Page 1

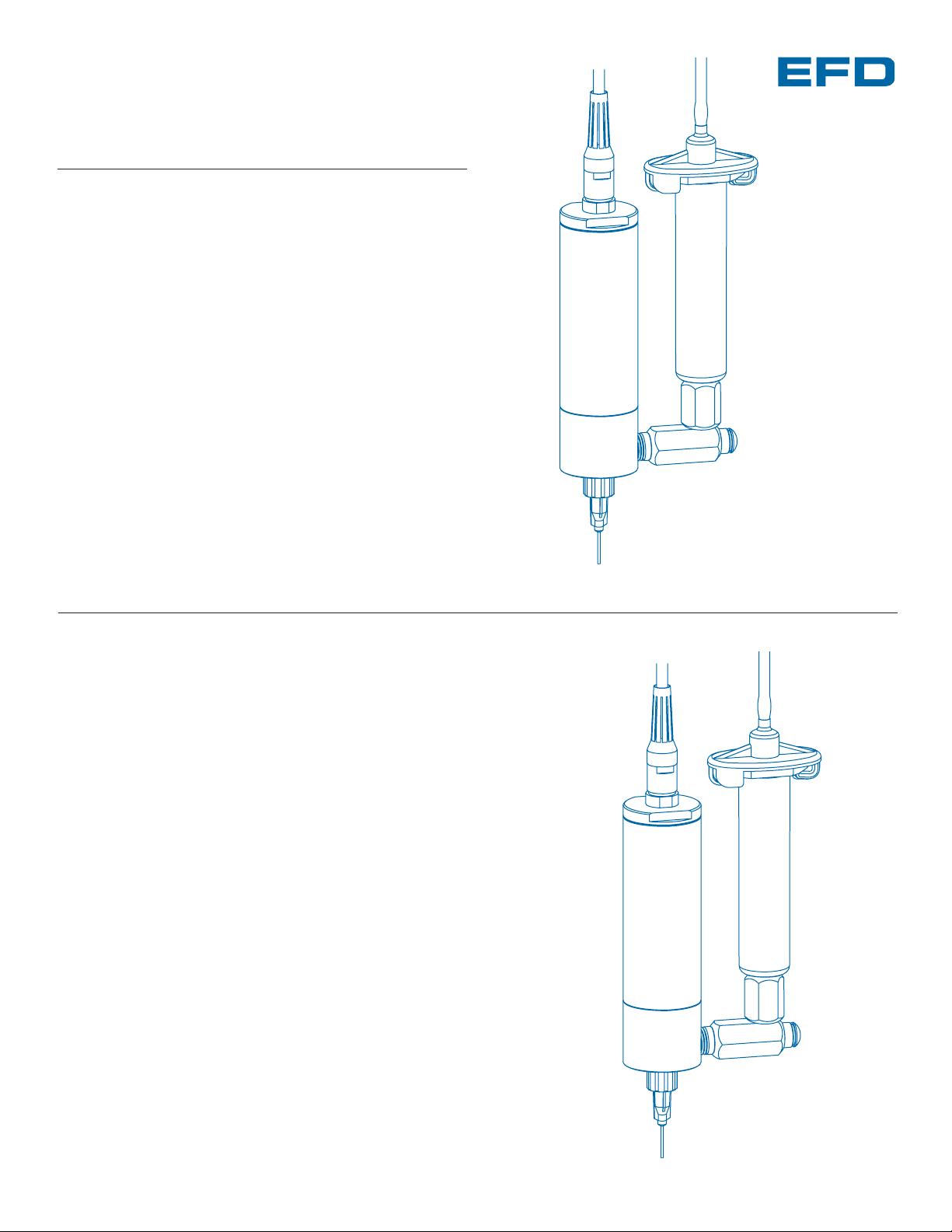

Introduction

The 790 is a precision dispense valve specifically

designed for metering controlled deposits of solder

pastes, thick sealants and other particle-filled materials.

By combining screw-feed principles with precise time,

pressure and dispensing control, the 790 valve is able to

provide accurate, repeatable deposits without damaging

the metal particles of the solder. These features are not

possible with any other type of conventional control valve.

790 Dispense Valve

INSTALLATION GUIDE

USA: 800-556-3484 or +1-401-434-1680

Europe: 0800 585733 or +44 (0) 1582 666334

Asia: +86 (21) 5854 2345

technical@efd-inc.com www.efd-inc.com

Electronic pdf files of EFD®manuals are also available at

www.efd-inc.com/manuals.html.

®

A NORDSON COMPANY

Power cable

Motor chamber

Fluid feed fitting

Dispensing tip

Barrel

retaining

clamp

Page 2

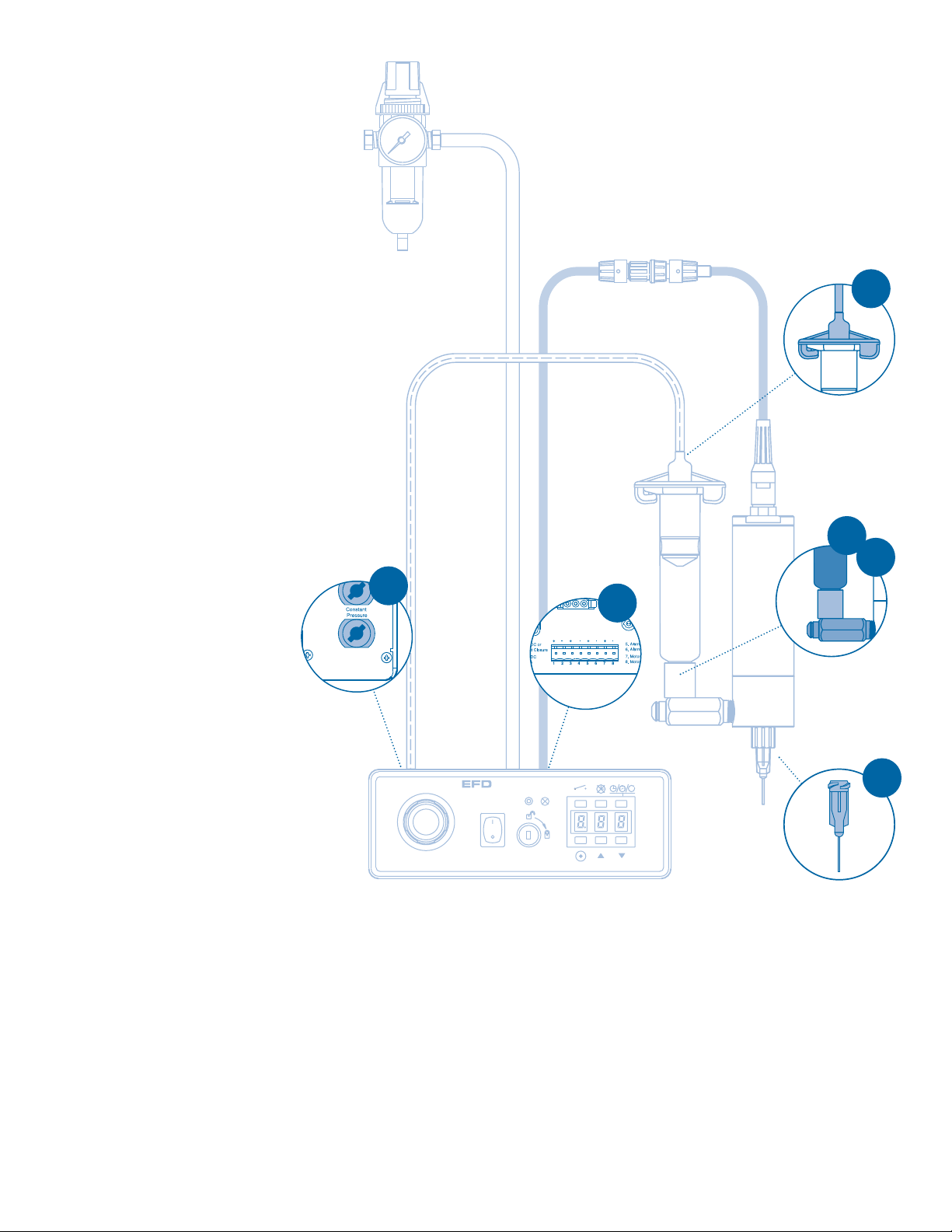

Installation

1. Connect the motor lead wire to

the I/0 connector position 7 (white

wire) and position 8 (brown wire).

2. Install the barrel of red purge

compound (supplied) onto the

dispense valve-inlet fitting.

3. Press the barrel into the fitting

while rotating one-half turn

clockwise. Do not overtighten.

4. Attach the yellow end of the

barrel adapter assembly to the

barrel of red purge compound.

5. Install the black quick-connect

into the air output connector

labeled "Constant Pressure.”

6. Install a pink 20 gauge dispens-

ing tip (supplied, part #5120-1/4)

onto the valve outlet.

Prior to installing this valve, please

read the associated reservoir and

valve controller operating instructions to become familiar with the

operation of all components of the

dispensing system.

1

4

5

2

3

6

VALVEMATE

7090

M

M

Page 3

How the Valve Operates

ValveMate Concept

The ValveMate 7090 provides

easy adjustment of valve output

for maximum end-user convenience and efficiency. Valve opentime is the primary control of

deposit. The 7090 puts pushbutton adjustment of valve opentime where it needs to be – at

the valve.

Microprocessor circuitry provides

exact control of the spray valve

to achieve exceptional spray pattern definition. The ValveMate

7090 also incorporates microprocessor-controlled functions

that include motor start-up

open closed

➁➁

➀➀

Input-air pressure at 65 psi (4.5 bar) is

applied to the material reservoir, forcing fluid

➀➀

into the path of the auger.

As the auger rotates, fluid moves along

the auger flutes

➁➁

and is forced-out

through the dispense orifice.

The ValveMateTM7090 controller regulates the reservoir pressure, ensuring

that there is enough pressure to keep

the valve primed with fluid without

forcing it past the auger.

Duration of the dispensing time

is controlled by adjusting the

time control up or down until the

required deposit size is established, at which point it is repeated

with each initiate cycle.

acceleration limits and maximum current overload protection for extended motor life.

Deposit size can be programmed by pressing the

PROGRAM button in the

SETUP mode. This affords

an easy starting point for

selecting deposit size.

Note: The EFD Ultra

®

TT 325

and 525 XYZ automated dispensing systems have integrated ValveMate controllers

for operating all EFD dispense

valves.

www.efd-inc.com technical@efd-inc.com USA 800-556-3484 Europe +44 (0) 1582 666334 Asia +86 (21) 5854 2345

VALVEMATE

7090

Rear Panel

air input

power input

(voltage selector)

air output to valve

connector for

optional foot pedal

M

Control Pad

set time

timer bypass

display – pressure (psi, bar)

– time

– motor volts

TEACH program

test cycle

purge

reset

M

Page 4

Specifications

General

Size: 155.4 mm length x 28.7 mm diameter (6.12" x 1.13")

Weight: 314 grams (11.07 oz)

Fluid body: Type 303 stainless steel (Acetal optional)

Auger: Type 303 stainless steel (Acetal optional)

"U" cup: Viton

®

Fluid feed fitting: Type 303 stainless steel (Polypro optional)

Auger speed: 250 RPM (400 RPM optional)

Auger pitch: 8 threads per inch (16 threads per inch optional)

For consistent dispense valve operation and easy adjustment

of valve output, EFD recommends using the ValveMate 7090

controller on all automatic, semi-automatic and benchtop

applications.

The EFD Ultra TT Series positioning systems incorporate

dispensing control into the main system.

Contact the EFD Dispense Valve Systems Group for details.

For EFD sales and service in over 30 countries,

contact EFD or go to www.efd-inc.com/contact

EFD, Inc.

East Providence, RI USA

800-556-3484; +1-401-434-1680 (outside the USA)

info@efd-inc.com www.efd-inc.com

EFD International Inc.

Dunstable, Bedfordshire, UK

0800 585733 or +44 (0) 1582 666334

Ireland 00800 8272 9444

europe@efd-inc.com www.efd-inc.com

EFD, Inc., Asia

China: +86 (21) 5854 2345

china@efd-inc.com www.efd-inc.com/cn

Singapore: +65 6896 9630 sin-mal@efd-inc.com

Viton is a registered trademark of E.I. DuPont.

©2006 Nordson Corporation 790-INSTALL-01 v062606

®

A NORDSON COMPANY

This equipment is regulated by the European Union under WEEE

Directive (2002/96/EC). See www.efd-inc.com for information about

how to properly dispose of this equipment.

Loading...

Loading...