Page 1

Service Data

Vickers

®

Piston Pumps

PVH131/141 Variable Displacement

Piston Pump - 11 Design

Revised 05/01/97

M-2209-S

Page 2

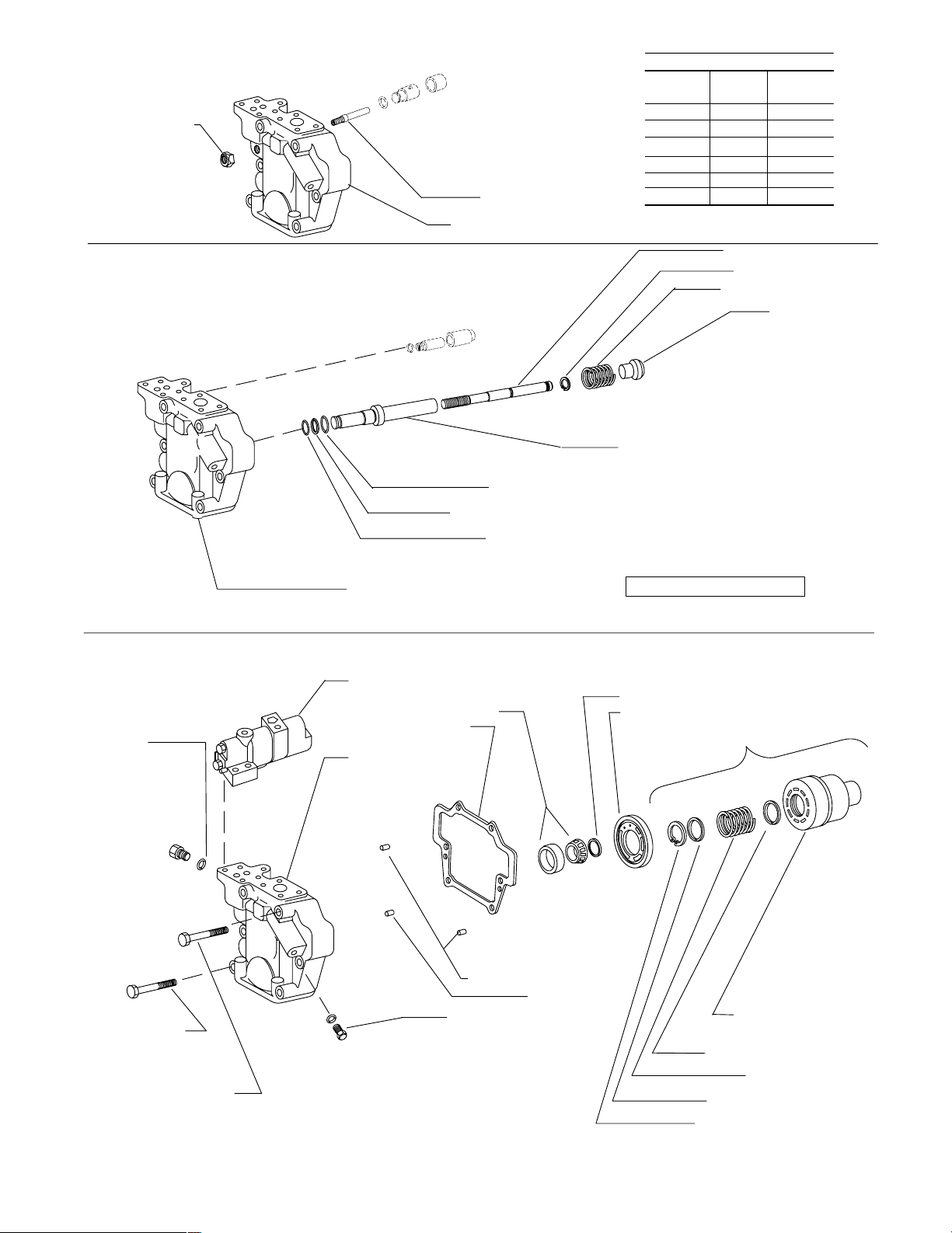

Maximum Adjustable Stop – S Option

913341 Locknut

Torque 25-50 N.m.

(18-37 lb. ft.)

860739 Adj. screw

Valve block (See table)

Valve Block Table

Pump

Type

F–11–C

M–11–C

SF–11–C

SM–11–C

F–11–CT

M–11–CT

RH LH

928637

928638

928624

928625

860852

860853

928687

928688

928673

928674

860861

860862

Torque Limiter – T Option

Standard – C/CM/CMV/CV/IC

396093 O-ring

(2 Req’d)

263500 O-ring

197597 Back-up ring

262359 O-ring

Valve block (See table)

Pump control (see controls pages)

513433 Bearing S/A

526760 Gasket

Valve block

(see table)

928453 Bias piston

928457 Lock ring

526690 Bias spring

928455 Cap

928454 Bias sleeve

Torque 129-142 N.m (95-105 lb. ft)

Grade RC30 compound

Torque control models

02-142690 Shaft spacer kit

Valve plate (see table)

Rotating group kit (See table)

473806 Screw

(4 Req’d)

Torque 103-127 N.m.

(76-94 lb. ft.)

473833 Screw (2 req’d)

Torque 257-315 N.m. (190-232 lb. ft.)

Eaton Hydraulics, Incorporated 2000

All Rights Reserved

471512 Pin (2 Req’d)

248935 Pin

689461 Plug (2 Req’d)

Torque 12.7-13 N.m. (8.9-9.5

lb.ft.)

Cylinder block

(See table)

417667 Spring guide

626111 Spring

581104 Spring guide

135066 Retaining ring

Page 3

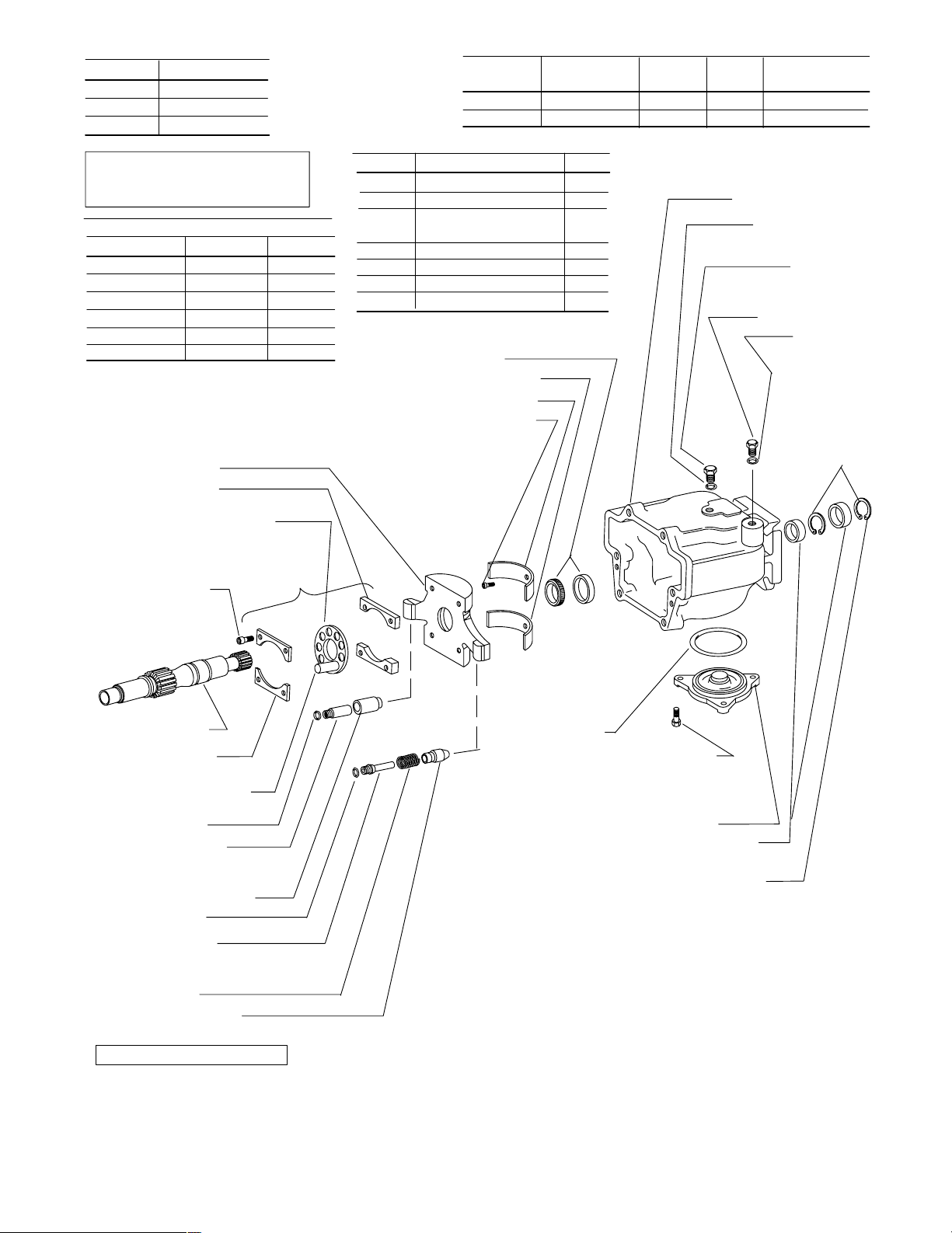

Housing Flange/Seal

692944

876277

864310

-C-*S

-C-*D

-C3-*S

Model

Designation

131 Size

141 Size

Piston & Shoe

S/A (9 req’d)

02-159749

02-306332

Cylinder

Block

680628

928786

Shoe

Cage

683791

928776

Rotating Group

Kit

877419

02-322898

Note

Complete replacement via rotating

group kits is recommended.

V alve Plate Table

Pump Type

131 527164 527163

131QI 864381 876045

131QP 913578 N/A

141 928774 934240

141QI 934242 934243

141QP 934241 N/A

692941 Yoke S/A

526757 Spacer

(2 Req’d)

Shoe cage (See table)

Rotating group kit (See table)

473764 Screw

(4 Req’d)

Torque 31-37 N.m.

(23-27 lb. ft.)

RH LH

Shaft Type Key

876177 3 – Splined thru-drive –

860594 12 – Splined thru-drive –

876176 16 – Straight keyed 633260

thru drive

860802 2 - Splined –

877042 3 - Splined –

860593 12 - Splined –

876175 13 - Straight keyed 140282

388206 Bearing S/A

692948 Saddle bearing

692949 Saddle bearing

690339 Screw (2 Req’d)

Torque 3.6-4.4 N.m.

(2.3-3 lb. ft.)

Housing (See table)

396102 O–Ring

513602 Plug

Torque 97-106 N.m.

(71-78 lb. ft.)

396100 O–Ring

181792 Plug

Torque 75-83 N.m.

(40-43 lb. ft.)

Shaft (See table)

526758 Limiter

(2 Req’d)

Piston & Shoe S/A

(See table)

262355 O–Ring

526754 Control rod

Torque 82-91 N.m. (60-67 lb. ft.)

Grade RC30 compound

526753 Control piston

262355 O–Ring

526752 Bias rod

Torque 82-91 N.m. (60-67 lb. ft.)

Grade RC30 compound

526690 Spring

692152 Bias piston

Non-torque control models

Available in double shaft

seal kit 02–102266

Available in bearing kit 877426

Available in bearing/yoke

kit 02-334838

335659 O–Ring

Available in PVH131 rotating group kit.

Available in PVH141 rotating group kit.

470794 Screw

(3 Req’d)

Torque 7-9 N.m.

(5-6.6 lb. ft.)

692946 Cover

864200 Shaft seal

(2 Req’d if dual seal)

194030 Retaining ring

(2 Req’d if dual seal)

NOTE

Right hand rotation shown. View

is opposite for left hand rotation.

Please refer to Overhaul Manual

M-2210-S.

NOTE

Use shims as required to obtain

0.01–0.10 mm (.0004–.004 in.) axial

shaft end play.

NOTE

For satisfactory service life of these

components in industrial applications,

use full flow filtration to provide fluid

which meets cleanliness code 16/14/12

or cleaner.

Page 4

Load Sensing & Pressure

Compensator Control C(M)*V

857688 Load sense spring

857674 Spring guide

181728 Plug Torque 29-32 N.m. (21-24 lb. ft.)

396096 O-Ring

473765 Screw

(4 Req’d) Torque 31-37 N.m. (23-28 lb. ft.)

857733 CV Body

857673 Load sense spool

857674 Spring guide

857679 Pin spring stop

396100 O-Ring

860748 Plug

Torque 75-83 N.m.

(55-60 lb. ft.)

860747 Nut

(2 Req’d)

Torque 14-20 N.m.

(10-14 lb. ft.)

860749 Plug

Torque 97-106 N.m.

(71-78 lb. ft.)

396102 O-Ring

860750 Adj. screw (2 Req’d)

857734 Spring guide

857681 Control spring

627391 Plug

(2 Req’d)

Torque 29-32 N.m.

(21-24 lb. ft.)

396096 O-Ring

(2 Req’d)

857672 Pressure limiter spool

177969 O-Ring (3 Req’d)

Pressure Compensator Control C & CM

Control spring (See table)

857734 Spring guide (2 Req’d)

857722 Body

473765 Screw (4 Req’d)

Torque 31-37 N.m. (23-28 lb. ft)

857672 Spool

396096 O-Ring

CV

CVB

CMV

Control Kit

02–125161

02–160591

02–306056

Control

Type

All parts shown are included in control kit.

Kit must be set by user to circuit requirements.

Pressure

range

140–280 Bar

35–140 Bar

857681

857675

857734 Spring guide

BodySpring

857733

928442

857733

396102 O-Ring

860750 Adj. screw

Torque 97-106 N.m.

Orifice

Plug

–

433543

–

860749 Plug

(71-78 lb. ft.)

627391 Plug

Torque 29-32 N.m.

(21-24 lb. ft.)

177969 O-Ring (3 Req’d)

860747 Nut

Torque 14-20 N.m.

(10-14 lb. ft.)

Control Type

C

CM

All parts shown are included in control kit.

Pressures must be set by user to circuit requirements.

Control Kit

02–125160

02–125162

Pressure range

70-250 Bar

40-130 Bar

Spring

857681

857675

Page 5

Industrial Control (IC)

473769 Screw (2 Req’d)

Torque 31-37 N.m. (23-28 lb. ft.)

407533 Plug

Torque 12.1-12.4 N.m. (8.9-9.1 lb. ft.)

396093 O-Ring

396092 O-Ring (3 Req’d)

398071 Plug (3 Req’d)

Torque 9.8-10.2 N.m. (7.2-7.5 lb. ft.)

Body (see table)

626157 Spring

860606 Spring guide (2 Req’d)

396100 O-Ring

860747 Nut

Torque 14-20 N.m.

(10-14 lb. ft.)

860750 Adj. screw

860748 Plug

Torque 75-83 N.m. (55-60 lb. ft.)

Torque Limiter – T Option

860749 Plug

Torque 75-83 N.m

(102-112 lb. ft.)

860750 Adjusting Screw

860747 Nut

Torque 8-10 N.m

(11-14 lb. ft.)

1649 Ball

471627 Pin

937272 Check valve

Torque 1.7-2.3 N.m

(2.3-3.1 lb. ft.)

217669 O-ring

177969 O-ring

(2 req’d)

Control Kit Threads Body

02–151906 inch 883386

02–151907 metric 860628

All parts shown are included in control

kit. Pressures must be set by user to circuit

requirements.

928388 Guide

857675 Spring

857734 Guide

263069 O-ring

473765 Screw

(2 Req’d) Torque 31-37 N.m. (23-28 lb. ft.)

113000 Plug

Torque 5.1-5.9 N.m. (3.7-4.4 lb. ft.)

860566 Orifice plug

Torque 1.7-2.3 N.m.

(1.2-1.7 lb. ft.)

396096 O-Ring

181728 Plug

Torque 29-32 N.m.

(21-24 lb. ft.)

627391 Plug

Torque 29-32 N.m.

(21-24 lb. ft.)

396096 O-Ring

939816 Spool

177969 O-Ring

(2 req’d)

216630 O-Ring

NOTE

IC kits pre-set to 20-30 bar differential

pressure with all orifices/plugs in

place. Reference Vickers Overhaul

Manual M-2210-S for proper orifice/

plug configuration in various circuits

prior to control installation.

913453 Guide

473773 Screw (4 req’d)

Torque to 31-37 N.m

(42-50 lb. ft.)

197594 Back-up ring

262356 O-ring

860655 Plug Torque 75-83

N.m (102-112 lb. ft.)

248823 Pin

186580 Plug

Torque 54-59 N.m

(73-80 lb. ft.)

263497 O-ring

113000 Plug

Torque 15-17 N.m

(20-23 lb. ft.)

913454 Spool

860653 Body

177969 O-ring (5 req’d)

577639 Sleeve

262499 O-ring

Model designation Control Kit

C**T**-31

C**T**S-31

02–314944

02–335254

248845 Pin

932716 Retainer Ring

(Screw into bottom of thread)

932716Connector

Torque 54-59 N.m

(73-80 lb. ft.)

263497 O-ring

Torque summation parts

Page 6

*A* Thru–drive

Valve block

(See table)

Thru–drive

Adapter location

(See table)

473806 Screw (4 Req’d)

Torque 83-102 N.m. (61-75 lb. ft.)

‘‘A’’ Thru–drive

473833 Screw (2 req’d)

Torque 257-315 N.m. (189-232 lb. ft.)

473800 Screw (2 Req’d, SAE

“B”/“C” pad) Torque 103-127 N.m.

(76-94 lb. ft.)

Coupling

(See table)

Rear

Pump

O-Ring

(See table)

Model designation

LAF–11–C*

LAM–11–C*

RAF–11–C*

RAM–11–C*

LAF–11–CT

LAM–11–CT

RAF–11–CT

RAM–11–CT

‘‘B’’ & ‘‘C’’ Thru–drive Adapter

Model Designation

*–*BF–11–*

*–*BM–11–*

*–*CF–11–*

*–*CM–11–*

Notes:

1.‘‘F’’ type equal SAE threads

2. ‘‘M’’ type equal metric threads

3. ‘‘B’’ and ‘‘C’’ thru-drives created from

‘‘A’’ thru-drive pump with ‘‘B’’ or ‘‘C’’

thru-drive adapter kit installed.

4. All screws/O-rings are included with

each ‘‘kit’’ to convert from ‘‘A’’ to

‘‘B’’ or ‘‘C’’ thru-drive unit.

Valve block

w/ SAE ‘‘A’’ Pad

928713

928714

928736

928737

860843

860844

860834

860835

Adapter

Pad Kit

876390

876394

876389

876392

Adapter

Flange

526670

876393

692934

876391

O-Ring

576601 877039

Coupling

Type

O-Ring CouplingTypes

401525

353264

877040 SAE-B 13 tooth

877044 SAE-BB 15 tooth

877045 SAE-C 14 tooth

877046 SAE-CC 17 tooth

SAE–A, 2–Bolt Cover

Plate 939790

(Fits –031 Suffix Pumps)

*AF Units use Screw 170177

(2 req’d)

**AM Units use Screw 470837

(2 req’d)

Page 7

Typical Cross Section

Control Piston

Control Rod

Valve Block

Port #1

Position outer shaft

seal facing shaft end

Position inner shaft

seal facing bearing

Pump Startup

Make sure the reservoir and circuit are

clean and free of dirt and debris prior

to filling with hydraulic fluid.

Fill the reservoir with filtered oil to a

level sufficient to prevent vortexing at

suction connection to pump inlet. It is

good practice to clean the system by

flushing and filtering using an external

slave pump.

Before starting the pump, fill with fluid

through one of the ports. This is par-

ticularly important if the pump is above

the fluid level of the reservoir.

Note

Parts are shown as installed for right

hand rotation. For left hand rotation,

install control rod and control piston

in valve block port #2. Install bias

rod, bias piston and spring in valve

block port #2.

When initially starting the pump, remove

all trapped air from the system. This can

be accomplished by loosening the pump

outlet fittings or connections before

starting the pump, or by using an air

bleed valve. All inlet connections must

be tight to prevent air leaks.

Once the pump is started, it should

prime within a few seconds. If the pump

does not prime, check to make sure that

there are no air leaks in the inlet line

and connections. Also check to make

sure that trapped air can escape at the

pump outlet.

Valve Block

Port #2

Bias Rod

Bias Piston

Spring

After the pump is primed, tighten the

loose outlet connections, then operate

for five to ten minutes (unloaded) to remove all trapped air from the circuit. If

reservoir has a sight gage, make sure

the fluid is clear—not milky.

Add fluid to the reservoir up to the proper fill level.

Page 8

Model Code

1 2

1

Piston pump, variable

3 4 5876

displacement

2

Maximum geometric

displacement

131 - 131.1 cm

141 -141.6 cm

3

Application style

3

/r (8.0 in3/r)

3

/r (8.64 in3/r)

Blank - Mobile application (rated speed

& 250/280 bar (3600-4000 psi)

pressures)

QI - Quiet industrial application (1500 -

1800 rpm & 250/280 bar

(3600-4000 psi) pressures)

QP - Quiet power unit application (1800

rpm & 140 bar (2000 psi) max.

pressures – R.H. rotation only)

Mounting flange, prime

4

mover end

C - SAE “C” 4–bolt type (SAE

J744-127-4 )

C3 - Optional 4-bolt SAE-C pilot for

vertical pump mounting

5

Shaft rotation, viewed at prime

mover end

R - Right hand, clockwise

L - Left hand, counterclockwise

6

Configuration

Blank - Non-thru-drive (single pump)

A - SAE-A thru-drive pump, standard

(SAE J744-82-2)

B - SAE-B thru-drive pump, optional

(SAE J744-101-2/4)

C - SAE-C thru-drive pump, optional

(SAE J744-127-2/4)

S - Adjustable maximum volume

stop (‘‘S’’ option not available on

thru-drive and torque control pump

models.)

7

Main ports

9 10

11 12 13 14 15 16 17

F - SAE 4-bolt flange ports (standard)

M - SAE 4-bolt pads with metric

mounting bolt threads

8

Shaft-end type, at prime mover end

2 - SAE-C 14 tooth spline

3 - SAE-CC 17 tooth spline

12 - SAE-D 13 tooth spline

13 - SAE-CC straight keyed

16 - SAE-D straight keyed

9

Shaft seal, prime mover end

S - Single, one-way

D - Double, two-way

10

Pump design number

11 - (Subject to change. Installation

dimensions unaltered for design

numbers 10 to 19 inclusive. )

11

Pressure control type

C - Compensator, 140-280 bar

(2000-4000 psi)

CM - Compensator, 35-140 bar

(500-2000 psi)

IC - CETOP 3 interface compensator,

20 bar factory ‘‘differential’’ pressure

setting (QI and QP models only)

12

Factory compensator pressure

setting

Blank - Leave blank for ‘‘IC’’ controls only

7 - 70 bar (1015 psi) normal ‘‘CM7’’

setting (all pump sizes)

23 - 230 bar (3335 psi) normal ‘‘C23’’

setting (63, 81, 106, 141 models)

25 - 250 bar (3625 psi) normal ‘‘C25’’

setting (57, 74, 98, 131 models)

13

Optional pressure control

functions

Blank - Leave blank for basic compensator

controls of IC models.

V - Load sensing, 20 bar (290 psi)

factory ‘‘differential’’ pressure setting

T - Torque limiting control (Used with

sections and .

14

15

VT - Load sensing with torque limiting

VB - Load sensing with internal bleed

down (0.15” dia. orifice)

VBT-Load sensing with internal bleed

down and torque limiting

Torque limiting control pressure

14

setting

Blank - Leave blank if no torque limiting

control is used

4 - Standard minimum 40 bar setting of

‘‘T’’ torque control option

Torque limiting control

15

summation

Blank - Standard torque control

S - Optional torque control with

summation feature

16

Control design number

31 - All control options

Special feature suffix

17

031- Mounting with SAE-A, 2-bolt cover

plate

Printed in U.S.A.

Page 9

Eaton Hydraulics

15151 Highway 5

Eden Prairie, MN 55344

Telephone: 612 937-7254

Fax: 612 937-7130

www.eatonhydraulics.com

46 New Lane, Havant

Hampshire PO9 2NB

England

Telephone: (44) 170-548-6451

Fax: (44) 170-548-7110

Form No. 00-000 Copyright Eaton Corporation, 0000

All rights reserved.

Printed in U.S.A

Loading...

Loading...