Page 1

Introduction

The 750 Series fluid dispense valves are simple to

use and will operate many millions of cycles without

maintenance. The 750 Series incorporates a variety

of compact, precise, adjustable diaphragm valves

for dispensing low to medium viscosity fluids. These

include the 750V, 750V-SS, 751V, 752V, 752V-SS,

752V-UH, 752V-UHSS, 752V-DVD and 752V-UHDVD

models.

All 750 Series valves use the same actuating assembly.

But fluid body styles and diaphragms differ according

to the model. The 752V Series fluid bodys are constructed with the outlet at the end of the fluid body.

The 750V and 751V fluid bodys are constructed with

the outlet on the side of the fluid body.

Each valve is shipped with a dispensing tip adapter,

fluid inlet fitting and 5-foot actuating air hose installed.

750 Series

Dispense Valve

INSTALLATION GUIDE

USA: 800-556-3484 or +1-401-434-1680

Europe: 0800 585733 or +44 (0) 1582 666334

Asia: +86 (21) 5854 2345

technical@efd-inc.com www.efd-inc.com

Electronic pdf files of EFD®manuals are also available at

www.efd-inc.com/manuals.html.

®

A NORDSON COMPANY

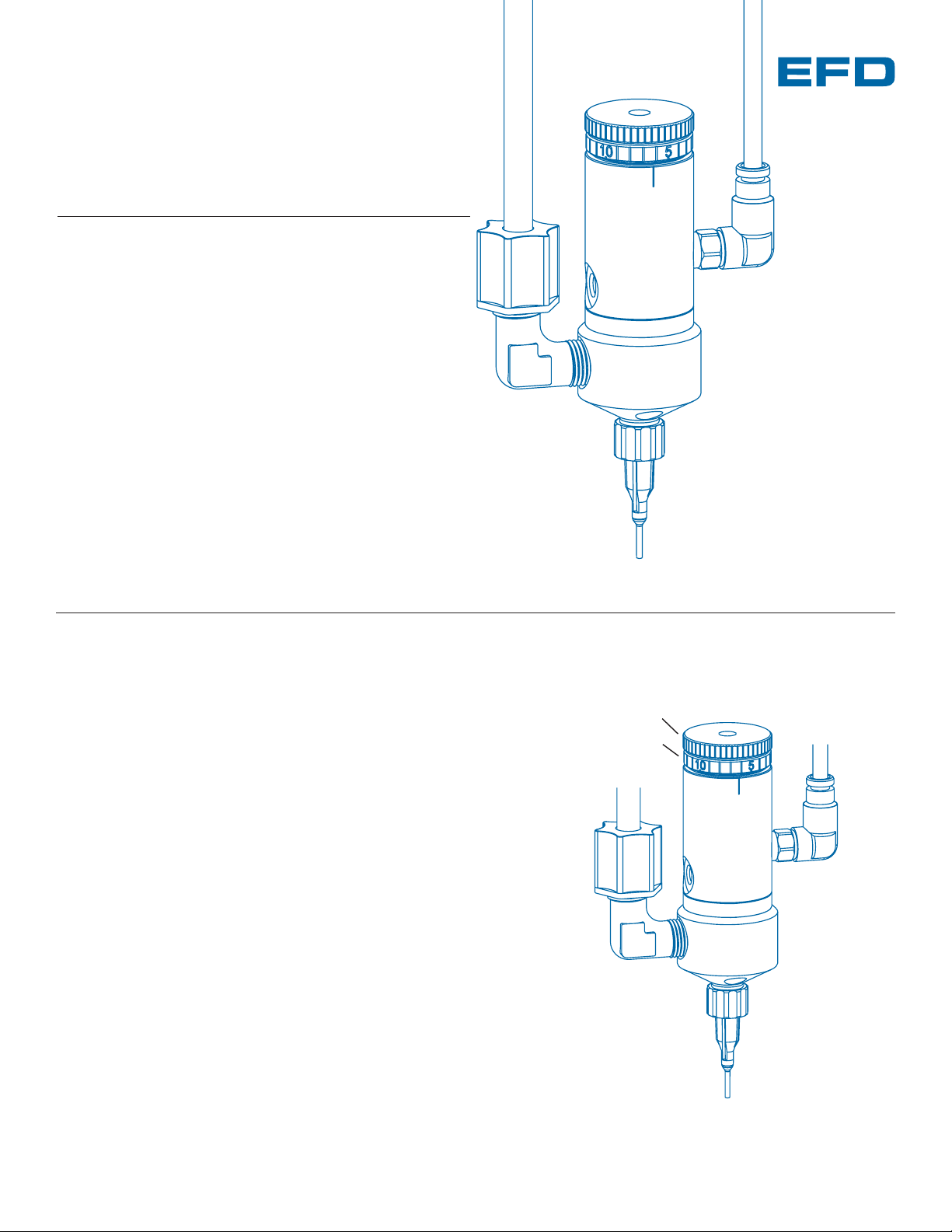

Stroke control knob

Stroke reference ring

Fluid supply line

Inlet fitting

Control

air hose

Fluid body

Dispensing tip

Page 2

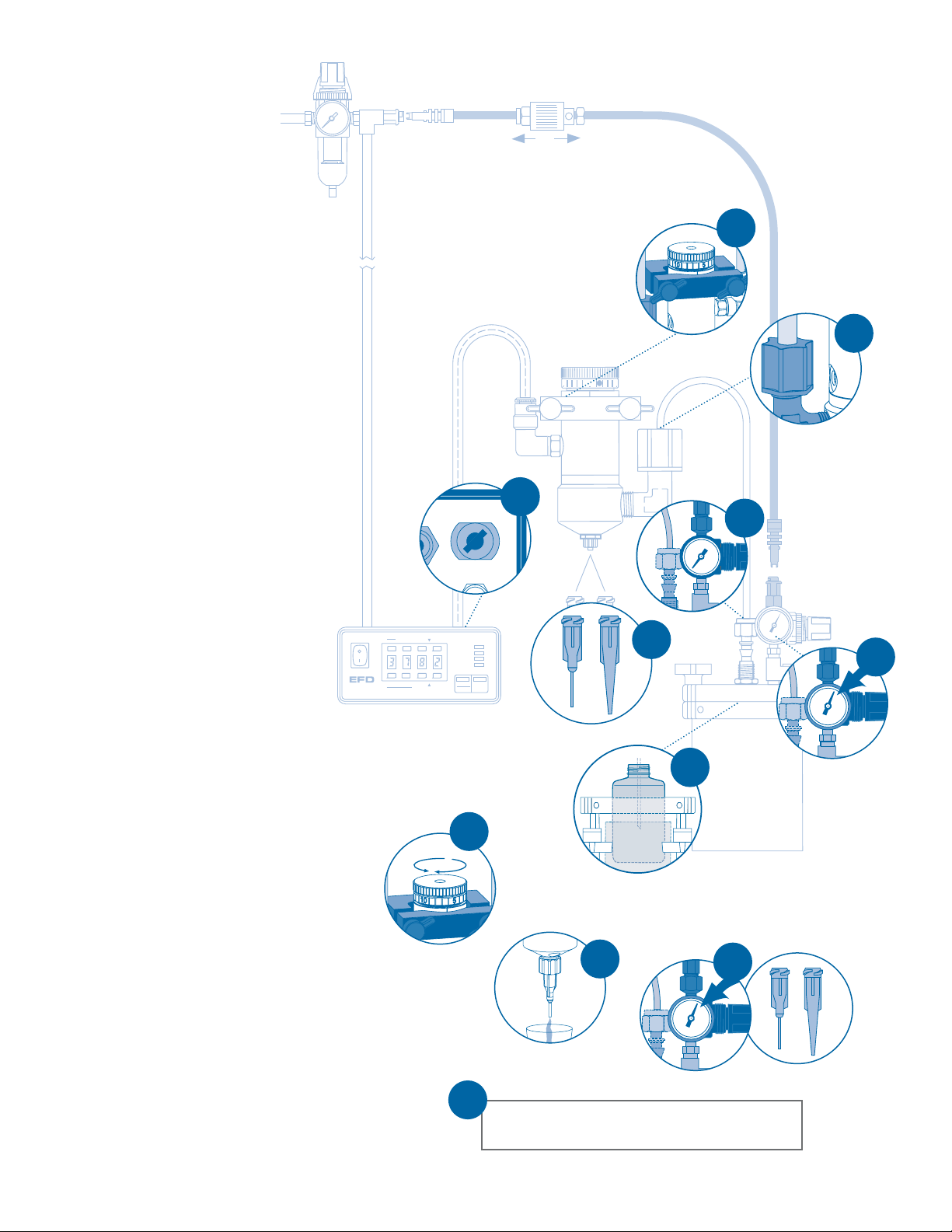

Installation

Set desired deposit size by adjusting valve open

time. Refer to valve controller operating manual.

11

1. Mount valve with an EFD universal

valve mount (#7002VM) or other fixture.

2. Connect fluid supply line to valve. If

3/8” OD tubing is used, change to

fitting #7610BP supplied.

3. Connect the fluid supply line to reservoir.

The reservoir can accept either OD or

1/4” OD or 3/8” OD tubing using

#62518PT supplied.

4. Connect valve control air hose to

ValveMate

™

controller (or other pneumatic switch) used to control valve

open time.

5. Choose a dispensing tip—small tips

(20 gauge) for low-viscosity fluids and

larger (14 gauge) for higher viscosities.

6. Fill reservoir by pouring fluid directly

into tank liner or manufacturer’s bottle

placed inside reservoir. Secure cover

prior to setting pressure.

7. Set reservoir pressure to low for thin

fluids and higher for thick fluids.

8. Set the diaphragm stroke starting with

no more than 1/2 turn open.

*

9. Place a cup under the dispensing tip

and actuate the valve until fluid lines,

valve and dispensing tip are free of air.

10. Set desired flow rate by adjusting

fluid reservoir pressure or changing

dispensing tip.

*

Do not overtighten the stroke adjustment knob or

open it more than two full turns. If open more than

two turns, pressurized liquid could force open the

diaphragm seal, resulting in continuous liquid flow.

9

Open

Close

8

Air Output

ut

Exhaust

r

Prior to installing this valve, please

read the associated reservoir and

valve controller operating instructions

to become familiar with the operation

of all components of the dispensing

system.

1

7

5

2

6

4

10

3

To exhaust

To pressurize

A NORDSON COMPANY

®

Steady

Test

Run

Setup Program

5

20

0

Time Set

Clear

Fast Slow

POWER

RUN

SETUP

CYCLE

Fast Slow

Time Set

Pressure

STOP

Time

Purge

Page 3

How the Valve Operates

Input air pressure at 70 psi (4.8 bar)

forces the internal piston ➀➀to move.

➁➁

The piston rod pulls open the

diaphragm seal,

➂➂

permitting fluid

flow. When the input air pressure is

relieved, the spring retracts the piston

and the diaphragm closes.

The primary control of deposit size is the valve open time.

ValveMate Concept

The ValveMate 7000 provides easy

adjustment of valve output for maximum

end-user convenience and efficiency.

Valve open time is the primary control of

deposit. The 7000 puts push-button

adjustment of valve open time where it

needs to be—at the valve.

Deposit size can be programmed by

pressing the PROGRAM button in the

SETUP mode. This affords an easy

starting point for selecting deposit size.

Note: The EFD Ultra®TT 325 and 525

XYZ automated dispensing systems have

integrated ValveMate controllers for

operating all EFD dispense valves.

The amount of fluid dispensed will

depend on the time the valve is open,

the viscosity of the fluid, the air pressure

in the fluid reservoir, the dispensing tip

size and the diaphragm stroke.

Flow rate is a function of reservoir

pressure, tip size and fluid viscosity.

closed

➁➁

➂➂

open closed open

To calibrate the valve, the “0” mark on

the stroke reference ring should align

with one of the two reference marks

on the valve body. When the set-screw

is tightened, the valve is calibrated.

➀➀

➂➂

➁➁

➀➀

➁➁

➂➂

➀➀

➂➂

➁➁

➀➀

752V and 752V-UH Fluid Flow 750V and 751V Fluid Flow

www.efd-inc.com technical@efd-inc.com USA 800-556-3484 Europe +44 (0) 1582 666334 Asia +86 (21) 5854 2345

Steady

Test

A NORDSON COMPANY

VALVEMATE

7000

®

Run

Setup Program

Rear Panel

air input

power input

(voltage selector)

air output to valve

I/O connector with alarm

output (<60 psi)

connector for

optional foot pedal

Purge

Time Set

Clear

Fast Slow

Fast Slow

Time Set

POWER

RUN

SETUP

CYCLE

Pressure

STOP

Time

Control Pad

set time

timer bypass

display pressure (psi, bar)

TEACH program

test cycle

purge

reset

Function Indicators

Pressure/Time Toggle

Emergency Stop

Page 4

Specifications

General

Diaphragm: UHMW* polyethylene

Air pressure required: 70 to 90 psi (4.8 to 6.2 bar)

Maximum fluid pressure: 70 psi (4.8 bar)

Maximum operating temperature: 43°C (110°F)

Mounting: (1) 10-32 UNF tapped hole

750V and 750V-SS

Size: 64.7 mm length x 23.8 mm diameter

(2.55” x 0.94” )

Weight: 750V – 93.5 grams (3.30 oz)

750V-SS – 165.8 grams (5.85 oz)

Air cylinder body: 750V – Hard-coated aluminum

750V-SS – Type 303 stainless

steel

Fluid body: UHMW* polyethylene

Free flow orifice: 1.57 mm diameter (0.062”)

Fluid inlet thread: 1/4-28 UNF

Output thread: 5/16-28 UNF

Tip adapter: Polypropylene

751V

Size: 64.7 mm length x 26.9 mm diameter

(2.55” x 1.06”)

Weight: 101.7 grams (3.59 oz)

Air cylinder body: Hard-coated aluminum

Fluid body: Acetal copolymer

Free flow orifice: 2.03 mm diameter (0.08”)

Fluid inlet thread: 1/8 NPT female

Output thread: 1/8 NPT female

Tip adapter: Nylon

752V, 752V-UH/752V-SS and 752V-UHSS

Size: 80.7 mm length x 26.9 mm diameter

(3.18” x 1.06”)

Weight: 752V and 752V-UH – 99.5 grams (3.51 oz)

752V-SS and 752V-UHSS – 181.9 grams

(6.42 oz)

Air cylinder body: 752V and 752V-UH – Hard-coated

aluminum. 752V-SS and 752VUHSS – Type 303 stainless steel

Fluid body: 752V and 752V-SS – Acetal copolymer

752V-UH and 752V-UHSS – UHMW*

polyethylene

Free flow orifice: 2.5 mm diameter (0.10”)

Fluid inlet thread: 1/8 NPT female

Output thread: 1/4-28 UNF

Tip adapter: Polypropylene

752V-DVD and 752V-UHDVD

Size: 80.7 mm length x 26.9 mm diameter

(3.18” x 1.06”)

Weight: 752V-DVD – 172.9 grams (6.1 oz)

752V-UHDVD – 99.5 grams (3.51 oz)

Air cylinder body: Type 303 stainless steel

Fluid body: 752V-DVD – Type 303 stainless steel

752V-UHDVD – UHMW* polyethylene

Free flow orifice: 2.5 mm diameter (0.10”)

Fluid inlet thread: 1/8 NPT female

Output thread: 1/4-28 UNF 752V-UHDVD

752V-DVD (not applicable)

Tip adapter: 752V-DVD – Aluminum

752V-UHDVD – Polypropylene

* Ultra High Molecular Weight

For consistent dispense valve operation and easy adjustment of

valve output, EFD recommends using the ValveMate 7000 controller on all automatic, semi-automatic and benchtop applications.

The EFD Ultra TT Series positioning systems incorporate dispensing control into the main system.

Contact the EFD Dispense Valve Systems Group for details.

For EFD sales and service in over 30 countries,

contact EFD or go to www.efd-inc.com/contact

EFD, Inc.

East Providence, RI USA

800-556-3484; +1-401-434-1680 (outside the USA)

info@efd-inc.com www.efd-inc.com

EFD International Inc.

Dunstable, Bedfordshire, UK

0800 585733 or +44 (0) 1582 666334

Ireland 00800 8272 9444

europe@efd-inc.com www.efd-inc.com

EFD, Inc., Asia

China: +86 (21) 5854 2345

china@efd-inc.com www.efd-inc.com/cn

Singapore: +65 6896 9630 sin-mal@efd-inc.com

©2006 Nordson Corporation 750-INSTALL-01 v062606

®

A NORDSON COMPANY

Loading...

Loading...