EFD 741MD-SS INSTALLATION GUIDE

Introduction

The 741MD-SS Series is simple to use and will

operate many millions of cycles without maintenance.

The 741MD-SS is a pneumatically operated,

adjustable needle valve designed to apply precise

microdeposits of low to high viscosity fluids down

to fractions of a microliter. It is ideal for automated

assembly processes that require small dispensing

tips (from 22 to 33 gauge). The 741MD-SS provides

exceptional control and the absolute minimum dead

fluid volume.

741MD-SS Series

Dispense Valve

INSTALLATION GUIDE

Electronic pdf files of EFD®manuals are also available at

www.efd-inc.com/manuals.html.

USA: 800-556-3484 or +1-401-434-1680

Europe: 0800 585733 or +44 (0) 1582 666334

Asia: +86 (21) 5854 2345

technical@efd-inc.com www.efd-inc.com

®

A NORDSON COMPANY

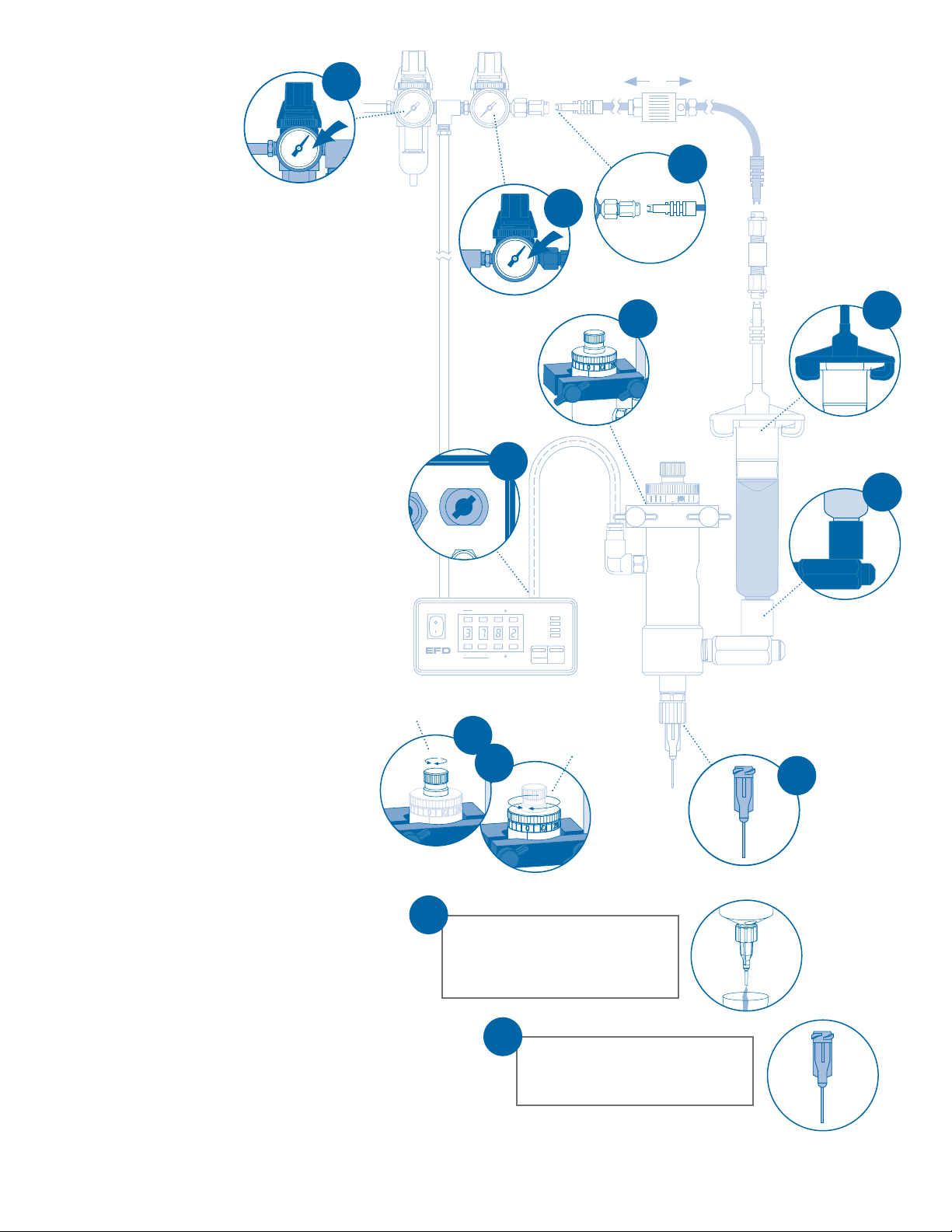

Barrel reservoir

Barrel adapter assembly

Stroke reference ring

Control

air hose

Inlet fitting

Dispensing tip

Fluid body

0

1

0

2

0

3

0

40

50

60

7

0

80

9

0

100

7

6

5

4

3

2

1

0

1

0

2

0

3

0

40

50

60

7

0

80

9

0

100

7

6

5

4

3

2

1

Installation

Open the valve with an air pulse

long enough to fill the valve and

start fluid flow. Test the dispensed

amount with a nominal time setting.

11

Set desired deposit size by changing

tip size, reservoir pressure, needle

stroke and valve open time.

12

1. Mount valve with an EFD universal valve

mount (#7002VM) or other fixture.

2. Connect valve control air line to

ValveMate

™

controller (or other pneumatic

switch) used to control operating air to

the valve.

3. Connect the white male quick-connect

on the flexible air line to the white female

quick-connect at the air pressure regulator.

4. Install the barrel reservoir on the fluid

inlet fitting (installed for use with

Ultra

®

barrel reservoirs). For low viscosity fluids,

fill the reservoir after installing it on the

fluid-inlet fitting. High viscosity materials

can be loaded into the reservoir before

installing on the inlet fitting.

Note: Fill barrels no more than 2/3 full. Always

use a SmoothFlow

™

piston when dispensing medium to high viscosity materials (see setup illustration).

5. Attach the barrel adapter head to the

barrel reservoir using air interconnect

coupler to connect the barrel adapter

assembly to the flexible air line.

6. Install appropriate size EFD SafetyLok

™

dispensing tip on the tip adapter. Tighten

the tip retaining nut fully to position the

needle hub against the shoulder of the

tip adapter.

7. Refer to back page for instructions on

calibrating the needle stroke.

8. Open stroke adjustment knob to desired

position (1/2 turn open is the recommended starting point).

9. Set reservoir pressure to low for thin

fluids and higher for thick fluids. Use the

in-line air shut-off valve to pressurize or

depressurize barrel reservoir.

10. Set valve control air pressure at 70

psi (4.8 bar). Refer to valve controller

operating manual.

Open

Close

Air Output

ut

Exhaust

r

Prior to installing this valve, please read the

associated reservoir and valve controller

operating instructions to become familiar

with the operation of all components of the

dispensing system.

5

2

4

00

1010

2020

303

0

4040

5050

606

0

707

0

8080

9090

1

0

0

1

0

0

77

66

55

44

33

22

11

1

9

00

1010

2020

303

0

404

0

5050

606

0

707

0

8080

9090

1

0

0

1

0

0

77

66

55

44

33

22

11

0

10

20

3

0

4

0

50

6

0

7

0

80

90

1

0

0

7

6

5

4

3

2

1

10

6

3

Open

Close

7

8

adjustment knob

calibration knob

50

60

40

4

7

3

0

0

3

5

2

80

0

2

6

1

1

0

0

9

7

0

100

50

60

40

4

7

3

0

0

3

5

2

80

0

2

6

1

1

0

0

9

7

0

100

To exhaust

To pressurize

A NORDSON COMPANY

®

Steady

Test

Run

Setup Program

5

Time Set

Clear

Fast Slow

POWER

RUN

SETUP

CYCLE

Fast Slow

Time Set

Pressure

STOP

Time

Purge

20

0

Loading...

Loading...