Page 1

750V, 750V-SS and 751V

Dispense Valves

MAINTENANCE & PARTS GUIDE

IMPORTANT!

Save this Sheet.

Forward to

Maintenance or

Tool Crib

Supervisors

Electronic pdf files of EFD®manuals are also available at

www.efd-inc.com/manuals.html.

For EFD sales and service in over 30 countries,

contact EFD or go to www.efd-inc.com/contact

EFD, Inc.

East Providence, RI USA

800-556-3484; +1-401-434-1680 (outside the USA)

info@efd-inc.com www.efd-inc.com

EFD International Inc.

Dunstable, Bedfordshire, UK

0800 585733 or +44 (0) 1582 666334

Ireland 00800 8272 9444

europe@efd-inc.com www.efd-inc.com

EFD, Inc., Asia

China: +86 (21) 5854 2345

china@efd-inc.com www.efd-inc.com/cn

Singapore: +65 6896 9630 sin-mal@efd-inc.com

A NORDSON COMPANY

Page 2

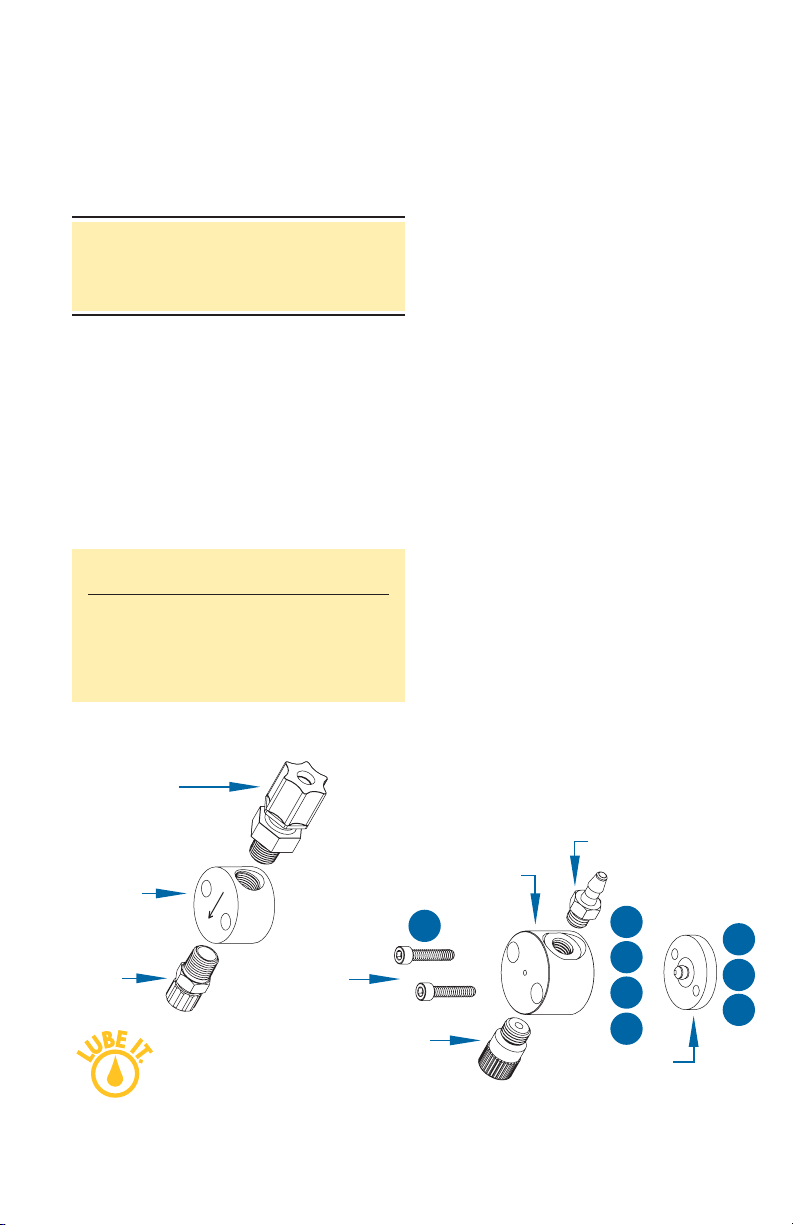

Fluid Body

1. Remove the two retainer screws.

2. To reinstall the fluid body, align fluid

body holes with diaphragm and air

cylinder body holes and reinsert

retainer screws. Tighten in accordance with the following torque

specifications:

newton

Fluid body meters (inch pounds)

Acetal (black) 1.58 Nm (14 inch pounds)

UHMW*(yellow) 0.79 Nm (7 inch pounds)

Stainless steel 1.58 Nm (14 inch pounds)

*

Ultra High Molecular Weight

Diaphragm

3. Back-out stroke control knob two

turns counterclockwise from the

closed position.

4. Remove fluid body.

5. Unscrew diaphragm (counterclockwise) and remove it from

the piston rod.

6. Thread-on the new diaphragm

and tighten with medium pressure.

7. Align the holes of the diaphragm

with the appropriate holes in the

air cylinder body by inserting a

flat tip screwdriver through the

hole in the stroke control knob

and engage piston rod slot.

8. Rotate rod, piston and diaphragm

assembly clockwise until holes

are aligned.

9. Reinstall fluid body.

10. Turn stroke control knob clockwise until closed, and then

reopen to approximate stroke.

1

2

4

5

6

7

9

11

Valve Disassembly and

Reassembly Procedures

CAUTION: To prevent damage, the valve

must be disassembled starting at the fluid

outlet end of the valve.

www.efd-inc.com info@efd-inc.com USA 800-556-3484 Europe +44 (0) 1582 666334 Asia +86 (21) 5854 2345

Sales and service of EFD dispensing systems are available worldwide.

751V assembly

Fluid inlet fitting

Fluid inlet fitting

Fluid body

Tip

Adapter

(2) Retainer

screws

#7524

Tip Adapter

Fluid body

Diaphragm

UHMW

Page 3

Piston O-ring

11. Remove fluid body and diaphragm.

12. Remove stroke control knob and

spring by turning counterclockwise.

13. Remove the piston retainer ring and

anti-torque washer.

14. Remove the piston.

15. Lubricate O-ring, piston shaft and air

cylinder wall with Nye Lubricant #865.

16. Reinstall components in reverse order

of disassembly.

Tools required:

7/64" hex wrench

1/8" flat-tip screwdriver

6" adjustable wrench

6" needle-nose pliers

snap-ring pliers

Replacement Parts for Specific Valve Models

——— Fluid Body ———

Model UHMW Acetal Stainless* Fluid Inlet Fitting Tip Adapter Diaphragm

750V &

750V-SS 7521 n/a 7521-SS* 7511BP (1/8” ID Tube) 7514 7510

751V n/a 7521D 7521D-SS 7611BP (1/4” OD Tube) 7514B 7510

7610BP (3/8” OD Tube)

*optional

3

8

10

12

13

14

15

16

www.efd-inc.com info@efd-inc.com USA 800-556-3484 Europe +44 (0) 1582 666334 Asia +86 (21) 5854 2345

Sales and service of EFD dispensing systems are available worldwide.

Air cylinder body

#7527-SS (stainless steel)

#7527 (hard-coated aluminum)

Piston and rod

includes O-ring

#7518

Anti-torque washer

#7533

Air input hose & fitting

#78518A

Stroke control knob

#750SR-KIT (stroke reference, aluminum)

#750SSR-KIT (stroke reference,

stainless steel)

Piston spring #7525

Piston retainer ring

#7526

750SR-KIT

750V

750SSR-KIT

750V-SS

Page 4

Troubleshooting Guide

No fluid flow

• If valve operating air pressure is too low,

the valve will not open. Increase air

pressure to 70 psi (4.8 bar) minimum.

• The reservoir air pressure may not be

high enough. Increase pressure.

• The dispensing tip may be clogged.

Replace tip.

• The stroke adjustment may be closed.

Open stroke adjustment.

• Fluid may have solidified in the valve.

Clean the fluid body.

Fluid drools after the valve closes,

eventually stopping

• This is caused when air is trapped in the

outlet section of the fluid chamber or the

fluid has entrapped air. The air will expand

after the valve closes, causing extrusion

until the air reaches atmospheric pressure.

Purge the valve by dispensing at a steady

flow until clear. If a small tip is used, it

may be necessary to remove the tip while

purging to obtain sufficient flow to carry

the air down through the tip adapter.

• If the fluid has entrapped air, the material

must be degassed before dispensing.

Fluid drips at a steady rate after the

valve closes

• A steady drip can be caused by exces-

sive reservoir pressure. Check to be

sure the reservoir pressure is not above

70 psi (4.8 bar).

• If the stroke adjustment knob is turned-out

more than two full turns, resulting in reservoir pressure that will force the diaphragm

open. Check the stroke adjustment knob

to be sure it is less than two turns out.

• A steady drip also indicates failure of

the diaphragm to close fully due to particle build-up or wear. In either case,

replace the sealing head in accordance

with the maintenance instructions.

Fluid leaks out between fluid body and

diaphragm

• Fluid leakage between the fluid body and

diaphragm indicates the annular sealing ridge on the fluid body is damaged or

the fluid body is distorted due to excessive torque on the retaining screws. In

either case, replace the fluid body.

Fluid flows out of the drain hole

• Fluid flowing out of the drain hole indicates

a ruptured diaphragm. Replace in accordance with the maintenance instructions.

Valve responds slowly when opening

and closing

• Valve response is related to control air

hose length and size. The valve is supplied with 5-feet of 3/32” ID tubing

attached. Any additional length or size

change will affect response time. Check

to be sure the length and size have not

been changed.

Inconsistent deposits

• Inconsistent deposits can result if the

air pressure controlling the valve and/or

supplying the reservoir is fluctuating or if

the valve operating pressure is less than

70 psi (4.8 bar). Check to be sure air

pressures are constant and the valve

operating pressure is 70 psi (4.8 bar).

• The time the valve is open must be constant. Check to be sure the valve controller is providing a consistent output.

A NORDSON COMPANY

USA: 800-556-3484 or +1-401-434-1680

Europe: 0800 585733 or +44 (0) 1582 666334

Asia: +86 (21) 5854 2345

technical@efd-inc.com www.efd-inc.com

©2006 Nordson Corporation 750V-MAINT-01 v062606

Loading...

Loading...