Introduction

The 782RA is a precision, air-actuated spray valve that

produces a narrow radial output ideal for coating the interiors of cylinders. LVLP (low volume low pressure) air is

used to atomize the fluid, while a precision air motor

drives a rotating air cap that produces the radial output.

The 782RA valve has a 5.6 cm (2.2”) extended rotor air

cap that will reach inside cylinders with a minimum inner

diameter of 2.5 cm (1.0”). The valve is simple to use and

will operate many millions of cycles without maintenance.

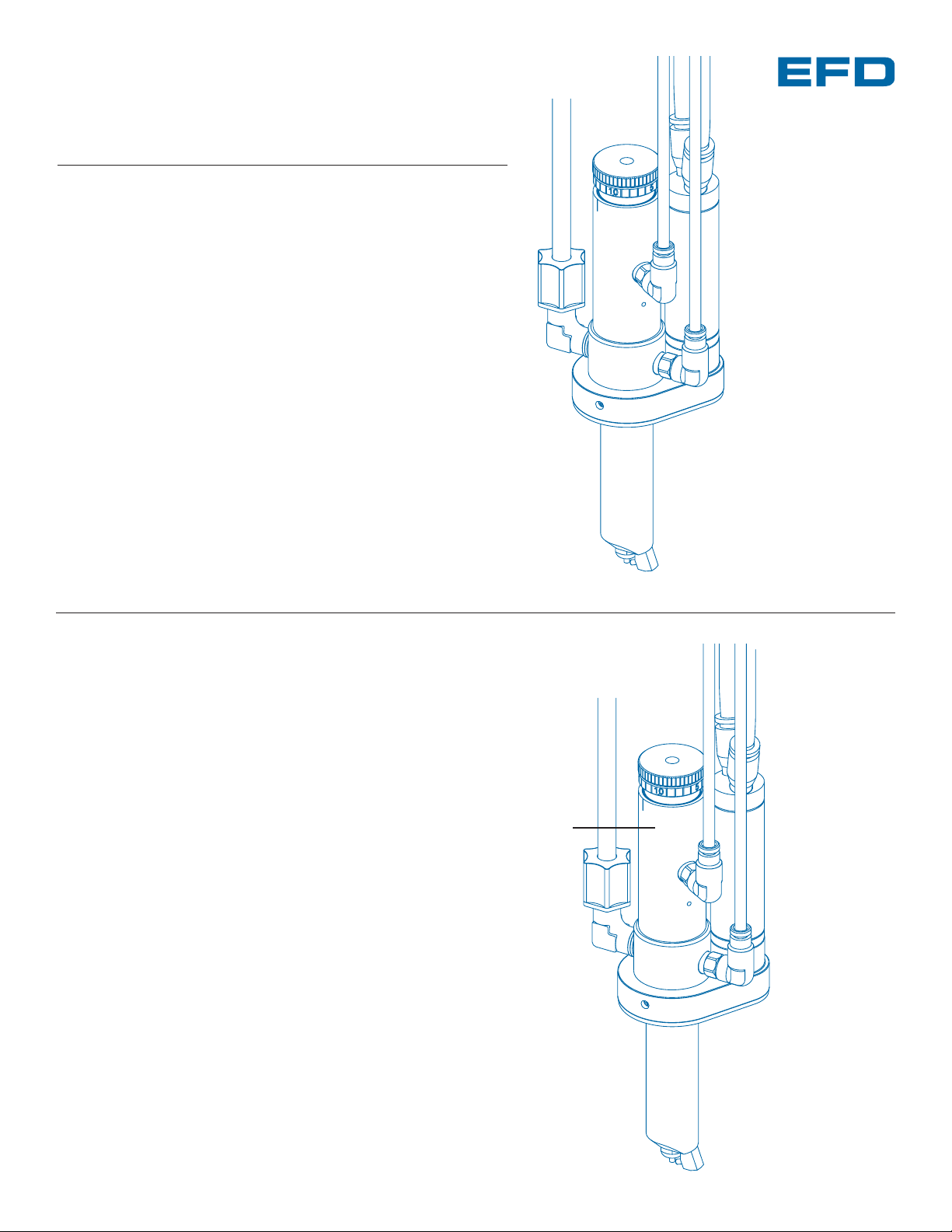

782RA Spray Valve

INSTALLATION GUIDE

Rotor

Fluid inlet

fitting

Air cylinder

body

Fluid supply line

USA: 800-556-3484 or +1-401-434-1680

Europe: 0800 585733 or +44 (0) 1582 666334

Asia: +86 (21) 5854 2345

technical@efd-inc.com www.efd-inc.com

Electronic pdf files of EFD®manuals are also available at

www.efd-inc.com/manuals.html.

®

A NORDSON COMPANY

0

5

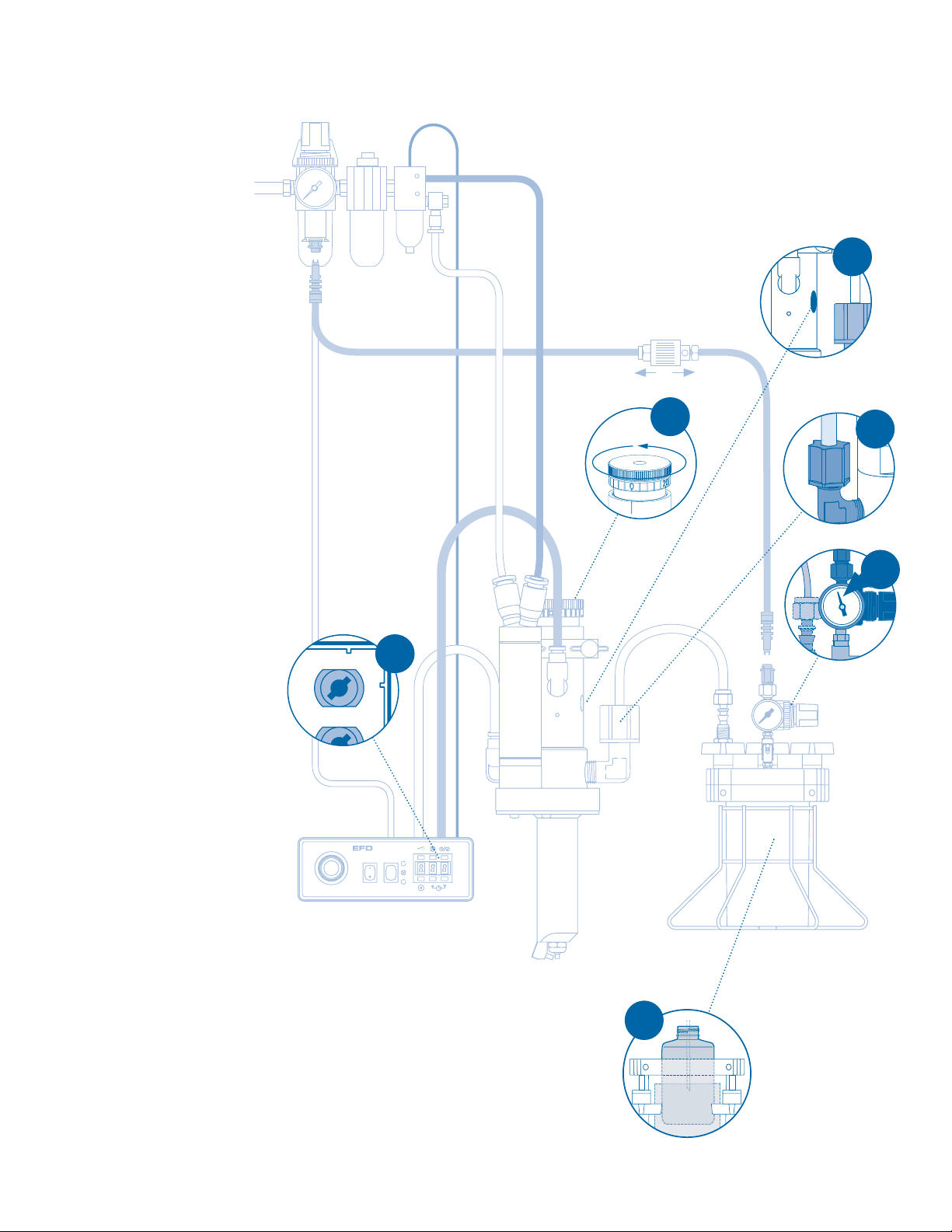

Installation

1. Mount valve using the 1/4-28

UNF tapped hole on the air

cylinder body.

2. Connect the fluid feed hose to

the reservoir outlet and the

valve-inlet port using the

appropriate fittings (supplied).

3. Connect the 4 mm diameter

air hoses from the valve to the

controller. The white goes to

the “A” port and the black

goes to the “B” port.

4. Connect the 6 mm diameter

air hoses from the motor to

the air preparation assembly.

The white connects to the

control valve. The black

connects to the motor speed

control fitting.

5. Fill the fluid reservoir. After

filling, secure the cover and

connect the reservoir air pressure regulator to the air tee

using the flexible air line (supplied). Attach the black male

quick-connect on the air line

to the reservoir regulator and

then attach the white quickconnect to the air tee. To

pressurize the system, slide

the shut-off valve on the air

line toward the fluid reservoir.

6. Set the reservoir pressure reg-

ulator according to fluid viscosity, to low for thin fluids 1

to 3 psi (0.07 to 0.2 bar) and

higher for thick fluids.

7. Set the needle stroke control

at one turn open. This is a

starting point. Final setting will

be determined by the desired

flow rate.

Prior to installing this valve,

please read the associated

reservoir and valve controller

operating instructions to

become familiar with the operation of all components of the

dispensing system.

Output A

Output B

3

5

1

7

2

6

Air Preparation Assembly: See pages 6 – 7,

ValveMate 7060RA Controller Operating Manual.

To pressurize

To exhaust

®

VALVEMATE

A NORDSON COMPANY

7060RA

M

M

M

How the Valve Operates

ValveMate Concept

The ValveMate 7060RA provides

easy adjustment of valve output

for maximum end-user convenience and efficiency. Valve opentime is the primary control of

deposit size. The 7060RA puts

push-button adjustment of valve

open time where it needs to be –

at the valve.

The controller incorporates

unique microprocessor circuitry

to provide exact time control and

interact with the host computer.

A built-in air pressure regulator

provides low volume low pressure nozzle air to ensure high

open

closed

➃➃

➂➂

➁➁

➀➀

Input-air pressure at 70 psi (4.8 bar)

acts on a piston

➀➀

that retracts the

needle

➁➁

from its nozzle seat ➂➂, permitting fluid flow from the nozzle ➃➃. At

the same time, atomizing air from the

ValveMate™7060RA controller is turned

on and flows from the rotor air tube

➄➄

across the fluid nozzle at a 70° angle.

This atomizing air creates a pressure

drop around the nozzle, causing fluid

to atomize into fine droplets and follow

the direction of the atomizing air flow.

The rotor, spinning at approximately

2500 rpm, causes the radial output to

sweep around and evenly coat the

inner circumference of the cylinder.

When the timed actuating air

from the ValveMate 7060RA

controller shuts off, the piston

spring moves the needle onto

the nozzle seat and shuts-off

fluid flow. An adjustable

atomizing air delay ensures

that all fluid is atomized after

the valve closes, eliminating

post-deposit spatter.

transfer efficiency without

overspray.

Deposit size can be programmed by pressing the

PROGRAM button in the

SETUP mode. This affords

an easy starting point for

selecting deposit size.

Note: The EFD Ultra

®

TT 325

and 525 XYZ automated dispensing systems have integrated ValveMate controllers

for operating all EFD dispense

valves.

➄➄

www.efd-inc.com technical@efd-inc.com USA 800-556-3484 Europe +44 (0) 1582 666334 Asia +86 (21) 5854 2345

®

A NORDSON COMPANY

7060RA

Rear Panel

air input

power input

air output to valve

I/O interface terminal strip

air exhaust

atomizing air output

connector for

optional foot pedal

VALVEMATE

M

M

M

Control Pad

cycle / test

time override

time / pressure

and psi / bar toggle

program

time set

Specifications

General

Size: 174.5 mm length x 68.6 mm diameter (6.87” x 2.70”)

Weight: 408.2 grams (14.4 oz)

Air consumption: <0.3 SCFM at 80 psi (5.4 bar)

Air cylinder body: Hard-coated aluminum

Fluid body: Hard-coated aluminum

Piston: Type 303 stainless steel

Piston return spring: Stainless steel

Needle and nozzle: Stainless steel

Rotor: Hard-coated aluminum

Fluid inlet hole: 1/8 NPT female

Air pressure required: 70 psi (4.8 bar)

Mounting: 1/4-28 UNF tapped hole

Spray Coverage

782RA distance from nozzle center to inside diameter of

cylinder wall.

14˚

Spray coverage shown 1/2 actual size

Nozzle distance to inside diameter

For consistent dispense valve operation and easy adjustment

of valve output, EFD recommends using the ValveMate

7060RA controller on all automatic, semi-automatic and

benchtop applications.

The EFD Ultra TT Series positioning systems incorporate

dispensing control into the main system.

Contact the EFD Dispense Valve Systems Group for details.

For EFD sales and service in over 30 countries,

contact EFD or go to www.efd-inc.com/contact

EFD, Inc.

East Providence, RI USA

800-556-3484; +1-401-434-1680 (outside the USA)

info@efd-inc.com www.efd-inc.com

EFD International Inc.

Dunstable, Bedfordshire, UK

0800 585733 or +44 (0) 1582 666334

Ireland 00800 8272 9444

europe@efd-inc.com www.efd-inc.com

EFD, Inc., Asia

China: +86 (21) 5854 2345

china@efd-inc.com www.efd-inc.com/cn

Singapore: +65 6896 9630 sin-mal@efd-inc.com

©2006 Nordson Corporation 782-INSTALL-01 v062606

®

A NORDSON COMPANY

25.4 mm (1.0”)

4.3 mm (0.17”)

76.2 mm (3.0”)

12.7 mm (0.5”)

152.4 mm

(6.0”)

25.4 mm

(1.0”)

Loading...

Loading...