Page 1

Vickers

®

Piston Pumps

Overhaul Manual

PVE Variable Pump

12–21 USgpm capacity at 1800 rpm

M-2854-SReleased 8/1/90

Page 2

Table of Contents

Section Page

I. Introduction

A. Purpose of Manual 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. General Information (Related Publications/Model Code) 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II. Description 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A. General 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. Application 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

III. Principles of Operation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A. Piston Pump 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. Compensator (Flat Cut-Off Type - “C”) 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. Compensator (Remote Control Type - “CG”) 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. Compensator (Load Sensing Type - “CV”) 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. Compensator (Load Sensing with Pressure Limiting - “CVP”, “CVPC”, “CVPD”) 10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV. Installation and Operating Instructions 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A. Installation Drawings 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. Mounting and Drive Connections 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. Shaft Rotation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. Piping and Tubing 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. Hydraulic Fluid Recommendations 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F. Overload Protection 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G. Start–up 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V. Service and Maintenance 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A. Service Tools 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. Inspection 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. Adding Fluid to the System 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. Adjustments 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. Lubrication 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F. Replacement Parts 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G. Troubleshooting 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VI.Overhaul 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A. General 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. Disassembly 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. Inspection, Repair and Replacement 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. Assembly of Compensator 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. Removal and Disassembly of Rotating Group 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F. Inspection, Repair and Replacement 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G. Assembly of Housing Parts 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H. Disassembly of Valve Block 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I. Inspection, Repair and Replacement 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

J. Assembly of Valve Block 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

K. Shaft Bearing Preload Adjustment 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

L. Final Assembly of PVE Series Pump 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VII.Test Procedure 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A. Test Conditions 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. Preliminary Check 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C. Preliminary Set–Up 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D. Performance Test 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E. Performance Test of Piston Pump with “C” Compensator Control 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F. Performance Test of PVE 12/19/21 Piston Pump with “CG” Compensator Control 31. . . . . . . . . . . . . . . . . . . . . . . . . .

G. Performance Test of PVE 12/19/21 Piston Pump with “CV”, “CVP”, “CVPC” and “CVPD” Compensator Control 32. . .

H. Load Sensing Control Test 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

Page 3

Section I – Introduction

A. Purpose Of Manual

This manual describes operational characteristics and

overhaul information for the PVE12, 19(*) and the

PVE21(*)–** variable displacement piston pumps. The

information contained herein pertains to the latest design

series as listed in Table 1.

B. General Information

1. Related Publications - Service parts information

and installation dimensions are not contained in this

manual. The parts and installation drawings listed in

Table 1 are available from authorized distributors or sales

engineers.

34561

2

1

Pump, Variable Displacement,

Inline Piston, E-Series

2

Flow Rating

USgpm @ 1800 rpm

3

Shaft Rotation

(Viewed from shaft end)

R – Right hand (clockwise)

L – Left hand (counterclockwise)

4

Noise Level Rating

Blank – Standard Unit

Q – Industrial Quieter

1800 rpm @ 207 bar (3000 psi)

5

Mounting Flange

B – SAE B 2 bolt

6

Input Shaft Type

1 – SAE B Straight keyed

2 – SAE B Splined

7

Port Configuration

E – End ported, SAE O-ring

M – End ported, metric O-ring

(per ISO 6149)

Shaft Seal

8

S – Standard shaft seal

N – No shaft seal

Design

9

10

Control Options

(** = Pressure setting in tens of bars)

C** –

C**VP** –

C**VPC** –

C**VPD** –

Model

Series

PVE12

PVE19

PVE21

Parts

Drawing

M-2853-G

M-2841-S

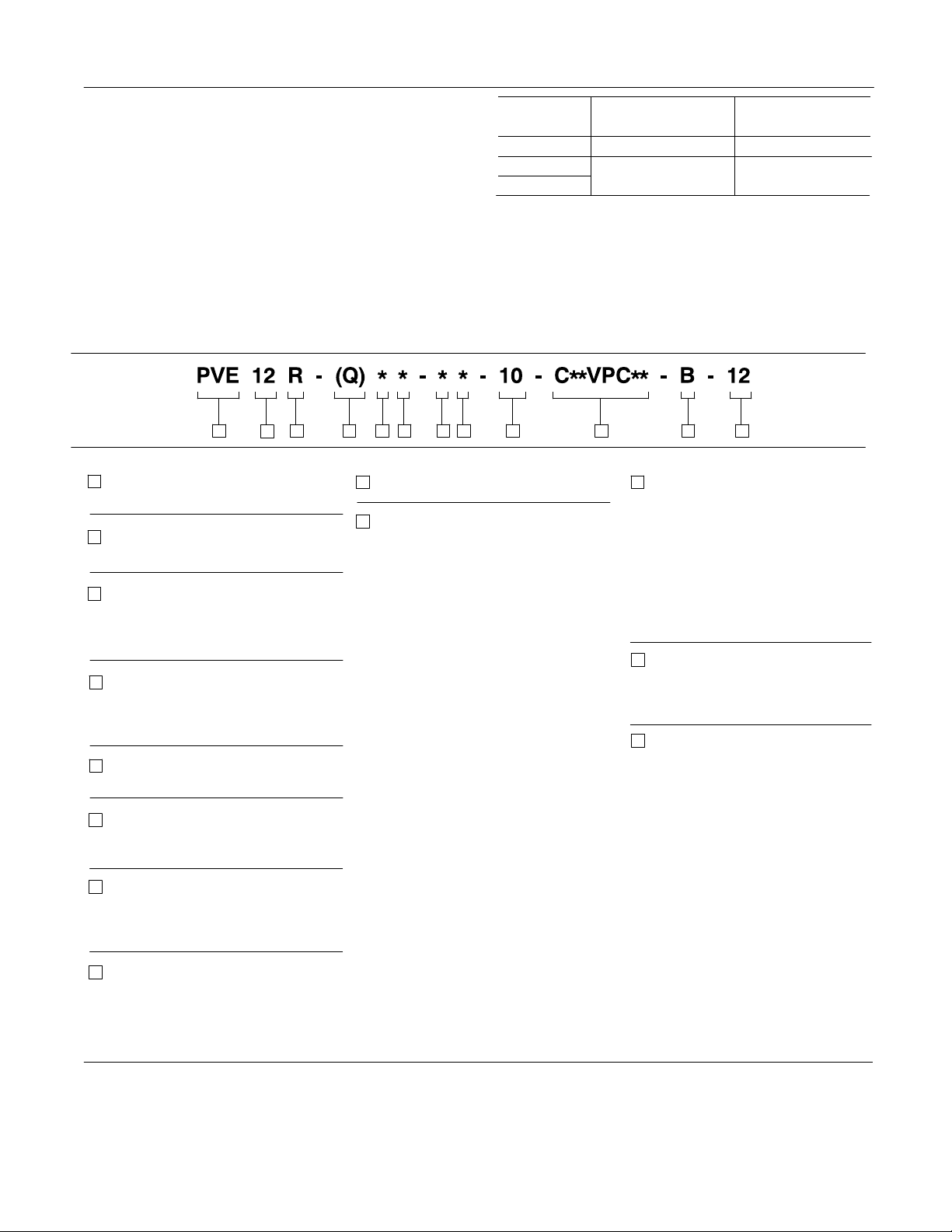

2. Model Codes - Variations within each basic model

series are covered in the model code. Table 2 shows a

complete breakdown of the model codes covering these

units. Service inquiries should always include the complete

model code number as stamped on the mounting flange.

87 9 10 11

10

Control Options (Con’t)

(** = Pressure setting in tens of bars)

CC** -

Pressure compensator

CG**-

Max. setting 207 bar

(3000 psi)

Range 02-21 bar

Pressure & load sensing

Pressure compensating

(see C**)

Load sensing (see CV**)

Pressure and load sensing

Pressure compensating

(see C**)

Load setting 24 bar

(350 psi)

CD CCD -

11

Control Bleed Down

Blank – C, CC, CG, CD, CCD

B – Bleed down orifice (CVP & CVPC)

P – Plug (no orifice) (CVP & CVPC)

12

Control Design

Range 17-31 bar

(251-450 psi)

Pressure & load sensing

Pressure compensating

(see C**)

Load setting 41 bar

(600 psi)

Range 32-45 bar

(451-650 psi)

Same as C** except with

max. adj. stop.

Pressure compensation

with remote control

(see C**)

Electric dual range compensation

Same as CD except with

max. adj. stop

Installation

Drawing

_____

322C

Table 1.

12

Same as C** except with

max. adj. stop.

Pressure compensation with

remote control (see C**)

Electric dual range compensation

Same as CD except with

max. adj. stop

Table 2. Model Code Breakdown

3

Page 4

361

2

4 5

7 8

1

Pump, Variable Displacement,

Inline Piston, E–Series

2

Flow Rating

USgpm @ 1800 rpm

19 – 19 USgpm

21 – 21 USgpm

3

Shaft Rotation

(Viewed from shaft end)

R – Right hand (clockwise)

L – Left hand (counterclockwise)

4

Input Shaft Type

1 – SAE B Straight keyed

2 – SAE B 15 tooth splined

9 – SAE B 13 tooth spline

5

Pump Design

6

Control Options

(** = Pressure setting in tens of bars)

C-10 –

Pressure compensated

(PVE19, 250-3000 psi)

(PVE21, 250-2700 psi)

CG-10 –

Remote control pressure

compensator adjustable

from 350-3000 psi using

and external relief valve.

CV-10 –

CVP-12 –

Load sensing PVE19/21

Load sensing (160 psid)

with pressure compensation

PVE 19/21

CVPC-12 –

Load sensing (350 psid)

with pressure compensation

PVE 19/21

Table 2. Model Code Breakdown (Con’t)

7

Control Design

Special Suffix

8

4

Page 5

Shaft

Shaft

Seal

Housing

Yoke

Compensator

Drive

Shaft

Tapered

Roller

Bearing

Yoke

Bearing

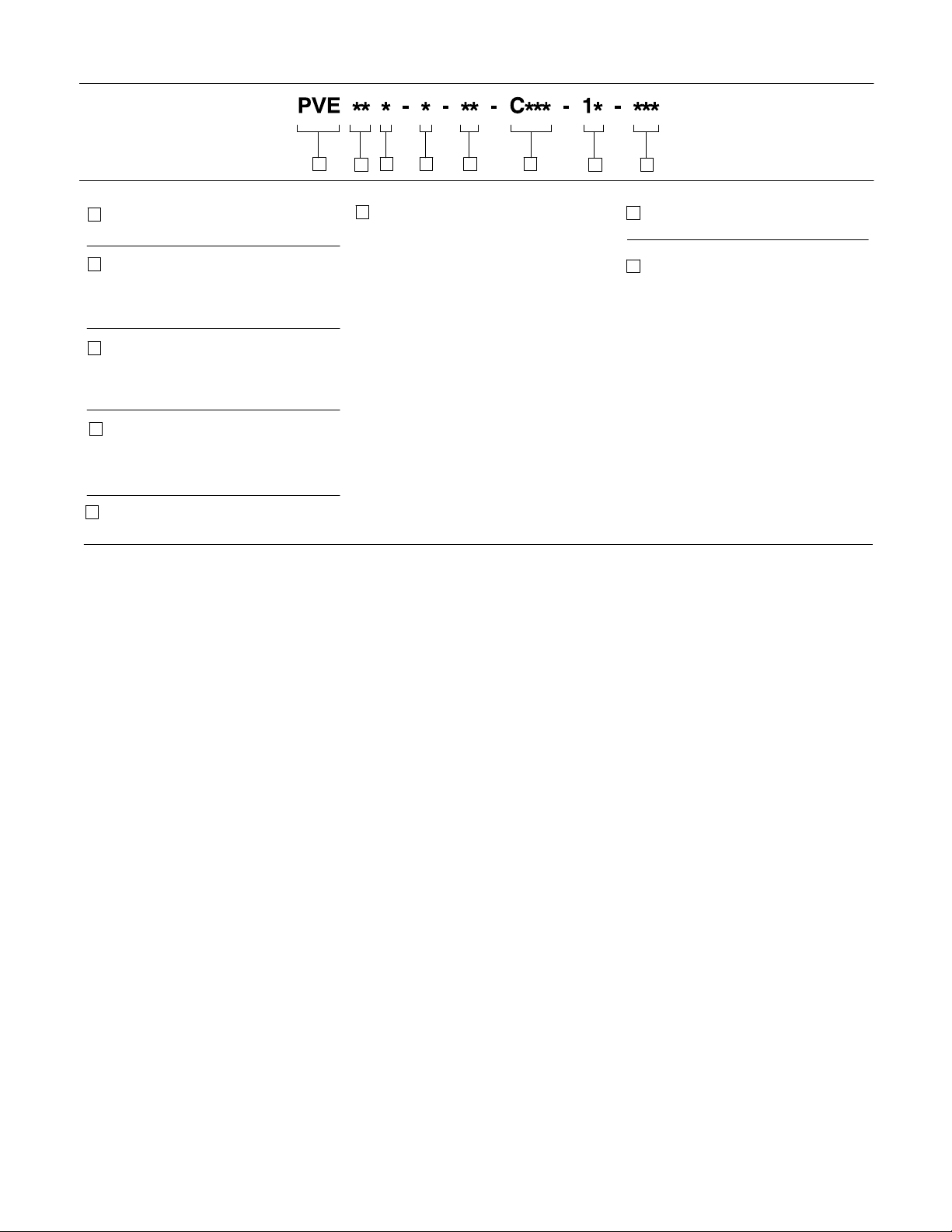

PVE12 Section View

Wafer Plate

Piston

Valve Block

Compensator

Housing

Rotating Group

PVE19 Section View

Figure 1. Sectional Views of the PVE Pumps

5

Page 6

Section II – Description

A. General

Assembly of a typical pump package is shown in Figure 1.

Six types of compensator subassemblies are used with the

PVE series pumps. Refer to Section III for principles of

operation. See Model Code for pressure settings.

1. Compensator (C), (Flat Cut-Off Type): A pump using

this compensator will maintain a constant load pressure for

all values of flow within the capacity of the pump.

2. Compensator (CG), (Remote Control Type): This

compensator is similar to the “C” type compensator except

the compensator is controlled by a remote hydraulic source

such as a relief valve.

3. Compensator (CV), (Load Sensing Type): A load

sensing compensator provides flow at a pressure equal to

that required by the load plus a constant value used as a

pressure drop across a metering valve. The pump will

change its flow with changes in size of the metering valve

orifice. The pump and compensator together provide a

constant flow source for the load, at a pressure established

by the requirements of the load, hence the title “Load

Sensing”.

CAUTION

4. Compensator (CVP), (Load Sensing Pressure

Limiting Type): The CVP control is a combination of the

standard flat cut-off compensator (C) and the load sensing

compensator (CV). The load sensing compensator controls

flow to the load across an external valve orifice. If pressure

build–up exceeds the flat cut-off compensator setting, the flat

cut-off compensator overrides the load sensing compensator

and lowers the flow to prevent excessive pressure build-up

at the pump.

5. Compensator (CVPC), (Load Sensing Pressure

Limiting Type): This compensator is the same as the “CVP”

compensator except the load sensing spring is heavier. The

heavier spring provides a slightly higher pressure differential

(160nP vs. 350nP) across the external valve orifice. See

Figure 5.

6. Compensator (CVPD), (Load Sensing, Pressure

Limiting Type): Same as “CVPC” except with higher

pressures.

B. Application

Pump ratings in USgpm as shown in the model coding are at

1800 rpm. For ratings at other speeds, methods of installation and other application information, contact an authorized

distributor or sales engineer.

A relief valve must be provided in the external circuit

to prevent excessive pressure build up at the pump.

Outlet Wafer Plate

Kidney Slot

Outlet Port

Inlet Port

Intake Kidney

Slot Area

Wafer Plate

Figure 2.

Cylinder

Block Bore

Piston

Shoe Plate

Yoke Face

Drive Shaft

6

Page 7

Section III – Principles of Operation

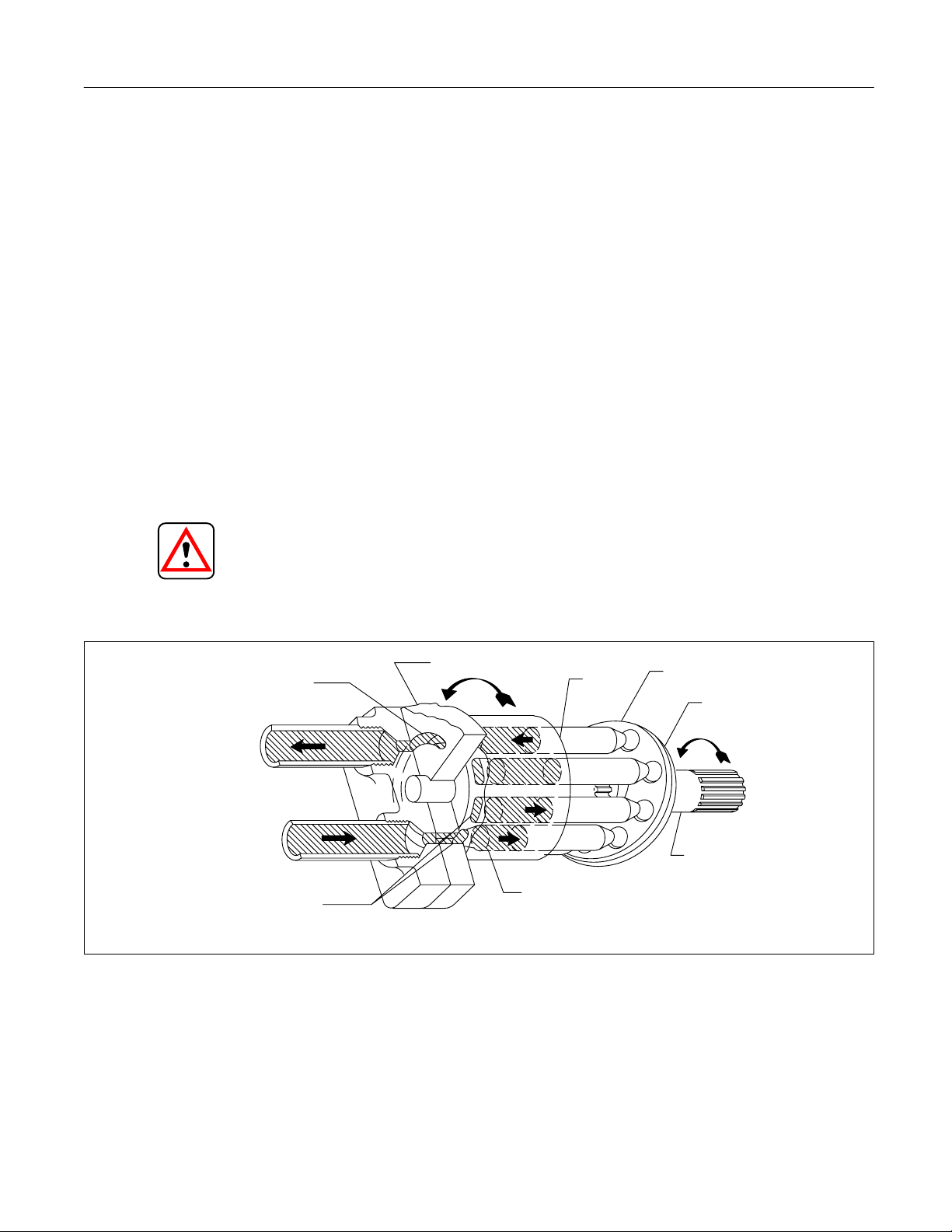

A. Piston Pump

Rotation of the pump drive shaft causes the cylinder block,

shoe plate and pistons to rotate. See Figure 2. The piston

shoes are held against the yoke face by the shoe plate. The

angle of the yoke face imparts a reciprocating motion to

each piston within the cylinder block. Inlet and outlet ports

connect to a kidney slotted wafer plate. As the pistons move

out of the cylinder block, a vacuum is created and fluid is

forced into the void by atmospheric pressure. The fluid

moves with the cylinder block past the intake kidney slot to

the outlet (pressure) kidney slot. The motion of the piston

reverses and fluid is pushed out the cylinder block into the

outlet port.

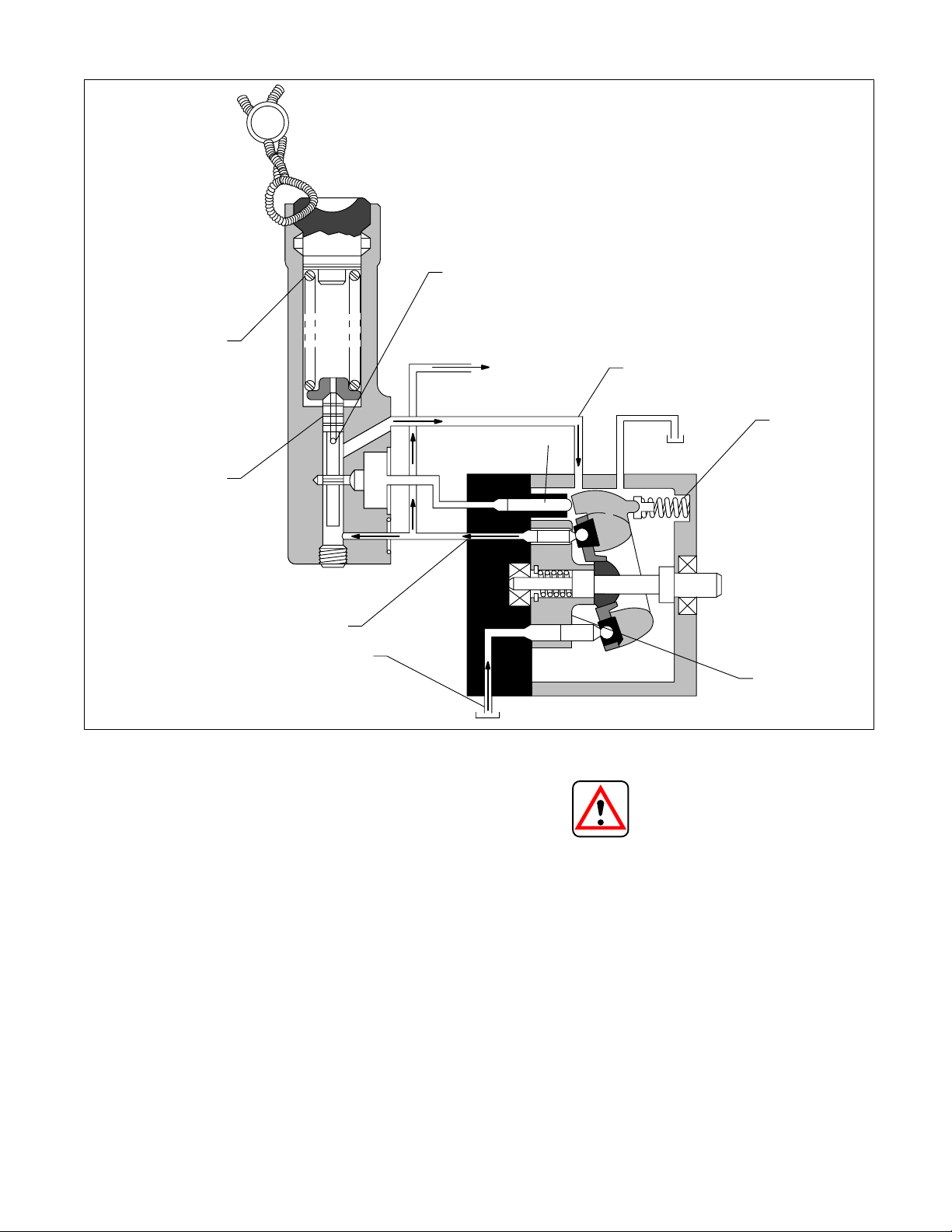

B. Compensator (Flat Cut-Off Type)

A flat cut-off compensated pump will maintain a constant

load pressure for all values of flow within the capacity of the

pump providing the load is sufficient to build up pressure.

A step by step description of the flat cut-off type compensator control follows. Refer to Figure 3 throughout this

discussion.

When a no load condition exists, the pump will deliver

maximum flow at zero pressure. As the actuator load

increases, pressure will rise; however, flow will remain at

maximum until pressure reaches the compensator spring

setting (cracking pressure). As a further increase in load

occurs, system pressure will cause the compensator spool to

move against the compensator spring, metering flow to the

yoke stroking piston. The yoke stroking piston then moves the

yoke to reduce flow. As flow is reduced, system pressure

reduces slightly causing the compensator spool to return to the

null position. At null, flow to the yoke stroking piston stops.

Movement of the yoke will stop and the flow will stabilize at a

reduce value. If the load were to continue to increase, the

pump flow will reduce to zero (0) and a deadhead pressure

condition would exist. The pressure differential needed to

cause the compensator spool to change from maximum flow

(cracking pressure) to zero flow (deadhead pressure) is

approximately 50 to 150 PSI.

Pump outlet flow is proportional to the control range from

cracking pressure to deadhead pressure. (i.e. If cracking

pressure is 2900 PSI (max. flow) and deadhead pressure is

3000 PSI (min. flow), a pressure of 2950 PSI would be equal

to 1/2 maximum flow.)

If the load decreases, pressure will decrease proportionally

and the compensator spring will move the spool down,

opening the yoke stroking piston to case drain. As fluid is

metered from the yoke stroking piston, the yoke spring will

stroke the yoke to increase flow. The increase in flow causes

a proportional increase in system pressure. The increase in

system pressure returns the compensator spool to a null

position and flow from the yoke stroking position will stop;

simultaneously, movement of the yoke will stop. The flow will

stay constant until another change of load occurs.

If the load continues to decrease, pump flow will continue too

increase, holding the outlet at compensator cracking

pressure. When maximum flow is reached (max. stroke), a

maximum flow and a maximum pressure condition exists. A

further decrease in load will lower the outlet pressure until a

final theoretical condition of maximum flow and zero

pressure is obtained.

C. Compensator (Remote Control - “CG”)

This compensator allows the operator to change the

pressure setting through the use of a remote control valve.

The “CG” compensator has the same performance

characteristics as the “C” type compensator.

7

Page 8

Compensator Spring

Compensator Spool

Outlet

Inlet

Cross Hole (Open to

Spring Area)

Pump Load

Yoke Stroking Piston

Drain

Yoke Spring

Rotating Group

Figure 3. Flat Cut-Off Compensator

D. Compensator

(Load Sensing Type - “CV”)

Application

A frequent application of pressure compensator pumps is to

supply sevo valves or mechanically operated metering

valves, whose function is to control flow to a hydraulic

actuator (cylinder or motor).

In such circuits it is often desirable that flow be proportional

only to an external valve spool position. This requires a

constant pressure drop across the external valve. (NOTE:

Flow through a valve varies with pressure drop as well as

with valve spool position.)

Pumps incorporating the load sensing feature have a

constant flow characteristic: Flow is constant regardless of

the load pressure.

CAUTION

A relief valve must be used to prevent outlet pressure from exceeding pump ratings if the load is

excessive.

Minimum Pump Pressure

The minimum outlet pressure developed by the pump (no

load) is a function of the compensator spring force versus

the yoke spring force, whichever is greater. (Please note that

external valve spool position (orifice size), has nothing to do

with the minimum outlet pressure of the pump). The orifice

size controls pump rate of flow only. The minimum outlet

pressure will be constant for all settings of the valve spool

orifice and is considered the pressure drop across the orifice

(nP).

8

Page 9

Actuator

Load

Compensator Spring

Compensator Spool

Outlet

Relief

Valve

Inlet

External Valve

Spool Orifice

(nP-Pressure Drop)

Yoke Stroking Piston

Drain

Yoke Spring

Rotating Group

Figure 4. Load Sensing Compensator (CV).

Circuit Operation At Minimum Pressure

Refer to Figure 4 during the following description. Assume a

no load condition.

The pump load consists of the pressure drop across the

valve spool orifice (nP), plus the pressure developed by the

work being performed at the actuator. (In this case the

actuator is unloaded and only the pressure drop across the

valve spool orifice (nP) will be considered.)

Flow is restricted through the valve spool orifice and

develops a pressure at the outlet of the pump. This pressure

is applied to the lower end of the compensator spool. Initially,

the compensator spring is holding the spool in the down

position and the yoke is at maximum delivery position. When

the pump is started, the increasing flow increases pressure

at the lower end of the compensator spool and the

compensator spool opens pressure to the yoke stroking

piston. The yoke then strokes to a lower flow, lowering the

pressure drop across the external valve orifice. When

pressure reaches nP, the compensator spool will null. At this

time, the stroking piston will remain stable until the external

valve spool orifice is changed. (See Figure 4.)

External Valve Spool Orifice Size Reduced

If the external valve spool orifice is reduced in size, pressure

at the pump outlet will rise proportionally causing the

compensator spool to move against the compensator spring.

When the compensator spool moves far enough to open the

yoke stroking piston to pump outlet pressure, the yoke

stroking piston will move the yoke to a lower flow setting.

The compensator senses pressure at the downstream side

of the external valve spool orifice and compares this

pressure to the pump outlet pressure. The compensator then

adjusts the yoke to a flow which holds a constant pressure

drop (nP) across the external valve spool orifice.

The pressure developed at the pump outlet is a summation

of the pressure drop across the external valve spool orifice

and the actuator load pressure. As the actuator load

pressure increases, the increase is reflected directly back to

the pump outlet. Since the compensator monitors the

difference between pump outlet pressure and actuator load

pressure, and this difference (nP) does not change with load

variations, flow from the pump will stay constant.

9

Page 10

External Valve Spool Orifice Size Increased

If the external valve spool orifice size is increased, pump

outlet pressure will decrease, lowering force against the

compensator spool. (See Figure 4.) The compensator spring

causes the spool to move, opening the yoke stroking piston

to case drain. As fluid is metered from the yoke stroking

piston, the yoke spring force strokes the yoke to a higher

flow. The increase in flow through the external valve spool

orifice establishes once again the constant pressure drop

(nP). With differential pressure (nP) across the external

valve orifice, the compensator spool nulls. Flow from the

yoke stroking piston stops, and the pump flow rate stabilizes

at a higher value.

Operation of the load sensing compensator is such that as

the load pressure varies, the pump outlet pressure will follow

the variations, holding a constant pressure drop (nP) across

the external valve spool orifice, and a constant flow through

the external valve and actuator. Pump flow will change only

with changes in external valve spool orifice size.

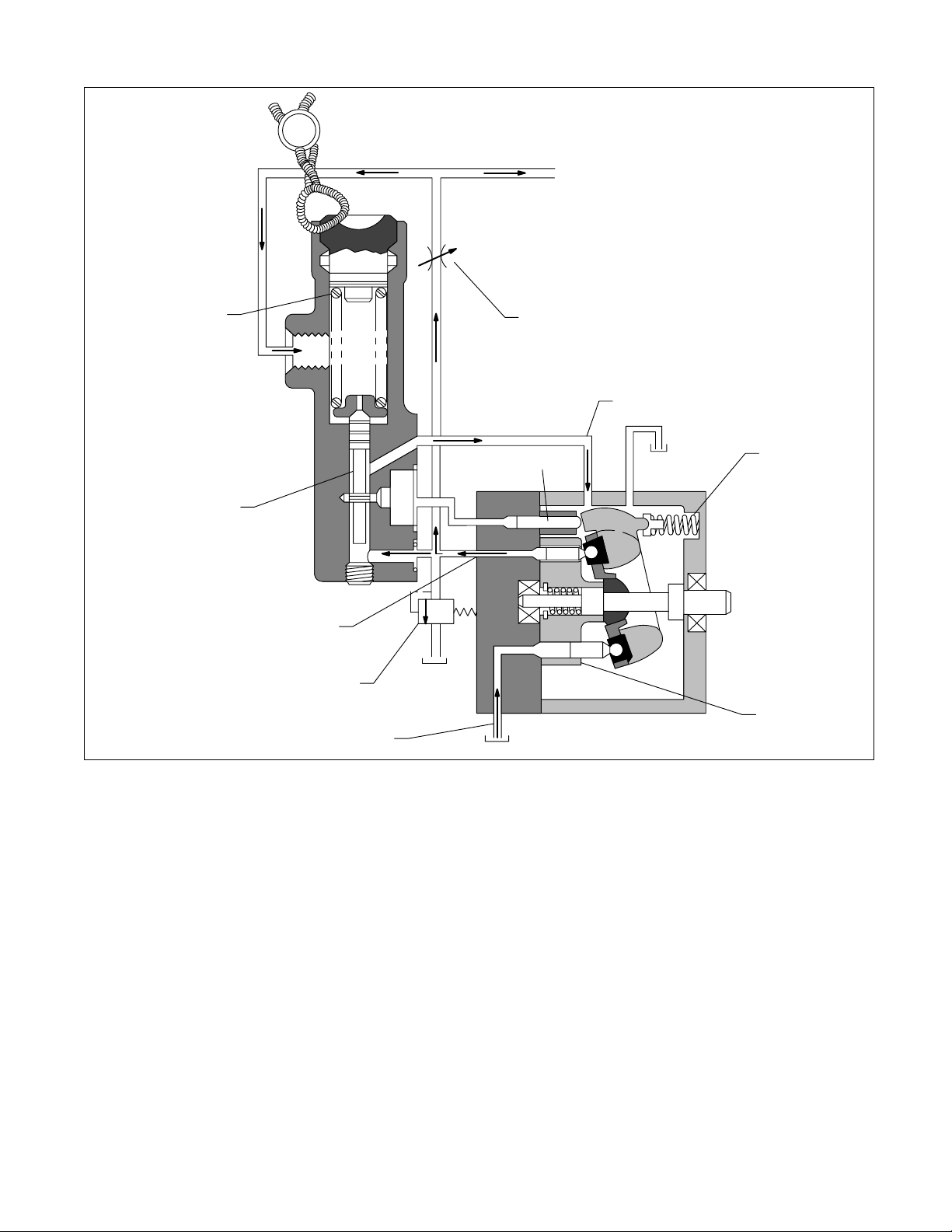

E. Compensator (Load Sensing with Pressure

Limiting “CVP”, “CVPC”, “CVPD”)

As expected from the above title, these units are a combination of the flat cut-off and load sensing compensators.

The load sensing portion functions at pressures below the

flat cut-off compensator setting and provides a constant flow

characteristic. If pressure exceeds the flat cut-off compensator setting, the yoke will stroke to zero flow at maximum

pressure lowering the horsepower requirements for holding

circuits and protecting the pump. Refer to Figure 5

throughout the following circuit explanation.

Assume an actuator load that is increasing gradually. Also,

assume the pump outlet pressure is lower than the flat

cut-off compensator cracking pressure. As actuator load

pressure increases, the load sensing compensator spool

senses the difference between pump outlet pressure and

actuator load pressure. As long as the difference between

the pump outlet pressure and the actuator load pressure

(nP) is constant, flow to the load will stay constant. As

pressure rises across the load, leakage will increase in the

pump and load. The load sensing portion of the compensator

adjusts pump outlet flow to compensate for leakage while

providing a constant flow through the valve spool orifice.

The pump outlet pressure continues to increase until the flat

cut-off compensator spool reaches cracking pressure. The

flat cut-off compensator spool then meters flow to the yoke

stroking piston. The yoke stroking piston starts moving the

yoke to reduce flow while holding the outlet pressure at

compensator cracking pressure. This action continues until

the pump is fully compensated (zero flow and maximum

pressure).

Standby Operation Feature

Standby defined: When the external valve spool is shifted to

zero flow, the circuit is placed in standby.

The small fixed orifice located in the compensator body

provides a decompression feature for the load circuit during

standby operation. The decompression feature allows the

pump to stroke to zero flow and minimum pressure (nP), if

the load is blocked and the external valve spool orifice is

closed. (Refer to Figure 5.)

The circuit functions as follows:

Assume the pump is at zero flow with maximum pressure to

the load. The flat cut-off compensator spool will be in the up

position (compressing the spring) and the load sensing spool

will be in the down position due to actuator load pressure

plus the spring force. If the external valve spool orifice is

closed at this time, fluid under pressure will be trapped in the

load circuit and will hold the load sensing spool in the down

position. This will keep the pump outlet pressure at flat

cut–off compensator cracking pressure (a power loss since

no work is being performed at this time). To prevent this

condition from continuing, the small orifice meters the fluid

trapped in the load back through the flat cut-off compensator

spool to case drain. The actuator load pressure will decrease

gradually causing the load sensing spool to open pressure to

the yoke stroking piston, bypassing the flat cut-off compensator. As the actuator load pressure reduces, the pump

outlet pressure will reduce until minimum pump pressure is

obtained. When the minimum flow/minimum pressure

condition occurs, the pump is considered to be in standby.

During standby, the CVP(C) control reduces the input power

well below that of a standard “C” type compensator. This

provides an increase in system efficiency and reduces the

cost of operation.

10

Page 11

Compensator

Spring

Set Screw

Compensator

Spool

Load Sensing

Spool

External Valve

Spool Orifice

Yoke Stroking Piston

Outlet

Inlet

Figure 5. Load Sensing Pressure Limiting Compensator (CVP, CVPC, CVPD)

Actuator

Load

Drain

Yoke Spring

Rotating Group

11

Page 12

Section IV – Installation and Operating Instructions

A. Installation Drawings

The installation drawing listed in Table 2 will show installation

dimensions and port locations.

B. Mounting and Drive Connections

CAUTION

Pump shafts are designed to be installed in couplings

with a slip fit. Pounding can injure the bearings. Shaft

tolerances are shown on the installation drawing.

(See Table 1.)

1. Direct Mounting - A pilot on the pump mounting

flange (Figure 6) assures correct mounting and shaft alignment. Make sure the pilot is firmly seated in the accessory

pad of the power source. Care should be exercised in tightening the mounting screw to prevent misalignment.

2. Indirect drive is not recommended for these pumps

without engineering approval.

D. Piping and Tubing

1. All pipes and tubing must be thoroughly cleaned before

installation. Recommended methods of cleaning are sand

blasting, wire brushing, and pickling.

NOTE

For instructions on pickling, refer to instructions

sheet 1221-S.

2. To minimize flow resistance and the possibility of

leakage, only as many fittings and connections as are

necessary for proper installation should be used.

3. The number of bends in tubing should be kept to a

minimum to prevent excessive turbulence and friction of oil

flow. Tubing must not be bent too sharply. The recommended

radius for bends is three times the inside diameter of the tube.

E. Hydraulic Fluid Recommendations

General Data

Oil in a hydraulic system performs the dual function of

lubrication and transmission of power. It constitutes a vital

factor in a hydraulic system, and careful selection of it should

be made with the assistance of a reputable supplier. Proper

selection of oil assures satisfactory life and operation of

system components with particular emphasis on hydraulic

pumps. Any oil selected for use with pumps is acceptable for

use with valves or motors.

Data sheets for oil selection are available from any

authorized distributor or sales engineer.

Oil Recommendations noted in the data sheet are based on

our experience in industry as a leading hydraulic component

manufacturer.

Where special considerations indicate a need to depart from

the recommended oils or operating conditions, contact an

authorized distributor or sales engineer.

Figure 6. Pump Pilot Flange.

C. Shaft Rotation

Rotation is determined as viewed from the shaft end of the

pump. A pump made for left-hand rotation is identified by an

”L” and right-hand by an ”R” in the model code. (See Table

2.) An arrow stamped on the mounting flange indicates the

correct rotation.

CAUTION

NEVER drive a pump in the wrong direction of rotation.

Seizure may result causing expensive repairs.

Cleanliness

Thorough precautions should always be observed to insure

the hydraulic system is clean:

1. Clean (flush) entire new system to remove paint,

metal chips, welding shot etc.

2. Filter each change of oil to prevent introduction of

contaminants into the system.

3. Provide continuous oil filtration to remove sludge and

products of wear and corrosion generated during the life of

the system.

4. Provide continuous protection of system from entry of

airborne contamination, by sealing the system and/or by

proper filtration of the air.

5. During usage, proper oil filling and servicing of oil filters,

breathers, reservoirs, etc. cannot be over emphasized.

6. Thorough precautions should be taken by proper system

and reservoir design to insure that aeration of the oil wIll be kept

to a minimum.

12

Page 13

Sound Level

Noise is only indirectly affected by the fluid selection, but the

condition of the fluid is of paramount importance in obtaining

optimum reduction of system sound levels.

Some of the major factors affecting the fluid conditions that

cause the loudest noises in a hydraulic system are:

1. Very high viscosities at start-up temperatures can

cause pump noises due to cavitation.

2. Running with a moderately high viscosity fluid will

impede the release of entrained air. The fluid will not be

completely purged of such air in the time it remains in the

reservoir before recycling through the system.

3. Aerated fluid can be caused by ingestion of air

through the pipe joints of inlet lines, high velocity discharge

lines, cylinder rod packings, or by fluid discharging above the

fluid level in the reservoir. Air in the fluid causes a noise

similar to cavitation.

H. Start-Up

Before starting pump the case MUST be filled with clean

hydraulic fluid.

With a minimum drive speed of 650 rpm, a pump should

prime almost immediately if provision is made to initially

purge the air from the system.

Failure to prime within a reasonable length of time may result

in damage due to lack of lubrication. Inlet lines must be tight

and free from air leaks. However, it may be necessary to crack

a fitting on the outlet side of the pump to purge trapped air.

Load Sensing Control Port Location for L.H. Rotation

5.18

2.94

F. Overload Protection

Relief valves limit pressure in the system to a prescribed

maximum and protect components from excessive pressure.

The setting of the relief valve depends on the work

requirements of the system components.

2.19

Compensator Position

for R.H. Rotation

Figure 7. C/CV/CVP Compensator Positions for Right and

Left Hand Shaft Rotation

Compensator Position

for L.H. Rotation

13

Page 14

Section V – Service and Maintenance

A. Service Tools

The following standard tools for overhauling the piston pump

are shown in Figure 8.

Standard Tools and Equipment:

1. Torque wrench with short extension and sockets

2. 1” micrometer

3. 1” depth micrometer

4. External Truarc pliers

5. Internal Truarc pliers

In addition to the above tools, an arbor press is required to

service bearings, etc. Maintenance of this unit is intricate

and should not be attempted without the proper tools.

Special Tools:

Special tools are shown in Figures 9, 10, 11 and 12.

B. Inspection

Periodic inspection of the fluid condition and tube or piping

connections can save time consuming breakdowns and

unnecessary parts replacement. The following should be

checked regularly:

4. Air bubbles in the reservoir can ruin the pump and

other components. If bubbles are seen, locate the source of

the air and seal the leak. (See Table 3).

5. A pump which is running excessively hot or noisy is a

potential failure. Should a pump become noisy or

overheated,the machine should be shut down immediately

and the cause of improper operation corrected.

C. Adding Fluid to the System

When hydraulic fluid is added to replenish the system, it

should always be poured through a 10 micron (absolute) or

better filter.

It is important that the fluid be clean and free of any

substance which could cause improper operation or wear of

the pump or other hydraulic units. Therefore, the use of cloth

to strain the fluid should be avoided to prevent lint from

getting into the system.

D. Adjustments

No periodic adjustments are required, other than to maintain

proper shaft alignment with the driving medium.

E. Lubrication

1. All hydraulic connections must be kept tight. A loose

connection in a pressure line will permit the fluid to leak out.

If the fluid level becomes so low as to uncover the inlet pipe

opening in the reservoir, extensive damage to the pump can

result. In suction or return lines, loose connections permit air

to be drawn into the system resulting in noisy and/or erratic

operation.

2. Clean fluid is the best insurance for long service life.

Therefore, the reservoir should be checked periodically for dirt

or other contaminants. If the fluid becomes contaminated the

system should be drained and the reservoir cleaned before

new fluid is added.

3. Filter elements also should be checked and replaced

periodically. A clogged filter element results in a higher pressure drop. This can force particles through the filter which

would ordinarily be trapped or can cause the by-pass to

open, resulting in a partial or complete loss of filtration.

Internal lubrication is provided by the fluid in the system.

Lubrication of the shaft couplings should be as specified by

their manufacturers. Coat shaft splines with a dry lubricant

(Molycoat or equivalent) to prevent wear.

F. Replacement Parts

Reliable operation throughout the specified operating range

is assured only if genuine manufacturer’s parts are used.

Sophisticated design processes and materials are used in

the manufacture of these parts. Substitutions may result in

early failure. Part numbers are shown in the parts service

drawings listed in Table 2.

14

Page 15

1

1.232

“A”

6

1.500

.005.005

Use for “A”

Intermediate shaft bearing installation

3

5

4

2

Figure 8. Standard Tools.

0.1875

thread 1/2” -13 thru

Drive shaft bearing installation

Drive shaft bearing removal

1 1/2” heavy wall tubing

Figure 9. Special Shaft Bearing Removal

and Installation Tools.

4”

6”

9”

1/4” bolt hole

loose fit.

“A”

“B”

1/4”

0.120

1/2”

2”

Bearing Race Puller

Description A B C

Valve Block 1.675 1.300 1.250

Housing 2.125 1.625 1.500

Use a 5” long 1/2” -13 hex head screw with this tool.

Figure 10. Bearing Race Removal Tools.

Figure 10a. Bearing Race Removal Tools.

“C”

15

Page 16

“C”“B”

“A”

Figure 11. Special Bearing Race Installation Tools.

6.50

1.500

Heavy wall tubing

0.250

.375

.375

1.440

.005

Nominal

Pipe

Size

1 1/2” 4” 1.625 1.900

2” 4” 2.125 2.375

Schedule 80 (extra heavy)

ABC

1.439

.005

Press ring on end of tubing.

Figure 12. Shaft Seal Driver.

F. Replacement Parts

Reliable operation throughout the specified operating range

is assured only if genuine manufacturer’s parts are used.

Sophisticated design processes and materials are used in

the manufacture of these parts. Substitutions may result in

early failure. Part numbers are shown in the parts service

drawings listed in Table 2.

2.500

0.125

Aluminum ring

16

Page 17

G. Troubleshooting

Table 3 lists the common difficulties experienced with piston

pumps and hydraulic systems. It also indicates probable

causes and remedies for each of the troubles listed.

TROUBLE PROBABLE CAUSE REMEDY

Excessive pump noise. Low oil level in the reservoir

Fill reservoir to proper level with the

recommended transmission fluid. DO NOT

over fill transmission or damage may result.

Air in the system

V acuum condition

Oil too thick

Cold weather

Pump overheating Internal leakage

Heat exchanger not functioning

Fluid level low

System not developing pressure Relief valve open

Compensator misadjusted

Open reservoir cap and operate hydraulic

system until purged.

“Bleed” hydraulic lines at highest point

downstream of auxiliary pump and while

system is under pressure.

Check inlet (suction) lines and fittings for air

leaks.

Check auxiliary pump function.

Be certain correct type of oil is used for

refilling or adding to the system.

Run hydraulic system until unit is warm to

the touch and noise disappears.

If established that excessive internal

leakage is evident, return vehicle to

maintenance shop for evaluation and repair.

Locate trouble and repair or replace.

Add oil to operating level.

Replace one or both. Do not attempt to

repair cartridges, they are factory

assembled and preset.

Loss of fluid internally (slippage)

Loss of fluid Ruptured hydraulic lines

Loose fittings

Leaking gaskets or seals in pump or circuit

Miscellaneous Sheared shaft key

Disconnected or broken drive mechanisms

Table 3. Troubleshooting Chart

Return vehicle to maintenance shop for

repair of hydraulic system.

Check all external connections, tubing and

hoses. Tighten connections, replace

ruptured tube or hose.

Observe mating sections of hydrostatic

transmission for leaks. Replace seals or

gaskets if possible.

Replace seals or gaskets if possible.

Locate and repair.

17

Page 18

Section VI – Overhaul

A. General

CAUTION

Before breaking a circuit connection, make certain

that power is off and system pressure has been

released. Lower all vertical cylinders, discharge

accumulators, and block any load whose movement

could generate pressure.

After removing the pump from the system and before

disassembly, cap or plug all ports and disconnected

hydraulic lines. Clean the outside of the unit thoroughly

to prevent entry of dirt into the system.

CAUTION

Absolute cleanliness is essential when working on a

hydraulic system. Always work in a clean area. The

presence of dirt and foreign materials in the system

can result in serious damage or inadequate operation.

Periodic maintenance of the pump will generally not require

disassembly to the extent described here. However, the

sequence can also be used as a guide for partial

disassembly. In general, disassembly is accomplished in the

item number sequence shown in Figure 13. Special

procedures are included in the following steps.

NOTE

Discard and replace all O-Rings, gaskets, and shaft

seals removed during disassembly.

B. Disassembly

Removal and Disassembly of the Compensator S/A

a. Remove four screws (1) that hold the compensator

S/A to valve block (26) and pull the compensator away from

the valve block.

b. Remove compensator gasket (2) and O-Ring (3)

from body (11) of compensator S/A.

c. Remove lockwire (4), plug (5) and O-Ring (7)

(6 and 7 on the CV compensator).

d. Remove spring (8), seat (9), and spool (10) from

the compensator body (11) and set aside for inspection.

e. Do not remove plug(s) (24) unless it is necessary

for inspection of the bore.

NOTE

The following steps concern only the CVP and

CVPC compensator S/A.

f. Unscrew plug (12) and remove parts (13)

through (18).

g. Remove plug (19) to gain access to orifice plug

(20). Remove orifice plug (20). Do not remove check valve

S/A (21) from body (11). Item (20) may or may not be an orifice. If the circuit has a bleed down, orifice (20) may be a plug.

h. Remove plug (22) and O-Ring (23).

i. Remove plug(s) (24) only if necessary to inspect

the spool bore.

NOTE

All parts must be thoroughly cleaned and kept clean

during inspection and assembly. The close tolerance of

the parts makes this requirement very important. Clean

all removed parts using a commercial solvent that is

compatible with the system fluid. Compressed air may

be used in cleaning, but it must be filtered to remove

water and contamination. Clean compressed air is

particularly useful in cleaning the spool, compensator

body, and valve block passages.

C. Inspection Repair and Replacement

NOTE

Replace all parts that do not meet the following

specifications.

1. Inspect all components for excessive wear, erosion,

and/or seizure.

2. Inspect plugs (5), (12), (19), (20), (22) and (24) for

damaged threads, burrs, etc. Make sure orifice hole is open

in plug (20). Replace if defective.

18

Page 19

23

43

71

41

70

39

38

36

28

32

64

65

66

69

74

31

68

67

25

26

29

42

44

49

50

5251

5453

Refer to Service Drawings

for assembly instructions

and torque values.

Item Description Qty

70 O-ring 1

71 Retaining Ring 1

25 Screw 5

67 Plug 1

68 O-ring 1

69 Plug 1

74 O-ring 1

29 Pin 2

64 Seat 1

65 Valve 1

66 Spring 1

31 Pin 2

32 Bearing 1

26 Valve Block 1

28 Valve Plate 1

30 Gasket 1

37

34

40

60

30

55

27

45

54

55

Item Description Qty

27 Housing 1

73 Piston Rod 1

72 Piston 1

43 Piston & Shoe S/A 9

42 Shoe Plate 1

41 Shperical Washer 1

40 Pin Retainer 1

39 Pin 3

35 Retaining Ring 1

36 Spring Washer 1

37 Spring 1

38 Spring Washer 1

34 Cylinder Block 1

49 Screw 8

50 Cover 2

35

59

53

34

58

52

35

72

57

33

36

27

51 50

49

Item Description Qty

51 Shim 2

52 O-ring 2

53 Spacer 2

54 Bearing Race 2

55 Bearing 2

56 Yoke 1

57 Roll Pin 1

58 Seat 1

59 Seat 1

60 Spring 1

44 Retaining Ring 1

48 Shaft 1

47 Retaining Ring 1

61 Bearing 1

47 Retaining Ring 1

45 Shaft Seal 1

Figure 13. PVE19/21 Exploded View

19

Page 20

PVE 19/21

Figure &

Index

No.

1

Y

2

Y

3

4

5

Y

6

Y

7

8

9

10

11

12

Y

13

14

15

16

17

18

19

20

21

22

Y

23

24

25

26

27

28

29

Y

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

Description

Screw

Gasket

O-Ring

Lockwire and Seal

Adjusting Plug

Back-Up Ring

O-Ring

Spring (pressure limiter)

Seat

Spool (pressure limiter)

Body (compensator)

Plug

O-Ring

Adjusting Screw

Seat

Spring (load sensing)

Seat

Spool (load sensing)

Plug

Orifice Plug

Check Valve S/A

Plug

O-Ring

Plug

Screw

Valve Block

Housing

Wafer Plate

Pin

Gasket

Roll Pin

Bearing

Bearing Spacer Kit

Cylinder Block

Retaining Ring

Washer (notched)

Spring

Washer (pin)

Pin

Pin Retainer

Spherical Washer

Shoe Plate

Piston and Shoe Subassembly

Retaining Ring

Shaft Seal

Units

per

Assembly

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

6

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Figure

& Index

No.

46

47

48

49

50

51

Y

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

Y

68

69

Y

70

71

72

73

Description

Shaft Key

Retaining Ring

Shaft

Screw

Pintle Cover

Shims (kit)

O-Ring

Bearing Spacer

Bearing Race

Bearing

Yoke

Roll Pin

Seat

Seat

Spring

Bearing (shaft)

Bearing Race

Bearing Race

Seat (check valve)

Check Valve

Spring (check valve)

Plug

O-Ring

Plug

O-Ring

Snap Ring

Piston

Piston Rod

Units

per

Assembly

1

1

1

4

2

1

2

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Y

Indicated parts included in seal kit. Refer

to parts drawing tabulated in Figure 2 for

seal kit number and parts information.

NOTE

20

Page 21

10

9

58

1

56

57

24

3

2

59

60

8

7

6

5

4

72

27

30

55

54

53

52

62

61

51

50

49

46

48

47

5049

51

52

53

54

55

25

45

44

Figure 13. PVE19/21 Exploded View

21

Page 22

24

23

22

1

73

13

8

68

7

5

4

12

71 70

67

10

3

2

20

11

18

17

16

63

21

19

9

15

14

69

43

42

41

40

39

34

38

37

36

35

33

28

32

64

65

26

29

31

66

22

Page 23

3. Inspect spring (8) and (16) for wear and parallelism.

Spring ends must be parallel. Replace if spring is warped or

wear is evident.

4. Inspect seat (9) for wear in the area of spool contact.

5. Inspect spool (10) for excessive wear, galling,

scratches, etc. If scratches exist across the spool land,

replace the spool and inspect the body bore. Rotate the spool

while moving in and out of the bore to check the binding.

Binding cannot be tolerated. If binding is evident, use an India

stone to break the sharp edges of the balancing grooves. Use

500 grit paper lightly on the outer surface of the spool. Clean in

solvent and lubricate, then try the bind test again. If bonding

persists, replace the spool and/or body .

6. Inspect the screws for damaged threads. Replace all

damaged threads. Replace all damaged screws.

NOTE

The following step pertains to the CVP or CVPC

compensator S/A.

7. Inspect the load sensing section of the CVP compensator as follows:

a. Inspect the load sensing section of the CVP com-

pensator if wear is evident. Clean up burrs with an India stone.

b. If wear is evident, replace the part. Note: After

assembly the compensator must be readjusted to the correct

pressure. Refer to the test procedure Section VII for instructions on compensator adjustment.

c. Discard adjusting screw (14). Check seat (17) and

spool (18) for wear. Refer to step B.5 for procedure when

checking the pressure limiting spool.

d. Inspect body S/A (11) bores for scratches. Make

sure the orifice plug (20) opening is clear.

d. Install O-Ring (13) over plug (12) and thread plug

(12) into compensator body (11).

2. Install plug (24) into the “C” and “CV” compensator

bodies. Plugs were installed into the “CVP” compensator

body during the preceding step.

3. Install parts (10) through (3) into compensator body

(11). Make certain the spool (10) does not bind within the

bore. Refer to procedure established in step B.5 for further

information. Lockwire and seal (4) will be installed during test

procedure section VII.

4. Install gasket (2) in place in the face of compensator

body (11). Cover the compensator body with clean Kraft paper and set aside for final assembly of the pump.

NOTE

Readjustment of the pressure limiter and load

sensing compensators is required.

E. Removal and Disassembly of

Rotating Group

1. Remove the six screws (25) which hold pump housing

(27) to valve block (26).

2. Pull valve block (26) away from housing (27) then

discard gasket (30).

3. Remove wafer plate (28) and pins (29) from the valve

block set aside for inspection.

4. Remove bearing (32) and bearing spacer (33 on PVE

19/21 models) from the end of drive shaft (48).

5. Slide the rotating group from the pump housing. (Hold

the shoe plate with both hands during removal to prevent the

group from separating.)

D. Assembly of Compensator

Replace the gaskets and O-Rings removed from the unit

with those supplied in the seal kit. DO NOT use grease to

hold the seals in place. Use a viscosity improver (STP or

equivalent). Flood all parts with system fluid to provide initial

lubrication and prevent seizure. Assembly of the parts will be

in the reverse numerical sequence. Special procedures are

included in the following steps.

NOTE

The following step refers to the CVP or CVPC

compensator only.

1. Install parts (24) through (22) into body (11).

a. Install parts (20), (19), and spool (18). Make certain

the spool does not bind or hang up in the body bore.

b. Assemble parts (17) through (15) together. Insert

the assembled parts (seat first) into compensator body (1 1).

Assemble with spool bores in vertical position to prevent seat

from falling into cross port. Visually observe proper assembly

through load sensing port. The seat must rest against compensator spool (18) at completion of assembly .

c. Thread adj. screw (14) into body (11) bore until top

of adj. screw is .065 below body (11) surface.

NOTE

The rotating group consists of a cylinder block S/A

(34), nine piston and shoe subassemblies (43), a shoe

plate (42), a spherical washer (41), three pins (39), and

a pin retainer (40).

CAUTION

The spring located within the cylinder block S/A is

under a high tension and can cause bodily harm if the

retaining ring is removed. See Figure 14 for

disassembly instructions.

6. Separate the rotating group components and set

aside for inspection. Use care when handling these close

tolerance parts to prevent burrs from forming.

23

Page 24

Figure 14. Cylinder block subassembly disassembly tool.

(Tighten nut, remove snap ring, loosen nut to relieve

spring tension).

Figure 14a. Cylinder Block Subassembly parts.

F. Inspection Repair and

Replacement

1. Check bearing (32) for scoring or brinelling of the rollers

(PVE 19/21).

2. Check bearing spacer (33) for burrs (PVE 19/21).

3. Inspect cylinder block S/A face (34) for wear,

scratches and/or erosion between cylinders. Check the

spring, washers and retaining ring located within the cylinder

block S/A.

4. Check each cylinder block bore for excessive wear.

Use the piston and shoe subassemblies (43) for this purpose.

The piston should be a very close fit and slide easily in and

out of the bore. No bind can be tolerated. If binding is evident,

clean the cylinder block and piston, lubricate with clean hydraulic fluid and try again. Even minor contamination of the

fluid could cause the piston to freeze up in the cylinder bore.

5. Inspect each piston and shoe subassembly (43) for a

maximum end play of 0.005 inch between the piston and shoe.

6. The face thickness dimension of each shoe must be

within 0.001 inch of each other.

7. Inspect shoe plate (42) for excessive wear and

cracking in the area of spherical washer (41). If heavy wear or

cracks are found, replace the shoe plate and spherical washer

at the same time.

8. Check spherical washer (41) for burrs, wear, and

possible scratches due to pin breakage. Replace if wear is

excessive.

9. Inspect pins (39) for equal length, excessive wear and

possible bending. Replace all pins simultaneously if one is

defective.

10. The pin retainer (40) may develop burrs. Remove all

burrs with an India stone.

11. Inspect the face of the wafer plate (28) for excessive

wear, scratches, and possible fracture. If the wafer plate is

fractured, make sure the new plate rests flat against the valve

block at assembly and that wafer plate pin (29) does not extend

too far and hold the wafer plate away from the valve block.

NOTE

Inspect the yoke face and shaft bearing as follows: If

either are defective, perform step F.14 and remove

the yoke from the housing. If the drive shaft is

defective, follow procedure shown in step F.17 to

remove the drive shaft from the front bearing. If the

drive shaft, shaft bearing, housing or valve block are

replaced, a shaft bearing preload adjustment must

be performed. See Section VI.K.

12. Inspect pump drive shaft (48) for wear, chipped

splines and burrs. Remove burrs with an India stone.

13. Inspect shaft bearing (61) for brinelling, pitting of the

rollers, and roughness when turned in race (62) located in the

housing. If the bearing is defective, both the bearing and the

race must be replaced. If the bearing shows no evidence of

wear, d o not remove the bearing race from the housing or the

bearing from the shaft. If the bearing requires removal,

perform the following steps 14 through 18.

14. Inspect yoke (56) face for wear, roughness or scoring.

a. Remove the four screws (49) that hold pintle covers

(50) on each side of the housing. Remove the pintle covers.

Be careful not to damage the shims which lie directly under

the covers.

b. Retain shims (51), if possible, and use a micrometer

to measure the total shim thickness. If the bearings are not

defective, the same shims or a new shim of the same thickness

will be needed to preload the bearings at installation. Remove

O–Rings (52) and bearing spacers (53) from each pintle.

24

Page 25

NOTE

If shims (51) were destroyed during disassembly, a

yoke bearing preload adjustment must be made at

assembly.

c. Slide the yoke from side to side to loosen the yoke

bearing races (54) within the housing. The races are a normal

slip fit but may be tight. Use an open end wrench between the

yoke and the pintle bearing to help slide out the races. Apply

pressure to bearing (55) at the approximate center and allow

the bearing rollers to gently press the race out of the housing.

15. Remove yoke (56) and drive shaft (48) from the

housing together. Turn the yoke at an angle and slide the two

parts out of the housing. See Figure 15.

Figure 15. Removal of Yoke and Shaft from Housing.

16. After removal of yoke from the housing, remove seat

(59) and yoke spring (60). Seat (58) and rollpin (57) will be

attached to the yoke (56). Do not disassemble further unless

seat (58) is damaged.

NOTE

Normally a wear pattern will exist on seat (58). If the

seat is damaged or shows heavy wear, replace seat

(58) and (59) and rollpin (57).

NOTE

If drive shaft (48) is defective, perform step F.17. If

front bearing (61) was defective, perform steps F.17

and 18.

17. Remove bearing (61) from shaft (48) with the nine

inch piece of 1 1/2” heavy wall tubing shown in Figure 9. Press

off with an arbor press.

18. Remove bearing race (62) from housing (27) as

shown in Figure 16. Use special tool shown in Figure 10.

NOTE

For units without shaft seal, omit shaft seal removal

and installation procedure.

19. Remove retaining ring (44) then press shaft seal (45)

from pump housing (27).

NOTE

If yoke (56) and front shaft bearing (61) were not

defective, perform the following step.

20. Remove and replace shaft seal (42) located within

housing (27) as follows: (Refer to figure 17.)

NOTE

For units without a shaft seal, this step will be used

to remove a defective drive shaft only. In addition,

references to shaft seal installation and removal

must be omitted.

a. Install a nine inch piece of 1 1/2” heavy wall tubing

over drive shaft (48) within the housing. The end of the tubing will rest against the inner race of tapered roller bearing

(61) and extend out beyond the end of the pump housing.

Place the complete unit with tubing into an arbor press with

drive spline up. Press the drive shaft through the bearing

and out of the unit. A 0.001 press exists between the shaft

and bearing so considerable force is required to remove the

bearing. See Figure 17 (PVE19/21).

b. Remove retaining ring (44) and pull shaft seal (45)

from housing (27). Be careful not to damage the aluminum

die cast housing in the seal area.

c. Press drive shaft (48) into shaft bearing (61) as

follows: Use a short piece of 1 1/2” inch heavy wall tubing

(approximately 6” long) over the drive spline of the shaft. The

tubing must be long enough to go through the shaft seal end

of the pump and make contact with the inner race of the front

bearing. Press the shaft through the bearing with an arbor

press until the bearing bottoms against the shoulder of the

shaft (snap ring on the PVE12). See Figure 18.

d. Remove the short piece of tubing and turn shaft

bearing (69) in its race with the end of the shaft. The bearing

rollers must turn free and smooth.

e. Tape the spline end of drive shaft (48) with plastic

tape to prevent cutting new shaft seal (45). Start taping the

shaft close to the housing and work toward the end of the

shaft. Install a new shaft seal in position over the shaft and

press evenly into the housing. Use shaft seal driver shown in

Figure 12. The seal must be positioned just below the retaining

ring groove. Install retaining ring (44, 47 for PVE12) into the

housing. Use internal Truarc pliers to install retaining ring.

25

Page 26

Figure 16. Removal of Front Bearing Race.

Retaining Ring

Shaft

Seal

Arbor Press Here

Arbor Press Here

Shoulder

1 1/2” heavy wall

tubing 6” long.

See Figure 11.

1 1/2” heavy wall

tubing 6” long.

See Figure 11.

Figure 17. Front Bearing Removal.

Figure 18. Front Bearing Installation.

G. Assembly of Housing Parts

NOTE

If a new shaft bearing (61), shaft (48), valve block

(26), or housing (27) is required, a complete preload

adjustment must be performed. If the same parts are

returned to service, the preload adjustment can be

omitted. The same procedure applies to yoke (56) and

its associated bearings.

1. If the shaft bearing (61) requires replacement, install a

new bearing race (62) into housing (27). Use tool shown in

Figure 11 to press bearing race in place. Make sure the bearing race (62) is oriented properly to accept the roller bearing

before pressing into the housing. The race must be bottomed

against the shoulder of the housing at completion of press.

2. Place housing (27) on a flat surface with the shaft

seal end down. Lay the front shaft bearing (61) into the race.

Install yoke spring (60) and seat (59) into the housing.

3. Position the yoke pintle properly and install yoke into

housing. Assemble the yoke bearings, races, and spacers as

follows.

26

Page 27

a. Assemble pintle bearings (55) on each end of the

yoke and insert bearing races (54).

b. Install bearing spacer (53) at one pintle end.

c. Install O-Ring (52) against spacer (53) into the

groove, then install a 0.010 inch shim (51) under pintle cover

(50). Install four pintle cover screws (49) and torque to

175–185 lbf. in.

NOTE

Early designs used a screw and washer arrangement. These should be torqued to 115–125 lbf. in.

d. Set housing (27) on i ts s ide s o t he o ther p intle i s u p.

Install bearing spacer (53) and r otate t he y oke b ack and f orth t o

seat bearings (55) within the b earing races. W ith s pacer (53)

fully in against the b earing r ace, m easure t he h eight of t he

spacer with respect to the h ousing p intle f ace i n t wo p laces

(180° apart). Use a d epth m icrometer to perform t his measurement. See Figure 19. Average the readings to obtain a n ominal

value. A 0.007-0.009 inch p reload i s r equired o f t he p intle b earings. Calculate the necessary shims to p rovide this p reload a s

follows: Assume the depth readings w ere 0 .029 a nd 0 .027

inch. Add the two figures t ogether a nd d ivide b y t wo t o o btain

the average. In this c ase t he a verage calculated i s 0 .028 i nch.

Subtract the nominal preload o f 0.008 i nch f rom t he calculated

average to obtain the r equired s him t hickness.

Figure 19a. Measuring height of pintle bearing spacer with

respect to the pintle face.

NOTE

If the calculated shim thickness is greater than 0.020,

another shim must be added to the opposite side of

the yoke to reduce the total shim thickness to less

than 0.020. Shim thickness at either pintle must not

exceed 0.020. This is necessary to provide proper

O-Ring compression and prevent pintle seal leakage.

Figure 19. Pintle bearing spacer height with respect to

pintle face.

e. Install the correct shims (51) and cross torque pintle

cover (50) screws to 175–185 lbf. in.

NOTE

The yoke (56) will be stiff but should be loose

enough to be moved by hand (approximately 20 lb.

in. torque). The tightness/drag indicates the bearings

are preloaded. If the yoke cannot be moved by

hand, the preload is too great. Repeat the preload

adjustment until correct.

4. Assemble the rotating group and install into housing as

follows:

a. Assemble the spring, two washers and retaining

ring into the cylinder block. The washer with three notches is

assembled next to retaining ring. See Figure 14 for instructions. Set the cylinder block S/A (34) face on a flat clean

surface. Use Kraft paper between the block and surface to

prevent scratching the cylinder block face.

b. Install pin retainer (40) into cylinder block. Position

the pin retainer approximately 1/4” below the surface, and

orient the open end of the pin retainer to be away from the

large spline openings.

c. Slide the three pins (39) into cylinder block S/A (34)

until they bottom against the spring washer within the block.

d. Place spherical washer (41) on top of the three

pins, then install shoe plate (42) with nine piston and shoe

subassemblies (43) over spherical washer (41) and into cylinder block. Wobble shoe plate (42) to make sure that each

piston is free within its bore in the cylinder block.

e. Set housing (27) on its side and hold pump shaft

(48) horizontal. Slide rotating group into the housing. Rotate

the shaft to match the shaft splines to the cylinder block and

spherical washer.

5. If alignment pins (31) were removed, install two alignment rollpins (31) into housing (27). Place gasket (30) over

the rollpins, cover with Kraft paper and set aside for final

assembly.

27

Page 28

H. Disassembly of Valve Block

1. Do not disassemble check valve parts (64) through

(66), unless action of the valve indicates a problem. Check

the valve action with a pencil or a screwdriver. Press the

check valve in against the spring, it should return and hold

firm against the seat. If the check valve is defective, remove

and replace the complete assembly. Press new seat (64)

flush with face of valve block. DO NOT scratch the face of

valve block (26).

2. Remove parts (67) through (73) from valve block (26).

NOTE

If bearing (32) was defective, perform the following

step.

3. For PVE19/21, remove bearing race (63) from valve

block (36). The PVE12 roller bearing is in the valve block.

Refer to Figure 20 for removal information and use tool shown

in Figure 10 for PVE**G units. Use tool shown in Figure 10a

and procedure shown in Figure 20a for PVE** units with a

blind hole in valve block (26). BE CAREFUL not to scratch

face of the valve block during removal of the race.

Figure 20a. Removal of Bearing Race from valve Block

with Blind Hole.

5. Inspect valve block (26) for burrs, nicks, plugged body

passages, flatness of the pump wafer plate area and porosity .

Inspect check valve seat (64). Make sure the seat is tight within the valve block and does not protrude above the valve block

face. Repair or replace the valve block if defective.

J. Assembly of Valve Block

Figure 20. Removal of Bearing Race from Valve Block.

I. Inspection, Repair, and Replacement

1. Clean all parts and place them on a clean sheet of

Kraft paper for inspection. Follow general procedure noted in

paragraph VI. GENERAL.

2. Inspect the threaded plugs for worn corners on the

hex head, stripped threads and burrs in the O–Ring groove.

Use an India stone to remove burrs. If threads are defective,

replace the plug.

3. Inspect compensator piston rod (73) for nicks and

burrs. Remove burrs and sharp edges with an India stone.

4. Inspect compensator piston (72) for wear at the area

of yoke contact. The compensator piston and the piston rod

are a close tolerance fit and must assemble together without

evidence of wear or bind. Rotate the piston through 360°

when checking for bind.

NOTE

Refer to Figure 13 during the following assembly

procedures.

1. If bearing (32) was defective and bearing race (63 for

the PVE19/21) has been removed, a new bearing race must

be installed into the valve block. Refer to Figure 21 and

press a new bearing race in place with an arbor press. The

bearing race must bottom against the shoulder of valve block

at completion of press.

Figure 21. Installation of Bearing Race into Valve Block.

NOTE

Check flatness of the valve block face in the area

around each locating pin hole (31) and at bolt openings (25). Use an India stone to remove burrs or

raised metal in these areas.

28

Page 29

2. Install pipe plug (69) into valve block (26) and secure.

3. Assemble a new O—Ring (68) on hex plug (67) and

thread plug into place.

K. Shaft Bearing Preload Adjustment

(PVE 19/21 only)

NOTE

If the shaft bearings, shaft, valve block or housing

were not replaced, use the bearing spacer removed

during the disassembly procedure to preload the

shaft and perform step K.7. If preload adjustment is

necessary, perform steps K.1 through K.7

1. Install the thickest bearing spacer (33) over shaft (48)

with the chamfer facing into the housing (toward the

shoulder on the shaft).

2. Slide new bearing (32) on the shaft and up against

spacer (33). The small diameter of the tapered roller bearing

must face out of the housing.

3. Install housing (27) to valve block (26) without gasket

(30) and rotating group. Turn shaft (48) to seat the bearings

then torque the six housing attaching screws (25) to 5 lbf. in.

Check the opening between the valve block and housing to

be as even as possible after tightening.

4. Use a feeler gauge to measure the opening between

valve block (26) and housing (27). Four measurements

should be obtained equidistant around the unit. A tapered

feller gauge is especially useful for this purpose. Average the

four readings by adding them together and dividing by 4.

Calculate thickness of the shaft bearing spacer as follows:

+

0.150

–

0.027

+

0.003 ±0.001

+

0.020

0.146±0.001

5. Remove six mounting screws (25) then remove housing (27) from the valve block.

6. Remove bearing (32) and bearing spacer (33).

7. Locate a bearing spacer with calculated dimensions

and place next to the new bearing on the shaft. Chamfer must

face shoulder on shaft. Use the original spacer and bearing if

preload is not performed. Set aside for final assembly .

Measured thickness of bearing spacer

Average gap (estimated)

Preload setting

Compressed thickness of gasket

Required bearing spacer thickness to

provide a 0.003±.001 bearing preload.

L. Final Assembly of the PVE Series

Pump

NOTE

Lubricate all moving parts of the piston pump with

system fluid to facilitate assembly and provide initial

lubrication. Pour system fluid liberally over the rotating group and wafer plate as these parts are without

lubrication until the pump primes.

2. Assemble wafer plate (28) over the bearing race (pins

on the PVE12) and locating pin (29) with wear surface away

from valve block (26). Determine from the model code which

wafer plate is used. See Figure 22.

CAUTION

The wafer plate must be flat against the valve block

face. Check to make sure it does not rock back and

forth. If rocking of the wafer plate occurs, check

locating pin (29), it may not be bottomed out in the

valve block. Rocking of the wafer plate will induce

high stress conditions across the wafer plate and

cause fractures to appear.

Left Right

Figure 22. Wafer plates showing right and left hand.

3. Place valve block (26) on its side. See Figure 13 for

position required.

4. Install compensator piston rod (73) into valve block

(26) and attach spirolox retaining ring (71).

5. Install a new O-Ring (70) in the compensator piston

rod O-Ring groove.

6. Install compensator piston (72) over compensator

piston rod (73).

7. Assemble housing (27) and valve block (26) together

as shown in Figure 13. Thread six screws (25) hand tight

through the housing into the valve block. Cross torque the

screws to bring the valve block and housing together against

gasket (30). Final torque screws (25) to 31–35 N.m (23–26

lbf. ft.) for the PVE19/21 and 22-27 N.m. for the PVE12.

8. Check the shaft torque to verify correct bearing preload. If the torque exceeds eight (8) N.m (6 lbf. ft.), perform a

shaft bearing preload adjustment, Section VI.K. and repeat

steps VI.L.7 and 8.

9. Determine shaft rotation from the model code

stamped on the mounting flange. Refer to Figure 7 and