®

A NORDSON COMPANY

4

This equipment is regulated by the European Union under WEEE Directive (2002/96/EC).

See www.efd-inc.com for information about how to properly dispose of this equipment."

www.efd-inc.com

Loading...

Loading...