User’s Guide

®

A NORDSON COMPANY

Ultra®2800 Dispensing System

2800-3

3cc syringe barrels

2800-5

5cc syringe barrels

2800-10

10cc syringe barrels

2800-30

30cc syringe barrels

Electronic pdf files of EFD manuals are also available at www.efd-inc.com/manuals.html

The Ultra 2800 Dispensing System uses a patented positive displacement technology to provide

precise, controlled fluid dispensing. This User’s Guide will help you maximize the usefulness of your

new dispensing system.

Please spend a few minutes to become familiar with the controls and features. Follow our

recommended testing procedures. Review the helpful information we have included, which is based

on more than 30 years of industrial dispensing experience.

Most questions you will have are answered in this guide. However, if you need assistance, please do

not hesitate to contact EFD or your authorized EFD distributor.

In the USA, call 800-556-3484 between 8:30 a.m. and 5:30 p.m. Eastern time.

In Europe, call +44 (0) 1582 666334.

In Asia, call +86 (21) 5854 2345.

In all other areas, call your authorized EFD distributor or +1-401-434-1680.

The EFD Pledge

We pledge that you will be completely satisfied with our products. We endeavor to ensure that every

EFD product is produced to our no-compromise quality standards.

If you feel that you are not receiving all the support you require, or if you have any questions or

comments, I invite you to write or call me personally.

Our goal is to build not only the finest equipment and components, but also to build long-term customer

relationships founded on superb quality, service, value and trust.

Peter Lambert, President

Introduction

2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Unpacking the dispenser and activating the warranty

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Features and Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–13

Attaching the Syringe Barrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Removing the syringe barrel . . 14

Program Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

How to Make a Bead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Modify Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operating Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pre-Load Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Syringe Barrel Filling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Input/Output Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Productivity Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover

Contents

3

Safety

4

Introduction

Read and follow these safety instructions. Task- and equipment-specific warnings, cautions and

instructions are included in equipment documentation where appropriate.

Make sure all equipment documentation, including these instructions, is accessible to persons operating or

servicing equipment.

Qualified Personnel

Equipment owners are responsible for making sure that EFD equipment is installed, operated and serviced

by qualified personnel. Qualified personnel are those employees or contractors who are trained to safely

perform their assigned tasks. They are familiar with all relevant safety rules and regulations and are

physically capable of performing their assigned tasks.

Intended Use

Use of EFD equipment in ways other than those described in the documentation supplied with the

equipment may result in injury to persons or damage to property.

Some examples of unintended use of equipment include:

Regulations and Approvals

Make sure all equipment is rated and approved for the environment in which it is used. Any approvals obtained

for EFD equipment will be voided if instructions for installation, operation and service are not followed.

Personal Safety

To prevent injury follow these instructions.

• Do not operate or service equipment unless you are qualified.

• Do not operate equipment unless safety guards, doors or covers are intact and automatic interlocks are

operating properly. Do not bypass or disarm any safety devices.

• Keep clear of moving equipment. Before adjusting or servicing moving equipment, shut off the power

supply and wait until the equipment comes to a complete stop. Lock out power and secure the

equipment to prevent unexpected movement.

• If you receive even a slight electrical shock, shut down all electrical or equipment immediately. Do not

restart the equipment until the problem has been identified and corrected.

• Obtain and read Material Safety Data Sheets (MSDS) for all materials used. Follow the manufacturer’s

instructions for safe handling and use of materials, and use recommended personal protection devices.

• To prevent injury, be aware of less-obvious dangers in the workplace that often cannot be completely

eliminated, such as hot surfaces, sharp edges, energized electrical circuits and moving parts that

cannot be enclosed or otherwise guarded for practical reasons.

• Using incompatible materials

• Making unauthorized modifications

• Removing or bypassing safety guards or

interlocks

• Using incompatible or damaged parts

• Using unapproved auxiliary equipment

• Operating equipment in excess of maximum

ratings

Safety

5

High-Pressure Fluids

High-pressure fluids, unless they are safely contained, are extremely hazardous. Always relieve fluid

pressure before adjusting or servicing high pressure equipment. A jet of high-pressure fluid can cut

like a knife and cause serious bodily injury, amputation, or death. Fluids penetrating the skin can

also cause toxic poisoning.

If you suffer a fluid injection injury, seek medical care immediately. If possible, provide a copy of the

MSDS for the injected fluid to the health-care provider. A copy of the hydraulic fluid used in this unit is

included with this manual.

WARNING: Any injury caused by high pressure liquid can be

serious. If you are injured or even suspect an injury:

• Go to an emergency room immediately.

• Tell the doctor that you suspect an injection injury.

• Show the doctor this note.

• Tell the doctor what kind of material you were dispensing.

Fire Safety

To avoid a fire or explosion, follow these instructions.

• Shut down all equipment immediately if you notice static sparking or arcing. Do not restart the

equipment until the cause has been identified and corrected.

• Do not smoke, weld, grind or use open flames where flammable materials are being used or

stored.

• Provide adequate ventilation to prevent dangerous concentrations of volatile particles or vapors.

Refer to local codes or your material MSDS for guidance.

• Do not disconnect live electrical circuits when working with flammable materials. Shut off

power at a disconnect switch first to prevent sparking.

• Know where emergency stop buttons, shutoff valves and fire extinguishers are located.

• Clean, maintain, test and repair equipment according to the instructions in your equipment

documentation.

• Use only replacement parts that are designed for use with original equipment. Contact your EFD

representative for parts information and advice.

Action in the Event of a Malfunction

If a system or any equipment in a system malfunctions, shut off the system immediately and perform

the following steps:

• Disconnect and lock out system electrical power.

• Slowly unscrew barrel retainer and remove barrel from actuator.

• Identify the reason for the malfunction and correct it before restarting the system.

Disposal

Dispose of equipment and materials used in operation and servicing according to local codes.

MEDICAL ALERT–

AIRLESS SPRAY

WOUNDS:

NOTE TO

PHYSICIAN

Injection in the

skin is a serious

traumatic injury.

It is important to

treat the injury

surgically as soon

as possible.

Do not delay

treatment to

research toxicity.

Toxicity is a

concern with

some exotic

coatings injected

directly into the

bloodstream.

The Ultra 2800 Dispensing System is designed to provide complete process control using a patented

positive displacement technology.

There are four core variables to the system: Deposit Volume, Dispense Rate, Pause and Pullback. To

achieve the ideal deposit size, adjust only one of these variables at a time, in small increments.

Key features include

• Repeatable, precise fluid control

• All electric; no requirement for compressed air

• Programmable Pullback to eliminate oozing

• Menu-driven touch pad

• 100 user-defined memory cells for storing barrel size, deposit volume, dispense rate, pause and

pullback

The Ultra 2800 Dispensing System provides consistent results, regardless of changes in fluid

volume, viscosity or temperature. It is ideal for use with 2-part epoxies and other fluids with

changing viscosities, or where a specific flow rate is needed.

First Steps

1. Unpack the dispenser.

2. For step-by-step setup instructions, see the Ultra 2800 Quick Start Guide.

3. Now is a good time to ACTIVATE your Two Year Warranty. Please follow the instructions in the

enclosed “Welcome” letter to register your warranty online. Or if you prefer, call the appropriate

toll-free number listed below, provide the serial number of your dispensing system and respond

to a few short questions.

In the USA, call 800-556-3484 between 8:30 a.m. and 5:30 p.m. Eastern time.

In Europe, call +44 (0) 1582 666334.

In Asia, call +86 (21) 5854 2345.

In all other areas, call your authorized EFD distributor or +1-401-434-1680.

Getting

Started

6

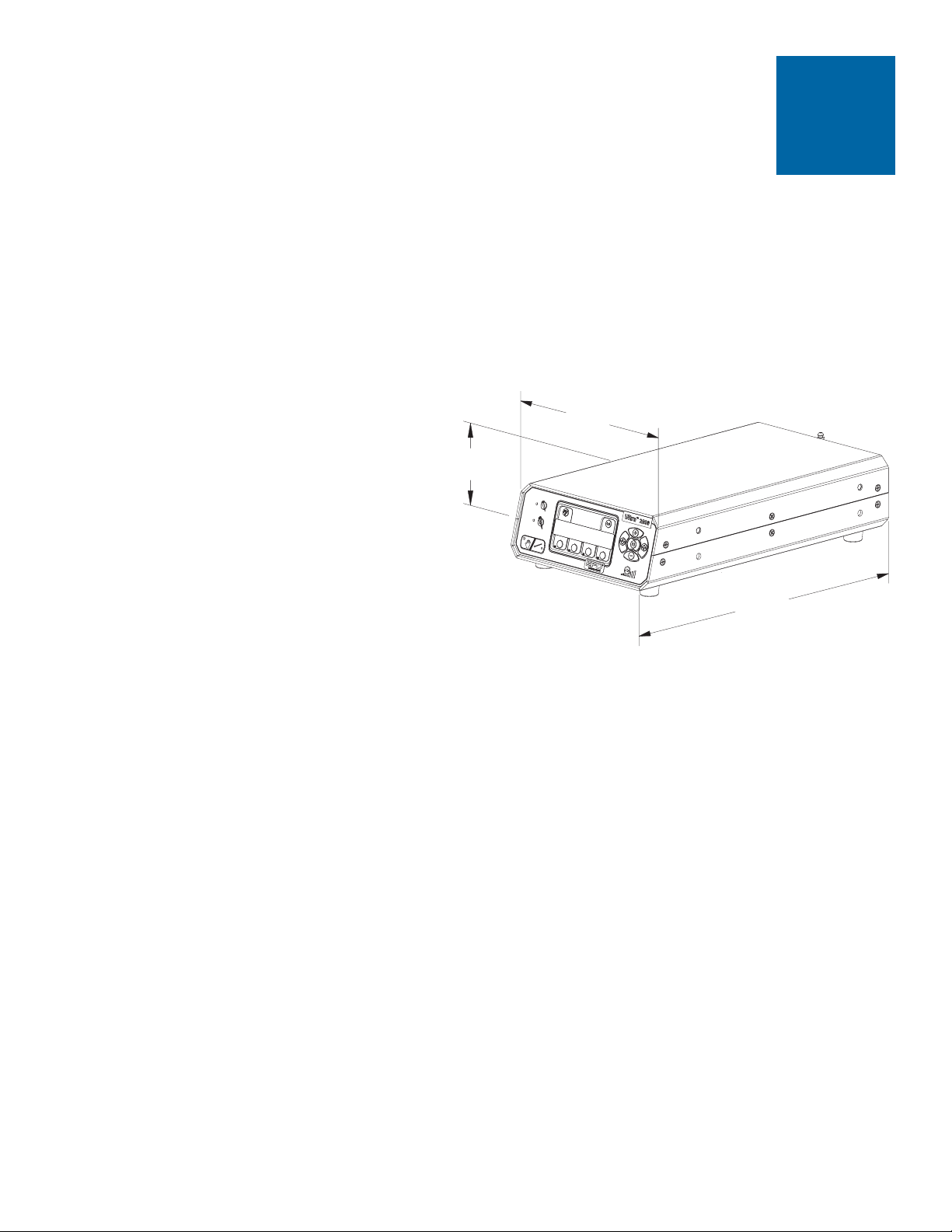

Cabinet size: 18.4 W x 8.1 H x 32.3 D cm (7.25 x 3.18 x 12.73")

Weight: 3.7 kg (8.2 lbs)

Flexible cable assembly length: 1.8 m (6 ft) to end of handset

Flexible cable assembly weight: .113 kg (4 oz)

Flexible cable assembly bend radius: 7.62 cm (3.0")

Internal power supply: Input voltage range, 100-240 VAC

Max inrush current: 50A/264 VAC

Input frequency range: 47-63 Hz

Output voltage: 24 VDC

Output current: 2.5A

Output power: 60W

Fuse rating: 1.0A/250 VAC (EFD part #28139 or equivalent)

Initiate circuit: Foot pedal, Cycle Start button or 5 to 24 VDC signal

Drive motor: 1.8º microstepping, 1,600 steps/rev

Control circuitry: CMOS microprocessor

Interface: Tactile keypad

Hydraulic fluid: Petroleum-based lubricant

Enclosure rating: NEMA 1

Dispense rate: Exceeds 20 cycles per minute

Minimum dispense volume: 0.1 microliters (with 3cc syringe barrel)

Meets or exceeds CE requirements

US Patent No. 6,575,331

Note: Specifications and technical details are subject to change without prior notification.

MSDS for hydraulic fluid enclosed separately. Contact EFD if extra copy is required.

Specifications

7

18.4 cm

7.25"

8.1 cm

3.18"

32.3 cm

12.73"

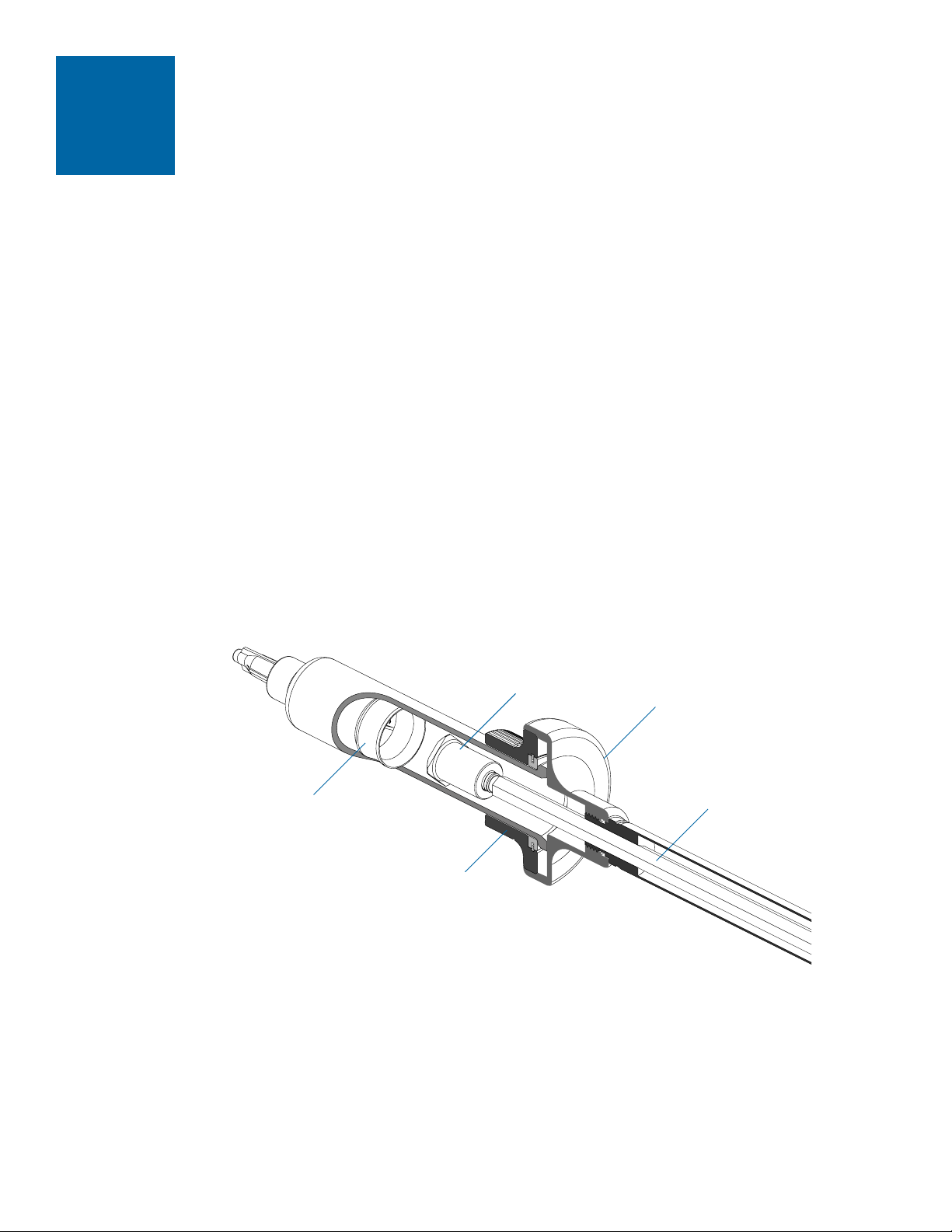

The Ultra 2800 Dispensing System uses a flexible hydraulic link to transfer linear force from the drive

motor to the syringe barrel. The motor lead screw and drive shaft are also linked mechanically. This

patented link allows the transfer of up to 200 pounds of force from the motor to the assembly fluid.

Once a dispense cycle is complete, a programmed mechanical pullback retracts the plunger,

attached to the EFD piston. The combined action of the plunger with the unit’s Forward steps,

programmed Pause function and Pullback feature creates a consistent deposit and prevents fluid

from oozing.

The bore and stroke of the syringe barrel are used to calculate deposit volume. For example, the

inside diameter of a 5cc syringe barrel measures 1.27 cm. One step moves the plunger 0.00008 cm,

resulting in 0.0001cc of fluid being displaced. With a 3cc barrel, it takes two steps to displace the

same amount of fluid.

Flexible cable assembly

The force of the stepper motor is transferred to the syringe barrel by a flexible cable assembly.

The plunger, attached at the end of the cable, drives into the EFD piston inside the syringe barrel.

This action forces the fluid out to make the deposit.

8

Adapter

Drive shaft

EFD piston

Plunger

Barrel retainer

Power Input Receptacle

The Ultra 2800 features a universal power supply. It automatically adjusts for input voltages ranging

from 100 VAC to 240 VAC. There is no adjustment required by the user.

Dispenser

Operation

Manual/Programmed Dispense Select

• Each mode allows you to access different features on the menu-driven display. Press the

“hand” icon to change from Manual mode to PROGRAMMED DISPENSE mode.

• In MANUAL mode, you can use the foot pedal to dispense a continuous bead of fluid. You are

in MANUAL mode when the red light next to the “hand” icon is on.

• In PROGRAMMED DISPENSE mode, you can set several variables, including Program Number,

Syringe Barrel Size, Deposit Volume, Dispense Rate, Pause and Pullback. You can also use the

foot pedal or the Cycle Start button to dispense a single dot of fluid. You are in PROGRAMMED

DISPENSE mode when the light next to the “hand” icon is off.

Cycle Start

Cycle Start in PROGRAMMED DISPENSE mode

• In PROGRAMMED DISPENSE mode, pressing the Cycle Start button once will return you to the

Home screen. Pressing it a second time will dispense a single deposit.

• Note: pressing the Cycle Start button accidentally while already in a dispense cycle can abort

your program. Therefore, we recommend that you use the foot pedal (instead of Cycle Start) to

activate the dispense cycle.

Cycle Start in MANUAL mode

• In Manual mode, pressing the Cycle Start button once cancels the Manual selection and returns

you to Programmed Dispense mode and the Home screen.

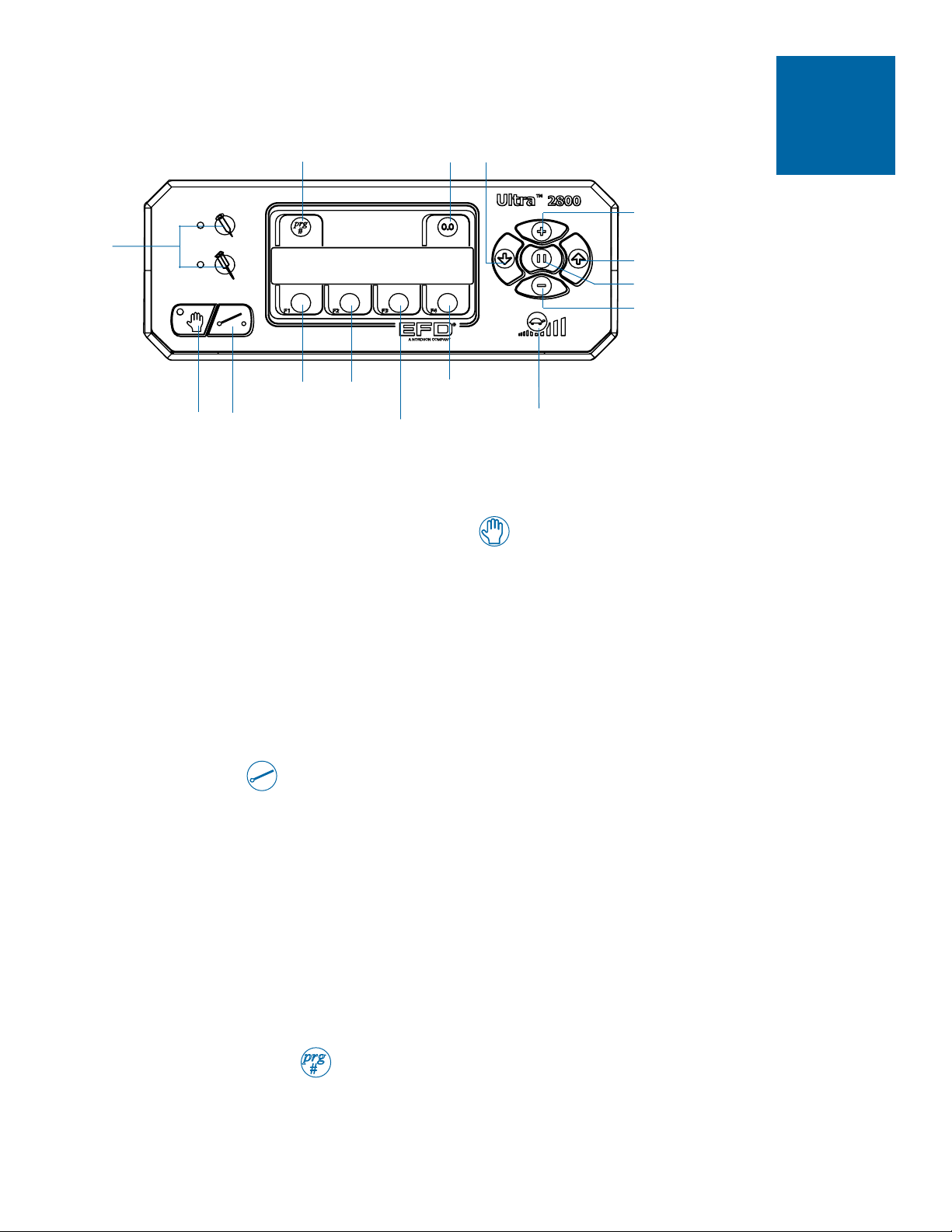

Program Number

In both PROGRAMMED DISPENSE and MANUAL mode, select the Program Number by pressing

the prg button. The Program Number will flash. Use the (+) or (-) buttons to change or select the

Program Number as needed. For more details, see the Program section on page 15.

Program

number

Reset

Barrel

select

Manual/Program

select

Cycle

start

Home

F1

F2

Jog

F3

Dispense rate &

Shot count/Volume

F4

Reset

shot count

Manual dispense rate

Decrease

Pullback/Back

Increase

Deposit volume/

Forward

Pause

Features &

Controls

9

Barrel Select

In both PROGRAMMED DISPENSE and MANUAL mode, pressing the top Single Barrel Select

button activates the screen for the barrel size menu and pre-set dispense rates.

• Press the F1 button to set barrel size. Use the (+) or (-) buttons to scroll through the various

size options.

• Press the F3 button to set Dispense Rate. Select Low, Medium, or High.

The dual barrel select button is not active.

Reset

In PROGRAMMED DISPENSE mode, press the Reset button to reset a range of variables,

depending on the screen selected. Reset choices include syringe barrel volume level to 100%,

Dispense Volume to 0cc, Pause to 0 ms, Pullback to 0 steps, and Dispense Rate to the lowest

minimum value possible, depending on the selected syringe barrel size. (Note: to reset Shot Count,

use the F4 button.)

In MANUAL mode, the Reset button is not active.

Home (F1)

In both PROGRAMMED DISPENSE and MANUAL mode, pressing the F1 button activates the

“Retract to Home” screen. This step is required to remove the syringe barrel and/or when you want

to prepare the unit for storage or shipping.

• Choose Yes by pressing the F3 button. This will fully retract the plunger.

• Choose No by pressing the F4 button. This will return you to the Home screen.

Jog (F2)

In PROGRAMMED DISPENSE mode, pressing the F2 button activates the Jog screen. Jog allows

you to make small adjustments to the position of the plunger as it extends forward. Press and hold

F2 until the “g” of Jog is highlighted. Use the FORWARD and BACK buttons to move the plunger

slightly in either direction as needed.

In MANUAL mode, the F2 button is not active.

Features &

Controls

10

Shot Count/Deposit Volume (F3)

In PROGRAMMED DISPENSE mode, pressing the F3 button lets you toggle between Shot Count

and Deposit Volume.

• Shot Count displays and tracks the number of deposit cycles. You can reset the Shot Count

display to 0 by pressing the F4 button.

• Deposit Volume displays the current volume programmed in cc’s.

In MANUAL mode, the F3 button is not active.

Other F3 commands:

• From the Retract to Home screen, F3 allows you to select the Yes option.

• After you press the Barrel Select button, F3 allows you to set the Dispense Rate.

• From the Modify screen, F3 allows you to adjust the syringe barrel specification for diameter.

(See MODIFY, page 17.)

F4 Button

In both PROGRAMMED DISPENSE and MANUAL mode, the F4 button is not active until you are in

the screens noted below.

• From the Shot Count screen (F3), the F4 button allows you to reset the Shot Count to 0.

• From the Retract to Home screen (F1), F4 allows you to select the No option.

• From the Modify screen, F4 allows you to adjust the syringe barrel specifications for stroke.

(See MODIFY, page 17.)

Deposit Volume/Forward

In PROGRAMMED DISPENSE mode, press the Forward button to activate the Deposit Volume

screen. Use the (+) or (-) buttons to change the deposit volume as needed.

Deposit volume, measured in cc’s, is automatically linked to Forward steps in the Ultra 2800 stepper

motor. When you increase the cc setting, it automatically increases the number of Forward steps.

The maximum number of Forward steps is 65,534.

Deposit Volume is displayed when you press the F3/Shot Volume button.

In MANUAL mode, pressing and holding the Forward button will extend the plunger from the cable

assembly.

Features &

Controls

11

Pause

The Pause function “pauses” the action of the plunger during a dispense cycle, acts as a settling

period and allows the relief of back pressure between Forward and Pullback steps. Pause is helpful

when you are dispensing a large amount of material with a very small tip. In most cases you will not

need to use the Pause function.

In PROGRAMMED DISPENSE mode, press the Pause button to insert an end-of-cycle pause. Use

the (+) or (-) buttons to set the Pause time.

In MANUAL mode, the Pause button is not active.

• Pause is measured in milliseconds. The maximum Pause is 60,000 ms (one minute).

• The default setting for Pause is 0 ms.

Pullback/Back

Pullback sets the number of steps that the plunger will retract into the cable assembly, in

preparation for the next dispense cycle. Be conservative when setting the Pullback. With thick fluids,

too much Pullback can disengage the plunger from the piston. With thin fluids, excess Pullback can

introduce air into the syringe barrel.

In PROGRAMMED DISPENSE mode, press the Back button to activate the Pullback screen. Use

the (+) or (-) buttons to change the number of Pullback steps as needed.

• Use Pullback to eliminate dripping and oozing. We recommend a minimum Pullback of 200

steps for low viscosity fluids.

• For thicker fluids, set the Pullback to 300 steps or more.

• In general, adjust Pullback in small increments of 50 steps at a time for best results. Press the

foot pedal to dispense, and visually check the deposit. Adjust Pullback again if necessary.

When setup is correct, there should be no oozing or dripping.

• The maximum number of Pullback steps is 20,000.

• The default setting for Pullback is 200 steps.

In MANUAL mode, press and hold the Back button to manually retract the plunger as needed.

Features &

Controls

12

Dispense Rate

In both PROGRAMMED DISPENSE and MANUAL mode, pressing the Turtle button allows you to

manually set the Dispense Rate. Use the (+) or (-) buttons to change the speed manually if needed.

In most cases, however, we recommend that you simply use one of the preset Dispense Rates.

• Press the Single Barrel Select button.

• Press F3 to access the Dispense Rate options.

• Select Low, Medium or High.

Dispense Rate is based on cc’s per second. For best results, use the slowest Dispense Rate practical

to your application. In general, start with the preset default rate of Medium. Slower dispense rates

give you better repeatability, since they create less fluid compression. This helps prevent oozing.

Increase and Decrease

In both PROGRAMMED DISPENSE and MANUAL mode, press the (+) or (-) button to change a

number of variables, including Program Number, Deposit Volume, Dispense Rate, Pause milliseconds,

Pullback steps and more.

When the (+) or (-) buttons are pressed briefly, the settings will adjust slowly. When the (+) or (-)

buttons are pressed and held, the settings will adjust faster.

Features &

Controls

13

Back Panel

Connect foot pedal

Power Input

On/Off

Connect I/O

Attach Barrel/Purge Tip

Note: Stay in MANUAL mode for all steps to attach the barrel.

1. Unscrew and remove the barrel retainer from the adapter.

2. Put a tip cap on the syringe barrel and hold barrel next to the flexible cable assembly.

3. From MANUAL mode (hand icon light on), advance the plunger by pressing the Forward button,

just until the plunger reaches past the piston.

4. By hand, insert the plunger into the barrel, pressing it snugly into the piston.

5. Press the Pullback button to retract barrel, until there is just a small gap between barrel and

adapter.

6. Slide barrel retainer over the barrel and thread one turn onto the adapter.

7. Replace tip cap with dispense tip. Tighten barrel retainer.

8. Still in MANUAL mode, press the foot pedal to purge dispense tip. Press until fluid almost fills

the tip and dispenses. Be sure not to overfill the tip since this results in excess back pressure,

which can cause oozing.

Note: See the handout provided with your Ultra 2800 dispenser, Syringe Barrel Attachment

Guide, for simple, step-by-step instructions.

Removing the syringe barrel

1. Press F1 to get the Retract to Home screen. Select Yes. This will retract the plunger into the

cable assembly.

2. Unscrew the barrel retainer from the adapter.

3. Slide the syringe barrel off the plunger.

4. Discard the barrel, or if storing for later use, replace the dispense tip with a tip cap.

5. Screw the barrel retainer back onto the adapter.

Attaching

the Syringe

Barrel

14

Barrel retainer

Adapter

Plunger

Piston

Flexible cable assembly without the syringe barrel

Flexible cable assembly with the syringe barrel

Caution: When the

plunger fits into

the piston, stop

pressing Forward.

If you continue,

excess pressure

can build inside

the barrel and

may cause it to

burst, resulting in

serious injury.

Plunger

Adapter

1

30cc

Shot

Steps

0.0500cc

160

Program

number

Barrel

select

Hand icon

Back

Forward

Pause

Program

Function

15

The Ultra 2800 Dispensing System offers 100 user-defined memory programs, ranging from 0-99.

The programs store the following information.

• Syringe barrel size

• Deposit volume

• Dispense rate

• Pause

• Pullback

Follow these steps to define a program

1. Select PROGRAMMED DISPENSE mode. (Press “hand” icon so red light is off.)

2. Press prg to highlight the program number. Use the (+) or (-) buttons to assign or select the

program number.

3. Press the icon for Single Barrel Select. Set Dispense Rate from this screen by pressing F3 for

Rate, then selecting Medium.

4. Select Deposit Volume by pressing the FORWARD button. Use the (+) or (-) buttons to set

volume.

5. Select Pullback by pressing the BACK button. Use the (+) or (-) buttons to set Pullback.

6. Press the foot pedal once to return to the Home screen. The settings are automatically saved.

7. Press the foot pedal again to dispense the first deposit.

To deposit a continuous bead of fluid, instead of a single dot, follow these steps.

1. Select PROGRAMMED DISPENSE mode. (Press “hand” icon so red light is off.)

2. Press Forward and use (+) or (-) buttons to set Dispense Volume to lowest setting.

3. As a beginning point, keep Pause set to 0 ms and Pullback at 200 steps, then adjust as needed

to eliminate drooling.

4. For best results, set Dispense Rate to the preset of Lo, to minimize back pressure in the syringe

barrel. (Press Single Barrel Select button, then Rate, then Lo.)

5. Select MANUAL mode. (Press “hand” icon so red light is on.)

6. Press and hold the foot pedal until the required amount is dispensed. (Note: the Cycle Start

button is not active in Manual mode, so use the foot pedal to activate the dispense cycle.)

1

10cc

Shot

Steps

0.0001cc

1

Forward

Hand icon

16

How to

Make a

Bead

The Ultra Dispensing System includes pre-set specifications based on industry-standard EFD

syringe barrel dimensions. In most cases, you will want to use these pre-set specifications.

However, you have the option to adjust the settings with the Modify function.

Follow these steps to use the Modify function

1. From either the PROGRAMMED DISPENSE mode or the MANUAL mode, press the Single

Barrel Select button. The MOD (Modify) option will appear.

2. If needed, press F1 to highlight the syringe barrel size. Use the (+) or (-) buttons to select the

correct barrel size — for example, 3cc, 5cc, 10cc, or 30cc.

3. Press F4. This activates the Modify screen.

4. Press F3 to highlight the specifications for the diameter of the syringe barrel. This is

displayed in centimeters. The settings will vary according to the syringe barrel size you have

selected. Use the (+) or (-) buttons to adjust as needed.

5. Press F4 to highlight the specifications for the stroke of the syringe barrel, also listed in

centimeters. Again, the settings will vary depending on the syringe barrel size you have

selected. Use the (+) or (-) buttons to adjust as needed.

Note: The stroke should reflect the distance the EFD piston will travel to dispense

all of the fluid in the syringe barrel. For example, if the barrel is loaded half-full, a certain

stroke length (measured in centimeters) will be required to empty it. By adjusting the stroke

for a specific barrel fill level, you will ensure that the “Level” display on the Home screen

provides an accurate reading.

6. When finished, press the foot pedal once to return to the Home screen.

1

30cc

2.265

Dia

7.60

Strk

Barrel

select

F1/Button

Modify

Function

Modify

Function

17

Helpful Hints

• Faster dispense rates require more Pullback steps. That’s because you are putting more

pressure on the fluid, creating compression inside the syringe. For best results, use the preset

default dispense rate of Medium.

• If you are making small deposits, you are likely creating a lot of pressure trying to force the fluid

through a small dispense tip. Begin with the largest tip practical to your application, with a slow

dispense rate. Depending on how thick your fluid is, you may also need to increase Pullback to

relieve back pressure in the syringe barrel.

• Changing the dispense rate changes the deposit size. The Ultra 2800 provides a metered

deposit based on Forward steps at a specific dispense rate. When you change the dispense

rate, the deposit size also changes, even though the number of Forward steps remains the

same. For example, 25 Forward steps at the high dispense rate produces a smaller deposit than

25 Forward steps at the low rate. That’s because the slower rate gives the fluid more time to

dispense, while the faster rate compresses the fluid and restricts the flow path. For optimum

consistency, stay at the same dispense rate once you have stabilized your deposit settings.

Setting up the First Shot

• Go through the steps outlined in the Ultra 2800 Quick Start Guide to establish your initial

deposit. Work first with the EFD test material, included with your dispensing kit.

• Check the Ultra 2800 Settings Grid for recommended settings, including Forward steps, Pause,

Dispense Rate and Pullback. The grid is included in your dispensing kit.

• Keep your Pullback setting low to reduce the risk of introducing air into your syringe barrel.

• Experiment with different values for each variable. Change only one value at a time and allow

the deposit to stabilize before adjusting or changing another value.

Components

• Always use new EFD barrels and tips. Carefully dispose of after use. This procedure ensures

maximum cleanliness, prevents contamination and provides proper safety.

• You must use a piston with the Ultra 2800. Besides being required to connect with the plunger,

the piston makes barrel loading, dispensing and fluid handling cleaner, safer and more accurate.

• Use the largest tip size possible. Smaller tips require more pressure, which can compress the

fluid and cause oozing, and more time. For best results when working with thick fluids, use EFD

tapered tips. Tapered tips are specially designed to reduce the amount of pressure needed and

are available in a range of sizes. They also help prevent drooling and oozing.

Cycle Start & Abort

The Cycle Start button serves the same purpose as the foot pedal. Pressing either of these once will

return you to Home. However, pressing the Cycle Start button twice can abort your program. Therefore

we recommend that you use the foot pedal to dispense from Programmed mode. A dispense cycle

can be stopped at any time by pressing the Cycle Start button.

Operating

Tips

18

The pre-load on the cable within the flexible cable assembly is preset at the factory. However, over

time the cable may stretch slightly causing a change in performance. The pre-load adjustment block

allows the user to make corrections to the pre-load due to cable stretch. If this happens, turn the

pre-load plug clockwise to readjust the hex shaft to the 1/8" (3.2 mm) to 3/8" (9.5 mm) pre-load

setting range. Do not exceed the 3/8" (9.5 mm) pre-load limit as damage to the unit may result.

The pre-load adjustment block can compensate for approximately 1.5cc’s of hydraulic fluid volume.

However, only a small portion of this volume should ever need to be used. In addition, the pre-load

typically needs to be adjusted just once during the early operation of the unit, and depending on use,

may never be required.

Pre-load adjustment block

(view from underneath)

Pre-load adjustment plug

Follow these steps to make the adjustment

1. Turn power off and detach power cord.

2. Turn unit over.

3. Use slotted screwdriver to turn plug clockwise.

4. Turn until the actuator extends to the 1/8" pre-load dimension, as shown in the figure below.

1/8" (3.2 mm) to 3/8" (9.5 mm) pre-load dimension

Pre-Load

Adjustment

19

Avoid air in the syringe barrel

Air in the fluid is a critical issue with the Ultra 2800 Dispensing System. It can create problems with

inconsistent deposits and drooling. For best results, use an EFD barrel filling station (see below), or

bottom fill the syringe barrel. Simply insert the red piston and push it all the way inside the barrel,

flush to the dispense tip. Then fill through the tip, pushing the piston down as the fluid enters. This

prevents air from entering the syringe barrel.

If needed, eliminate air in the syringe barrel by using centrifuge or a vacuum chamber.

If the fluid being dispensed is pourable, attach an orange tip cap to the syringe barrel and pour the

fluid in. Insert the piston and carefully press it down until it contacts the fluid. The syringe barrel is

now ready for use.

If the fluid is thick or non-leveling, it

can be spooned into the barrel with a

spatula. Or, if the fluid comes packed

in a 1/10 gallon cartridge, the barrel

can be loaded with a caulking gun.

After loading, press in the piston to

move the fluid to the bottom of the

barrel and to remove trapped air.

Caution: Do not completely fill syringe

barrels. The optimum fill is a

maximum 2/3 of the barrel capacity.

If you are working with assembly fluids

with a short pot life, you may want to

fill to 1/2 of the syringe barrel.

EFD offers productive, air-free

alternatives to traditional barrel loading methods. Here are a few suggestions that can help keep the

work area clean, save time and reduce the chance of entrapped air in the fluid.

1. The EFD #8000BF Series automatic syringe filler provides consistent filling for all types of

nonpourable assembly fluids. It features built-in flow controls to prevent spillage and air

entrapment.

2. If you receive frozen epoxies or other fluids in medical type syringes with a manual plunger,

request the EFD luer-to-luer fitting #2160 to transfer the material from the original syringe to

the EFD syringe barrel.

3. Another option is the EFD #920BL barrel loader. Pack the fluid into the 12-ounce cartridge.

Place the pre-filled cartridge into the barrel loader. Using air pressure, the barrel loader fills the

syringe barrel (with piston) from the bottom up.

4. If the fluid comes prepackaged in a 1/10 gallon (300 ml) caulking type cartridge, use the EFD

#940BL barrel loader.

For additional assistance please contact an EFD Fluid Application Specialist.

Fill procedure for thick fluids

(shown: caulking gun)

2/3 maximum fill

2/3

maximum

fill

Piston

Fill procedure for pourable fluids

Syringe

Barrel

Filling

20

Input/Output

Connection

21

Voltage Initiate Circuit

The Ultra 2800 workstation may be initiated with a 5 to 24 VDC signal across pins 1 and 2. These

two input pins are current driven and optically isolated. From Programmed Dispense mode, this

signal can be momentary (no less than 0.01 seconds) or maintained. In this mode, a new dispense

cycle begins once the 5 to 24 VDC signal is removed and then applied again.

When this input circuit is activated in Manual mode, a continuous bead is dispensed until the signal

is removed.

Mechanical Contact Initiate

The Ultra 2800 can be initiated via the closure of mechanical contacts such as a relay or switch

using pins 7 and 8. The timing and actuation rules for the contact closure input are identical to the

voltage initiate input description.

End-of-Cycle Feedback Circuit

Upon completion of a dispense cycle, a solid-state switch closes and remains closed until the next

dispense cycle. This circuit is normally closed when a dispense cycle is not active. Pins 3 and 4 of

this circuit can be used to signal back to a host computer, start another device in sequence or

initiate other operations that need to be tied into the completion of the dispense cycle.

The circuit is an optically isolated transistor output designed to operate between 5 to 24 VDC,

100mA maximum.

Pin Function

1. Voltage initiate +, 5-24 VDC (22mA at 24 VDC)

2. Voltage initiate -

3. End-of-cycle feedback output +, 5-24 VDC (100mA maximum)

4. End-of-cycle feedback output -

5. 24 VDC supply + (100mA maximum)

6. 24 VDC supply – (ground)

7. Contact closure +, 10mA

8. Contact closure – (ground)

Notes

1. An 8-pin DIN connector and cable assembly is available. Order EFD part #2446.

2. 2800 operation is identical for dispense initiation from I/O inputs or the foot pedal.

3. Pins 6 & 8 of the I/O connector are internally connected to signal ground.

2

813

76

54

If you encounter a problem that you cannot readily solve, call EFD.

Trouble Possible cause and correction

No power Check the fuses and replace as needed. Follow these steps:

1. Disconnect the power to the unit prior to performing this service.

2. Locate the power entry module on the lower left corner of the rear panel.

3. If the electrical cord is still connected to the back of the unit, remove it now.

4. There is a small vertical slot just to the right of the red window on the power

entry module. Insert a small screwdriver in the slot to pry latch open.

Door swings open to the left.

5. Pull out the red fuse tray. Note the location and orientation of the fuses.

6. Pull both fuses out of the fuse tray and discard.

7. Replace both with 1.0A/250 VAC 5x20 mm fuses (EFD part #28139 or

equivalent). Orient the fuses in the same manner as the fuses that were removed.

8. Insert fuse tray back into power module, close fuse door and reconnect power.

Blow by If you are dispensing a watery-thin fluid, request the EFD yellow wiper piston,

available for the Ultra 2800-30 model only. Specify EFD part # A678-B.

Oozing 1. There is too much fluid compression in the syringe barrel. Change to a fresh

dispense tip and start over. If needed, switch a slower dispense rate.

2. The plunger has become disengaged from the piston. To check, unscrew the

retainer from the adapter and turn the syringe barrel upside down. If the syringe

barrel falls off, the plunger is disengaged. See the handout, “Syringe Barrel

Attachment Guide,” for step-by-step instructions on how to properly engage the

plunger and piston.

Inconsistent 1. There is air in the syringe barrel, either entering the barrel during filling, or from

shot size excessive Pullback. Eliminate air from the barrel, or adjust the Pullback.

2. The Dispense Rate may be too fast for the combination of fluid viscosity and

dispense tip. Reduce the Dispense Rate.

3. The plunger is fouled. Remove the syringe and clean as needed. Also, check

dispensing tip, barrel and material for possible clogging. For best results,

change the dispense tip.

4. You may need to adjust the pre-load adjustment block. See page 19.

Dispense Rate If nothing seems to happen when you press the (+) or (-) button to manually adjust

does not adjust the Dispense Rate, the rate may already be set to a very low speed. Try switching to

the preset default for Medium.

Service The interior mechanics of the Ultra 2800 system are not field serviceable.

Attempting to repair or service the unit by removing the enclosure cover voids

factory warranty. Please contact your EFD service representative for assistance.

Troubleshoot

22

Choose from several optional productivity tools to maximize your Ultra 2800

dispensing kit.

Barrel Hand Grip

Ergonomic hand grip is available for the 2800-30 model only and easily

holds 30cc syringe barrels. Specify EFD part #2441.

Safety Shield

Large, acrylic shield mounts on a flexible arm to either side of the Ultra

2800 cabinet and provides splash guard protection when adhesives and

toxic fluids are used. Specify EFD part #2436 plus the assembly mount

(#2800AM).

Magnifying Lens

1.7x magnification ensures more accurate deposit placement, improves

repeatability and reduces operator strain. Mounts to either side of the

Ultra 2800 cabinet. Specify EFD part #2442 plus the assembly mount

(#2800AM).

Syringe Barrel Production Stand

Holds syringe barrel in a fixed position for bringing the production part to

the dispense tip. Specify EFD part #2856.

Productivity

Tools

23

Replacement

Parts

24

Part # Description

Barrel/Piston Sets

5109CPD-B 3cc BP Kits Clr/Red (50)

5110CPD-B 5cc BP Kits Clr/Red (40)

5111CPD-B 10cc BP Kits Clr/Red (30)

5112CPD-B 30cc BP Kits Clr/Red (20)

5109LBPD-B 3cc BP Kits LB/Red (50)

5110LBPD-B 5cc BP Kits LB/Red (40)

5111LBPD-B 10cc BP Kits LB/Red (30)

5112LBPD-B 30cc BP Kits LB/Red (20)

Pistons

5109PDP-B 3cc red pistons (50)

5110PDP-B 5cc red pistons (40)

5111PDP-B 10cc red pistons (30)

5112PDP-B 30cc red pistons (20)

A678-B 30cc yellow wiper pistons (20)

Part # Description

Flexible Cable Assembly

2800P-3 3cc plunger

2800P-5 5cc plunger

2800P-10 10cc plunger

2800P-30 30cc plunger

2800R-3 3cc retainer

2800R-5 5cc retainer

2800R-10 10cc retainer

2800R-30 30cc retainer

2800A 3/5/10cc adapter

2800A-30 30cc adapter

Replacement Parts

2422 Omnidirectional foot pedal

2800PS-KIT Power Supply Kit

2800CL-KIT Cylinder Kit

2800FPL-KIT Front Panel Kit,-3cc/5cc

2800FPH-KIT Front Panel Kit,-10cc/30cc

2800CPU-KIT Microprocessor Kit

1000RTM-3 (-5, -10, -30) Red test material with red piston

Productivity Tools

2427-B Replacement sleeve/5 pk

2436 Safety Shield

2441 Barrel Hand Grip (for 2800-30 only)

2442 Magnifying Lens

2446 8-pin Connector Assembly

2856 Syringe Barrel Production Stand

2800AM Accessory Mount

2800BH Syringe Barrel Holder

2800CG Cable Guide Holder

IMPORTANT SAFETY NOTE: To accommodate smaller syringe barrels,

the Ultra 2800-3 and 2800-5 systems use a stepped-down motor.

Do not use 3cc or 5cc replacement parts or components with

a 2800-10 or 2800-30 system.

Replacement

Parts

25

Notes

26

Notes

27

EFD Two Year Limited Warranty

This EFD dispenser is warranted to the original end user for two years from date of purchase.

Within the period of this warranty, EFD will repair or replace any defective component, or the

entire dispenser at EFD’s option, on authorized return of the part or the complete dispenser,

prepaid to the factory.

In no event shall any liability or obligation of EFD arising from this warranty exceed the purchase

price of the equipment. Before using, user shall determine the suitability of the product for its

intended use, and user assumes all risk and liability whatsoever in connection therewith.

EFD makes no warranty whatsoever of merchantability or fitness for a particular purpose.

In no event shall EFD be liable for incidental or consequential damages.

To register your warranty in the USA, please call 800-828-3331 within 30 days, or go to

www.efd-inc.com/warranty/two-2800.

©2006 Nordson Corporation 2800-MAN-01 v062606

This equipment is regulated by the European Union under WEEE Directive (2002/96/EC).

See www.efd-inc.com for information about how to properly dispose of this equipment.

For EFD sales and service in over 30 countries,

contact EFD or go to www.efd-inc.com/contact

EFD, Inc.

East Providence, RI USA

800-556-3484; +1-401-434-1680 (outside the USA)

info@efd-inc.com www.efd-inc.com

EFD International Inc.

Dunstable, Bedfordshire, UK

0800 585733 or +44 (0) 1582 666334

Ireland 00800 8272 9444

europe@efd-inc.com www.efd-inc.com

EFD, Inc., Asia

China: +86 (21) 5854 2345

china@efd-inc.com www.efd-inc.com/cn

Singapore: +65 6896 9630 sin-mal@efd-inc.com

A NORDSON COMPANY

Loading...

Loading...