Page 1

US: 88-333-0311

UK: 0800 585733

Mexico: 001-800-556-3484

740V Series Dispense Valve

Operating Manual

20

0

5

®

A NORDSON COMP ANY

Page 2

If you require any assistance, or have

specific questions, please contact us.

US: 888-333-0311

Telephone: (401) 434-1680

Fax: (401) 431-0237

E-mail: technical@efd-inc.com

Mexico: 001-800-556-3484

UK: 0800 585733

EFD Inc.

977 Waterman Avenue, East Providence, RI 02914-1342 USA

Sales and service of EFD Dispense Valve Systems is available

through EFD authorized distributors in over 30 countries.

Please contact EFD U.S.A. for names and addresses.

Page 3

740V-MAN ©2003 EFD Inc.

This manual is for the express and sole use of EFD valve purchasers and

users, and no portion of this manual may be reproduced in any form.

Teflon is a registered trademark of E.I. DuPont.

EFD, VALVEMATE and SafetyLok are trademarks of EFD Inc.

Contents

Introduction..................................................................2

Specifications and Flow Chart ....................................3

How The Valve Operates..........................................4-5

Typical Setup ............................................................ 6

Setup Instructions........................................................7

740V-SS Exploded View ..............................................8

Maintenance and Cleaning ....................................9-12

Troubleshooting..........................................................13

Warranty ......................................................back cover

Page 4

Note: For consistent dispense valve operation and easy adjust-

ment of valve output, EFD recommends using the

VALVEMATE™7000 controller on all automatic, semiautomatic

and bench-top applications.

Contact EFD Dispense Valve Systems Group for details.

Introduction

The 740V Series dispense valves are precise, needletype valves manufactured to the highest quality standards. The valves are produced to very close tolerances

to ensure proper and reliable operation. Each valve has

been thoroughly tested prior to shipping.

The 740V valves are used with VALVEMATE™controllers for precise, repeatable outputs from a fraction of

a microliter up to continuous stripes of low to high viscosity fluids. It is an ideal valve for use on automatic

assembly machines.

Each valve comes equipped with a 5-ft actuating air

hose and male quick-connect, adjustable stroke control

and fluid inlet fitting. The dispensing tip adapter fea-

tures a SafetyLok™collar for secure dispensing tip

attachment.

To obtain the maximum performance from this fine

equipment, please read through these instructions

carefully.

2 / Introduction

Page 5

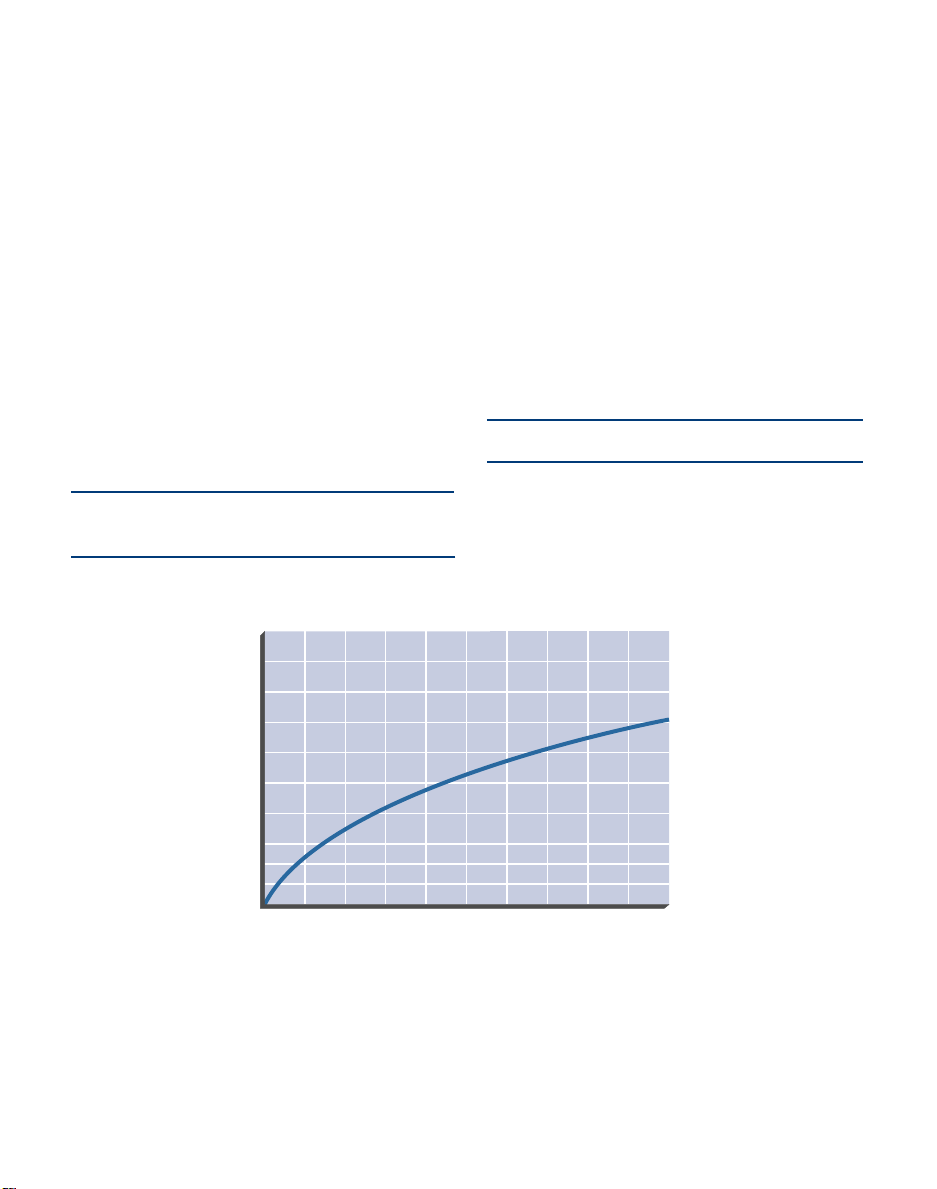

740V-SS Flow Chart

Free flow of water through tip adapter with no dispensing tip

restrictions.

Note: All stainless steel valve parts are passivate

d.

Construction

Air cylinder body: Hard-coated aluminum

Fluid chamber: 740V-SS: Type 303 stainless steel

740V: Hard-coated aluminum

Piston: Type 303 stainless steel

Needle: Type 303 stainless steel

Tip adapter/needle seat: Type 303 stainless steel

SafetyLok™collar: Nylon

Needle packings: Teflon

®

3 / Specifications and Flow Chart

Specifications

Size: 4.510" x 1.060" diameter

(114.6 mm x 26.9 mm)

Weight: 740V-SS: 9.0 oz (255 g)

740V: 6.36 oz (180.3 g)

Fluid inlet thread: 1/8 NPT Female

Fluid outlet: Male luer lock

Air pressure required: 70 psi (4.8 bar)

Maximum input fluid pressure: 300 psi (21 bar)

Mounting: 1/4-28 UNF tapped hole

Operation frequency: Exceeds 400 per minute

Output variation: ±0.5% nominal

Note:

Specifications and technical details are subject

to engineering changes without prior notification.

10 20 30 40 50 60 70 80 90 100

Reservoir Pressure - psi

0

Fluid Flow ml/second

5

10

15

20

25

30

35

40

45

50

Page 6

4 / How the Valve Operates

How the Valve Operates

The 740V Series valve is a normally closed, fail-safe,

adjustable opening needle valve.

The amount of fluid dispensed is determined by length

of time the valve is open; fluid reservoir pressure; output

dispensing tip size; needle stroke; and fluid viscosity.

The 740V Series require 70 psi (4.8 bar) air pressure.

This air pressure acting on the piston ➀ retracts the piston and needle ➁ from the needle seat ➂, permitting

fluid flow from the output tip adapter ➃. Piston and

needle stroke and fluid flow are controlled by the stroke

control knob ➄.

Once the cycle is complete, air is exhausted back

through the valve controller, ensuring rapid and positive

fluid shutoff.

The 740V Series can be operated in any position without affecting flow. Vibration normally has no effect on

performance. The valve can be moved in and out of dispense position at high-cycle rates (such as a reciprocating device installed on a production line) without

affecting dispensing performance.

➂

➀

➄

➁

➃

open

closed

Page 7

Stroke Control Reference

The Stroke Control Reference feature is used

to calibrate the stroke control setting or document the dispensing process.

To calibrate the valve, the stroke control

knob is first closed all the way. The set

screw is then loosened and the stroke reference ring turned so that the zero on the

reference ring is aligned with one of the two

reference marks engraved on the valve body.

When the set screw is tightened, the valve is

calibrated.

Tamper Resist Option

Any 740V Series valve can be ordered in the

tamper resist configuration to limit unauthorized adjustment.

In -TR configuration, stroke adjustment can

only be made when a special stroke control

knob is inserted into the stroke mechanism.

A kit can also be ordered as a retrofit for

existing valves.

Part # Description

740V-TR Tamper resist 740V valve

7544SS Tamper resist stroke kit

5 / How the Valve Operates

Removable

stroke control

knob

Stroke

mechanism

20

0

5

Stroke

reference

ring

Reference

mark

Stroke control

knob

Set screw

Page 8

CAUTION: Always depressurize the reservoir before opening. To do this,

slide the shutoff valve on the air line away from the reservoir. If using an EFD

tank reservoir, open the pressure relief valve as well. Before opening the

reservoir, check the pressure gauge to verify that pressure is zero (0).

Typical Setup

6 / Typical Setup

Flexible air line

#2310S

Black quick-connect

#7543BP for 1/4"

OD tube (installed)

#7610BP for 3/8"

OD tube (optional)

Five-micron filter regulator #2000F755

Set at 70 psi (4.8 bar)

Air tee #1116

To pressurizeTo exhaust

White quick-connect

Fluid feed hose

Pressure relief

Pressurized reservoir

with air regulator

20

0

5

POWER

RUN

SETUP

CYCLE

STOP

Clear

Purge

Run

Setup Program

Fast Slow

Time Set

Pressure

Time

Fast Slow

Time Set

Test

Steady

Note: Use only oil-free,

clean, dry filtered air.

Fluid inlet fitting

740V

valve

Control air line

Shutoff valve

VALVEMATE

7000 Controller

Pulsed air for

valve operation

®

A NORDSON COMPANY

Page 9

Figure 1

➁ Rotate fluid

chamber to desired

position.

➀ Set stroke

adjustment two

full turns out.

Note: Do not rotate fluid chamber more than one

complete turn.

Install an appropriate size dispensing tip on

the output tip adapter. The adapter accepts

EFD SafetyLok™tips. Use small diameter

(20 to 25 gage) for low viscosity fluids, and

larger tips (14 to 18 gage) for higher viscosity fluids.

Fill the fluid reservoir (refer to reservoir user's

guide).

After filling, check to be certain the reservoir

cover is secured and that all connections

are tight.

Set the reservoir pressure. For low viscosity

fluids, start with a pressure of approximately

5 psi (0.3 bar). For higher viscosity, use 20 to

40 psi (1.4 to 2.8 bar). Increase or decrease

as necessary.

Note: If solvents or other watery fluids are to be

dispensed in very small amounts, specify 0 to 15

psi (0 to 1.0 bar) precision regulator to control

reservoir pressure.

Set the needle stroke. Start at one full turn

open.

Set the valve control air pressure to 70 psi

(4.8 bar). Refer to the VALVEMATE™7000

manual.

Open the valve with an air pulse long

enough to fill the valve and start fluid flow.

Then test the dispensed amount with a

nominal time setting.

Increase or decrease reservoir pressure,

needle stroke and valve open time to arrive

at the desired deposit size.

Setup

Mount the 740V valve with an EFD universal

valve mount (#7002VM) or other appropriate

fixture, using the 1/4-28 UNF tapped hole on

the air cylinder body.

The 740V Series valves are shipped with the

fluid inlet fitting installed for use with 1/4" OD

x 1/8" ID flexible fluid hose. An optional fluid

inlet fitting for 3/8" OD tube is enclosed.

Connect the control air line to the valve controller or other pneumatic switch that is used

to control operating air to the valve. (Refer to

EFD VALVEMATE™7000 operating manual.)

Connect the fluid feed hose to the fluid inlet

fitting and fluid reservoir.

The valve fluid chamber with inlet fitting can

be rotated to prevent possible interference

with machine parts (See Figure 1).

To reposition the fluid chamber, first turn the

needle stroke control out two full turns ➀ ,

then rotate the chamber ➁ to the desired

position.

7 / Setup Instructions

20

0

5

Page 10

Items included in

repair kit #740V-RK

are underlined

and listed in blue.

740V Exploded View

Nye gel lubricant, 1 gram

foil packet (not shown)

#H-147-P

8 / Exploded View

Tip adapter/seat assembly

#7401

O-ring (Buna) #7517

Needle packing assembly

#7810

Piston return spring #7802

Snap ring #7526

O-ring (Buna) #7519

Air cylinder body

#7811-SS (stainless steel)

#7811 (aluminum)

O-ring (Buna) #7806

Retaining washer

#7807

Packing spring #7808

Air input hose

#78518A

O-ring (Viton) #5148RV

Fluid inlet fitting

#7543BP (installed) for 1/4" OD tubing

#7610BP (supplied) for 3/8" OD tubing

Thrust washer

#7809

Fluid chamber

#7402-SS (stainless steel)

#7402 (aluminum)

Piston and needle assembly

#7805-SS

20

0

5

Needle stroke control

#780SR-KIT (aluminum)

#780SSR-KIT (stainless steel)

SafetyLok collar

#7403

Page 11

Maintenance Tools

6" adjustable wrench

snap ring pliers

packing extraction tool #7803

Figure 1

Pushing the needle packings

from the fluid chamber.

Maintenance and Cleaning

Normal cleaning is accomplished by purging with

appropriate solvent. The tip adapter/seat assembly can

be removed (after the reservoir pressure has been bled

off) for cleaning without demounting the valve.

CAUTION: Always relieve the reservoir pressure and disconnect

the power before performing any maintenance on the system. On

all EFD tank reservoirs, there is a pressure relief valve that should

be activated before opening the reservoir to ensure that all pressure is bled off.

On all EFD cartridge reservoirs, the unique threaded design provides fail-safe air pressure release during cap removal.

To thoroughly clean valve chamber and replace needle

packings:

1. Remove the needle stroke control and piston

return spring to prevent damage to the needle and

seat during reassembly. Turn counterclockwise

until free.

2. Remove the inlet fitting and tip adapter/seat

assembly from the fluid chamber.

3. Remove the fluid chamber from the cylinder body

by turning counterclockwise until free. Then

remove the O-ring from the fluid chamber.

4. Remove the needle packings from the fluid chamber, using tool #7803 supplied with the valve.

Insert through outlet end of the fluid chamber and

gently push out the packings (see Figure 1).

Do not use sharp instruments to scrape or clean

these components. Scratches may cause the valve

to leak.

5. Remove any remaining packings and the packing

spring from the needle.

Continued on Next Page

9 / Maintenance and Cleaning

Packing extraction

tool #7803

Fluid chamber

O-ring

Needle packing

assembly

Page 12

Note: The lower cylinder needle O-ring is held in place by a flat

retaining washer that also serves as the packing spring seat. The

washer may come out with the spring. Ensure that it is back in

place before reinstalling the packing spring (see Figure 2).

6. Clean the needle with a cloth dampened in solvent.

7. Lubricate the needle with Nye Lubricant #865 gel

(EFD #H-147-P). Reinstall the needle packing

spring and new packing kit in accordance with

Figure 2.

8. Install a new O-ring (#7517) on the fluid chamber.

Screw the cylinder onto the fluid chamber. Hand

tighten only. The chamber can be turned back out

up to one turn to orient the fluid inlet fitting to the

desired position.

9. Reinstall the tip adapter/seat assembly.

10. To reinstall the piston return spring, first put one

thrust washer over the spring pilot (at the top of the

piston), then the other thrust washer into the needle

stroke control, followed by the spring.

11. Reinstall the needle stroke control by aligning the

piston return spring with the spring pilot. Turn the

needle stroke control clockwise until it stops and

then back it out to the desired setting.

Figure 2

Proper assembly order for reinstalling needle packings.

10 / Maintenance and Cleaning

Needle

packings

Packing

seat

Packing

expander

Air cylinder

body

O-ring

Retaining

washer

Spring

Continued on Next Page

Page 13

T o replace the piston and needle assembly or piston O-ring:

1. Remove the needle stroke control by turning counterclockwise until free.

2. Remove the piston return spring and thrust washers located on each end of the spring.

3. Remove the snap ring using snap ring pliers.

4. Pull the piston and needle assembly out of the

cylinder, using small pliers on the spring pilot (at

the top of the piston).

Note: The piston and needle assembly is replaced as a unit and

cannot be disassembled.

5. Clean the cylinder body wall and apply Nye

Lubricant #865 gel (EFD #H-147-P).

6. Replace the O-ring on the piston, apply Nye

Lubricant #865 gel (EFD #H-147-P), then reinstall in

the cylinder.

7. Reinstall the snap ring.

8. To reinstall the piston return spring, first put one

thrust washer over the spring pilot, then the other

thrust washer into the needle stroke control, followed by the spring.

9. Reinstall the needle stroke control by aligning the

piston return spring with the spring pilot. Turn the

needle stroke control clockwise until it stops and

then back it out to the desired setting.

Note:

Do not overtighten the needle stroke control, or needle

damage will occur.

11 / Maintenance and Cleaning

Continued on Next Page

Page 14

Note: After performing maintenance, the valve should be leak

tested before it is returned to service.

To leak test the valve:

1. Set the needle stroke control at two turns open.

2. Shut off actuating air. Install an air hose in the

valve's fluid inlet and connect it to a 100 psi (7 bar)

air supply.

3. Submerge the tip adapter/seat assembly in a container of water. If air bubbles appear, perform the

following procedure to reseat the parts.

To reseat the needle and tip adapter/seat assembly:

1. Disconnect or shut off all air to the valve.

2. Open the needle stroke control two turns.

3. Using the appropriate wrench, loosen the tip

adapter/seat assembly one full turn, then turn it

back in and retighten. This causes any small irregularities on the needle and seat to conform with one

another and become a matched set.

4. Restore actuating air and cycle the valve a few

times, then perform the leak test again.

5. Steps 3 and 4 may be repeated up to three times to

obtain satisfactory results.

6. If the valve continues to leak after three attempts to

reseat the needle, replace the needle and tip

adapter/seat assembly.

Bubble test for leaks.

No air bubbles should appear.

12 / Maintenance and Cleaning

20

0

5

Page 15

Inconsistent deposits.

Fluid leaks out the drain hole.

Steady drip.

Troubleshooting Guide

No fluid flow.

Valve Trouble Possible cause and correction

13 / Troubleshooting

Air operating pressure may be too low. Increase air

pressure to 70 psi (4.8 bar).

The reservoir air pressure may not be high enough.

Increase pressure.

The needle stroke adjustment may be closed. If it is

closed, open counter-clockwise one full turn.

Material may have clogged the valve head or output tip

adapter.

Clean the valve. (Refer to Maintenance & Cleaning on

pages 9-12.)

A steady drip can be caused by a worn needle and seat,

or a particle holding the needle off the seat.

Remove the tip adapter/seat assembly, clean and

inspect the needle and seat for wear. Replace worn or

damaged parts.

Fluid leaking out the drain hole on the side of the valve

indicates the needle packings are worn. Replace needle packings.

Inconsistent deposits can result if:

1. Air pressure controlling the valve is fluctuating.

2. Air pressure supplying the reservoir is fluctuating.

3. Air pressure controlling the valve is less than 70 psi

(4.8 bar).

Check to be sure the air pressures are constant and the

valve operating air pressure is 70 psi (4.8 bar).

The time the valve is open must be constant. Check to

be sure the valve controller is providing a consistent

output.

Page 16

977 Waterman Avenue, East Providence, Rhode Island 02914-1342 USA

U.S. toll free: 888-333-0311 Mexico: 001-800-556-3484

Telephone: 401-434-1680 Fax: 401-431-0237 www.efd-inc.com

e-mail: technical@efd-inc.com

Unit 14, Apex Business Centre, Boscombe Road, Dunstable, Beds. LU5 4SB UK

Telephone: 01582 666334 Fax: 01582 664227 UK: 0800 585733

Ireland: 00800 8272 9444 e-mail: uk@efd-inc.com

EFD International Inc. is incorporated with limited liability in the U.S.A.

EFD ONE YEAR LIMITED WARRANTY

All components of EFD Dispense Valves are warranted for one year from date of

purchase to be free from defects in material and workmanship (but not against

damage caused by misuse, abrasion, corrosion, negligence, accident, faulty

installation or by dispensing material incompatible with equipment) when the

equipment is installed and operated in accordance with factory recommendations

and instructions. EFD will repair or replace free of charge any part of the equipment thus found to be defective, on authorized return of the part prepaid to our

factory during the warranty period. The only exceptions are those parts which

normally wear and must be replaced routinely, such as but not limited to valve

needle packings and needle assemblies.

In no event shall any liability or obligation of EFD arising from this warranty

exceed the purchase price of the equipment. This warranty is valid only when oilfree, clean, dry, filtered air is used.

EFD makes no warranty of merchantability or fitness for a particular purpose. In

no event shall EFD be liable for incidental or consequential damages.

©2003 EFD Inc.

740V-MAN 1.5P403

®

A NORDSON COMP ANY

Loading...

Loading...