Page 1

Intelligent Technologies (IT.)

D77A I/O Module Products

Installation and User Manual

November 2006

Supersedes October 2005

Part Numbers

D77A-DI8 D77A-RQ8

D77A-DI16 D77A-RQ16

D77A-DQ8 D77A-DI8DQ8

D77A-DQ16 D77A-DI8RQ8

D77A-AI8 D77A-AI8AQ8

D77A-AI16 D77A-AI8RQ8

D77A-AQ8 D77A-NI4

D77A-AQ16 D77A-NQ2

MN05002001E For more information visit: www.EatonElectrical.com

Page 2

Page 3

Intelligent Technologies (IT.) D77A I/O Module Products

Important Notice — Please Read

The product discussed in this literature is subject to terms and conditions outlined in Eaton Electrical Inc. selling policies. The sole

source governing the rights and remedies of any purchaser of this equipment is the relevant Eaton Electrical Inc. selling policy.

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE OR

MERCHANTABILITY, OR WARRANTIES ARISING FROM COURSE OF DEALING OR USAGE OF TRADE, ARE MADE REGARDING THE

INFORMATION, RECOMMENDATIONS AND DESCRIPTIONS CONTAINED HEREIN. In no event will Eaton Electrical Inc. be responsible

to the purchaser or user in contract, in tort (including negligence), strict liability or otherwise for any special, indirect, incidental or

consequential damage or loss whatsoever, including but not limited to damage or loss of use of equipment, plant or power system,

cost of capital, loss of power, additional expenses in the use of existing power facilities, or claims against the purchaser or user by its

customers resulting from the use of the information, recommendations and descriptions contained herein.

The information contained in this manual is subject to change without notice.

®

Cover Photo: Eaton’s Cutler-Hammer

Intelligent Technologies (IT.) D77A I/O Module Products

MN05002001E For more information visit: www.EatonElectrical.com i

Page 4

Intelligent Technologies (IT.) D77A I/O Module Products

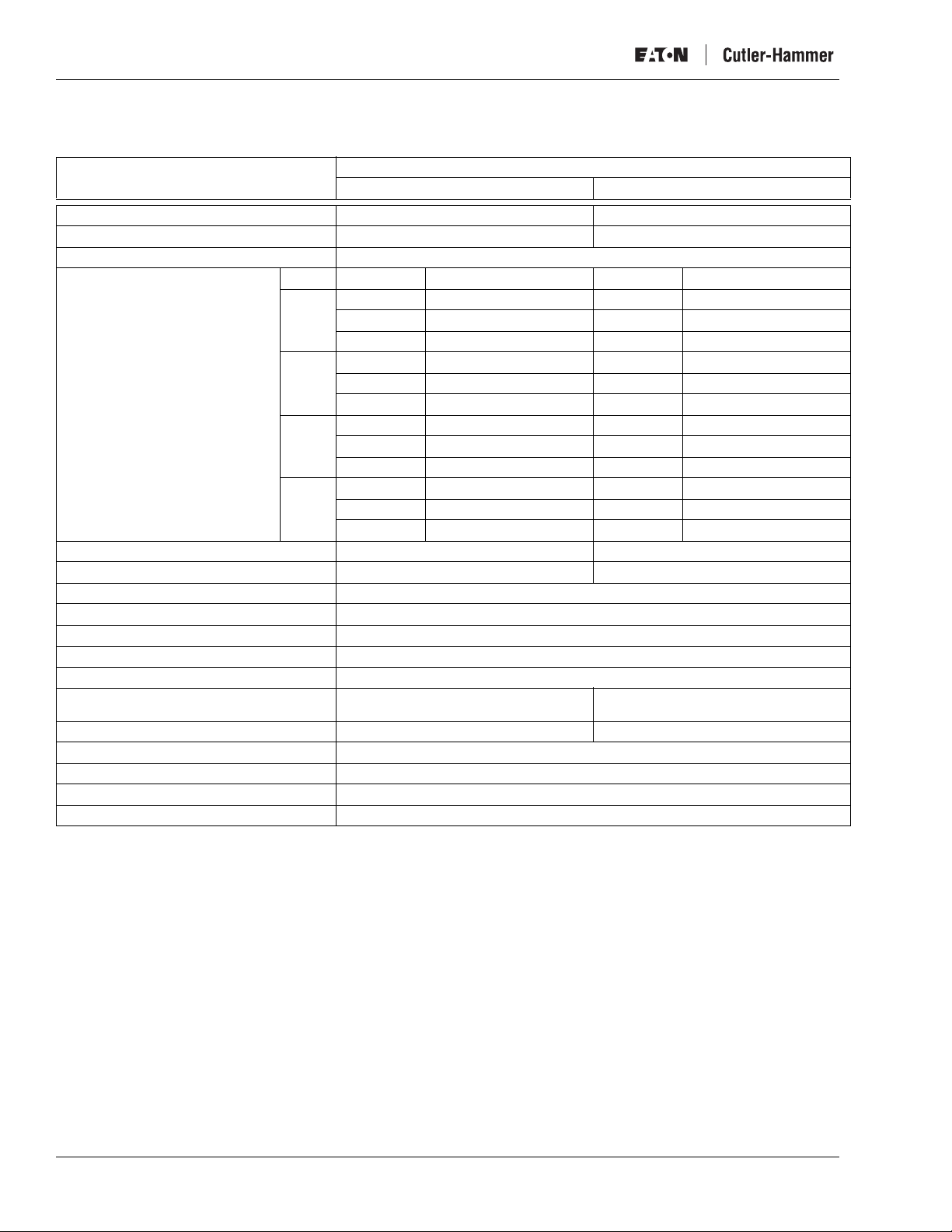

Table of Contents

LIST OF FIGURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

LIST OF TABLES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Definitions and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Hazardous High Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Component Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Catalog Numbering System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Surge Suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Device Default I/O Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

I/O Module Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Output Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Special I/O Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

THEORY OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Out-of-box Default Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Typical Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

I/O Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Setting Group ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

QCPort Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

TROUBLESHOOTING AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Renewal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Communication Troubleshooting Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

APPENDIX A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Data Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Analog Data Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

IT. PUBLICATIONS AND SUPPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

ii For more information visit: www.EatonElectrical.com MN05002001E

Page 5

List of Figures

Figure 1: I/O Module Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 2: Module Physical Dimensions, mm [in] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3: AC Input Module Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4: DC Input Module Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 5: D77A-NI4 Analog Input Module Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6: Analog Input Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 7: AC Output Module Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 8: DC Output Module Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 9: Relay Output Module Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 10: D77A-NQ2 Combination Module Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 11: Analog Output Curves for 14 Bit Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 12: D77A-DI8DQ8 Combination Module Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 13: D77A-DI8RQ8 Combination Module Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 14: D77A-AI8AQ8 Combination Module Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 15: D77A-AI8RQ8 Combination Module Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 16: Panel Layout: Adapter, I/O and QSNAP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 17: Discrete Input Module Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 18: Discrete Output Module Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 19: Discrete Combination Module Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 20: Analog Input Module Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 21: Analog Output Module Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 22: Group ID Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 23: Removable Terminal Locking Tabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 24: Unlock DIN Rail Locking Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 25: Lock DIN Rail Locking Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 26: Removable Terminal Locking Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 27: Removable Terminal Locking Tabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 28: Unlock DIN Rail Locking Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 29: Lock DIN Rail Locking Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 30: Removable Terminal Locking Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 31: QCPort Backplane Interconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 32: QCPort Interconnect Backplane Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 33: QCPort Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 34: I/O Property Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 35: AC Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 36: DC Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 37: Analog Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 38: AC Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 39: DC Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 40: Relay Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 41: Analog Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 42: Combination I/O Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Intelligent Technologies (IT.) D77A I/O Module Products

List of Tables

Table 1: Approvals/Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table 2: Catalog Numbering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table 3: Environmental Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 4: 8 Point Discrete Input Module (Produced) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 5: 8 Point Discrete Output Module (Consumed). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 6: 16 Point Discrete Input Module (Produced) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 7: 16 Point Discrete Output Module (Consumed). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 8: 16 Point Discrete Combination Module (Produced) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 9: 16 Point Discrete Combination Module (Consumed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 10: 4 Channel Analog Input Module (Produced) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 11: 2 Channel Analog Output Module (Consumed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 12: I/O Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 13: AC Input Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 14: DC Input Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 15: D77A-NI4 Analog Input Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 16: AC Output Module Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 17: DC Output Module Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

MN05002001E For more information visit: www.EatonElectrical.com iii

Page 6

Intelligent Technologies (IT.) D77A I/O Module Products

Table 18: Relay Output Module Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 19: D77A-NQ2 Analog Output Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 20: D77A-DI8DQ8 Combination Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 21: D77A-DI8RQ8 Combination Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 22: D77A-AI8AQ8 Combination Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 23: D77A-AI8RQ8 Combination Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 24: Analog Input Signal Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 25: Symbol Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 26: Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 27: Analog 10 Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 28: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 29: I/O Module Renewal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 30: Explanation of LED Duty Cycle States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 31: Status LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 32: Communication Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 33: 0x0001 (1) Production Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 34: 0x0002 (2) Consumption Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 35: 0x0003 (3) QCPort Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 36: 0x0004 (4) Application Status (Available in I/O As Control Elements). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 37: 0x0005 (5) Discrete Data Input (Available in I/O As Control Elements). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 38: 0x0006 (6) Discrete Data Output (Available in I/O As Control Elements) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 39: 0x006B (107) Analog Input Status (Available in I/O As Control Elements) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 40: 0x006C (108) Analog Output Status (Available in I/O As Control Elements). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 41: 0x006F (111) 16 bit Signed Analog Input Data (Available in I/O As Control Elements). . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 42: 0x0070 (112) 16 bit Signed Analog Output Data (Available in I/O As Control Elements) . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 43: 0x8001 (32769) Device Identity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 44: 0x8002 (32770) Configuration CRC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 45: 0x8003 (32771) Node ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 46: 0x8004 (32772) Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 47: 0x8005 (32773) QCPort Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 48: 0x8006 (32774) Slave Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 49: 0x8007 (32775) Production Destination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 50: 0x8008 (32776) Device ID Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 51: 0x8009 (32777) Production Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 52: 0x800A (32778) Consumption Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 53: 0x800B (32779) Parameter List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 54: 0x800C (32780) Production List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 55: 0x800D (32781) Consumption List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 56: 0x800E (32782) Languages Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 57: 0x800F (32783) Language Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 58: 0x8010 (32784) Device Semaphore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 59: 0x8023 (32803) Output Comm Loss Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 60: 0x8024 (32804) Input Debounce. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 61: 0x804D (32845) Physical Node ID Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 62: 0x80CF (32975) Analog Output Communication Loss Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 63: 0x80D0 (32976) Analog Output Communication Loss Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 64: 0x80D1 (32977) Input Range Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 65: 0x80D2 (32978) Analog Output Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 66: Register 1; Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 67: Register 2; Hardware Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 68: Register 3; Analog Filter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 69: IT. Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

. . . . . . . . . . . . . 52

iv For more information visit: www.EatonElectrical.com MN05002001E

Page 7

Intelligent Technologies (IT.) D77A I/O Module Products

Safety

Servicing and operating this I/O system, like all industrial control components and systems, involves significant hazards. The most

obvious hazard is that of electrical shock. These hazards are not limited to electrical shock. They also involve hazards related to

managing energy that is converted from electricity into mechanical energy as motors, solenoids controlled valves and other

equipment perform work. Every effort is made to provide the safest equipment possible. Every effort is made to provide the safest

operating and servicing procedures possible. It is, however, the user’s responsibility to ensure that the design and application are safe

and appropriate.

Throughout this document are found various safety warnings. Observe these messages carefully. Each is described as follows:

Definitions and Symbols

WARNING AVERTISSEMENT ADVERTENCIA

This symbol indicates high voltage. It calls

your attention to items or operations that

could be dangerous to you and other

persons operating this equipment. Read the

message and follow the instructions

carefully.

CAUTION PRÉCAUTION PRECAUCIÓN

Indicates a potentially hazardous situation

which, if not avoided, can result in minor to

moderate injury, or serious damage to the

product. The situation described in the

CAUTION may, if not avoided, lead to

serious results. Important safety measures

are described in CAUTION (as well as

WARNING).

Ce symbole indique la haute tension. Il sert à

attirer votre attention aux articles et

opérations qui pourraient vous être

dangereux, ainsi qu’à tout autre personne

utilisant cet équipement. Lisez ce message

et suivez prudemment les instructions.

.

Indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, peut

entraîner des blessures mineures à

modérées ou de graves dégâts au produit.

La situation décrite dans l’article intitulé

PRÉCAUTION peut, si elle n’est pas évitée,

mener à de sérieux résultats. Les mesures

de sécurité importantes sont décrites dans

les articles intitulés PRÉCAUTION (aussi

bien que AVERTISSEMENT).

Este símbolo indica alto voltaje. Le llama su

atención en cuanto a artículos u operaciones

que pueden ser peligrosas para usted y

otras personas que operan este equipo. Lea

el mensaje y siga cuidadosamente las

instrucciones.

Indica que existe una situación

potencialmente peligrosa, que si no es

evitada, podrá resultar en heridas

corporales menores o moderadas, o en

serios daños al producto. La situación

descrita en la PRECAUCIÓN podrá causar

serios resultados si no es evitada. Medidas

importantes de seguridad son descritas en la

PRECAUCIÓN (como también en la

ADVERTENCIA).

Hazardous High Voltage

WARNING AVERTISSEMENT ADVERTENCIA

Some control equipment and electronic

controllers are connected to hazardous line

voltages. When servicing the I/O system,

related starters and other electronic

controllers, there may be exposure to

components with housings or protrusions at

or above line potential. Extreme care should

be taken to protect against shock. Stand on

an insulating pad and make it a habit to use

only one hand when checking components.

Always work with another person in case an

emergency occurs. Disconnect power before

checking controllers or performing

maintenance. Be sure equipment is properly

grounded. Wear safety glasses whenever

working on electronic components or

industrial machinery.

Des commandes électroniques et

équipement de commande sont connectés à

des lignes de tension dangereuse. Lors de

l’entretien du système I/O, des démarreurs

et des commandes électroniques connexes,

vous pourrez être exposé à des composants

dont le boîtier et les protubérances

conduisent la tension de la ligne, voire

même supérieure. Vous devriez faire

extrêmement attention à vous protéger

contre les électrochocs. Tenez-vous sur un

tapis isolant et habituez-vous à n’utiliser

qu’une main quand vous contrôlez des

composants. Travaillez toujours en

compagnie d’une autre personne en cas

d’urgence. Coupez le courant avant de

vérifier les commandes ou de réaliser

l’entretien. Assurez-vous que l’équipement

est correctement mis à la terre. Portez des

lunettes de sécurité quand vous travaillez

sur des composants électroniques ou la

machinerie industrielle.

Algunos equipos de control y controladores

electrónicos están conectados a tensiones

de línea peligrosas. Al darle servicio al

sistema de I/O, arranques relacionados y

otros controladores electrónicos, pueda que

hayan componentes expuestos con carcasas

o protuberancias en el potencial de línea o

más altos. Se deberá tener extremo cuidado

para protegerse contra electrochoque.

Párese sobre un tapete aislante y habitúese

a usar sólo una mano al comprobar

componentes. Siempre trabaje con otra

persona en caso que ocurra una

emergencia. Desconecte la energía antes de

comprobar controladores o efectuar

mantenimiento. Asegúrese de que el equipo

esté conectado apropiadamente a tierra. Use

gafas de seguridad cuando trabaje en

componentes electrónicos o en maquinas

industriales.

MN05002001E For more information visit: www.EatonElectrical.com v

Page 8

Intelligent Technologies (IT.) D77A I/O Module Products

General Safety

Notice Avis Aviso

Make sure you read and understand the

installation procedures in this manual

before you attempt to operate or set up the

equipment.

WARNING AVERTISSEMENT ADVERTENCIA

This instruction manual should be used for

proper installation, setup and operation of

the IT. D77A I/O modules. Improperly

installing and maintaining this product can

result in serious personal injury or property

damage. Before attempting installation,

setup or operation, read and understand this

entire manual.

WARNING AVERTISSEMENT ADVERTENCIA

Hazardous voltage can cause electric shock

and burns. Always disconnect power before

proceeding with any work on this product.

Assurez-vous de lire et comprendre les

procédures d’installation comprises dans ce

manuel avant d’essayer d’utiliser ou

d’installer l’équipement.

Ce mode d’emploi devrait être utilisé pour

installer ou opérer correctement les

modules IT. D77A I/O. Mal installer et

maintenir ce produit peut entraîner de

graves blessures corporelles ou de grands

dégâts matériels. Avant d’essayer de

l’installer ou de l’utiliser, lisez et comprenez

ce manuel dans son intégralité.

La tension dangereuse peut causer des

électrochocs et des brûlures. Coupez

toujours le courant avant d’entreprendre

tout travail sur ce produit.

Asegúrese de leer y comprender los

procedimientos de instalación dados en este

manual antes de intentar operar o

configurar el equipo.

Este manual de instrucciones deberá ser

usado para instalar, configurar y operar

apropiadamente el IT. Módulos I/O D77A El

instalar y mantener impropiamente este

producto podrá resultar en serias heridas

corporales o en daños a la propiedad. Antes

de comenzar la instalación, configuración o

la operación, lea y comprenda el manual

completo.

Los voltajes peligrosos pueden causar

electrochoque y quemaduras. Siempre

desconecte la energía antes de proceder con

cualquier trabajo en este producto.

WARNING AVERTISSEMENT ADVERTENCIA

Only apply 24V DC to the I/O module power

terminals. Use of any other voltage may

result in personal injury, property damage

and damage to the IT. D77A I/O module.

WARNING AVERTISSEMENT ADVERTENCIA

To provide continued protection against fire

or shock hazard, the complete IT

modules must be replaced if they become

inoperative.

. D77A I/O

N’appliquez que du courant continu de 24 V

aux bornes de courant des modules I/O.

L’emploi de toute autre tension peut

entraîner des blessures corporelles, des

dégâts matériels et des dégâts au module

IT. D77A I/O.

Pour fournir une protection continue contre

le risque d’incendie ou d’électrochoc, les

modules IT. D77A I/O complets doivent être

remplacés s’ils deviennent inopérables.

Sólo aplique 24V CD a los terminales de

energía del módulo I/O. El uso de cualquier

otro voltaje podrá resultar en heridas

corporales, daños a la propiedad o daños al

IT. Módulo I/O D77A.

Con el fin de suministrar protección

continua contra peligro de fuego o

electrochoque, los módulos I/O D77A

completos del IT. tendrán que ser

reemplazados si se tornan inoperantes.

vi For more information visit: www.EatonElectrical.com MN05002001E

Page 9

Intelligent Technologies (IT.) D77A I/O Module Products

Introduction

Description

Cutler-Hammer® Intelligent Technologies (IT.) D77A I/O Modules from Eaton Corporation® are part of the IT. family of products that

are best by design. These modules are designed and built for industrial applications with standard features including removable

locking terminal blocks and connectivity to IT. motor control. The size and features are a substantive engineering and marketing effort,

involving extensive customer input. For more information on the IT. family of products, visit our website:

www.EatonElectrical.com

IT. D77A I/O discrete modules are available in 8 and 16 point densities, and in AC or DC voltage configurations. Input modules have

two points per isolated common. Output modules are available in relay and solid-state configurations with two points per isolated

common.

The IT. D77A I/O analog modules are available in variable voltage and current loop modules. Input modules support four analog

channels and output modules support two analog channels.

D77A I/O products are designed for industrial applications, installed in a manner consistent with the guidelines outlined in this

document. They are designed for Pollution Degree 2 environments (clean and dry).

Component Characteristics

This section identifies special features engineered into the Cutler-Hammer IT. D77A I/O modules.

All Modules

The IT. D77A I/O modules have the following common features:

• LED Status — When the LED is illuminated the proper ON state signal is received at the input or at the output point.

• Removable Lockable Terminals — Terminals are easily removable for I/O module replacement and are lockable so they will not

vibrate loose. Terminals are available in screw type, cage clamp and insulation displacement.

• Terminal Identification — Each terminal is marked for ease of wiring and troubleshooting.

• Isolation — Each module is optically isolated between the field I/O and the backplane communication.

• Securing Tabs — Each I/O module has a locking mechanism to secure it to the DIN rail.

• Barrier Type Terminals — Each terminal has a barrier to minimize shorting of field wiring.

Discrete Input Modules

The IT. D77A Input modules have the following common feature:

• Adjustable Debounce — Each point has adjustable debounce from 1 to 65 ms.

• Sink/source — Each DC input module has back-to-back LEDs in the optical isolating circuit that can accept sinking or sourcing

signals.

Discrete Output Modules

The IT. D77A I/O Output modules have the following common features:

• Configurable Safe State — Each output point has a loss of communication safe state setting.

• Configurable Power ON State — Each output point has a power-up setting.

MN05002001E

For more information visit: www.EatonElectrical.com 1

Page 10

Intelligent Technologies (IT.) D77A I/O Module Products

Discrete Combination Modules

The input and output features found in the input and output modules are also found in the combination modules.

Analog Input Modules

• Four Analog Channels — Each module has four analog input channels.

• Adjustable Input Filter — Each analog channel can be set for frequencies between 50 and 500 Hz.

• Type Selection — Each analog channel can be set as a voltage input or a current loop input.

Analog Output Modules

• Two Analog Channels — Each analog channel has two analog output channels.

• Type Selection — Each module can be set as a voltage output or a current loop output.

Approval Certifications

Table 1: Approvals/Certifications

Standard Approval/Certifications

Agency Certifications UL 508

Radiated and Conducted Emissions EN 5011 Class A

Electrical/EMC

ESD Immunity (IEC 61000-4-2) ±8 kV air, ±4 kV contact

Radiated Immunity (IEC 61000-4-3) 10 V/m 80 – 1000 MHz, 80% amplitude modulation @ 1 kHz

Fast Transient (IEC 61000-4-4) ±2 kV supply and control

Surge (IEC 61000-4-5) ±1 kV line-to-line

RF Conducted (IEC 61000-4-6) 10V, 0.15 – 80 MHz

Magnetic Field (IEC 61000-4-8) 30 A/m, 50 Hz

Ingress Protection Code IP20

CE (Low Voltage Directive, ATEX Directive)

CUL (CSA C22.2 No. 14)

±1 kV communications

±2 kV line-to-ground

2 For more information visit: www.EatonElectrical.com

MN05002001E

Page 11

Intelligent Technologies (IT.) D77A I/O Module Products

Catalog Numbering System

Catalog numbers have three or five groups of characters, depending on the kind of module the catalog number represents. The

catalog numbering system used for IT. D77A I/O modules is illustrated as follows:

For discrete digital and analog I/O, the first four positions in the first group indicate the product family. The next two places in the

second group indicate the I/O type. The third group uses one or two places to indicate the number of points in the module. The last

group is used only for combination modules.

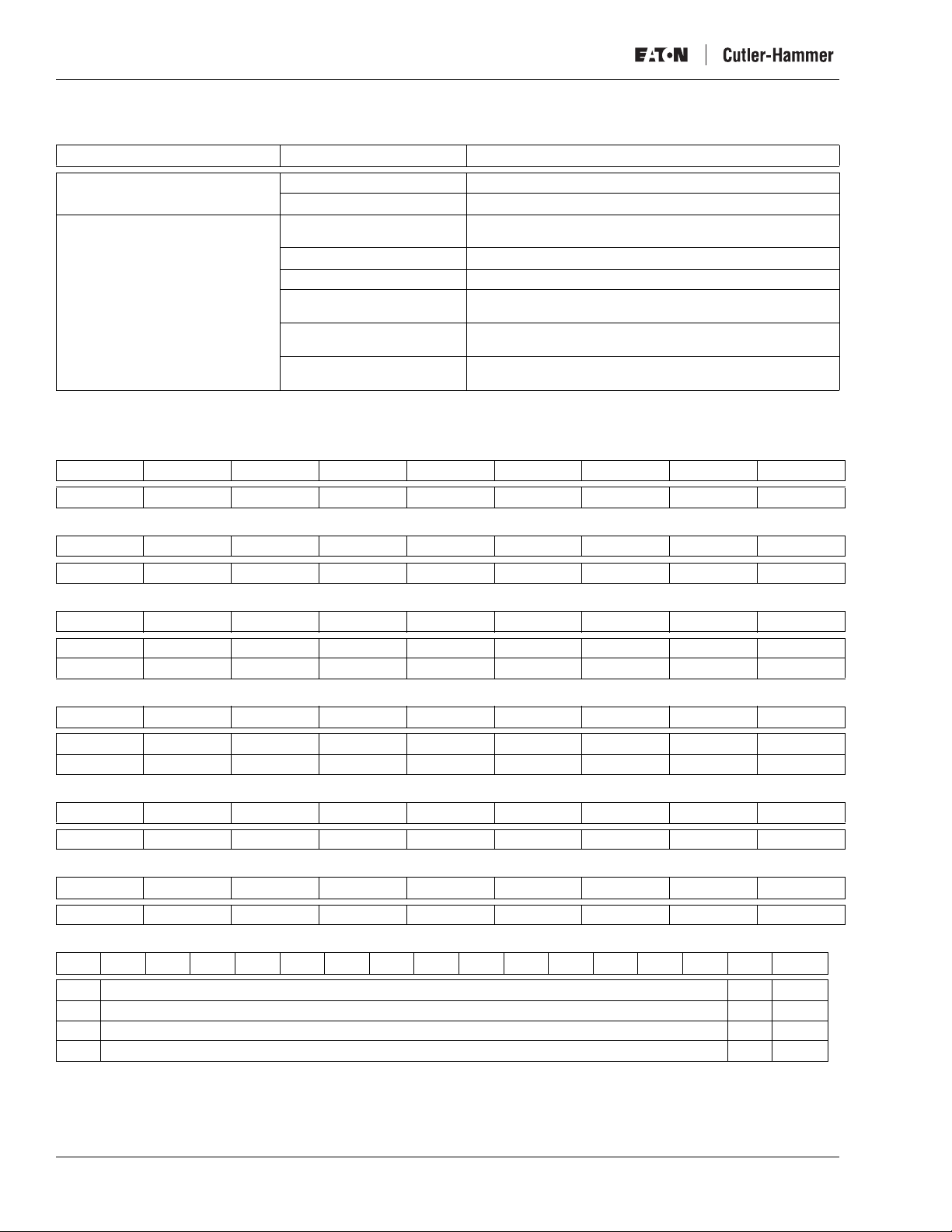

Table 2: Catalog Numbering System

Q

AD77A

-

16 XX

Product Line Prefix

D77A = I/O Module Products

A = AC

D = DC

R = Relay

N = Analog

I/O Type

Input or Output

I = Input

Q = Output

Expansion Module

DQ8 (DC Output, 8 Points)

RQ8 (Relay Output, 8 Points)

AQ8 (AC Output, 8 Points)

Number of Points

2 = 2 Points

4 = 4 Points

8 = 8 Points

16 = 16 Points

MN05002001E

For more information visit: www.EatonElectrical.com 3

Page 12

Intelligent Technologies (IT.) D77A I/O Module Products

Specifications

Physical Description

Figure 1 illustrates the front and back of a typical IT. D77A I/O module.

a

j

24V 8 Pt

i

h

g

f

e

Figure 1: I/O Module Component Location

I

0

14

2

4

12

6

10

8

0

1

C0

2

3

C1

4

5

C2

6

7

C3

a) Number of points

b) Terminal Blocks (Removable)

c) DIN Rail Locking Tab

d) D77 Part Number

e) QC Port, Backplane Connector

f) I/O Status LED

g) Group ID Selector Switch (Address)

h) Status LED

i) I/O Type (“I” for Input, “Q” for Output)

j) Voltage (AC, DC, Relay, Analog)

0

1

C0

2

3

C1

4

5

C2

6

7

C3

b

24V 8 Pt

I

14

12

0

1

C0

2

3

C1

4

5

C2

6

7

C3

0

IT.IT.

2

4

6

10

8

c

d

D

I

8

D77A-001

4 For more information visit: www.EatonElectrical.com

MN05002001E

Page 13

Dimensional Data

Figure 2 illustrates the dimensional data of the IT. D77A I/O modules.

Intelligent Technologies (IT.) D77A I/O Module Products

90

[3.5]

22.5

[0.9]

a b

90

[3.5]

45

[1.8]

Figure 2: Module Physical Dimensions, mm [in]

a) Single Wide Module

b) Double Wide Module

12

[0.5]

68

[2.7]

D77A-002

Note: Ventilation requirements necessitate a minimum of 50 mm (2 in) on the top and bottom of each module and to each side of a

module grouping.

Power Requirements

The current draw for the IT. D77A I/O modules can be found in the module specification table for each specific module type. When

specifying the 24 volt DC power supply, the power rating must support the sum of all the modules’ current draw added to the system

power requirements.

For more information on the sizing of power supplies, refer to the IT. QCPort System Install and Planning Guide (Publication No.

MN05001002E).

Surge Suppression

IT. D77A Discrete I/O output modules have built-in surge suppression (snubbers) to reduce the effects of transient voltages. When

connecting output devices that have inductive loads (e.g., solenoids, relays, motor starters, etc.) additional surge suppression is

recommended and should be added across the load. The addition of customer-supplied surge suppression for inductive loads

prolongs the D77A output life.

MN05002001E

For more information visit: www.EatonElectrical.com 5

Page 14

Intelligent Technologies (IT.) D77A I/O Module Products

Environmental Specifications

Table 3: Environmental Ratings

Category Description Specification

Transportation

and Storage

Temperature -50°C to 80°C [-58°F to 176°F]

Humidity 5 – 95% non-condensing

Operating Temperature -25°C to 55°C [-13°F to 131°F]

0°C to 55°C [32°F to 131°F] (analog I/O only)

Humidity 5% – 95% non-condensing

Altitude Above 2000 meters [6600 feet] consult factory

Shock

(IEC 68-2-27)

Vibration

(IEC 68-2-6)

15G any direction for 11 milliseconds

Relay Operation 8G any direction

5 – 150 Hz, 5G, 0.7 mm maximum peak-to-peak

Relay Operation 10 – 55 Hz, 3G, 0.7 mm maximum peak-to-peak

Pollution Degree Devices are intended to be installed in a pollution degree 2

environment.

Device Default I/O Data

The following tables display the device default data mapping for D77A I/O modules as the data would appear on a network.

Table 4: 8 Point Discrete Input Module (Produced)

Bit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0Byte

I7 I6 I5 I4 I3 I2 I1 I0 0

Table 5: 8 Point Discrete Output Module (Consumed)

Bit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0Byte

Q7 Q6 Q5 Q4 Q3 Q2 Q1 Q0 0

Table 6: 16 Point Discrete Input Module (Produced)

Bit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0Byte

I7 I6 I5 I4 I3 I2 I1 I0 0

I15 I14 I13 I12 I11 I10 I9 I8 1

Table 7: 16 Point Discrete Output Module (Consumed)

Bit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0Byte

Q7 Q6 Q5 Q4 Q3 Q2 Q1 Q0 0

Q15 Q14 Q13 Q12 Q11 Q10 Q9 Q8 1

Table 8: 16 Point Discrete Combination Module (Produced)

Bit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0Byte

I7 I6 I5 I4 I3 I2 I1 I0 0

Table 9: 16 Point Discrete Combination Module (Consumed)

Bit 7Bit 6Bit 5Bit 4Bit 3Bit 2Bit 1Bit 0Byte

Q7 Q6 Q5 Q4 Q3 Q2 Q1 Q0 1

Table 10: 4 Channel Analog Input Module (Produced)

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 WORD

SB * Analog Input Data/Channel 0 N/A** 0

SB * Analog Input Data/Channel 1 N/A** 1

SB * Analog Input Data/Channel 2 N/A** 2

SB * Analog Input Data/Channel 3 N/A** 3

*Sign Bit

1 = True (-)

0 = False (+)

**Not Used

6 For more information visit: www.EatonElectrical.com

MN05002001E

Page 15

Intelligent Technologies (IT.) D77A I/O Module Products

Table 11: 2 Channel Analog Output Module (Consumed)

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0 WORD

SB * Analog Output Data/Channel 0 N/A**

SB * Analog Output Data/Channel 1 N/A**

*Sign Bit

1 = True (-)

0 = False (+)

**Not Used

I/O Module Summary

Table 12: I/O Devices

Part Nu mber

AC D77A-AI8 120V AC Input AC Input Module Page 8

D77A-AI16 120V AC Input AC Input Module Page 8

D77A-AQ8 120V AC Output AC Output Module Page 13

D77A-AQ16 120V AC Output AC Output Module Page 13

DC D77A-DI8 24V DC Input DC Input Module Page 9

D77A-DI16 24V DC Input DC Input Module Page 9

D77A-DQ8 24V DC Output DC Sink Output

D77A-DQ16 24V DC Output DC Sink Output

Relay D77A-RQ8 0 – 30V DC Output Relay Output Module Page 15

D77A-RQ16 0 – 30V DC Output Relay Output Module Pa ge 15

Combo D77A-DI8DQ8 24V DC Input Combination Module Page 18

D77A-DI8RQ8 24V DC Input Combination Module Pa ge 19

D77A-AI8AQ8 120V AC Input Combination Module Page 20

D77A-AI8RQ8 120V AC Input Combination Module Pa ge 21

Analog D77A-NI4 0 – 5V Input Analog Module Page 10

D77A-NQ2 0 – 5V Output Analog Module Page 16

Volt ag e

(Current) Type (I/O) Description Page

Module

Module

0 – 125V AC

0 – 125V AC

24V DC Output

Relay Output

120V AC Output

Relay Output

1 – 5V

0 – 10V

0 – 20 mA

4 – 20 mA

1 – 5V

0 – 10V

0 – 20 mA

4 – 20 mA

Page 14

Page 14

0

1

MN05002001E

For more information visit: www.EatonElectrical.com 7

Page 16

Intelligent Technologies (IT.) D77A I/O Module Products

Input Specifications

AC Input Module Specifications

Table 13: AC Input Module Specifications

Catalog Number D77A-AI8 D77A-AI16

Nominal Input Voltage 120V AC, 50/60 Hz 120V AC, 50/60 Hz

Operating Voltage 80 – 140V AC, 50/60 Hz 80 – 140V AC, 50/60 Hz

Number of Inputs 8 16

Points per Common 2 2

OFF State Voltage 0 – 30V AC * 0 – 30V AC *

ON State Voltage 80V AC – 140V AC 80V AC – 140V AC

Nominal Input Current 15 mA 15 mA

Signal Delay 8.33 ms @ 60 Hz / 10 ms @ 50 Hz 8.33 ms @ 60 Hz / 10 ms @ 50 Hz

QCPort Current Draw 33 mA 46 mA

Isolation 1.5kV 1.5kV

Terminal Screw Torque 4.5 inch-pounds

(0.51 Newton-meters)

* A 50V transition range exists between 30V and 80V.

4.5 inch-pounds

(0.51 Newton-meters)

VAC

VAC

VAC

VAC

a

Ø

1

CØ

2

3

C1

4

5

C2

6

7

C3

Ø

1

CØ

VAC VAC

2

3

VAC VAC

C1

4

5

C2

VAC VAC

6

7

C3

VAC

VAC

b

8

9

C4

COM

10

11

C5

12

13

C6

14

15

C7

IN

IN

c

D77A-006

Figure 3: AC Input Module Diagrams

a) D77A-AI8, Eight-Point Module

b) D77A-AI16, Sixteen-Point Module

c) Internal Circuit

8 For more information visit: www.EatonElectrical.com

MN05002001E

Page 17

Intelligent Technologies (IT.) D77A I/O Module Products

DC Input Module Specifications

Table 14: DC Input Module Specifications

Catalog Number D77A-DI8 D77A-DI16

Type Sink/Source Sink/Source

Nominal Input Voltage 24V DC 24V DC

Operating Voltage 18 – 30V DC 18 – 30V DC

Number of Inputs 8 16

Points per Common 2 2

Signal Delay 5 ms 5 ms

OFF State Voltage 0 – 6V DC * 0 – 6V DC *

ON State Voltage 18V – 30V DC 18V – 30V DC

Nominal Input Current 5 mA 5 mA

QCPort Current Draw 35 mA 63 mA

Isolation 1.5kV 1.5kV

Terminal Screw Torque 4.5 inch-pounds

(0.51 Newton-meters)

* A 12V transition range exists between 6V and 18V.

4.5 inch-pounds

(0.51 Newton-meters)

VDC

VDC

VDC

VDC

a

VDC

VDC

VDC

VDC

Ø

1

CØ

2

3

C1

4

5

C2

6

7

C3

Ø

1

CØ

2

3

C1

4

5

C2

6

7

C3

VDC

VDC

VDC

VDC

C4

10

11

C5

12

13

C6

14

15

C7

8

9

IN

IN

COM

c

D77A-008

b

Figure 4: DC Input Module Diagrams

a) D77A-DI8, Eight-point Module

b) D77A-DI16, Sixteen-point Module

c) Internal Circuit

MN05002001E

For more information visit: www.EatonElectrical.com 9

Page 18

Intelligent Technologies (IT.) D77A I/O Module Products

Analog Input Module Specifications

Table 15: D77A-NI4 Analog Input Module Specifications

D77A-NI4

Catalog Number

Voltage Input 0 – 5V, 1 – 5V, 0 – 10V DC —

Current Input — 4 – 20 mA, 0 – 20 mA

Input Type Single End, Uni-polar

Resolution

Note: Input filter settings affect the

effective resolution of the channels.

Input Full Scale Range 0 – 10.5V or 0 – 5.25V 0 – 21 mA

Maximum Overload at Input Terminal 30VDC 32 mA

Number of Channels 4

Selectable Input Filter Frequency 50Hz, 60Hz, 250Hz, 500Hz

Input Group-to-Bus Isolation 500 VAC for 60 seconds

Common Mode Rejection Greater than 60 db @ 50/60 Hz

Normal Mode Rejection ratio -50 db @ 50/60 Hz

Accuracy +/– 0.3% Full Scale @ 25°C

Input Impedance 15M ohm 250 ohm

Operating Temperature 0–55°C

Status LED Indication Module Status

QCPort Current Draw 60 mA

Terminal Screw Torque 4.5 inch-pounds (0.51 Newton-meters)

50Hz 0-5VDC 14 bit 0-20mA 14 bit

60Hz 0-5VDC 14 bit 0-20mA 14 bit

250Hz 0-5VDC 14 bit 0-20mA 12 bit

500Hz 0-5VDC 9 bit 0-20mA 9 bit

Voltage Input Current Loop Input

Voltage Resolution Current Resolution

0-10VDC 14 bit 4-20mA 14 bit

1-5VDC 14 bit

0-10VDC 14 bit 4-20mA 14 bit

1-5VDC 14 bit

0-10VDC 13 bit 4-20mA 12 bit

1-5VDC 12 bit

0-10VDC 10 bit 4-20mA 9 bit

1-5VDC 9 bit

+/– 0.4% Full Scale @ 0-55°C

+/– 0.45% Full Scale @ 25°C

+/– 0.5% Full Scale @ 0-55°C

(See Figure 5 for circuit diagram)

10 For more information visit: www.EatonElectrical.com

MN05002001E

Page 19

Intelligent Technologies (IT.) D77A I/O Module Products

+

(V)

-

+

(V)

-

+

(V)

-

+

(V)

-

NC

NC

NC

NC

V0

I0

C0

V1

I1

C1

V2

I2

C2

V3

I3

C3

a b

Figure 5: D77A-NI4 Analog Input Module Diagrams

a) D77A-NI4 Voltage Input Channels

b) D77A-NI4 Current Input Channels

(See D77A-NI4 Analog Input Module Specifications on page 10)

(I)

(I)

(I)

(I)

V2

V0

C0

V1

C2

V3

C3

C1

I0

I1

I2

I3

JIC-0013

MN05002001E

For more information visit: www.EatonElectrical.com 11

Page 20

Intelligent Technologies (IT.) D77A I/O Module Products

32766

31206

0

0V

(A)

32766

31206

0

(D)

14 Bit Resolution Equations

Vdc = Voltage input value

mA = Current input value

N = Decimal value

0-5 Vdc, 1-5 Vdc

• Vdc = (1/6241.2) x N

0-10 Vdc

• Vdc = (1/3120.6) x N

4-20 mA, 0-20 mA

• mA = (1/1560.2) x N

32766

31206

6242

3120

0

32766

31206

6242

4992

0V

1V

0.5V

0

3.2mA

(B) (C)

4mA

5.25V5V

21mA20mA0mA

5.25V5V

21mA20mA0mA

(E)

Figure 6: Analog Input Curves

a) 0-5V Range Setting

b) 1-5V Range Setting

c) 0-10V Range Setting

d) 0-20mA Range Setting

e) 4-20mA Range Setting

32766

31206

0

0V

10.5V10V

D77A-031

12 For more information visit: www.EatonElectrical.com

MN05002001E

Page 21

Intelligent Technologies (IT.) D77A I/O Module Products

Output Specifications

AC Output Module Specifications

Table 16: AC Output Module Specifications

Catalog Number D77A-AQ8 D77A-AQ16

Nominal Output Voltage 120V AC, 50/60 Hz 120V AC, 50/60 Hz

Operating Voltage 80 – 140V AC, 50/60 Hz 80 – 140V AC, 50/60 Hz

Number of Outputs 8 16

Points per Common 2 2

Minimum Load Current (Resistive) 15 mA 15 mA

Max. Current/Point (Resistive) .5A @ 30°C

.1A @ 55°C

Max. Current/Module (Resistive) .4A @ 30°C

.8A @ 0-55°C

Surge Current (10 ms) 10A 10A

OFF State Leakage 2 mA 2 mA

Signal Delay 8.33 ms @ 60 Hz

10 ms @ 50 Hz

QCPort Current Draw 120 mA 220 mA

Isolation 1.5kV 1.5kV

Terminal Screw Torque 4.5 inch-pounds

(0.51 Newton-meters)

.5A @ 30°C

.1A @ 55°C

8A @ 30°C

1.6A @ 0-55°C

8.33 ms @ 60 Hz

10 ms @ 50 Hz

4.5 inch-pounds

(0.51 Newton-meters)

CR

CR

VAC

CR

CR

VAC

CR

CR

VAC

CR

CR

VAC

a

CØ

C1

C2

C3

Ø

1

2

3

4

5

6

7

CR

CR

VAC

CR

CR

VAC

CR

CR

VAC

CR

CR

VAC

1

2

CØ

2

3

C1

4

5

C2

6

7

C3

b

CR

CR

VAC

CR

CR

VAC

CR

CR

VAC

CR

CR

VAC

C4

10

11

C5

12

13

C6

14

15

C7

8

9

L2

OUT

OUT

c

D77A-007

Figure 7: AC Output Module Diagrams

a) D77A-AQ8, Eight-Point Module

b) D77A-AQ16, Sixteen-Point Module

c) Internal Circuit

MN05002001E

For more information visit: www.EatonElectrical.com 13

Page 22

Intelligent Technologies (IT.) D77A I/O Module Products

T

T

DC Output Module Specifications

Table 17: DC Output Module Specifications

Catalog Number D77A-DQ8 D77A-DQ16

Type MOSFET Sink MOSFET Sink

Nominal Output Voltage 24V DC 24V DC

Operating Voltage 18 – 30V DC 18 – 30V DC

Number of Inputs 8 16

Points per Common 4 4

Signal Delay 1 ms 1 ms

Max. Current/Point 0.75A 0.75A

Max. Current/Module (Resistive) 6A 12A

Surge Current (10 ms) 4A 4A

OFF State Leakage 1 mA 1 mA

QCPort Current Draw 85 mA 126 mA

Isolation 1.5kV 1.5kV

Terminal Screw Torque 4.5 inch-pounds

(0.51 Newton-meters)

4.5 inch-pounds

(0.51 Newton-meters)

COM

VDC

COM

VDC

Ø

CR

1

CR

2

CR

3

CR

-

+

4

CR

5

CR

6

CR

7

CR

-

+

COM COM

VDC VDC

COM

VDC

a

Ø

CR

1

CR

2

CR

3

CR

-

+

4

CR

5

CR

6

CR

7

CR

-

COM

+

VDC

8

CR

9

CR

10

CR

11

CR

-

+

12

CR

13

CR

14

CR

15

CR

-

+

b

Figure 8: DC Output Module Diagrams

a) D77A-DQ8, Eight-Point Module

b) D77A-DQ16, Sixteen-Point Module

c) Internal Circuit

+24

OU

OU

C

c

D77A-009

14 For more information visit: www.EatonElectrical.com

MN05002001E

Page 23

Intelligent Technologies (IT.) D77A I/O Module Products

Relay Output Module Specifications

Table 18: Relay Output Module Specifications

Catalog Number D77A-RQ8 D77A-RQ16

Nominal Output Voltage 0 – 140V AC

0 – 30V DC

0 – 140V AC

0 – 30V DC

Number of Outputs 8 16

Points per Common 2 2

Relay OFF Time 6 ms 6 ms

Relay ON Time 3 ms 3 ms

Max. Current/Point (Resistive) 3 A 3 A

Max. Current/Module (Resistive) 24 A 48 A

Electrical Life 100,000 Cycles 100,000 Cycles

Mechanical Life 1,000,000 Cycles 1,000,000 Cycles

QCPort Current Draw 92 mA 164 mA

Isolation 1.5 kV 1.5 kV

Terminal Screw Torque 4.5 inch-pounds

(0.51 Newton-meters)

Ø

CR

CR

VAC/DC

CR

CR

VAC/DC

CR

CR

VAC/DC

CR

CR

VAC/DC

1

CØ

2

3

C1

4

5

C2

6

7

C3

CR

CR

VAC/DC

CR

CR

VAC/DC

CR

CR

VAC/DC

CR

CR

VAC/DC

Ø

1

CØ

2

3

C1

4

5

C2

6

7

C3

CR

CR

VAC/DC

CR

CR

VAC/DC

CR

CR

VAC/DC

CR

CR

VAC/DC

8

9

C4

10

11

C5

12

13

C6

14

15

C7

4.5 inch-pounds

(0.51 Newton-meters)

c

OUT

OUT

C

MN05002001E

a

b

D77A-010

Figure 9: Relay Output Module Diagrams

a) D77A-RQ8, Eight-point Module

b) D77A-RQ16, Sixteen-point Module

c) Internal Circuit

For more information visit: www.EatonElectrical.com 15

Page 24

Intelligent Technologies (IT.) D77A I/O Module Products

Analog Output Module Specifications

Table 19: D77A-NQ2 Analog Output Module Specifications

D77A-NI4

Catalog Number

Voltage Output 0 – 5V, 1 – 5V, 0 – 10V DC —

Current Output — 4 – 20 mA, 0 – 20 mA

Output Type Single End, Uni-polar

Resolution Voltage Resolution Current Resolution

Output Full Scale Range 0 – 10.5V or 0 – 5.25V 0 – 21 mA

Maximum Overload at Input Terminal 36V DC

Number of Channels 2

Resistive Load — Less than 500 ohms

Load Range Greater than 1k ohm —

Maximum Inductive Load — 0.1 mH

Maximum Capacitive Load 1 µF —

Accuracy +/– 0.8% Full Scale @ 25°C

Update Rate 350 NS

Output Impedance 10 ohm

Output Ripple (0-50 Hz) +/-0.1%

Operating Temperature 0–55°C

Status LED Indication Module Status

QCPort Current Draw 40 mA

External Power 24 VDC, 60 mA Maximum

Output group-to-bus Isolation 1.5kV for 60 Sec.

Terminal 12 Pins (Pitch, 5.2 mm)

Terminal Screw Torque 4.5 inch-pounds (0.51 Newton-meters)

Voltage Output Current Loop Output

0-5VDC 13bit 0-20mA 14 bit

0-10VDC 14 bit 4-20mA 14 bit

1-5VDC 13 bit

+/– 1.0% Full Scale @ 0-55°C

V0

I0

C0

V1

I1

C1

NC

NC

NC

NC

+

(V)

-

+

(V)

-

-

+

24VDC

+-

a

Figure 10: D77A-NQ2 Combination Module Diagrams

a) D77A-NQ2 Module, Voltage Output Channels

b) D77A-NQ2 Module Current Output Channels

V0

C0

V1

C1

NC

NC

NC

NC

I0

I1

-

+

24VDC

+

b

See D77A-NQ2 Analog Output Module Specifications on page 16

16 For more information visit: www.EatonElectrical.com

(I)

(I)

-

JIC-0014

MN05002001E

Page 25

Intelligent Technologies (IT.) D77A I/O Module Products

32766

31206

32766

31206

32766

31206

6242

3120

0

0V

5.25V5V

(A)

0

21mA20mA0mA

(D)

32766

31206

6242

4992

0

0

0V

3.2mA

0.5V

1V

5.25V5V

(B) (C)

4mA

21mA20mA0mA

(E)

32766

31206

0

0V

10.5V10V

D77A-031

14 Bit Resolution Equations

Vdc = Voltage input value

mA = Current input value

N = Decimal value

0-5 Vdc, 1-5 Vdc

• Vdc = (1/6241.2) x N

0-10 Vdc

• Vdc = (1/3120.6) x N

4-20 mA, 0-20 mA

• mA = (1/1560.2) x N

Figure 11: Analog Output Curves for 14 Bit Resolution

a) 0-5V Range Setting

b) 1-5V Range Setting

c) 0-10V Range Setting

d) 0-20mA Range Setting

e) 4-20mA Range Setting

MN05002001E

For more information visit: www.EatonElectrical.com 17

Page 26

Intelligent Technologies (IT.) D77A I/O Module Products

T

T

Special I/O Specifications

Combination Module Specifications

Table 20: D77A-DI8DQ8 Combination Module Specifications

D77A-DI8DQ8

Catalog Number

Nominal Voltage 24V DC 24V DC

Operating Voltage 18 – 30V DC 18 – 30V DC

Number of Points 8 8

Points per Common 2 2

Signal Delay 5 ms —

OFF State Voltage 0 – 6V DC * —

ON State Voltage 18V – 30V DC —

Nominal Current 5 mA —

Signal Delay — 1 ms

Max. Current/Point (Resistive) — 0.75A

Max. Current/Module (Resistive) — 6A

Surge Current (10 ms) — 4A

OFF State Leakage — 1 mA

QCPort Current Draw 99 mA

Isolation 1.5kV

Terminal Screw Torque 4.5 inch-pounds (0.51 Newton-meters)

DC Sink/Source Input DC MOSFET Sink Output

* A 12V transition range exists between 6V and 18V.

Ø

CR

VDC

VDC

VDC

VDC

Ø

1

CØ

2

3

C1

VDC

4

5

C2

6

COM

7

C3

VDC

COM

1

CR

CR

2

CR

3

-

+

4

CR

5

CR

6

CR

7

CR

-

+

a

Figure 12: D77A-DI8DQ8 Combination Module Diagrams

IN

IN

COM

b

a) D77A-DI8DQ8 Module

b) Internal DC Input Circuit

c) Internal DC Output Circuit

+24

OU

OU

C

c

D77A-011

18 For more information visit: www.EatonElectrical.com

MN05002001E

Page 27

Intelligent Technologies (IT.) D77A I/O Module Products

Table 21: D77A-DI8RQ8 Combination Module Specifications

D77A-DI8RQ8

Catalog Number

Nominal Voltage 24V DC —

Operating Voltage 18-30V DC 0-140V AC

Number of Points 8 8

Points per Common 2 2

Signal Delay 5 ms —

OFF State Voltage 0-6V DC * —

ON State Voltage 18V-30V DC —

Nominal Current 5 mA —

Signal Delay — Relay ON Time 3 ms

Max. Current/Point (Resistive) — 3A

Max. Current/Module (Resistive) — 24A

Mechanical Life — 1,000,000 Operations

Electrical Life — 100,000 Operations

QCPort Current Draw 121 mA

Isolation 1.5kV

Terminal Screw Torque 4.5 inch-pounds (0.51 Newton-meters)

DC Sink/Source Input Relay Output

0-30V DC

Relay OFF Time 6 ms

* A 12V transition range exists between 6V and 18V.

Ø

CR

CR

VAC/DC

CR

CR

VAC/DC

CR

CR

VAC/DC

CR

CR

VAC/DC

C4

C5

C6

C7

1

2

IN

3

4

IN

5

COM

6

7

VDC

VDC

VDC

VDC

Ø

1

CØ

2

3

C1

4

5

C2

6

7

C3

a

Figure 13: D77A-DI8RQ8 Combination Module Diagrams

b

a) D77A-DI8RQ8 Module

b) Internal DC Input Circuit

c) Internal Relay Output Circuit

OUT

OUT

C

c

D77A-028

MN05002001E

For more information visit: www.EatonElectrical.com 19

Page 28

Intelligent Technologies (IT.) D77A I/O Module Products

Table 22: D77A-AI8AQ8 Combination Module Specifications

D77A-AI8AQ8

Catalog Number

Nominal Voltage 120V AC, 50/60 Hz 120V AC, 50/60 Hz

Operating Voltage 80-140V AC 80-140 V AC

Number of Points 8 8

Points per Common 2 2

OFF State Voltage 0-30V AC * —

ON State Voltage 80V-140V AC —

Minimal Load Current (Resistive) 15 mA —

Signal Delay 8.33 ms @ 60 Hz

Max. Current/Point (Resistive) — 0.5A @ 30°C

Max. Current/Module (Resistive) — 4A @ 30°C

Surge Current (10 ms) — 10A

OFF State Leakage 2 mA

QCPort Current Draw 132 mA

Isolation 1.5 kV

Terminal Screw Torque 4.5 inch-pounds (0.51 Newton-meters)

AC Input AC Output

10 ms @ 50 Hz

0.1A @ 55°C

0.8A @ 55°C

* A 50V transition range exists between 30V and 80V.

CR

CR

VAC

CR

CR

VAC

CR

CR

VAC

CR

CR

VAC

C4

C5

C6

C7

Ø

1

COM

2

3

4

5

IN

IN

6

7

VAC

VAC

VAC

VAC

Ø

1

CØ

2

3

C1

4

5

C2

6

7

C3

a

Figure 14: D77A-AI8AQ8 Combination Module Diagrams

b

a) D77A-AI8AQ8 Module

b) Internal AC Input Circuit

c) Internal AC Output Circuit

L2

OUT

OUT

c

D77A-029

20 For more information visit: www.EatonElectrical.com

MN05002001E

Page 29

Intelligent Technologies (IT.) D77A I/O Module Products

Table 23: D77A-AI8RQ8 Combination Module Specifications

D77A-AI8RQ8

Catalog Number

Nominal Voltage 120V AC, 50/60 Hz —

Operating Voltage 80-140V AC 0-140V AC

Number of Points 8 8

Points per Common 2 2

Signal Delay 5 ms —

OFF State Voltage 0-80V AC* —

ON State Voltage 180V-140V AC —

Maximum Load Current (Resistive) 15 mA —

Signal Delay 8.33 ms @ 60 Hz

Max. Current/Point (Resistive) — 3A

Max. Current/Module (Resistive) — 24A

Mechanical Life — 1,000,000 Operations

Electrical Life — 100,000 Operations

QCPort Current Draw 104 mA

Isolation 1.5kV

Terminal Screw Torque 4.5 inch-pounds (0.51 Newton-meters)

AC Input Relay Output

0-30V DC

10 ms @ 50 Hz

Relay ON Time 3 ms

Relay OFF Time 6 ms

* A 60V transition range exists between 80V and 140V.

Ø

CR

CR

VAC/DC

CR

CR

VAC/DC

CR

CR

VAC/DC

CR

CR

VAC/DC

C4

C5

C6

C7

1

COM

2

3

4

5

6

7

IN

IN

AC

AC

AC

AC

Ø

1

CØ

2

3

C1

4

5

C2

6

7

C3

a

Figure 15: D77A-AI8RQ8 Combination Module Diagrams

b

a) D77A-AI8RQ8 Module

b) Internal DC Input Circuit

c) Internal Relay Output Circuit

OUT

OUT

C

c

D77A-030

MN05002001E

For more information visit: www.EatonElectrical.com 21

Page 30

Intelligent Technologies (IT.) D77A I/O Module Products

Theory of Operation

The IT. D77A I/O system consists of a collection of input and output modules connected together by QCPort to a network adapter. The

network adapter connects to the industrial network where the controller usually is a PLC or DCS. The input modules collect digital or

linear signals from sensors (limit switches, proximity sensors, temperature transmitters, etc.) and deliver these data to the control

device. In the control device, input data values are placed in data registers. Based on the input data, the control algorithm manipulates

values in the output registers. With each scan of the network, the input and output data registers are updated. With this update, the

output modules have their digital or linear data changed to reflect the control algorithm found in the control device software. The

output devices (solenoid valves, motor starters, temperature gauges, etc.) effect changes to the machinery being controlled.

Out-of-box Default Operation

When the IT. D77A I/O modules are properly installed and each has a properly configured Group ID (address), no additional

configuration is needed for standard operation. To customize the configuration, refer to Configuration on page 34. After customizing

the configuration, the system can be restored to the default out-of-box configuration without a software tool such as CH Studio by

following these steps.

1. Using a screwdriver, rotate the Group ID Switch from the “0” position to the “1” position.

2. Repeat this action five times.

The status LED rapid flashes, signaling that the system is reset to the out-of-box default settings.

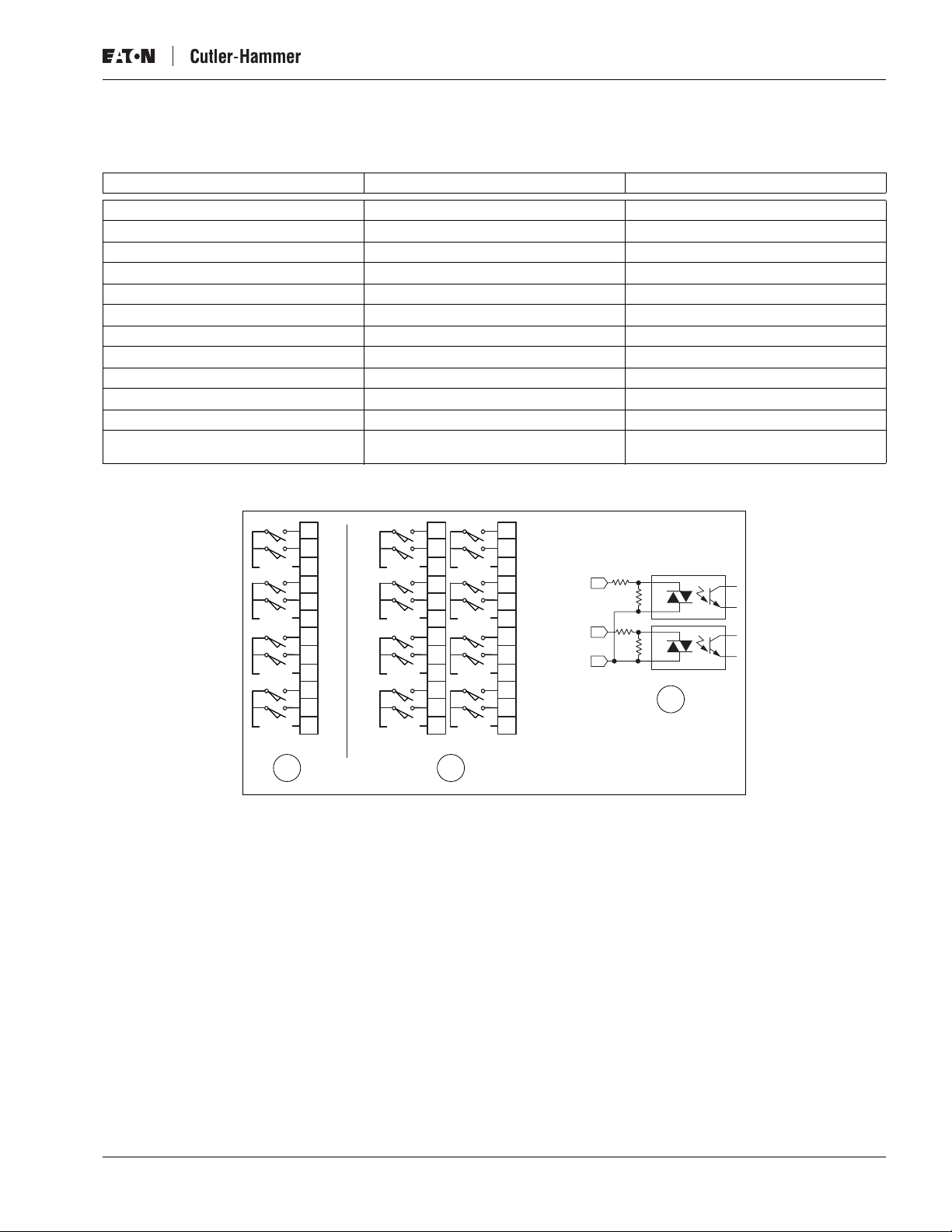

Typical Application

Figure 16 illustrates a typical D77A I/O module application this is integrated with a number of IT. starters with QSNAPs. In this

example, a D77A I/O is part of a larger system where motor control and I/O are required within a single panel. On the same QCPort

connection, both the I/O and the motor control are connected to a single network Adapter. The network adapter then represents the

D77A I/O and motor control as remote I/O, allowing for control and monitoring of the QCPort devices.

a

b

e

d

f

c

D77A-003

Figure 16: Panel Layout: Adapter, I/O and QSNAP

a) PC or PLC Connection

b) I/O Modules

c) QCPort Connection

d) IT. Starters with QSNAPs

e ) P o w e r Ta p/ Term i n a to r R es is t o r

f) 24 V DC Power Supply

22 For more information visit: www.EatonElectrical.com

MN05002001E

Page 31

Intelligent Technologies (IT.) D77A I/O Module Products

I/O Function

Discrete Input Modules

Figure 17 illustrates the basic signal processing operation. When a signal is present at the input point, the module responds with the

following sequence:

1. Optical Isolation — Optical isolation protects the I/O circuits and communication circuits from possible damage due to

transients and over-voltage.

2. Debounce Logic/Control — A debounce circuit and software limits the effects of transients and electrical noise by requiring the

input to be true for a certain period of time before the logic acknowledges a true signal. Once a true signal is achieved, the logic

turns on the LED.

3. QCPort Com./Logic — The logic updates the QCPort communication on a regular, scheduled basis as to the status of the input

point.

Input

Optical

Isolation

LED

Indication

Figure 17: Discrete Input Module Operation

Debounce

Logic/Contr ol

QCPort

Com.

D77A-004

Discrete Output Modules

Figure 18 illustrates the basic logic processing operation. When the processor activates an output point, the module responds with

the following sequence:

1. QCPort Com./Logic — QCPort communication updates the logic circuit on a regular, scheduled basis as to the status of the

output points.

2. Optical Isolation — Optical isolation protects the I/O circuits and communication circuits from possible damage due to

transients and over-voltage. Once an active signal is transmitted to the optical isolation circuit, the LED is forward-biased.