Page 1

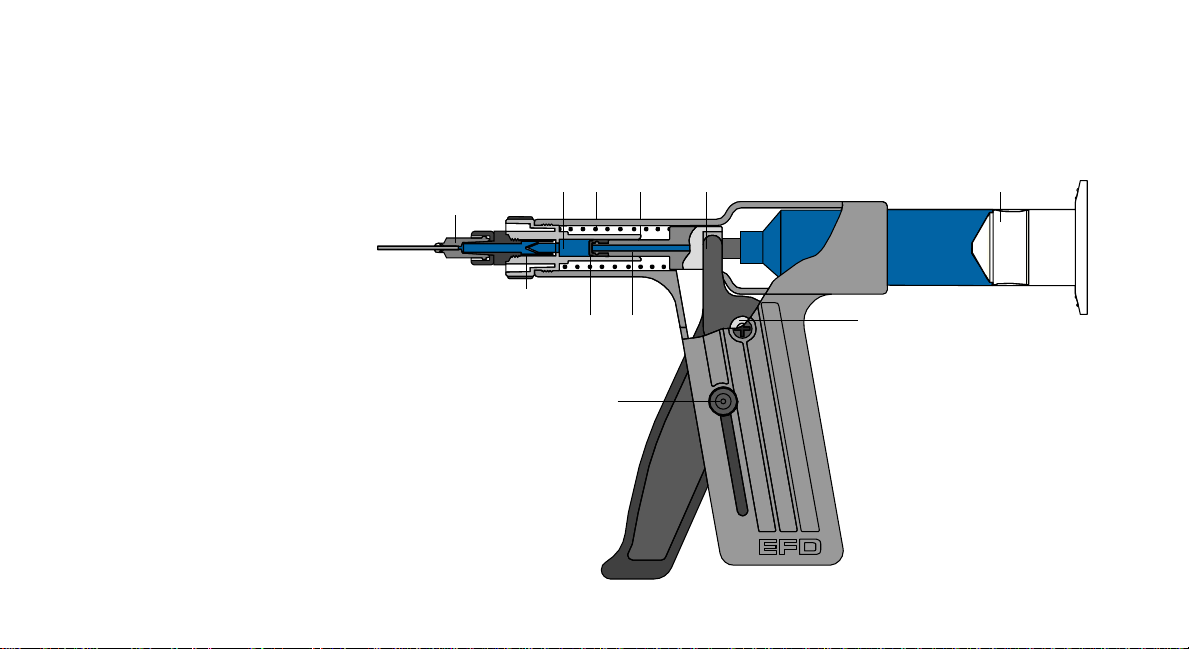

DotMaker

Operating Instructions

dispense tip

™

fluid

chamber

return

spring

fluid

inlet

thrust

arm

disposable barrel

reservoir and piston

The DotMaker™ 2000PD is a positive displacement

dispensing gun for making repeatable deposits of

low to medium viscosity materials.

The position of a volume control knob regulates the

trigger stroke and, in turn, controls the volume

displaced by the internal pump. Squeezing the

trigger displaces the shot and releasing the trigger

charges the chamber.

Follow this step-by-step guide to begin using

your new DotMaker™ 2000PD.

outlet check valve

inlet check valve

piston

volume

control knob

pivot

5

4

3

2

1

L

Page 2

The unique DotMaker™ simplifies

application of low to medium

viscosity fluids.

It is very easy to use and less

fatiguing than other manual

applicators.

This manual is for the express and sole use of EFD DotMaker™ purchasers

and users, and no portion of this manual may be reproduced in any form.

The DotMaker is patented by EFD Inc. Patent #D-403,933 ©2001

®

A NORDSON COMPANY

US: 800-556-3484 info@efd-inc.com

Features

• Rugged die cast zinc construction.

• Adjustable volume control.

• Designed specifically for use with ULTRA System™ component technology

to eliminate drooling or dripping of fluids.

• Accepts five barrel sizes: 3cc, 5cc, 10cc, 30cc and 55cc.

• Quick change pump assembly for easy maintenance.

Specifications

Handle and Trigger: Die cast zinc with powder coat finish

Pump chamber: Polypropylene, nylon, aluminum

Check valves: Viton® (alternate EPR )

Output: Variable. 0.01 grams to 0.250 grams

Weight, gun only: 13.4 oz (375 gm)

Page 3

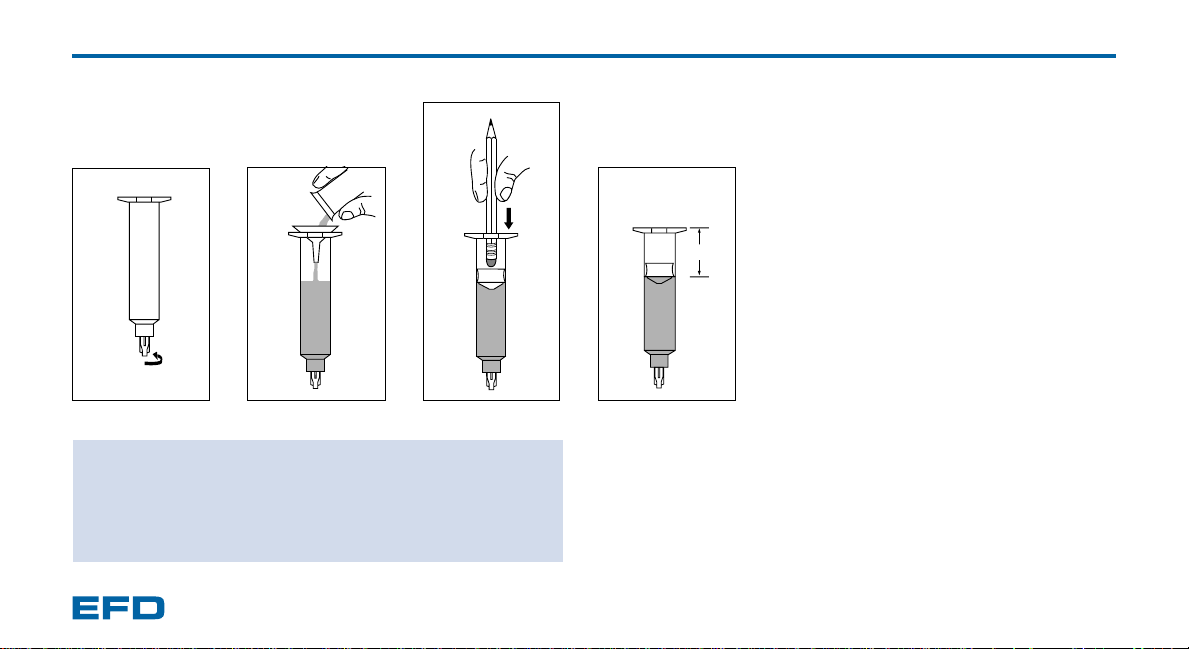

Fill level

Filling the barrel reservoir

➀ Install an orange tip cap (#5113).

➁ Load the fluid into the barrel, filling to the

recommended level (see chart).

➂ Insert a SmoothFlow

it just touches the fluid.

NOTE: For high volume applications, consider

prefilled reservoirs from fluid packagers.

™

white PE piston so that

➀

➁

NOTE: The 2000PD performs best with fluids that pour and thixotropic

materials which will move with pressure of 15 psi or less. Do not use high

viscosity materials such as RTV silicone and heavy grease. Contact EFD

for recommendations.

®

A NORDSON COMPANY

US: 800-556-3484 info@efd-inc.com

➂

Barrel Fill Level

3cc ⅝"

5cc ⅝"

10cc ¾"

30cc ¾"

55cc ¾"

Page 4

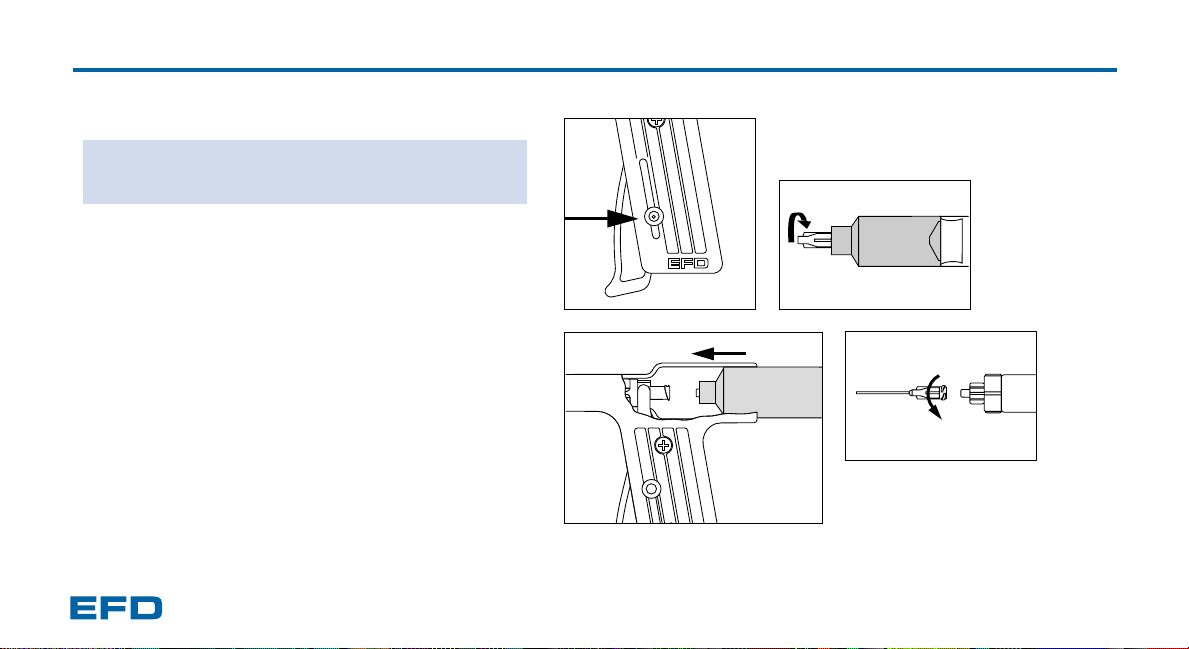

Setup

NOTE: Prime the 2000PD at the lowest possible volume

setting to minimize waste during final volume adjustments.

➀ Loosen the volume control knob. Pull the trigger in while

sliding the knob to the #1 position; then tighten the knob.

➁ Remove the orange tip cap from the end of the barrel

reservoir.

➂ Look into the inlet port and align the barrel reservoir with

the inlet luer lock adapter. Press the reservoir in and twist

to the right to secure.

CAUTION: Use light pressure to secure the reservoir.

Be careful not to overtighten.

➃ Remove the tip cap from the outlet end of the 2000PD and

install a dispensing tip. Use a small diameter tip for thin

fluids or a larger one for thicker materials.

®

A NORDSON COMPANY

US: 800-556-3484 info@efd-inc.com

➀

5

4

3

2

1

L

➂

5

5

4

4

3

3

➁

➃

Page 5

A NORDSON COMPANY

®

US: 800-556-3484 info@efd-inc.com

Priming the 2000PD

➀ Place the dispensing tip on the test paper and

squeeze the trigger repeatedly (about 20 times) until

fluid begins to dispense.

➁ With thicker material, it may help to apply light

pressure on the piston while squeezing the trigger.

Continue to dispense until fluid flows free of air.

5

4

3

2

1

L

Page 6

Operating the 2000PD

NOTE:

chamber to refill between deposits. Thicker materials

require more time (1 to 2 seconds). When deposits

begin to decrease from shot to shot, it is an indication that more time is required between shots.

➀ The position of the volume control knob determines

the deposit volume. Position the knob near #1 for low

volume and toward #5 for higher output.

Sufficient time must be allowed for the

high volume

low volume

➀

5

4

3

2

1

L

➁

➁ To adjust the volume control knob, place the dis-

pensing tip on the test paper. Squeeze and hold the

trigger in (some material will dispense). Loosen the

knob and slide it to the desired position; then tighten

the knob and release the trigger.

For best results, hold the dispensing tip at a 45°

angle and in contact with the work surface. Use

the test sheet to practice.

®

A NORDSON COMPANY

US: 800-556-3484 info@efd-inc.com

45°

5

4

3

2

1

L

Page 7

Recommendations

• The DotMaker™ has Viton® seals which work well with most fluids. If your

fluid reacts with Viton®, order pump assembly #2000EPR with ethylene

propylene seals.

• Do not use the DotMaker™ with cyanoacrylate instant-cure adhesives. Contact

EFD for recommendations.

• Anaerobic sealants and thread-locking materials can be dispensed but should

be purged at the end of the day to avoid curing inside the pump.

• UV-cure adhesives work best with the EPR pump assembly #2000EPR.

• Certain high viscosity materials can be dispensed; however, they require more

time to fill the chamber between shots.

Contact EFD if you have questions or need us

to evaluate a material: 800-556-3484.

®

A NORDSON COMPANY

US: 800-556-3484 info@efd-inc.com

Fluid Compatibility

anaerobics ●

coatings ●

cyanoacrylates ✕

gel cyanoacrylates ✕

carpenter's glue ●

white glue ●

epoxies ✕

inks ●

grease ●

oils ●

sealants ●

silicones ●

solder pastes ✕

braze pastes ✕

solvents ●

UV cure ●

Key

● recommended

● conditional

✕ do not use

Page 8

Maintenance & Cleaning

1

L

3

2

4

5

Purging

To perform a simple purge procedure, remove tip and

install a reservoir filled with an appropriate cleaning

solution. Set the volume control knob to #5 and operate

the trigger until all the solution has been dispensed through

the gun. Repeat if necessary.

Pump Replacement

Remove the fluid reservoir.

➀

➁ Remove the dispensing tip.

➂ Set volume control knob to #5.

➀

➁

➃ Squeeze the trigger until the remaining material is

cleared from the gun.

®

A NORDSON COMPANY

US: 800-556-3484 info@efd-inc.com

➂

➃

Page 9

➄

➄ Remove the pump assembly and spring from the

front by unthreading the pump chamber to the left

(counterclockwise).

pump chamber

a.

A NORDSON COMPANY

spring

piston

➅

b.

View from rear of gun

showing correct alignment

of pump assembly.

®

US: 800-556-3484 info@efd-inc.com

piston

trigger thrust arm

Separate the piston from the chamber and save the

spring.

5

4

3

2

1

L

➅ Install the replacement pump assembly, part #2000V

(Viton®) or alternate #2000EPR (ethylene propylene):

a. Separate the piston from the chamber.

b. Install the piston into the front of the gun. Look

through the back of the gun and align the flats on

the piston with the thrust arm on the trigger.

c. Insert the pump chamber and spring through the

front of the gun and hand tighten to the right

c.

(clockwise).

Page 10

The 2000PD will not prime or dispense. One of the check valves is not closing properly. Purge the gun with cleaner

The 2000PD drips after the deposit. There is air in the dispensing tip. Operate the gun until the air is dispelled.

Accessories and Parts

Molded Field Case

Durable, molded carrying case

protects the 2000PD. Includes

space for accessories.

Part# PDCASE

®

A NORDSON COMPANY

US: 800-556-3484 info@efd-inc.com

Troubleshooting

or replace the pump assembly.

The material is too thick.

The seals may have reacted and swelled. Replace with the alternate EPR

pump assembly #2000EPR.

The seals may have reacted and swelled. Replace with the alternate EPR

pump assembly #2000EPR.

For further assistance, contact EFD at: 800-556-3484.

Holster

Tough nylon holster straps onto

a tool belt. Provides gun storage

and holds two prefilled barrels.

Part# PDHOLSTER

Illuminator

™

Flashlight and attachment to light

up recesses for accurate

dispensing. Spot or flood beam.

Part# PDLIGHT

5

4

3

2

1

L

Page 11

Accessories and Parts

Barrels/pistons: Each box contains the

same quantity of barrels and pistons.

part # description

5109CP-B (50) sets for 3cc size gun

5110CP-B (40) sets for 5cc size gun

5111CP-B (30) sets for 10cc size gun

5112CP-B (20) sets for 30cc size gun

5113CP-B (15) sets for 55cc size gun

Snap-tight barrel end caps: These caps

ensure sealing of filled barrels for storage.

Finger tab for easy removal .

part # size qty / box

5109EC-B 3cc (50)

5110EC-B 5cc (40)

5111EC-B 10cc (30)

5112EC-B 30cc/55cc (20)

®

A NORDSON COMPANY

US: 800-556-3484 info@efd-inc.com

Smooth-flow tapered tips: Molded polyethylene.

Packaged (50) tips per transparent box for easy part

identification.

tapered gage ID color

5114TT-B 14 .063" olive

5116TT-B 16 .047" grey

5118TT-B 18 .033" green

5120TT-B 20 .023" pink

5122TT-B 22 .016" blue

5125TT-B 25 .010" red

General-purpose precision tips: Stainless steel tips

with color-coded polypropylene hubs. 1/2" and 1" free

lengths. Packaged (50) tips per box.

1/2" 1" gage ID color

5114-B 5114-1-B 14 .061" olive

5115-B 5115-1-B 15 .054" amber

5118-B 5118-1-B 18 .033" green

5120-B 5120-1-B 20 .024" pink

5121-B 5121-1-B 21 .020" purple

Barrel tip caps: Seals barrel outlet for

storage. One size fits all barrels.

part # qty / box

5113-B 50

Replacement Pump

Screw-in replacement pump assembly

and seals for the 2000PD. Available in

®

Viton

and ethylene propylene.

Viton®#2000V

EPR #2000EPR

Page 12

®

A NORDSON COMPANY

Headquarters:

977 Waterman Avenue, East Providence, RI 02914-1378 USA

Toll free: 800-556-3484 telephone: 401-434-1680

fax: 401-431-0237 e-mail: info@efd-inc.com www.efd-inc.com

EFD, DotMaker and SmoothFlow are registered trademarks

of EFD Inc. Viton is a registered trademark of E.I. Dupont.

©2001 EFD Inc. #PD-MAN

Unit 14, Apex Business Centre, Boscombe Road, Dunstable, Bedfordshire LU5 4SB UK

freephone: 0800 585733 telephone: 01582 666334 fax: 01582 664227

Ireland: 00800 8272 9444 e-mail: sales@efd-inc.co.uk www.efd.co.uk

Loading...

Loading...