Efd 725-HL User Manual

User’s Guide

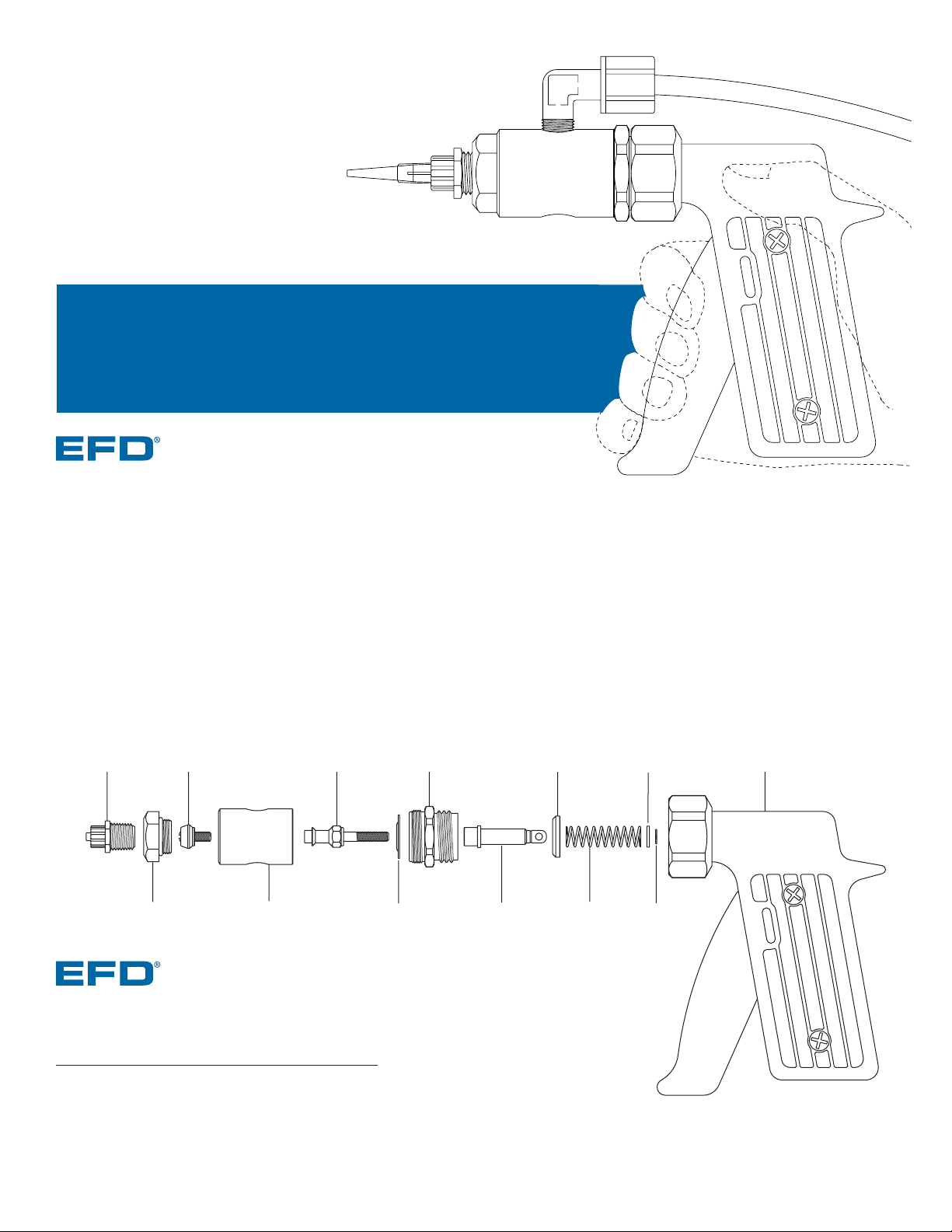

725-HL Dispense Gun

The 725-HL dispense gun is a rugged

industrial hand-operated fluid dispensing

valve. The valve incorporates a quick

change fluid body for fast and easy

maintenance. Included with the valve

are two fluid inlet fittings for 1/4" OD or

3/8" OD feed tubing and an assortment

of dispensing tips.

USA: 800-556-3484 or +1-401-434-1680

Europe: 0800 585733 or +44 (0) 1582 666334

Asia: +86 (21) 5854 2345

technical@efd-inc.com www.efd-inc.com

Electronic pdf files of EFD

®

manuals are also available at www.efd-inc.com/manuals.html

Replacement Parts

For EFD sales and service in over 30 countries,

contact EFD or go to www.efd-inc.com/contact

USA: 800-556-3484 or +1-401-434-1680

Europe: 0800 585733 or +44 (0) 1582 666334

Asia: +86 (21) 5854 2345

technical@efd-inc.com www.efd-inc.com/contact

©2006 Nordson Corporation 725HL-MAN-01 v062606

A NORDSON COMPANY

#2186BP

Tip adapter

#72543

Fluid body cap with O-ring

#72539

Sealing head

with screw

#72538

Fluid body

#72537

Shaft

#72599

Fluid body adapter

#72590

Diaphragm

#72596

Shaft guide with

O-ring (#72594)

#72597

Push rod

#72593

Spring

#72592

Spring retaining

washer

#72587

Retaining ring

#72589

Handle assembly

A NORDSON COMPANY

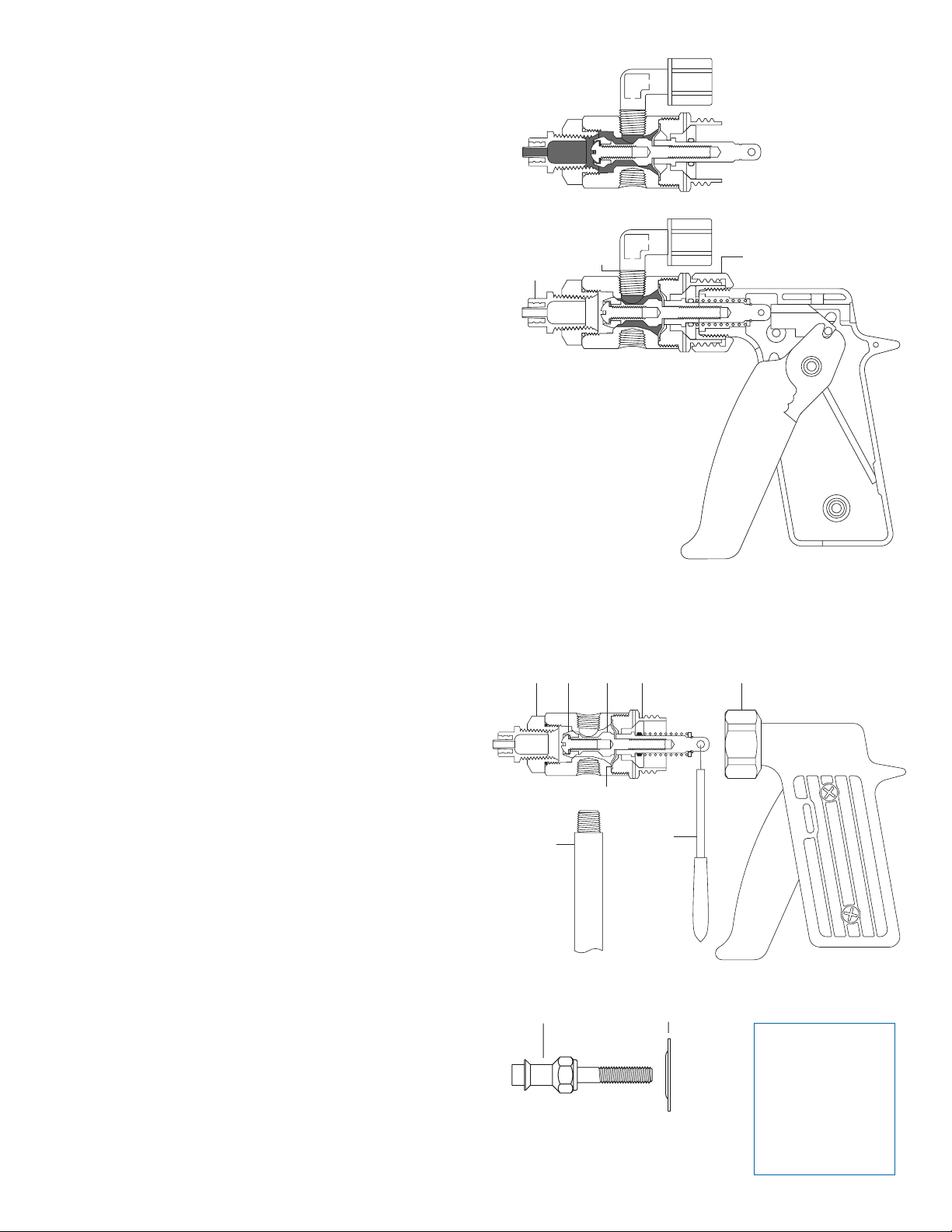

Service

Follow the exact sequence below to service the fluid body.

1. Loosen the retaining nut

➀ and remove the fluid body.

2. Insert maintenance rod

➁ and remove fluid body cap ➂.

3. Insert rod

➃ through push rod hole and remove sealing head

➄ with flat screwdriver. Remove rod ➃.

4. Hold rod

➁ and remove the fluid body adapter➅ from the

fluid body.

5. Insert and hold rod ➃ and remove shaft ➆ and diaphragm.

6. Clean fluid body components and replace sealing head and

diaphragm if required.

7. Install diaphragm in direction shown in

Figure 1

. Hold rod ➃

and install shaft; tighten to 15 inch pounds.

8. Apply a film of lubricant to fluid body shoulder “A”. Hold rod

➁ and reinstall adapter ➅.Tighten to 10 foot pounds.

9. Insert and hold rod

➃ and install sealing head; tighten to

15” pounds. Install fluid body cap

➂.

10. Install fluid body onto handle, align body to desired position

and tighten retaining nut ➀.

"A"

➀➅➆➄➂

➁

➃

Figure 1

Maintenance Tools:

1/8" rod (part #7803)

1/8" NPT maintenance rod

(part #72561)

10" adjustable wrench*

flat screwdriver*

*customer supplied

shaft

diaphragm

❶

❸

❷

Operation

1. Install the fluid fitting into the inlet port ❶. Use the 1/4”fitting

for low to medium viscosity fluids and the 3/8” fitting for high

viscosity fluids.

2. Install the appropriate size feed tube to the inlet fitting and

tighten the compression nut to secure. The position of the

inlet fitting can be adjusted. Loosen the fluid body retaining nut

❷,rotate the fluid body to the desired position and tighten the

retaining nut.

3. Apply air pressure to the fluid reservoir.Start with a low setting

of 20 psi (1.4 bar). If using an EFD fluid reservoir, refer to the

User’s Guide for further instructions.

4. Install an appropriate size dispensing tip to the outlet tip adapter

❸. Use large tips for high viscosity materials and small tips

for low viscosity.

5. Pull the trigger to begin fluid flow.Release trigger to stop flow.

6. To achieve desired flow,change the size of the dispensing tip

or adjust the reservoir fluid pressure.

open

closed

Loading...

Loading...