Page 1

I.B. 29C892B

Effective 8/99 Supersedes I.B. 29C892A dated October 1996

Cutler-Hammer

Instructions for Operation of OPTIMizer

Hand Held Programmer

(For Use with Digitrip OPTIM Trip Units)

PROTECTION AND COORDINATION

COMMUNICATIONS SYSTEMS

E

N

E

R

G

Y

M

O

N

I

T

O

R

I

N

G

P

O

W

E

R

Q

U

A

L

I

T

Y

Page 2

I.B. 29C892B

Page iii

Effective 8/99

All possible contingencies which may arise during installation, operation or maintenance, and all details and

variations of this equipment do not purport to be covered by these instructions. If further information is

desired by purchaser regarding his particular installation, operation or maintenance of particular equipment,

contact a Cutler-Hammer representative.

WARRANTY AND LIABILITY INFORMATION

NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF FITNESS FOR A PARTICULAR

PURPOSE OF MERCHANTABILITY, OR WARRANTIES ARISING FROM COURSE OF DEALING OR USAGE OF

TRADE, ARE MADE REGARDING THE INFORMATION, RECOMMENDATIONS AND DESCRIPTIONS CONTAINED HEREIN. In no event will Cutler-Hammer be responsible to the purchaser or user in contract, in tort (including negligence), strict liability or otherwise for any special, indirect, incidental or consequential damage or loss whatsoever, including but not limited to damage or loss of use of equipment, plant or power system, cost of capital, loss of

power, additional expenses in the use of existing power facilities, or claims against the purchaser or user by its customers resulting from the use of the information and descriptions contained herein.

Page 3

I.B. 29C892B

Page iv

Effective 8/99

TABLE OF CONTENTS

Page

SECTION 1: INTRODUCTION

1-1 Common Terms...................................................................................................................................................1

1-2 Preliminary Comments and Safety Precautions..................................................................................................1

1-2.1 Safety Precautions .................................................................................................................................1

1-3 Product Overview ................................................................................................................................................2

1-4 Features and Functions.......................................................................................................................................2

SECTION 2: HARDWARE DESCRIPTION

2-1 General ...............................................................................................................................................................3

2-2 Package and External Connections ....................................................................................................................3

2-2.1 Internal Battery Power............................................................................................................................4

2-2.2 External Connections .............................................................................................................................5

2-3 Operator Panel ....................................................................................................................................................6

2-3.1 Pushbuttons ...........................................................................................................................................6

2-3.2 General Pushbuttons..............................................................................................................................6

2-3.3 View Function Pushbuttons....................................................................................................................6

2-3.4 Edit Values Pushbuttons ........................................................................................................................7

2-3.5 Display....................................................................................................................................................8

2-4 Specification Summary......................................................................................................................................10

SECTION 3: OPERATION AND USE

3-1 General .............................................................................................................................................................11

3-2 Getting Started ..................................................................................................................................................11

3-3 Power Application..............................................................................................................................................11

3-4 Function Overview.............................................................................................................................................14

3-4.1 Select Address .....................................................................................................................................14

3-4.2 Find Baud/Address...............................................................................................................................14

3-4.3 Find Product ID ....................................................................................................................................14

3-4.4 Change Baud/Addr...............................................................................................................................14

3-4.5 Rating Plug...........................................................................................................................................14

3-4.6 Metered Value ......................................................................................................................................15

3-4.7 Test Mode ............................................................................................................................................15

3-4.8 Setpoints Menu ....................................................................................................................................15

3-4.9 Password..............................................................................................................................................15

3-4.10 Trip Event Count ..................................................................................................................................15

3.4-11 Cause of Trip........................................................................................................................................15

3-4.12 Firmware Version/Revision ..................................................................................................................16

3-5 Security Password.............................................................................................................................................16

3-5.1 Change Security Password ..................................................................................................................17

3-6 Assign Address/Select Baud Rate ....................................................................................................................17

3-6.1 Directly Connected Breaker Address and Baud Rate ..........................................................................17

3-6.2 INCOM Connected Address and Baud Rate........................................................................................18

3-7 Configure Trip Unit ............................................................................................................................................19

3-8 Displayed Information........................................................................................................................................20

3-9 Test Trip Unit.....................................................................................................................................................21

Page 4

I.B. 29C892B

Page v

Effective 8/99

LIST OF FIGURES

Figure Title Page

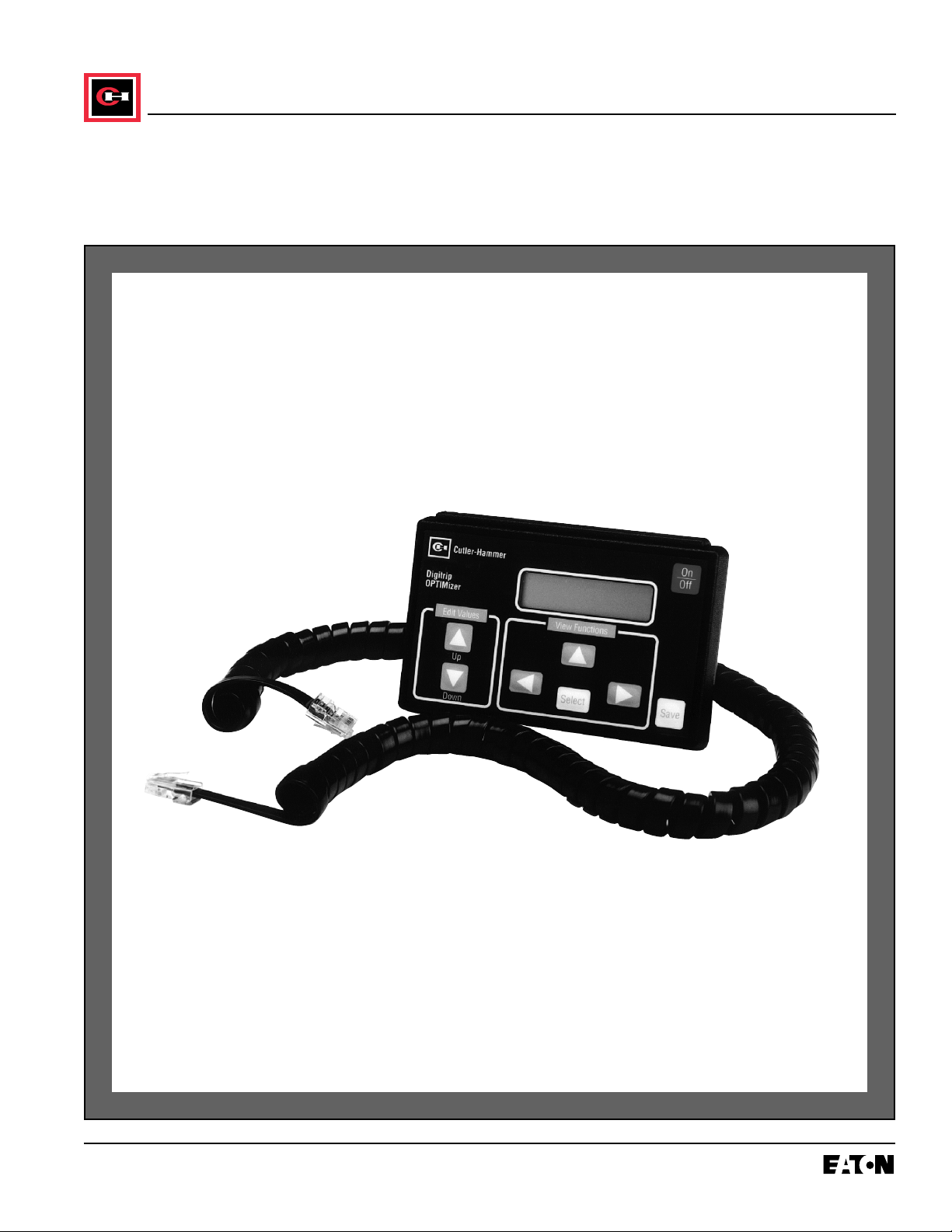

1-1 Hand Held Programmer in Use with Series C R-Frame Circuit Breaker ...................................................2

2-1 OPTIMizer Operator Panel ........................................................................................................................3

2-2 OPTIMizer Top View..................................................................................................................................4

2-3 OPTIMizer Hinged Protective Cover (Open Position)................................................................................4

2-4 OPTIMizer Battery Compartment with Battery Installed ............................................................................5

2-5 Auxiliary Power Module Shown Connected to OPTIMizer.........................................................................5

2-6 OPTIMizer Shown Connected to Series C L-Frame Circuit Breaker.........................................................6

2-7 General Pushbuttons.................................................................................................................................6

2-8 View Functions Pushbuttons .....................................................................................................................7

2-9 Top Level Main Menu Display ...................................................................................................................7

2-10 Edit Values Pushbuttons ...........................................................................................................................7

2-11 Main Menu Options Screens .....................................................................................................................8

3-1 OPTIMizer Menu Diagram.......................................................................................................................12

3-2 Initial Power Application Message Display ..............................................................................................14

3-3 Momentary Connect Failure Message Display........................................................................................14

3-4 Address Invalid Display ...........................................................................................................................14

3-5 Typical Momentary Successful Connection Message Display ................................................................14

3-6 Cursor on Password in Main Menu..........................................................................................................14

3-7 Password Menu.......................................................................................................................................15

3-8 Present Valid Password Entry Screen.....................................................................................................15

3-9 Password Accepted Display ....................................................................................................................15

3-10 Password Error Display ...........................................................................................................................15

3-11 Password Change Display.......................................................................................................................15

3-12 Password Code Change Display.............................................................................................................16

3-13 Cursor on CHANGE BAUD/ADDR in Main Menu....................................................................................16

3-14 Present Baud Rate and Address Displayed ............................................................................................16

TABLE OF CONTENTS (Continued from previous page)

3-10 Copy and Download Commands.......................................................................................................................22

3-10.1 Using the Copy Command ...................................................................................................................22

3-10.2 Using the Download Command............................................................................................................22

3-11 Reset Trip Unit ..................................................................................................................................................22

SECTION 4: TROUBLESHOOTING AND MAINTENANCE

4-1 Level of Repair ..................................................................................................................................................23

4-2 Troubleshooting.................................................................................................................................................23

4-3 Maintenance and Care ......................................................................................................................................23

4-4 Return Procedure ..............................................................................................................................................23

4-5 Technical Assistance.........................................................................................................................................23

APPENDIX A INSTRUCTIONAL REFERENCES .....................................................................................................25

Page 5

I.B. 29C892B

Page vi

Effective 8/99

LIST OF FIGURES (Continued from previous page)

3-15 Address/Baud Rate Change Accepted Display .......................................................................................17

3-16 Network Address Selection Display.........................................................................................................17

3-17 Cursor on Setpoints in Main Menu ..........................................................................................................18

3-18 Initial Setpoints Menu ..............................................................................................................................18

3-19 Setpoints Menu with Long Delay Slope Active ........................................................................................18

3-20 Long Delay Slope Present Setting Displayed..........................................................................................18

3-21 Long Delay Slope with New Setting Displayed........................................................................................18

3-22 Cursor on Metered Values in Main Menu ................................................................................................19

3-23 First Display in Metered Values...............................................................................................................19

3-24 Cursor Indicating Phase B Current Active ...............................................................................................19

3-25 PHASE B (IB) Current Selected and Displayed.......................................................................................19

3-26 Cursor on Test Mode in Main Menu ........................................................................................................20

3-27 First Display in Test Mode .......................................................................................................................20

3-28 Displayed Choices After Phase or Ground..............................................................................................20

3-29 Momentary Notice Displayed...................................................................................................................20

3-30 Momentary Notice Displayed...................................................................................................................20

3-31 Displayed Choice After Trip or No Trip....................................................................................................20

3-32 Typical Cause of Trip Message ...............................................................................................................21

LIST OF TABLES

Figure Title Page

2.1 Programmable Categories.........................................................................................................................9

2.2 OPTIMizer/Accessory Specifications.......................................................................................................10

4.1 Troubleshooting Guide ............................................................................................................................24

A.1 Instructional References..........................................................................................................................25

Page 6

I.B. 29C892B

Page 1

Effective 8/99

SECTION 1: INTRODUCTION

1-1 COMMON TERMS

Several commonly used terms or phrases are used

throughout this manual. They are defined here to eliminate any confusion that might arise when reading the

text.

IMPACC (Integrated Monitoring, Protection and

Control Communications) – A family of communicat-

ing electrical power distribution protective devices,

meters, motor control devices, communications networks and protocols and software packages to provide

power distribution monitoring and control.

INCOM (Industrial Communications) – A noise

immune communications system designed specifically

for power distribution monitoring and control applications.

PONI (Product Operated Network Interface) – A

plug-in communications module that enables network

communications.

1-2 PRELIMINARY COMMENTS AND SAFETY

PRECAUTIONS

This instructional manual is intended to present specific

descriptive, operational and maintenance information

associated with the Hand Held Programmer (OPTIMizer)

only. The OPTIMizer is used exclusively with the Digitrip

OPTIM Trip Unit System. For a general overview of the

entire Digitrip OPTIM Trip Unit System and certain specific application possibilities, refer to Instruction Book

29C890 entitled “Instructional Overview for Use of the

Digitrip OPTIM Trip Unit System.”

Detailed instructional material relative to the installation,

use and maintenance of specific devices is included

under separate cover by a manual dedicated to each

device. A series of four manuals brings together the

wide array of capabilities offered by the most advanced

programmable trip unit system - Digitrip OPTIM. Refer

to Appendix A for all instructional material references.

Please read and understand this manual and all other

relevant manuals before proceeding with the installation

and operation of any device included in the trip unit sys-

tem. Pay particular attention to all WARNINGS and

CAUTIONS. They are intended to help insure personnel

safety and equipment protection. Refer to the WARNING and CAUTION in Paragraph 1-2.1 before proceeding to any other section in this manual or any other manual. If further information is required by the purchaser

regarding a particular installation, application or maintenance activity, a Cutler-Hammer representative should

be contacted.

1-2.1 SAFETY PRECAUTIONS

All safety codes, safety standards and/or regulations

must be strictly observed in the installation, operation

and maintenance of any device in this system.

THE WARNINGS AND CAUTIONS INCLUDED AS

PART OF THE PROCEDURAL STEPS IN THIS DOCUMENT ARE FOR PERSONNEL SAFETY AND PROTECTION OF EQUIPMENT FROM DAMAGE. AN

EXAMPLE OF A TYPICAL WARNING LABEL HEADING IS SHOWN ABOVE IN REVERSE TYPE TO

FAMILIARIZE PERSONNEL WITH THE STYLE OF

PRESENTATION. THIS WILL HELP TO INSURE

THAT PERSONNEL ARE ALERT TO WARNINGS,

WHICH MAY APPEAR THROUGHOUT THE DOCUMENT. IN ADDITION, CAUTIONS ARE ALL UPPER

CASE AND BOLDFACE AS SHOWN BELOW.

COMPLETELY READ AND UNDERSTAND THE

MATERIAL PRESENTED IN THIS DOCUMENT

BEFORE ATTEMPTING INSTALLATION, OPERATION

OR APPLICATION OF THE EQUIPMENT. IN ADDITION, ONLY QUALIFIED PERSONS SHOULD BE

PERMITTED TO PERFORM ANY WORK ASSOCIATED WITH THE EQUIPMENT. ANY WIRING INSTRUCTIONS PRESENTED IN THIS DOCUMENT MUST BE

FOLLOWED PRECISELY. FAILURE TO DO SO

COULD CAUSE PERMANENT EQUIPMENT DAMAGE.

WARNING

CAUTION

Page 7

I.B. 29C892B

Page 2

Effective 8/99

1-3 PRODUCT OVERVIEW

The OPTIMizer Hand Held Programmer is required for all

OPTIM Trip Unit Systems. It plugs into the front of

OPTIM 550, 750 or 1050 Trip Units and is powered by a

standard nine volt battery (Figure 1-1) or auxiliary power

module. The OPTIMizer accesses, displays, and configures information from OPTIM Trip Units. The OPTIMizer

Hand Held Programmer provides a broad range of programming possibilities available with the OPTIM Trip Unit

System and the range of compatible circuit breakers.

1-4 FEATURES AND FUNCTIONS

An OPTIMizer must be used to configure the trip unit for

communications on the INCOM Network. This requires

an operator, during initial start-up, to:

• Assign Unique Device Addresses

• Select Baud Rates

In addition, the OPTIMizer can be used to:

• Configure OPTIM Trip Unit

- Select frequency (50/60 Hz)

- Set security passwords

- Change time-current setpoints

- Select protection options

- Select High Load Alarm level

• Display Information

- Breaker description

- Time-current setpoints

- Metered values

- Trip event information

• Test OPTIM Trip Unit Performance

- Phase and ground

- Trip or no trip

• Communicate over INCOM

• Copy Trip Unit Settings

- To download to any OPTIM breaker of any type

Figure 1-1 Hand Held Programmer in Use with Series C

R-Frame Circuit Breaker

Page 8

I.B. 29C892B

SECTION 2: HARDWARE DESCRIPTION

2-1 GENERAL

The purpose of this section is to familiarize the reader

with OPTIMizer hardware, its nomenclature, and any

applicable specifications. The information presented is

divided into the following three sections:

• Package and External Connections

• Operator Panel

• Specification Summary

Notice: Integral to the OPTIMizer Hand Held Program-

mer is the ability to lock out changes to a

breaker’s settings through the use of a password. The correct password must be entered

to proceed with setpoint changes, baud rate

changes or the initiation of a test. The password entry field contains four digits that can be

changed. The factory installed password 1000

can be used until a new password is selected

by the user.

Page 3

CAUTION

THIS IS A SOPHISTICATED PIECE OF ELECTRICAL

EQUIPMENT. AS SUCH, IT SHOULD BE HANDLED

CAREFULLY AT ALL TIMES TO AVOID POSSIBLE

DEVICE DAMAGE.

2-2 PACKAGE AND EXTERNAL CONNECTIONS

The OPTIMizer Hand Held Programmer is packaged in

a high strength plastic housing with approximate dimensions of 5.75 inches by 3.5 inches by 1.25 inches. An

operator panel with a display and associated pushbuttons are located on the front of the device (Figure 2-1).

External connections are made on the top of the hand

held programmer (Figure 2-2). A top hinged protective

cover is provided to protect external connections from

the entrance of foreign matter. The protective cover is

opened through the use of a thumb nail notch (Figure 2-

3). A storage case holds the hand held programmer and

its phone type connection cord.

7

7

Figure 2-1 OPTIMizer Operator Panel

Effective 8/99

8

4

6 5

3

1

1

On/Off Pushbutton

2

Save Pushbutton

Select Pushbutton

3

View Functions

4

Up-Arrow Pushbutton

Right-Arrow

5

Pushbutton

Left-Arrow

6

Pushbutton

Edit Values Up and

7

Down Pushbuttons

Liquid Crystal Display

2

8

Page 9

Page 4

I.B. 29C892B

4

Figure 2-2 OPTIMizer Top View

1

2

3

5

1

Custom Phone Jack Port (HDR1)

2

2-Pin Auxiliary Power Receptacle

3-Pin Network Receptacle (J2)

3

Communication Indicating LED

4

Display Intensity

5

N o t i c e : A small red LED located on the top of the hand

held programmer near the external connections

blinks when the hand held programmer is communicating with a trip unit.

2-2.1 INTERNAL BATTERY POWER

A 9-volt battery compartment with a slide out access

cover located on the back of the device provides easy

access to an internal 9-volt battery (Figure 2-4). The

number of continuous operation hours the 9-volt battery

will support depends upon the type of battery used.

Refer to Table 2.2 for information about battery choices.

When an auxiliary power supply is not being used, the

programmer will automatically turn off to save battery

power or provide an indication of insufficient power

under the following conditions:

1. The programmer turns itself off when the battery

power available is not sufficient to carry out all programmer functions, including both powering of the

programmer and the trip unit. When this occurs the

battery should be replaced.

Figure 2-3 OPTIMizer Hinged Protective Cover (Open

Position)

Effective 8/99

Page 10

I.B. 29C892B

Page 5

Figure 2-4 OPTIMizer Battery Compartment with

Battery Installed

2. If none of the pushbuttons on the operator panel are

used for approximately 2 1/2 minutes, the programmer turns itself off. This includes the performance of

a non-trip test. External power is required to perform

a trip test. Refer to the next paragraph for external

power details.

2-2.2 EXTERNAL CONNECTIONS

Three receptacles are provided on the top of the device,

one for an external power connection and two different

means for connecting the programmer to the trip unit

(Figure 2-2).

External Power Connection

Use external power to:

• Save internal battery power

• Perform trip test on circuit breaker

• Communicate over INCOM

External power is provided by connecting an Auxiliary

Power Module (Catalog Number PRTAAPM) to the

OPTIMizer through the 2-pin male receptacle. The

Auxiliary Power Module requires a 120 Vac 50/60 Hz

input and delivers a 32 Vdc 4 VA output (Figures 2-2

and 2-5). Note that OPTIM trip units with external

power connections (K, L and N) operate from a 24 Vdc

power source.

Figure 2-5 Auxiliary Power Module Shown Connected

to OPTIMizer

Direct Breaker Connection

The first method for connecting the hand held programmer to the trip unit is by means of the 8 conductor custom phone cord provided with the programmer. One end

plugs into the front panel of the trip unit and the other

end into a custom phone jack port (HDR1) on the top of

the programmer. This direct connection is intended only

for use with the hand held programmer, and is normally

associated with the direct programming of individual trip

units (Figures 1-1, 2-2 and 2-6).

Network Connection

The second means for connecting the hand held programmer is through the 3-pin male connector (J2) located on the top of the programmer. This connection is

made through an INCOM shielded twisted-pair. The

hand held programmer has an internal INCOM transformer permitting it to communicate over the network.

This is the method normally associated with network programming (Figure 2 - 2). Auxiliary power to the OPTIMizer

is required to communicate over the INCOM network.

Notice: A direct connection will override an INCOM

connection. This will also signal a no response

alarm on other network devices.

Effective 8/99

Page 11

Page 6

I.B. 29C892B

Figure 2-6 OPTIMizer Shown Connected to Series C LFrame Circuit Breaker

2-3 OPERATOR PANEL

The operator panel provides a means to initially assign

addresses, select baud rates, configure trip units, display information, and perform testing (Figure 2-1). For

the purpose of familiarization, the panel is divided into

two sub-sections:

• Pushbuttons

• Display

2-3.1 PUSHBUTTONS

The operator panel contains eight membrane pushbuttons. Pushbuttons generally accomplish their function

when pressed and released. Variations in the use of a

particular pushbutton are detailed in the description for

that particular pushbutton. The pushbuttons are categorized as follows:

• General Pushbuttons

• View Functions Pushbuttons

• Edit Values Pushbuttons

Figure 2-7 General Pushbuttons

On/Off Pushbutton

The On/Off pushbutton turns the hand held programmer

on and off. To achieve power-up, the pushbutton must

be pushed and held for approximately one second. The

programmer cannot be turned off while Find Baud/Addr

is displayed. When the programmer is on, power is

delivered to the trip unit.

Save Pushbutton

The Save pushbutton is used in conjunction with the

Select pushbutton to cause any programmer initiated

change to be saved to memory. The Save pushbutton

must be pressed and held followed by depression of the

Select pushbutton to accomplish the saving function.

Changes must be saved individually before moving to

another menu. This feature minimizes the possibility that

re-programming would be required if the programmer

turns itself off during the programming process.

2-3.3 VIEW FUNCTIONS PUSHBUTTONS

(Figure 2-8)

2-3.2 GENERAL PUSHBUTTONS

(Figure 2-7)

Select Pushbutton

The Select pushbutton performs two functions. First, it is

used in conjunction with the Save pushbutton to save

Effective 8/99

Page 12

I.B. 29C892B

changes to memory as previously described. In addition,

the Select pushbutton by itself causes the programmer to

select a particular category indicated by the blinking cursor and move further into that particular selected menu.

Up-Arrow Pushbutton

The Up-Arrow pushbutton is used to move the blinking

cursor back to the first selection Select Address (SA)

when the programmer is displaying the top level menu

(Figure 2-9). It is similar to the Escape Key of a PC. If

the programmer is displaying a lower level menu, use of

this pushbutton moves the display back one menu level,

eventually ending at SA.

Right-Arrow Pushbutton

The Right-Arrow pushbutton moves the blinking cursor

horizontally to the right in the display from category to

category. Continued use of this pushbutton will wrap

around and eventually return to the starting category.

Left-Arrow Pushbutton

The Left-Arrow pushbutton performs the same function

as the previously described Right-Arrow pushbutton

except movement of the blinking cursor is horizontally to

the left.

Page 7

<SA FI I D BA>

SELECT ADDRESS

Figure 2-9 Top Level Main Menu Display

2-3.4 EDIT VALUES PUSHBUTTONS

(Figure 2-10)

Up Pushbutton

The Up pushbutton is used to edit already programmed

values and/or selections. Use of this pushbutton

increases the value and/or selection presently programmed. When this pushbutton is held depressed, the

displayed values scroll at a more rapid rate. Eventually,

the display will wrap around to the original starting point.

Figure 2-8 View Functions Pushbuttons

Effective 8/99

Figure 2-10 Edit Values Pushbuttons

Page 13

Page 8

Down Pushbutton

The Down pushbutton performs the same function as

the previously described Up pushbutton except movement is in the opposite direction down through the values and/or selections.

2-3.5 DISPLAY

N o t i c e : This manual utilizes a gray rectangular box

underlined in black to represent a blinking

cursor in all illustrations of the programmer’s

display (Figure 2-9).

A 2-line, 16-character per line liquid crystal display is

used to display all trip unit data, setpoints and mes-

I.B. 29C892B

sages. The brightness of the display can be adjusted

through the use of a small, recessed adjusting screw

located in the top side of the programmer (Figure 2-2).

The first line of the display is normally used to show the

main menu selection possibilities. A blinking cursor indicates which category on the first line is active. The second line of the display either defines the first line category highlighted by the blinking cursor or, in lower level

menus, presents a field that is capable of being changed,

as indicated by a blinking cursor. Note in Figure 2 - 9 t h a t

the blinking cursor is positioned just to the left of S A i n

the top line of the display. Note also that the second display line defines that category as Select Address. Table

2 . 1 outlines all the displayed menu items that can be

encountered in the OPTIMizer display along with their

specific definitions. Figure 2 - 1 1 shows the twelve avail-

able options accessible from the main menu.

Figure 2-11 Main Menu Option Screens

Effective 8/99

Page 14

I.B. 29C892B

Table 2.1 Programmable Categories

Page 9

Displayed Display

Menu Items Definition

SA SELECT ADDRESS Network use only – permits selection of specific trip unit address within network

FI FIND BAUD/ADDR Search to identify address and baud rate of connected trip unit (8 conductor custom phone cord only)

ID FIND PRODUCT ID Identification of type and frame rating of connected breaker

BA CHANGE BAUD/ADDRESS Permits the initial setup or changing of address and baud rate of connected trip unit –

valid password required to setup or change address

RP RATING PLUG Rating plug size installed in connected trip unit

ME METERED VALUES Depending on trip unit connected, some or all of the values are displayed:

• Current (A) - Phases A, B, C, Ground and Neutral

• Energy (kWh) - Total, Forward and Reverse

• Power (kW) - Power and Peak Demand

• Power Factor

• THD Currents (%) - Phases A, B, C and Neutral

• Harmonic Content - Phases A, B, C and Neutral

TM TEST MODE Provides for Phase or Ground, Trip or Non-Trip Test (valid password)

SP SETPOINTS Permits viewing, initial setup and changing of setpoints for connected trip unit – valid password

required to setup or change setpoints:

• LD - Long Delay Setting

• LDTI - Long Delay Time

• LDA - Long Delay Action

• LDS - Long Delay Slope

• SDPU - Short Delay Setting

• SDTI - Short Delay Time

• SDA - Short Delay Action

• SDS - Short Delay Slope

• IN - Instantaneous Setting

• INA - Instantaneous Action

• DSC - Discriminator

• GFP - Ground Fault Setting

• GFT - Ground Fault Time

• GFA - Ground Fault Action

• GFS - Ground Fault Slope

• HLA - High Load Setting

• PTM - Powered ThermalMemory

• UPM - Unpowered Thermal Memory

• FRQ - Line Frequency

• NR - Neutral Ratio

• AWC - Auto Waveform Capture

• PI - Phase A Identification

PA PASSWORD Permits authorized personnel to change or enter 4 digit password

TC TRIP EVENT COUNT Display of number of circuit breaker automatic trip operations

CT CAUSE-OF-TRIP Displays one of four possible modes of trip on most recent automatic trip operation:

• Long Delay

• Short Delay

• Instantaneous

• Ground Fault

FW FIRMWARE REV/VER Displays Firmware Revision and Version of OPTIMizer or connected trip unit

CP COPY COMMAND Loads trip unit settings into OPTIMizer

DL DOWNLOAD COMMAND Sends stored settings in OPTIMizer to trip unit (valid password)

RE RESET TRIP UNIT Resets trip unit LEDs, historical current etc.

Additional Comments

Effective 8/99

Page 15

Page 10

2-4 SPECIFICATION SUMMARY

Refer to Table 2.2.

Table 2.2 OPTIMizer/Accessory Specifications

I.B. 29C892B

Power Supply:

• Battery

• Auxiliary Power Module Cutler-Hammer

➀ Alkaline type batteries can be used but will require more

frequent replacement.

➀

Lithium Power Cell Part #U9VL

(+9 volts dc)

ULTRALIFE Batteries Inc.

Catalog #PRTAAPM

Input 120 Vac

Output +32 Vdc, 4 VA

Effective 8/99

Page 16

I.B. 29C892B

Page 11

SECTION 3: OPERATION AND USE

3-1 GENERAL

This section specifically describes the effective operation

and functional use of the OPTIMizer Hand Held Programmer. The OPTIMizer is used to access the many

capabilities of OPTIM 550, 750 and 1050 Trip Units.

Specific details associated with the trip units are covered

in Instruction Book 29C891 entitled “Instructions for

Installation, Operation and Maintenance of CutlerHammer Digitrip OPTIM Trip Units.” It is recommended

that the operator review the material presented in

Section 2 prior to operating and using the hand held prog r a m m e r .

Familiarization with the information presented in Table

2 . 1 will prove helpful. Table 2 . 1 outlines the menu items

accessed from the top level menu (Figure 2 - 9). Menu

item definitions are provided in the user friendly display

with additional explanatory information provided in Table

2 . 1. In addition, an OPTIMizer Menu Diagram provides

an overall picture of the device’s capabilities (Figure 3 - 1) .

This diagram is also shown on the OPTIMizer back

panel for quick and easy reference (Figure 2 - 4) .

Section 3 covers the operation and use of the OPTIMizer.

It is broken down into the following general categories:

• Getting Started

• Power Application

• Security Password

• Assign Address/Select Baud Rate

• Configure Trip Unit

• Displayed Information

• Test Trip Unit

3-2 GETTING STARTED

The OPTIMizer Hand Held Programmer is a simple to

use device. Before applying power and using the

device, it is recommended that the following preliminary

steps be taken:

Step 1: If the programmer is to be operated by battery

power only, be sure that a fresh battery is

properly installed. Refer to paragraph 2-2.1 for

battery information.

Step 2: If power will be supplied by an Auxiliary Power

Module, be certain that the Auxiliary Power

Module is connected to the appropriate 120

Vac source and the OPTIMizer Hand Held

Programmer. Refer to paragraph 2-2.2 for

details on an external power connection.

Notice: Keep in mind that an Auxiliary Power Module

is always required if a “Trip” Test is to be performed on a circuit breaker.

Step 3: When a Direct Breaker Connection is being

made, plug either end of the custom phone

cord into the phone jack port on the top of the

programmer first, and then plug the other end

into the port provided on the trip unit. The connections should be made before power is

applied. Refer to paragraph 2-2.2 for details on

a Direct Breaker Connection.

Notice: A direct breaker connection will override an

INCOM connection. This will also signal a no

response alarm on other network devices.

Clear the alarms when finished.

Step 4: If a Network Connection is being made using

an INCOM twisted-pair connection to the 3-pin

connector located on the top of the programmer, refer to paragraph 2-2.2 for details on a

Network Connection.

Step 5: No matter which connection approach is used,

be certain that all plug-in connections are

properly seated. This includes trip unit, external power and INCOM connections to the programmer as well as connections from the programmer to the trip unit or INCOM.

The programmer is now ready to have power applied.

3-3 POWER APPLICATION

Turn the programmer on by holding the red On/Off

pushbutton in the depressed position for approximately

one second. Upon release of the pushbutton, the first

message will be displayed.

Three different types of messages can be displayed

before the top level menu appears (Figure 2-9). The

messages displayed will depend on the programmer

connection or lack of a proper connection as follows:

• If the programmer detects the lack of a proper connection, two consecutive messages will be displayed.

Figure 3-2 shows the first message displayed while

the programmer searches for a compatible device. If

the programmer is unable to make a connection,

Figure 3-3 shows the second message that appears

momentarily before the top level main menu is displayed (Figure 2-9).

Effective 8/99

Page 17

Page 12

M A I N M E N U

➀

CHANGE BAUD/ADDRSELECT ADDRESS FIND BAUD/ADDR

SETPOINTS

TEST MODEMETERED VALUES

RATING PLUG

FIND PRODUCT ID

➂ ➃

➂ ➃ ➄ ➅

➂

➂➂ ➃ ➄ ➅

➂

➂ ➃ ➄ ➅

➂ ➃ ➄ ➅

Figure 3-1 OPTIMizer Menu Diagram — continued to next page

➁

➁ ➁ ➁ ➁ ➁ ➆ ➁

INCOM Only

Identification of Baud

Rate/Address

Identification of

Type/Frame of Breaker

Setup or Change to

Address/Baud Rate

Installed Plug Size Phase A Current

Phase B Current

Phase C Current

Phase or Ground

Trip or No Trip

Test Current

Ground Current

Neutral Current

Total Energy

Forward Energy

Reverse Energy

Power

Peak Demand

Power Factor

Harmonic Distortion

A, B, C and N

Harmonic Content

A, B, C and N

➁ ➆

Long Delay Setting

Long Delay Time

Long Delay Action

Long Delay Slope

Short Delay Setting

Short Delay Time

Short Delay Action

Short Delay Slope

Instantaneous Setting

Instantaneous Action

Discriminator

Ground Fault Setting

Ground Fault Time

Ground Fault Action

Ground Fault Slope

High Load Setting

Powered Thermal

Memory

Unpowered Thermal

Memory

Line Frequency

Neutral Ratio

Auto Waveform

Capture

Phase A Identification

I.B. 29C892B

Effective 8/99

Page 18

I.B. 29C892B

M A I N M E N U

➀

➀ Use Right-Arrow or Left-Arrow Pushbuttons to move from one Main Menu item to another.

➁ Use Select Pushbutton to enter a specific Main Menu item.

➂ Use View Functions Up-Arrow Pushbutton to return to Main Menu or return is automatic.

➃ Use Right-Arrow or Left-Arrow Pushbuttons to move to different selections.

➄ Use Edit Values Up or Down Pushbuttons to alter active item or value.

➅ Use Select and Save Pushbuttons simultaneously to save to memory or initiate test.

➆ Some entries in Metered Values and Setpoints may not be visible due to other settings.

(continued from previous page)

FIRMWARE REV/VERPASSWORD TRIP EVENT COUNT

RESETDOWNLOAD

COPY

CAUSE OF TRIP

➂ ➃

➂

➂➂ ➃ ➄ ➅

➁

➁ ➁ ➁

Change or Enter

Number of

Automatic Trips

Reason for

Automatic Trip

Present Revision

and Version

➁ ➅➁

➁

Copy Trip Unit

Settings into

OPTIMizer

Send Stored Settings

of OPTIMizer to

Product

Trip Unit Reset

Page 13

Effective 8/99

Page 19

Page 14

I.B. 29C892B

FIND BAUD/ADDR

** WORKING **

Figure 3-2 Initial Power Application Message Display

CONNECT FAILURE

Figure 3-3 Momentary Connect Failure Message

Display

ADDRESS INVALID

OVER INCOM PORT

Figure 3-4 Address Invalid Display

• If the programmer is connected to an INCOM Network,

the message shown in Figure 3 - 2 will first be displayed

followed by the INCOM message shown in Figure 3 - 4.

The top level menu will then be displayed (Figure 2 - 9) .

• If the programmer is successful in its device search,

the same in progress type message is displayed as

shown in Figure 3-2. Refer to Figure 3-5 for a typical

baud rate and address message momentarily displayed once the trip unit is identified. The top level

main menu is ultimately displayed and the programmer is ready for use (Figure 2-9).

3-4 FUNCTION OVERVIEW

3-4.1 SELECT ADDRESS (SA)

The Select Address menu item is used when it is

desired to communicate over the 3-pin INCOM connection to an OPTIM trip unit. The address of the breaker

you desire to communicate to is entered here. Note that

an auxiliary power module must be plugged into the

OPTIMizer for the OPTIMizer’s INCOM transceiver to

work. Selectable addresses are in the range 001-FFE

hexadecimal (001 to 4094 decimal).

FIND BAUD/ADDR

TARGET = 96B/012

Figure 3-5 Typical Momentary Successful Connection

Message Display

<ME TM SP PA>

PASSWORD

Figure 3-6 Cursor on Password in Main Menu

3-4.2 FIND BAUD/ADDRESS (FI)

This menu item is used to retrieve the address and baud

rate of the OPTIM trip unit connected to the OPTIMizer’s

custom phone cord. The OPTIMizer executes this function automatically when the OPTIMizer is first turned on.

Several attempts will be made to retrieve the address

and baud rate. If no trip unit is connected to the

OPTIMizer at the time the OPTIMizer is turned on,

an error message will be displayed.

3-4.3 FIND PRODUCT ID (ID)

The breaker frame type is displayed when this menu

item is selected.

3-4.4 CHANGE BAUD/ADDR (BA)

The baud rate of the trip unit can be changed to that of

the system by using this menu item. The baud rate is

programmable to either 1200 or 9600 baud. All breakers

connected together on a line must communicate at the

same baud rate.

The address of a given breaker can be changed by

using this menu item. Valid addresses of 001-FFE

Hexadecimal (001 to 4094 decimal) can be used, however, when OPTIM trip units are connected to a Breaker

Interface Module (BIM) the range of usable addresses is

from 1-32 hexadecimal (1-50 Decimal).

3-4.5 RATING PLUG (RP)

The rating plug installed in a trip unit can be read using

this command.

Effective 8/99

Page 20

I.B. 29C892B

Page 15

PASSWORD

<=CHANGE ENTER=>

Figure 3-7 Password Menu

PASSWORD ENTER

SET CODE 0000

Figure 3-8 Present Valid Password Entry Screen

3-4.6 METERED VALUE (ME)

The phase, neutral and ground currents are displayed

in the Metered Values menu, as well as Total Energy,

Forward Energy, Reverse Energy, Power, Peak

Demand, Power factor, %THD of each phase, and

Harmonic Content of each phase.

3-4.7 TEST MODE (TM)

Simulations of either a long delay, short delay, or

instantaneous fault condition can be performed by using

Test Mode. This can be done by first reading

the setpoints and noting their adjustment. The trip mode

menu item can then be selected and a current above

the noted settings can be entered. A trip or no trip test

can be performed. A test in progress may be terminated

if the currents through the breaker under test are above

40% of the rating plug value. See section 3-9.

3-4.8 SETPOINTS MENU (SE)

*** PASSWORD ***

*** ACCEPTED***

Figure 3-9 Password Accepted Display

*PASSWORD ERROR*

ENTER CODE AGAIN

Figure 3-10 Password Error Display

PASSWORD CHANGE

SET CODE 0000

Figure 3-11 Password Change Display

settings or use certain features. To change the baud

rate or trip unit address, setpoints, run test mode, or

download copied setpoints, a correct password must be

used. The OPTIMizer’s factory default setting is 1000.

See section 3-5 for additional details.

3-4.10 TRIP EVENT COUNT (TC)

The trip unit records the number of times that the trip

unit has initiated a trip. This is displayed when the

Trip Event Count is selected.

The trip unit can be adjusted for various time-current

characteristic curves. This is done within the Setpoints

Menu. See section 3-7, and Figure 3-1.

Notice: 1) Short Delay and Instantaneous Action can

not be turned off at the same time.

2) When long delay is set to I4t, the short

delay slope must be set to Flat.

3-4.9 PASSWORD (PA)

For system security, a password is required to change

Effective 8/99

3-4.11 CAUSE OF TRIP (CT)

The OPTIMizer can display the cause of trip, similar

to the cause of trip LEDs of the trip unit, but in some

cases with more specific information. This information is

available as long as the trip unit Reset pushbutton has

not been pressed after a trip condition. For example, a

non-compliant rating plug may cause an instantaneous

trip to occur which will light the Instantaneous LED of

the trip unit. However, the OPTIMizer in this case

would display that the instantaneous trip is a result of

a Bad Plug.

Page 21

Page 16

I.B. 29C892B

PASSWORD CHANGE

CODE BEING SAVED

Figure 3-12 Password Code Change Display

<SA FI ID BA>

CHANGE BAUD/ADDR

Figure 3-13 Cursor on CHANGE BAUD/ADDR in Main

Menu

The Cause-of-Trip function may also be used in

conjunction with the Metered Values menu item. After

reading the cause of trip, the operator should enter the

Metered Values menu to read the last current that the

trip unit recorded before a trip was initiated. In this way

the type of trip as well as the magnitude of the current

on each phase is known. Pressing the Reset pushbutton clears these values.

CHANGE BAUD/ADDR

96B/FFE

Figure 3-14 Present Baud Rate and Address Displayed

can be entered in either of the two following methods:

Method 1: Proceed directly to Password (PA) in the

main menu to enter a valid password. Entry of a valid

password in this manner will apply to any procedure

requiring a valid password as long as the programmer

does not turn off. To initially enter a valid password, proceed with the following steps:

N o t i c e : If the programmer automatically turns off or is

intentionally turned off, the procedure must be

repeated from the beginning. Use of an Auxiliary

Power Module will eliminate Auto-Power Down

and retain password while unit is on.

Step 1: With the programmer turned on and the main

menu displayed, use the Right-Arrow or Left-

Arrow pushbuttons to move the blinking cursor

to Password (PA) (Figure 3-6).

3-4.12 FIRMWARE VERSION /REVISION (FW)

This feature allows the operator to read the firmware

version and revision of either the trip unit or the

OPTIMizer.

3-5 SECURITY PASSWORD

The OPTIMizer Hand Held Programmer utilizes a password to restrict access to certain functional options. A

valid password is required to make changes or initiate

certain actions within the following main menu options:

• Change Baud/Address

• Test Mode

• Setpoints

• Password

• Download

The OPTIMizer Hand Held Programmer is supplied with

a factory programmed password of 1000. If it is desirable to establish a new password, follow the procedure

outlined in paragraph 3-5.1.

When the programmer is being used, a valid password

Step 2: Use the Select pushbutton to enter Password

(PA) (Figure 3-7).

Step 3: Use the Right-Arrow pushbutton to select

E n t e r = in the display. A screen that permits en-

try of a valid password is displayed (Figure 3 - 8) .

Step 4: The blinking cursor indicates which of the four

displayed zeros is active and able to be altered.

Use the U p or Down pushbuttons to change

the active number. Use the R i g h t - A r r o w o r

Left-Arrow pushbuttons to move the cursor

from one digit to another.

Step 5: Once the password displayed is correct, hold

Save p u s h b u t t o n depressed and depress

Select p u s h b u t t o n. This simultaneous use of

the two pushbuttons will enter the password. If

the password entered is valid, Password

Accepted will be displayed (Figure 3-9). If the

password is not valid, a Password Error message will be displayed momentarily. In both

cases the display will automatically return to

the main menu (Figure 3-10).

Method 2: Enter a valid password when requested

Effective 8/99

Page 22

I.B. 29C892B

Page 17

CHANGE BAUD/ADDR

*** ACCEPTED ***

Figure 3-15 Address/Baud Rate Change Accepted

Display

during use of the programmer. To accomplish this, follow Steps 4 and 5 just outlined for Method 1.

3-5.1 CHANGE SECURITY PASSWORD

Step 1: With the programmer turned on and the main

menu displayed, use the Right-Arrow or LeftArrow pushbuttons to move the blinking cursor

to Password (PA) (Figure 3-6).

Step 2: Use the Select pushbutton to enter Password

(PA) (Figure 3-7).

Step 3: Use the Left-Arrow pushbutton to select

=Change in the display. A screen that permits

entry of the present valid password is displayed (Figure 3-8).

Step 4: The blinking cursor indicates which of the four

displayed zeros is active and able to be altered.

Use the Edit Values U p or Down p u s h b u t t o n s

to change the active number. Use the R i g h t -

A r r o w or Left-Arrow pushbuttons to move the

cursor from one digit to another.

Step 5: Once the present password is displayed cor-

rectly, hold Save pushbutton depressed and

depress Select pushbutton. This simultaneous

use of the two pushbuttons will enter the password. If the password entered is valid, Pass-

word Accepted will be displayed (Figure 3-9).

If the password is not valid, a Password Error

message will be displayed momentarily and

the display will automatically return to the main

menu (Figure 3-10).

Step 6: If the password entered in Step 5 was valid,

Password Accepted will continue to be displayed until the Up-Arrow pushbutton of View

Functions is pressed and released. When the

pushbutton is used, Password Change is displayed (Figure 3-11). This display permits the

entry of a new password.

Step 7: The blinking cursor indicates which of the four

SELECT ADDRESS

INCOM ONLY 000

Figure 3-16 Network Address Selection Display

displayed zeros is active and able to be altered.

Use the U p or Down pushbuttons to change the

active number. Use the R i g h t - A r r o w or L e f t -

Arrow pushbuttons to move the cursor from one

digit to another.

Step 8: Once the password displayed is as required,

hold Save pushbutton depressed and depress

Select pushbutton. This simultaneous use of

the two pushbuttons will enter the new password, and Password Code Change Being

Saved will be momentarily displayed (Figure 3-

12). When the new password is saved, the dis-

play automatically returns to the main menu.

3-6 ASSIGN ADDRESS/SELECT BAUD RATE

The OPTIMizer Hand Held Programmer must be used

to initially establish the baud rates and unique addresses of connected circuit breakers. Assigning or changing

circuit breaker addresses and/or baud rates takes place

within the same category of the main menu, Change

Baud/Addr (BA). Each circuit breaker must have a

unique address with all addresses containing three digits. The three digit address will be in a HEXADECIMAL

Format with choices of 0 through 9 and A through F.

The two baud rate choices are 1200 or 9600, displayed

as 96B or 12B.

Notice: All circuit breakers are supplied from the facto-

ry with a 9600 baud rate “96B” and an address

of “FFE” (Hex Form) already programmed.

Keep in mind, however, when assigning

addresses, the Breaker Interface Module will

only recognize addresses at or below 32 HEX

(two digits).

3-6.1 DIRECTLY CONNECTED BREAKER ADDRESS

AND BAUD RATE

Use the following steps as a guide to assigning or

changing addresses and selecting baud rates when the

programmer is directly connected to a circuit breaker:

Effective 8/99

Page 23

Page 18

I.B. 29C892B

<RP ME TM SP>

SETPOINTS

Figure 3-17 Cursor on Setpoints in Main Menu

LD LDTI

LD SET

Figure 3-18 Initial Setpoints Menu

Step 1: Use the On/Off pushbutton to turn the program-

mer on. The baud rate/address of the connected circuit breaker will automatically be identified

and momentarily displayed (Figure 3 - 4), before

the main menu is displayed (Figure 2 - 9).

Step 2: Use the R i g h t - A r r o w or Left-Arrow p u s h b u t-

tons to move the cursor to Change Baud/Addr

( B A ) in the main menu (Figure 3 - 1 3) .

LDA LDS

LD SLOPE

Figure 3-19 Setpoints Menu with Long Delay Slope

Active

LDA LDS

LD SLOPE I2T

Figure 3-20 Long Delay Slope Present Setting

Displayed

LDA LDS

LD SLOPE I4T

Figure 3-21 Long Delay Slope with New Setting

Displayed

Step 3: Use the Select pushbutton to enter C h a n g e

Baud/Addr (BA) and the present baud rate and

address of the connected circuit breaker are

displayed (Figure 3 - 1 4) .

Step 4: The blinking cursor indicates which digit of the

display is active and able to be altered. Use

the Up or Down p u s h b u t t o n s to change the

active number. Use the Right-Arrow or Left-

Arrow p u s h b u t t o n s to move the cursor from

one digit to another.

Step 5: Once the desired baud rate and address are

correctly displayed, hold Save p u s h b u t t o n

depressed and depress Select p u s h b u t t o n.

This simultaneous use of the two pushbuttons

will enter the new baud rate and address. If the

changes are accepted, the display will indicate

the acceptance momentarily before returning

to the main menu (Figure 3-15).

Notice: Keep in mind that a change in the baud rate

and/or address is password protected. Step 5

may require the entry of a valid password

before any changes are accepted. If the programmer was already turned on, and a valid

password was initially entered as described in

paragraph 3-4 Method 1, entry of a password

will not be required again and the baud rate

and/or address changes will be saved. If a

valid password was not initially entered, the

display will require the entry of a valid password before any changes can be saved (Figure

3-8). Follow the steps outlined in paragraph 34 Method 2 to enter a valid password.

Notice: Any time a circuit breaker address or baud rate

is changed, verify that the correct address and

baud rate are displayed by using the Right-

Arrow or Left Arrow p u s h b u t t o n s to move the

blinking cursor in the main menu to Find

Baud/Addr (FI). Use the Select pushbutton to

enter Find Baud/Addr (FI), and the newly

assigned address and selected baud rate will

be displayed.

3-6.2 INCOM CONNECTED ADDRESS AND BAUD

RATE

Step 1: If the programmer is INCOM connected and a

Baud Rate and/or Address Change to a net-

Effective 8/99

Page 24

I.B. 29C892B

Page 19

<ID BA RP ME>

METERED VALUES

Figure 3-22 Cursor on Metered Values in Main Menu

IA IB IC IG

PHASE A

Figure 3-23 First Display in Metered Values

work connected circuit breaker is required,

proceed by using the On/Off pushbutton to

turn the programmer on.

Notice: Keep in mind that a change in the baud rate

and/or address is password protected. Entry of

a valid password will be required before any

changes are accepted. If the programmer was

already turned on, and a valid password was

initially entered as described in paragraph 3-4

Method 1, entry of a password will not be

required again and the baud rate and/or

address changes will be saved. If a valid password was not initially entered, the display will

require the entry of a valid password before

any changes can be saved (Figure 3-8). Follow

the steps outlined in paragraph 3-4 Method 2

to enter a valid password.

Step 2: Once the main menu is displayed, use the

Select pushbutton to enter Select Address

(SA) which is active as indicated by the blink-

ing cursor. This network display provides a

means for selecting the three digit address of

the circuit breaker of interest within the network

(Figure 3-16). The blinking cursor indicates

which of the three digits is active and able to

be changed.

Step 3: Use the Up or Down pushbuttons to change

the active digit. Use the Right-Arrow or Left-

Arrow pushbuttons to move the cursor from

one digit to another.

Step 4: Once the desired breaker address is displayed,

IA IB IC IG

PHASE B

Figure 3-24 Cursor Indicating Phase B Current Active

IA IB IC IG

PHASE B 600

Figure 3-25 PHASE B (IB) Current Selected and

Displayed

hold Save pushbutton depressed and depress

Select pushbutton. This simultaneous use of

the two pushbuttons will enter the address of

the circuit breaker in question. The user will be

automatically returned to the main menu

(Figure 2-9).

Step 5: Proceed with Step 4 and 5 of paragraph 3-5.1

to complete the process.

3-7 CONFIGURE TRIP UNIT

The OPTIMizer Hand Held Programmer can be used to

program the protective, coordination and alert features

of OPTIM 550, 750 and 1050 Trip Units, such as:

• Time-Current Setpoints

• Protection Options

• High Load Alarm

• Phase A Identification

The features to be configured are contained under the

Setpoints (SP) option of the main menu (Table 2.1).

Proceed with the following steps as a guide to configur-

ing a trip unit:

Step 1: Use the On/Off pushbutton to turn the pro-

grammer on.

Step 2: Since a valid password will be required to con-

figure the trip unit, it is recommended that

paragraph 3-4 “Security Password” be

reviewed before moving into the Setpoints

Effective 8/99

Page 25

Page 20

I.B. 29C892B

<BA RP ME TM>

TEST MODE

Figure 3-26 Cursor on Test Mode in Main Menu

PHASE GND

**PHASE TEST**

Figure 3-27 First Display in Test Mode

TRIP< >NO TRIP

**TRIP**

Figure 3-28 Displayed Choices After Phase or Ground

AUX.POWER NEEDED

FOR TRIP TEST

Figure 3-29 Momentary Notice Displayed

GETTING

FRAME/PLUG VALUE

Figure 3-30 Momentary Notice Displayed

ENTER CURRENT IN

AMPS 400

Figure 3-31 Displayed Choice After Trip or No Trip

(SP) option. Method 1 or Method 2 can be

used to enter a valid password, although

Method 1 is recommended. Directions on how

to enter a password will not be given in the following steps covering setpoint changes.

Step 3: Once a valid password is entered and accept-

ed, use the Right-Arrow or Left-Arrow pushbuttons to move the blinking cursor to

Setpoints (SP) (Figure 3-17).

Step 4: Use the Select pushbutton to enter Setpoints

(SP) (Figure 3-18). The blinking cursor indi-

cates which programmable category is active

and available for programming. The second

line of the display defines the active category.

Step 5: Use of the Right-Arrow or Left-Arrow push-

buttons to move from one programmable category to another (Figure 3-19).

Step 6: Use the Select pushbutton to enter an active

category, such as Long Delay Slope (Figure

3-20). The present programmed setpoint for

Long Delay Slope is I2t, for example.

Step 7: Use the Up or Down pushbuttons to establish

a new setpoint, such as I4t (Figure 3-21).

Step 8: Hold Save pushbutton depressed and depress

Select pushbutton. This simultaneous use of

the two pushbuttons will enter the new setpoint

into memory.

Notice: Keep in mind that changes must be saved indi-

vidually to minimize the possibility that re-programming would be required if the programmer

turns itself off during the programming process.

Step 9: All setpoint changes are made using the same

repetitive steps just described.

3-8 DISPLAYED INFORMATION

The OPTIMizer Hand Held Programmer displays a comprehensive list of:

• Circuit Breaker Information

• Time-Current Setpoints

• Metered Values

• Trip Event Information

Use the following steps as a guide for obtaining specific

displayed information:

Step 1: Use the On/Off pushbutton to turn the pro-

Effective 8/99

Page 26

I.B. 29C892B

SHORT DELAY TRIP

Page 21

Step 9: Repeating Steps 7 and 8 will permit the view-

ing of all the metered values outlined in Table

2.1.

TRIP TIME .03s

Figure 3-32 Typical Cause of Trip Message

grammer on. If the programmer is directly connected to a trip unit, it will momentarily identify

the baud rate and address, and move to the

main menu (Figure 2-9). If the programmer is

INCOM connected, proceed with Steps 2, 3

and 4, otherwise move directly to Step 5.

Step 2: Once the main menu is displayed, use the

Select pushbutton to enter Se l e c t Ad d r e s s

( S A ) which is active as indicated by the blinking

cursor. This network display provides a means

for selecting the three digit address of the circuit

breaker of interest within the network (Figure 3 -

1 6). The blinking cursor indicates which of the

three digits is active and able to be changed.

Step 3: Use the Up or Down pushbuttons to change

the active digit. Use the Right-Arrow or Left-

Arrow pushbuttons to move the cursor from

one digit to another.

Step 4: Once the desired breaker address is displayed,

hold Save pushbutton depressed and depress

Select pushbutton. This simultaneous use of

the two pushbuttons will enter the address of

the circuit breaker in question, and the main

menu will be displayed.

Step 5: Use the Right-Arrow or Left-Arrow pushbut-

tons to move the cursor to Metered Values

(ME) in the main menu (Figure 3-22).

Step 6: Use the Select pushbutton to enter Metered

Values (ME) and the first four metered values

are displayed with the blinking cursor indicating

that Phase A Current is active (Figure 3-23).

Step 7: Use the Right-Arrow or Left-Arrow pushbut-

tons to move the blinking cursor to a metered

value of interest, Phase B current for example

(Figure 3-24).

Step 8: Use the Select pushbutton to choose the

metered value of interest and have the present

value displayed (Figure 3-25).

Step 10: Use the Up-Arrow pushbutton to return to the

main menu (Figure 2-9).

3-9 TEST TRIP UNIT

Digitrip OPTIM 550, 750 and 1050 Trip Units contain a

test capability. One of the means for performing tests is

through the use of the OPTIMizer Hand Held Programmer. The intent is to permit the periodic performance of

tests that verify the functional performance of the trip

unit. Two types of testing are possible through the use

of the OPTIMizer Hand Held Programmer, the “No-Trip”

and the “Trip” tests.

No-Trip Test: This test can be performed using the

internal battery power of the programmer. It verifies that

the trip unit is performing under test within acceptable

limits of the programmed protective setpoints.

Trip Test: This test can only be performed using external power supplied by an Auxiliary Power Module or by

auxiliary power supplied to the circuit breaker. The additional power is required to activate the breaker’s flux

transfer shunt trip. This test verifies the trip unit’s performance, as well as the trip circuitry and mechanical operation of the circuit breaker.

Notice: Keep in mind that an Auxiliary Power Module is

required to perform a “Trip” test. Refer to paragraph 2-2.2 for details on the use of an

Auxiliary Power Module.

Notice: Basic protection functions are not affected dur-

ing the performance of testing procedures.

Proceed with the following steps to perform a “Trip” or a

“No-Trip” test:

Step 1: With the programmer turned on and the main

menu displayed, use the Right-Arrow or Left-

Arrow pushbuttons to move the blinking cursor

to Test Mode (TM) (Figure 3-26).

Step 2: Use the Select pushbutton to enter the Test

Mode (TM). The blinking cursor indicates

which test category is active and able to be

selected (Figure 3-27).

Step 3: Use the Right-Arrow or Left-Arrow pushbut-

tons, if required, to move the blinking cursor to

a different test category. Use the Select push-

Effective 8/99

Page 27

Page 22

I.B. 29C892B

button to choose a particular category, Phase

for example, and the next selections are displayed Trip or No Trip (Figure 3-28).

Step 4: Once again, use the Right-Arrow or Left-

Arrow pushbuttons, if required, to move to a

different test category. Use the Select pushbutton to choose a particular category, Trip for

example, and two different notices are momentarily displayed before the next selection

appears (Figures 3-29 and 3-30).

Step 5: After the two momentary displays, the test cur-

rent screen is displayed permitting the selection of the desired test current (Figure 3-31).

Step 6: The blinking cursor indicates the selectable test

current field. The current initially displayed is

the minimum test current value. Use the U p o r

Down pushbuttons to alter the current value.

Step 7: Once all the test parameters have been select-

ed, hold Save pushbutton depressed and

depress Select pushbutton to initiate the test.

When the test is completed, a cause of trip

message is displayed (Figure 3-32).

3-10.1 USING THE COPY COMMAND (CP)

Plug the OPTIMizer into the trip unit that the settings are

to be copied from. Move the cursor to the main menu

item CP. Press the Select key and wait while the

OPTIMizer reads the trip unit’s setpoints. The message

Accepted will be displayed if the copy was successfully

completed. The settings are now stored within the

OPTIMizer's memory and will be retained even after the

OPTIMizer is turned off.

3-10.2 USING THE DOWNLOAD COMMAND (DL)

Plug the OPTIMizer into the trip unit that the stored

settings are to be downloaded to. Enter the password

for the OPTIMizer within the password main menu item

PA. Move the cursor to the main menu item DL. Press

the Select key and wait while the OPTIMizer gets the

address of the trip unit and then downloads the

OPTIMizer's stored settings to the trip unit. If the

OPTIMizer’s password was not entered, the operator

will be required to first enter their password and then

reselect the Download menu item from the main menu.

The message Accepted will be displayed if the settings

were successfully downloaded.

Step 8: Use the Up-Arrow pushbutton to return to the

main menu.

Testing will not be permitted to proceed if there is

greater than 0.4 per unit of current flowing on a phase

circuit or 0.2 per unit of current on a ground circuit. The

maximum permitted current value can be determined by

multiplying the appropriate per unit value (0.4 or 0.2)

times the ampere rating of the installed rating plug.

Notice: For currents less than the trip unit setpoint, no

message is displayed after the “Accepted

Message.” The trip unit will not be placed in a

Test Mode and, therefore, no pickup LEDs will

flash. The trip unit, however, must be reset.

The OPTIMizer will eventually return to the

main menu.

3-10 COPY AND DOWNLOAD COMMANDS

The OPTIMizer can quickly download trip unit setpoints

from one breaker to other breakers in a system. The

per-unit values (not the current ampere values) are

copied from one breaker and downloaded to any other

breaker in the OPTIM family within a system. The settings are permanently retained in the memory of the

OPTIMizer until another copy sequence replaces them.

Notice: The Copy /Download commands will not

change factory enabled functions such as

ground fault trip or alarm. When copying from a

trip unit with ground fault trip to a trip unit with

ground fault alarm, only the pick-up, slope, and

time adjustments are copied.

Some breakers such as the DS will have setting limitations based on the rating plug value. If settings are

downloaded which are not within the allowable limits of

the trip unit and rating plug, an error message will be

displayed. See I.L. 29C891 Table 3.3 for allowable settings. This may also be the case for ground fault settings in breakers above 1200 amps.

3-11 RESET TRIP UNIT (RE)

The trip unit status indicators are generally reset by

pressing the Reset pushbutton on the trip unit. In some

instances, such as when a motor operator is used with

on an OPTIM breaker, it may be desirable to use a

remote reset. The reset trip feature is used in this case.

Effective 8/99

Page 28

I.B. 29C892B

Page 23

Effective 8/99

SECTION 4: TROUBLESHOOTING AND

MAINTENANCE

4-1 LEVEL OF REPAIR

This manual is written based on the assumption that

only unit-level troubleshooting will be performed. If the

cause of a malfunction is traced to an OPTIMizer Hand

Held Programmer, the device should be replaced. The

malfunctioning programmer should be returned to

Cutler-Hammer.

4-2 TROUBLESHOOTING

Refer to Table 4.1 for troubleshooting guidelines.

4-3 MAINTENANCE AND CARE

The OPTIMizer Hand Held Programmer is designed to

be a self contained and maintenance free device,

except for battery replacement. Refer to paragraph 2-

2.1 for battery information.

The OPTIMizer Hand Held Programmer should be

stored in an environment that does not exceed the storage temperature range of -30°C to +85°C. The environment should also be free of excess humidity. Store the

device in its original packing material or the provided

carrying case.

4-4 RETURN PROCEDURE

The Troubleshooting Guide (Table 4.1) is intended for

service personnel to identify whether a problem being

observed is external or internal to the device. If a problem is determined to be internal, the device should be

returned to the factory for replacement. To have an

OPTIMizer returned, contact your local Cutler-Hammer

authorized distributor.

4-5 TECHNICAL ASSISTANCE

For information, technical assistance or referral to a

local authorized distributor, contact the Advanced

Product Support Center at 412-494-3750.

Page 29

I.B. 29C892B

Page 24

Effective 8/99

“Low Battery – Replace Soon”

Replace with Lithium battery or use

displayed as on/off is Dead Battery

auxiliary power module

Aux. supply #PRTAAPM, Table 2.2

depressed

“Connection Failure” when

Custom phone cord not

Check connection to OPTIMizer or

selecting “Find Address”

plugged into OPTIMizer or

trip unit

Paragraphs 2-2.2 and 3-2

OPTIM trip unit

OPTIMizer powers down Battery power is insufficient for

Change battery Paragraph 2-2.1

repeatedly proper operation

Warning displayed while

Short delay slope is not set to

Change short delay slope and long Paragraph 3-6 and appropriate

changing long delay slope

flat; long delay time not set to