Page 1

TM

4Sight2

Smart, scalable and easy to use

Calibration and asset management

software that works for you

Page 2

4Sight2 is your next

generation solution

for calibration and

asset management.

4Sight2, from Baker Hughes, a GE company, makes

calibration management easy to use, cost eective

and scalable. Equally eective for single use or global

multi-site operations, this software is designed to

empower your organization to operate simply and

securely, connecting your people to instruments,

data, and enhanced analytics.

Purpose-built with custom installation support

available, 4Sight2 is designed to deliver

actionable intelligence and transformative

insights. Developed in-house, the bespoke software

package enhances the visibility of your assets and

data, helping you plan resources that impact

eective maintenance, process eciency and

regulatory compliance.

Page 3

Challenges in

calibration and

asset management

• Easy to use software systems

• Scalability

• Finding an eective software solution

• Consolidated records and data

• Accessible from mobile devices

• Cyber security

• Asset management

• Maintenance eciency

• Managing complex data

integration requirements

• Access to tailored support

Page 4

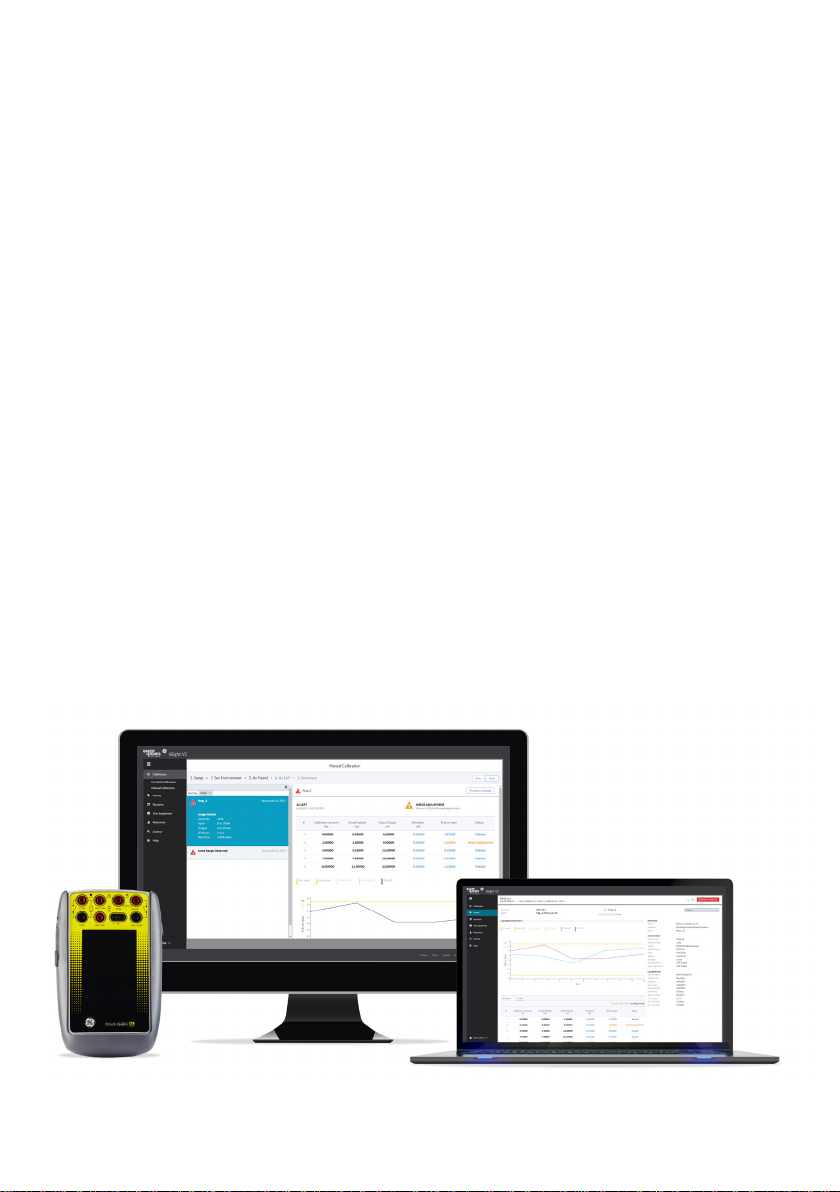

Easy to use

and Accessible

Compliant,

Audit-ready, real

time management

4Sight2 allows

signicantly lower

investment costs and

minimal IT requirement

costs in terms of server

support, upgrade

management and data

backup. Users can

simply log in to the

application software from

a browser, with location

and PC compatibility.

Alternatively, 4Sight2

may be installed directly

on a company server.

We oer a range of

supported installation

options if required.

Managing your installed

base of instrumentation

can be a challenging task,

regardless of its size.

4Sight2 oers seamless

integration with BHGE’s

calibration equipment,

providing automatic

task downloads and

direct uploads of results,

removing the need for

manual work arounds.

4Sight2 gives you simple

control over calibration

and maintenance workow

and data, along with

automated worksheets and

insights into performance

management, ensuring

compliant, audit-ready data.

Page 5

Smart Asset

Management

Predictive

maintenance

Enhancements

4Sight2 enables access

to mobile paperless

calibrations, automated

eld calibration and

deviation management.

Users can record the cause

of deviations, investigate

the reasons and focus on a

resolution. The audit trail

demonstrates that

a robust solution is in

place to manage deviations

with strict procedures

for corrective action and

preventative action (CAPA),

reducing operator error and

improving overall quality.

4Sight2’s historical

trending module allows a

device’s performance to

be monitored over time.

This powerful feature is

a key tool in improving

eciency and planning

preventative maintenance,

helping to:

• Plan robust

preventative actions

• Determine the most

cost eective and

reliable devices and

manufacturers

• Extend calibration

intervals

• Optimize your process

• Smart analytics

• Dashboard capability

• Maintenance module

• Automated calibrations

with controllers

• Congurable certicates

• Messages and alerts

• SAAS

• Scalable support

and service packages

are available

Page 6

Baker Hughes, a GE company (NYSE:BHGE) is the world’s rst and only fullstream

provider of integrated oileld products, services and digital solutions. Drawing on

a storied heritage of invention, BHGE harnesses the passion and experience of its

people to enhance productivity across the oil and gas value chain.

BHGE helps its customers acquire, transport and rene hydrocarbons more

eciently, productively and safely, with a smaller environmental footprint and at

lower cost per barrel. Backed by the digital industrial strength of GE, the company

deploys minds, machines and the cloud to break down silos and reduce waste and

risk, applying breakthroughs from other industries to advance its own.

With operations in over 120 countries, the company’s global scale, local know-how

and commitment to service infuse over a century of experience with the spirit of a

startup – inventing smarter ways to bring energy to the world.

For more information please contact

your local BHGE representative, or visit

www.gemeasurement.com/test-calibration

Powered by Predix™

© 2017. Baker Hughes, a GE company – All Rights Reser ved

*4Sight2: Trademark of Baker Hughes, a GE company

**Predix: Trademark of the General Electric Company

BR-24 0A

gemeasurement.com/test-calibration

Loading...

Loading...