Page 1

Drager

“MEDICAL

OPERATION

Minimum

Outlet

Dew

Power

Current

Circuit

Weight:

Noise

Compressor

*

PRECAUTIONS

AIR

AND

Continuous

Pressure:

Point

Depression:

Requirement:

Leakage:

Breaker:

126

Ibs.

Level:

52

Safety

COMPRESSOR

SERVICE

SPECIFICATIONS:

37-49

15

Amps

dBa + 2

Valve:

MANUAL

Output:

psi

3° C below

115V,

60Hz,

normal

less

than

dBa

85

psig t 5

60

Ipm © 37

room

10

Amps

polarity

85

microamps

ambient

open

psig

psi

ground

Before

with

all

use

the

service

WARNING:

-

WARNING:

-

WARNING:

WARNING:

-

CAUTION:

|

CAUTION:

operating

the

precautions,

compressor

manual

To

personnel.

Do

anesthetics.

The

outlet

Never

are

It

the

moisture

(portable

emptied

The

lubricated.

or

servicing

if

to

perform

avoid

not

compressor

not

is

recommended

inlet

compressor

notes

repair

scheduled

shock

use

the

or

an

adaptor.

put

oxygen

approved

of

all

in

case

or

daily.

the

air

and

is

needed.

hazard,

compressor

is

into

for

blenders,

the

piped)

is

compressor,

warnings.

Replace

maintenance

refer

grounded.

the

compressor.

oxygen

that

you

respirators,

drying

fails.

The

of

the

oil-less

read

and

understand

Drager

all

in

the

DO

use.

install a transparent

system

water

is

not

broken

and

repairs.

servicing

presence

NOT

plug

The

etc.

to

of

the

trap

should

type

and

responsible

or

worn

to

qualified

of

it

electrical

protect

compressed

MUST

parts

flammable

into

an

ungrounded

components

water

them

be

checked

NOT

be

all

the

accompanying

for

damages

immediately.

trap

at

from

air

source

and

caused

Follow

manuals.

by

misuse.

the

instructions

Be

familiar

Do

ОКАСЕК

JUNE

not

in

0-18

this

ОЛ

199!

Page 2

|

TABLE

OF

CONTENTS

ROUTINE

WEEKLY

QUARTERLY

YEARLY

BETWEEN

TROUBLE

A.

B.

C.

D.

E.

F.

-

SERVICE

A.

B.

EXTERNAL

A.

B.

REPLACEMENT

WIRING

SCHEMATIC

PNEUMATIC

MAINTENANCE

8000-9000

SHOOTING

PRESSURE

GAUGE

OVERHEATING

NOISE/EXCESSIVE

WATER

HIGH

LOW

TO

ADJUSTING

AIR

AIR

INSTALLING

PROBLEMS

PRESSURE

PRESSURE

If

the

If

the

CHECK

RESERVOIR

OUTLET

PARTS

compressor

compressor

FOR A FAULTY

THE

MODIFICATIONS

OPTIONAL

LIST

SCHEMATIC

HOURS

NEEDLE

VIBRATION

is

is

PRESSURE

KIT

EXTERNAL

STICKS

not

running

running

SOLENOID

SWITCH

ROUTINE

OR

VIBRATES

AIR

RESERVOIR

MAINTENANCE

KIT

NN

Mn

OO

Y“

Y“

Y

“Y

00

© © © ©

©

O

Note:

WEEKLY

Remove

and

the

reinstall.

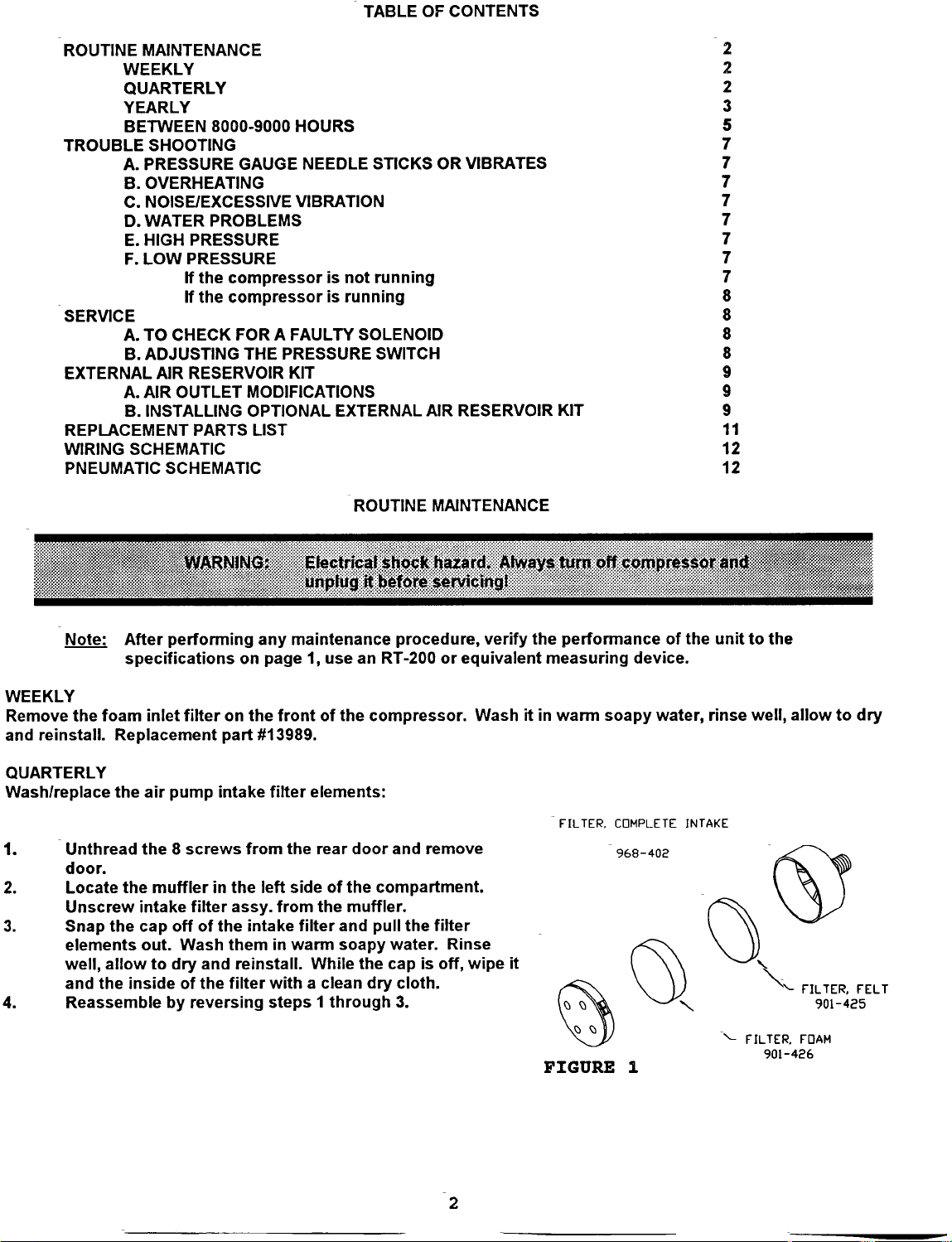

QUARTERLY

Wash/replace

1.

_Unthread

door.

Locate

Unscrew

Snap

elements

well,

and

4.

Reassemble

After

performing

specifications

foam

inlet

Replacement

the

air

pump

the 8 screws

the

muffler

intake

the

cap

out.

allow

to

the

inside

by

filter

part

intake

in

filter

off

of

the

Wash

dry

and

of

the

reversing

any

maintenance

on

page

on

the

front

#13989.

filter

from

the

the

left

side

assy.

from

intake

them

in

warm

reinstall.

filter

with a clean

steps 1 through

1,

use

of

the

elements:

rear

of

the

the

muffler.

filter

and

soapy

While

procedure,

an

RT-200

compressor.

door

and

compartment.

pull

the

water.

the

cap

is

dry

cloth.

3.

or

equivalent

remove

filter

Rinse

off,

verify

Wash

wipe

the

it

it

performance

measuring

in

warm

“FILTER,

FIGURE

device.

soapy

COMPLETE

968-402

i

of

the

water,

INTAKE

unit

rinse

—

to

the

well,

allow

“

FILTER,

901-426

to

FILTER,

901-425

FOAM

dry

FELT

Page 3

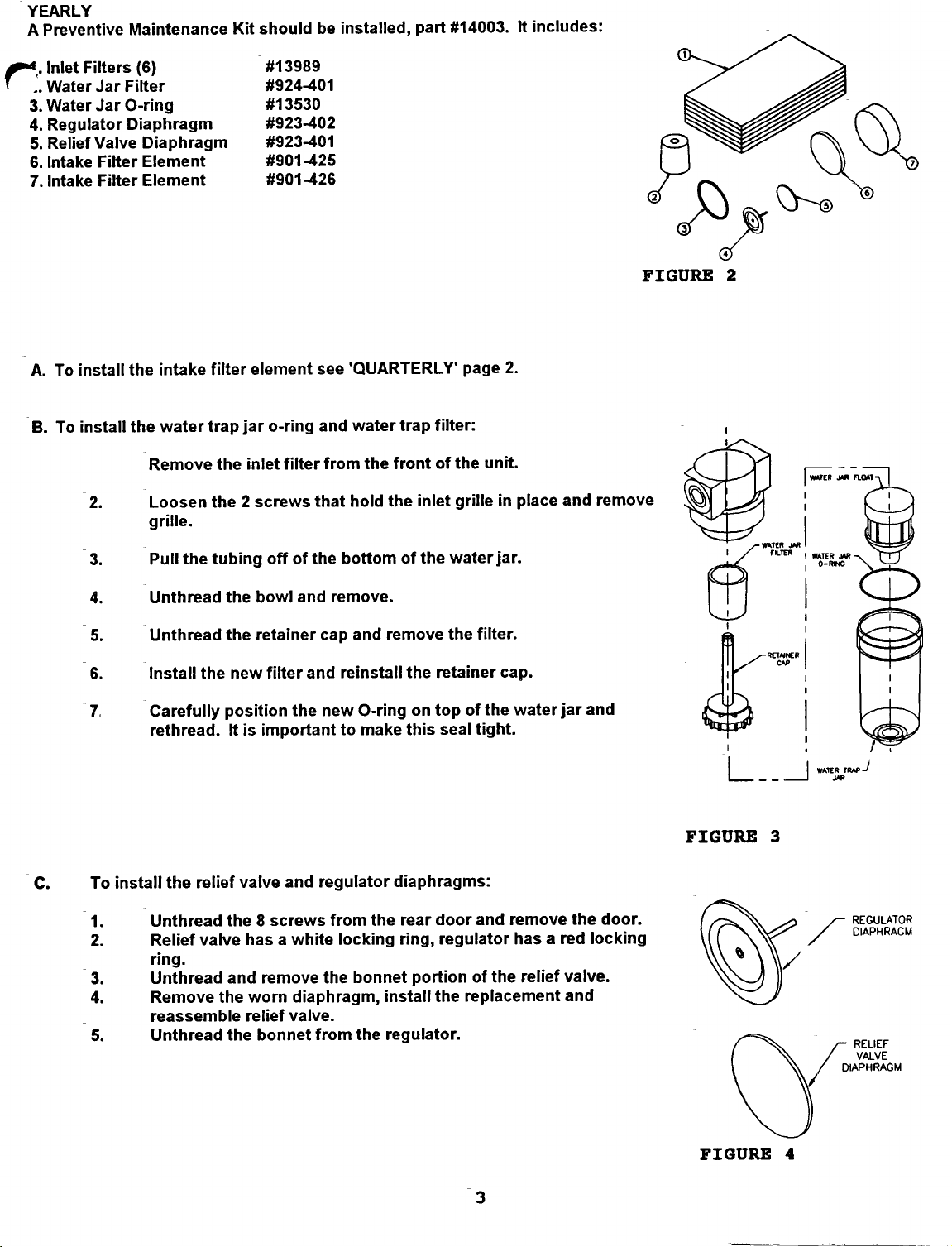

YEARLY

Preventive

A

|.

Inlet

..

Water

3.

Water

4.

Regulator

5.

Relief

6.

Intake

7.

Intake

Maintenance

Filters

Jar

Filter

Jar

O-ring

Diaphragm

Valve

Filter

Filter

(6)

Diaphragm

Element

Element

Kit

should

be

#13989

#924-401

#13530

#923-402

#923-401

#901-425

#901-426

installed,

part

#14003.

includes:

It

=

No

À,

A.

B.

To

install

To

install

2.

3

4.

5

6

7

the

intake

the

water

‘Remove

‘Loosen

grille.

Pull

the

'Unthread

‘Unthread

Install

Carefully

rethread.

filter

element

trap

jar

o-ring

the

inlet

the 2 screws

tubing

the

off

the

bowl

the

retainer

new

filter

position

!t

is

important

see

and

filter

that

of

the

and

cap

and

the

new

'QUARTERLY'

water

from

the

hold

bottom

remove.

and

reinstall

O-ring

to

make

trap

front

the

inlet

of

the

remove

the

on

this

page

filter:

of

the

unit.

grille

water

the

filter.

retainer

top

of

the

seal

tight.

2.

in

jar.

cap.

place

water

and

jar

remove

and

FIGURE

2

©

“To

1

2.

|

3.

4.

.

5.

install

the

‘Unthread

Relief

ring.

Unthread

Remove

reassemble

Unthread

relief

valve

the 8 screws

valve

has a white

and

the

worm

relief

the

and

remove

diaphragm,

valve.

bonnet

regulator

from

the

locking

the

bonnet

from

the

diaphragms:

rear

door

ring,

regulator

portion

install

the

regulator.

and

remove

has a red

of

the

relief

replacement

the

door.

locking

valve.

and

L

FIGURE

O

FIGURE

ーー

=

mues

que)

3

Y

-

REGULATOR

DIAPHRAGM

RELIEF

VALVE

DIAPHRAGM

A

/

4

Page 4

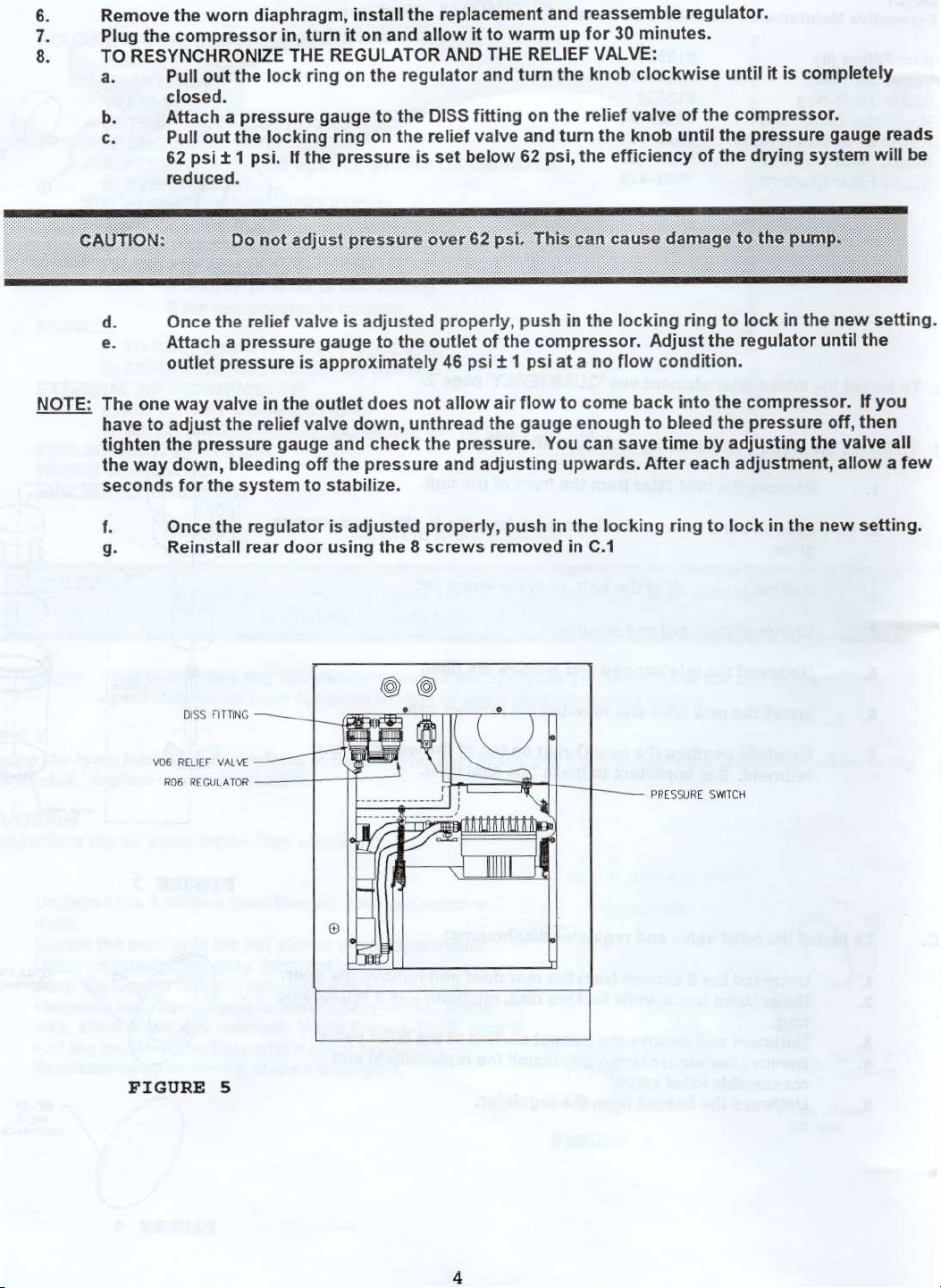

6.

&

8.

Remove

Plug

the

TO

RESYNCHRONIZE

a.

b.

c.

the

worn

diaphragm,

compressor

out

Pull

closed.

Attach a pressure

Pull

out

+

psi

62

reduced.

the

the

psi.

1

in,

turn

THE

lock

locking

the

If

it

REGULATOR

on

ring

gauge

ring

pressure

install

on

the

on

and

to

the

regulator

the

the

replacement

allow

it

AND

and

DISS

fitting

relief

valve

below

set

is

to

THE

warm

RELIEF

turn

on

and

62

and

reassemble

up

for 30

knob

the

the

relief

turn

the

psi,

minutes.

VALVE:

clockwise

valve

the

knob

efficiency

regulator.

until

of

the

compressor.

until

the

pressure

drying

the

of

completely

is

it

system

gauge

reads

be

will

AA

CAUTION:

NOTE:

d.

e.

The

one

have

tighten

the

way

seconds

TE

3.

E

not

Do

©

Once

the

relief

Attach a pressure

outlet

to

the

Once

Reinstall

way

valve

adjust

pressure

down,

for

the

the

Diss

FITTING

pressure

the

relief

bleeding

system

regulator

rear

一 一

adjust

valve

is

in

the

valve

gauge

off

to

door

|

en

pressure

is

adjusted

gauge

approximately

outlet

to

the

does

down,

and

check

the

pressure

stabilize.

is

adjusted

using

the 8 screws

not

unthread

psi,

62

over

properly,

outlet

of

46 psi t 1

allow

air

the

the

pressure.

and

adjusting

properly,

removed

ne

This

push

the

compressor.

psi

flow

gauge

You

push

in

e

cause

can

in

the

at a no

to

come

enough

can

upwards.

the

locking

in

C.1

damage

locking

Adjust

flow

condition.

back

to

bleed

save

time

After

ring

LE

ring

the

into

by

each

to

the

to

P

to

lock

in

regulator

the

compressor.

the

pressure

adjusting

adjustment,

lock

in

pump.

the

new

until

off,

the

valve

allow a few

the

new

setting.

the

If

you

then

all

setting.

vo6

R06

FIGURE

REUEF

wLvE 一 一 一 |

REGULATOR

5

|

ーー

PRESSURE

SWITCH

Page 5

©

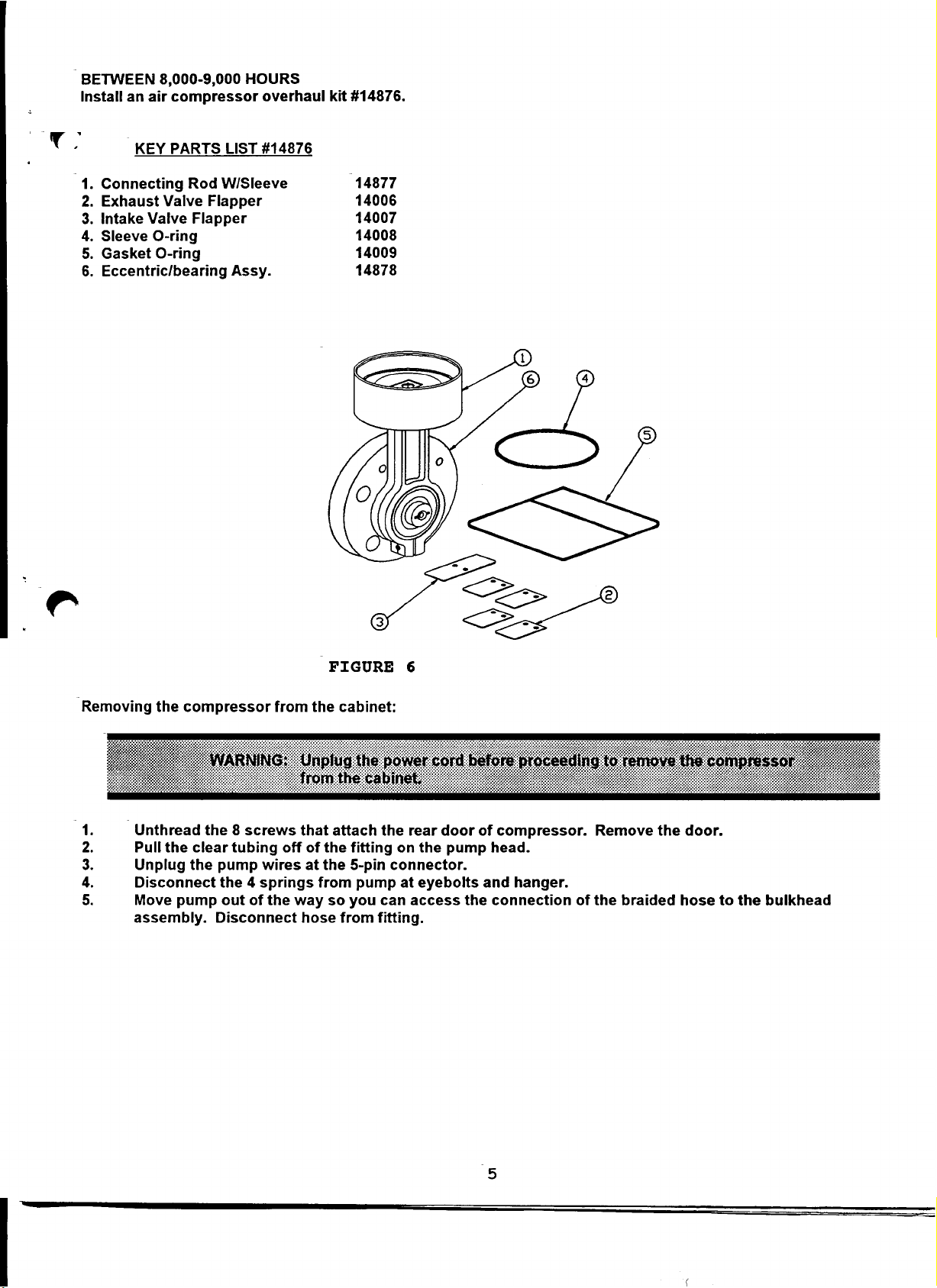

BETWEEN

Install

8,000-9,000

an

air

compressor

HOURS

overhaul

kit

#14876.

T.

KEY

PARTS

1.

Connecting

2.

Exhaust

3.

Intake

4.

Sleeve

5.

Gasket

6.

Eccentric/bearing

Valve

Valve

O-ring

O-ring

LIST

Rod

W/Sleeve

Flapper

Flapper

£14876

Assy.

14877

14006

14007

14008

14009

14878

‘Removing

Unthread

Pull

Unplug

Disconnect

Move

apenp

assembly.

the

compressor

the

clear

the

pump

from

the 8 screws

tubing

pump

wires

the 4 springs

out

of

the

Disconnect

off

way

the

that

of

at

the

from

hose

the

FIGURE

cabinet:

attach

fitting

5-pin

pump

so

you

from

fitting.

6

the

rear

on

the

connector.

at

eyebolts

can

access

door

pump

of

compressor.

head.

and

the

connection

hanger.

of

Remove

the

braided

the

door.

hose

to

the

bulkhead

Page 6

pra

10.

11.

12.

13.

Install

|

Unthread

Remove

Remove

drop

Unthread

fan.

Using

screw

With

connecting

eccentric/bearing.

out

Using

screws

can

Slide

motor

eccentric/bearing

shaft.

shaft,

allow

on

the

Install

assembly

cap

15

in-lbs

Reinstall

O-ring

Reinstall

through

Turn

to

allow

shaft.

screws

Reinstall

on

the 6 screws

the

valve

flapper

the

of

loctite

the

long

a

the

on

slotted

a

rod.

through

be

the

the

screw

the

page 5 in

the

long

a

in

the

removed

new

shaft

so

Turn

the

then

turn

eccentric/bearing

shaft.

new

the

with

to

(1.7

the

gasket

the

the

hole

motor

the

eccentric

Tighten

to

80

compressor

fan

5/32"

lower

5/32”

eccentric/bearing.

eccentric/

N-m).

valve

fan,

in-ibs

reverse.

the

Overhaul

and

plate

assembly.

screws

#271

on

flapper

screw.

screwdriver

Pull

top

by

that

line

set

them

connecting

sleeve

using

putting

in

with

the

Remove

of

end

the

connecting

of

the

Allen

the

spread

connecting

housing.

Allen

(4mm)

The

(4mm)

twisting

bearing

the

set

screws

up

with

screws

back

out

O-ring

plate,

and

six

screws.

the

the

fan

the

fan

to

self-align

eccentric/bearing

(9.0

N-m)

by

following

Kit

#14876

remove

replace

and

screws

the

wrench,

connecting

the

.

rod

wrench,

The

side

from

onto

in

the

flats

in

against

just

enough

to

slide

rod/sleeve

and

tighten

head

with a new

fan

screw

marked:

approx.

on

steps 1 to

head.

flappers.

when

reinstalling.

screw,

bottom

rod

eccentric/bearing

to

the

the

the

in

and

1007.

12

set

loosen

rod

off

can

loosen

side

on

the

out

the

times

the

washer

the

assembly.

the

of

the

of

be

now

the

slightly.

to

5

a

Place

and

GASKET

一

———

一

ンー

ー

ТИ

—

ーー

EXHAUST

FLAPPERS

VALVE

o

INTAKE

SLEEVE

SCREWS

&

0-RING

cap

lifted

set

2

|

CONNECTING

WITH

ROD

SLEEVE

"ECCENTRIC

BEARING

“FIGURE

7

Page 7

A.

SYSTEM

PERFORMANCE

GAUGE

NEEDLE,

“TROUBLE

STICKING

SHOOTING

OR

VIBRATING

Aemove

the

setting

-B.

the 4 screws

needle

is

important

OVERHEATING

The

The

The

The

Φος

The

_C.

NOISE/EXCESSIVE

1

|

2.

2.

_

4.

D.

1

3

|

WATER

The

and

Hose

The

The

The

section

Flowrate

valve

clockwise

inlet

filter

unit

is

operating

inlet

filter

cooling

cabinet

fan

air

compressor

inspected.

to

intake

PROBLEMS

compressor

regulator

automatic

B of

is

exceeding

that

in

preventing

is

clogged

is

blocked

is

not

outlet

VIBRATION

is

SEE

muffler

(

Water

has

is

out

float

YEARLY,

secure

will

worn,

in

the

eliminate

damage

and

needs

in a hot,

working

is

unventilated

by

curtains,

blocked.

making a loud

page

5,

“BETWEEN

is

disconnected

coming

overheated.

of

synchronization.

the

water

page 3 for

compressor

control

vibration.

to

the

to

properly.

out

of

See

trap

is

access

limits

panel,

remove

Counter

performance

be

cleaned.

area.

bedding,

clattering

8,000-9,000

from

the

OVERHEATING.

To

etc.

noise

HOURS".

the

compressor.

air

outlets)

resynchronize

malfunctioning.

to

the

water

jar.

and

pressure

the

control

clockwise

gauge.

in

the

see

Check

gauge

panel

and

rotation

compressor

YEARLY

to

see

if

needle

is

locate

will

correct

chamber.

section

the

water

no

longer

the

needle

sticking. A proper

it

C.8,

page

jar

is

in

the

should

4.

full

of

green

valve.

water.

Turning

be

removed

See

section.

|

pe.

(F.

“Hf

2.

i

3.

-

1.

2.

the

1.

4.

5.

HIGH

PRESSURE

The

The

LOW

PRESSURE

compressor

The

The

compressor

The

30

overload

a.

b.

The

Low

regulator

regulator

power

circuit

thermal

minutes.

protector

Any

A

motor

levels

power

line

voltage

is

set

diaphragm

motor

cord

is

breaker

back

overload

If

the

of

the

defect

should

from

the

too high.

is

not

running:

unplugged.

needs

on.

If

the

protector

power

causes

is

caused

switch

is

not

wall

outlet

at

wail

outlet.

See section C of

needs

causing

exceed

to

be

unit

by:

listed

to

be

reset

continues

in

the

is

left

in

OVERHEATING

it

to

10

amps

has

been

Plug

cleaned

(push

compressor

on,

draw

reset

to

the

too

or

trip

fan

during

interrupted.

compressor

YEARLY,

page

replaced.

button

the

will

much

normal

circuit

motor

cool

page

power.

on

has

the

7.

compressor

into a separate

3.

See

section

control

breaker,

activated.

motor

This

electrical

C.8

panel).

call

It

faster.

will

quickly

usage.

of

YEARLY,

Wait

your

dealer

will

automatically

Activation

overheat

circuit.

5-10

page

seconds

or

Drager.

of

the

the

4.

then

reset

thermal

motor.

turn

within

Current

the

20-

Page 8

If

the

compressor

is

running:

1.

4.

A

.

TO

>

en

P

NAA

The

outlet

The

water

O-ring

The

An

internal

compressor's

The

a.

b.

с.

regulator

The

solenoid

The

pressure

The

CHECK

Unplug

Remove

Locate

Disconnect

Attach

Plug

the

Submerge

plunger

is

leaking.

trap

jar

is

water

the

on

brass

fitting

pop-off

lock

Loosen

Adjust

Tighten

the

the

is

the

set

end

lock

dump

gauge

FOR A FAULTY

the

compressor

the 8 screws

solenoid

long

a

power

inside

the

piece

other

the

valve,

hose

cord

end

valve

improperly

trap

is

leaking.

valve

nut

nut

with a 7/16"

nut.

low.

too

leaking

is

valve

needle

is

SOLENOID

from

that

secure

near

from

the

tubing

1/4"

of

in

and

turn

1/4"

the

of

probably

is

installed.

is

jar

is

the

on

section

See

stuck.

the

wall

lower

solenoid

the

tube

improperly

defective.

pop-off

wrench.

C.8

stuck

or

section

See

VALVE

outlet

the

rear

left

of

cabinet.

valve

fitting

to

compressor

water

in

causing

dirty

installed

Replace

valve

of

open.

SERVICE

before

door

outlet.

the

on

and

or

the

a

with

YEARLY,

See

TROUBLE

of

A

servicing.

and

remove

solenoid

on.

check

valve

the

missing.

valve

wrench.

1/2"

page

section

door.

valve

bubbles

for

to

readjust

or

4.

SERVICE.

of

A

SHOOTING.

and

to

Replace

leak.

to

run

appear.

to

the

85

outside

If

the

5

psit

bubbles

solenoid

psi:

the

of

appear,

valve.

compressor.

the

B.

ADJUSTING

NOTE:

PRD?

THE

cut-in/cut-out

The

differential

Unplug

Remove

Locate

There

screw

system

turns

The

the

the 8 screws

the

an

is

adjusts

on

compressor

the

difference

COMPRESSOR

deadband

pressure

compressor

is

compressor

adjustment

the

both

pressure

the

when

between

DISCONNECT

or

3.5

PSI

from

the

that

secure

disconnect

screw

and

cut-in

system

off

these

differential

with

a

maximum

wall

outlet

the

rear

switch

disconnect

the

on

cut-out

the

when

readings

to

attached

two

PRESSURE

pressure

of

5.0

before

door

and

upper

the

in

switch

pressures.

"WALL"

the

pressure

is

the

differential

SWITCH

adjustable,

not

is

PSI.

servicing.

remove

left

door.

hand

above

cut-in

The

fitting

attached

compartment

terminal

the

pressure

below

falls

the

to

pressure.

is

it

setting

that

"WALL"

of

the

preset.

factory

connections

turns

setting.

fitting

rises

typical

The

compressor.

fig.

(see

compressor

the

cut-out

The

above

that

This

8).

pressure

setting.

Page 9

5

Attach

air

inlet

adjustment

supply

Turn

the

click.

switch

Slowly

an

air

supply

fitting

screw

pressure

adjustment

turn

click

again.

with a self-relieving

marked

"WALL"

counter-clockwise

to

30.0

psi + .5

screw

the

The

clockwise

adjustment

cut-in

on

the

two

psi.

screw

pressure

regulator

back

of

full

until

you

counter-clockwise

is

now

and

the

compressor.

turns

hear

set

at

pressure

and

the

30.0

then

adjust

pressure

until

psi.

gauge

Turn

switch

you

the

the

hear

to

the

the

-

Adjustment

Screw

Note:

“A.

AİR

Factory

OUTLET

1

2

set

Cut-in

pressure

MODIFICATIONS:

‘Remove

(Clean

“Clean

(Clean

‘Install

‘Install

fitting

connects

the

threads

all

residue

threads

the

air

this

assembly

without

by

air

of

of

DISS

hose

DISS

the

from

the

fitting

check

to

is

30

(See

figure

fitting

DISS

the

tee

assembly

into

should

the

psi + 0.5

psi.

EXTERNAL

9)

with

check

fitting

with

the

ventilator.

and

internal

check

bulkhead

point

threads

and apply

down when

AIR

from

apply

into

fitting

RESERVOIR

the

bulkhead

teflon

the

of

the

teflon

tee

tape

bulkhead

assembly.

that the

this

KIT

fitting

to

the

tape

to

air

DISS

assembly

marked

clean

fitting.

the

male

fitting

is

in

male

threads

was

it's

final

FIGURE

"OUT"

threads

removed

position.

on

8

the

cabinet.

from.

This

The

DISS

fitting

`В.

INSTALLING

1.

THE

OPTIONAL

"Remove

cabinet

Reinstall

‘Remove

‘Install

included

‘Install

with

Connect

assembly.

‘Check

the

the

this

all

EXTERNAL

the

(4)

cord

beside

and

(8)

the

screws

retain

reservoir and

with

this

reservoir

kit.

one

end

Connect

new

connections

door.

into

the

kit.

tie

of

the

the

wraps

the

(4)

connector

down

air

other

AIR

that

are

mounting

screws

strap

hose

end

for

leaks.

RESERVOIR:

attached

holes

that

occupy

assembly

to

the

door

included

of

this

with

hose

(See

to

the

on the

the

to

the

assembly

this

to

the

figure

door

and

door.

mounting

door

assembly

using

kit

to

the

DISS

9)

reinstall

holes

(2)

DISS

fitting

them

for

the

using

of

the

fitting

without

on

the

reservoir

(2)

of

the

flat

head

on

the

reservoir

check

on

compressor

brackets.

flat

head

screws

the

included

connector

tee

assembly.

screws

Page 10

INSTALL

TEE

AIR

WITHOUT

AIR

ASSEMBLY

DISS

FITTING

CHECK

ο

DISS

o

FITTING

VALVE

OUT

WITH

WALL

AIR

Le]

Y

CHECK

AIR

DISS

BULKHEAD

“a

SC

FITTING

FITTING

2

[e

WITH

|

CHECK

ο

VALVE

ο ο

A]

^

LOT

RESERVOIR

DOWN

STRAP

FLATHEAD

SCREWS

RESERVOIR

ASSEMBLY

TIE

10-32

CONN.

Figure

10

9

Page 11

#8134

PART

#

510-502

11477

11530

8628

8629

901-408

901-425

901-426

903-401

903-402

911-411

923-401

923-402

924-401

968-402

990-434

991-420

13530

13979

14003

14876

14852

14767

S122-176-001-RPL

DESCRIPTION

Power

Elapsed

Indicator

Indicator

Current

Solenoid

Water

Felt

Foam

Relief

Regulator

Water

Relief

Regulator

Water

Intake

Pop-off

Water

Water

Cord

Preventive

Pump

External

Compressor

Compressor

Switch

Time

Sensing

Jar

Intake

Intake

Valve

Jar

Valve

Jar

Filter,

Valve

Jar

Jar

Hook

Overhaul

Air

Light,

Light,

Valve

Assy.

(FIG.5)

Float

Diaphragm

Filter

w/bushing

O-ring

Indicator

Green

Red

Relay

Complete

Filter

Element

Filter

Element

(FIG.5)

Assy.

Diaphragm

(FIG.3)

Complete

(FIG.3)

Maint.

Kit

Kit

Reservoir

Assembly

Disconnect

_REPLACEMENT

(FIG.3)

(FIG.1)

(FIG.1)

(FIG.3)

(FIG.4)

(FIG.4)

(FIG.1)

and

nut

(FIG.3)

(FIG.2)

(FIG.6)

and

Connector

Pressure

PARTS

Assembly

Switch

LIST

11

Loading...

Loading...