Page 1

The World Leader in Fluid Dispensing Technology

User’s Guide

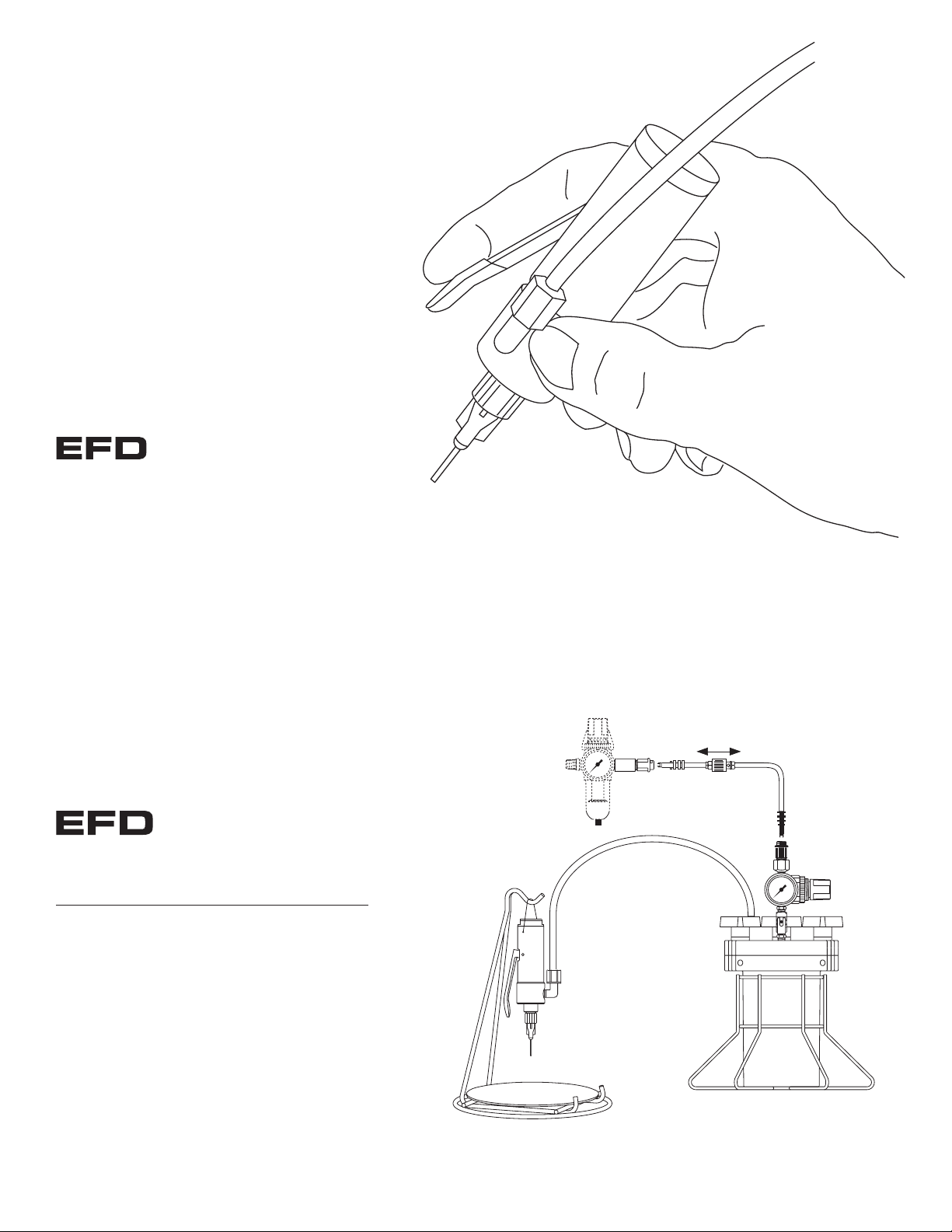

752V-HL Dispense Gun

The 752V-HL hand-operated dispense gun is a

rugged industrial lever-actuated fluid dispensing

valve. The valve incorporates a quick change fluid

body for fast and easy maintenance. The fluid inlet

fitting for 1/4" OD feed tubing and an assortment of

dispensing tips are included.

#615DTH

1.0 liter tank accommodates

a one pound bottle.

#61522

Hand-lever

valve stand

#2000F755

Five micron filter regulator for

clean, dry filtered factory air.

For dispensing with cyanoacrylates, order #2000756

with coalescing filter.

Shutoff valve

Typical system setup

USA: 800-556-3484 or +1-401-434-1680

Europe: 0800 585733 or +44 (0) 1582 666334

Asia: +86 (21) 5854 2345

technical@efd-inc.com www.efd-inc.com

For EFD sales and service in over 30 countries,

contact EFD or go to www.efd-inc.com/contact

EFD, Inc.

East Providence, RI USA

800-556-3484; +1-401-434-1680 (outside the USA)

info@efd-inc.com www.efd-inc.com

EFD International Inc.

Dunstable, Bedfordshire, UK

0800 585733 or +44 (0) 1582 666334

Ireland 00800 8272 9444

europe@efd-inc.com www.efd-inc.com

EFD, Inc., Asia

China: +86 (21) 5854 2345

china@efd-inc.com www.efd-inc.com/cn

Singapore: +65 6896 9630 sin-mal@efd-inc.com

©2006 Nordson Corporation 752V-HL-MAN-01 v062606

Electronic pdf files of EFD®manuals are also available at www.efdinc.com/manuals.html

®

A NORDSON COMPANY

®

A NORDSON COMPANY

Page 2

Service

Normal cleaning is accomplished by purging with appropriate solvent.

Some material, however, may cause a buildup on the fluid body and

diaphragm, which will require a periodic, thorough cleaning by removing

the fluid body.

To remove the fluid body:

Remove the two retainer screws. It is not always necessary to

remove the fittings from the fluid body for cleaning. If the fittings

must be removed, be careful—solidified material on the fitting thread

could cause the fluid body thread to strip out.

NOTE: Avoid using sharp probes for cleaning. Any scratches or nicks on

the diaphragm or the sealing side of the fluid body may cause the valve

to leak and require replacement of both the diaphragm and fluid body.

To reinstall the fluid body:

Align fluid body holes with diaphragm and air cylinder body holes,

and reinsert retainer screws. Tighten 1/2 turn after screws contact

the fluid body. Proper torque is 7” pounds.

If diaphragm holes do not line up with the tapped holes in the air

cylinder body, follow Step #4 below.

Getting started ...

1. Install the feed tube from the fluid reservoir to the inlet fitting and

tighten the compression nut to secure. The location of the inlet

fitting can be changed by removing the two fluid body retainer

screws and fluid body. Follow the service instructions to reinstall the fluid body with the inlet fitting in the desired position.

2. Apply air pressure to the fluid reservoir. Start with a low setting

of 20 psi (1.4 bar). If using an EFD fluid reservoir, refer to the

User’s Guide for further instructions.

3. Install an appropriate size dispensing tip to the outlet tip

adapter. Use large tips for high viscosity materials and small

tips for low viscosity.

4. Press the hand lever to begin fluid flow. Release lever to stop

fluid flow.

5. To achieve desired flow, change the size of the dispensing tip or

adjust the reservoir fluid pressure.

Maintenance Tools:

7/64" hex wrench (part #7509)

1/8" flat tip screwdriver (part #7508)

snap ring pliers (customer supplied)

6" adjustable wrench (customer supplied)

CAUTION: Check the reservoir pressure gauge prior to performing any

maintenance to assure that pressure is zero (0). To confirm this on EFD

tanks: slide the shutoff valve on the air hose away from the tank, and

open the pressure relief valve on the tank.

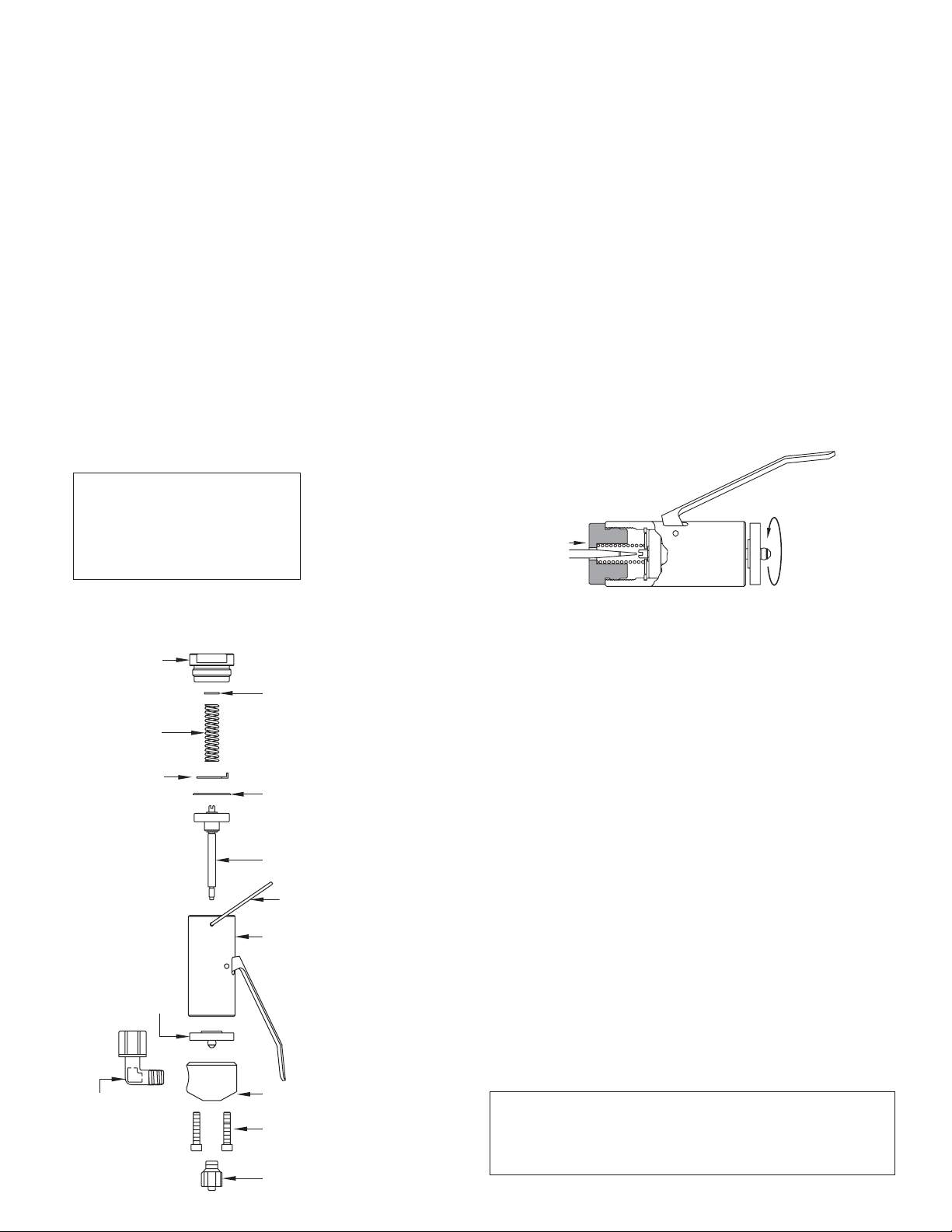

To change the diaphragm:

1. Remove the fluid body.

2. Place the 1/8" flat tip screwdriver (supplied) through the center

hole in the air cylinder cap.

See above.

Engage the slot in the

end of the piston shaft ➀. While holding the screwdriver, unscrew

the diaphragm counterclockwise ➁.

3. While holding the screwdriver, carefully thread on the new

diaphragm. Be careful not to strip or cross-thread the diaphragm

thread. Finger-tighten with medium pressure until the diaphragm

bottoms against the shoulder on the piston rod.

4. Before installing the fluid body, determine the operator’s desired

position of the fluid inlet fitting. Use the screwdriver inserted

through the hole in the air cylinder cap to align the holes on the

diaphragm with the appropriate holes in the air cylinder body.

Holding the air cylinder body, rotate the piston shaft clockwise

using the screwdriver until the appropriate holes line up.

5. Reinstall the fluid body. Tighten retainer screws 1/2 turn after

contacting the fluid body. Proper torque is 7 inch pounds.

➁ To unscrew

diaphragm,

turn counterclockwise.

➀ Engage the screwdriver into

the piston shaft and hold.

Air cylinder cap

Piston return

spring #7802

Tab washer

Diaphragm

Fluid inlet fitting

#7543BP

#7529

#7533

#7510

Thrust washer

#7809

Snap ring #7526

Piston and shaft assembly

#7523

Bail hanger #7412

Air cylinder and lever assembly

#7527HL

Fluid body #7521F

(2) Retainer screws

#7524

Tip adapter #7536NP

Loading...

Loading...