EFD 790 MAINTENANCE GUIDE

790 Dispense Valve

MAINTENANCE & PARTS GUIDE

IMPORTANT!

Save this Sheet.

Forward to

Maintenance or

Tool Crib

Supervisors

Electronic pdf files of EFD®manuals are also available at

www.efd-inc.com/manuals.html.

For EFD sales and service in over 30 countries,

contact EFD or go to www.efd-inc.com/contact

EFD, Inc.

East Providence, RI USA

800-556-3484; +1-401-434-1680 (outside the USA)

info@efd-inc.com www.efd-inc.com

EFD International Inc.

Dunstable, Bedfordshire, UK

0800 585733 or +44 (0) 1582 666334

Ireland 00800 8272 9444

europe@efd-inc.com www.efd-inc.com

EFD, Inc., Asia

China: +86 (21) 5854 2345

china@efd-inc.com www.efd-inc.com/cn

Singapore: +65 6896 9630 sin-mal@efd-inc.com

®

A NORDSON COMPANY

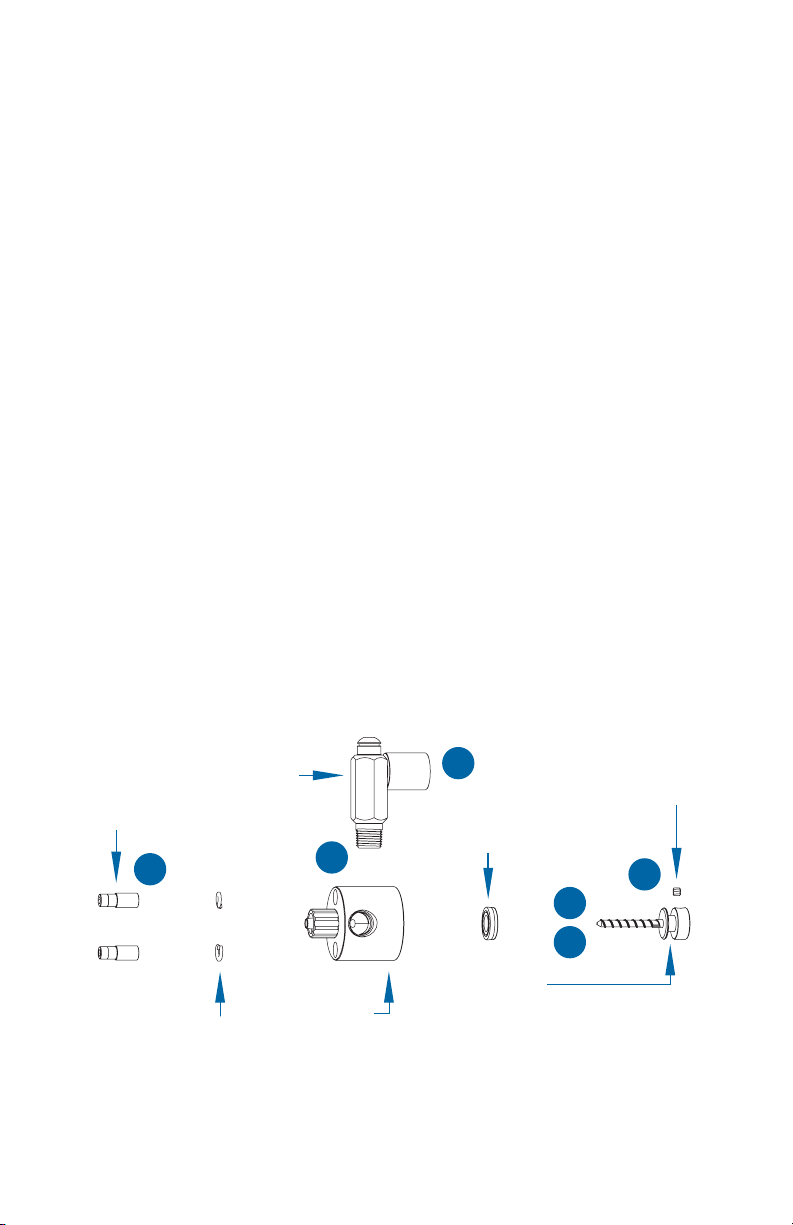

4

1

5

6

7

10

Preventive maintenance with

valve purge compound

The use of valve purge compound

(#6-460-B) between production shifts

or after every eight hours of run time is

highly recommended. The compound

cleans any material residue from the

fluid path and conditions the valve for

future use.

1. Install the barrel of valve purge

compound on the fluid-inlet fitting.

2. Apply reservoir pressure and cycle

the valve until the valve purge

compound has pushed all residual

material from the valve. Leave

the compound in the valve until

future use.

3. To remove the valve purge compound, install material to be dispensed and cycle valve until all

compound has been pushed from

the valve.

Valve Disassembly

and Reassembly Procedures

www.efd-inc.com info@efd-inc.com USA 800-556-3484 Europe +44 (0) 1582 666334 Asia +86 (21) 5854 2345

Sales and service of EFD dispensing systems are available worldwide.

Fluid body

retaining nut (2)

#79025R

Inlet fitting

#79005

Auger set screw

Auger seal

#79011 (Viton)

#79011EPR (EPR)

#HM3X3MM

Auger

Spring lock

washer #H4

Fluid body

#79003-SS (stainless)

#79003A (acetal)

#79004-8SS (std. 8 pitch ss)

#79004-16SS (16 pitch ss)

#79004-8A (8 pitch acetal)

#79004-16A (16 pitch acetal)

Loading...

Loading...