Page 1

Medical Air Compressor

Operating Instructions

MT-763-90a

Page 2

NOTICE

Proprietary Information

This document contains information in which Dräger Medical, Inc.

claimed proprietary rights. The information may not be reproduced in

whole or in part except as authorized in writing by Dräger. This information is the property of Dräger Medical, Inc., it is provided solely for the

use intended.

Repairs/Modifications

Repairs on this device shall be performed only by Dräger Service or its

Authorized Service Centers. Information about repairs can be obtained

from Dräger or Authorized Dealers. Dräger Medical, Inc. will not be

responsible for injury to persons or damage to property arising directly or

indirectly out of unauthorized repairs or modifications to this device.

Furthermore, any unauthorized repairs or modifications void any warranty

extended by Dräger.

This document is provided for your information only. It will not be

exchanged or updated without request.

Trademarks

The Dräger name and logo are registered trademarks of

Drägerwerk Aktiengesellschaft, Lübeck, Germany

Dräger Medizintechnik GmbH,1998

All rights reserved, Subject to modifications

Page 3

Contents

Contents

Important Safety Information READ THIS FIRST........4

Operator's Responsibility for Patient Safety..................4

Limitation of Liability..................................................... 4

Warranty......................................................................5

Definitions.................................................................... 6

General WARNINGS and CAUTIONS......................... 6

Precautions During Preparation.................................... 7

Precautions During Care.............................................. 7

Precautions During Maintenance.................................. 8

Precautions During Installation......................................8

Intended Use.............................................................. 9

Preparation................................................................10

Before First Use......................................................... 10

Connecting Compressor............................................ 10

Standby Mode (Option).............................................. 11

Operation.................................................................. 12

Standby Mode............................................................12

Switching Off............................................................. 12

Care...........................................................................13

Wipe Disinfection....................................................... 13

Installation Procedures............................................. 20

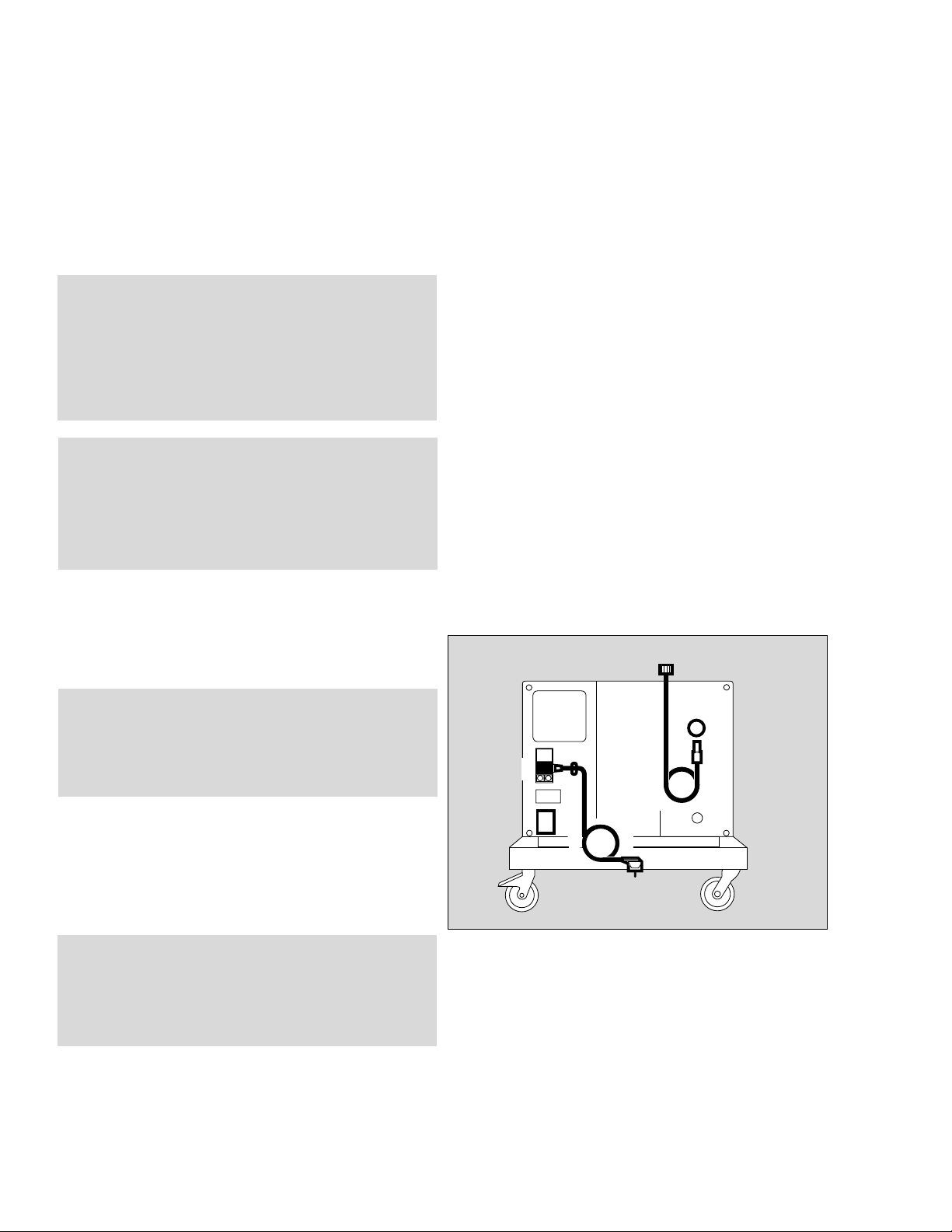

Installing Compressor On the Ventilator Cart or

Standalone cart.......................................................... 22

Installing the Power Cord........................................... 23

Preventive Maintenance Procedures........................ 24

Removing the Filter Assembly.....................................24

Changing the Prefilter.................................................25

Changing the Main Filter.............................................25

Changing the Intake Filter...........................................27

Installing the Filter Assembly.......................................28

Replacing a Fuse........................................................28

Ordering Information................................................ 29

Index......................................................................... 30

Maintenance..............................................................14

Preventive Maintenance Intervals................................ 14

Troubleshooting........................................................15

What's What.............................................................. 16

Technical Data.......................................................... 17

Ambient Conditions.................................................... 17

Performance Characteristics...................................... 17

Operating Characteristics...........................................18

Theory of Operation..................................................19

Operating Instructions Medical Air Compressor

3

Page 4

Important Safety Information

Operator's Responsibility for Patient Safety

Limitation of Liability

Important Safety Information

Operator's Responsibility for Patient Safety

For correct and effective use of the product and in

order to avoid hazards it is mandatory to carefully

read and to observe all portions of this manual.

The design of this device, accompanying literature, and

the labeling on the equipment, take into consideration

that the purchase and use of the equipment are

restricted to trained professionals, and that certain

inherent characteristics of the equipment are known to

the trained operator. Instructions, warnings, and

caution statements are limited, therefore, largely to the

specifics of the Dräger design. This publication

excludes references to various hazards which are

obvious to a medical professional and operator of

respiratory care equipment, to the consequences of

misuse of such equipment, and to potentially adverse

effects in patients with abnormal conditions. Product

modification or misuse can be dangerous.

Dräger Medical, Inc. disclaims all liability for the consequences of product alterations or modifications, as well

as for the consequences which might result from uses

of the product not covered by its intended use or from

the combination of this product with other products

whether supplied by Dräger or by other manufacturers

if such a combination is not endorsed by

Dräger Medical, Inc.

Limitation of Liability

Dräger Medical, Inc.'s liability, whether arising out of or

related to manufacture and sale of the goods, their installation, demonstration, sales representation, use,

performance, or otherwise, including any liability based

upon Dräger Medical, Inc.'s Product Warranty, is subject to and limited to the exclusive terms and conditions

as set forth, whether based upon breach of warranty or

any other cause of action whatsoever, regardless of

any fault attributable to Dräger Medical, Inc. and

regardless of the form of action (including, without limitation, breach of warranty, negligence, strict liability, or

otherwise).

THE STATED EXPRESSED WARRANTlES ARE IN

LlEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, INCLUDING, WITHOUT LIMITATION,

WARRANTlES OF MERCHANTABILITY, FITNESS

FOR ANY PARTICULAR PURPOSE, OR

NONINFRINGEMENT.

Dräger Medical, Inc. shall not be liable for, nor shall

buyer be entitled to recover any special incidental, or

consequential damages or for any liability incurred by

buyer to any third party in any way arising out of or

relating to the goods.

The operators of ventilator systems must recognize

their responsibility for choosing appropriate and reliable

electrical and gas supplies for the support of all systems. Backups for the supplies and alarm functions in

case of a supply failure are mandatory while using lifesupporting ventilators. Patient safety may be achieved

through a wide variety of different means ranging from

electronic surveillance of equipment performance and

patient condition to simple, direct observation of clinical

signs. The responsibility for the selection of the best

level of patient monitoring lies solely with the equipment

operator.

4

Operating Instructions Medical Air Compressor

Page 5

Valid for US and Canada

Warranty

Important Safety Information

Warranty

All Dräger products are guaranteed to be free of

defects for a period of one year from date of delivery.

The following are exceptions to this warranty:

1. The defect shall be a result of workmanship or

material. Defects caused by misuse, mishandling,

tampering, or by modifications not authorized by

Dräger Medical, Inc. or its representatives are not

covered.

2. Rubber and plastic components and materials are

warranted to be free of defects at time of delivery.

3. Oxygen sensors capsules have a six-month limited

warranty from the date of delivery.

Any product which proves to be defective in workmanship or material will be replaced, credited, or repaired

with Dräger Medical, Inc. holding the option.

Dräger Medical, Inc. is not responsible for deterioration,

wear, or abuse. In any case, Dräger Medical, Inc. will not

be liable beyond the original selling price.

Application of this warranty is subject to the following

conditions:

1. Dräger Medical, Inc. or its authorized representative must be promptly notified, in writing, upon

detection of the defective material or equipment.

2. Defective material or equipment must be returned,

shipping prepaid, to Dräger or its authorized

representative.

3. Examination by Dräger Medical, Inc. or its authorized representative must confirm that the defect is

covered by the terms of this warranty.

4. Notification in writing of defective material or equipment must be received by Dräger Medical, Inc. or

its authorized representative no later than two (2)

weeks following expiration of this warranty.

The above is the sole warranty provided by

Dräger Medical, Inc. No other warranty expressed or

implied is intended. Representatives of Dräger are not

authorized to modify the terms of this warranty.

Dräger Medical, Inc., Telford, PA

Operating Instructions Medical Air Compressor

5

Page 6

Important Safety Information

Definitions

General WARNINGS and CAUTIONS

Definitions

WARNING !

A WARNING statement refers to conditions

with a possibility of personal injury if disregarded.

CAUTION !

A CAUTION statement designates the possibility

of damage to equipment if disregarded.

NOTE: A NOTE provides additional information

intended to avoid inconveniences during operation.

Inspection = examination of actual condition

Service = measures to maintain specified

condition

Repair = measures to restore specified

condition

Maintenance = inspection, service, and repair,

where necessary

General WARNINGS and CAUTIONS

WARNING !

Strictly follow Operator's Instruction Manual!

Use of the compressor requires full under-

standing and strict observation of all portions

of these instructions. The equipment is only to

be used for the purpose specified under

"Intended Use" (page 9). Observe all

WARNINGS and CAUTIONS as rendered

throughout this manual and on labels on the

equipment.

WARNING !

DANGER, risk of explosion if used in the

presence of flammable anesthetics.

The equipment is neither approved nor certified for use in areas where combustible or

explosive gas mixtures are likely.

WARNING !

Do not spray flammable liquids near the

compressor. Fire hazard!

Preventive = Maintenance measures at regular

Maintenance intervals

Typing conventions in this manual

Controls are designated as »Control Name«, e.g. »NNNN«

WARNING !

Air supply to life-supporting ventilators:

If the compressor is used to supply air to life-

supporting ventilators, an adequate alternative

supply of medical air must be ensured in case

of a malfunction of the compressor!

Life-supporting ventilators supplied with air

from the compressor must be equipped with a

alarm function that is activated if the supply

pressure drops too low!

Operating Instructions Medical Air Compressor

CAUTION !

Accessories

Use only accessories listed in the Ordering

Information (page 29).

6

Page 7

Important Safety Information

Precautions During Preparation

Precautions During Care

Precautions During Preparation

WARNING !

Installation of the Medical Air Compressor

may be performed by factory trained service

personnel only. Follow installation procedures

on pages 20 to 23 of this manual.

WARNING !

To maintain grounding integrity, connect only

to a "hospital grade" power outlet. Always

disconnect supply before servicing.

CAUTION !

The medical air compressor must not be started

up before it has been properly installed on a

mobile cart.

The compressor unit may be damaged as a

result of poor air circulation if disregarded!

Precautions During Care

CAUTION !

The compressor housing consist of materials that

are sensitive to certain organic solvents sometimes used for cleaning and disinfecting

(e.g., phenols, halogen releasing compounds,

oxygen releasing compounds, strong organic

acids, etc.). Exposure to such substances may

cause damage that is not always immediately

apparent.

CAUTION !

Follow all accepted hospital procedures for

disinfecting parts contaminated by body fluids

(protective clothing, eyewear, etc.).

CAUTION !

Do not connect more than one ventilator to the

compressor!

Compressor overload may result.

CAUTION !

Do not operate compressor in salty air, as this

may cause the non-return valves in the

compressor to corrode.

Operating Instructions Medical Air Compressor

7

Page 8

Important Safety Information

Precautions During Maintenance

Precautions During Installation

Precautions During Maintenance

WARNING !

To avoid any risk of infection, clean and disinfect compressor and accessories before any

maintenance according to established hospital

procedures - this applies also when returning

compressors or parts for repair.

WARNING !

To avoid the risk of an electrical shock always

disconnect from power supply before

servicing.

WARNING !

Preventive Maintenance work on the Dräger

Medical Air Compressor may be performed by

factory trained and authorized personnel only.

CAUTION !

Maintenance

In case of malfunction of this device, contact

your local Dräger Service or our Factory

Authorized Technical Service Center.

The device must be inspected and serviced

(preventive maintenance) by factory trained and

authorized technical service representatives at

regular intervals. A record must be kept on this

preventive maintenance. We recommend

obtaining a service contract through your vendor.

Maintenance or repair of Dräger Medical Air

Compressors shall be performed only by Dräger

authorized technical service representatives.

Precautions During Installation

WARNING !

Installation of the Medical Air Compressor

may be performed by factory trained and

authorized service personnel only.

WARNING !

To avoid risk of electric shock, verify that

compressor is disconnected from line power.

CAUTION !

The transport braces must always be removed

before using the compressor, otherwise major

vibrations may develop in the compressor,

damaging the compressor unit!

CAUTION !

The internal transport braces must be installed

whenever the compressor is transported without

its cart, otherwise the rubber feet of the compressor unit may be damaged.

CAUTION !

Restriction of Distribution

Federal Law and Regulations in the United

States and Canada restrict this device to sale by

or on the order of an physician.

8

Operating Instructions Medical Air Compressor

Page 9

Intended Use

Air compressor supplying compressed air for medical

ventilators.

WARNING !

DANGER, risk of explosion if used in the

presence of flammable anesthetics.

The equipment is neither approved nor certified for use in areas where combustible or

explosive gas mixtures are likely.

WARNING !

Do not spray flammable liquids near the

compressor. Fire hazard!

Intended Use

WARNING !

Air supply to life-supporting ventilators:

If the compressor is used to supply air to life-

supporting ventilators, an adequate alternative

supply of medical air must be ensured in case

of a malfunction of the compressor!

Life-supporting ventilators supplied with air

from the compressor must be equipped with a

alarm function that is activated if the supply

pressure drops too low!

CAUTION !

Accessories

Use only accessories listed in the Ordering

Information (page 29).

Operating Instructions Medical Air Compressor

9

Page 10

Preparation

Before First Use

Connecting Compressor

Preparation

Before First Use

The compressor is supplied without cart. It can be

installed on the ventilator cart (eg. EvitaMobil) or on its

own standalone cart.

CAUTION !

The medical air compressor must not be started

up before it has been properly installed on a

mobile cart.

The compressor unit may be damaged as a

result of poor air circulation if disregarded!

WARNING !

Installation of the Medical Air Compressor

may be performed by factory trained and

authorized service personnel only. Follow

installation procedures on pages 20 to 23 of

this manual.

Connecting Compressor

1 Check that the operating voltage specified on the

rating plate matches the line voltage.

WARNING !

To maintain grounding integrity, connect only

to a "hospital grade" power outlet. Always

disconnect supply before servicing.

4 Plug the connector into a grounded outlet socket;

do not use an adapter ("cheater plug").

5 Screw DISS pressure hose connector to the ventilator

»Air « inlet port.

CAUTION !

Do not connect more than one ventilator to the

compressor!

Compressor overload may result.

5

2

6

3

1

4

Operating Instructions Medical Air Compressor

02129080

6 Firmly insert the connector on the pressure hose into

the quick-connect coupling on the compressor - until

it engages.

10

Page 11

● Place the compressor in a cool place, away from

radiators and other sources of heat.

Ensure that air can circulate freely around the

compressor.

CAUTION !

Do not operate compressor in salty air, as this

may cause the non-return valves in the

compressor to corrode.

Standby Mode (Option)

For emergency supply if the hospital's medical air system

fails.

Preparation

Connecting Compressor

1 Screw the pressure hose to the compressor inlet port.

2 Plug quick-connect adapter into wall outlet of the

medical air pipeline system.

1

2

02229080

Operating Instructions Medical Air Compressor

11

Page 12

Operation

Standby Mod

Switching Off

e

Operation

If the compressor has been stored at temperatures below

3 °C (38 °F):

● Wait approx. 2 hours for the compressor to warm up.

1 Press main switch on the rear.

3

02329080

2 The green LED » NN

NN

« in the front of the top cover will

light up = ON.

● Switch ventilator on now.

Refer to "Troubleshooting" on page 15 in the event of

fault conditions.

Standby Mode (Option)

For backup air supply if the hospital's medical air system

fails.

● Always leave the main switch ON .

● Green power status LED » NN

compressor top remains lit.

While switched on, the compressor continuously

monitors pressure in the central medical air system.

If the pressure drops below 40-5 psi (2,7-0,3 bar), the

compressor will automatically supply medical air to the

ventilator to which it is connected. The compressor

switches off its supply and remains on standby when the

pressure in the medical air pipeline system returns and

rises above 50 psi (3,4 bar).

NN

« in the right front of the

4

01029080

Operating Instructions Medical Air Compressor

Switching Off

After switching off the ventilator:

● Press main switch on the rear.

● Green power status LED » NN

NOTE: The compressor is vented automatically.

12

NN

« goes out = OFF.

Page 13

Care

If the filter mat is soiled:

1 Remove filter mat, shake out any dirt and insert mat

again.

● Wipe off any dirt on the compressor housing with a

disposable cloth.

Care

Wipe Disinfection

1

02429080

Wipe Disinfection

CAUTION !

The compressor housing consist of materials that

are sensitive to certain organic solvents sometimes used for cleaning and disinfecting

(e.g., phenols, halogen releasing compounds,

oxygen releasing compounds, strong organic

acids, etc.). Exposure to such substances may

cause damage that is not always immediately

apparent.

CAUTION !

Follow all accepted hospital procedures for disinfecting parts contaminated by body fluids (protective clothing, eyewear, etc.).

To prevent any damage, we recommend that only detergents and disinfectants are used that are compatible with

the materials used in the compressor and its accessories,

e.g. surface disinfectants on the basis of aldehydes,

alcohol, or quarternary ammonia compounds for

disinfection of the main unit.

Ensure that all disinfectants are registered with the U.S.

Environmental Protection Agency for use as intended.

● Wipe compressor housing, hoses and cable with

disinfectant. Always follow the instruction labels

specifically with respect to prescribed concentrations

and the necessary exposure times.

Operating Instructions Medical Air Compressor

13

Page 14

Maintenance

Preventive Maintenance Intervals

Maintenance

WARNING !

To avoid any risk of infection, clean and disinfect compressor and accessories before any

maintenance according to established hospital

procedures - this applies also when returning

compressors or parts for repair.

WARNING !

Always disconnect from power supply before

servicing.

WARNING !

Preventive Maintenance work on the Dräger

Medical Air Compressor may be performed by

factory trained and authorized personnel only.

CAUTION !

Maintenance

In case of malfunction of this device, contact

your local Dräger Service or our Factory

Authorized Technical Service Center.

The device must be inspected and serviced

(preventive maintenance) by factory trained and

authorized technical service representatives at

regular intervals. A record must be kept on this

preventive maintenance. We recommend

obtaining a service contract through your vendor.

Maintenance or repair of Dräger Medical Air

compressors shall be performed only by Dräger

authorized technical service representatives.

Preventive Maintenance Intervals

Every 6000 hours Change filter inserts in:

(see operating - prefilter,

hour meter): - main filter

- intake filter

Operating Instructions Medical Air Compressor

Perform preventive maintenance at shorter intervals

where necessary.

If the compressor is used less than 6000 hours per year:

● Perform preventive maintenance at least once a year.

See pages 24 to 28, "Preventive Maintenance

Procedures".

14

Page 15

Troubleshooting

Problem Likely Causes Remedy

Troubleshooting

Compressor vibrating

excessively

Compressor runs, but

builds up too little or no

pressure

Red LED »Temp [[[[«

lights up together with

audible alarm

Internal transport

braces have not been

removed

Rubber feet on

compressor unit

defective

Intake filter clogged Replace intake filter,

Leaks in the

compressor

components

High ambient

temperature

Filter mat clogged Shake dirt out of filter

Fan defective Call DrägerService

Remove braces,

page 22, 23

Call DrägerService

page 27

Call DrägerService

Place compressor in a

cool place and ensure

free air circulation

mat or install a new

filter mat

Compressor will not

start

For units with Standby

option:

Compressor starts up

although pressure in

medical air pipeline

system is over 40

Operating Instructions Medical Air Compressor

-5 psi

No power or

line voltage too low

Fuses defective Replace fuses, page 28

Compressor defective Call DrägerService

Pressure switch

defective

Check line voltage

Call DrägerService

15

Page 16

What's What

DANGER !

RISK OF EXPLOSION IF USED IN THE PRESENCE

OF FLAMMABLE ANESTHETICS

WARNING !

DISCONNECT SUPPLY BEFORE SERVICING

REPAIRS ON THIS EQUIPMENT TO BE PERFORMED

ONLY BY DRÄGER SERVICE OR ITS AUTHORIZED

SERVICE CENTERS

CAUTION !

TO MAINTAIN GROUNDING INTEGRITY, CONNECT

ONLY TO A "HOSPITAL GRADE" RECEPTACLE

What's What

1 Red alarm status LED »Temp [[[[«,

lit when temperature is too high

2 Green power status LED » NNNN«

indicates power on / standby

12

3 Filter mat

4 Main switch

5 Power cable

6 Fuses

7 Operating hour meter

8 Rating plate

9 Exhaust air duct

10 Connection for pressure hose from medical air

pipeline system (standby option only)

11 Main WARNING/CAUTION label

12 Quick-connect coupling for pressure hose from

ventilator

3

4

5

6

7

8

9

MT-780-97

12

11

10

Operating Instructions Medical Air Compressor

MT-781-97

16

Page 17

Technical Data

Ambient Conditions

Operation:

Temperature 50 to 104 °F (10 to 40 °C)

Relative humidity 30 to 95%

Height above sea level 0 to 13,000 ft (0 to 4000 m)

Storage:

Temperature -4 to 158 °F (-20 to 70 °C)

Relative humidity 0 to 99%

Height above sea level 0 to 52,500 ft (0 to 16,000 m)

Technical Data

Performance Characteristics

Operating pressure 59 psi + 7 psi (4 bar + 0.5 bar)

Continuous flow Minimum 30 L/min at 44 psi (3.0 bar)

Peak flow 180 L/min for max. 0.8 seconds while not

exceeding a total of max. 30 L/min

Dew point depression 9 °F (5 °C) below ambient temperature at > 30 L/min

at operating pressure and max. ambient temperature 104 °F (40 °C).

27 °F (15 °C) below ambient temperature at 15 L/min and

max. ambient temperature 104 °F (40 °C).

Air quality Dust-free and oil-free compressed air

Filter ≤ 1 micron

Compressed air outlet Quick-connect coupling with check valve

Alarm High temperature alarm, visual (red LED)

and audible (continuous buzzer)

Standby option - pressure monitoring

Compressor - medical air ON < 40-5 psi (2,7-0,3 bar)

Compressor - medical air OFF > 50 psi (3,4 bar)

Operating Instructions Medical Air Compressor

17

Page 18

Technical Data

Operating Characteristics

Physical Characteristics

Operating Characteristics

Connection for medical air NIST1) or DISS2) connection

pipeline system

Line supply voltage

Mains connection Current Fuses

consumption

230 V 50/60 Hz 2,2 A...2,4 A 4 A slow-blow

Other versions

100/ 110/ 115/ 127 V

50/60 Hz 4,2 A...5,9 A 8 A slow-blow

Electromagnetic Tested to EN 60601-1-2

compatibility EMC

Physical Characteristics

Sound pressure level Typically 46 - 49 dB(A)

Weight Approximately 45 kg (100 lbs)

Dimensions

(W x H x D) 50 x 38 x 41 cm (20 x 15 x 16 inches)

Classification II a

as per EC Directive 93/42/EEC

Annex IX

UMDNS-Code 10-972

Universal Medical Device

Nomenclature System –

Nomenclature for medical products

Operating Instructions Medical Air Compressor

1)

NIST = Non Interchangeable Screw Thread

2)

DISS = Diameter Indexed Safety System

18

Page 19

Theory of Operation

2

1

15

Theory of Operation

12

4

5

3

16

6

8

7

17

9

10

11

13

14

1 Intake filter

2 Compressor unit

3 Cooling coil

4 Solenoid valve

5 Prefilter

6 Water trap

7 Heat exchanger

8 Pressure limiter

9 Membrane drier

10 Pneumatic resistor

11 Non-return valve

12 Pressure vessel

13 Medical air outlet

14 Relief valve

15 Input for standby mode

16 Pressure switch

17 Non-return valve

Ambient air drawn via intake filter 1 is compressed in the

compressor unit 2 and cooled in the cooling coil 3.

Solenoid valve 4 briefly opens the system when the

compressor starts up.

The compressed air is cleaned by prefilter 5. Condensate

is collected and removed via water trap 6.

Heat exchanger 7 re-heats the purified air in order to

prevent further condensation before the air reaches membrane drier 9, where it is dehumidified to a dew point at

least 9 °F (5 °C) below ambient temperature.

The dehumidified air flows via resistor orifice 10 and

non-return valve 11 to the pressure vessel 12, where it is

dispensed at relief valve protected connector 14.

In standby mode, the ventilator draws air from the

medical air pipeline system via port 15, non-return valve

17 and self-closing coupling 13. The compressor unit 2 is

in standby.

Whenever the pressure in the medical air supply drops

below 40-5 psi (2,7-0,3 bar), pressure switch 16 will activate compressor unit 2.

When pressure in the supply pipeline returns to 50 psi

(3,4 bar), pressure switch 16 will switch compressor

unit 2 off again.

Operating Instructions Medical Air Compressor

Pressure regulator 8 limits system pressure to 59 psi

(4 bar) and relief valve 14 protects the unit against

excessively high pressure from the medical air pipeline

system.

19

Page 20

Installation Procedures

Installing Compressor On the Evita Ventilator Cart

Installation Procedures

WARNING !

Installation of the Medical Air Compressor

may be performed by factory trained and

authorized service personnel only.

Tools required:

5 mm hex key (Allen) wrench

#2 Phillips screwdriver

19 mm open end wrench

Installing Compressor on the

Evita Ventilator Cart

● Remove ventilator from the Ventilator cart.

● Place cart on the floor upside down so that the

underside of the cart is accessible.

1 Secure exhaust air cover to the cart frame with

enclosed Phillips head screws.

1

1

11

● Turn cart upright again.

2 Remove foam mat from cart.

● Cut foam mat off along the prepared line.

3 Place both parts in the cart.

01429080

2

Operating Instructions Medical Air Compressor

01529080

33

20

✂

01629080

Page 21

4 Undo the two screws and remove cover.

● Undo the two screws below the battery compartment

cover.

On the compressor:

1 Undo the four hex head screws on the rear of the

compressor unit.

Installation Procedures

Installing Compressor On the Ventilator Cart

44

1

1

01729080

WARNING !

To avoid risk of electric shock, verify that

compressor is disconnected from line power.

2 Carefully draw top cover forward approx. 4 inches

(10 cm) so that internal leads to the status light are

not pulled off.

1

1

00129080

approx. 4 inch

2

00129081

Operating Instructions Medical Air Compressor

21

Page 22

Installation Procedures

Installing Compressor On the Ventilator Cart or

Standalone cart

3 Undo Phillips head screw on the motor connector,

unplug connector and remove top cover completely.

4 Place compressor on the cart with the pressure

vessel alongside the column.

3

01829080

5 Tightly secure compressor unit to the cart with the

four hex head screws and washers.

6 Undo the four hex head screws securing the internal

transport braces.

4

55

5

1

6

5

00529080

Operating Instructions Medical Air Compressor

1

6

22

1

6

1

6

01929080

Page 23

1 Pull the two tabs from the braces.

2 Plug in the motor connector and secure it with the

Phillips head screw.

Installation Procedures

Installing the Power Cord

Keep tabs and screws from the internal transport

braces for future use.

CAUTION !

The transport braces must always be removed

before using the compressor, otherwise major

vibrations may develop in the compressor,

damaging the compressor unit!

CAUTION !

The internal transport braces must be installed

whenever the compressor is transported without

its cart, otherwise the rubber feet of the compressor unit may be damaged.

● Install the top cover, plug in its connector and secure

it with the Phillips head screw.

● Close the top cover and screw down the four hex

head screws on the rear of the unit.

1

2 2

2

3

1

02029080

Installing the Power Cord

3 Check that the operating voltage specified on the

rating plate matches the line voltage.

4 Unscrew cable clamp.

5 Plug in compressor power connector, pull cable

gently until taut, secure under clamp, and

4 screw clamp back into place.

Operating Instructions Medical Air Compressor

5

2

4

5

3

3

1

4

6

02129080

23

Page 24

Preventive Maintenance Procedures

Removing the Filter Assembly

Preventive Maintenance Procedures

Removing the Filter Assembly

Remove housing, see page 21.

1 Undo both Phillips head screws.

1

1

2 Disconnect tubing:

Push release ring towards the fitting body and hold

while pulling the tubing from the fitting at the same

time.

● Remove filter assembly.

03029080

2

2

2

02829080

Operating Instructions Medical Air Compressor

24

Page 25

Changing the Prefilter

1 Unscrew housing by hand.

2 Unscrew recessed-head screw and remove

screw and plastic washer.

3 Remove filter case and replace with a new one.

3 Install new filter case.

2 Screw tight with recessed-head screw and

plastic washer.

Preventive Maintenance Procedures

Changing the Prefilter

Changing the Main Filter

1

2

4 Remove old O-ring and install new O-ring.

● Tighten housing fully by hand.

Changing the Main Filter

5 Pull and hold catch while simultaneously

6 turning the housing until the marks ( II ) line up.

● Remove housing.

3

4

03129080

66

Operating Instructions Medical Air Compressor

5

02629080

25

Page 26

Preventive Maintenance Procedures

Changing the Main Filter

1 Remove old O-ring from housing and install new

O-ring.

1

03729080

2 Unscrew old filter case by hand and screw in new

filter case.

● Insert housing so that the marks line up, then turn until

the catch audibly engages.

● Lightly pull on the housing to verify that it has

engaged.

2

02729080

Operating Instructions Medical Air Compressor

26

Page 27

Changing the Intake Filter

1 Remove the two hex head screws on the front of the

mounting brackets of the compressor unit. Undo the

two rear hex head screws two turns.

2 Unscrew pressure hose with a 19 mm open end

wrench. Hold the connector to the heat exchanger

with a second wrench to prevent it from turning loose.

● Pull compressor unit out from its enclosure until the

outlet pipe at the rear of the filter housing no longer

protrudes from its hole.

3 Turn filter housing clockwise and remove.

Preventive Maintenance Procedures

Changing the Intake Filter

2

3

4 Remove old intake filter and insert a new filter in the

filter housing.

● Position filter housing with its outlet pipe facing to the

rear in approximately 11 o'clock position.

3 Turn filter housing counterclockwise until locked.

The pipe should now be positioned horizontally.

● Pull gently to check that the filter housing is secure.

● Push compressor unit back into its enclosure, guiding

the outlet pipe into the hole at the same time.

1

1

03329080

4

03229080

2 Secure pressure hose with a 19 mm open end

wrench and hold connector to the heat exchanger

with a second wrench to prevent it from turning.

1 Secure compressor unit with the front and rear hex

head screws.

Operating Instructions Medical Air Compressor

27

Page 28

Preventive Maintenance Procedures

Installing the Filter Assembly

Replacing a Fuse

Installing the Filter Assembly

● Connect tubing to the filter group, see page 24.

● Screw filter assembly into place, see page 24.

● Install top cover, plug in its connector and secure it

with the Phillips head screw.

● Close the top cover and screw down the four hex

head screws on the rear of the unit.

Replacing a Fuse

● Unplug power cord from wall outlet.

WARNING !

Always disconnect from power supply before

servicing.

1 Turn fuse caps counterclockwise with a screwdriver

and remove.

2 Remove blown fuses from their caps and insert new

fuses. Always use fuses of correct type and rating,

see "Technical Data" on page 18.

1 Screw caps with the new fuses back into place.

2

1

03529080

Operating Instructions Medical Air Compressor

28

Page 29

Ordering Information

Name/Description Order No.

Medical air compressor 84 13 890

Standard version 230 V, 50 Hz

Standby option 84 13 939

Pressure hoses for operating the

compressor on the Ventilator cart:

NIST connecting hose 0.8 m (31 "), black 84 11 517

NIST connecting hose 0.8 m (31 "), 84 11 538

gas color-coding to ISO 32

Ordering Information

Parts set

for 6000-hours’ maintenance for medical 84 14 501

air compressors from ARMJ 0020

(see rating plate)

The following hoses may be ordered

instead of the 0.8 m hose:

NIST connecting hose 5 m (16 ft 5"), black 84 11 519

NIST connecting hose 5 m (16 ft 5"), 84 11 541

gas color-coding to ISO 32

For standby mode:

NIST medical air connecting hose 3 m (5 ft) M 34 408

NIST medical air connecting hose M 34 409

5 m(16 ft 5")

Mobile cart (standalone) 84 11 520

Technical documentation on request

Operating Instructions Medical Air Compressor

29

Page 30

Index

Ambient conditions.....................................................17

Accessories........................................................... 6, 29

Cart, Evita..................................................................20

Cart, mobile............................................................... 23

Cautions...................................................................... 6

Cleaning/disinfection.................................................. 13

Connecting................................................................ 10

Disinfection, wipe.......................................................13

DISS..........................................................................18

Electrical supply.........................................................18

Electromagnetic compatibility......................................18

End of operation.........................................................12

Environmental Protection Agency................................13

Explosion hazard.......................................................... 6

Filter assembly..................................................... 24, 28

Filter, intake......................................................... 14, 27

Filter, main........................................................... 14, 25

Filter, mat...................................................................20

Fuse, replacing...........................................................28

Gas supply, connecting to..........................................11

Standby option...............................................11, 12, 29

Storage...................................................................... 17

Temperature, high................................................15, 16

Transport braces........................................................ 23

Troubleshooting..........................................................15

Wall pipeline, gas supply from.................................... 12

Warnings..................................................................... 6

Warranty......................................................................5

What's what...............................................................16

Wipe disinfection........................................................13

Index..........................................................................30

Inspection and maintenance....................................6, 14

Installation.................................................................. 10

Installation procedures................................................20

Intended use................................................................ 9

Intervals, maintenance................................................ 14

Main filter.............................................................14, 25

Maintenance intervals............................................. 6, 14

Maintenance, routine procedures................................24

Medical air..................................................................19

Operating hours...................................................14, 16

Operation...................................................................12

Ordering information...................................................29

NIST..........................................................................18

Packaging, for transport.......................................22, 23

Performance characteristics....................................... 17

Prefilter...................................................................... 25

Responsibility, operator's ...for patient safety................4

Operating Instructions Medical Air Compressor

30

Page 31

31

Page 32

These Instructions for Use apply only to

Medical Air Compressor

with Serial No.:

If no Serial No. has been filled in by

Dräger these Instructions for Use are

provided for general information only and

are not intended for use with any specific

machine or device.

Manufactured by

Dräger Medizintechnik GmbH

Germany

H Moislinger Allee 53 – 55

D-23542 Lübeck

T (4 51) 8 82 - 0

X 26 80 70

FAX (4 51) 8 82-20 80

! http://www.draeger.com

Valid for USA and Canada only

Distributed by

Dräger Medical, Inc.

H 3136 Quarry Road

Telford, PA 18969

T 215-721-6910

FAX 215-721-6915

90 29 081 - GA 5692.200 en US

Dräger Medizintechnik GmbH

4th edition - July 2000

Subject to alteration

9000-607-22

Loading...

Loading...