Page 1

00825-0100-4686, Rev FA

Rosemount™ 1195 Integral Orifice

Assembly

Quick Start Guide

September 2017

Page 2

Quick Start Guide

September 2017

NOTICE

This document provides basic installation guidelines for the Rosemount1195 Integral Orifice Assembly. For

comprehensive instructions for detailed configuration, diagnostics, maintenance, service, installation, or

troubleshooting refer to the Rosemount 1195 Reference Ma nual

electronically on EmersonProcess.com /Rosemount

If the Rosemount 1195 Integral Orifice was ordered assembled to a Rosemount Pressure Transmitter, refer to

the following Quick Start Guides for information on configuration and hazardous locations cer tifications:

Rosemount 3051S Quick Start Guide

Rosemount 3051SMV Quick Start Guide

Rosemount 3051 Quick Start Guide

Process leaks may cause harm or result in death

To avoid process leaks, only use gaskets designed to seal with the corresponding flange and O-rings to seal

process connections.

.

. The manual and this guide are also available

Contents

Rosemount 1195 Integral Orifice Assembly

View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Location and orientation . . . . . . . . . . . . . page 3

Primary element orientation . . . . . . . . . . page 6

2

Primary element installation . . . . . . . . . . page 8

Preparing for operation . . . . . . . . . . . . . .page 10

Product certifications . . . . . . . . . . . . . . .page 14

Page 3

September 2017

A

B

C

D

E

F

G

Quick Start Guide

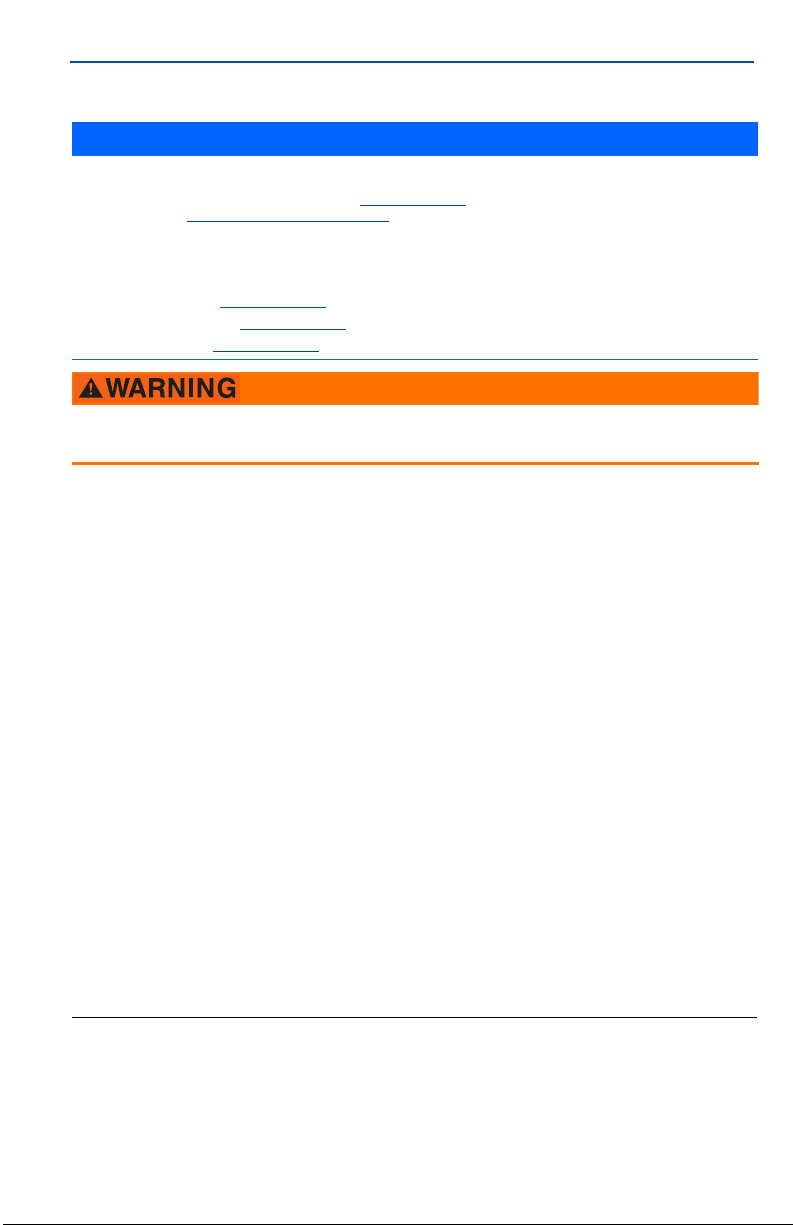

1.0 Rosemount 1195 Integral Orifice Assembly View

Figure 1. Enhanced Support Body

A. Manifold

B. Gaskets

C. Studs

D. Nuts

E. Transmitter

F. Rosemount 1195 enhanced support body

G. Enhanced support orifice plate

(1)

2.0 Location and orientation

Install the Rosemount 1195 Integral Orifice in the correct location within the

piping branch to prevent inaccurate measurement caused by flow disturbances.

2.1 Straight pipe length

Use the upstream (U) and downstream (D) lengths provided below in

conjunction with figures below to determine the appropriate upstream (U) and

downstream (D) pipe lengths. For example, for a 1-in. line size with a beta ratio

(β) of 0.4 using installation of Figure 3, the straight length of upstream piping

required is 25 ⫻ 1 = 25-in., and downstream 10 ⫻ 1 = 10-in.

Note

The Rosemount 1195 Integral Orifice comes with the associated pipe lengths

(18D upstream and 8D downstream) when ordered with process pipe-end connections.

1. Transmitter and housing are shown for clarity purposes - only supplied if ordered.

3

Page 4

Quick Start Guide

U D

U

D

U D

September 2017

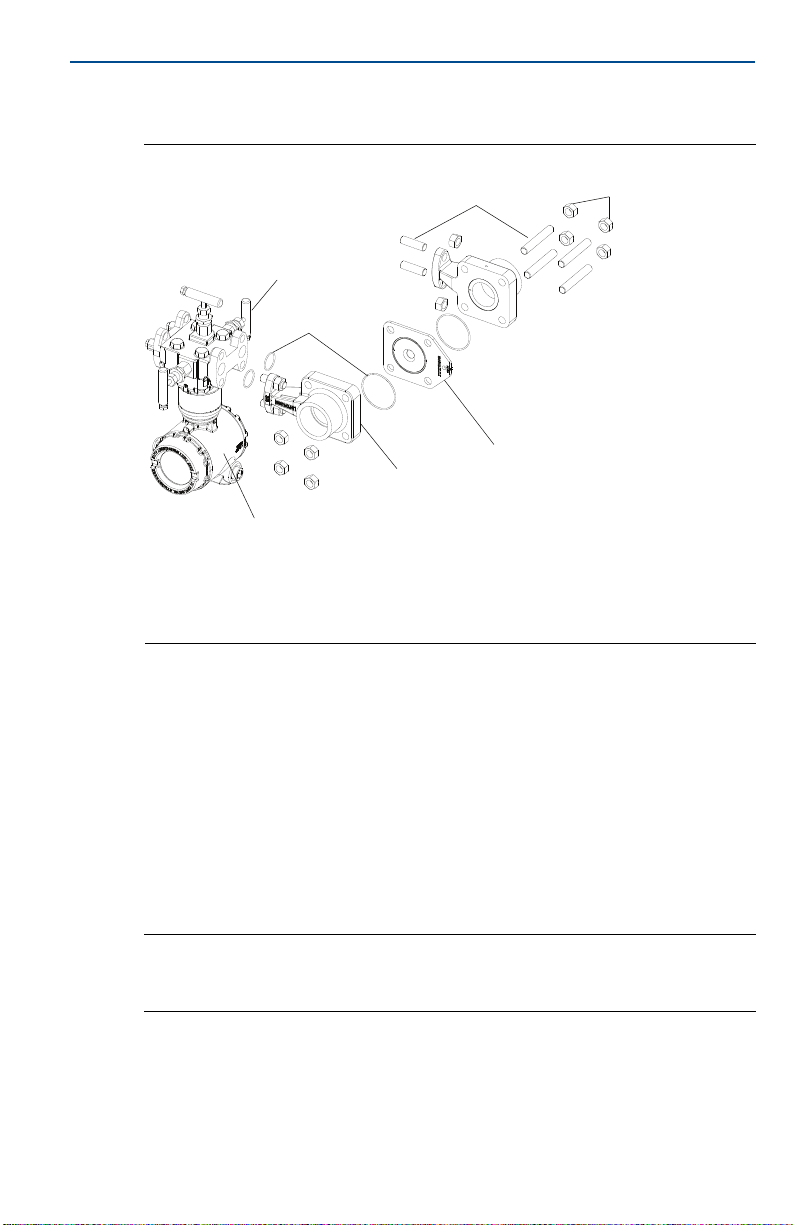

Straight run requirements

(1)

Figure 2. Reducer

U D

(2 d to d over a length of 1.5 d to 3 d)

Figure 3. Single 90° Bend Flow from One Branch

Figure 4. Two or More 90° Bends in Same Planes

Figure 5. Two or More 90° Bends in Different Planes

Figure 6. Expander

U D

(0.5 d to d over a length of d to 2 d)

1. For dimensions, see Tab le 1 on p age 5.

4

Page 5

September 2017

U D

Quick Start Guide

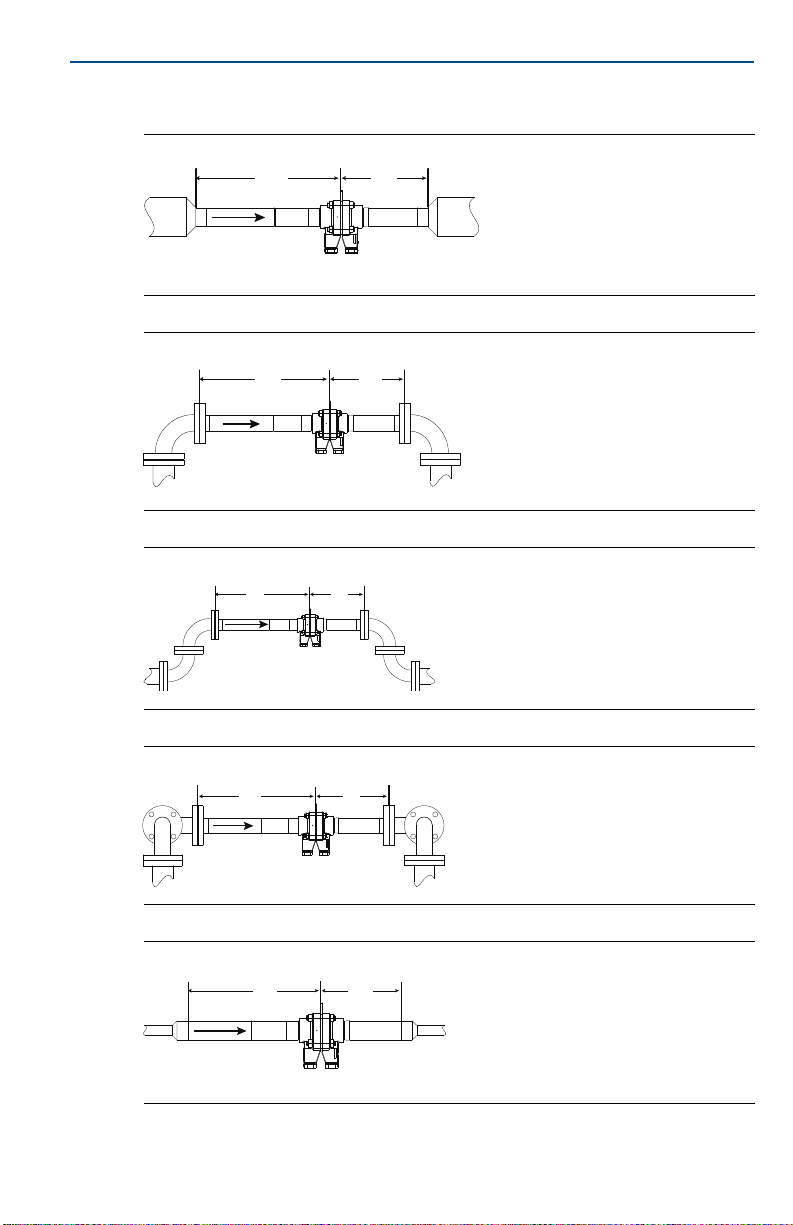

Figure 7. Ball/Gate Valve Fully Open

Table 1. Straight Run Requirements (in Pipe Diameters)

Figure 3

(1)

β

upstream

(U)

0.20 20 24 25 30 22 22 10

0.40 20 25 27 31 22 22 10

0.50 20 25 28 33 23 23 10

0.60 20 27 31 37 25 25 10

0.70 23 32 35 42 28 28 10

0.75 25 35 38 45 30 30 10

1. Interpolation of intermediate β values can be used.

All straight lengths are expressed as multiples of the pipe inside diameter (d) and shall be measured f rom the upstream face of orifice

2.

plate.

Figure 4

upstream

(U)

Figure 5

upstream

(U)

Figure 6

upstream

(U)

Figure 7

upstream

(U)

Figure 8

upstream

(U)

Figures 3–8

On downstream

(D)

(2)

5

Page 6

Quick Start Guide

D

FLOW

A

C

B

A

C

B

FLOW

F

E

D

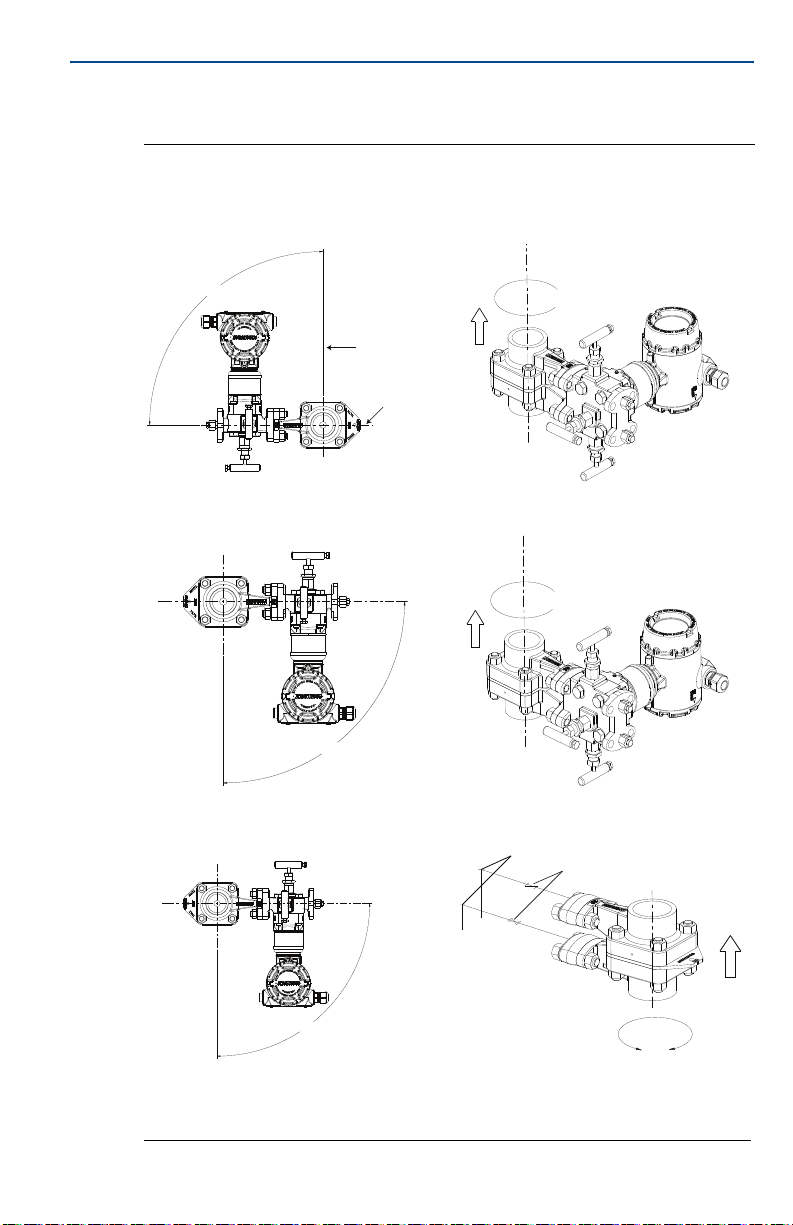

3.0 Primary element orientation

Figure 8. Rosemount 1195 Flowmeter Orientation with Traditional Style

Manifold

Gas (horizontal) Gas (vertical)

A

B

C

Liquid (horizontal) Liquid (vertical)

September 2017

D

FLOW

Steam (horizontal) Steam (vertical)

A. 90° recommended zone

B. Vertical plane

C. Horizontal plane

6

D. 360° recommended zone

E. Block valves

F. V ent valve s

Page 7

September 2017

A

B

C

D

A

B

C

D

FLOW

F

E

D

Figure 9. Rosemount 1195 Flowmeter Orientation with Flange by Flange

Quick Start Guide

Manifold

Gas (horizontal) Gas (vertical)

Liquid (horizontal) Liquid (vertical)

Steam (horizontal) Steam (vertical)

B

A. 120° recommended zone

B. Horizontal plane

C. Vertical plane

C

A

D. 360° recommended zone

E. Block valves

F. Ve nt valves

Note

For saturated steam that is not high quality, it is recommended to mount in a vertical line

to avoid damming effect of the liquid.

7

Page 8

Quick Start Guide

A

B

D

14

23

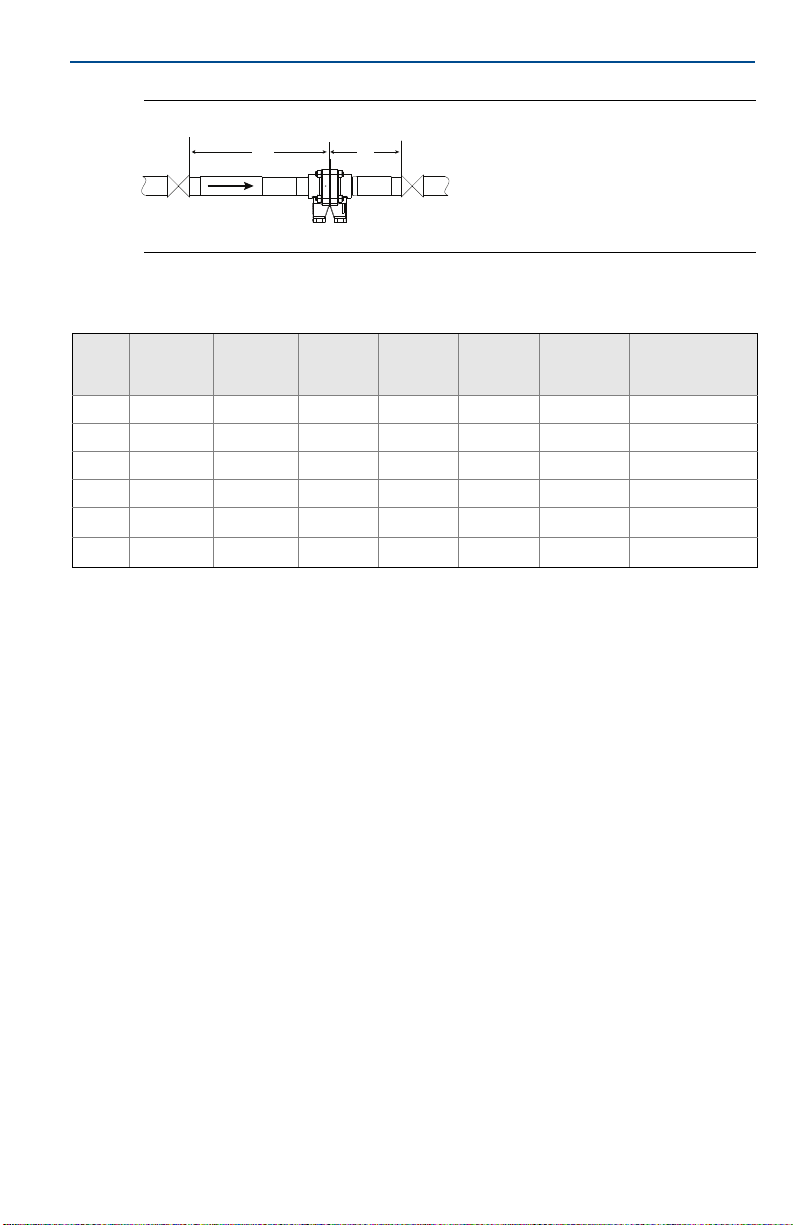

4.0 Primary element installation

1. Ensure the side of the orifice plate marked “inlet” is facing upstream. This

stamping is found on the part of the orifice plate that extends beyond the

orifice bodies. Before pressurizing line, insure torque values shown below are

met. See Ta bl e 2 and Figure 10 for torque requirements of manifold studs

and orifice body studs. See the appropriate transmitter manual for torque

requirements of transmitter bolts.

Table 2. Stud and Nut Torque Specifications

Manifold studs Tor qu e

All Line sizes and gasket types 32 lb-ft.(44 N-m)

Orifice body studs Tor qu e

All line sizes and gasket types 60 lb-ft. (82 N-m)

1. Studs and nuts should be tightened to specification in two to three steps following a cross pattern.

2. Never reuse gaskets. Always replace gaskets after disassembly to ensure proper seal.

Figure 10. Rosemount 1195 Assembly Fastener Naming Convention

Traditional body Enhanced support body

A

September 2017

(1)(2)

A. Transmitter bolts - 4⫻

B. Manifold studs - 4⫻

8

B

C

Torque cross pattern

C. Orifice body studs - 2⫻

D. Orifice body studs - 4⫻

Page 9

September 2017

2. Units with flanged process connections:

a. Install the flanges in the process pipe. The distance between flanges

b. Install the unit between the flanges, using studs, nuts, and gaskets

3. Units with threaded process connections:

a. Install the unit using the appropriate threaded connection hardware.

4. Units with Socketweld Bodies:

a. To ensure perpendicularity of the pipe to the orifice fitting, the socket

b. To prevent damage, remove the transmitter prior to welding.

Figure 11. Recommended Support Locations for Installation

Quick Start Guide

should be equal to the overall length of the flowmeter, plus clearance for

gaskets.

appropriate for the flange size/rating and process conditions. Proper

support is needed at the flange connections as shown below.

See Figure 11.

diameter is smaller than the standard pipe OD. The pipe OD must be

machined-to-fit prior to welding.

B

AA

A. Support

B. No step

5. Once the Rosemount 1195 is installed ensure that it is supported properly

and take precautions to ensure that it is not used as a step. Refer to Figure 11

for support locations.

9

Page 10

Quick Start Guide

5.0 Preparing for operation

Note

Serious injury can occur by opening the valves when the pipes are pressurized. Do not

bleed or vent process fluid if it is toxic or harmful to health or environment.

5.1 Direct mount 450 °F (232 °C) or less

Liquid applications

1. Pressurize line.

2. Open the equalizer valve.

3. Open the high and low side valves.

4. Bleed drain/vent valves until no gas is apparent in the liquid.

5. Close the vent/drain valves.

6. Close the low side valve.

7. Check the transmitter zero according to the transmitter product manual.

8. Close the equalizer valve.

9. Open the low side valve. The system is now operational.

Gas applications

1. Pressurize line.

2. Open the equalizer valve.

3. Open the high and low side valves.

4. Open drain/vent valves to ensure no liquid is present.

5. Close the vent/drain valves.

6. Close the low side valve.

7. Check the transmitter zero according to the transmitter product manual.

8. Close the equalizer valve.

9. Open the low side valve. The system is now operational.

September 2017

10

Steam applications

1. Remove pressure from line.

2. Open equalizer, high, and low side valves.

3. Fill manifold and transmitter with water via drain vents.

4. Close low side valve.

5. Pressurize line.

6. Gently tap electronics body, manifold head, and integral orifice body with a

small wrench to dislodge any entrapped air.

7. Check the transmitter zero according to the transmitter product manual.

8. Close equalizer valve.

9. Open the low side valve. The system is now operational.

Page 11

September 2017

FLOW

A

B

C

D

5.2 Remote mount

Gas applications-transmitter located above Rosemount 1195 Taps

1. Pressurize line.

2. Open equalizer valve on transmitter manifold.

3. Open high and low side transmitter manifold valves.

4. Open drain/vent valves on transmitter manifold to ensure no liquids are

present.

5. Close drain/vent valves.

6. Close low side transmitter manifold valve.

7. Check transmitter zero according to transmitter manual.

8. Close equalizer on transmitter manifold.

9. Open low side valve on transmitter manifold. The system is now operational.

Quick Start Guide

Figure 12. Remote Gas Service

A. Low valve

B. Vent

C. High valve

D. Equalizer valve

(1)

1. Applicable to both body assemblies.

11

Page 12

Quick Start Guide

Liquid applications-transmitter located below Rosemount 1195

Ta ps

1. Pressurize line.

2. Open equalizer valve on transmitter manifold. Close equalizer valve at

integral orifice, if one is used.

3. Open high and low side transmitter manifold valves and high and low block

valves at integral orifice.

4. Bleed drain/vent valves on transmitter manifold until no air is present.

5. Close transmitter manifold drain vent valves, then bleed vent valves at the

integral orifice block valves until no air is present.

6. Close vent valves at integral orifice block valves.

7. Close equalizer valve at transmitter manifold.

8. Close low and high side block valves at integral orifice.

9. Open vent valves at integral orifice block valves.

10. Check transmitter zero according to transmitter manual.

11. Close vent valves at integral orifice block valves.

12. Open high and low side block valves at integral orifice. The system is now

operational.

Steam service-transmitter located below Rosemount 1195 Taps

1. Remove pressure from line or close block valves at integral orifice.

2. Open equalizer valves, high and low side valves on the transmitter manifold.

Close equalize valve at integral orifice, if one is used.

3. Open vent valves at integral orifice block valves. To vent sensing lines.

4. Fill transmitter manifold and instrument lines with water via low side vent at

integral orifice block valves.

5. Open and close vent valves at transmitter to bleed out trapped air.

6. Close the equalizer valve at transmitter manifold.

7. Complete filling the low side and high side sensing lines.

8. Gently tap electronics body, transmitter manifold, instrument lines, and

integral orifice with a small wrench to dislodge any trapped air.

9. Check transmitter zero according to transmitter manual.

10. Close vent valves at integral orifice block valves.

11. If block valves at integral orifice had been closed they should now be

opened. System is now operational for steam flow measurement.

September 2017

12

Page 13

September 2017

FLOW

A

B

C

D

E

Quick Start Guide

Figure 13. Remote Steam and Liquid Service

A. Vent

B. High valve

C. Equalizer valve

D. Vent valves

E. Low valve

(1)

1. Applicable to both body assemblies.

13

Page 14

Quick Start Guide

6.0 Product certifications

6.1 Approved Manufacturing Locations

Emerson — Shakopee, Minnesota USA

Rosemount DP Flow Design and Operations — Boulder, Colorado USA

Emerson GmbH & Co. OHG — Wessling, Germany

Emerson Asia Pacific Private Limited — Singapore

Emerson Beijing Instrument Co., Ltd — Beijing, China

6.2 European Directive Information

The EU declaration of conformity for all applicable European directives for this

product can be found on the at Emerson.com/Rosemount

obtained by contacting our local sales office.

European Pressure Equipment Directive (PED) (97/23/EC)

Refer to EU declaration of conformity for conformity assessment.

Pressure Transmitter — See appropriate Pressure Transmitter QSG.

6.3 Hazardous Locations Certifications

For information regarding the transmitter product certification, see the

appropriate transmitter QSG:

Rosemount 3051S with HART Protocol Quick Start Guide

Rosemount 3051SMV Flowmeter Quick Start Guide

Rosemount 3051 Quick Start Guide

September 2017

. A hard copy may be

14

Page 15

September 2017

Figure 14. Rosemount 1195 Declaration of Conformity

Quick Start Guide

15

Page 16

Quick Start Guide

September 2017

16

Page 17

September 2017

Quick Start Guide

17

Page 18

Quick Start Guide

表表格

1B: 含有China RoHS

管控物峐超彯㚨⣏㳻⹎旸ῤ的部件型号列表

Rosemount 1195

Table 1B: List of Rosemount 1195 Parts with China RoHS Concentration above MCVs

部件名称

Part Name

有害物峐ġİġHazardous Substances

摭

Lead

(Pb)

汞

Mercury

(Hg)

擱

Cadmium

(Cd)

六价撔

Hexavalent

Chromium

(Cr +6)

多ⓤ俼劗

Polybrominated

biphenyls

(PBB)

多ⓤ俼劗慂

Polybrominated

diphenyl ethers

多ⓤ俼劗慂

(PBDE)

䬍ࡦᓖՐ

ᝏಘཆ༣㓴

Ԧ

Aluminum

RTD

Housing

Assembly

O O O X O O

本表格系依据

SJ/T11364

的奬⭂侴⇞ἄįġ

This table is proposed in accordance with the provision of SJ/T11364

O:

意宍悐ẞ䘬㚱⛯峐㛸㕁宍㚱⭛䈑峐䘬⏓慷⛯ỶḶ

GB/T 26572

所奬⭂䘬旸慷天㯪įġ

O: Indicate that said hazardous substance in all of the homogeneous materials for this part is below the limit requirement of

GB/T 26572.

X:

意⛐宍悐ẞἧ䓐䘬㚱⛯峐㛸㕁慴炻军⮹㚱ᶨ䰣⛯峐㛸㕁宍㚱⭛䈑峐䘬⏓慷檀Ḷ

GB/T 26572

所奬⭂䘬旸慷天㯪įġ

X: Indicate that said hazardous substance contained in at least one of the homogeneous materials used for this part is above

the limit requirement of GB/T 26572.

к䘠⭣᰾ӵ䘲⭘Ҿ䘹ᤙ䬍ࡦཆ༣㓴ԦⲴӗ૱DŽަԆᡰᴹᐞ⍱䟿а⅑ݳԦⲴ㓴ԦᡰᴹⲴ China RoHS ㇑᧗⢙䍘⎃

ᓖ൷վҾ GB/T 26572 ᡰ㿴ᇊⲴ䲀䟿㾱≲DŽޣҾᐞ⍱䟿䇑䘱ಘ㓴ԦⲴ㇑᧗⢙䍘⎃ᓖⲴ⭣᰾ˈ䈧৲ⴻ䘱ಘⲴᘛ

䙏ᆹ㻵ᤷইDŽ

The disclosure above applies to units supplied with aluminum connection heads. No other components supplied

with DP Flow primary elements contain any restricted substances. Please consult the transmitter Quick Start

Guide (QIG) for disclosure information on transmitter components.

September 2017

18

Page 19

September 2017

Quick Start Guide

19

Page 20

Global Headquarters

Emerson Automation Solutions

6021 Innovation Blvd.

Shakopee, MN 55379, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RFQ.RMD-RCC@Emerson.com

North America Regional Office

Emerson Automation Solutions

8200 Market Blvd.

Chanhassen, MN 55317, USA

+1 800 999 9307 or +1 952 906 8888

+1 952 949 7001

RMT-NA.RCCRFQ@Emerson.com

Latin America Regional Office

Emerson Automation Solutions

1300 Concord Terrace, Suite 400

Sunrise, FL 33323, USA

+1 954 846 5030

+1 954 846 5121

RFQ.RMD-RCC@Emerson.com

Europe Regional Office

Emerson Automation Solutions

Neuhofstrasse 19a P.O. Box 1046

CH 6340 Baar

Switzerland

+41 (0) 41 768 6111

+41 (0) 41 768 6300

RFQ.RMD-RCC@Emerson.com

Asia Pacific Regional Office

Emerson Automation Solutions

1 Pandan Crescent

Singapore 128461

+65 6777 8211

+65 6777 0947

Enquiries@AP.Emerson.com

Middle East and Africa Regional Office

Emerson Automation Solutions

Emerson FZE P.O. Box 17033

Jebel Ali Free Zone - South 2

Dubai, United Arab Emi rates

+971 4 8118100

+971 4 8865465

RFQ.RMTMEA@Emerson.com

*00825-0100-4686*

Quick Start Guide

00825-0100-4686, Rev FA

Linkedin.com/company/Emerson-Automation-Solutions

Twitter.com/Rosemount_News

Facebook.com/Rosemount

Youtube.com/us er/RosemountMeasur ement

Google.com/+RosemountMeasurement

Standard Terms and Conditions of Sale can be found on the Term s

and Conditions of Sale page.

The Emerson logo is a trademark and service mark of Emerson

Electric Co.

Rosemount and Rosemount logotype are trademarks of Emerson.

All other marks are the property of their respective owners.

© 2017 Emerson. All rights reserved.

September 2017

Loading...

Loading...